MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: high beam, fuel, spark plugs replace, lock, tire type, steering, drain bolt

Page 1121 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND Transaxle

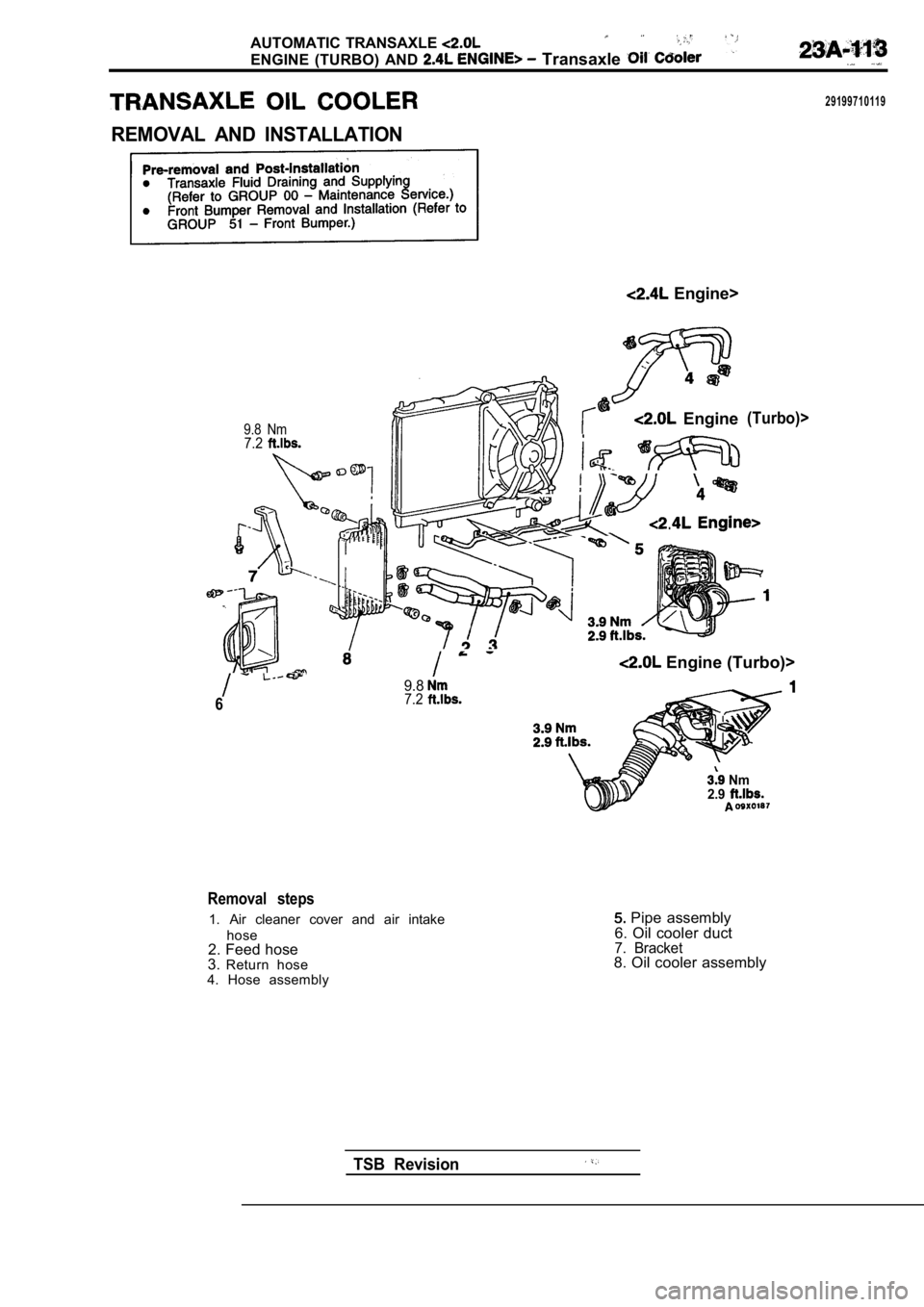

REMOVAL AND INSTALLATION

Engine>

Engine(Turbo)>9.8 Nm7.2

.

Engine (Turbo)>

6

9.87.2

Nm

2.9

29199710119

Removal steps

1. Air cleaner cover and air intake

hose

2. Feed hose

3. Return hose

4. Hose assembly Pipe assembly

6. Oil cooler duct

7. Bracket8. Oil cooler assembly

TSB Revision

Page 1122 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> -‘Transaxle Oil Cooler

INSPECTION231

l Check the hose for cracks, damage

lCheck for rusted or clogged transaxle oil cooler.

l Check oil cooler fins for

damage, and clogged

with foreign matter.

TSB Revision

Page 1123 of 2103

AUTOMATIC TRANSAXLE.

ENGINE

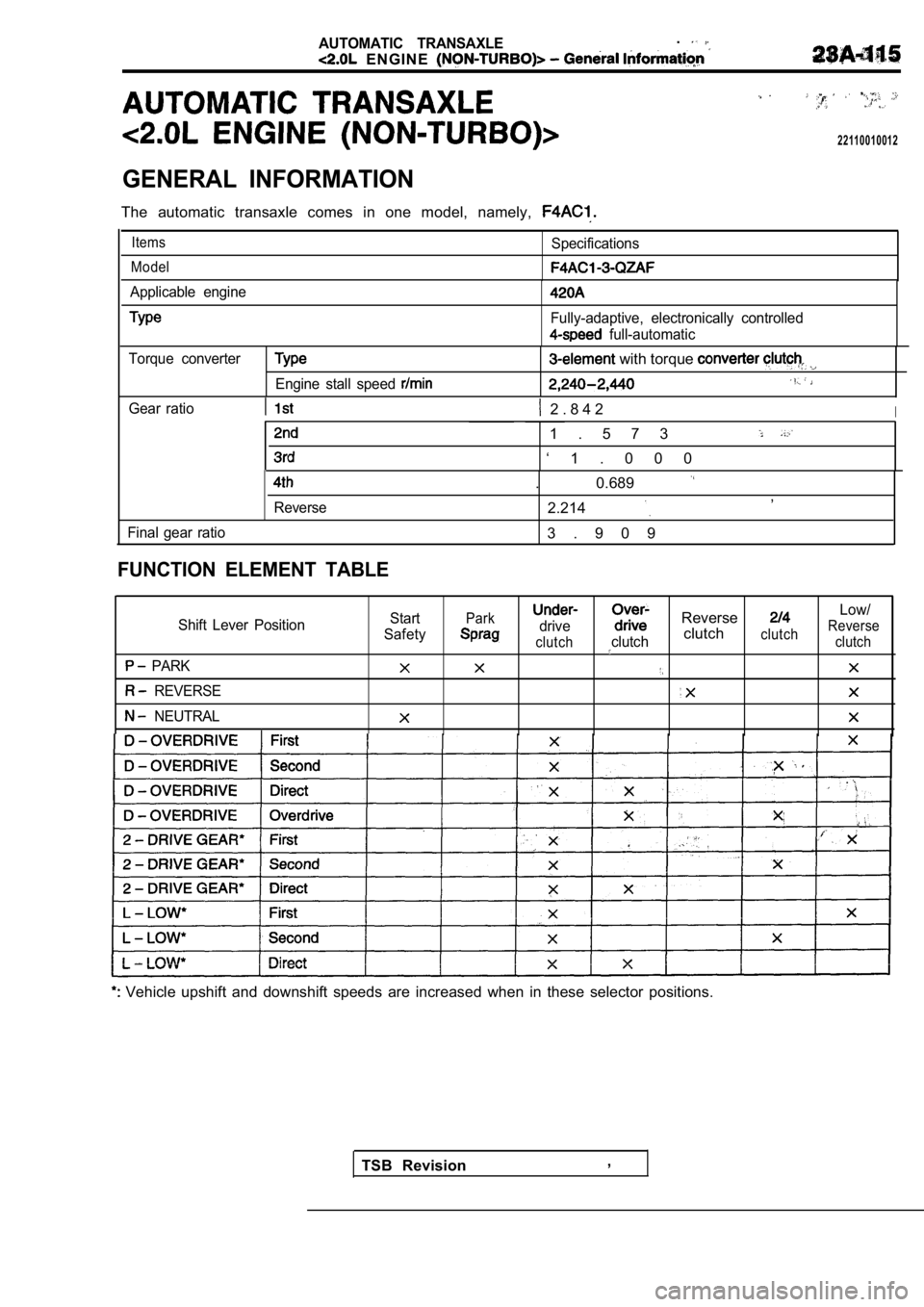

GENERAL INFORMATION

The automatic transaxle comes in one model, namely,

22110010012

Items

ModelSpecifications

Applicable engine

Fully-adaptive, electronically controlled

full-automatic

Torque converter

Engine stall speed

with torque

Gear ratio 2 . 8 4 2I

1 . 5 7 3

‘ 1 . 0 0 0

Reverse

Final gear ratio

FUNCTION ELEMENT TABLE

. 0.689 ,

2.214

3 . 9 0 9

Shift Lever Position

PARK

REVERSE

NEUTRAL

StartPark Reverse Low/

Safety

drive

clutch clutchclutchclutch Reverse

clutch

Vehicle upshift and downshift speeds are increased when in these selector positions.

TSB Revision ,

Page 1124 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)? General

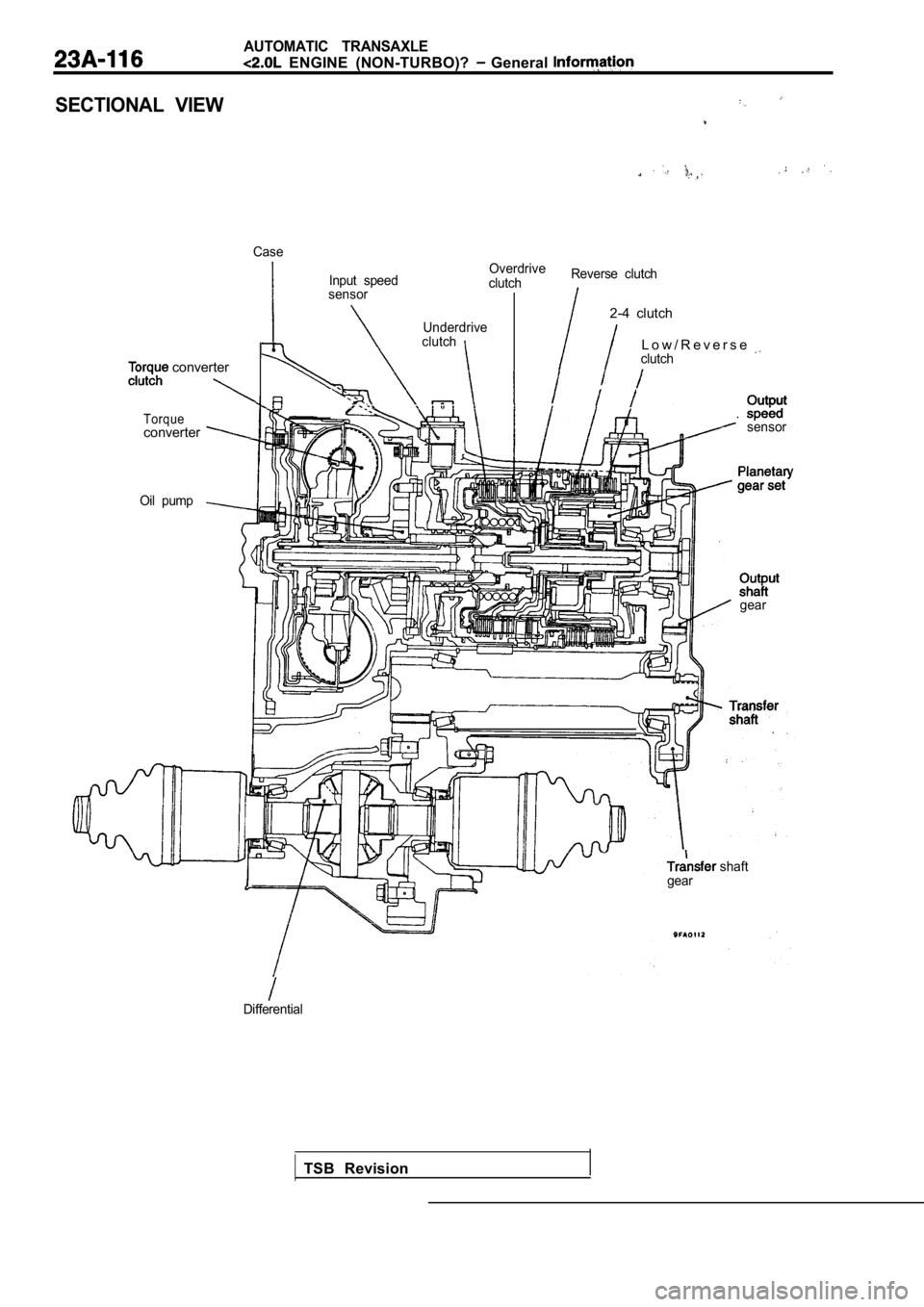

SECTIONAL VIEW

Case

Input speedOverdrive

clutch Reverse clutch

sensor

2-4 clutchUnderdrive

clutch

L o w / R e v e r s eclutch converter

Torqueconverter

.sensor

Oil pump

TSB Revision

shaft

gear

gear

Differential

Page 1125 of 2103

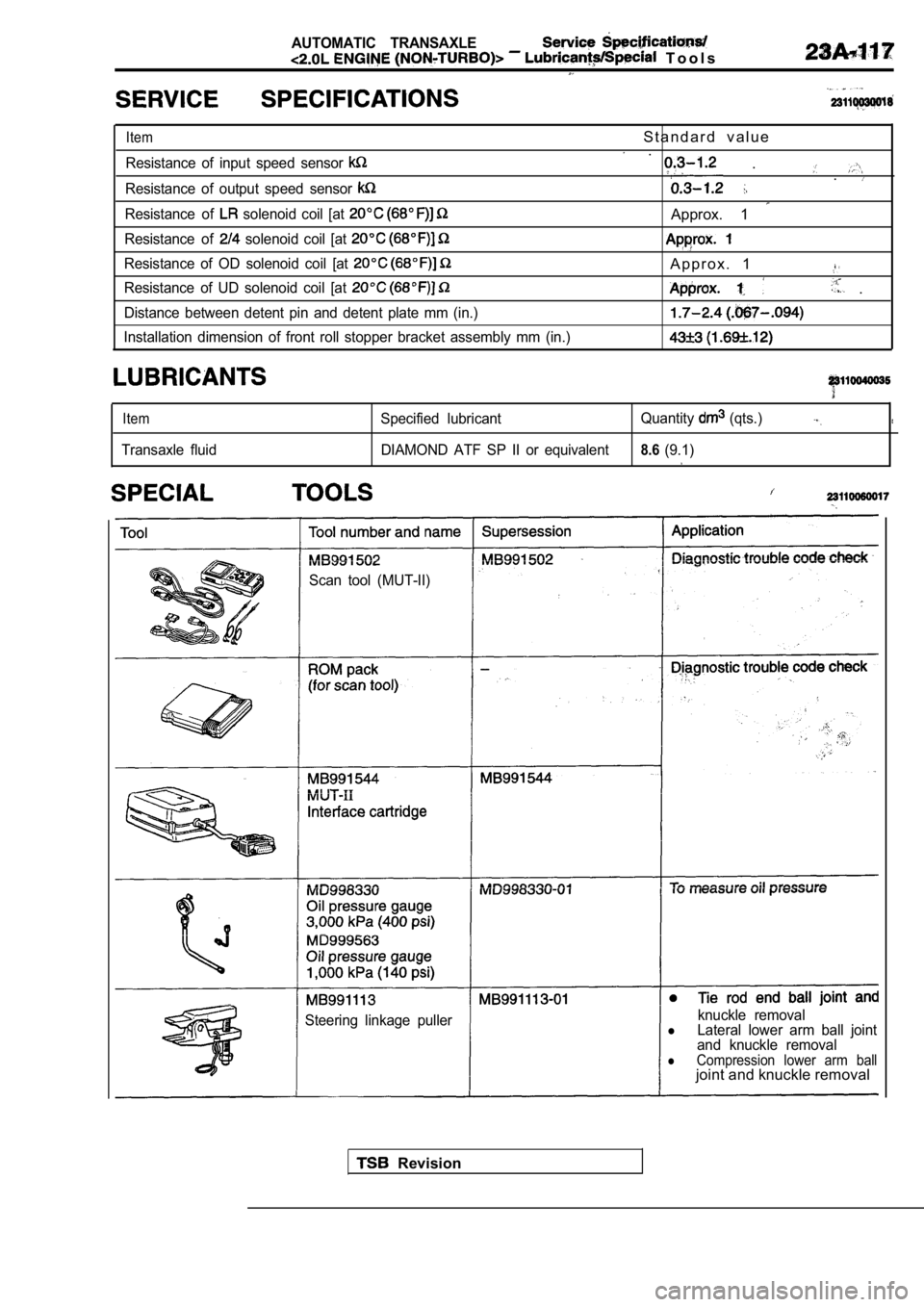

AUTOMATIC TRANSAXLE T o o l s

ItemS t a n d a r d v a l u e .Resistance of input speed sensor ..Resistance of output speed sensor

Resistance of solenoid coil [at Approx. 1

Resistance of solenoid coil [at

Resistance of OD solenoid coil [at A p p r o x . 1

Resistance of UD solenoid coil [at .

Distance between detent pin and detent plate mm (in.)

Installation dimension of front roll stopper bracket assembly mm (in.)

ItemSpecified lubricantQuantity (qts.)

Transaxle fluid DIAMOND ATF SP II or equivalent8.6(9.1)

Scan tool (MUT-II)

Steering linkage puller knuckle removal

lLateral lower arm ball joint

and knuckle removal

lCompression lower arm balljoint and knuckle removal

Revision

Page 1126 of 2103

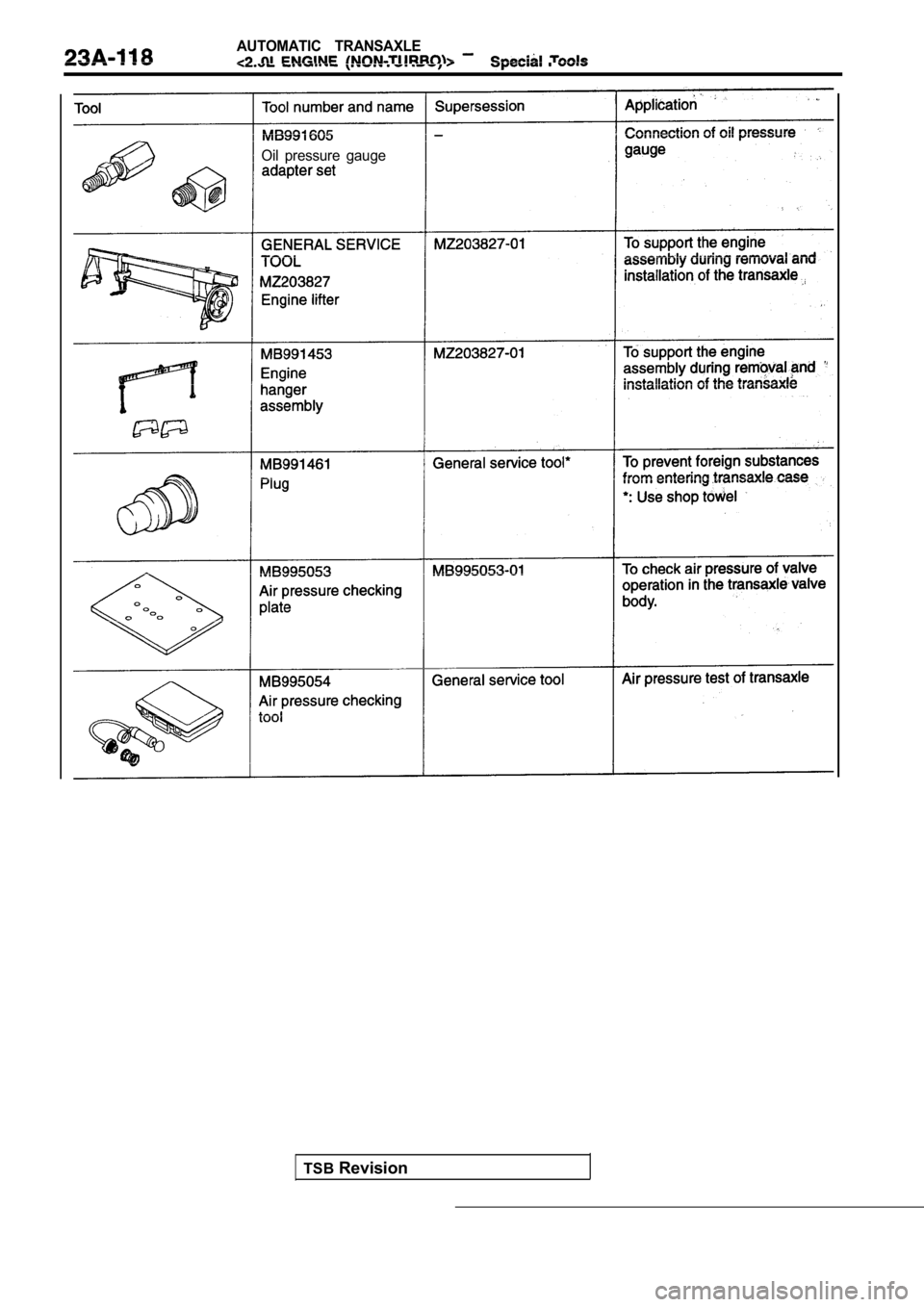

AUTOMATIC TRANSAXLE

Oil pressure gauge

TSBRevision

Page 1127 of 2103

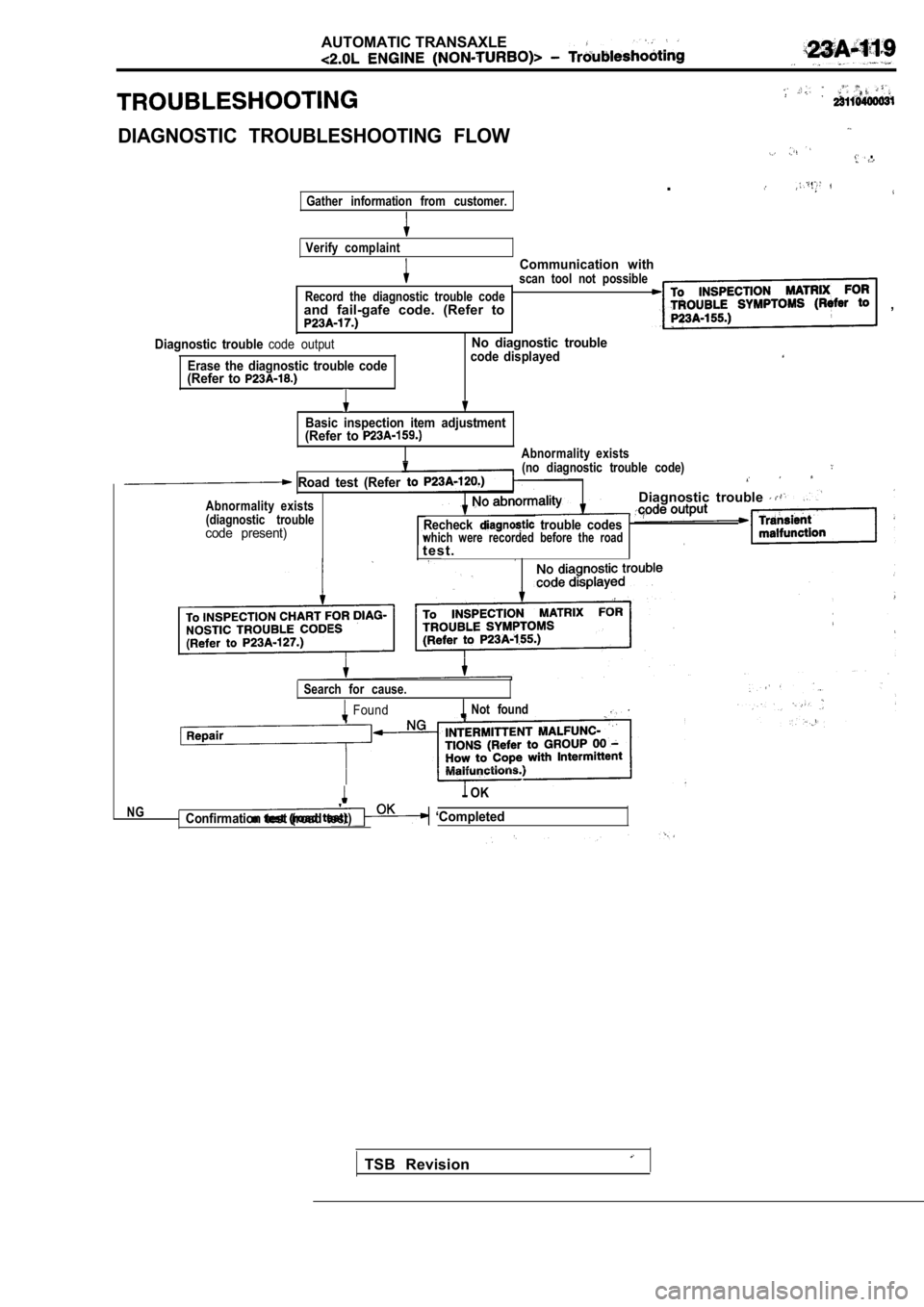

AUTOMATIC TRANSAXLE

DIAGNOSTIC TROUBLESHOOTING FLOW

.

.Gather information from customer.

Verify complaint

Communication withscan tool not possible

Record the diagnostic trouble code

and fail-gafe code. (Refer to ,

Diagnostic trouble code outputNo diagnostic trouble

Erase the diagnostic trouble code code displayed(Refer to

Basic inspection item adjustment(Refer to

Abnormality exists

(no diagnostic trouble code)

Road test (Refer

Abnormality exists

(diagnostic trouble

code present)

Diagnostic trouble

Recheck trouble codeswhich were recorded before the roadt e s t .

Search for cause.

FoundNot found

NG

OK

‘CompletedConfirmation test (road test)

TSB Revision

Page 1128 of 2103

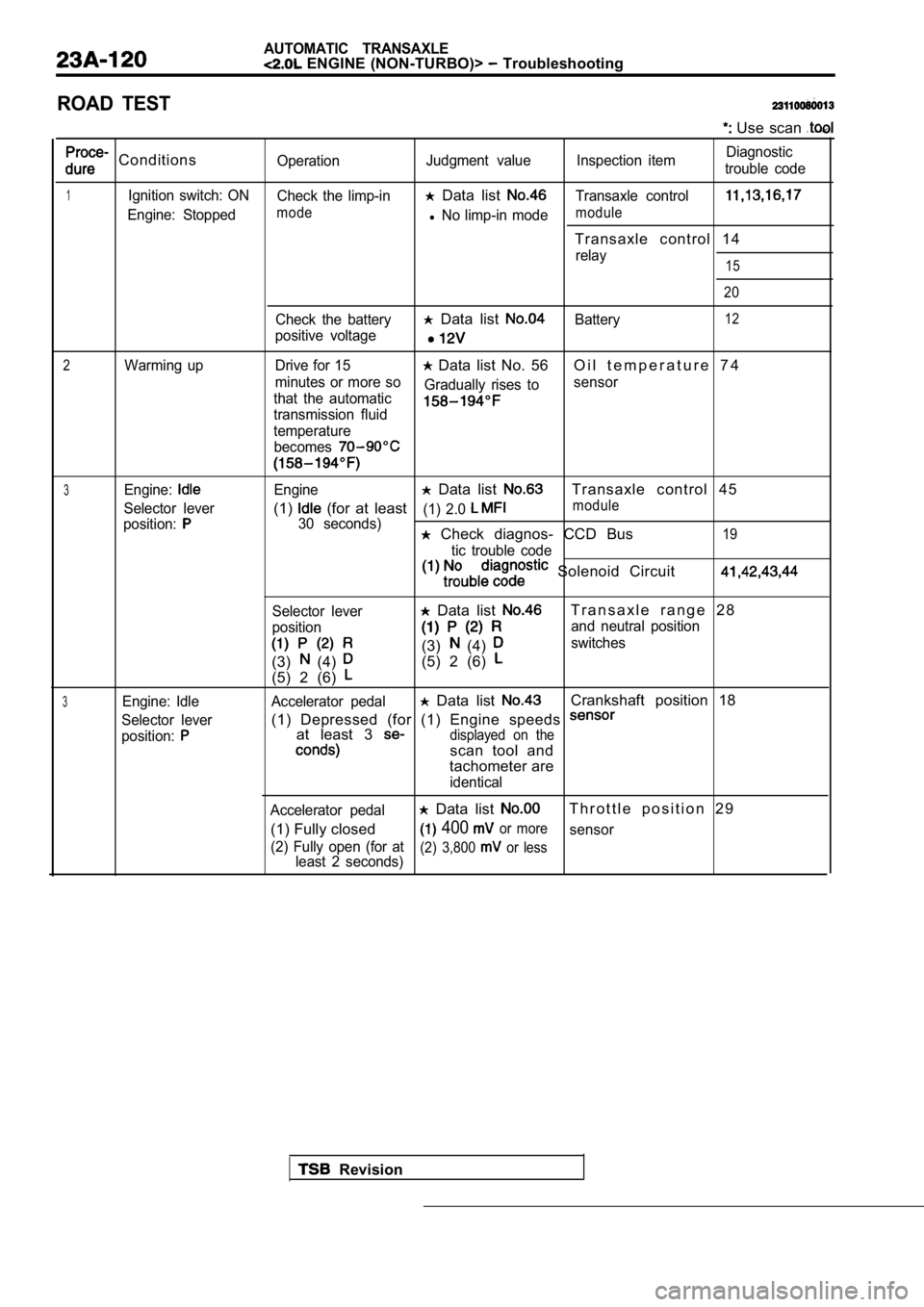

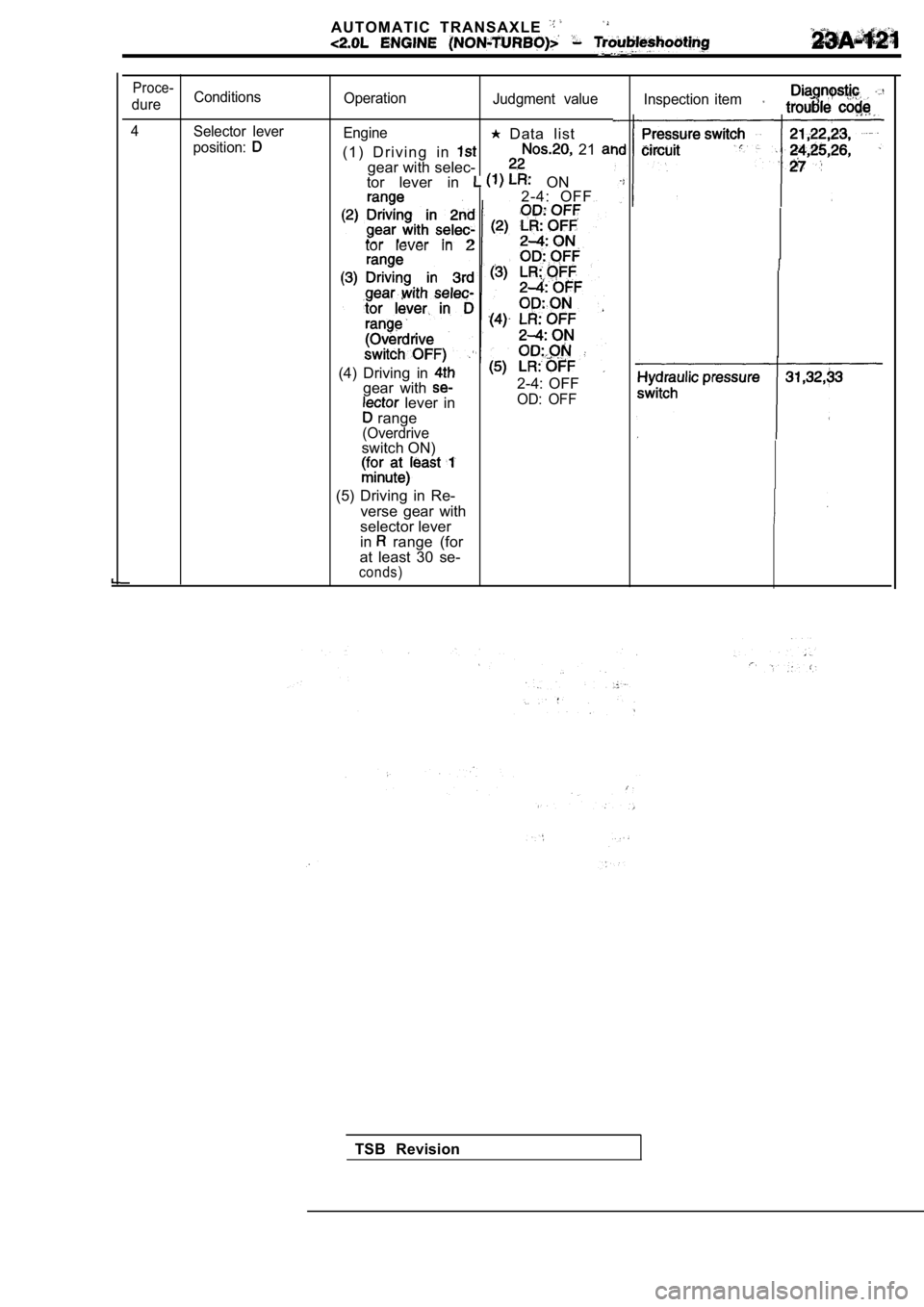

AUTOMATIC TRANSAXLE ENGINE (NON-TURBO)> Troubleshooting

ROAD TEST

Use scan

ConditionsOperationJudgment value Inspection item Diagnostic

trouble code

1Ignition switch: ON Check the limp-in Data list Transaxle control

Engine: Stoppedmodel No limp-in modemodule

Transaxle control 14

relay15

20

Check the battery Data list Battery12

positive voltage

2Warming up Drive for 15 Data list No. 56 O i l t e m p e r a t u r e 7 4

minutes or more so

that the automatic Gradually rises to

sensor

transmission fluid

temperature

becomes

3Engine:Engine Data list Transaxle control 45

Selector lever(1) (for at least(1) 2.0 module

position:30 seconds) Check diagnos- CCD Bus19

tic trouble code

Solenoid Circuit

Selector lever

position

(3) (4)

(5) 2 (6)

Data list T r a n s a x l e r a n g e 2 8

and neutral position

(3) (4) switches

(5) 2 (6)

3Engine: Idle Accelerator pedal Data list Crankshaft position 18

Selector lever(1) Depressed (for (1) Engine speeds

position:at least 3 displayed on the

scan tool and

tachometer are

identical

Accelerator pedal

Data list T h r o t t l e p o s i t i o n 2 9

(1) Fully closed

400 or moresensor

(2) Fully open (for at least 2 seconds)

(2) 3,800 or less

Revision

Page 1129 of 2103

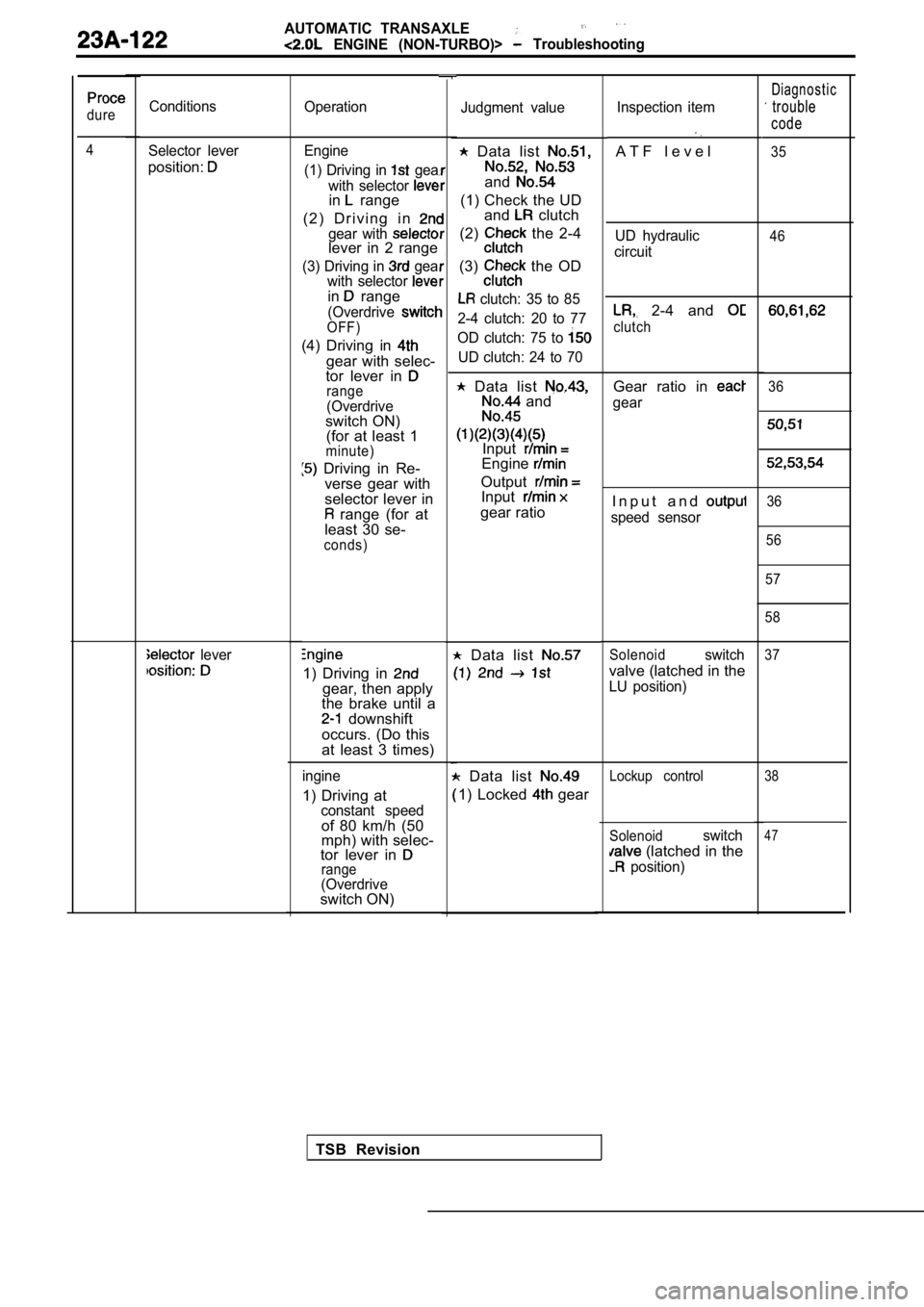

A U T O M A T I C T R A N S A X L E

Proce-

dureConditions

OperationJudgment value

4 Selector lever

Engine

Data listposition:( 1 ) D r i v i n g i n 21

tor lever in ON

gear with selec-

2-4: OFF

tor lever in 2

(4) Driving in

gear with lever in range(Overdriveswitch ON) 2-4: OFF

OD: OFF

(5) Driving in Re-

verse gear with

selector lever

in

range (for

at least 30 se-

conds)

Inspection item

TSB Revision

Page 1130 of 2103

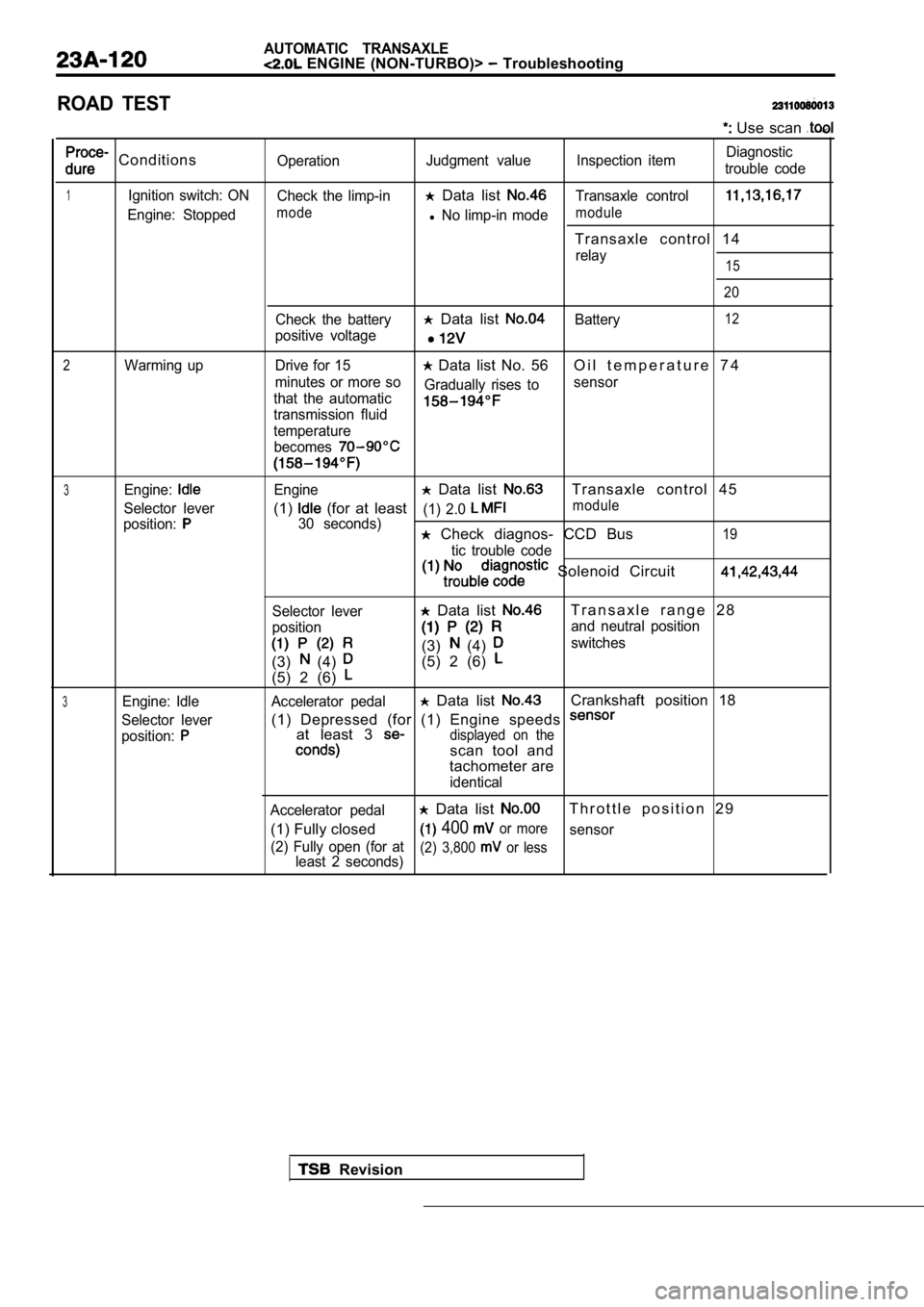

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

dure

4Conditions

Selector lever

position:

lever

Operation

Engine

(1) Driving in

gea

with selector

in range

( 2 ) D r i v i n g i n

gear with lever in 2 range

(3) Driving in gea

with selector

in range

(OverdriveOFF)

(4) Driving in

gear with selec-

tor lever in

range(Overdriveswitch ON) (for at least 1

minute)

Driving in Re-

verse gear with

selector lever in

range (for at

least 30 se-

conds)

1) Driving in gear, then apply

the brake until a

downshift

occurs. (Do this

at least 3 times)

ingine

1) Driving atconstant speedof 80 km/h (50

mph) with selec-

tor lever in

range(Overdriveswitch ON)

Judgment value

Data list

and

(1) Check the UD

and clutch

(2)

the 2-4

(3)

the OD

clutch: 35 to 85

2-4 clutch: 20 to 77

OD clutch: 75 to

UD clutch: 24 to 70

Data list and

InputEngine

OutputInput

gear ratio

Data list

Data list

1) Locked gear

Inspection item

A T F l e v e l

UD hydraulic

circuit

2-4 and

clutch

Gear ratio in

gear

I n p u t a n d

speed sensor

Solenoidswitch

valve (latched in the

LU position)

Lockup control

Solenoid

switch

(latched in the

position)

Diagnostic

trouble

code

35

46

TSB Revision

36

36

56

57

58

37

38

47

Trending: air filter, wiper fluid, power steering, fuel pump, fuel, drain bolt, wiring