wheel MITSUBISHI MONTERO 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 1053 of 1839

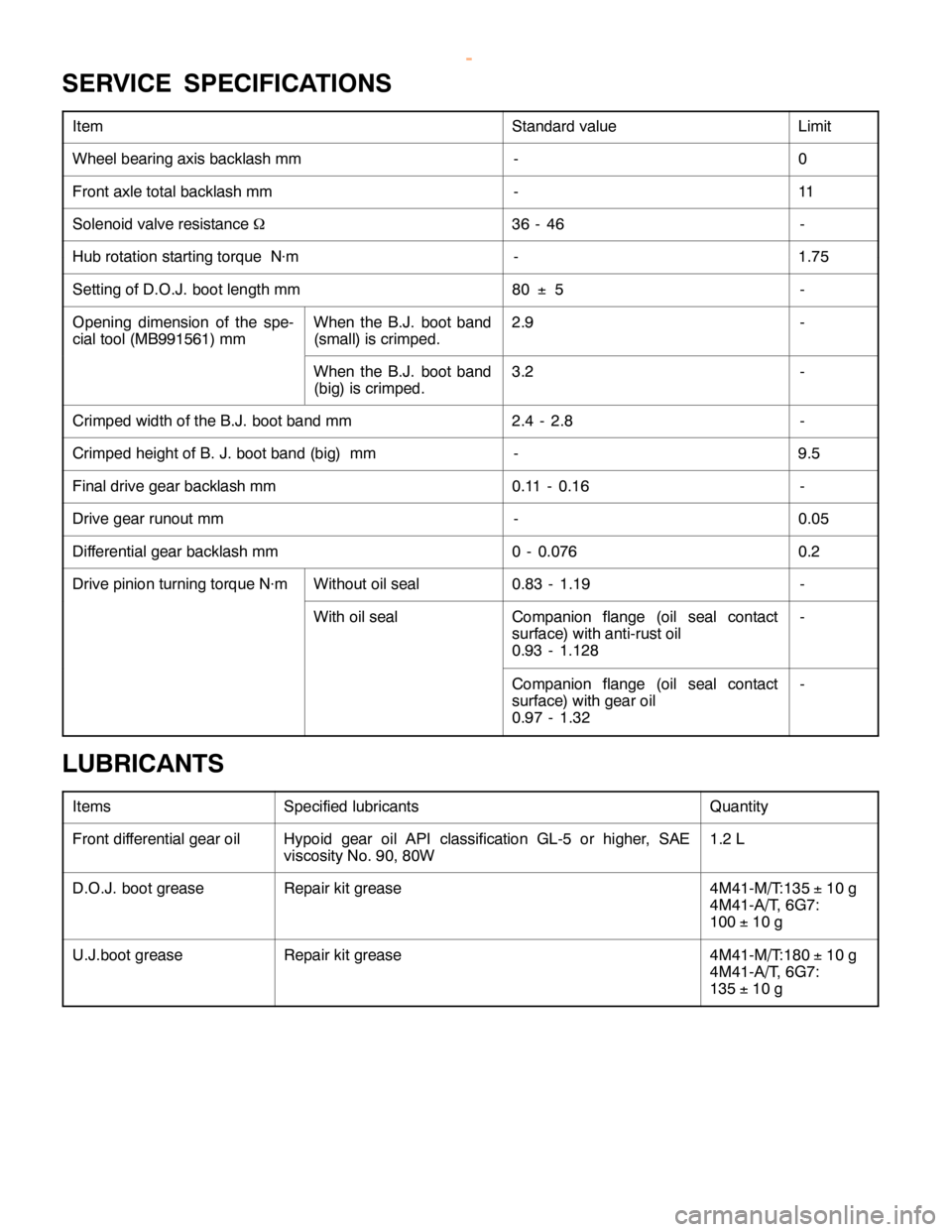

FRONT AXLE -Service Specifications/Lubricants26-4

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Wheel bearing axis backlash mm-0

Front axle total backlash mm-11

Solenoid valve resistanceW36 - 46-

Hub rotation starting torque N×m-1.75

Setting of D.O.J. boot length mm80±5-

Opening dimension of the spe-

cial tool (MB991561) mmWhen the B.J. boot band

(small) is crimped.2.9-

When the B.J. boot band

(big) is crimped.3.2-

Crimped width of the B.J. boot band mm2.4 - 2.8-

Crimped height of B. J. boot band (big) mm-9.5

Final drive gear backlash mm0.11 - 0.16-

Drive gear runout mm-0.05

Differential gear backlash mm0 - 0.0760.2

Drive pinion turning torque N×mWithout oil seal0.83 - 1.19-

With oil sealCompanion flange (oil seal contact

surface) with anti-rust oil

0.93 - 1.128-

Companion flange (oil seal contact

surface) with gear oil

0.97 - 1.32-

LUBRICANTS

ItemsSpecified lubricantsQuantity

Front differential gear oilHypoid gear oil API classification GL-5 or higher, SAE

viscosity No. 90, 80W1.2 L

D.O.J. boot greaseRepair kit grease4M41-M/T:135±10 g

4M41-A/T, 6G7:

100±10 g

U.J.boot greaseRepair kit grease4M41-M/T:180±10 g

4M41-A/T, 6G7:

135±10 g

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1103 of 1839

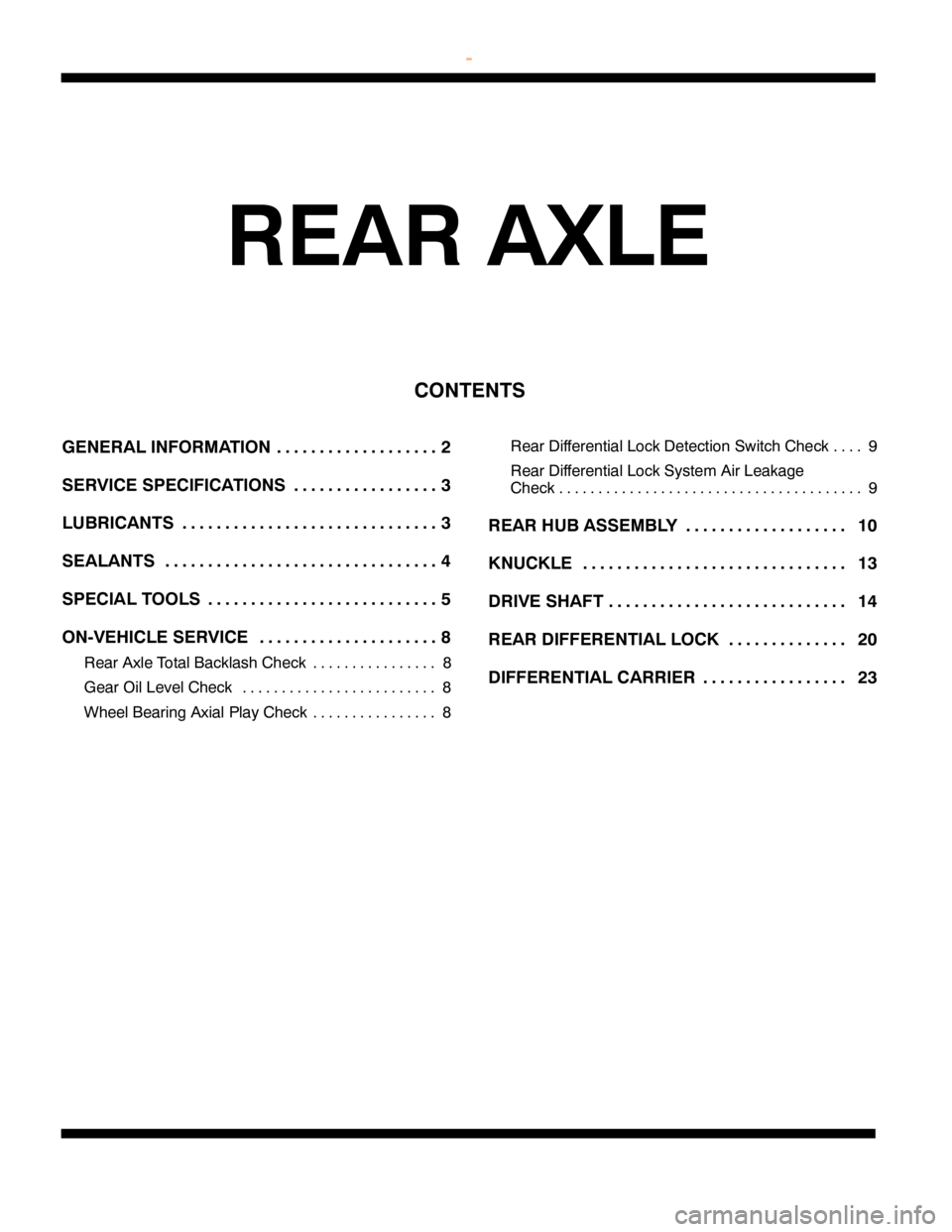

27-1

REAR AXLE

CONTENTS

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 3.................

LUBRICANTS 3..............................

SEALANTS 4................................

SPECIAL TOOLS 5...........................

ON-VEHICLE SERVICE 8.....................

Rear Axle Total Backlash Check 8................

Gear Oil Level Check 8.........................

Wheel Bearing Axial Play Check 8................Rear Differential Lock Detection Switch Check 9....

Rear Differential Lock System Air Leakage

Check 9.......................................

REAR HUB ASSEMBLY 10...................

KNUCKLE 13...............................

DRIVE SHAFT 14............................

REAR DIFFERENTIAL LOCK 20..............

DIFFERENTIAL CARRIER 23.................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1104 of 1839

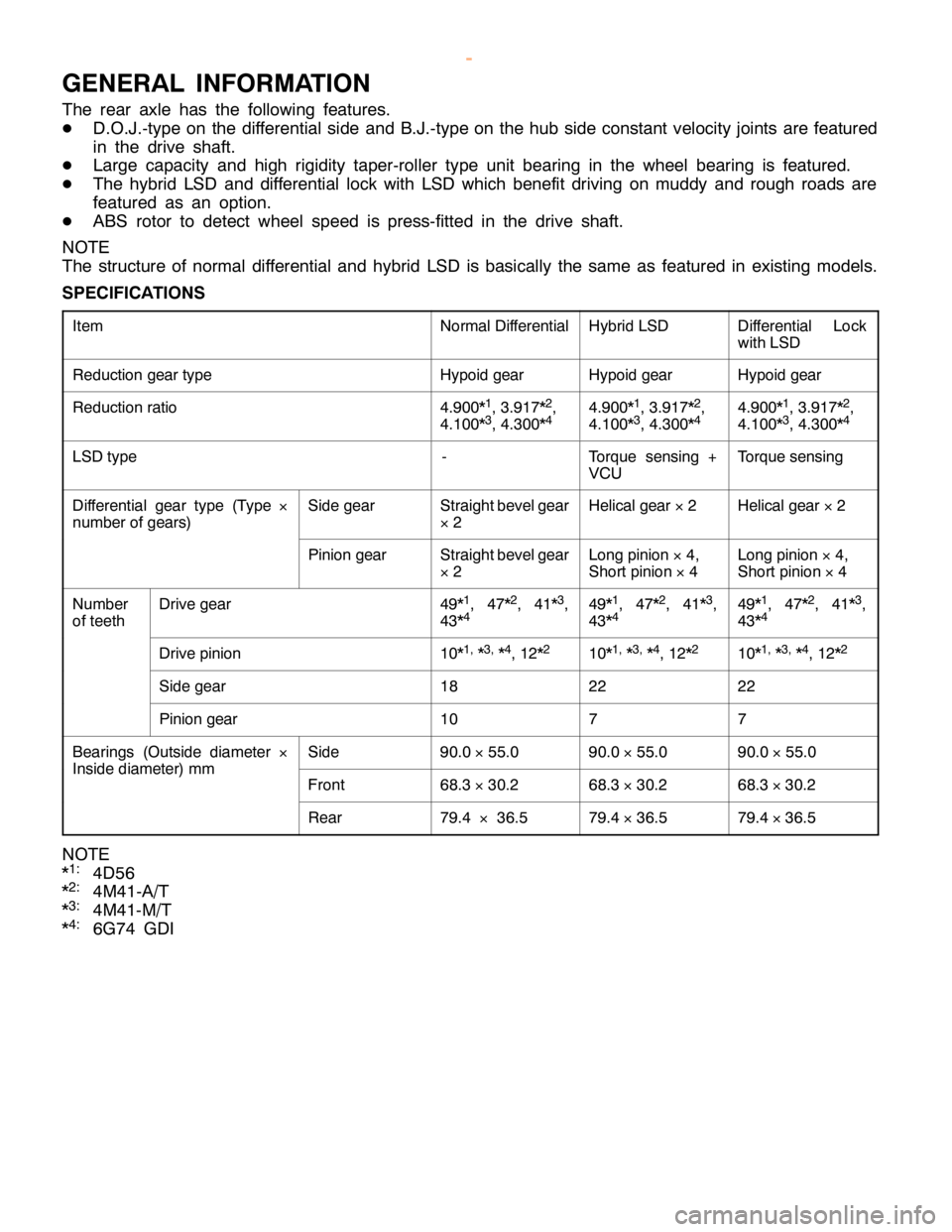

REAR AXLE -General Information27-2

GENERAL INFORMATION

The rear axle has the following features.

DD.O.J.-type on the differential side and B.J.-type on the hub side constant velocity joints are featured

in the drive shaft.

DLarge capacity and high rigidity taper-roller type unit bearing in the wheel bearing is featured.

DThe hybrid LSD and differential lock with LSD which benefit driving on muddy and rough roads are

featured as an option.

DABS rotor to detect wheel speed is press-fitted in the drive shaft.

NOTE

The structure of normal differential and hybrid LSD is basically the same as featured in existing models.

SPECIFICATIONS

ItemNormal DifferentialHybrid LSDDifferential Lock

with LSD

Reduction gear typeHypoid gearHypoid gearHypoid gear

Reduction ratio4.900*1, 3.917*2,

4.100*3, 4.300*44.900*1, 3.917*2,

4.100*3, 4.300*44.900*1, 3.917*2,

4.100*3, 4.300*4

LSD type-Torque sensing +

VCUTorque sensing

Differential gear type (Type´

number of gears)Side gearStraight bevel gear

´2Helical gear´2Helical gear´2

Pinion gearStraight bevel gear

´2Long pinion´4,

Short pinion´4Long pinion´4,

Short pinion´4

Number

of teethDrive gear49*1, 47*2, 41*3,

43*449*1, 47*2, 41*3,

43*449*1, 47*2, 41*3,

43*4

Drive pinion10*1,*3,*4, 12*210*1,*3,*4, 12*210*1,*3,*4, 12*2

Side gear182222

Pinion gear1077

Bearings (Outside diameter´Side90.0´55.090.0´55.090.0´55.0

Inside diameter) mm

Front68.3´30.268.3´30.268.3´30.2

Rear79.4´36.579.4´36.579.4´36.5

NOTE

*1:4D56

*2:4M41-A/T

*3:4M41-M/T

*4:6G74 GDI

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1112 of 1839

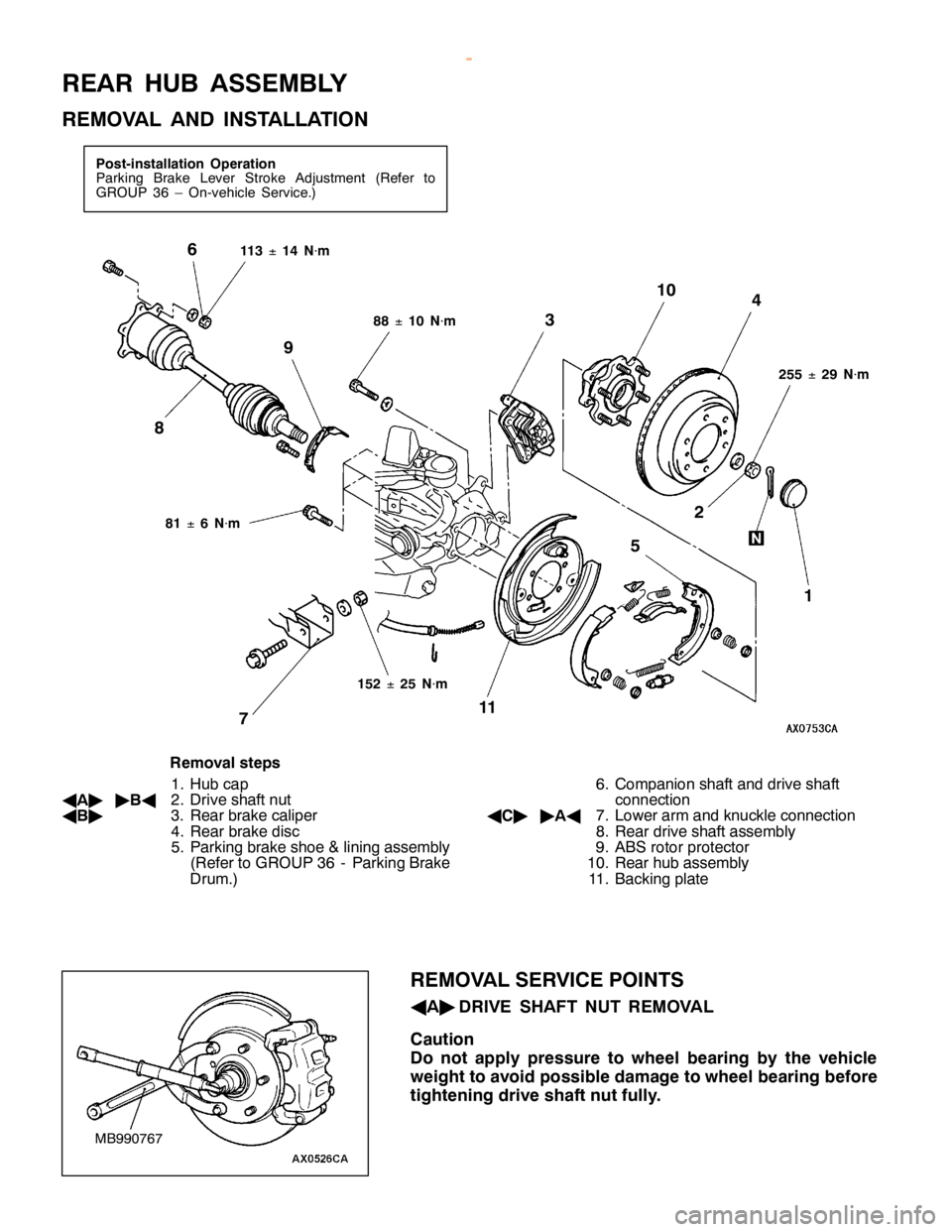

R

EA R HUB ASSEM BLY

R EM OVA L AND IN STA LLA TIO N 13

76

5

1

1 1

0 9 8

8 ±

10 N×

m 8

1 ±

6 N×

m

R em oval ste p s

1 . H ub ca p

A A"

"

BA

2. D riv e sh aft nut

A B"

3. R ear bra ke ca lip er

4 . R ear bra ke dis c

5 . P ark in g bra ke sh oe & lin in g asse m bly

( R efe r to GRO UP 36 -Park in g Bra ke

D ru m .) 6

. C om panio n sh aft and driv e sh aft

c o nnectio n

A C"

"

AA

7. Low er arm and kn uckle co nnectio n

8 . R ear driv e sh aft asse m bly

9 . A BS ro to r pro te cto r

1 0. R ear hub asse m bly

1 1 . B ackin g pla te

R EM OVA L SER VIC E PO IN TS

A A"

DRIV E SH AFT NUT REM OVA L

C au tio n

D o not ap ply pre ssu re to wheel bearin g by th e veh ic le

w eig htto avo id possib le dam ag e to wheel b earin g befo re

t ig hte n in g driv e sh aft nutfu lly .

Page 1116 of 1839

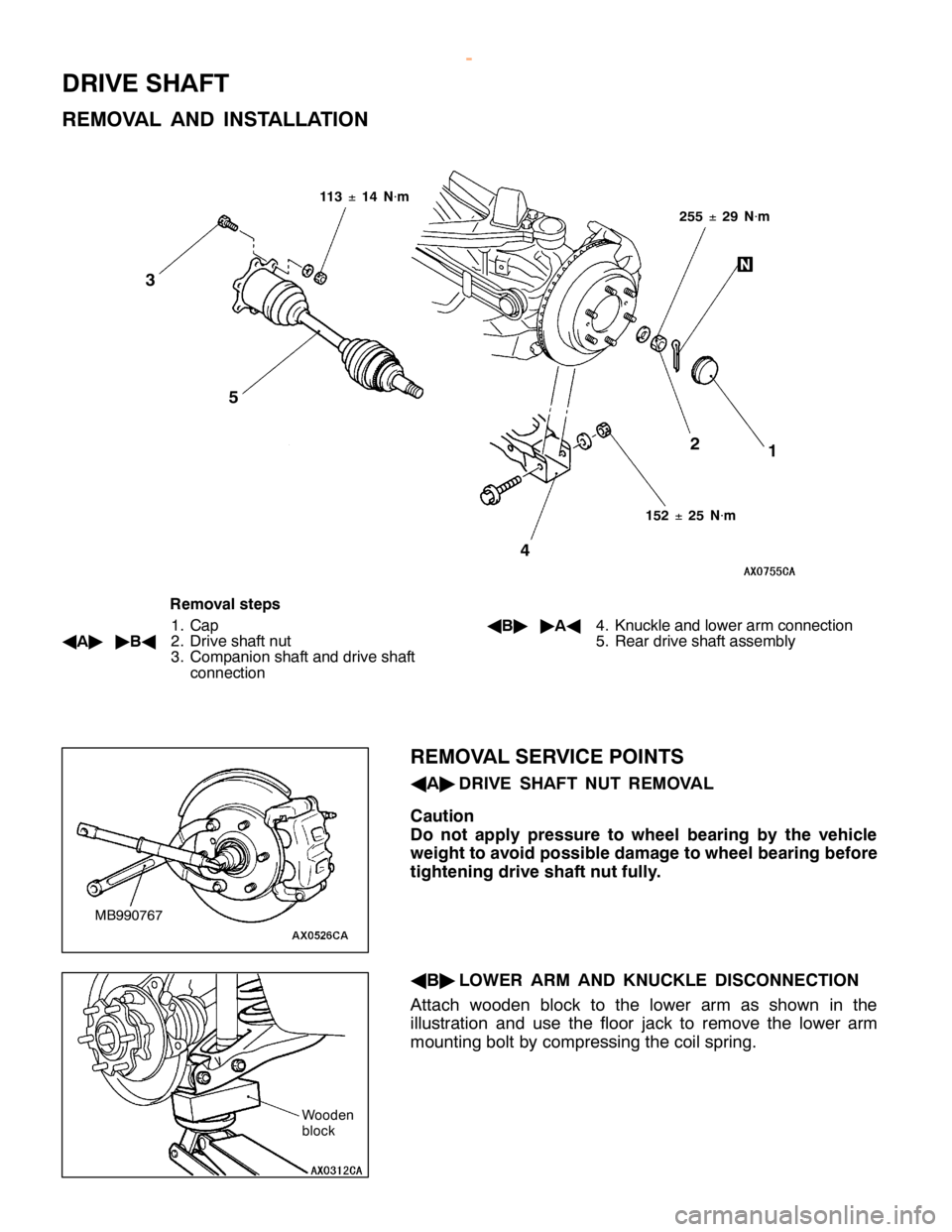

D

RIV E SH AFT

R EM OVA L AND IN STA LLA TIO N 13

45 1

1 3 ±

14 N×

m

R em oval ste p s

1 . C ap

A A"

"

BA

2. D riv e sh aft nut

3 . C om panio n sh aft and driv e sh aft

c o nnectio n A

B"

"

AA

4. K nuckle and lo w er arm co nnectio n

5 . R ear driv e sh aft asse m bly

R EM OVA L SER VIC E PO IN TS

A A"

DRIV E SH AFT NUT REM OVA L

C au tio n

D o not ap ply pre ssu re to wheel bearin g by th e veh ic le

w eig htto avo id possib le dam ag e to wheel b earin g befo re

t ig hte n in g driv e sh aft nutfu lly .

A B"

LO W ER ARM AND KNUCKLE DIS C O NNEC TIO N

A tta ch wooden blo ck to th e lo w er arm as sh ow n in th e

i llu str a tio n and use th e flo or ja ck to re m ove th e lo w er arm

m ountin g bolt by co m pre ssin g th e co il sp rin g. W

ooden

b lo ck

w

ww.W ork sh opM an uals .c o .u k

P urc h ased f r o m w ww.W ork sh opM an uals .c o .u k

Page 1143 of 1839

WHEEL AND TYRE

Click on the applicable bookmark to selected the required model year.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1144 of 1839

31-1

WHEEL AND TYRE

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

TROUBLESHOOTING 3.......................ON-VEHICLE SERVICE 7.....................

Tyre Inflation Pressure Check 7.................

Tyre Wear Check 7............................

Wheel Runout Check 7.........................

WHEEL AND TYRE 7........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1145 of 1839

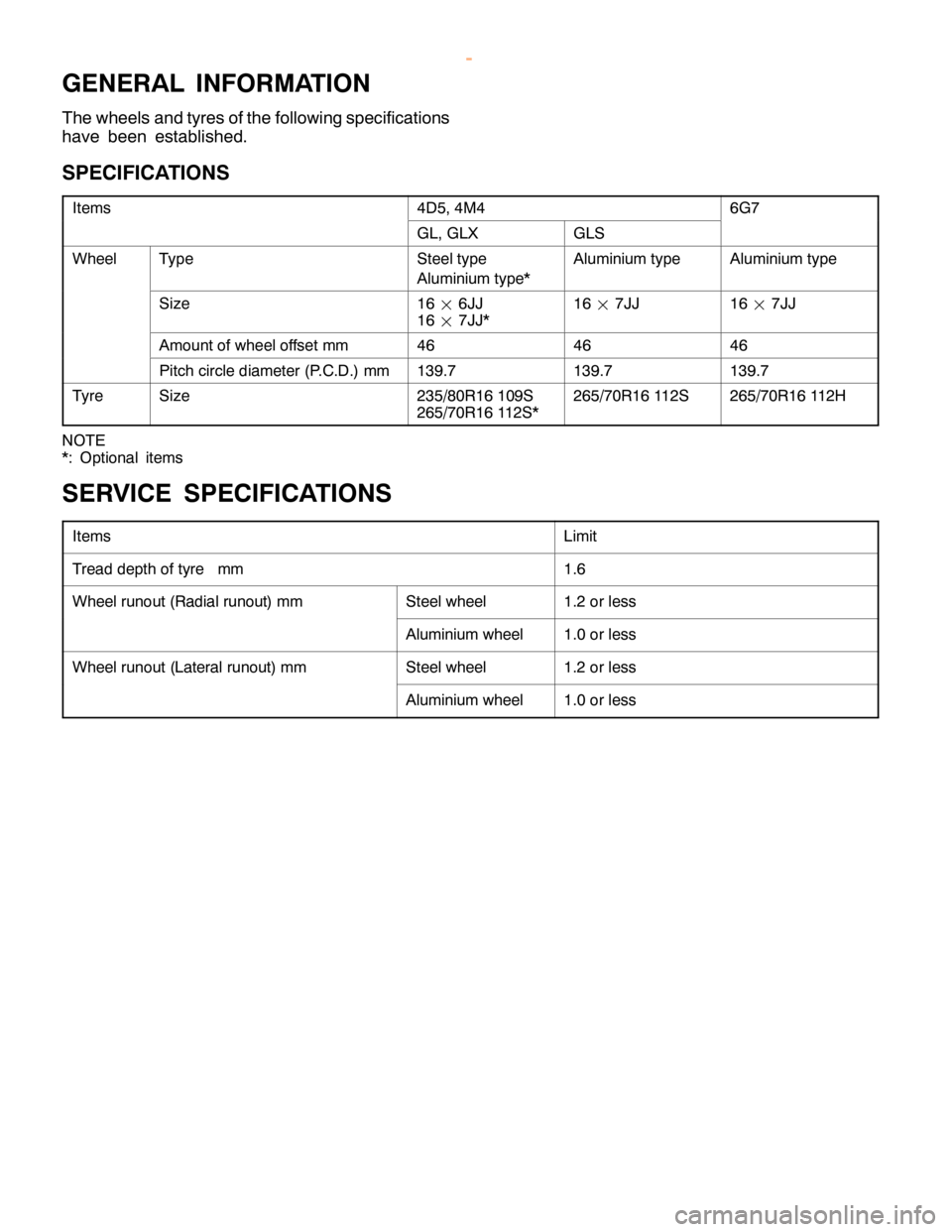

WHEEL AND TYRE -General Information/Service Specifications31-2

GENERAL INFORMATION

The wheels and tyres of the following specifications

have been established.

SPECIFICATIONS

Items4D5, 4M46G7

GL, GLXGLS

WheelTypeSteel type

Aluminium type*Aluminium typeAluminium type

Size16¢6JJ

16¢7JJ*16¢7JJ16¢7JJ

Amount of wheel offset mm464646

Pitch circle diameter (P.C.D.) mm139.7139.7139.7

TyreSize235/80R16 109S

265/70R16 112S*265/70R16 112S265/70R16 112H

NOTE

*: Optional items

SERVICE SPECIFICATIONS

ItemsLimit

Tread depth of tyre mm1.6

Wheel runout (Radial runout) mmSteel wheel1.2 or less

Aluminium wheel1.0 or less

Wheel runout (Lateral runout) mmSteel wheel1.2 or less

Aluminium wheel1.0 or less

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1146 of 1839

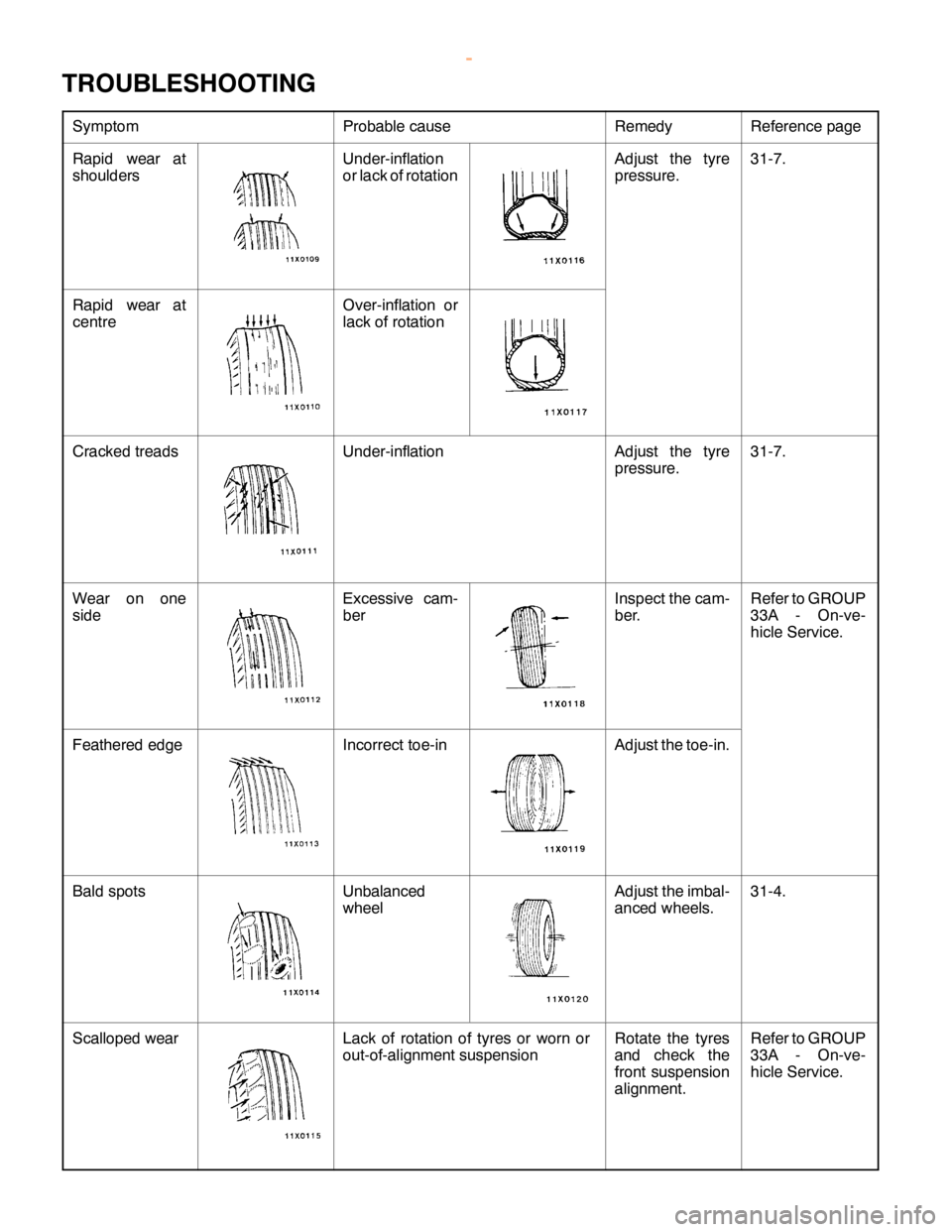

T

R O UBLE SH O OTIN G

S ym pto m P

ro bable ca use R

em edy R

efe re nce page R

apid wear at

s h ould ers U

nder-in fla tio n

o rla ck ofro ta tio n A

dju st th e ty re

p re ssu re . 3

1-7 . R

apid wear at

c e ntr e O

ve r-in fla tio n or

l a ck of ro ta tio n C

ra cke d tr e ads U

nder-in fla tio n A

dju st th e ty re

p re ssu re . 3

1-7 . W

ear on one

s id e E

xce ssiv e ca m -

b er I

n sp ect th e ca m -

b er. R

efe rto G RO UP

3 3A -On-v e -

h ic le Serv ic e . F

eath ere d edge I

n co rre ct to e-in A

dju stth e to e-in . B

ald sp ots U

nbala nce d

w heel A

dju st th e im bal-

a nce d wheels . 3

1-4 . S

ca llo ped wear L

ack of ro ta tio n of ty re s or w orn or

o ut- o f- a lig nm ent su sp ensio n R

ota te th e ty re s

a nd ch eck th e

f r o nt su sp ensio n

a lig nm ent. R

efe rto G RO UP

3 3A -On-v e -

h ic le Serv ic e .

Page 1148 of 1839

WHEEL AND TYRE -Troubleshooting31-5

DIf the imbalance is 5 g or less, the zero

calibration is OK. Rebalance the wheel, then

go to Step 4 to check static balance.

DIf the imbalance is more than 5 g, go to Step

3.

3. Loosen the balancer wing nut, rotate the wheel

1/4 turn (90

°), and retighten the nut. Recheck

the wheel balance.

DIf the imbalance is 5 g or less, the wheel may

not be centered on the balancer, or the

balancing cones, the cup, and/or wing nut are

damaged, dirty, or inappropriate for the wheel.

You may need to refer to the balancer

manufacturer’s instructions to verify the correct

attachments. after making the necessary

corrections, recheck the wheel balance. If OK,

then go to Step 4.

DIf the imbalance is more than 5 g, the balancer

requires calibration. Contact the balancer

manufacturer for calibration by their repair

representative.

4.

Attach a 5-g weight to the outer rim. Recheck

the balancer. The balancer should detect 5

±2

g of imbalance 170

°to 190

°away from both the

inner and outer 5-g weights.DIf the imbalance is within specification, the static

balance calibration is correct. Go to Step 5

to check the dynamic balance.

DIf the imbalance is out of specification, the

balancer requires calibration. Contact the

balancer manufacturer for calibration by their

repair representative.

5.

Attach a 5-g weight to the inner rim at 180

°

opposite the 5-g weight that was added in step

4. Recheck the balance. The balancer should

detect 5

±2g of imbalance 170

°to 190

°away

from both the inner and outer 5-g weights.

DIf the imbalance is within specification, the

dynamic balance calibration is correct. The

balancer calibration checks are complete.

DIf the imbalance is out of specification, the

balancer requires calibration. Contact the

balancer manufacturer for calibration by their

repair representative.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk