wheel MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 43 of 1839

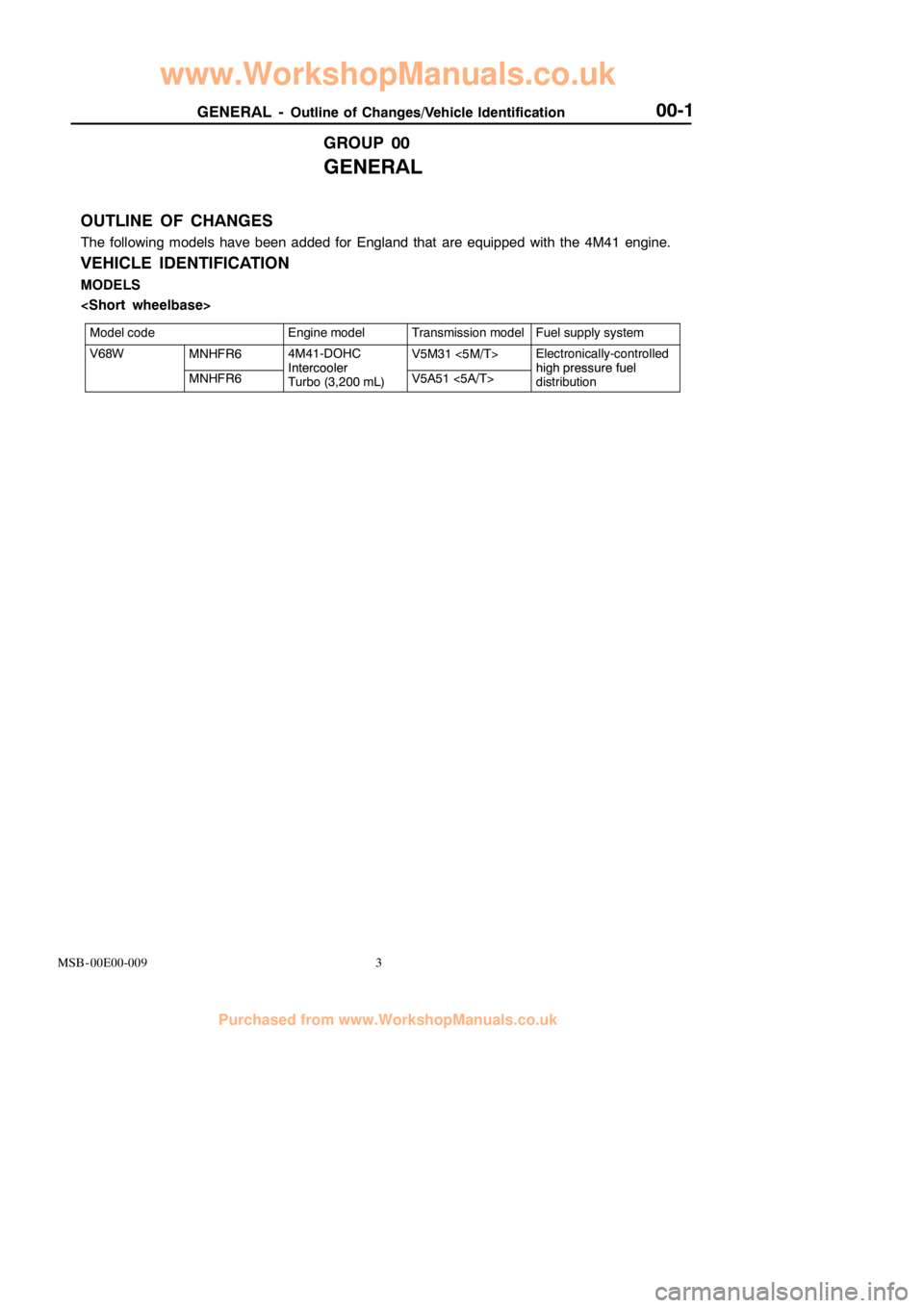

3 MSB - 00E00-009Model code

Engine modelTransmission modelFuel supply system

V68WMNHFR64M41-DOHC

Intercooler

V5M31 <5M/T>Electronically-controlled

highpressurefuelMNHFR6Intercooler

Turbo (3,200 mL)V5A51 <5A/T>highpressurefuel

distribution

GENERAL -Outline of Changes/Vehicle Identification00-1

GROUP 00

GENERAL

OUTLINE OF CHANGES

The following models have been added for England that are equipped with the 4M41 engine.

VEHICLE IDENTIFICATION

MODELS

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 47 of 1839

GENERAL -Outline of Changes/Vehicle Identification00-1

GROUP 00

GENERAL

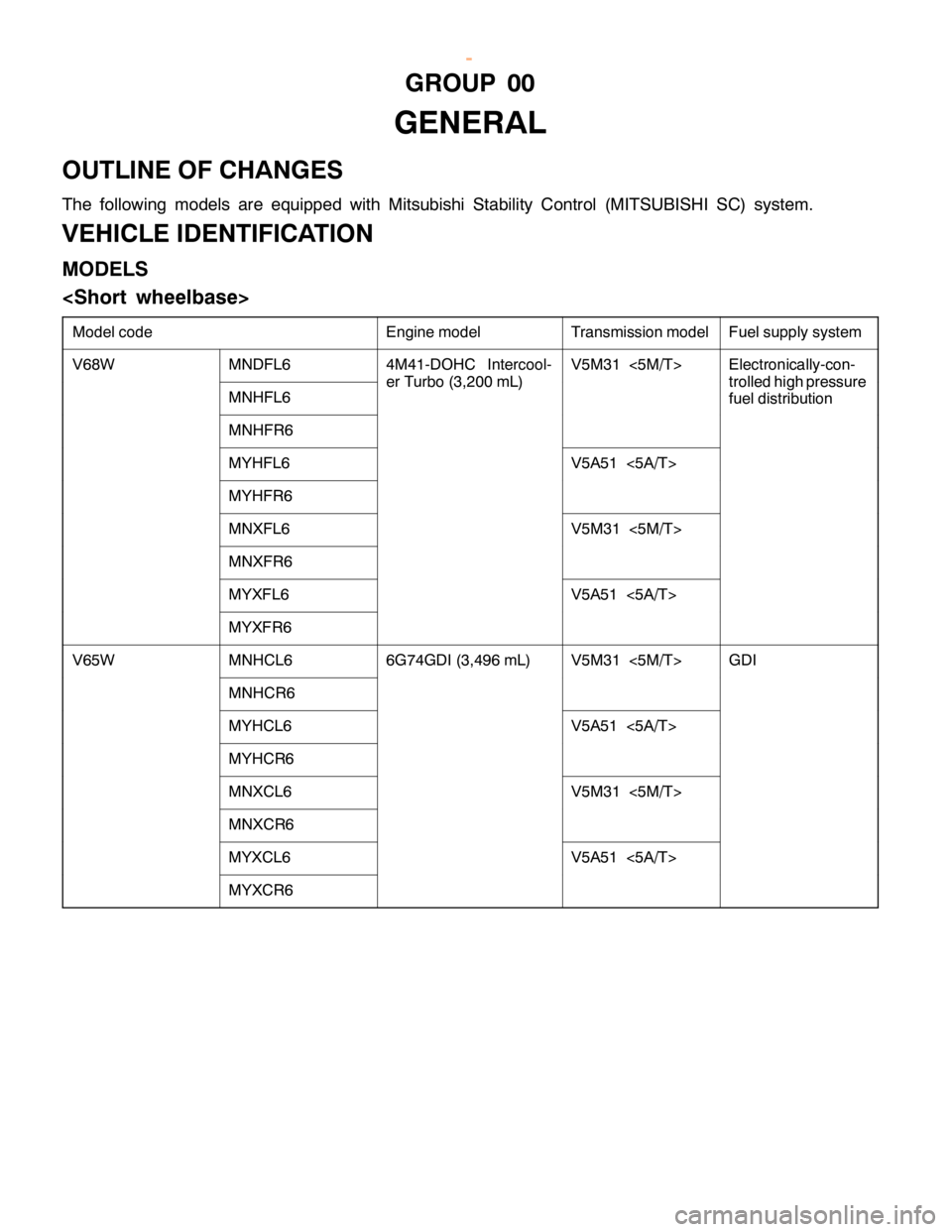

OUTLINE OF CHANGES

The following models are equipped with Mitsubishi Stability Control (MITSUBISHI SC) system.

VEHICLE IDENTIFICATION

MODELS

Model codeEngine modelTransmission modelFuel supply system

V68WMNDFL64M41-DOHC Intercool-V5M31 <5M/T>Electronically-con-

MNHFL6

er Turbo (3,200 mL)trolled high pressure

fuel distribution

MNHFR6

MYHFL6V5A51 <5A/T>

MYHFR6

MNXFL6V5M31 <5M/T>

MNXFR6

MYXFL6V5A51 <5A/T>

MYXFR6

V65WMNHCL66G74GDI (3,496 mL)V5M31 <5M/T>GDI

MNHCR6

MYHCL6V5A51 <5A/T>

MYHCR6

MNXCL6V5M31 <5M/T>

MNXCR6

MYXCL6V5A51 <5A/T>

MYXCR6

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 48 of 1839

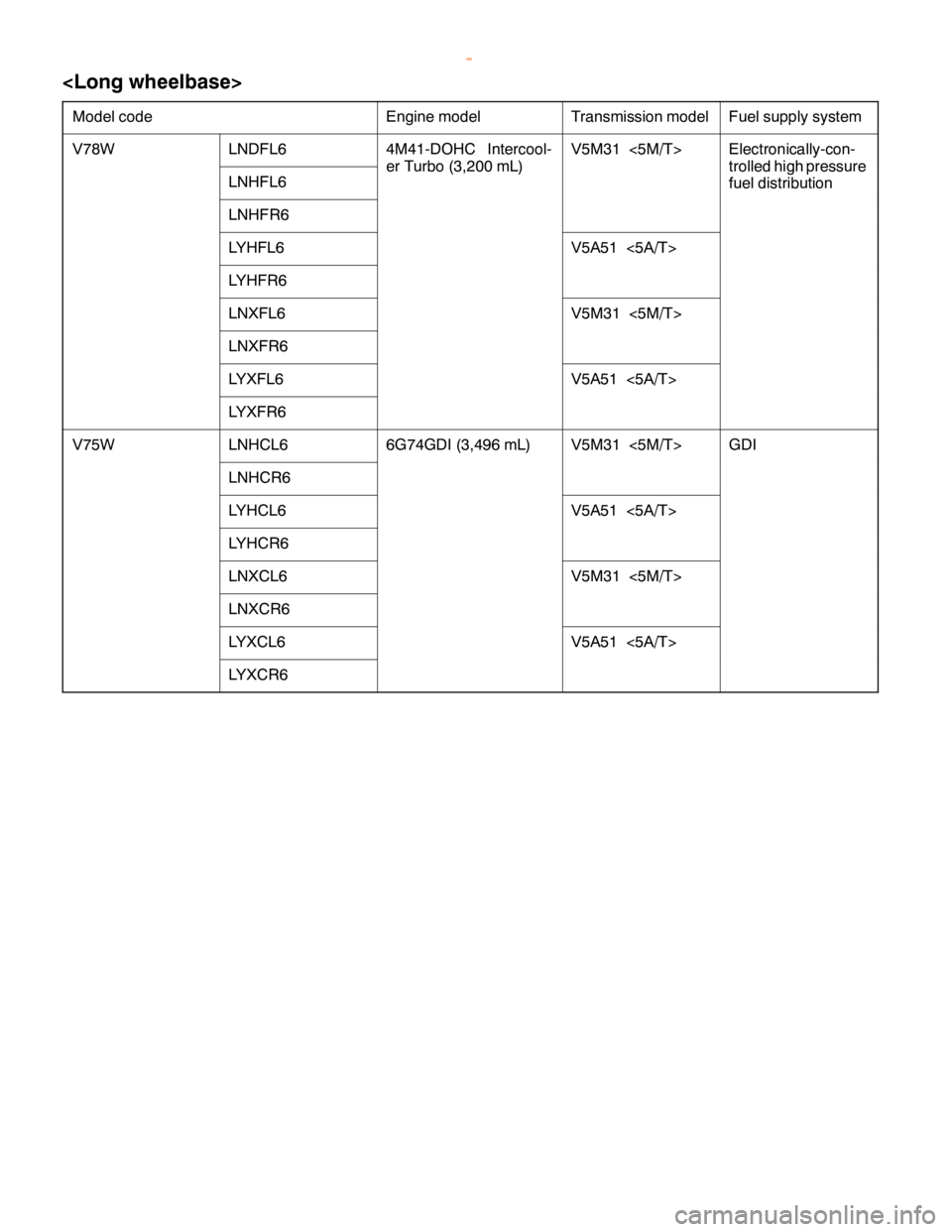

GENERAL -Vehicle Identification00-2

Model codeEngine modelTransmission modelFuel supply system

V78WLNDFL64M41-DOHC Intercool-V5M31 <5M/T>Electronically-con-

LNHFL6

er Turbo (3,200 mL)trolled high pressure

fuel distribution

LNHFR6

LYHFL6V5A51 <5A/T>

LYHFR6

LNXFL6V5M31 <5M/T>

LNXFR6

LYXFL6V5A51 <5A/T>

LYXFR6

V75WLNHCL66G74GDI (3,496 mL)V5M31 <5M/T>GDI

LNHCR6

LYHCL6V5A51 <5A/T>

LYHCR6

LNXCL6V5M31 <5M/T>

LNXCR6

LYXCL6V5A51 <5A/T>

LYXCR6

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 49 of 1839

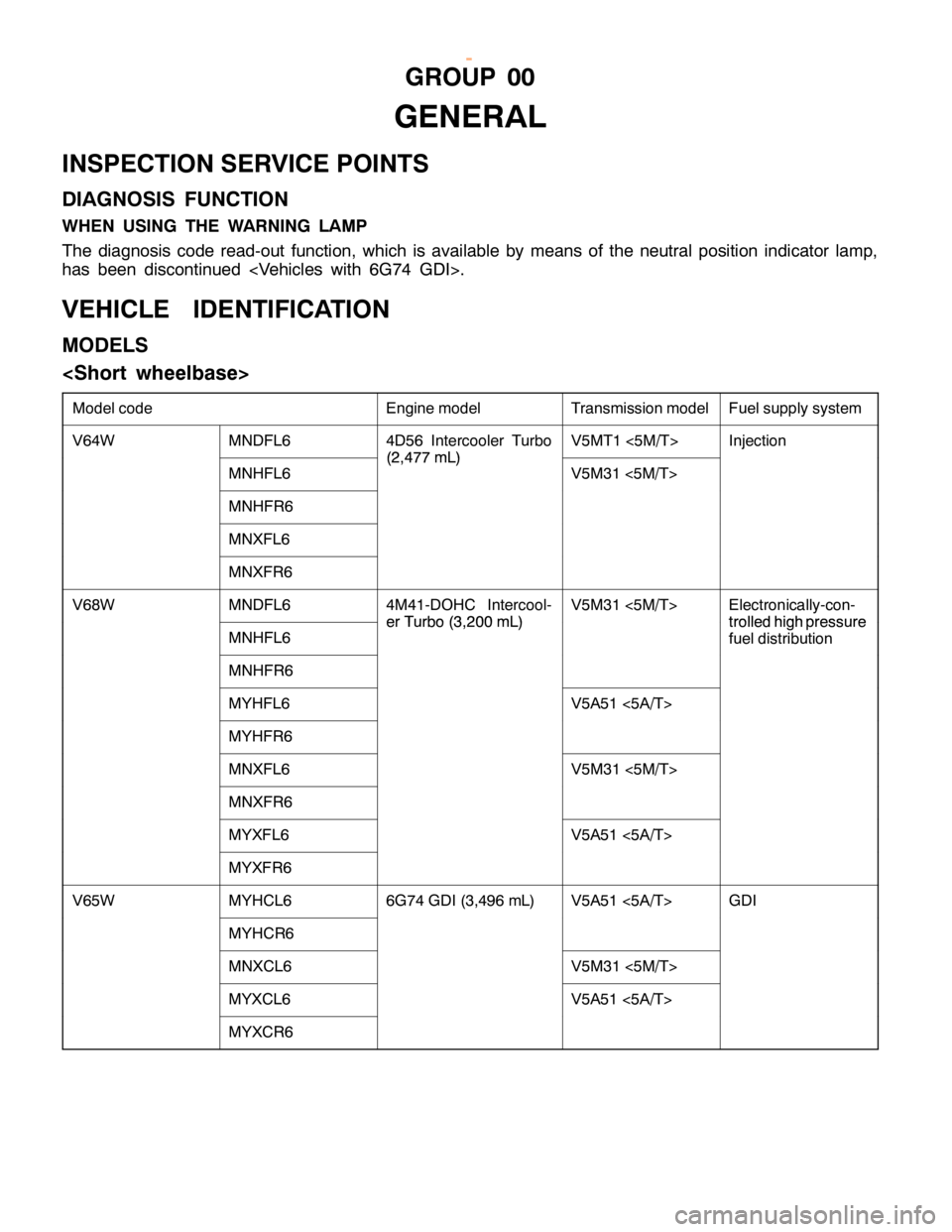

GENERAL -Vehicle Identification00-1

GROUP 00

GENERAL

INSPECTION SERVICE POINTS

DIAGNOSIS FUNCTION

WHEN USING THE WARNING LAMP

The diagnosis code read-out function, which is available by means of the neutral position indicator lamp,

has been discontinued

VEHICLE IDENTIFICATION

MODELS

Model codeEngine modelTransmission modelFuel supply system

V64WMNDFL64D56 Intercooler Turbo

(2 477mL)

V5MT1 <5M/T>Injection

MNHFL6

(2,477mL)

V5M31 <5M/T>

MNHFR6

MNXFL6

MNXFR6

V68WMNDFL64M41-DOHC Intercool-

erTurbo(3 200mL)

V5M31 <5M/T>Electronically-con-

trolledhighpressure

MNHFL6

erTurbo(3,200mL)trolledhighpressure

fuel distribution

MNHFR6

MYHFL6V5A51 <5A/T>

MYHFR6

MNXFL6V5M31 <5M/T>

MNXFR6

MYXFL6V5A51 <5A/T>

MYXFR6

V65WMYHCL66G74 GDI (3,496 mL)V5A51 <5A/T>GDI

MYHCR6

MNXCL6V5M31 <5M/T>

MYXCL6V5A51 <5A/T>

MYXCR6

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 50 of 1839

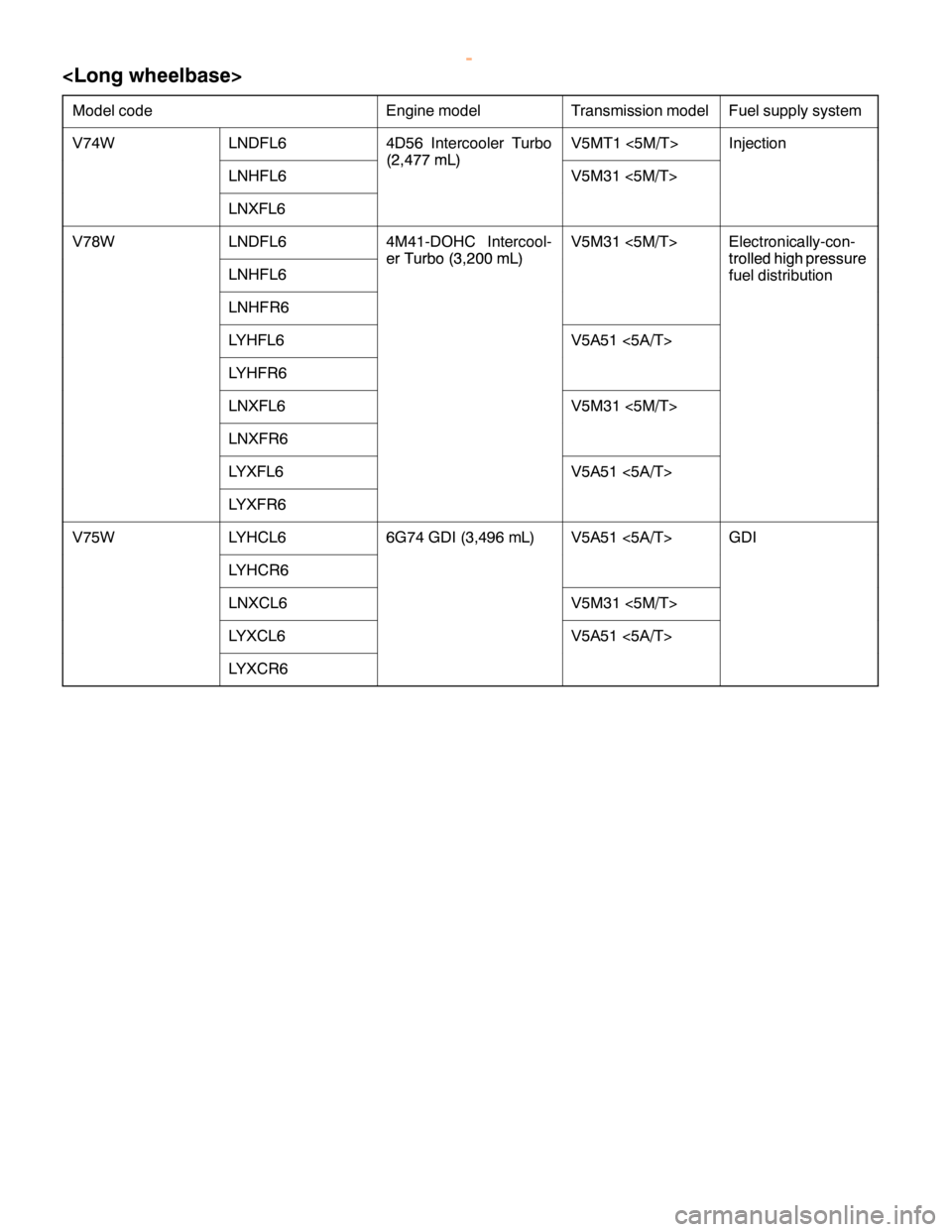

GENERAL -Vehicle Identification00-2

Model codeEngine modelTransmission modelFuel supply system

V74WLNDFL64D56 Intercooler Turbo

(2 477mL)

V5MT1 <5M/T>Injection

LNHFL6

(2,477mL)

V5M31 <5M/T>

LNXFL6

V78WLNDFL64M41-DOHC Intercool-

erTurbo(3 200mL)

V5M31 <5M/T>Electronically-con-

trolledhighpressure

LNHFL6

erTurbo(3,200mL)trolledhighpressure

fuel distribution

LNHFR6

LYHFL6V5A51 <5A/T>

LYHFR6

LNXFL6V5M31 <5M/T>

LNXFR6

LYXFL6V5A51 <5A/T>

LYXFR6

V75WLYHCL66G74 GDI (3,496 mL)V5A51 <5A/T>GDI

LYHCR6

LNXCL6V5M31 <5M/T>

LYXCL6V5A51 <5A/T>

LYXCR6

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 51 of 1839

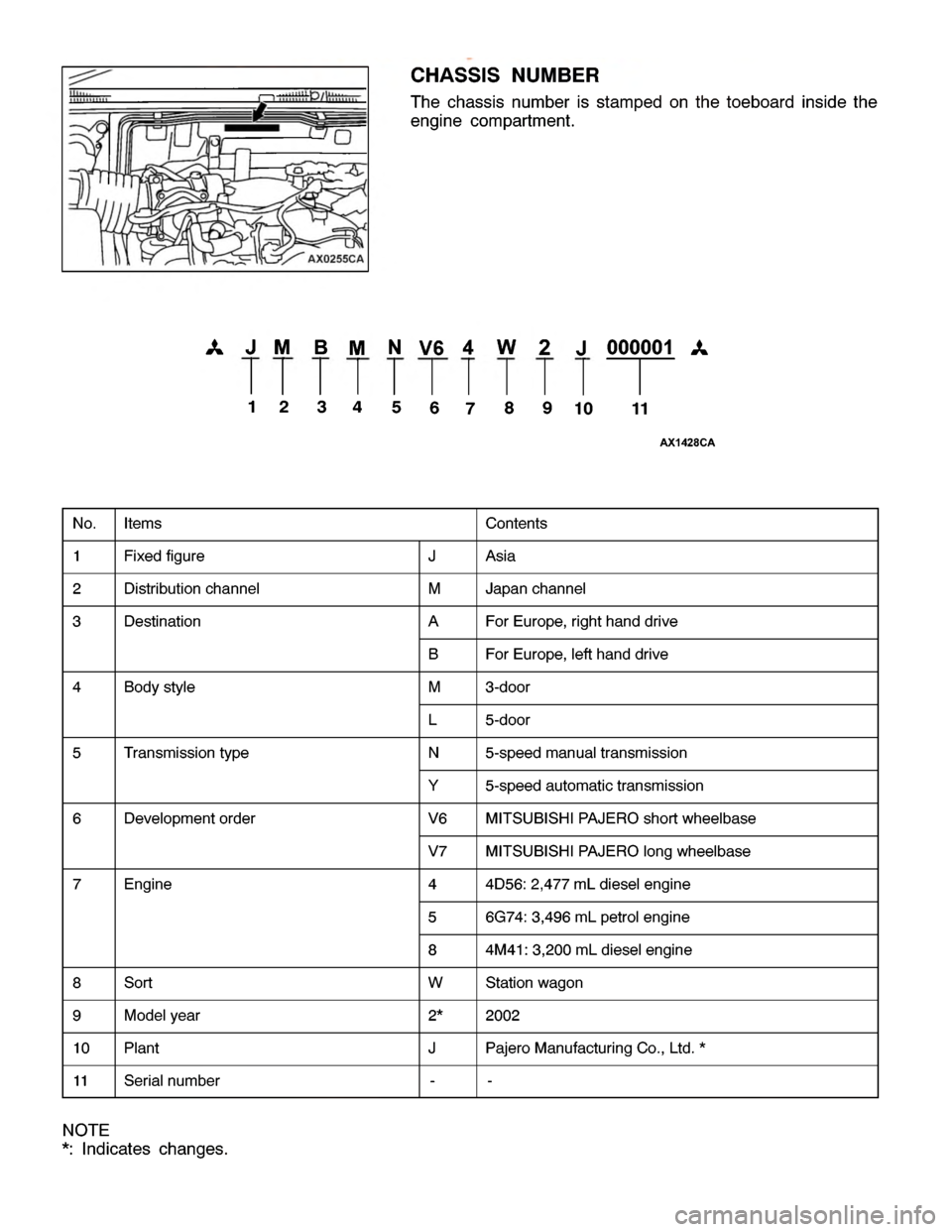

I

te m s C

onte nts 1 F

ix e d fig ure J A

sia 2 D

is tr ib utio n ch annel M J

a pan ch annel 3 D

estin atio n A F

or E uro pe,rig hth and driv e B F

or E uro pe,le ft h and driv e 4 B

ody sty le M 3

-d oor L 5

-d oor 5 T

ra nsm is sio n ty p e N 5

-s p eed manualtr a nsm is sio n Y 5

-s p eed auto m atic tr a nsm is sio n 6 D

eve lo pm ento rd er V

6 M

IT S U BIS H IP A JE R O sh ort w heelb ase V

7 M

IT S U BIS H IP A JE R O lo ng wheelb ase 7 E

ngin e 4 4

D 56:2 ,4 77 m Ldie se le ngin e 5 6

G 74:3 ,4 96 m Lpetr o le ngin e 8 4

M 41:3 ,2 00 m Ldie se le ngin e 8 S

ort W S

ta tio n wagon 9 M

odely e ar 2

* 2

002 1

0 P

la nt J P

aje ro M anufa ctu rin g Co., L td .* 1

1 S

eria ln um ber - -

Page 52 of 1839

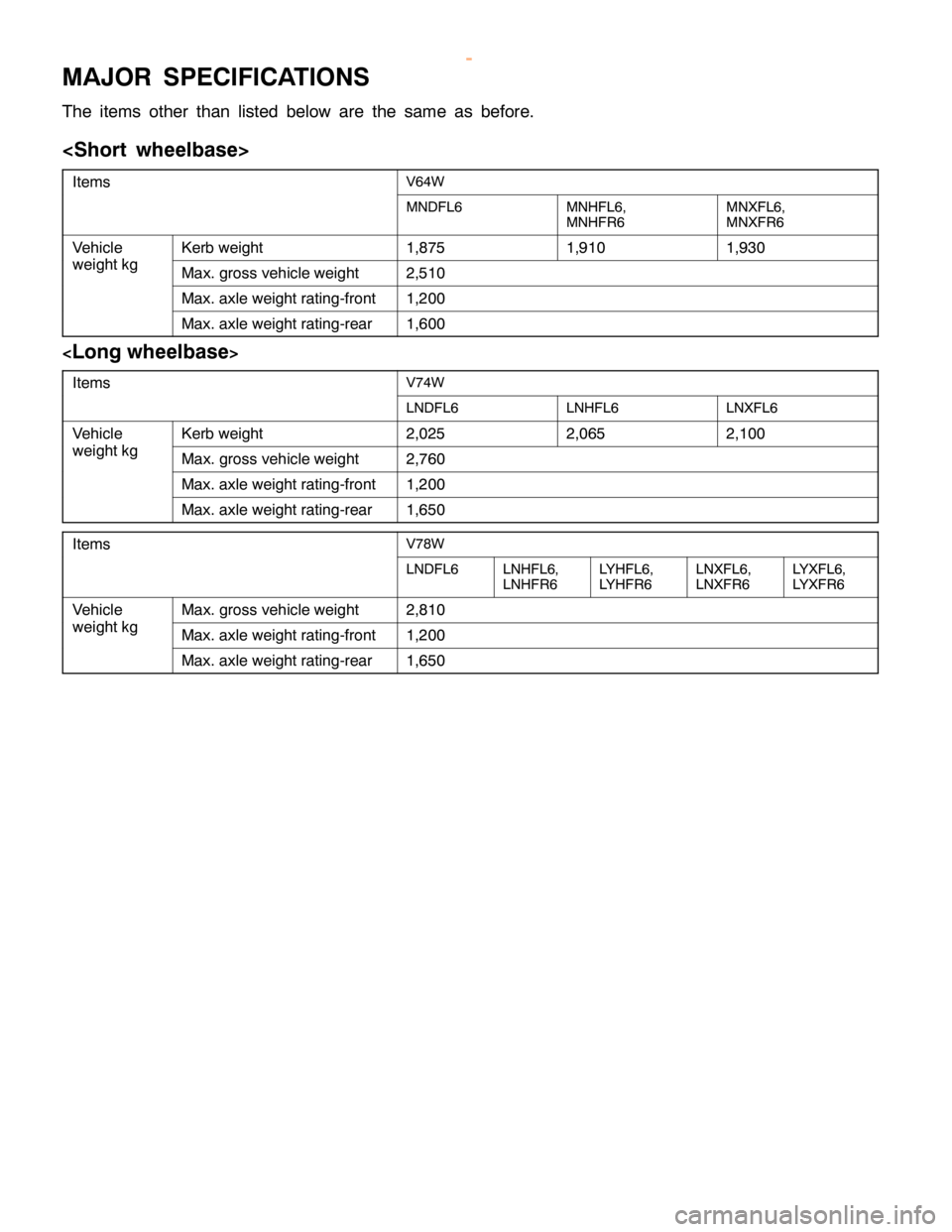

GENERAL -Major Specifications00-4

MAJOR SPECIFICATIONS

The items other than listed below are the same as before.

ItemsV64W

MNDFL6MNHFL6,

MNHFR6MNXFL6,

MNXFR6

Vehicle

ihtk

Kerb weight1,8751,9101,930

weight kgMax. gross vehicle weight2,510

Max. axle weight rating-front1,200

Max. axle weight rating-rear1,600

ItemsV74W

LNDFL6LNHFL6LNXFL6

Vehicle

ihtk

Kerb weight2,0252,0652,100

weight kgMax. gross vehicle weight2,760

Max. axle weight rating-front1,200

Max. axle weight rating-rear1,650

ItemsV78W

LNDFL6LNHFL6,

LNHFR6LYHFL6,

LYHFR6LNXFL6,

LNXFR6LYXFL6,

LYXFR6

Vehicle

ihtk

Max. gross vehicle weight2,810

weight kgMax. axle weight rating-front1,200

Max. axle weight rating-rear1,650

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 53 of 1839

GENERAL -Precautions Before Service00-5

PRECAUTIONS BEFORE SERVICE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS), SEAT BELT WITH PRE-TENSIONER

1. Items to follow when servicing SRS

(1) Be sure to read GROUP 52B - Supplemental Restraint System (SRS).

For safe operations, please follow the directions and heed all warnings.

(2) Wait at least 60 seconds after disconnecting the battery cable before doing any further work.

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the battery cable is disconnected.

(3) Warning labels must be heeded when servicing or handling SRS components and seat belt with

pre-tensioner. Warning labels are located in the following locations.

DHood

DSun visor

DGlove box

DSRS-ECU

DSteering wheel

DSteering gearbox

DAir bag module (driver’s side and front passenger’s side)

DFront impact sensor

DClock spring

DSeat belt with pre-tensioner

DSide air bag module

DSide impact sensor

(4) Always use the designated special tools and test equipment.

(5) Store components removed from the SRS and seat belt with pre-tensioner in a clean and dry

place.

The air bag module and seat belt with pre-tensioner should be stored on a flat surface and

placed so that the pad surface is facing upward.

Do not place anything on top of it.

(6) Never attempt to disassemble or repair the SRS components (SRS-ECU, air bag module, clock

spring and side impact sensor) and seat belt with pre-tensioner.

(7) Whenever you finish servicing the SRS and seat belt with pre-tensioner, check the SRS warning

lamp operation to make sure that the system functions properly.

(8) Be sure to deploy the air bag and seat belt with pre-tensioner before disposing of the air bag

module and seat belt with pre-tensioner or disposing of a vehicle equipped with an air bag and

seat belt with pre-tensioner. (Refer to GROUP 52B - Air Bag Module and Seat Belt with Pre-tensioner

Disposal Procedures.)

2. Observe the following when carrying out operations on places where SRS components and seat

belt with pre-tensioner are installed, including operations not directly related to the SRS air bag and

seat belt with pre-tensioner.

(1) When removing or installing parts do not allow any impact or shock to the SRS components

and seat belt with pre-tensioner.

(2) SRS components and seat belt with pre-tensioner should not be subjected to heat, so remove

the SRS components and seat belt with pre-tensioner before drying or baking the vehicle after

painting.

DSRS-ECU, air bag module, clock spring, front and side impact sensors: 93_C or more

DSeat belt with pre-tensioner: 90_C or more

After re-installing them, check the SRS warning lamp operation to make sure that the system

functions properly.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 287 of 1839

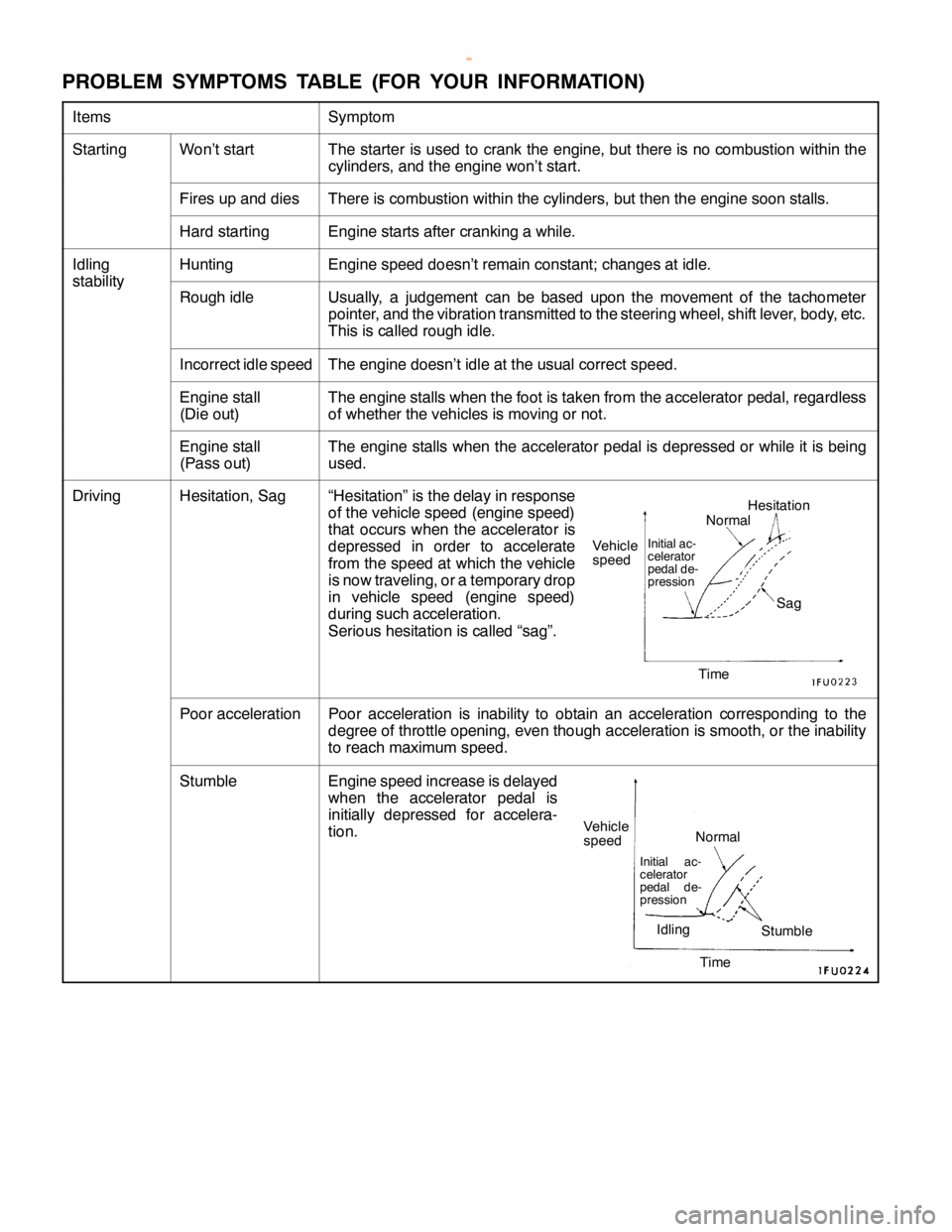

S

ym pto m S

ta rtin g W

on’t sta rt T

he sta rte r is use d to cra nk th e engin e, but th ere is no co m bustio n wit h in th e

c ylin ders , and th e engin e won’t sta rt. F

ir e s up and die s T

here is co m bustio n wit h in th e cylin ders , but th en th e engin e so on sta lls . H

ard sta rtin g E

ngin e sta rts afte r cra nkin g awhile . I

d lin g H

untin g E

ngin e sp eed doesn ’t re m ain co nsta nt; ch anges at id le . s

ta bilit y R

ough id le U

su ally , a ju dgem ent ca n be base d upon th e move m ent of th e ta ch om ete r

p oin te r, a nd th e vib ra tio n tr a nsm it te d to th e ste erin g wheel, s h if t le ve r, b ody, e tc .

T his is ca lle d ro ugh id le . I

n co rre ctid le sp eed T

he engin e doesn ’t id le at th e usu alco rre ct sp eed. E

ngin e sta ll

( D ie out) T

he engin e sta lls when th e fo otis ta ke n fr o m th e acce le ra to r pedal, re gard le ss

o f w heth er th e ve hic le s is m ovin g or not. E

ngin e sta ll

( P ass out) T

he engin e sta lls when th e acce le ra to r pedalis depre sse d or w hile it is bein g

u se d. D

riv in g H

esit a tio n, S ag “

H esit a tio n” is th e dela y in re sp onse

o f th e ve hic le sp eed (e ngin e sp eed)

t h at occu rs when th e acce le ra to r is

d epre sse d in ord er to acce le ra te

f r o m th e sp eed at w hic h th e ve hic le

i s now tr a ve lin g,o ra te m pora ry dro p

i n ve hic le sp eed (e ngin e sp eed)

d urin g su ch acce le ra tio n.

S erio us hesit a tio n is ca lle d “s a g”. V

ehic le

s p eed I

n it ia la c-

c e le ra to r

p edald e-

p re ssio n N

orm alH

esit a tio n

S ag

T im e P

oor acce le ra tio n is in abilit y to obta in an acce le ra tio n co rre sp ondin g to th e

d egre e of th ro ttle openin g, eve n th ough acce le ra tio n is sm ooth , or th e in abilit y

t o re ach maxim um sp eed. S

tu m ble E

ngin e sp eed in cre ase is dela ye d

w hen th e acce le ra to r pedal is

i n it ia lly depre sse d fo r acce le ra -

t io n.

Norm al

I n it ia l ac-

c e le ra to r

p edal de-

p re ssio n

I d lin g

Stu m ble

T im e

V

ehic le

s p eed

Page 321 of 1839

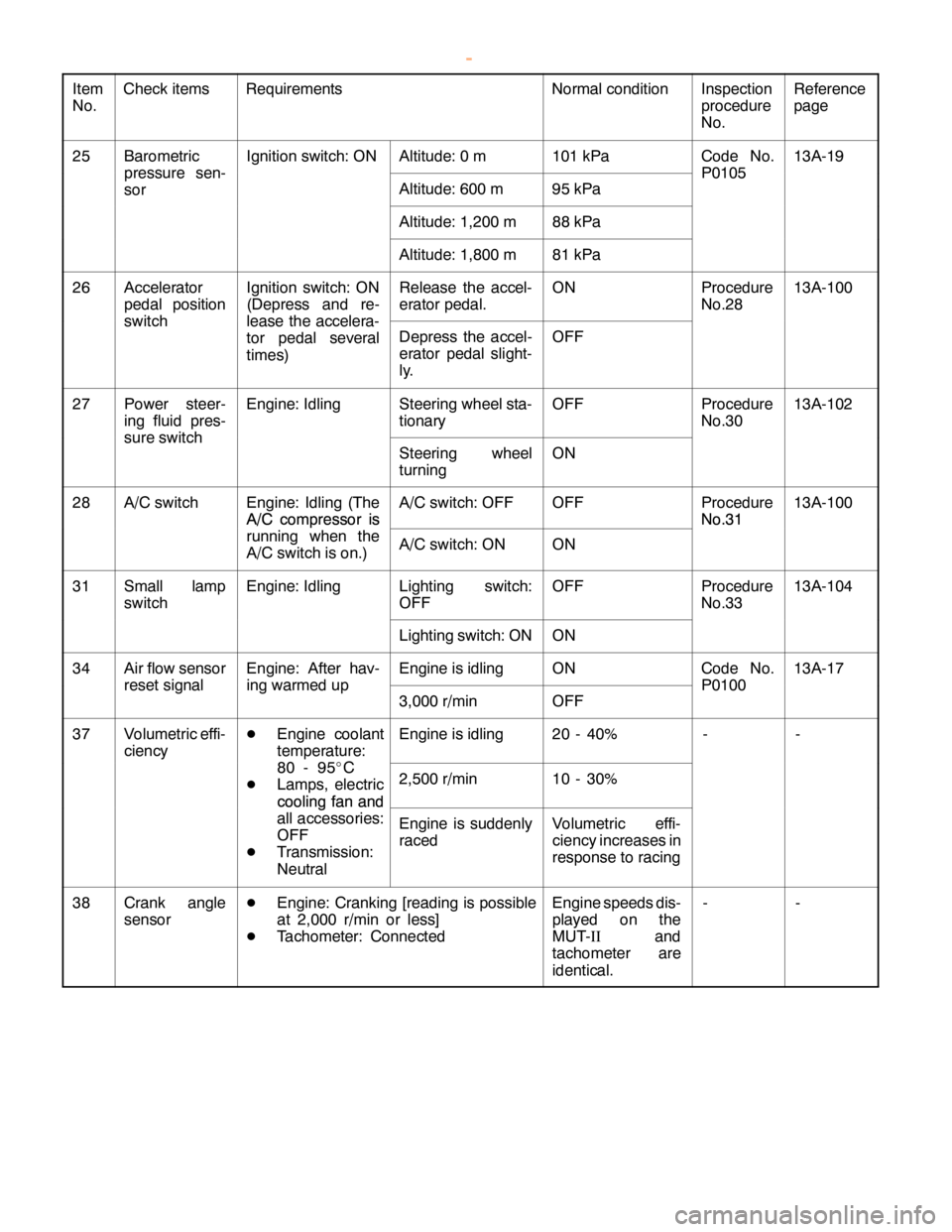

GDI -Troubleshooting

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

25BarometricIgnition switch: ONAltitude: 0 m101 kPaCode No.13A-19

pressure sen-

sor

Altitude: 600 m95 kPa

P0105

Altitude: 1,200 m88 kPa

Altitude: 1,800 m81 kPa

26Accelerator

pedal positionIgnition switch: ON

(Depress and re-Release the accel-

erator pedal.ONProcedure

No.2813A-100

switchlease the accelera-

tor pedal several

times)

Depress the accel-

erator pedal slight-

ly.OFF

27Power steer-

ing fluid pres-Engine: IdlingSteering wheel sta-

tionaryOFFProcedure

No.3013A-102

sure switch

Steering wheel

turningON

28A/C switchEngine: Idling (The

A/C compressor isA/C switch: OFFOFFProcedure

No.3113A-100

A/C compressor is

running when the

A/C switch is on.)

A/C switch: ONON

No.31

31Small lamp

switchEngine: IdlingLighting switch:

OFFOFFProcedure

No.3313A-104

Lighting switch: ONON

34Air flow sensorEngine: After hav-Engine is idlingONCode No.13A-17

reset signaling warmed up

3,000 r/minOFF

P0100

37Volumetric effi-

ciencyDEngine coolant

temperature:Engine is idling20 - 40%--

80 - 95_C

DLamps, electric

cooling fan and2,500 r/min10 - 30%

cooling fan and

all accessories:

OFF

DTransmission:

Neutral

Engine is suddenly

racedVolumetric effi-

ciency increases in

response to racing

38Crank angle

sensorDEngine: Cranking [reading is possible

at 2,000 r/min or less]

DTachometer: ConnectedEngine speeds dis-

played on the

MUT-IIand

tachometer are

identical.--

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk