wheel MITSUBISHI MONTERO 2000 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 976 of 1839

AUTOMATIC TRANSMISSION -Troublehshooting

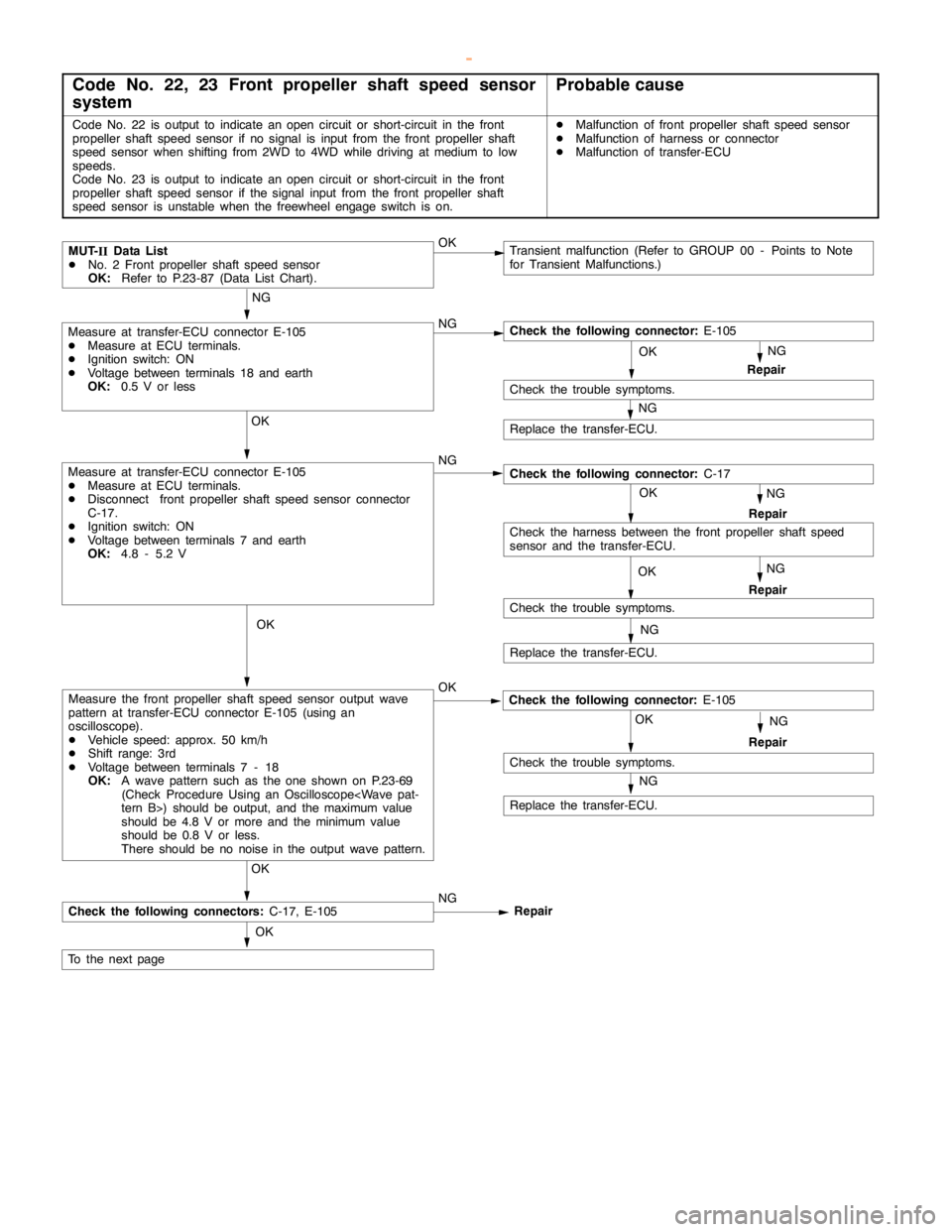

Code No. 22, 23 Front propeller shaft speed sensor

systemProbable cause

Code No. 22 is output to indicate anopencircuit or short-circuit in the front

propeller shaft speed sensor if no signal is input from the front propeller shaft

speed sensor when shifting from 2WD to 4WD while driving atmedium to low

speeds.

Code No. 23 is output to indicate anopencircuit or short-circuit in the front

propeller shaft speed sensor if the signal input from the front propeller shaft

speed sensor is unstable when the freewheelengageswitch is on.DMalfunction of front propeller shaft speed sensor

DMalfunction of harness or connector

DMalfunction of transfer-ECU

Transient malfunction (Refer to GROUP 00 - Points to Note

for Transient Malfunctions.)

OK NG

OK

OK

To the nextpage

NG

OK

NG

NG

Repair

Replace the transfer-ECU.

OKMUT-

IIData List

DNo. 2 Front propeller shaft speed sensor

OK:Refer to P.23-87 (Data List Chart).

OK

OK

NG

OK

Measure at transfer-ECU connector E-105

DMeasure at ECU terminals.

DIgnition switch: ON

DVoltage between terminals 18 and earth

OK:0.5 V or less

NG

Repair

Replace the transfer-ECU.

NG

Check the trouble symptoms.

Check the trouble symptoms.

Replace the transfer-ECU.

OK

OK

Measure at transfer-ECU connector E-105

DMeasure at ECU terminals.

DDisconnect front propeller shaft speed sensor connector

C-17.

DIgnition switch: ON

DVoltage between terminals 7 and earth

OK:4.8 - 5.2 V

Measure the front propeller shaft speed sensor output wave

pattern at transfer-ECU connector E-105 (using an

oscilloscope).

DVehicle speed: approx. 50 km/h

DShift range: 3rd

DVoltage between terminals 7 - 18

OK:A wave pattern such as the one shown on P.23-69

(Check Procedure Using an Oscilloscope

should be 4.8 V or more and the minimumvalue

should be 0.8 V or less.

There should be no noise in the output wave pattern.

NG

RepairCheck the following connectors:C-17, E-105NG

NG

Repair

Check the following connector:E-105Repair

NG

Check the harness between the front propeller shaft speed

sensor and the transfer-ECU.

Check the following connector:C-17

Check the trouble symptoms.

Check the following connector:E-105

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 978 of 1839

AUTOMATIC TRANSMISSION -Troublehshooting

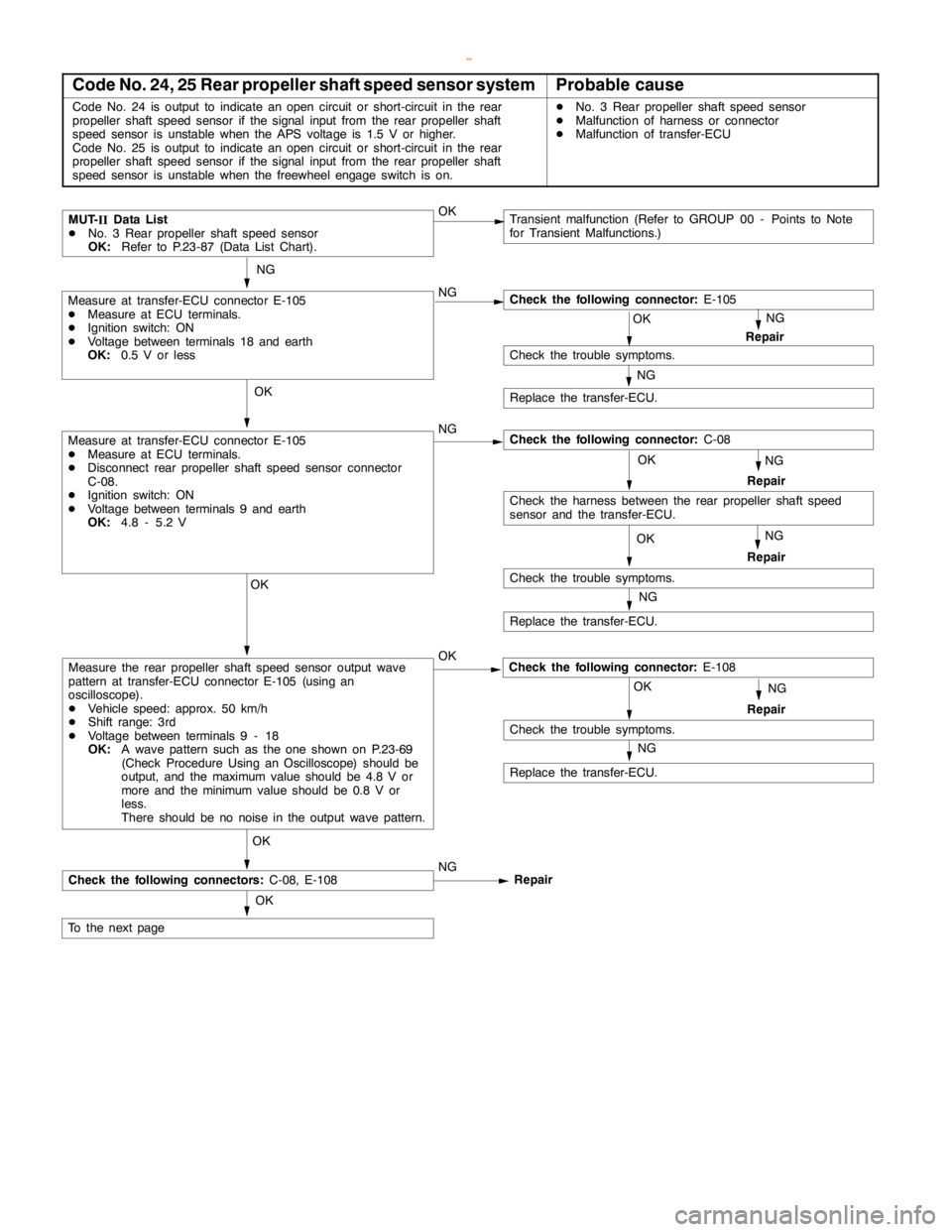

Code No. 24, 25 Rear propeller shaft speed sensor systemProbable cause

Code No. 24 is output to indicate anopencircuit or short-circuit in the rear

propeller shaft speed sensor if the signal input from the rear propeller shaft

speed sensor is unstable when the APS voltage is 1.5 V or higher.

Code No. 25 is output to indicate anopencircuit or short-circuit in the rear

propeller shaft speed sensor if the signal input from the rear propeller shaft

speed sensor is unstable when the freewheelengageswitch is on.DNo. 3 Rear propeller shaft speed sensor

DMalfunction of harness or connector

DMalfunction of transfer-ECU

Transient malfunction (Refer to GROUP 00 - Points to Note

for Transient Malfunctions.)

OK NG

Check the following connector:E-105

OK

OK

To the nextpage

NG

OK

NG

NG

Repair

Check the following connector:C-08

Replace the transfer-ECU.

OKMUT-

IIData List

DNo. 3 Rear propeller shaft speed sensor

OK:Refer to P.23-87 (Data List Chart).

OK

OK

NG

Check the trouble symptoms.

OK

Measure at transfer-ECU connector E-105

DMeasure at ECU terminals.

DIgnition switch: ON

DVoltage between terminals 18 and earth

OK:0.5 V or less

NG

Repair

Replace the transfer-ECU.

NG

Check the trouble symptoms.

Check the trouble symptoms.

Replace the transfer-ECU.

OK

OK

Measure at transfer-ECU connector E-105

DMeasure at ECU terminals.

DDisconnect rear propeller shaft speed sensor connector

C-08.

DIgnition switch: ON

DVoltage between terminals 9 and earth

OK:4.8 - 5.2 V

Measure the rear propeller shaft speed sensor output wave

pattern at transfer-ECU connector E-105 (using an

oscilloscope).

DVehicle speed: approx. 50 km/h

DShift range: 3rd

DVoltage between terminals 9 - 18

OK:A wave pattern such as the one shown on P.23-69

(Check Procedure Using an Oscilloscope) should be

output, and the maximum value should be 4.8 V or

more and the minimumvalue should be 0.8 V or

less.

There should be no noise in the output wave pattern.

NG

RepairCheck the following connectors:C-08, E-108NG

NG

Repair

Check the following connector:E-108Repair

NG

Check the harness between the rear propeller shaft speed

sensor and the transfer-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 983 of 1839

AUTOMATIC TRANSMISSION -Troublehshooting

Code No. 34 Freewheel engage solenoid valve systemProbable cause

Code No. 34 is output to indicate anopencircuit or short-circuit in the freewheel

engage solenoidvalve when the transfer-ECU terminal voltages are not the

same while current isbeing supplied to the freewheel engage solenoidvalve.DMalfunction of freewheel engage solenoidvalve

DMalfunction of harness or connector

DMalfunction of transfer-ECU

NG

NG

MUT-

IIActuator Test

DNo. 1 Freewheel engage solenoidvalve

OK:The solenoid valve operates for 5 seconds.Transient malfunction (Refer to GROUP 00 - Points to Note

for Transient Malfunctions.) OK

OK OK OKNG

DCheck the harness between the freewheelengage solenoid

valve and the transfer-ECU, and repair if necessary.

DCheck the harness between the freewheelengage solenoid

valve and the ignition switch, and repair if necessary.Repair

Check the harness between the freewheelengage solenoid

valve and the ignition switch, and repair if necessary.

OK OK

OK

NG

Check the trouble symptoms.Replace the transfer-ECU.

Measure at transfer-ECU connector E-108

DMeasure at ECU terminals.

DTransfer: 4WD

DIgnition switch: ON

DVoltage between terminals 41 and earth

OK:System voltage

Measure at freewheel engage solenoidvalve connectors A-40

and A-41.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 1 and earth

OK:System voltageNG

Replace

NG

Repair

Freewheel engage solenoidvalve check

(Refer to GROUP 26 - On-Vehicle Service.)

Check the following connectors:A-40, A-41

Repair NG

Check the following connector:E-108

NG

Repair

OK

Check the following connectors:

D-210, D-27, A-15, A-16, A-04, E-113, E-108,

D-208, D-210, D-27, A-15, A-16, D-143, E-113, E-108,

Check the following connectors:D-208, D-210, D-27, A-15

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 984 of 1839

AUTOMATIC TRANSMISSION -Troublehshooting

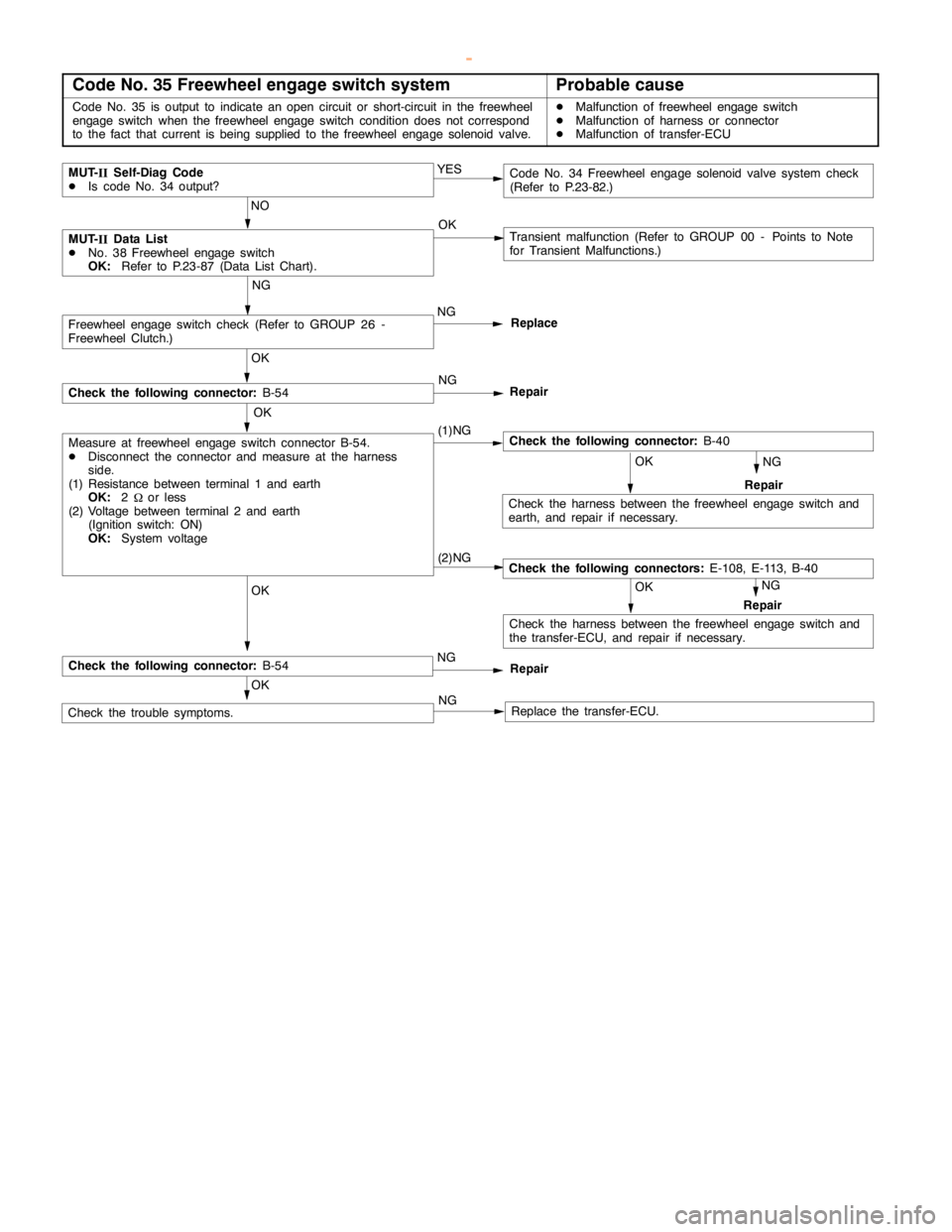

Code No. 35 Freewheel engage switch systemProbable cause

Code No. 35 is output to indicate anopencircuit or short-circuit in the freewheel

engageswitch when the freewheelengageswitch condition does not correspond

to the fact that current isbeing supplied to the freewheel engage solenoidvalve.DMalfunction of freewheel engageswitch

DMalfunction of harness or connector

DMalfunction of transfer-ECU

NG

(1)NG

MUT-

IIData List

DNo. 38 Freewheel engageswitch

OK:Refer to P.23-87 (Data List Chart).Transient malfunction (Refer to GROUP 00 - Points to Note

for Transient Malfunctions.) OK

OK OK OKNG

Repair

Check the following connector:B-40

Check the harness between the freewheelengageswitch and

earth, and repair if necessary.

OK

OK

Check the trouble symptoms.Replace the transfer-ECU.

Measure at freewheel engageswitch connector B-54.

DDisconnect the connector and measure at the harness

side.

(1) Resistance between terminal 1 and earth

OK:2

Wor less

(2) Voltage between terminal 2 and earth

(Ignition switch: ON)

OK:System voltageNG

Replace

NG

Repair

Freewheel engageswitch check (Refer to GROUP 26 -

Freewheel Clutch.)

Check the following connector:B-54

MUT-

IISelf-Diag Code

DIs code No. 34 output?Code No. 34 Freewheelengage solenoidvalve system check

(Refer to P.23-82.) YES

NO

NG

(2)NG

NG

OK

Repair

Check the following connectors:E-108, E-113, B-40

Check the harness between the freewheelengageswitch and

the transfer-ECU, and repair if necessary.

Check the following connector:B-54Repair

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 987 of 1839

AUTOMATIC TRANSMISSION -Troublehshooting

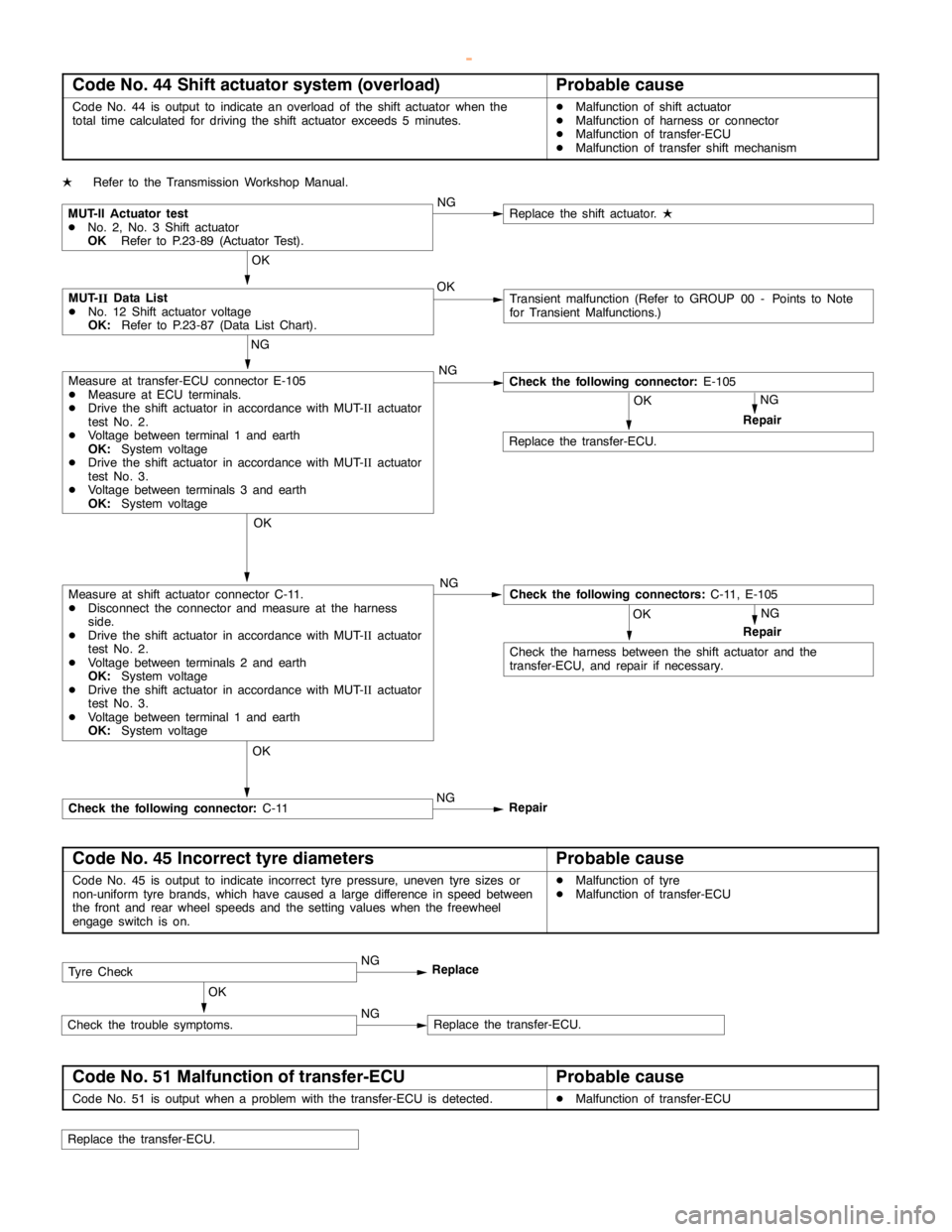

Code No. 44 Shift actuator system (overload)Probable cause

Code No. 44 is output to indicate an overload of the shift actuator when the

total time calculated for driving the shift actuator exceeds 5 minutes.DMalfunction of shift actuator

DMalfunction of harness or connector

DMalfunction of transfer-ECU

DMalfunction of transfer shift mechanism

LRefer to the Transmission Workshop Manual.

NG

NG

MUT-

IIData List

DNo. 12 Shift actuator voltage

OK:Refer to P.23-87 (Data List Chart).Transient malfunction (Refer to GROUP 00 - Points to Note

for Transient Malfunctions.) OK

OK NG

Check the harness between the shift actuator and the

transfer-ECU, and repair if necessary.Repair

Check the following connector:E-105

OK

NG

OK

OK

NG

Replace the transfer-ECU.

Check the following connectors:C-11, E-105Measure at shift actuator connector C-11.

DDisconnect the connector and measure at the harness

side.

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 2.

DVoltage between terminals 2 and earth

OK:System voltage

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 3.

DVoltage between terminal 1 and earth

OK:System voltage

Measure at transfer-ECU connector E-105

DMeasure at ECU terminals.

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 2.

DVoltage between terminal 1 and earth

OK:System voltage

DDrive the shift actuator in accordance with MUT-

IIactuator

test No. 3.

DVoltage between terminals 3 and earth

OK:System voltage

Repair NG

Check the following connector:C-11Repair

MUT-II Actuator test

DNo. 2, No. 3 Shift actuator

OKRefer to P.23-89 (Actuator Test).

OKNGReplace the shift actuator.

L

Code No. 45 Incorrect tyre diametersProbable cause

Code No. 45 is output to indicate incorrect tyre pressure, uneven tyre sizes or

non-uniform tyre brands, which have caused a large difference in speed between

the front and rear wheel speeds and the setting values when the freewheel

engageswitch is on.DMalfunction of tyre

DMalfunction of transfer-ECU

NG

Replace

Replace the transfer-ECU. NGCheck the trouble symptoms.

OK

Tyre Check

Code No. 51 Malfunction of transfer-ECUProbable cause

Code No. 51 is output when a problem with the transfer-ECU is detected.DMalfunction of transfer-ECU

Replace the transfer-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 989 of 1839

AUTOMATIC TRANSMISSION -Troubleshooting

Item

No.Normal condition Inspection conditions Check item

21Ignition switchIgnition switch: ONON

Ignition switch: OFFOFF

22Transmission identi-

ficationVehicles with A/TA/T

23Stop lamp switchIgnition switch: ONBrake pedal: DepressedON

Engine: StoppedBrake pedal: ReleasedOFF

24Transfer leverTransfer shift lever position: 2HON

switch 2HTransfer shift lever position: Other than the aboveOFF

25Transfer leverTransfer shift lever position: 4HON

switch 4HTransfer shift lever position: Other than the aboveOFF

26Transfer leverTransfer shift lever position: 4HLcON

switch 4HLcTransfer shift lever position: Other than the aboveOFF

27Transfer leverTransfer shift lever position: 4LLcON

switch 4LLcTransfer shift lever position: Other than the aboveOFF

28Engine identificationPetrol vehiclesPETROL

Diesel vehiclesDIESEL

30Freewheel engageDuring 2WDON

solenoid valveDuring 4WDOFF

31Inhibitor switch NSelector lever position: NON

Selector lever position: Other than the aboveOFF

32Inhibitor switch PSelector lever position: PON

Selector lever position: Other than the aboveOFF

332WD switchDriving conditions: 2WD (2H)ON

Driving conditions: Other than the aboveOFF

342WD/4WD switchDriving conditions: 2WD (2H), 4WD (4H)ON

Driving conditions: Other than the aboveOFF

354H switchDriving conditions: 4WD (4H), 4WD (4HLc)ON

Driving conditions: Other than the aboveOFF

36Center differentialDriving conditions: 4WD (4HLc), 4WD (4LLc)ON

lock switchDriving conditions: Other than the aboveOFF

374LLc switchDriving conditions: 4WD (4LLc)ON

Driving conditions: Other than the aboveOFF

38Freewheel engageDuring 2WDOFF

switchDuring 4WDON

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 991 of 1839

AUTOMATIC TRANSMISSION -Troubleshooting

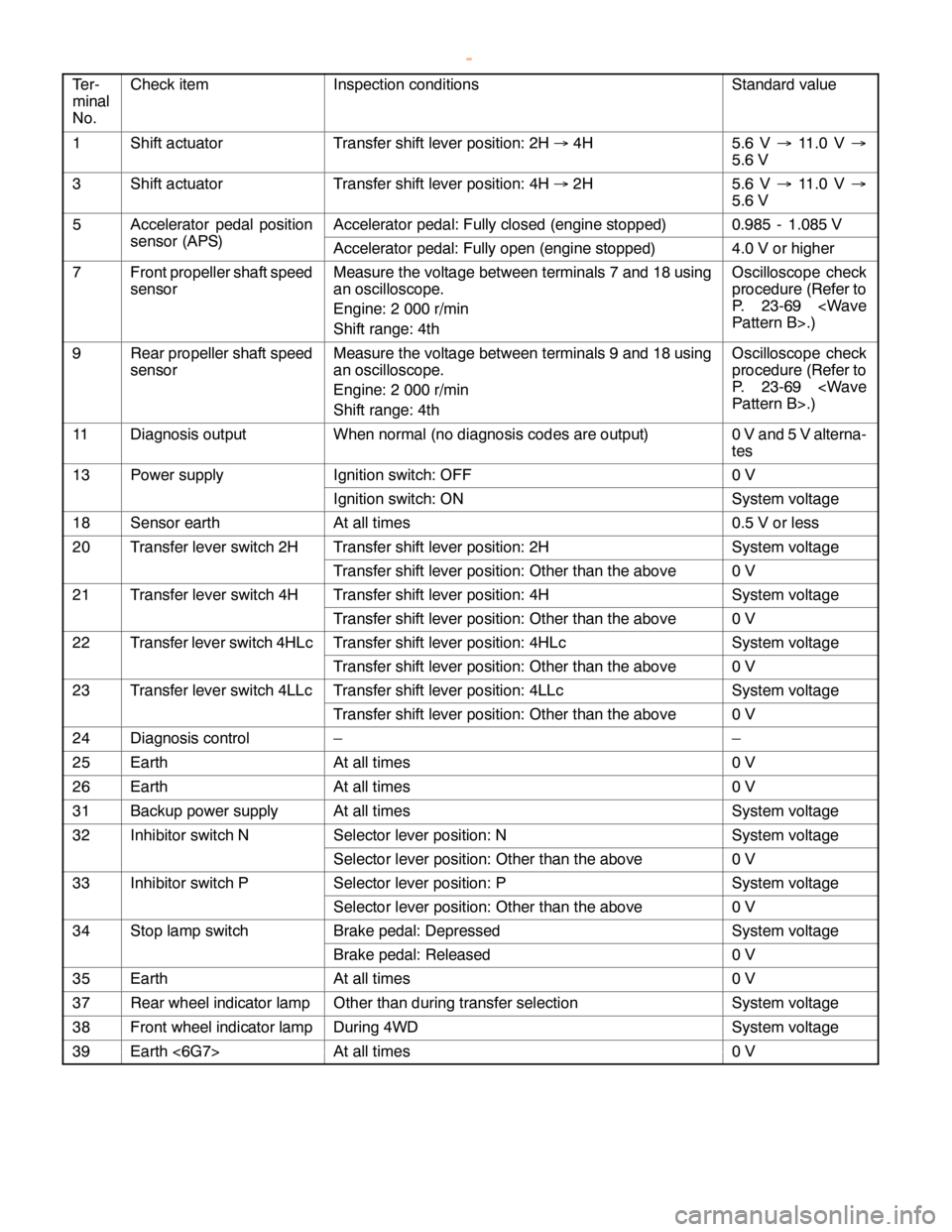

Ter-

minal

No.Check itemInspection conditionsStandard value

1Shift actuatorTransfer shift lever position: 2H®4H5.6 V®11.0 V®

5.6 V

3Shift actuatorTransfer shift lever position: 4H®2H5.6 V®11.0 V®

5.6 V

5Accelerator pedal positionAccelerator pedal: Fully closed (engine stopped)0.985 - 1.085 V

sensor (APS)Accelerator pedal: Fully open (engine stopped)4.0 V or higher

7Front propeller shaft speed

sensorMeasure the voltage between terminals 7 and 18 using

an oscilloscope.

Engine: 2 000 r/min

Shift range: 4thOscilloscope check

procedure (Refer to

P. 23-69

9Rear propeller shaft speed

sensorMeasure the voltage between terminals 9 and 18 using

an oscilloscope.

Engine: 2 000 r/min

Shift range: 4thOscilloscope check

procedure (Refer to

P. 23-69

11Diagnosis outputWhen normal (no diagnosis codes are output)0 V and 5 V alterna-

tes

13Power supplyIgnition switch: OFF0V

Ignition switch: ONSystem voltage

18Sensor earthAt all times0.5 V or less

20Transfer lever switch 2HTransfer shift lever position: 2HSystem voltage

Transfer shift lever position: Other than the above0V

21Transfer lever switch 4HTransfer shift lever position: 4HSystem voltage

Transfer shift lever position: Other than the above0V

22Transfer lever switch 4HLcTransfer shift lever position: 4HLcSystem voltage

Transfer shift lever position: Other than the above0V

23Transfer lever switch 4LLcTransfer shift lever position: 4LLcSystem voltage

Transfer shift lever position: Other than the above0V

24Diagnosis control––

25EarthAt all times0V

26EarthAt all times0V

31Backup power supplyAt all timesSystem voltage

32Inhibitor switch NSelector lever position: NSystem voltage

Selector lever position: Other than the above0V

33Inhibitor switch PSelector lever position: PSystem voltage

Selector lever position: Other than the above0V

34Stop lamp switchBrake pedal: DepressedSystem voltage

Brake pedal: Released0V

35EarthAt all times0V

37Rear wheel indicator lampOther than during transfer selectionSystem voltage

38Front wheel indicator lampDuring 4WDSystem voltage

39Earth <6G7>At all times0V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 992 of 1839

AUTOMATIC TRANSMISSION -Troubleshooting

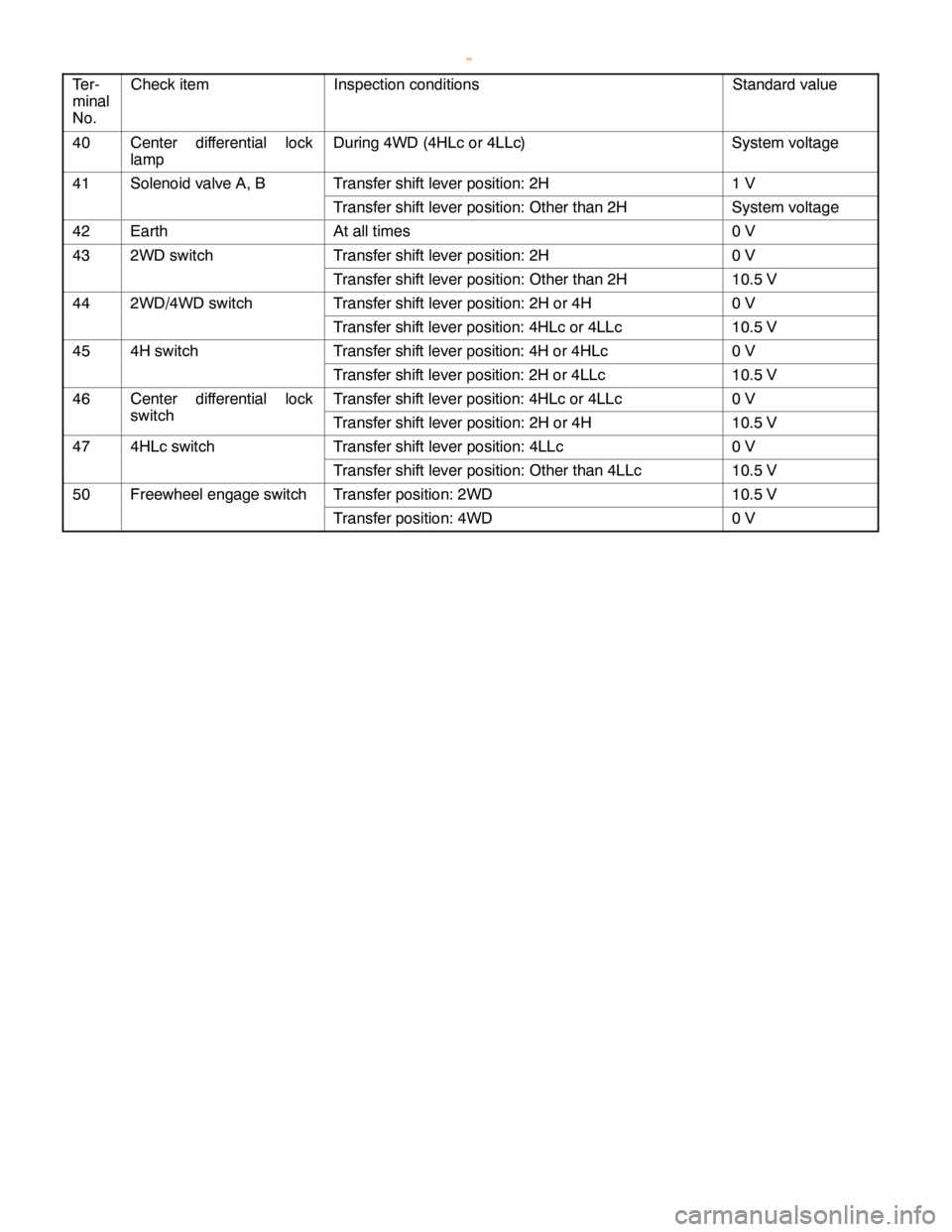

Ter-

minal

No.Standard value Inspection conditions Check item

40Center differential lock

lampDuring 4WD (4HLc or 4LLc)System voltage

41Solenoid valve A, BTransfer shift lever position: 2H1V

Transfer shift lever position: Other than 2HSystem voltage

42EarthAt all times0V

432WD switchTransfer shift lever position: 2H0V

Transfer shift lever position: Other than 2H10.5 V

442WD/4WD switchTransfer shift lever position: 2H or 4H0V

Transfer shift lever position: 4HLc or 4LLc10.5 V

454H switchTransfer shift lever position: 4H or 4HLc0V

Transfer shift lever position: 2H or 4LLc10.5 V

46Center differential lockTransfer shift lever position: 4HLc or 4LLc0V

switchTransfer shift lever position: 2H or 4H10.5 V

474HLc switchTransfer shift lever position: 4LLc0V

Transfer shift lever position: Other than 4LLc10.5 V

50Freewheel engage switchTransfer position: 2WD10.5 V

Transfer position: 4WD0V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1050 of 1839

26-1

FRONT AXLE

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANTS 4..............................

SEALANTS 5................................

SPECIAL TOOLS 5..........................

ON-VEHICLE SERVICE 10...................

Wheel Bearing Backlash Check 10..............

Front Axle Total Backlash Check 10.............

Front Axle Gear Oil Level Check 11.............

Differential Carrier Oil Seal Replacement 11......

Solenoid Valve Operation Check 12..............

FRONT HUB AND KNUCKLE ASSEMBLY 13.

DRIVE SHAFT 16...........................

INNER SHAFT, HOUSING TUBE 24..........

FREEWHEEL CLUTCH ASSEMBLY,

DIFFERENTIAL CARRIER 28.................

FREEWHEEL CLUTCH ASSEMBLY 31.......

DIFFERENTIAL CARRIER 34.................

SOLENOID VALVE, VACUUMPIPE, VACUUM

TANK 49....................................

FRONT DIFFERENTIAL MOUNT 51..........

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1051 of 1839

FRONT AXLE -General Information26-2

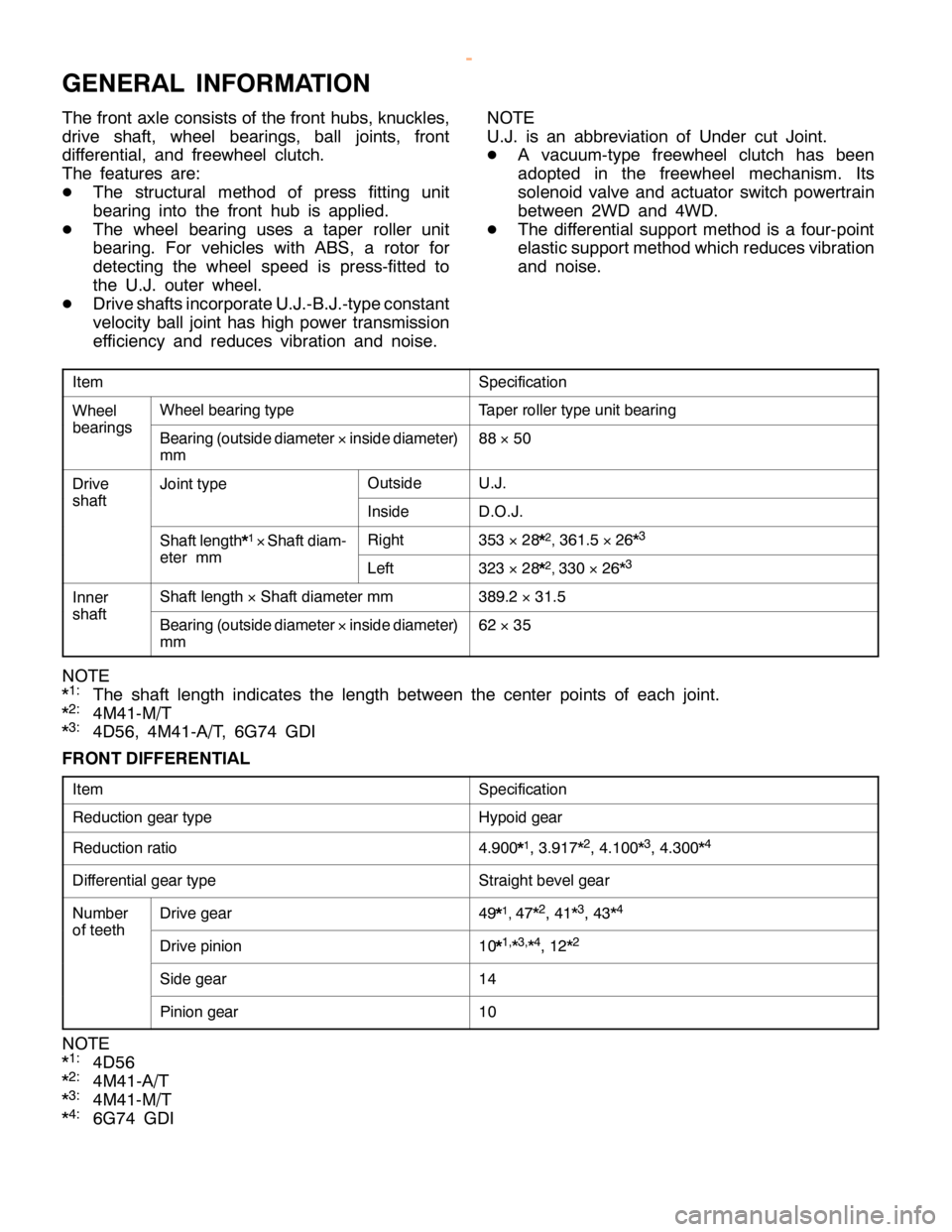

GENERAL INFORMATION

The front axle consists of the front hubs, knuckles,

drive shaft, wheel bearings, ball joints, front

differential, and freewheel clutch.

The features are:

DThe structural method of press fitting unit

bearing into the front hub is applied.

DThe wheel bearing uses a taper roller unit

bearing. For vehicles with ABS, a rotor for

detecting the wheel speed is press-fitted to

the U.J. outer wheel.

DDrive shafts incorporate U.J.-B.J.-type constant

velocity ball joint has high power transmission

efficiency and reduces vibration and noise.NOTE

U.J. is an abbreviation of Under cut Joint.

DA vacuum-type freewheel clutch has been

adopted in the freewheel mechanism. Its

solenoid valve and actuator switch powertrain

between 2WD and 4WD.

DThe differential support method is a four-point

elastic support method which reduces vibration

and noise.

ItemSpecification

WheelWheel bearing typeTaper roller type unit bearing

bearingsBearing (outside diameter´inside diameter)

mm88´50

DriveJoint typeOutsideU.J.

shaftInsideD.O.J.

Shaft length

*1´Shaft diam-Right353´28

*2,361.5´26*3

eter mmLeft323´28

*2,330´26*3

InnerShaft length´Shaft diameter mm389.2´31.5

shaftBearing (outside diameter´inside diameter)

mm62´35

NOTE

*1:The shaft length indicates the length between the center points of each joint.

*2:4M41-M/T

*3:4D56, 4M41-A/T, 6G74 GDI

FRONT DIFFERENTIAL

ItemSpecification

Reduction gear typeHypoid gear

Reduction ratio4.900

*1, 3.917*2, 4.100*3, 4.300*4

Differential gear typeStraight bevel gear

NumberDrive gear49

*1,47*2, 41*3, 43*4

of teeth

Drive pinion10

*1,*3,*4, 12*2

Side gear14

Pinion gear10

NOTE

*1:4D56

*2:4M41-A/T

*3:4M41-M/T

*4:6G74 GDI

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk