MITSUBISHI MONTERO 2000 Service Repair Manual

MONTERO 2000

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57331/w960_57331-0.png

MITSUBISHI MONTERO 2000 Service Repair Manual

Trending: audio, airbag off, parking, wheel, tow bar, interior, directional lamp

Page 1531 of 1839

Page 1532 of 1839

SRS -Air Bag Modules and Clock Spring52B-32

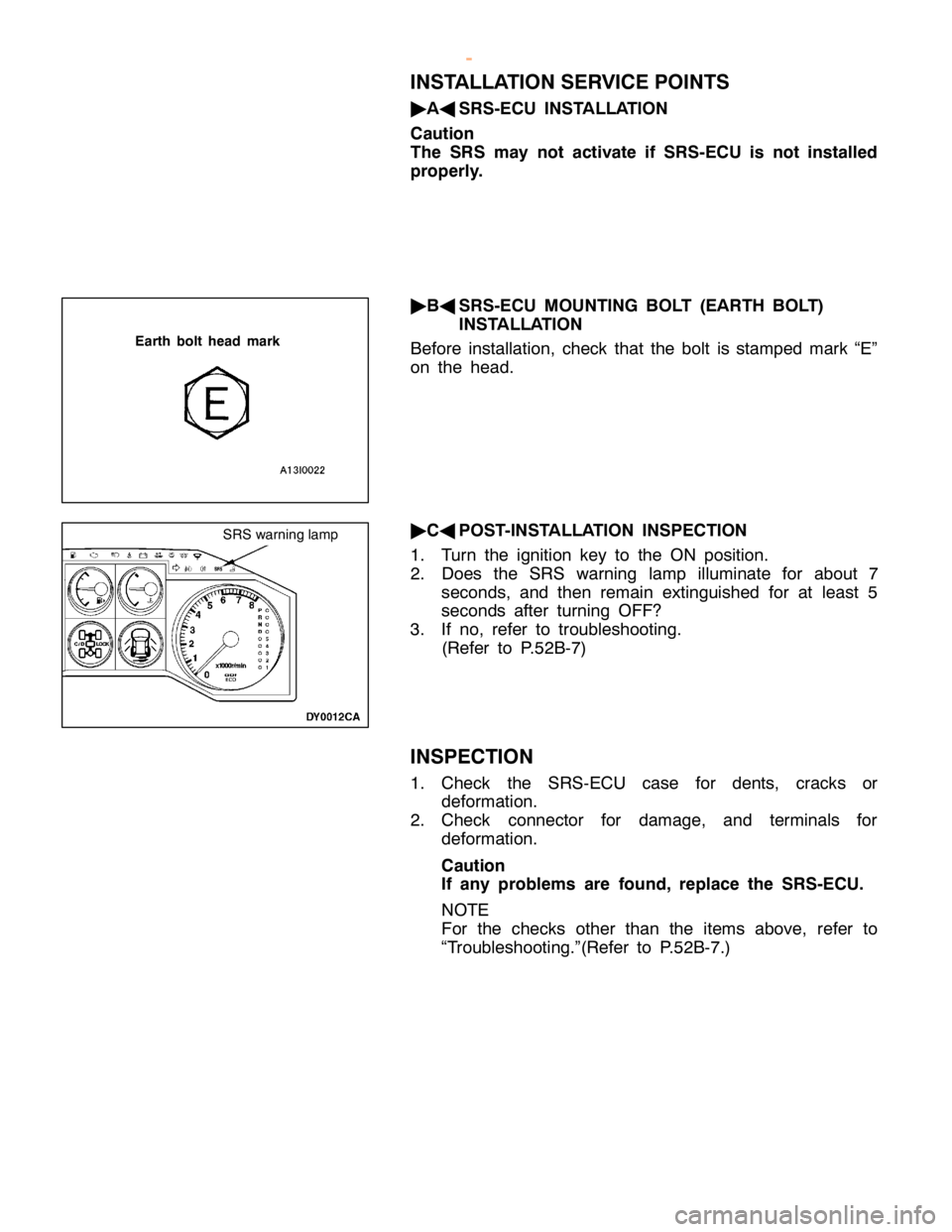

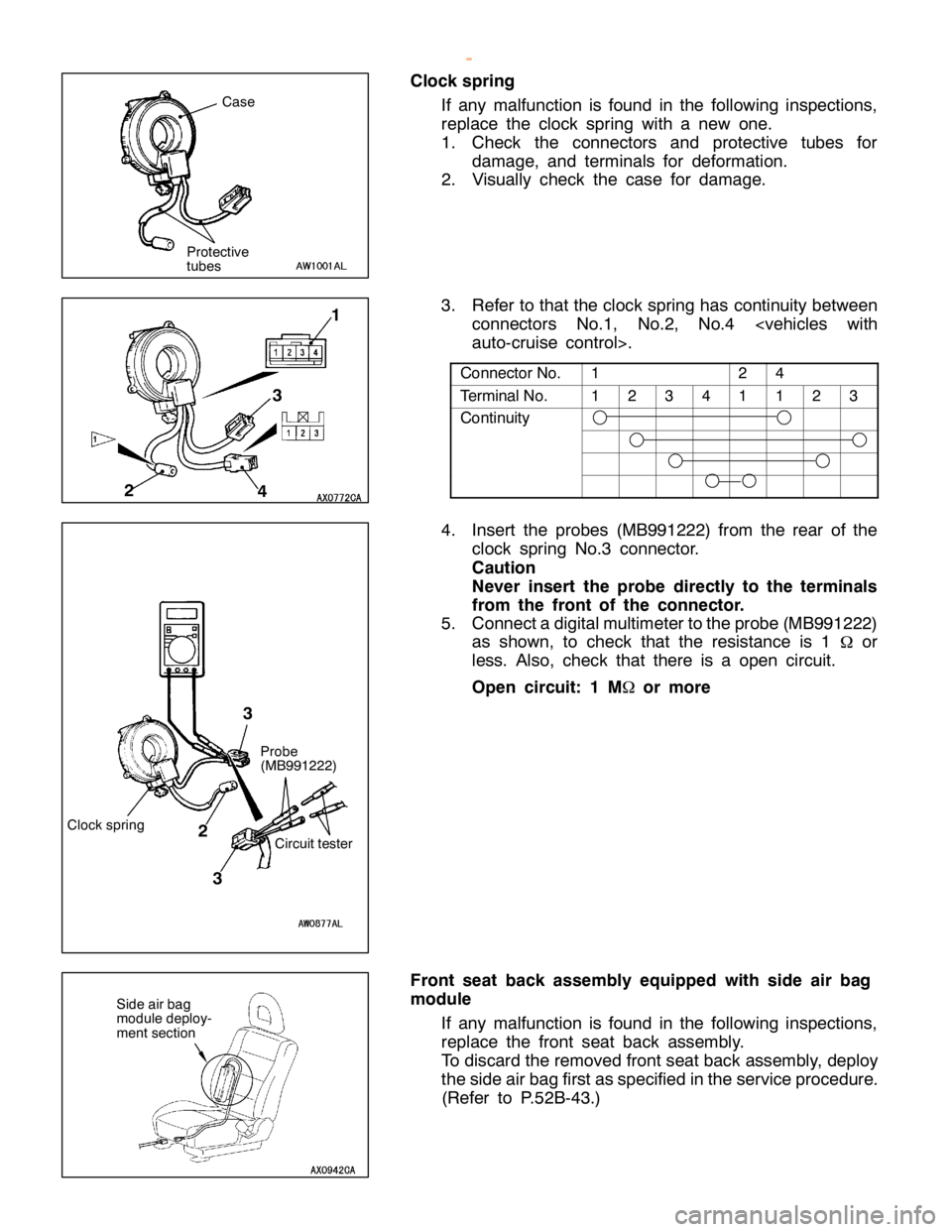

AIR BAG MODULES AND CLOCK SPRING

Caution

1. Disconnect the negative (–) battery terminal

and wait for 60 seconds or more before

starting work. Also, the disconnected

battery terminal should be insulated with

tape. (Refer to P.52B-4.)

2. Never attempt to disassemble or repair the

air bag modules and clock spring.

If faulty, just replace with new one(s).

3. Do not drop the air bag modules or clock

spring or allow contact with water, grease

or oil.

Replace if a dent, crack, deformation or rust

are present.

4. Store the air bag modules on a flat surface

with the deployment surface facing up.

Do not place anything on top of them.5. Do not store the air bag modules in a place

more than 93_

C.

6. When the driver’s and front passenger’s air

bags have been deployed, replace the

driver’s and passenger’s air bag modules

with new ones.

7. Put on gloves and safety glasses when

handling deployed air bags.

8. When discarding the undeployed air bag

module(s), be sure to deploy the air bag(s)

in advance as specified in the service

procedure.

(Refer to to P.52B-43.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1533 of 1839

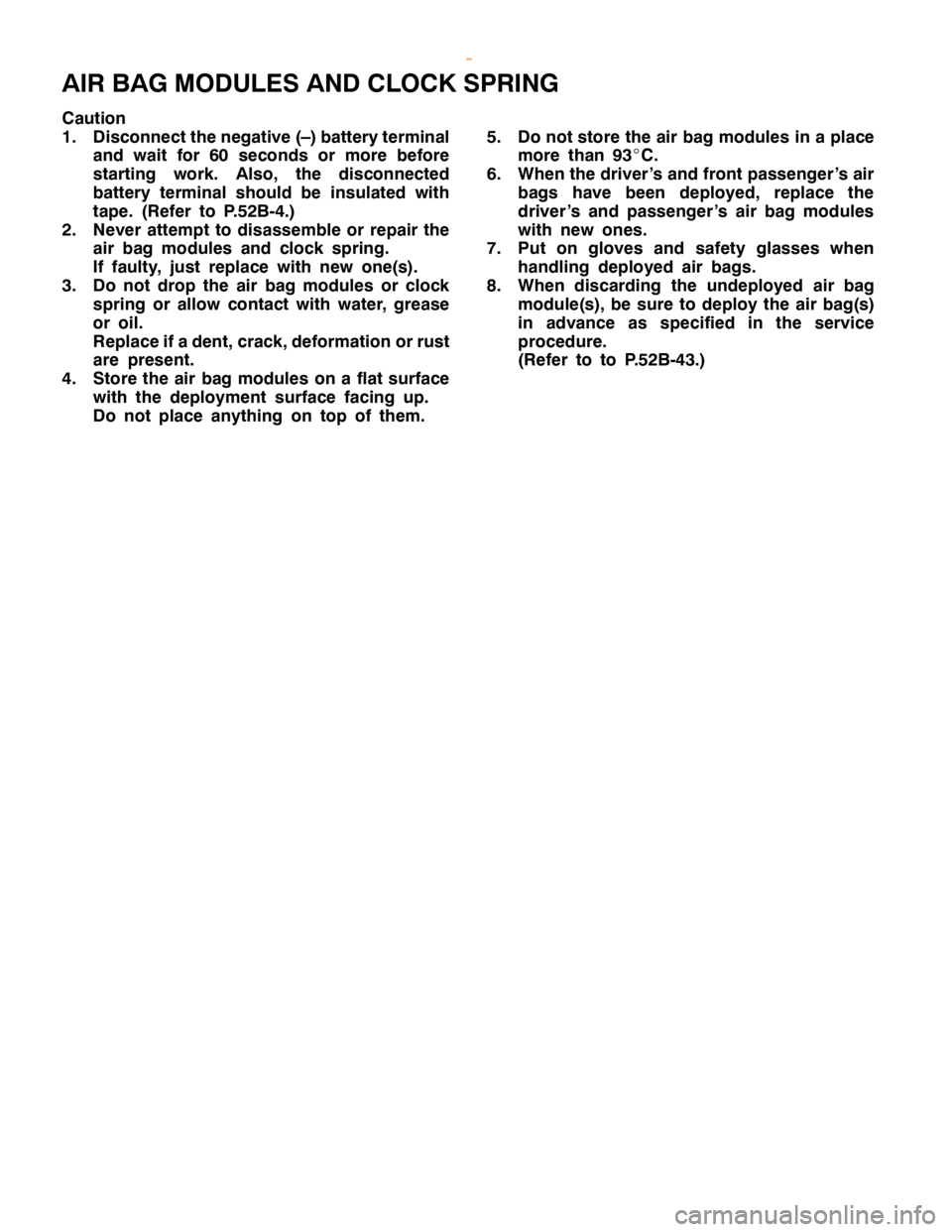

1

2

3

Sectio n B –B

S ectio n A –A

A

A

B B C

olu m nsw it c h

4

NO TE

: in dic a te s ta b. C

la w

C la w

S

ectio n C –C S

ectio n D –D

5

33 1

1

3

.9 ±

0.4 N×

m 3

.9 ±

0.4 N×

m

0

.6 9 ±

0.1 5 N×

m

5 0 ±

5 N×

m C

Page 1534 of 1839

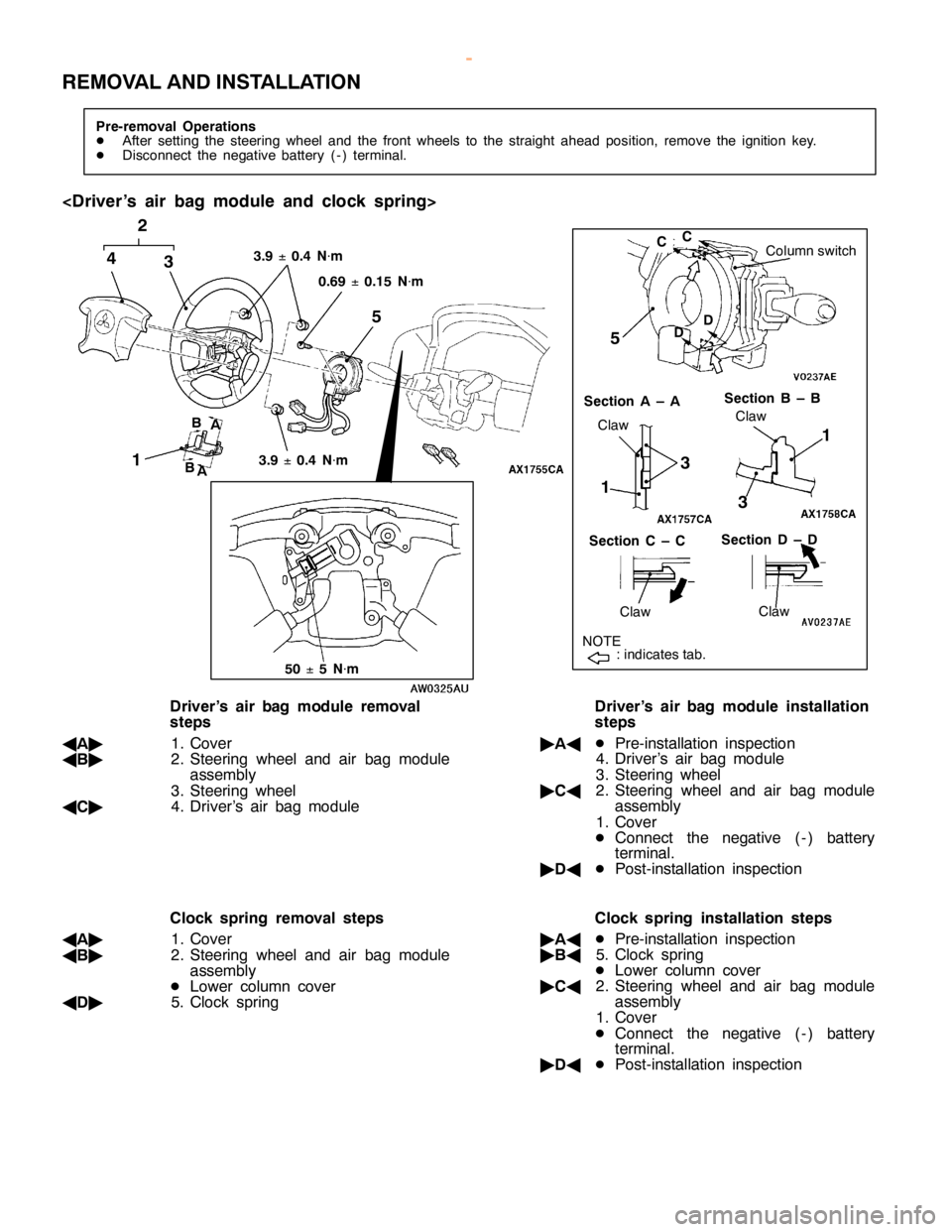

1

2

R em oval ste p s

D Upper glo ve box (R efe r to GRO UP

5 2A -In str u m ent Panel. )

D Glo ve box (R efe r to GRO UP 52A -

I n str u m ent Panel. )

A E"

1. A ir bag sid e pla te

A F"

2. P asse nger’s air bag module I

n sta lla tio n ste p s

" AA

D

Pre -in sta lla tio n in sp ectio n

2 . P asse nger’s air bag module

1 . A ir bag sid e pla te

D Glo ve box (R efe r to GRO UP 52A -

I n str u m ent Panel. )

D Upper glo ve box (R efe r to GRO UP

5 2A -In str u m ent Panel. )

D Connect th e negativ e (- ) batte ry

t e rm in al.

" DA

D

Post- in sta lla tio n in sp ectio n

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1535 of 1839

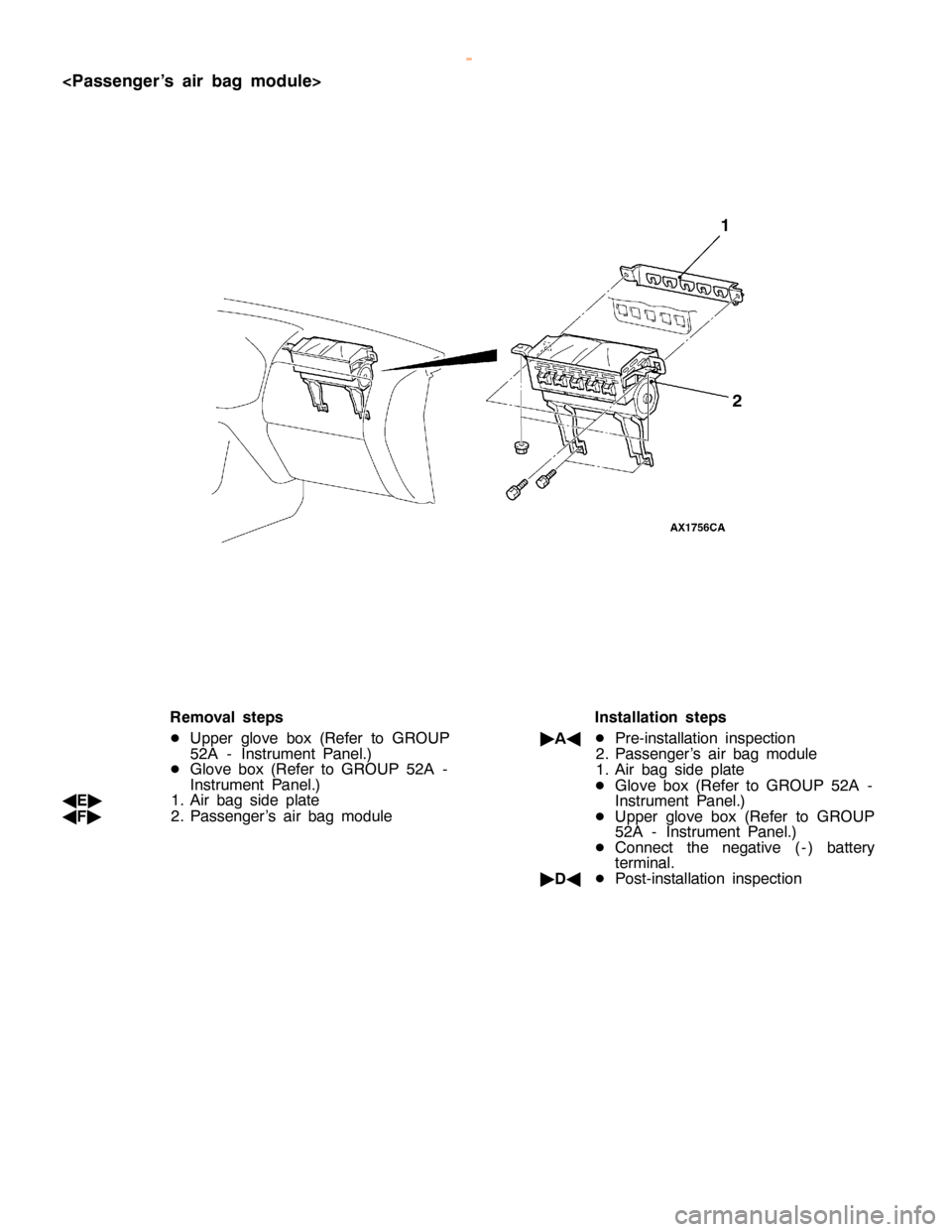

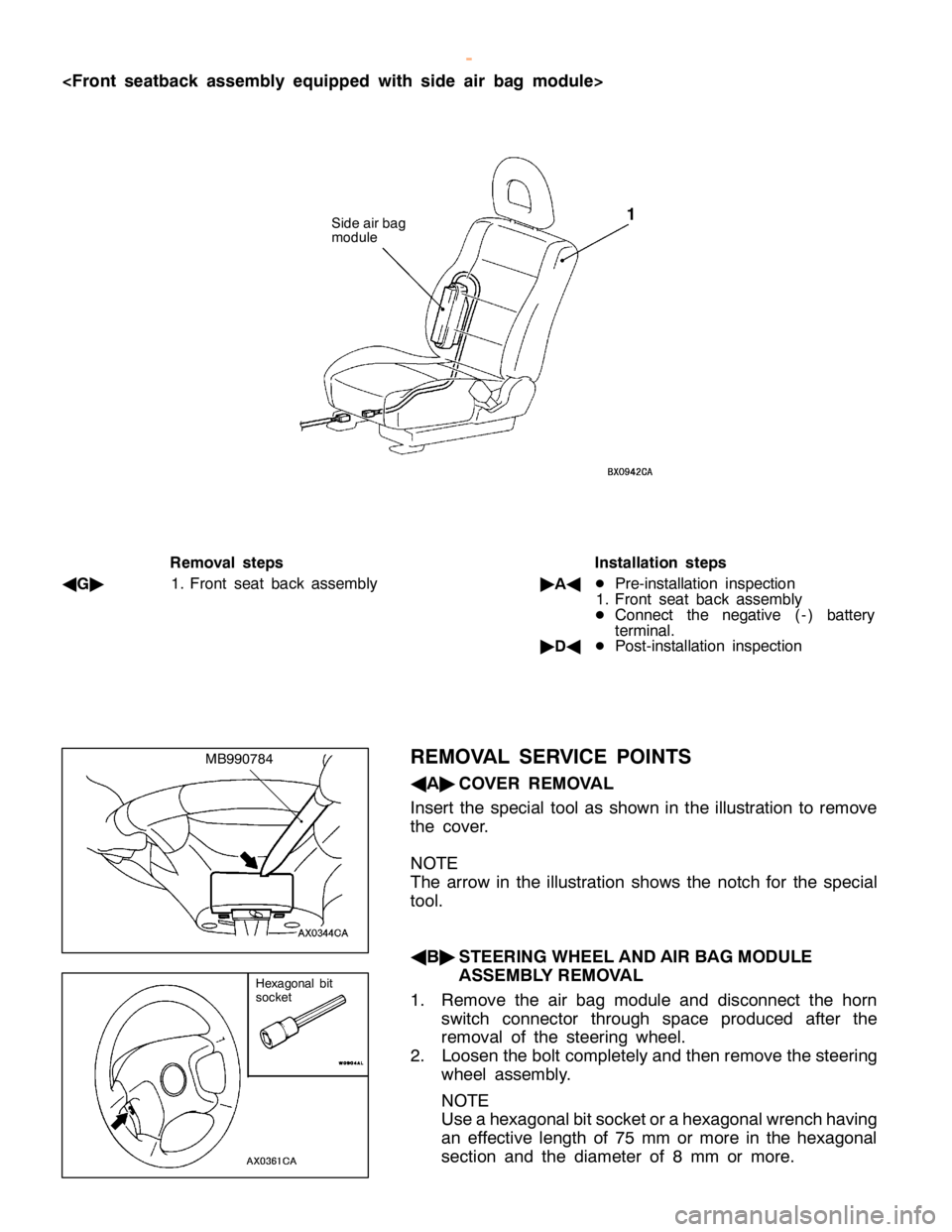

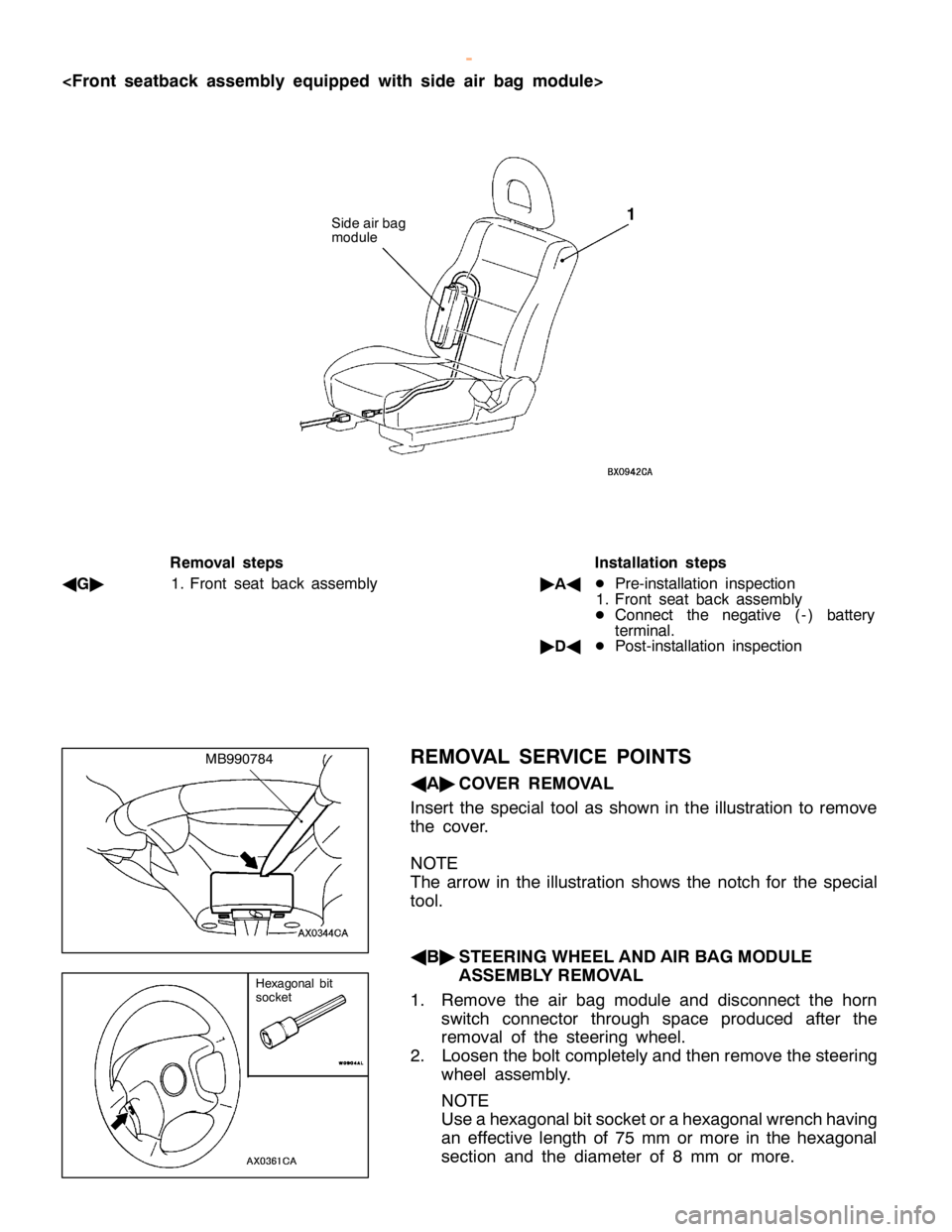

1

S id e air bag

m odule

R em oval ste p s

A G"

1. Fro nt se at back asse m bly I

n sta lla tio n ste p s

" AA

D

Pre -in sta lla tio n in sp ectio n

1 . Fro nt se at back asse m bly

D Connect th e negativ e (- ) batte ry

t e rm in al.

" DA

D

Post- in sta lla tio n in sp ectio n

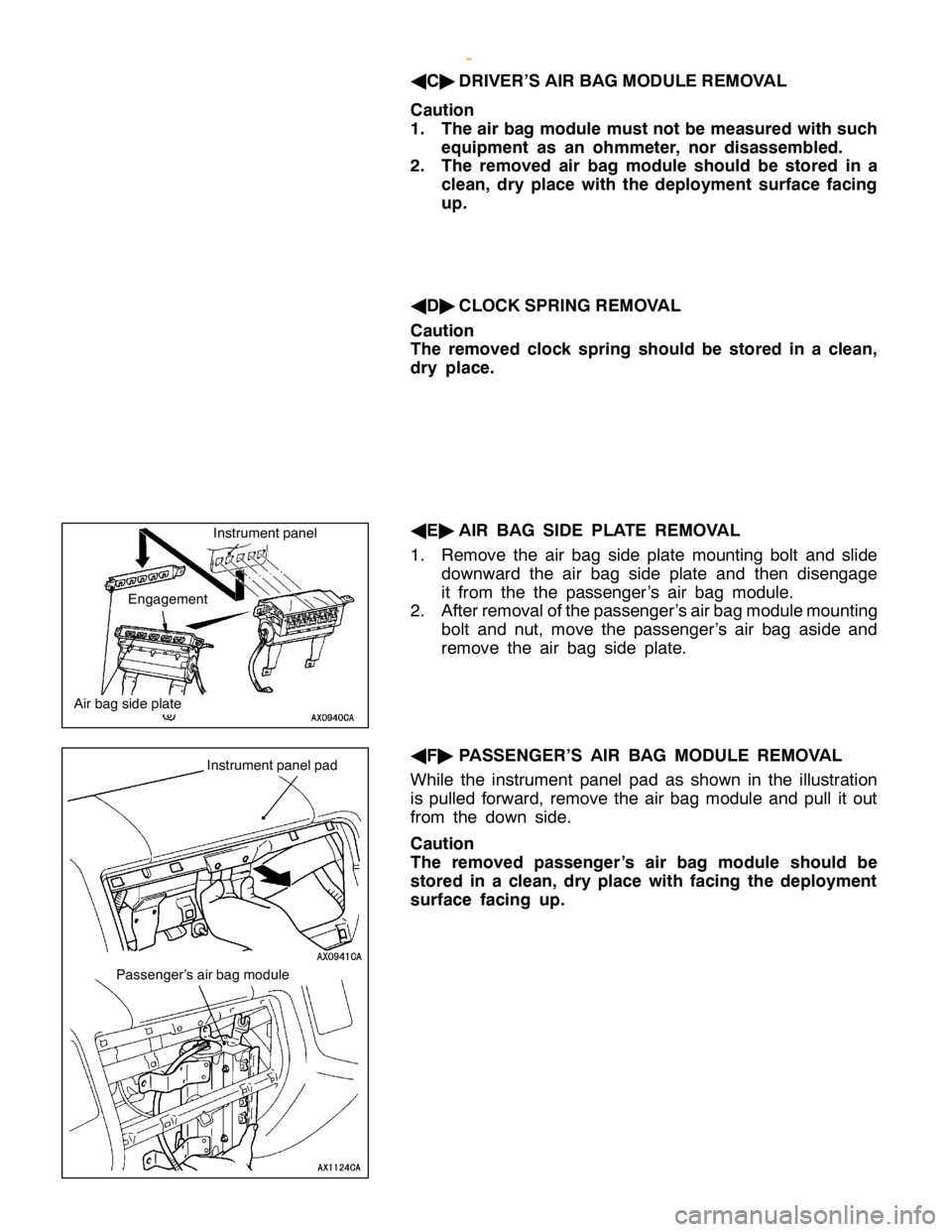

R EM OVA L SER VIC E PO IN TS

A A"

CO VER REM OVA L

I n se rt th e sp ecia l to ol as sh ow n in th e illu str a tio n to re m ove

t h e co ve r.

N O TE

T he arro w in th e illu str a tio n sh ow s th e notc h fo r th e sp ecia l

t o ol.

A B"

STE ER IN G WHEEL AND AIR BAG MODULE

A SSEM BLY REM OVA L

1 . Rem ove th e air bag module and dis co nnect th e horn

s w it c h co nnecto r th ro ugh sp ace pro duce d afte r th e

r e m ova l of th e ste erin g wheel.

2 . Loose n th e bolt co m ple te ly and th en re m ove th e ste erin g

w heel asse m bly .

N O TE

U se a hexa gonalb it so cke to r a hexa gonalw re nch havin g

a n eff e ctiv e le ngth of 75 mm or m ore in th e hexa gonal

s e ctio n and th e dia m ete r of 8 mm or m ore .

Page 1536 of 1839

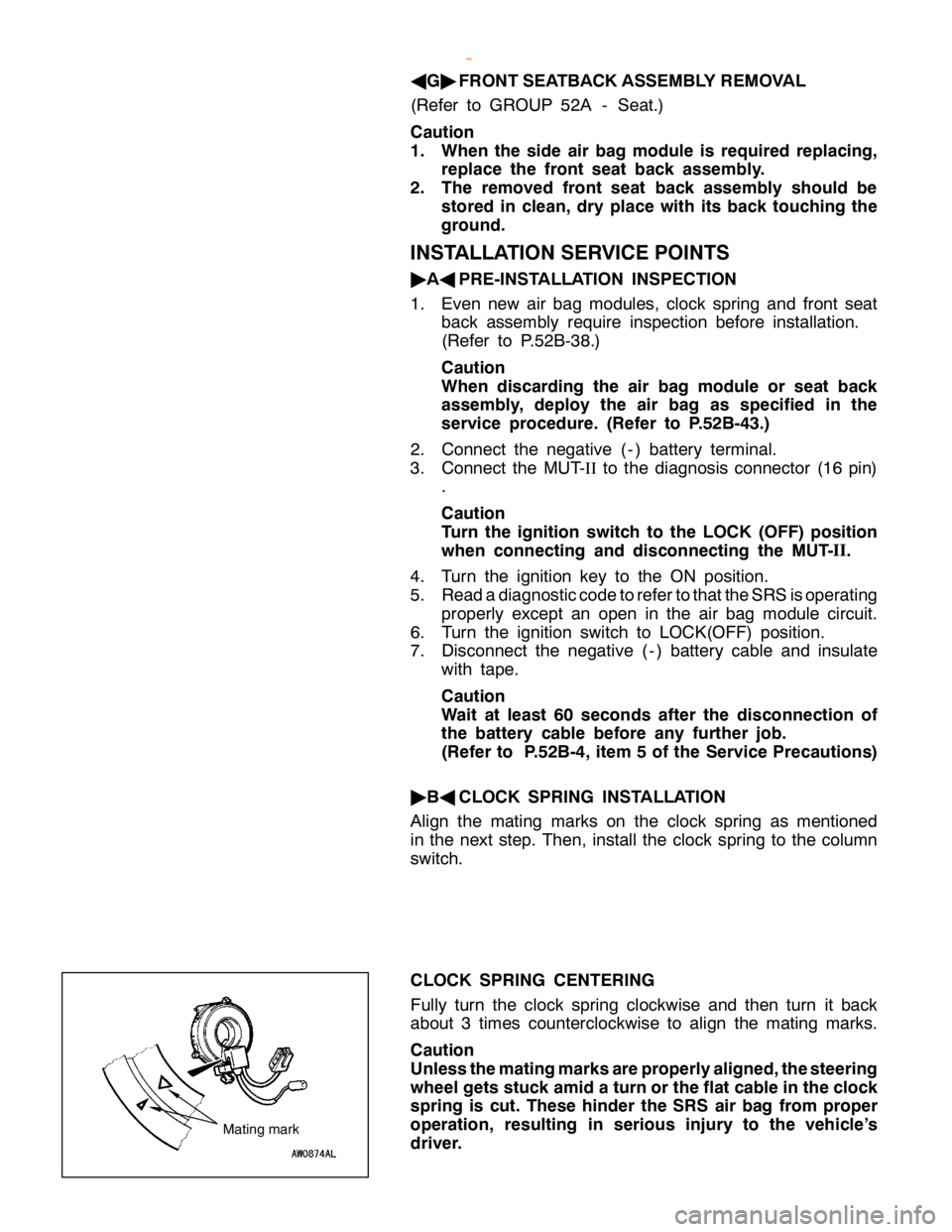

A

ir bag sid e pla te I

n str u m entp anel I

n str u m entp anelp ad P

asse nger’s air bag m odule

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1537 of 1839

Page 1538 of 1839

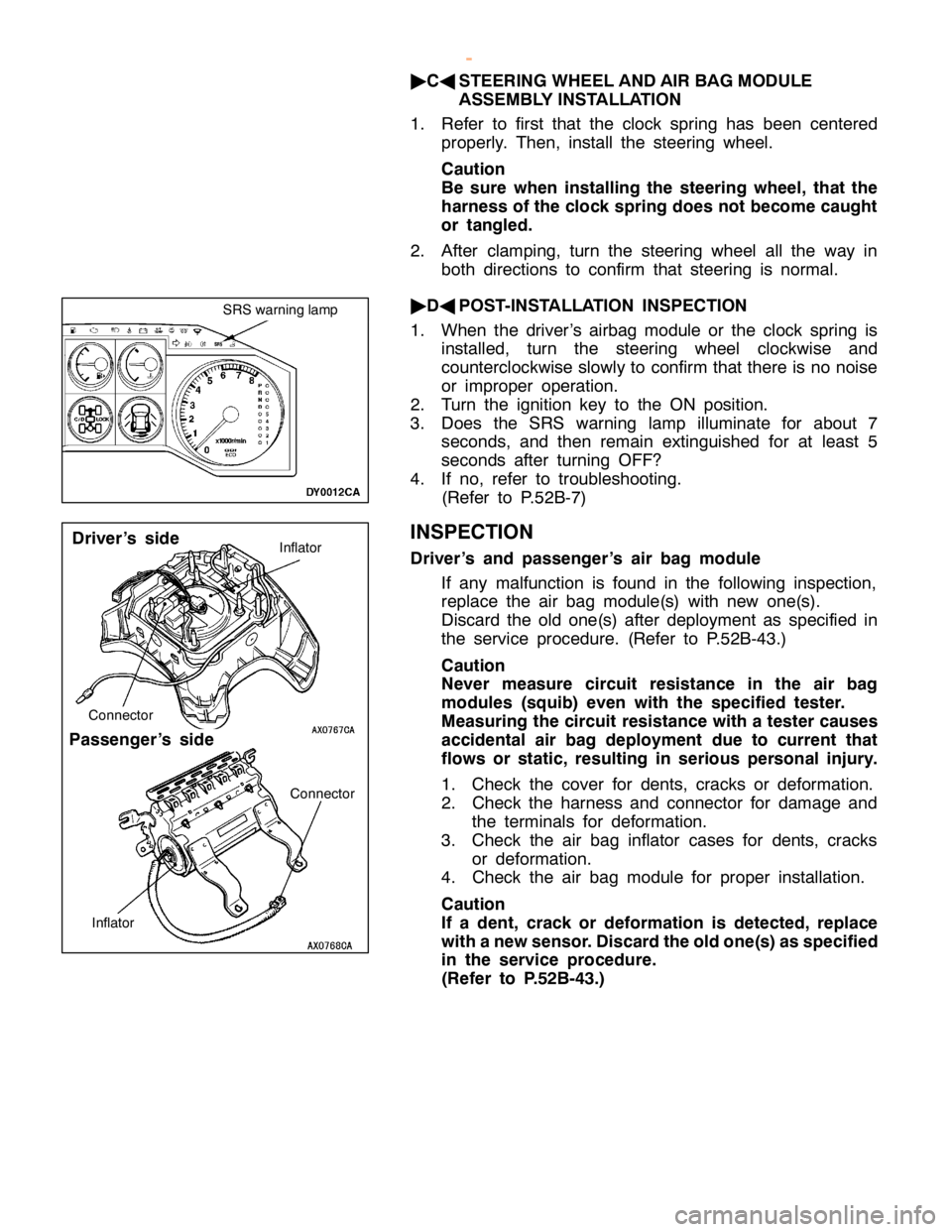

P

assen ger’s sid e C

onnecto r

I n fla to r C

onnecto r

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1539 of 1839

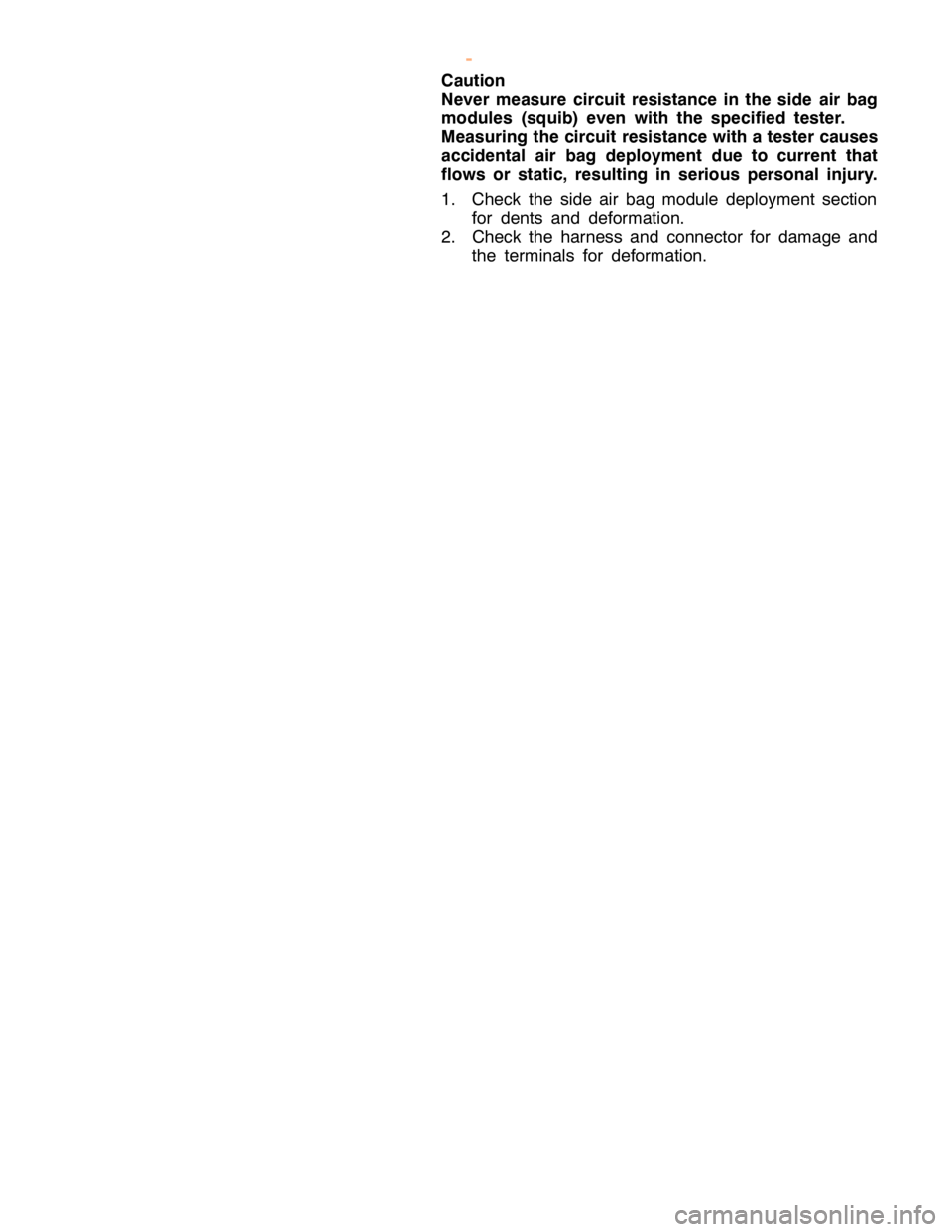

1 2 4

T

e rm in alN o. 1 2 3 4 1 1 2 3

C

ontin uit y P

ro be

( M B991222)

C ir c u it te ste r

3

2 3

Page 1540 of 1839

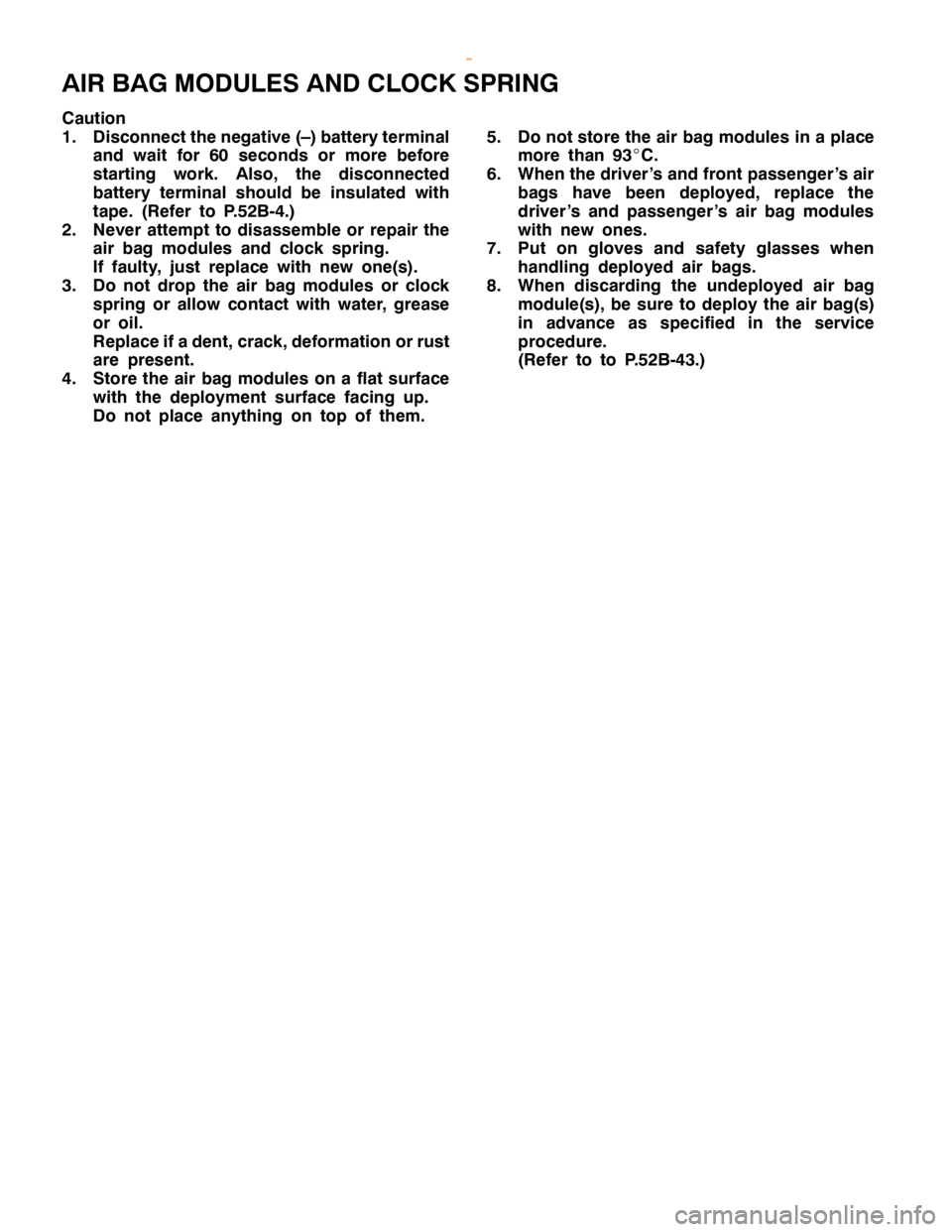

SRS -Air Bag Modules and Clock Spring52B-40

Caution

Never measure circuit resistance in the side air bag

modules (squib) even with the specified tester.

Measuring the circuit resistance with a tester causes

accidental air bag deployment due to current that

flows or static, resulting in serious personal injury.

1. Check the side air bag module deployment section

for dents and deformation.

2. Check the harness and connector for damage and

the terminals for deformation.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Trending: suspension, turn signal bulb, starter relay, battery, automatic transmission, sport mode, dimensions