MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1141 of 2103

AUTOMATIC TRANSAXLE.

ENGINE. (NON-TURBO)> ,

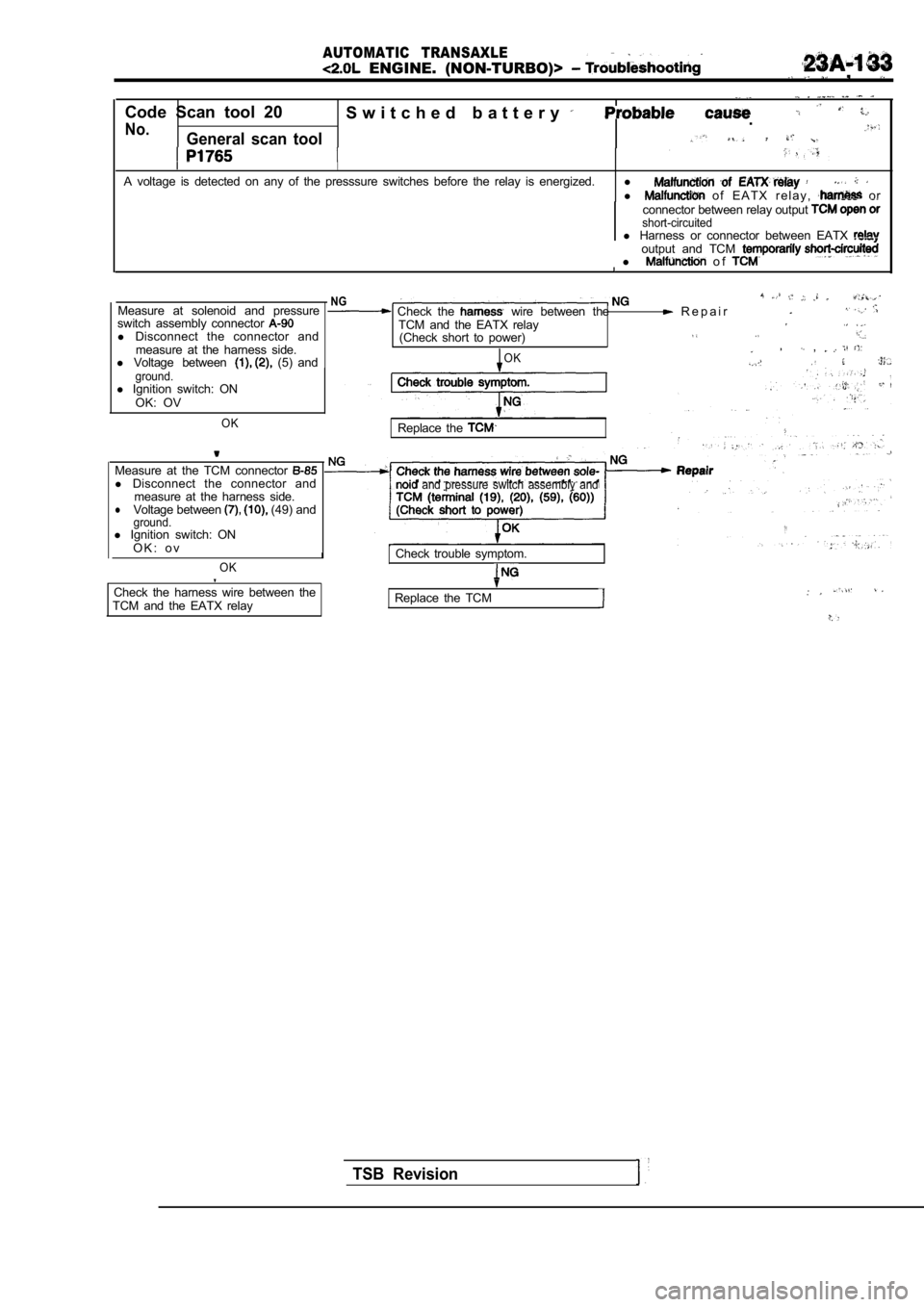

Code Scan tool 20S w i t c h e d b a t t e r y

No..

General scan tool

I

A voltage is detected on any of the presssure switc hes before the relay is energized.l l o f E A T X r e l a y , or

connector between relay output

short-circuitedl Harness or connector between EATX output and TCM l o f

Measure at solenoid and pressure

switch assembly connector

l Disconnect the connector and

measure at the harness side.

l Voltage between

(5) andground.l Ignition switch: ON

OK: OV

OK

Measure at the TCM connector l Disconnect the connector and

measure at the harness side.

lVoltage between (49) andground.l Ignition switch: ON

O K : o v

OK

NG Check the wire between the

TCM and the EATX relay (Check short to power)

OK

R e p a i r

,

Replace the

and pressure switch assembly and

Check trouble symptom.

Check the harness wire between the

TCM and the EATX relayReplace the TCM

TSB Revision

Page 1142 of 2103

34AUTOMATIC TRANSAXLE ENGINE (NON-TURBO)> Troubleshooting

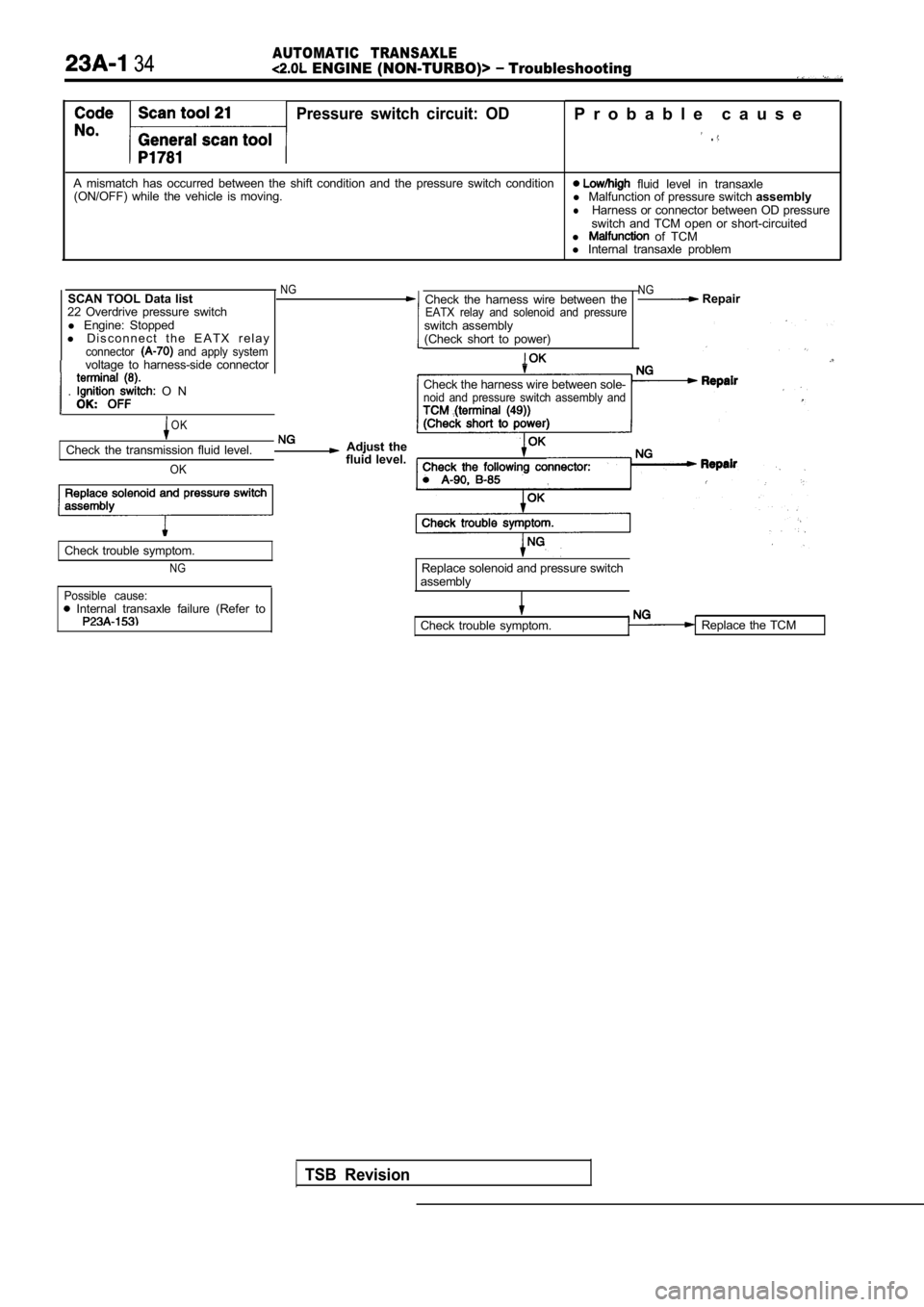

Pressure switch circuit: OD

A mismatch has occurred between the shift condition and the pressure switch condition

(ON/OFF) while the vehicle is moving.

SCAN TOOL Data list

NG

22 Overdrive pressure switch l Engine: Stopped

l D i s c o n n e c t t h e E A T X r e l a y

connector and apply systemvoltage to harness-side connector

. O N

OK

Check the transmission fluid level.

OK

Replace solenoid and pressure switch

Check trouble symptom.

NG

Possible cause: Internal transaxle failure (Refer to

Adjust the

fluid level.

P r o b a b l e c a u s e

.

fluid level in transaxle

l Malfunction of pressure switch assembly

lHarness or connector between OD pressure

switch and TCM open or short-circuited

l

of TCM

l Internal transaxle problem

Check the harness wire between the

EATX relay and solenoid and pressureswitch assembly

(Check short to power)

NG Repair

Check the harness wire between sole-noid and pressure switch assembly and

Replace solenoid and pressure switch

assembly

Check trouble symptom.

TSB Revision

Replace the TCM

Page 1143 of 2103

AUTOMATIC TRANSAXLE

ENGINE

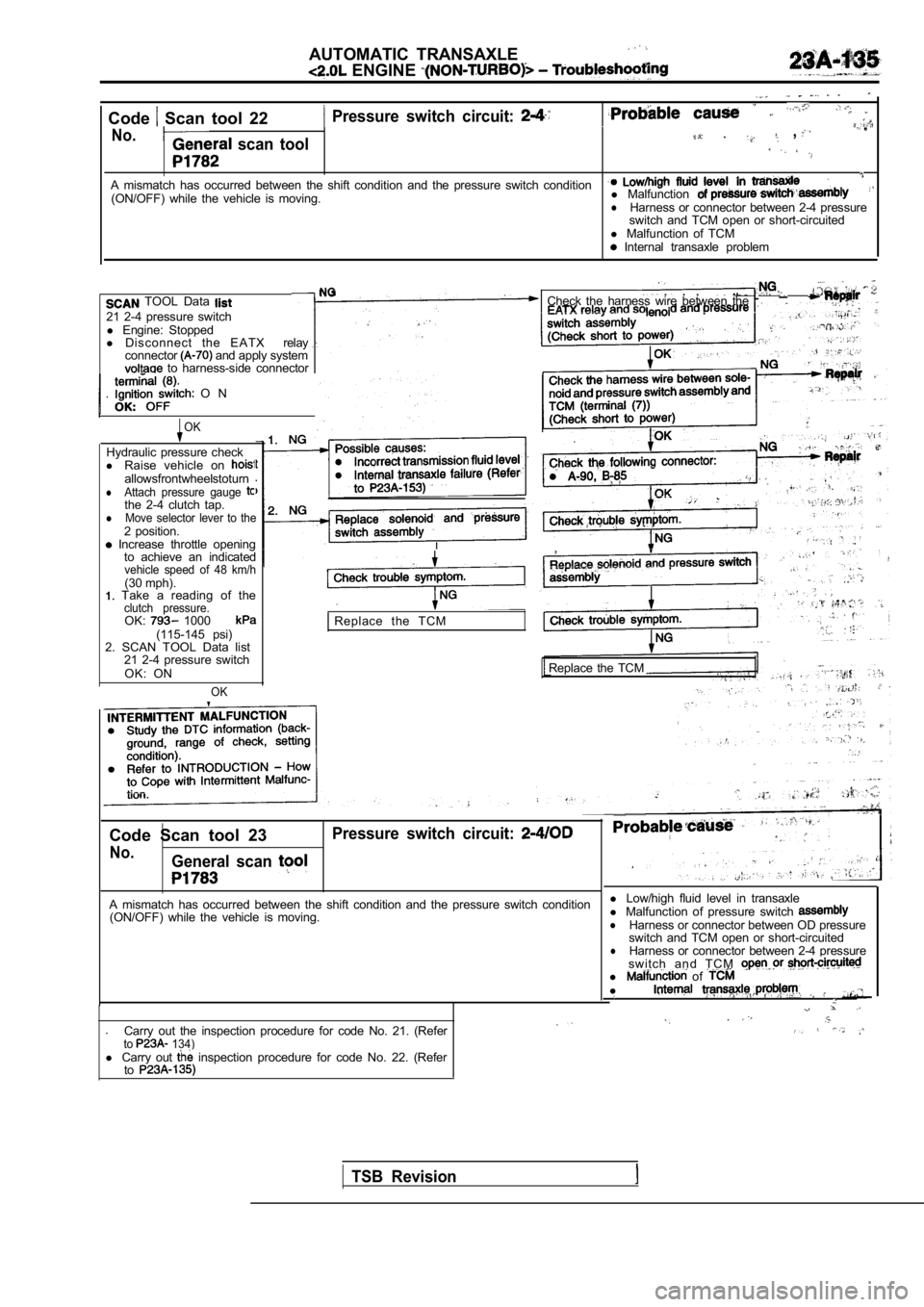

Code Scan tool 22

No.

Pressure switch circuit:

scan tool,

A mismatch has occurred between the shift condition and the pressure switch condition(ON/OFF) while the vehicle is moving. l

MalfunctionlHarness or connector between 2-4 pressure

switch and TCM open or short-circuited

l Malfunction of TCM

Internal transaxle problem

Check the harness wire between the NG TOOL Data 21 2-4 pressure switchl Engine: Stopped

l Disconnect the EATX relay

connector

and apply system to harness-side connector

. O N

OK

Hydraulic pressure check

l Raise vehicle on

allowsfrontwheelstoturnlAttach pressure gauge the 2-4 clutch tap.lMove selector lever to the2 position. Increase throttle opening

to achieve an indicated

vehicle speed of 48 km/h(30 mph). Take a reading of theclutch pressure.OK: 1000(115-145 psi)

2. SCAN TOOL Data list 21 2-4 pressure switch

OK: ON

OK

Replace the TCM

Replace the TCM

Code Scan tool 23

Pressure switch circuit:

No.General scan

A mismatch has occurred between the shift condition and the pressure switch condition

(ON/OFF) while the vehicle is moving. l

Low/high fluid level in transaxle

l Malfunction of pressure switch

lHarness or connector between OD pressure

switch and TCM open or short-circuited

lHarness or connector between 2-4 pressure

s w i t c h a n d T C M

l of l

.. Carry out the inspection procedure for code No. 21. (Referto 134)l Carry out inspection procedure for code No. 22. (Refer

to

TSB Revision

Page 1144 of 2103

36AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

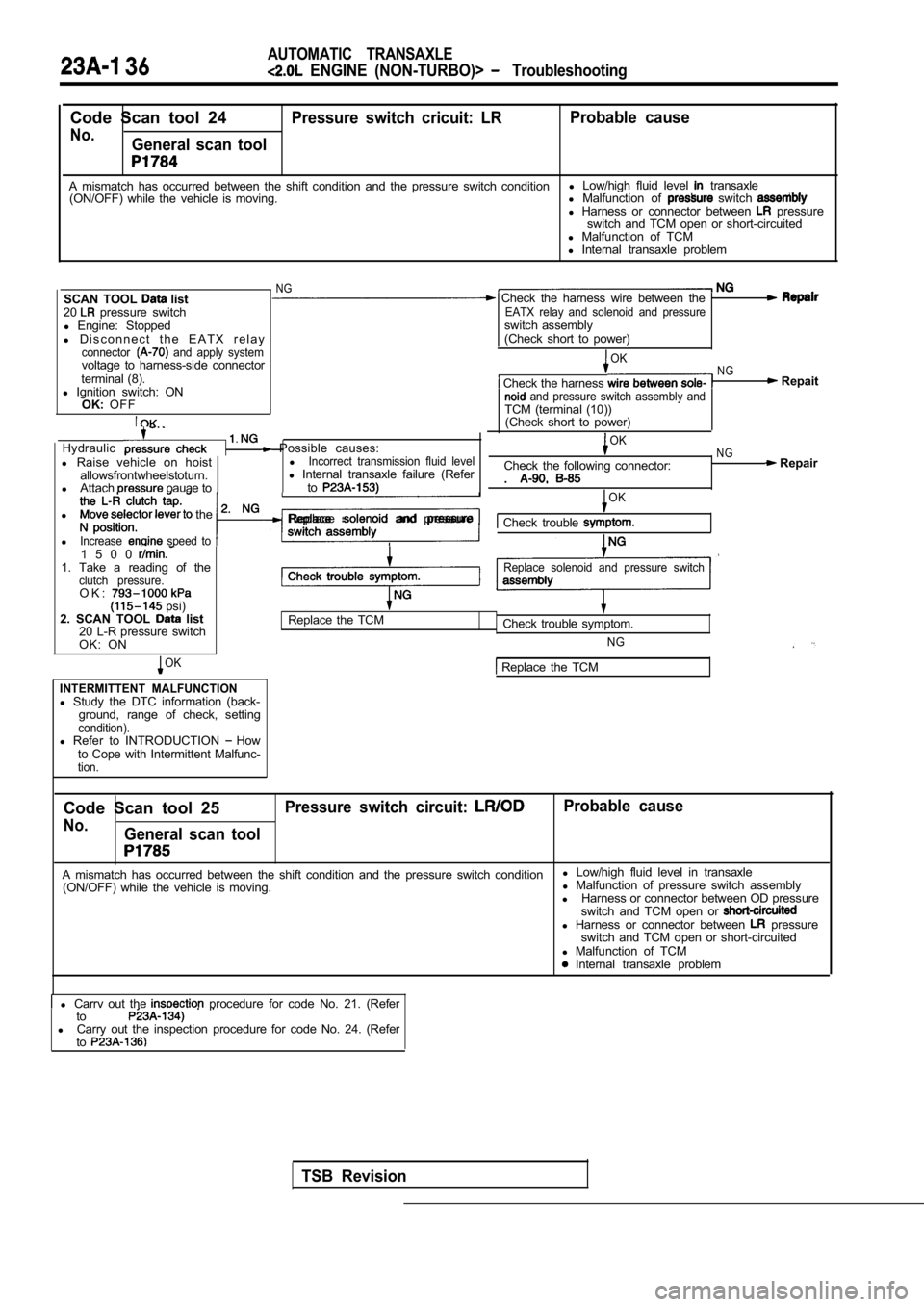

Code Scan tool 24Pressure switch cricuit: LRProbable cause

No.General scan tool

A mismatch has occurred between the shift condition

and the pressure switch conditionl

Low/high fluid level transaxle

(ON/OFF) while the vehicle is moving. l

Malfunction of switch l Harness or connector between pressure

switch and TCM open or short-circuited

l Malfunction of TCM

l Internal transaxle problem

SCAN TOOL

list

20 pressure switch

l Engine: Stopped

l D i s c o n n e c t t h e E A T X r e l a y

connector and apply systemvoltage to harness-side connector

terminal (8).

l Ignition switch: ON

OK: OFF

NG Check the harness wire between theEATX relay and solenoid and pressureswitch assembly

(Check short to power)

Hydraulic Possible causes:

l Raise vehicle on hoist lIncorrect transmission fluid levelallowsfrontwheelstoturn.l

Internal transaxle failure (Refer

l Attach oauae to to

l the Replace and pressure

l

Increase speed to1 5 0 01. Take a reading of theclutch pressure.O K : psi)

2. SCAN TOOL list

20 L-R pressure switch

OK: ON Replace the TCM

OK

INTERMITTENT MALFUNCTIONl

Study the DTC information (back-

ground, range of check, setting

condition).l Refer to INTRODUCTION How

to Cope with Intermittent Malfunc-

tion. OK

Check the harness N G Repait and pressure switch assembly andTCM (terminal (10))

(Check short to power)

OK

Check the following connector: .N G Repair

OK

Check trouble

TSB Revision

Replace solenoid and pressure switch

Check trouble symptom.

NG

Replace the TCM

Code Scan tool 25

Pressure switch circuit: Probable cause

No.General scan tool

A mismatch has occurred between the shift condition and the pressure switch conditionl

Low/high fluid level in transaxle

(ON/OFF) while the vehicle is moving. l

Malfunction of pressure switch assembly

l Harness or connector between OD pressure

switch and TCM open or

l Harness or connector between pressure

switch and TCM open or short-circuited

l Malfunction of TCM

Internal transaxle problem

l Carrv out the procedure for code No. 21. (Refer

to

l Carry out the inspection procedure for code No. 24. (Refer

to

Page 1145 of 2103

AUTOMATIC TRANSAXLE.

ENGINE Troubleshooting

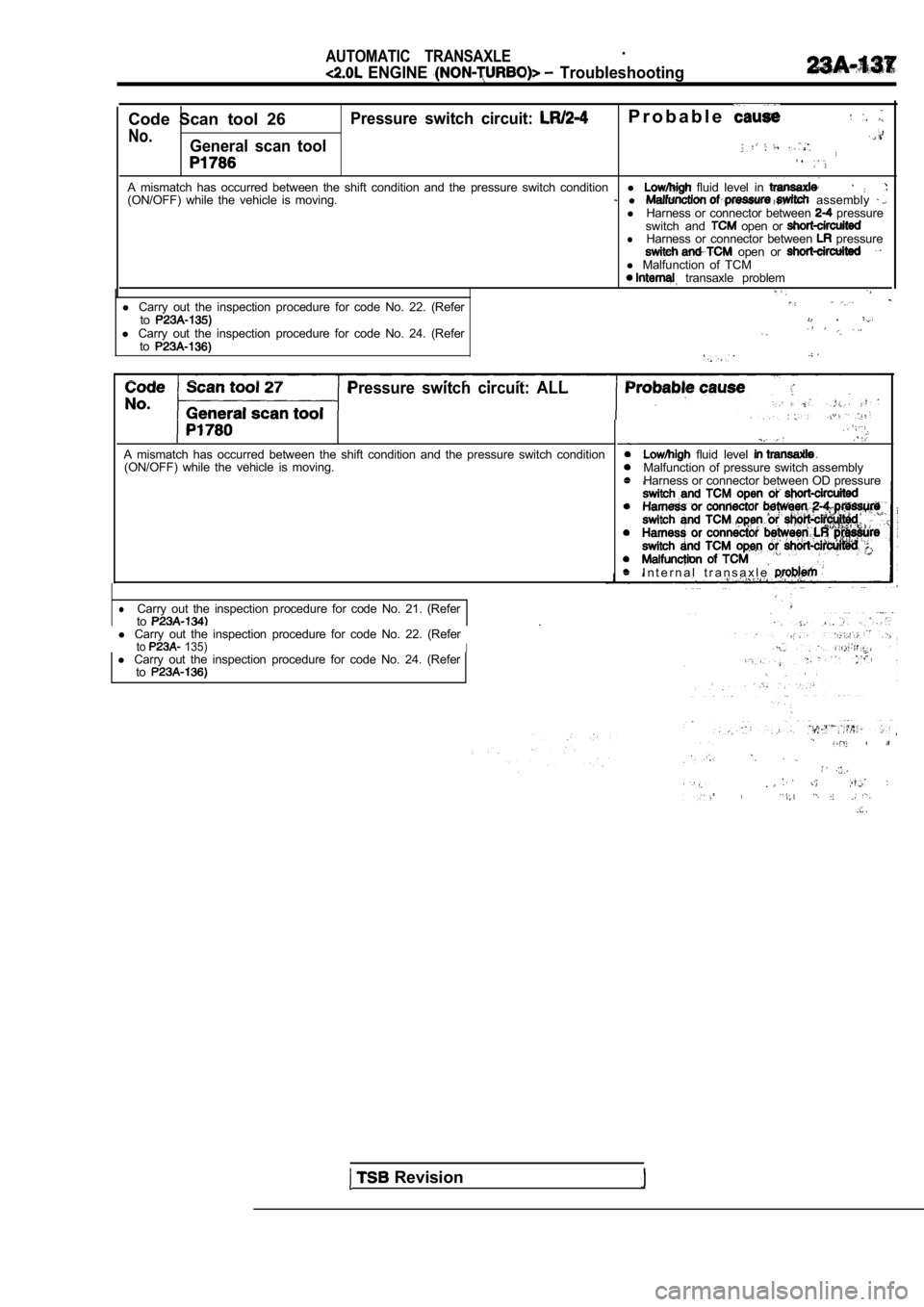

Code Scan tool 26Pressure switch circuit: P r o b a b l e

No. ,

General scan tool .

A mismatch has occurred between the shift condition and the pressure switch condition

(ON/OFF) while the vehicle is moving. l fluid level in l assembly l

Harness or connector between pressure

switch and open or lHarness or connector between pressure open or l Malfunction of TCM transaxle problem

l Carry out the inspection procedure for code No. 22. (Refer

to

l Carry out the inspection procedure for code No. 24. (Refer

to

Pressure switch circuit: ALL

A mismatch has occurred between the shift condition and the pressure switch condition

(ON/OFF) while the vehicle is moving. fluid level Malfunction of pressure switch assembly

Harness or connector between OD pressure

I n t e r n a l t r a n s a x l e

lCarry out the inspection procedure for code No. 21. (Refer

to.

l Carry out the inspection procedure for code No. 22. (Refer

to 135)l Carry out the inspection procedure for code No. 24. (ReferI

to

. ,

Revision

Page 1146 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> ‘Troubleshooting,

cause

Malfunction range lHarness or connector between transaxle rangesensor and open or short-circuited

lTransaxle range sensor ground open-circuitedl Malfunction of

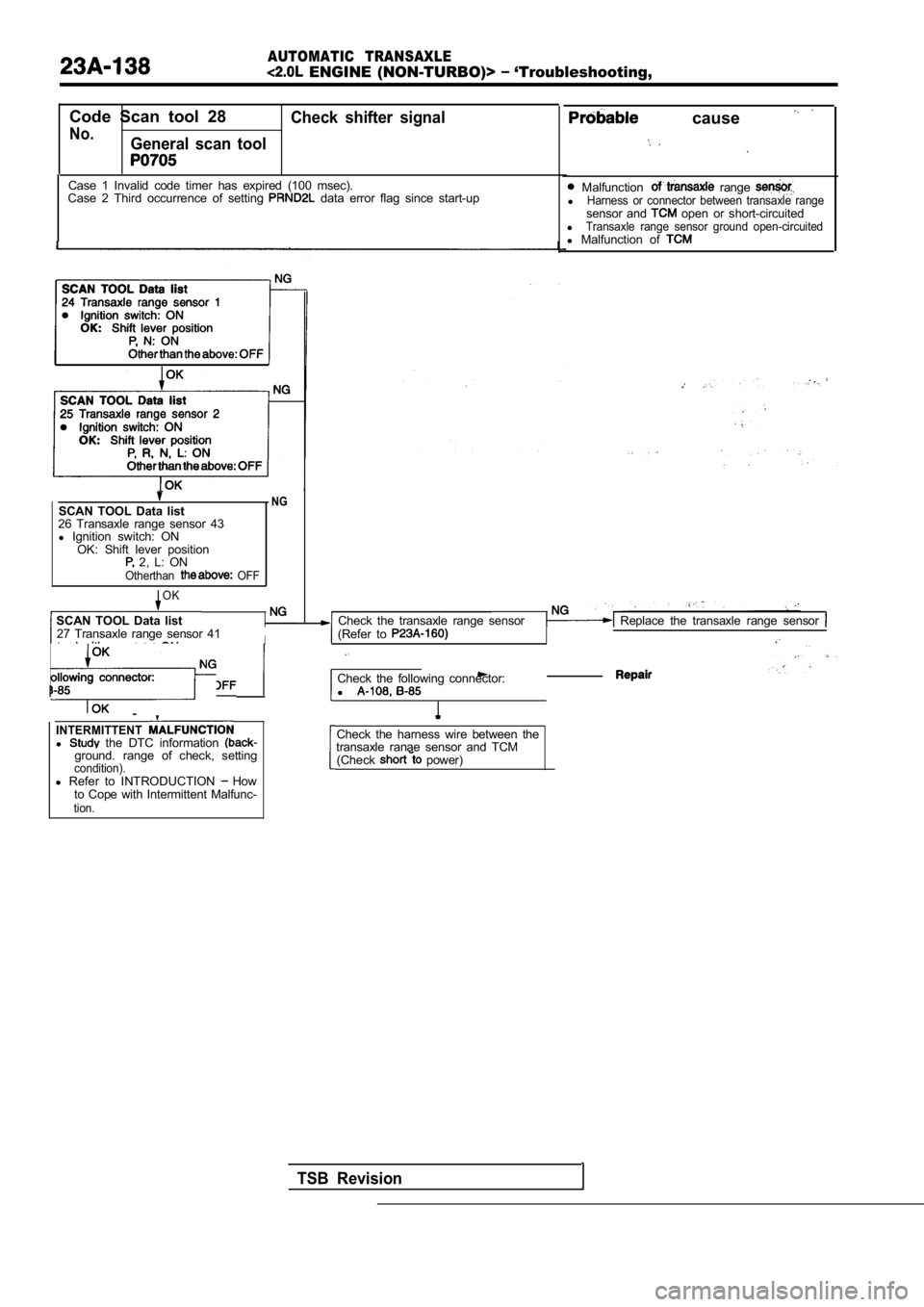

Code Scan tool 28Check shifter signal

No.General scan tool

Case 1 Invalid code timer has expired (100 msec).

Case 2 Third occurrence of setting data error flag since start-up

SCAN TOOL Data list

26 Transaxle range sensor 43 l Ignition switch: ON

OK: Shift lever position

2, L: ONOtherthan OFF

NG

OK

SCAN TOOL Data list Check the transaxle range sensor Replace the transaxle range sensor 27 Transaxle range sensor 41.. . . I

OK:

(Refer to

Check the following connector:

l

INTERMITTENTl the DTC information Check the harness wire between the

transaxle ranae sensor and TCM

(Check

power)

ground. range of check, settingcondition).l

Refer to INTRODUCTION How

to Cope with Intermittent Malfunc-

tion.

TSB Revision

Page 1147 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

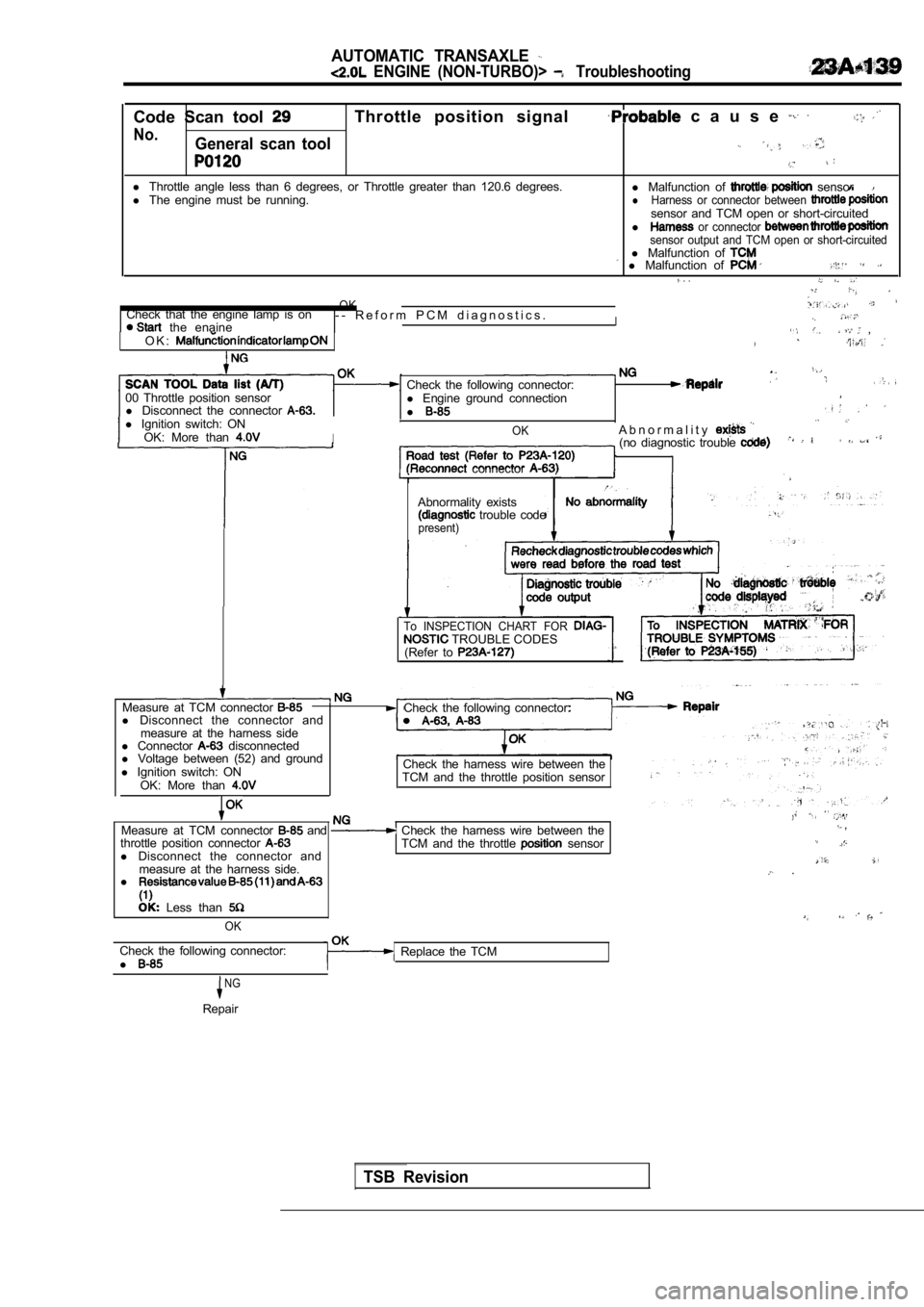

Code Scan tool Throttle position signal

No.General scan tool

l Throttle angle less than 6 degrees, or Throttle gre ater than 120.6 degrees.

l The engine must be running.

OKCheck that the engine lamp is on

- - R e f o r m P C M d i a g n o s t i c s . the enaine

c a u s e

l Malfunction of sensorlHarness or connector between sensor and TCM open or short-circuited

l or connector sensor output and TCM open or short-circuitedl Malfunction of l Malfunction of . .

I ,

O K :

00 Throttle position sensor

l Disconnect the connector Check the following connector:l Engine ground connectionl l Ignition switch: ONI ,

,OK: More than OKA b n o r m a l i t y(no diagnostic trouble

connector

Abnormality exists trouble codepresent)

To INSPECTION CHART FOR

TROUBLE CODES

(Refer to

Measure at TCM connector l Disconnect the connector and

measure at the harness side Check the following connector:

l Connector

disconnected

l Voltage between (52) and ground

l Ignition switch: ON

OK: More than

Check the harness wire between the

TCM and the throttle position sensor

Measure at TCM connector and Check the harness wire between the

throttle position connector TCM and the throttle sensor

l Disconnect the connector and

measure at the harness side.

l

Less than

OK

,

.

Check the following connector:

l Replace the TCM

NG

Repair

TSB Revision

Page 1148 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshootihg

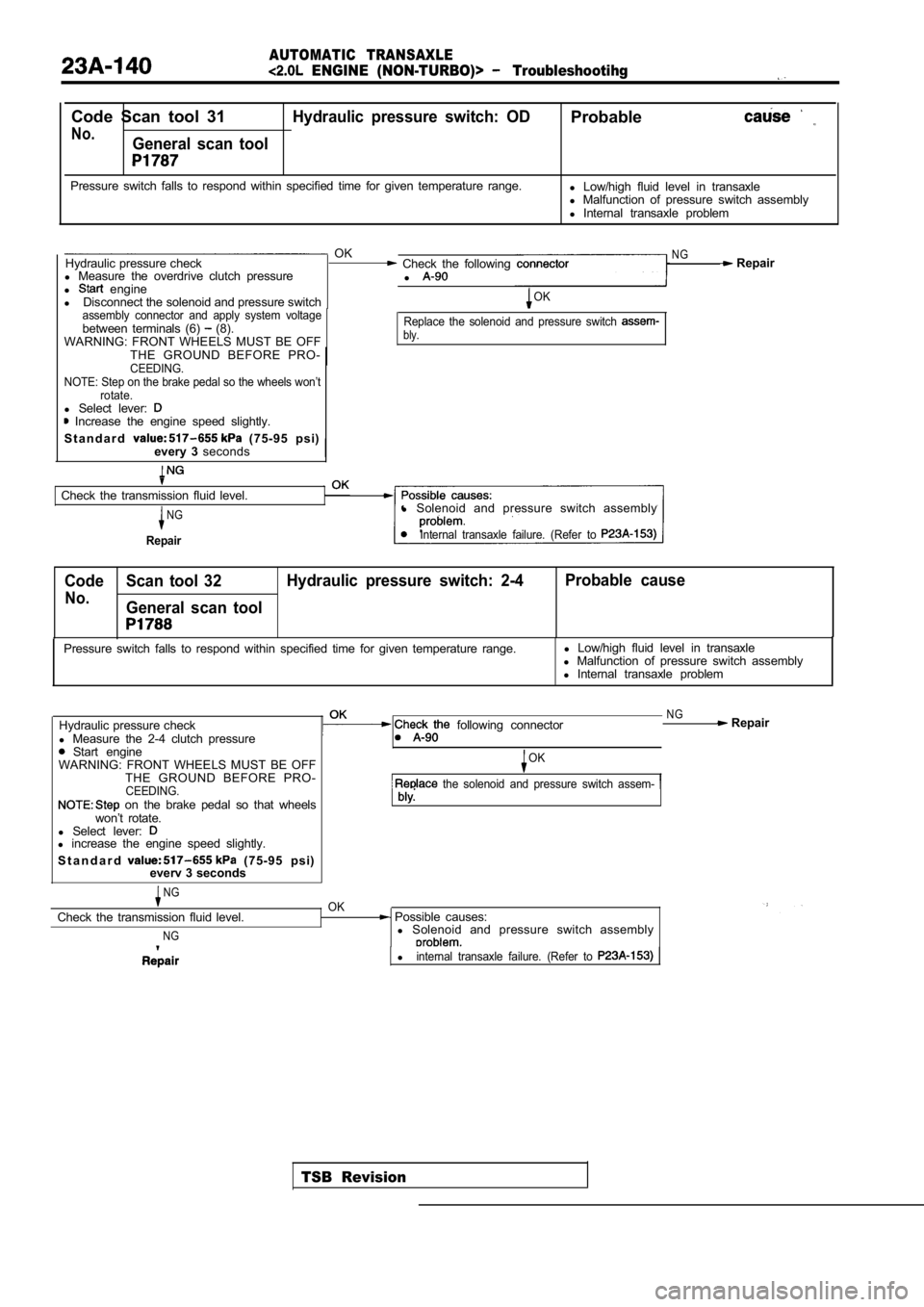

Code Scan tool 31Hydraulic pressure switch: ODProbable

No.General scan tool

Pressure switch falls to respond within specified time for given temperature range.

l Low/high fluid level in transaxle

l Malfunction of pressure switch assembly

l Internal transaxle problem

OKNGHydraulic pressure check Check the following Repair

l Measure the overdrive clutch pressure

l

l engine

l Disconnect the solenoid and pressure switchOK

assembly connector and apply system voltage

between terminals (6) (8).

WARNING: FRONT WHEELS MUST BE OFFReplace the solenoid and pressure switch bly.

THE GROUND BEFORE PRO-CEEDING.

NOTE: Step on the brake pedal so the wheels won’t rotate.

l Select lever: Increase the engine speed slightly.

S t a n d a r d

(75-95 psi)

every 3 seconds

Check the transmission fluid level.

NG

Repair

l Solenoid and pressure switch assembly

Internal transaxle failure. (Refer to

Code Scan tool 32 Hydraulic pressure switch: 2-4 Probable cause

No.General scan tool

TSB Revision

Pressure switch falls to respond within specified t

ime for given temperature range.l

Low/high fluid level in transaxle

l Malfunction of pressure switch assembly

l Internal transaxle problem

Hydraulic pressure check

l Measure the 2-4 clutch pressure

Start engine

following connector

WARNING: FRONT WHEELS MUST BE OFF THE GROUND BEFORE PRO-

CEEDING. on the brake pedal so that wheels

won’t rotate.

l Select lever:

l increase the engine speed slightly.

S t a n d a r d

(75-95 psi)

everv 3 seconds

NGOK

NG Repair

OK

the solenoid and pressure switch assem-

Check the transmission fluid level.

NG

Possible causes:

l Solenoid and pressure switch assembly

linternal transaxle failure. (Refer to

Page 1149 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

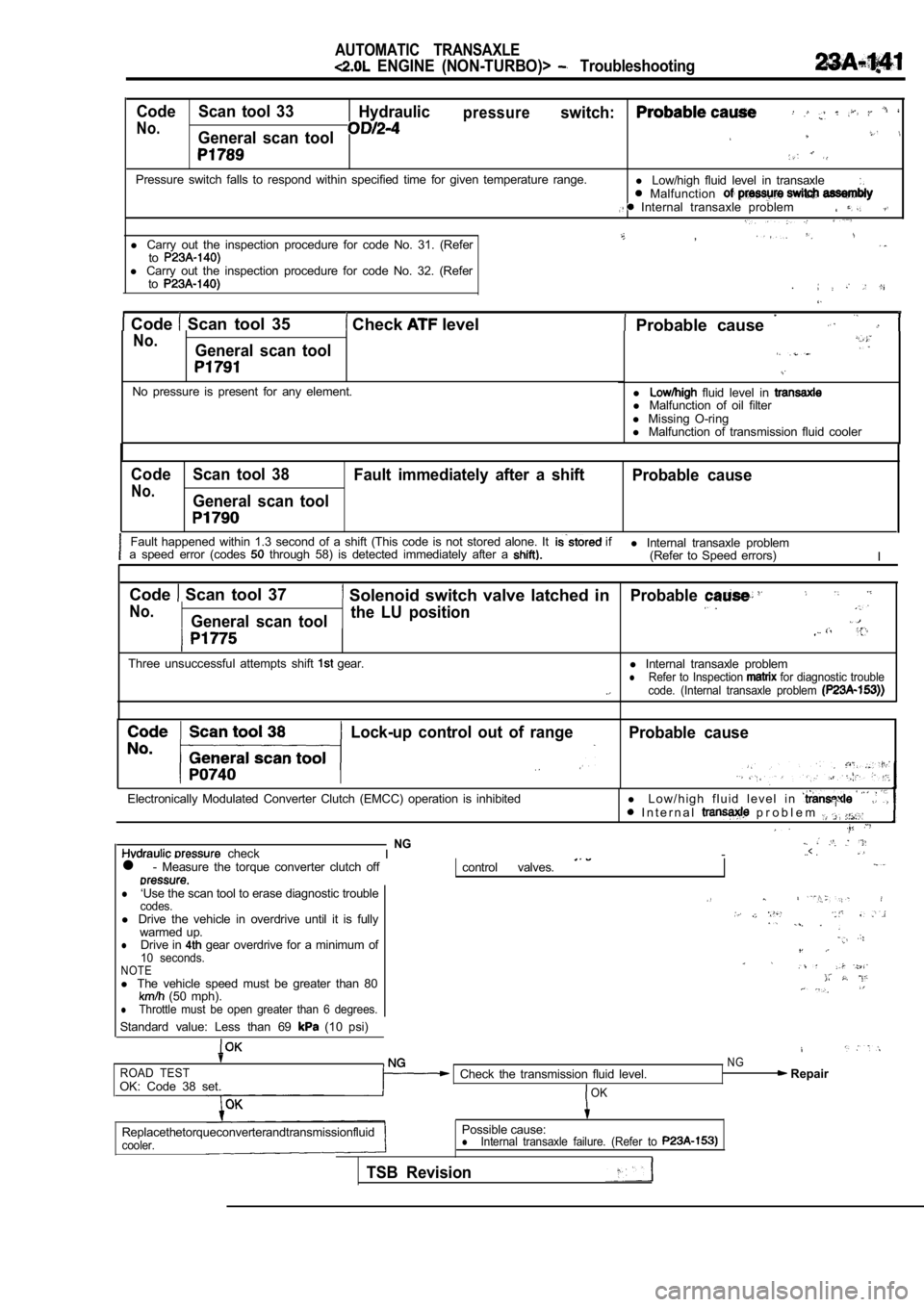

Code Scan tool 33Hydraulicpressureswitch:

No.General scan tool

Pressure switch falls to respond within specified t ime for given temperature range.

l Low/high fluid level in transaxle Malfunction Internal transaxle problem

,l Carry out the inspection procedure for code No. 31. (Refertol Carry out the inspection procedure for code No. 32. (Refer

to

Code Scan tool 35 Check level . Probable cause No.General scan tool

No pressure is present for any element.l fluid level in l

Malfunction of oil filter

l Missing O-ring

l Malfunction of transmission fluid cooler

Code Scan tool 38

Fault immediately after a shift Probable cause

No.General scan tool

Fault happened within 1.3 second of a shift (This code is not stored alone. It if

a speed error (codes through 58) is detected immediately after a l Internal transaxle problem

(Refer to Speed errors) I

Code

Scan tool 37 Solenoid switch valve latched in

No.General scan tool the LU position

Three unsuccessful attempts shift gear.

Probable

l

Internal transaxle problemlRefer to Inspection for diagnostic trouble

code. (Internal transaxle problem

Lock-up control out of rangeProbable cause

Electronically Modulated Converter Clutch (EMCC) op eration is inhibitedl L o w / h i g h f l u i d l e v e l i n I n t e r n a l p r o b l e m

checkNGI -..< .

l - Measure the torque converter clutch offcontrol valves.

l‘Use the scan tool to erase diagnostic troublecodes.l Drive the vehicle in overdrive until it is fully

warmed up.

lDrive in gear overdrive for a minimum of10 seconds.NOTEl The vehicle speed must be greater than 80 (50 mph).lThrottle must be open greater than 6 degrees.

Standard value: Less than 69 (10 psi)

ROAD TESTOK: Code 38 set. Check the transmission fluid level.OK

NG Repair

Replacethetorqueconverterandtransmissionfluid

cooler.

Possible cause:lInternal transaxle failure. (Refer to

TSB Revision

Page 1150 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

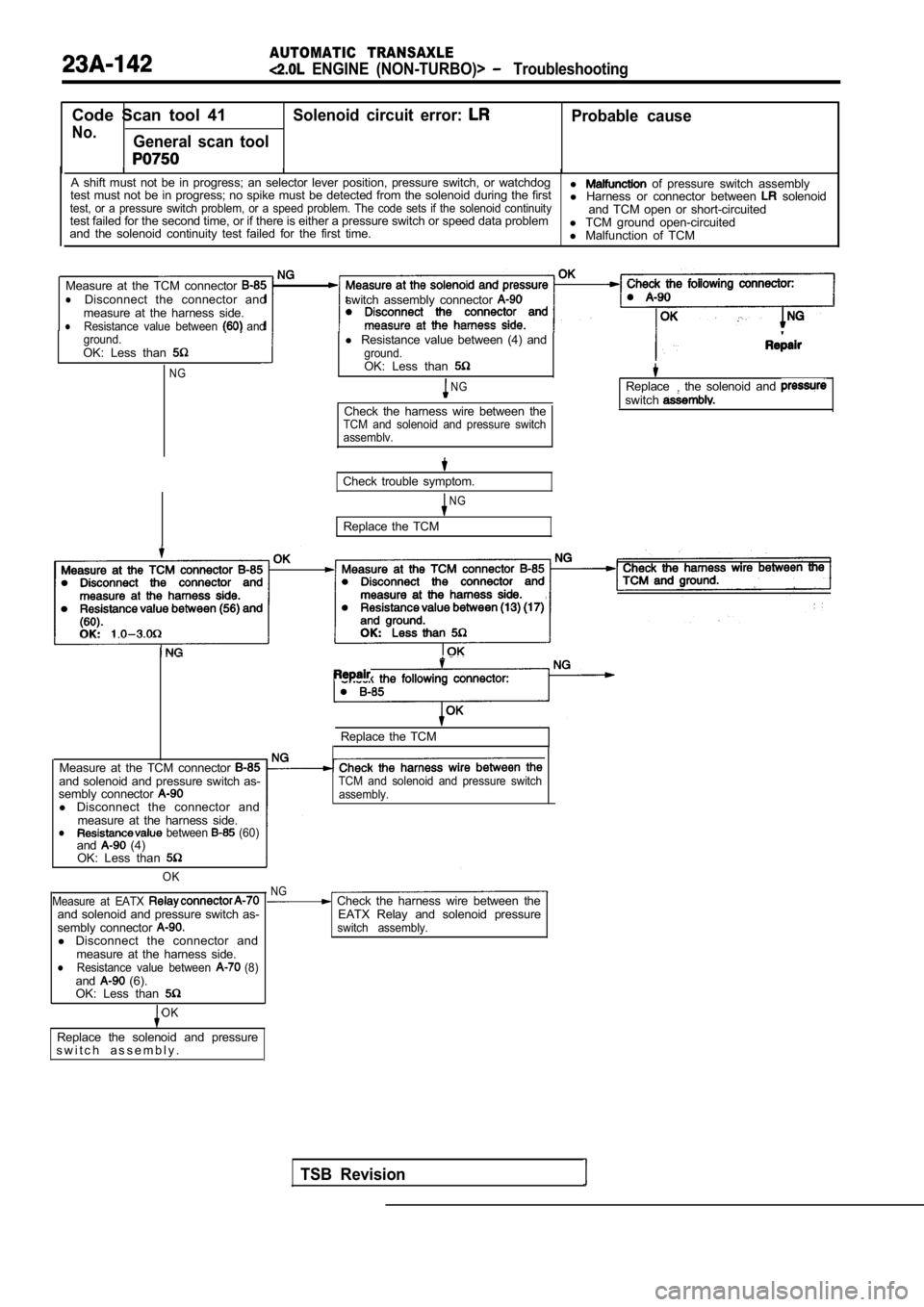

Code Scan tool 41Solenoid circuit error: Probable cause

No.General scan tool

A shift must not be in progress; an selector lever position, pressure switch, or watchdog

l of pressure switch assembly

test must not be in progress; no spike must be dete cted from the solenoid during the first

l Harness or connector between solenoidtest, or a pressure switch problem, or a speed prob lem. The code sets if the solenoid continuityand TCM open or short-circuited

test failed for the second time, or if there is eit her a pressure switch or speed data problem

l TCM ground open-circuited

and the solenoid continuity test failed for the fir st time.

l Malfunction of TCM

Measure at the TCM connector

lDisconnect the connector and

measure at the harness side.

lResistance value between and

switch assembly connector

ground.OK: Less than

NG

l Resistance value between (4) andground.OK: Less than

NG

Check the harness wire between theTCM and solenoid and pressure switch

assemblv.

Replace the solenoid and switch

Check trouble symptom.

N G

Replace the TCM

Measure at the TCM connector

and solenoid and pressure switch as-

sembly connector

l Disconnect the connector and

measure at the harness side.

l between (60)and (4)

OK: Less than

OK

Measure at EATX

and solenoid and pressure switch as-

sembly connector

l Disconnect the connector and

measure at the harness side.

lResistance value between (8)and (6).

OK: Less than

TSB Revision

Check the

Replace the TCM

OK

Replace the solenoid and pressure

s w i t c h a s s e m b l y .

TCM and solenoid and pressure switch

assembly.

NG Check the harness wire between the EATX Relay and solenoid pressure

switch assembly.