wheel MITSUBISHI MONTERO 2000 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 607 of 1839

MITSUBISHI SC-Troubleshooting/On-vehicle Service13E-18

Terminal No.Signal nameNormal condition

Between terminal 13 and body earthEarthContinuity

Between terminal 26 and body earthEarth

Between terminal 31 and body earthEarth

ON-VEHICLE SERVICE

OPERATION TEST OF MITSUBISHI SC

1. Connect the MUT-

IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the LOCK (OFF) position

when connecting and disconnecting the MUT-

II.

2. Move the shift lever to the neutral

lever to the P range.

3. Start the engine.

4. Use the MUT-

IIto activate the Actuator Test (item No.05)

while depressing the accelerator pedal fully. Check that

the engine speed should decrease gradually.

Caution

Activate the Actuator Test for three seconds.

Release the accelerator pedal immediately after the

Actuator Test is complete, or the engine speed will

rise.

NOTE

During the Actuator Test, the SC-ECU transmits the signal,

which requests no torque and wide open throttle, to the

engine-ECU or engine-A/T-ECU for three seconds.

WHEEL SPEED SENSOR (FR) CHECK

Refer to Basic Manual GROUP 35B - On-vehicle service.

VEHICLE SPEED SENSOR CHECK

Refer to Basic Manual GROUP 54A - Combination Meter.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 719 of 1839

INTAKE AND EXHAUST -Intake and Exhaust Manifold,

Turbocharger <4D5>15-13

INSTALLATION SERVICE POINT

"

AA

TURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

INSPECTION

TURBOCHARGER ASSEMBLY CHECK

DVisually check the turbine wheel and the compressor

wheel for cracking or other damage.

DCheck whether the turbine wheel and the compressor

wheel can be easily turned by hand.

DCheck for oil leakage from the turbocharger assembly.

DCheck whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 721 of 1839

INTAKE AND EXHAUST -Turbocharger and Exhaust

Manifold <4M4>15-15

INSTALLATION SERVICE POINT

"

AA

TURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

INSPECTION

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD CHECK

1. Check for damage or cracking of any part.

2. Using a straight edge and a thickness gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

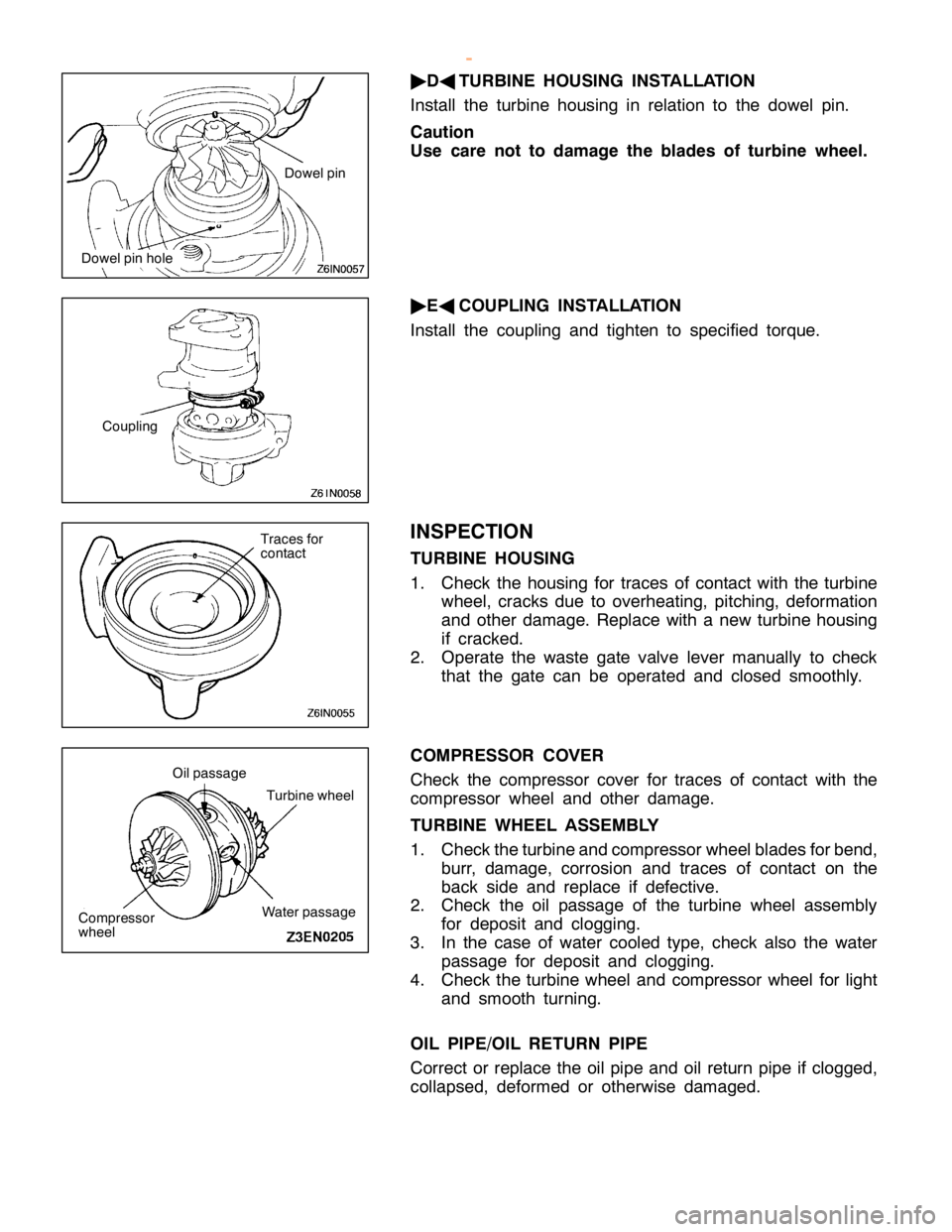

TURBOCHARGER ASSEMBLY CHECK

DVisually check the turbine wheel and the compressor

wheel for cracking or other damage.

DCheck whether the turbine wheel and the compressor

wheel can be easily turned by hand.

DCheck for oil leakage from the turbocharger assembly.

DCheck whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 724 of 1839

C

ouplin g T

ra ce s fo r

c o nta ct C

om pre sso r

w heel O

il p assa ge

Turb in e wheel

W ate r passa ge

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 730 of 1839

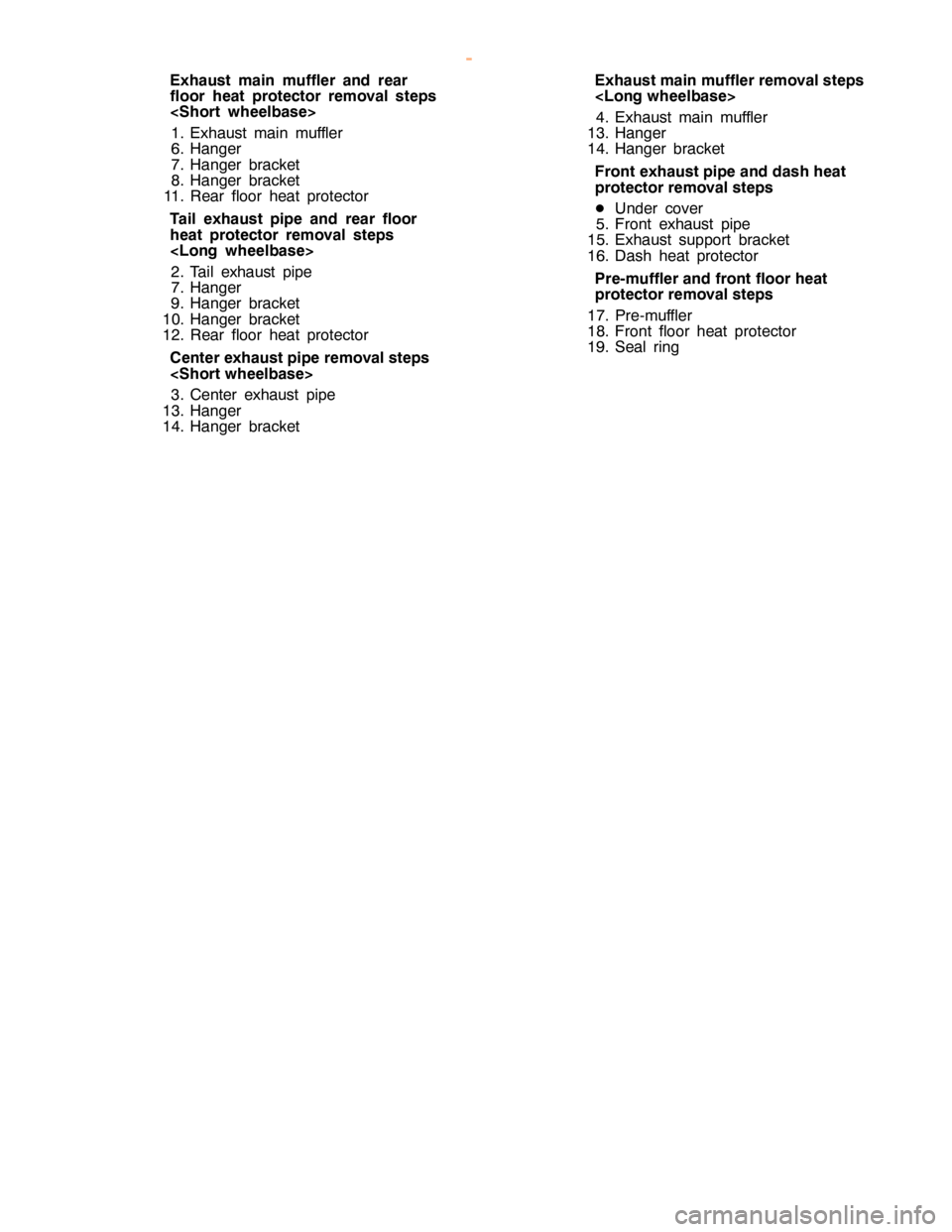

INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler <4D5>15-24

Exhaust main muffler and rear

floor heat protector removal steps

1. Exhaust main muffler

6. Hanger

7. Hanger bracket

8. Hanger bracket

11. Rear floor heat protector

Tail exhaust pipe and rear floor

heat protector removal steps

2. Tail exhaust pipe

7. Hanger

9. Hanger bracket

10. Hanger bracket

12. Rear floor heat protector

Center exhaust pipe removal steps

3. Center exhaust pipe

13. Hanger

14. Hanger bracketExhaust main muffler removal steps

4. Exhaust main muffler

13. Hanger

14. Hanger bracket

Front exhaust pipe and dash heat

protector removal steps

DUnder cover

5. Front exhaust pipe

15. Exhaust support bracket

16. Dash heat protector

Pre-muffler and front floor heat

protector removal steps

17. Pre-muffler

18. Front floor heat protector

19. Seal ring

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 731 of 1839

E

XH AUST PIP E AND MAIN MUFFLE R <4M 4>

R EM OVA L AND IN STA LLA TIO N 3

1

3

14

8

1 1

1

1 7 6

6

1 3

13

1

8

1 9

5 1

7

4 9

±4

N

×m

4

9

±1

0 N

×m

2 5

±4

N

×m 4

9

±1

0 N

×m 1

3

±2

N

×m

13

±2

N

×m

4

9

±1

0 N

×m

< L ong wheelb ase> 2

1 3 6

1 2

9 6

4

13

1

4

1

3

1 9 1

8

5

1

6

15 1

6

Page 732 of 1839

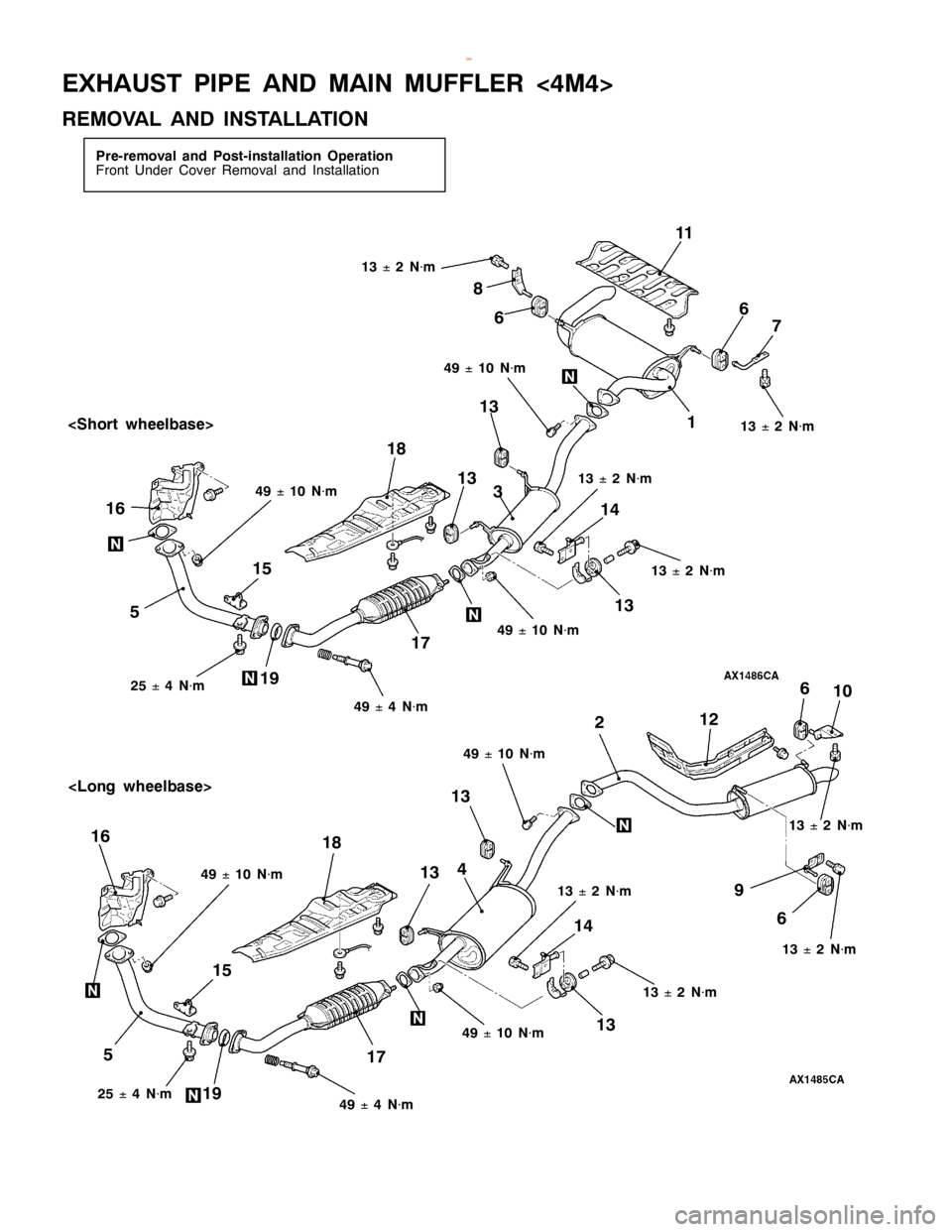

INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler<4M4>15-26

Exhaust main muffler and rear

floor heat protector removal steps

1. Exhaust main muffler

6. Hanger

7. Hanger bracket

8. Hanger bracket

11. Rear floor heat protector

Tail exhaust pipe and rear floor

heat protector removal steps

2. Tail exhaust pipe

7. Hanger

9. Hanger bracket

10. Hanger bracket

12. Rear floor heat protector

Center exhaust pipe removal steps

3. Center exhaust pipe

13. Hanger

14. Hanger bracketExhaust main muffler removal steps

4. Exhaust main muffler

13. Hanger

14. Hanger bracket

Front exhaust pipe and dash heat

protector removal steps

DUnder cover

5. Front exhaust pipe

15. Exhaust support bracket

16. Dash heat protector

Front floor heat protector removal

steps

17. Catalytic converter

18. Front floor heat protector

19. Seal ring

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 747 of 1839

INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler <4D5>15-15

Exhaust main muffler and rear

floor heat protector removal steps

1. Exhaust main muffler

6. Hanger

7. Hanger bracket

8. Hanger bracket

11. Rear floor heat protector

Tail exhaust pipe and rear floor

heat protector removal steps

2. Tail exhaust pipe

6. Hanger

9. Hanger bracket

10. Hanger bracket

12. Rear floor heat protector

Center exhaust pipe removal steps

3. Center exhaust pipe

13. Hanger

14. Hanger bracketExhaust main muffler removal steps

4. Exhaust main muffler

13. Hanger

14. Hanger bracket

Front exhaust pipe and dash heat

protector removal steps

DUnder cover

5. Front exhaust pipe

15. Exhaust support bracket

16. Dash heat protector

Front floor heat protector removal

steps

17. Catalytic converter

18. Front floor heat protector

19. Seal ring

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 898 of 1839

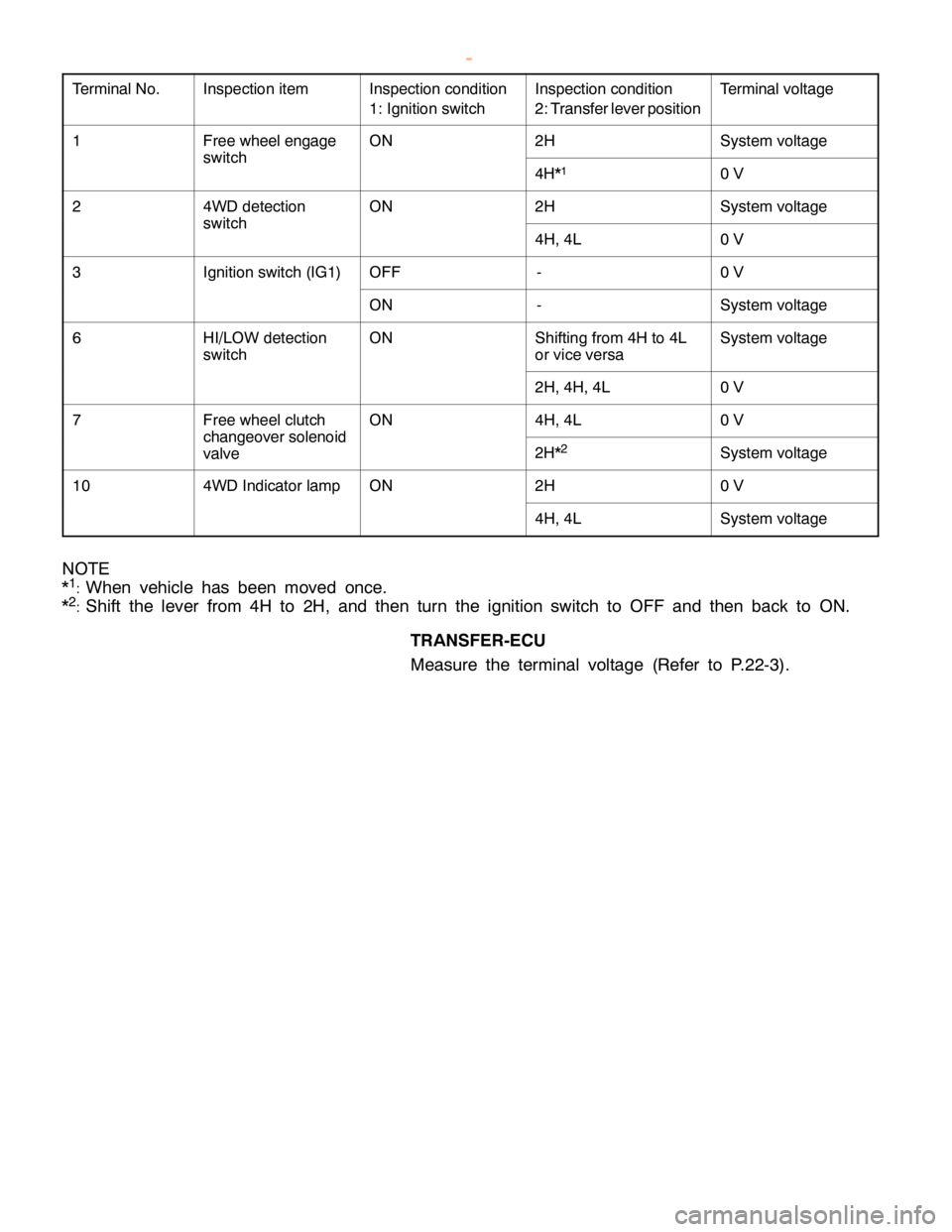

MANUAL TRANSMISSION -4WD Indicator-ECU/Transfer-ECU22-18

Terminal No.Inspection itemInspection condition

1: Ignition switchInspection condition

2: Transfer lever positionTerminal voltage

1Free wheel engageON2HSystem voltage

switch

4H*10V

24WD detectionON2HSystem voltage

switch

4H, 4L0V

3Ignition switch (IG1)OFF-0V

ON-System voltage

6HI/LOW detection

switchONShifting from 4H to 4L

or vice versaSystem voltage

2H, 4H, 4L0V

7Free wheel clutchON4H, 4L0V

changeover solenoid

valve

2H*2System voltage

104WD Indicator lampON2H0V

4H, 4LSystem voltage

NOTE

*1:When vehicle has been moved once.

*2:Shift the lever from 4H to 2H, and then turn the ignition switch to OFF and then back to ON.

TRANSFER-ECU

Measure the terminal voltage (Refer to P.22-3).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

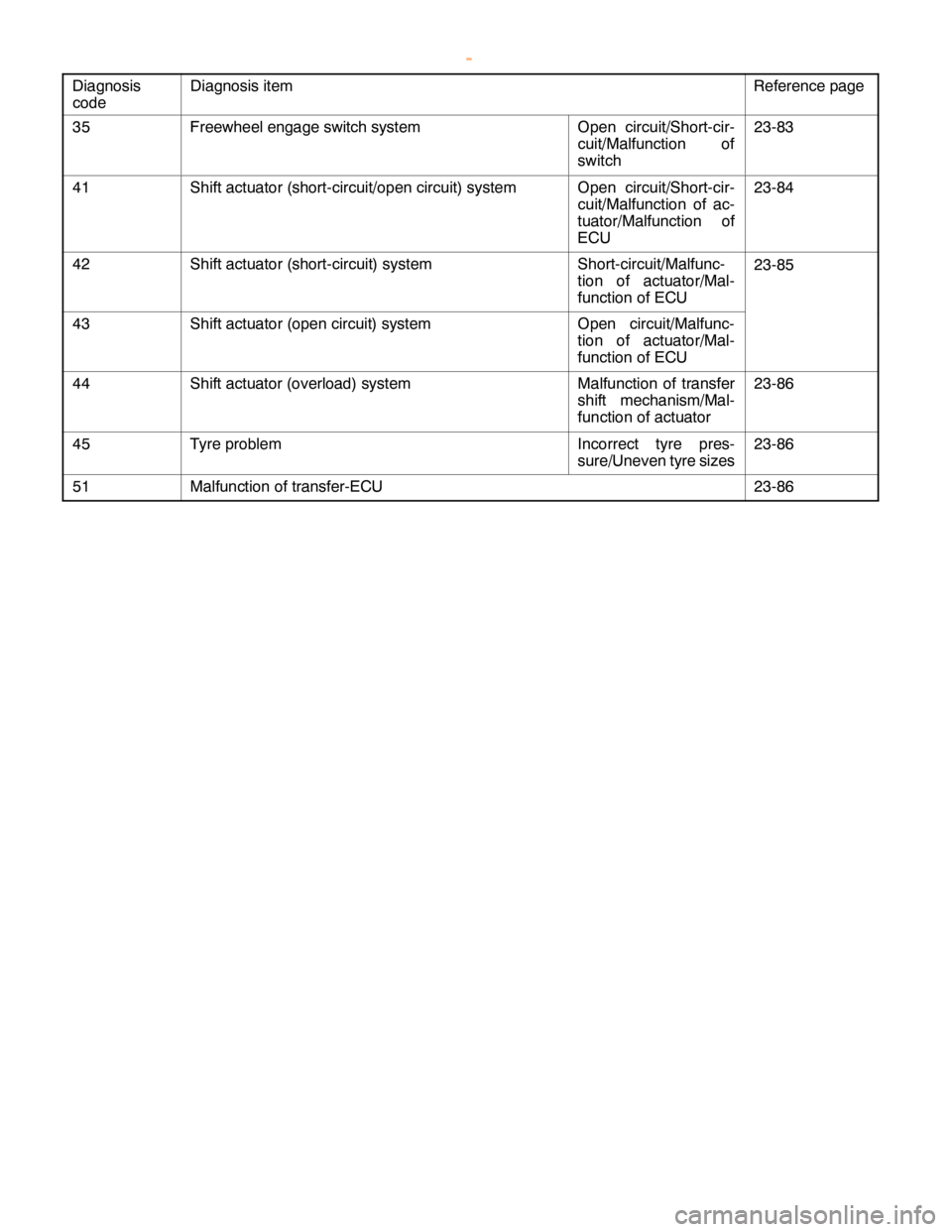

Page 972 of 1839

AUTOMATIC TRANSMISSION -Troubleshooting

Diagnosis

codeReference page Diagnosis item

35Freewheel engage switch systemOpen circuit/Short-cir-

cuit/Malfunction of

switch23-83

41Shift actuator (short-circuit/open circuit) systemOpen circuit/Short-cir-

cuit/Malfunction of ac-

tuator/Malfunction of

ECU23-84

42Shift actuator (short-circuit) systemShort-circuit/Malfunc-

tion of actuator/Mal-

function of ECU23-85

43Shift actuator (open circuit) systemOpen circuit/Malfunc-

tion of actuator/Mal-

function of ECU

44Shift actuator (overload) systemMalfunction of transfer

shift mechanism/Mal-

function of actuator23-86

45Tyre problemIncorrect tyre pres-

sure/Uneven tyre sizes23-86

51Malfunction of transfer-ECU23-86

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk