MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1091 of 2103

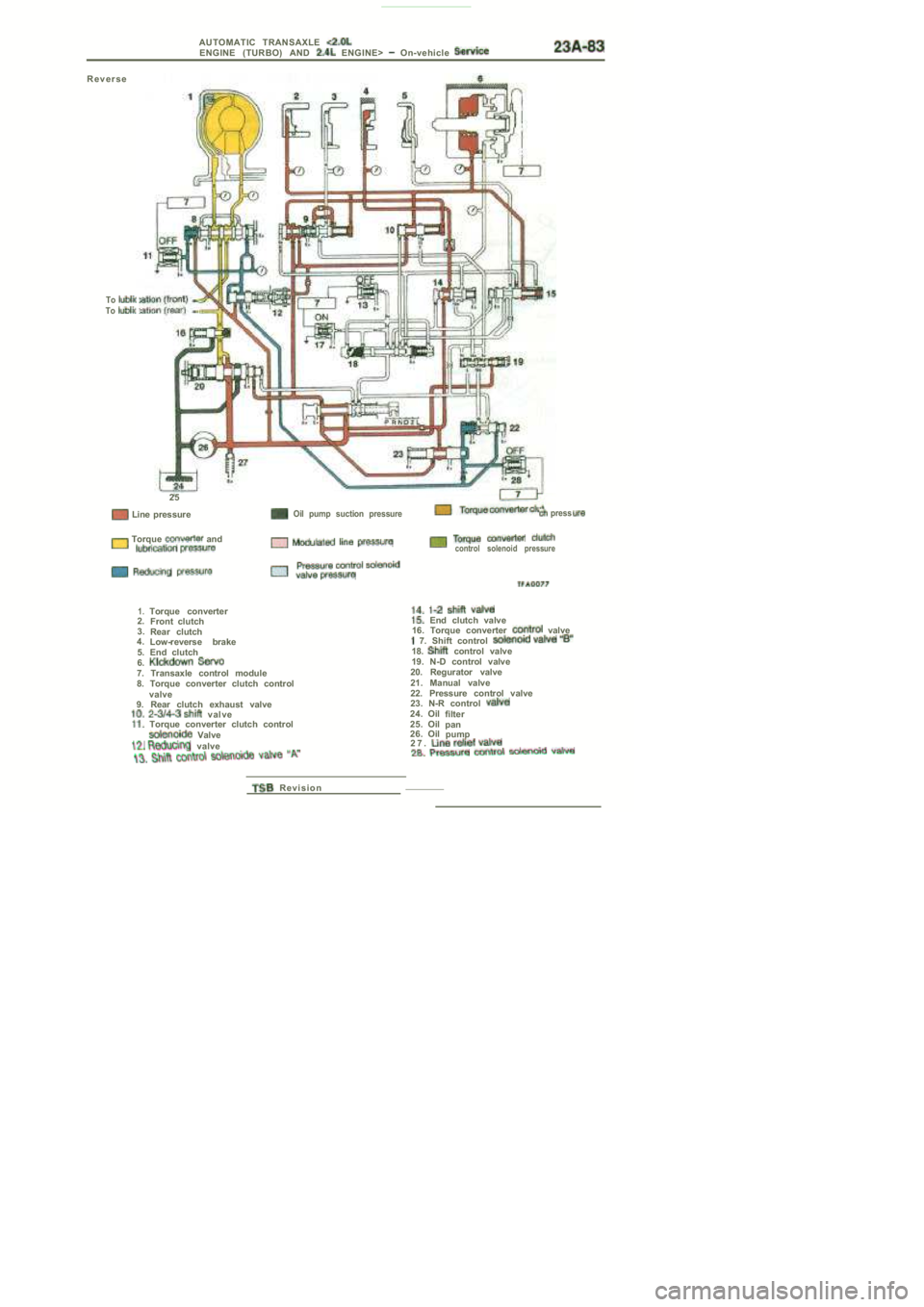

AUTOMATIC TRANSAXLE ENGINE (TURBO) AND ENGINE> On-vehicle

R e v e r s e

ToTo

25

Line pressure

Torque and

Oil pump suction pressure press

control solenoid pressure

1.Torque converter

2. Front clutch

3. Rear clutch

4. Low-reverse brake

5. End clutch

6.

7. Transaxle control module

8. Torque converter clutch control

valve

9. Rear clutch exhaust valve

v a l v e Torque converter clutch control Valve valve

R e v i s i o n

End clutch valve

16. Torque converter valve 7. Shift control 18. control valve

19. N-D control valve

20. Regurator valve

21. Manual valve

22. Pressure control valve

23. N-R control

24. Oil filter

25. Oil pan

26. Oil pump

2 7 .

Page 1092 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND On-vehicle Service

Lock nut

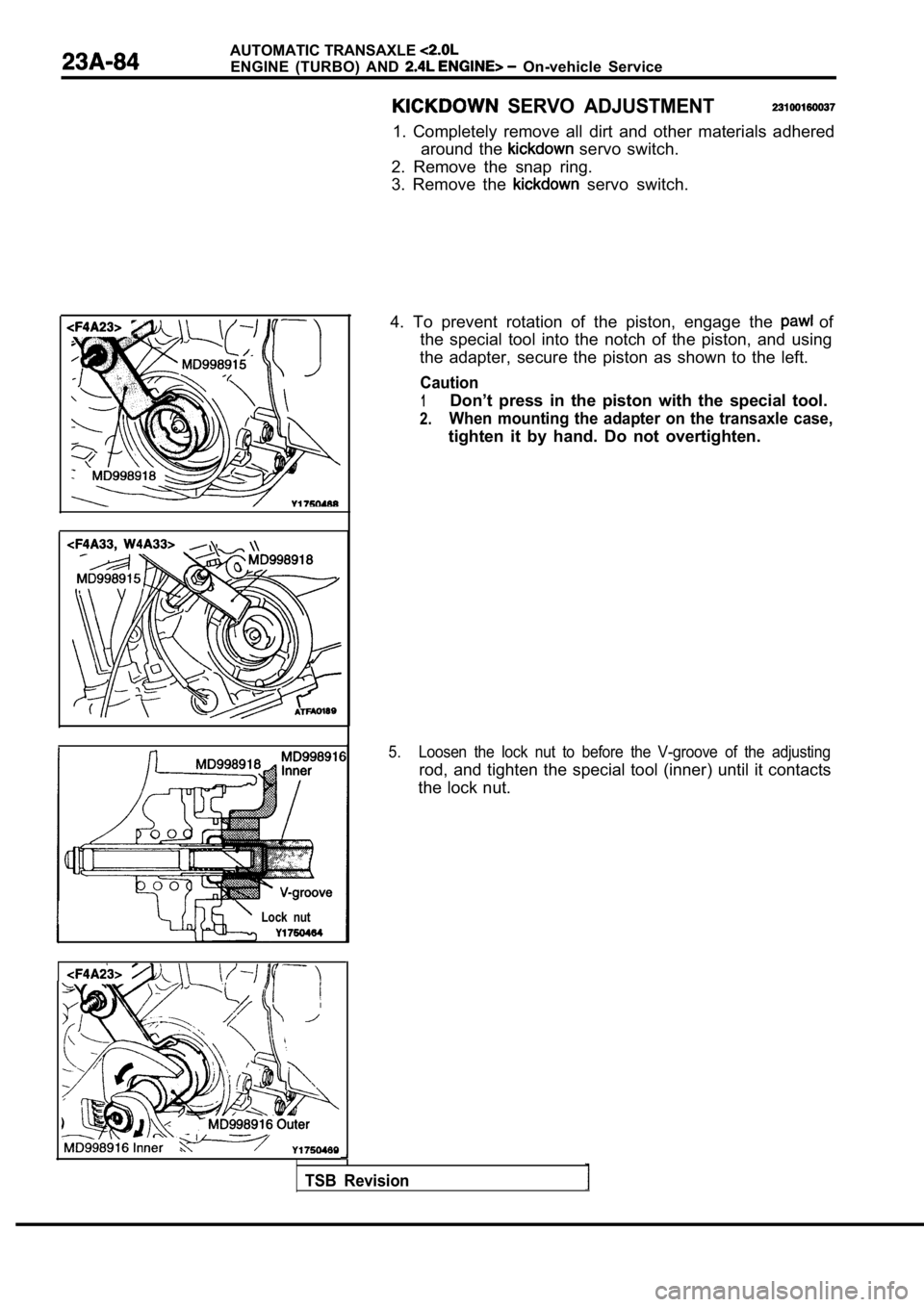

SERVO ADJUSTMENT

1. Completely remove all dirt and other materials adhered

around the

servo switch.

2. Remove the snap ring.

3. Remove the

servo switch.

4. To prevent rotation of the piston, engage the

of

the special tool into the notch of the piston, and using

the adapter, secure the piston as shown to the left .

Caution

1Don’t press in the piston with the special tool.

2.When mounting the adapter on the transaxle case,

tighten it by hand. Do not overtighten.

5. Loosen the lock nut to before the V-groove of the adjusting

rod, and tighten the special tool (inner) until it contacts

the lock nut.

TSB Revision

Page 1093 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> On-vehicle Service

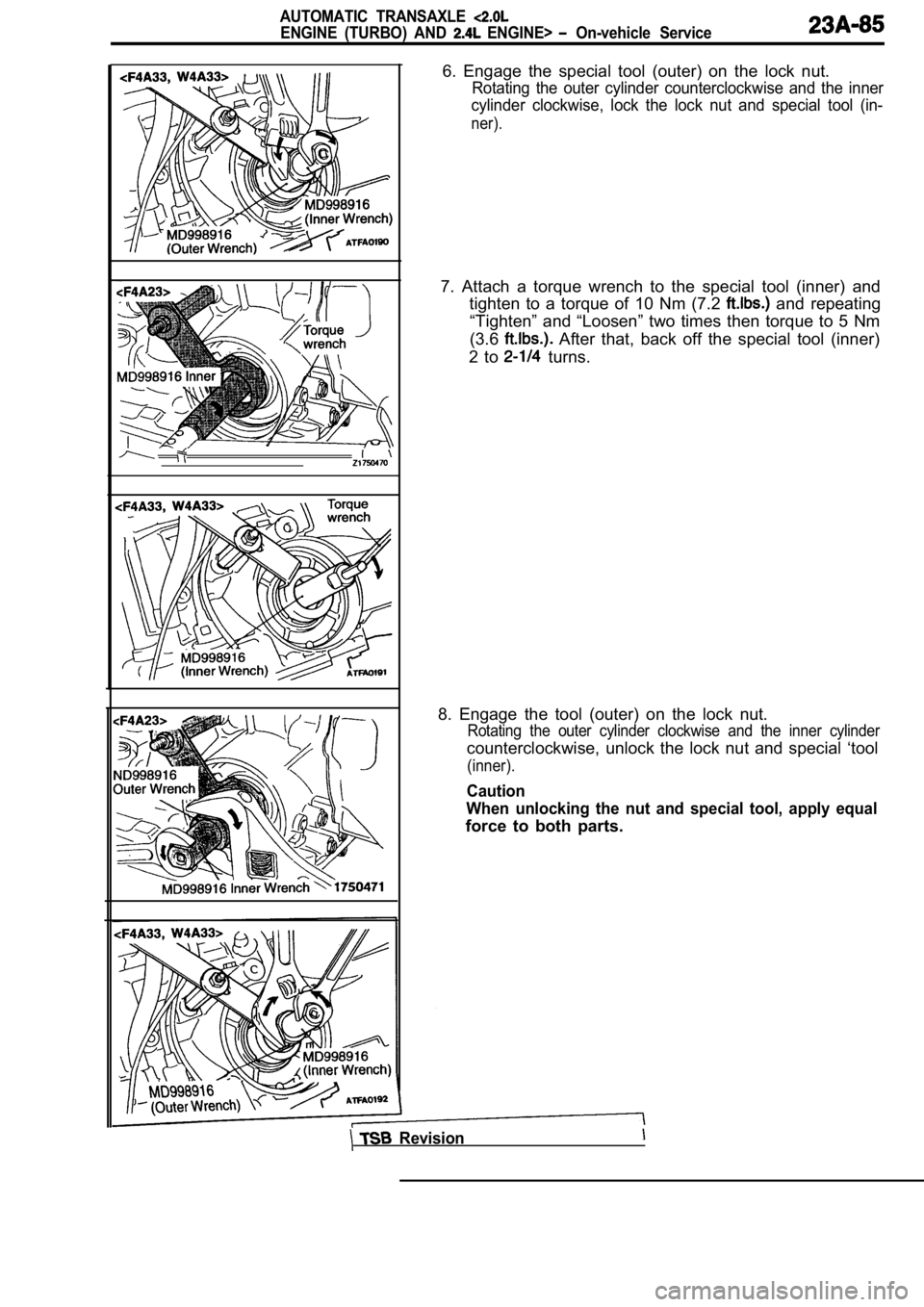

6. Engage the special tool (outer) on the lock nut.

Rotating the outer cylinder counterclockwise and the inner

cylinder clockwise, lock the lock nut and special t ool (in-

ner).

7. Attach a torque wrench to the special tool (inne r) and

tighten to a torque of 10 Nm (7.2

and repeating

“Tighten” and “Loosen” two times then torque to 5 N m

(3.6

After that, back off the special tool (inner)

2 to

turns.

8. Engage the tool (outer) on the lock nut.

Rotating the outer cylinder clockwise and the inner cylinder

counterclockwise, unlock the lock nut and special ‘tool

(inner).

Caution

When unlocking the nut and special tool, apply equa l

force to both parts.

Revision

Page 1094 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> On-vehicle Service

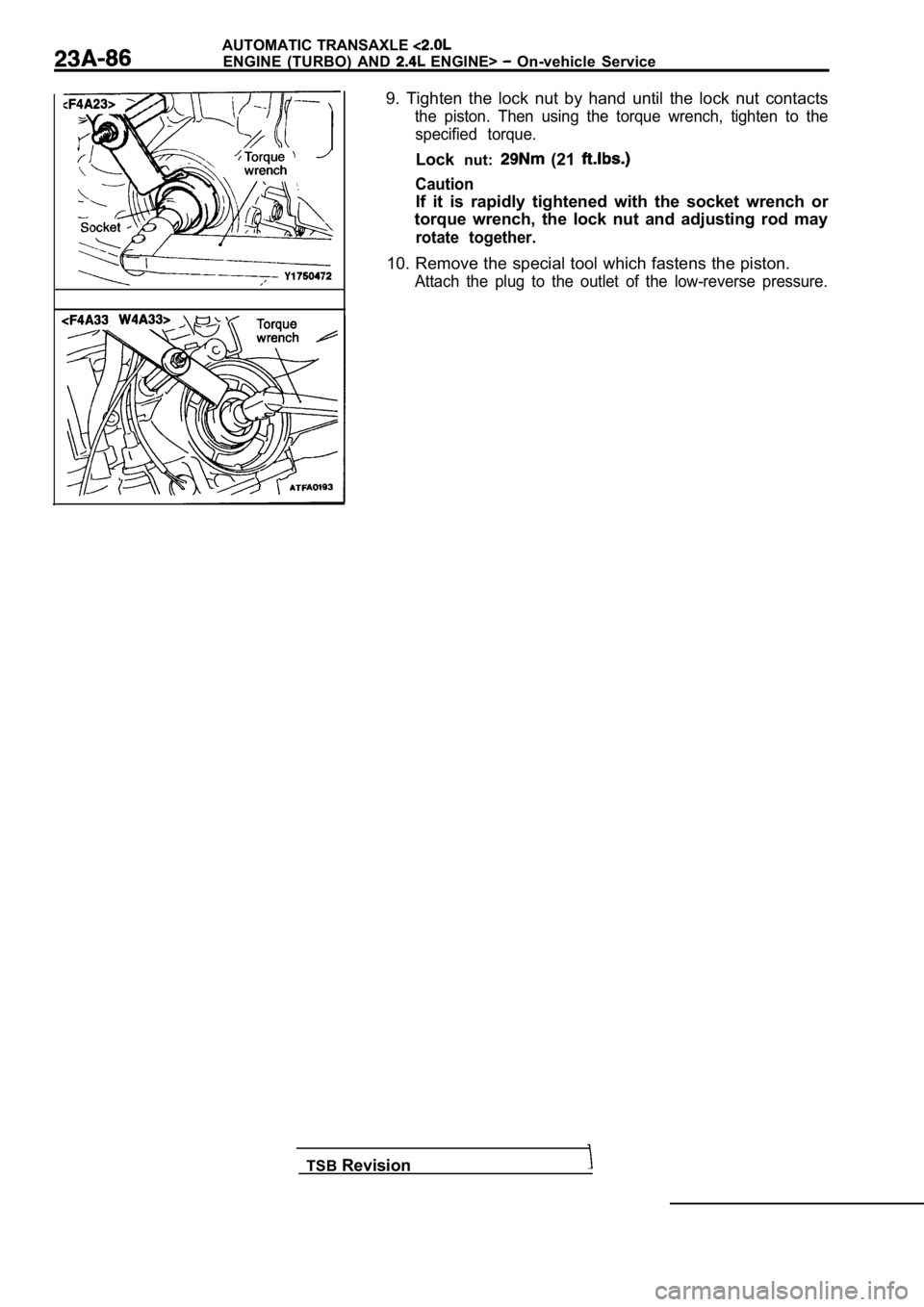

9. Tighten the lock nut by hand until the lock nut contacts

the piston. Then using the torque wrench, tighten t o the

specified torque.

Lock nut: (21

Caution

If it is rapidly tightened with the socket wrench o r

torque wrench, the lock nut and adjusting rod may

rotate together.

10. Remove the special tool which fastens the pisto n.

Attach the plug to the outlet of the low-reverse pressure.

TSBRevision

Page 1095 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> On-vehicle Service

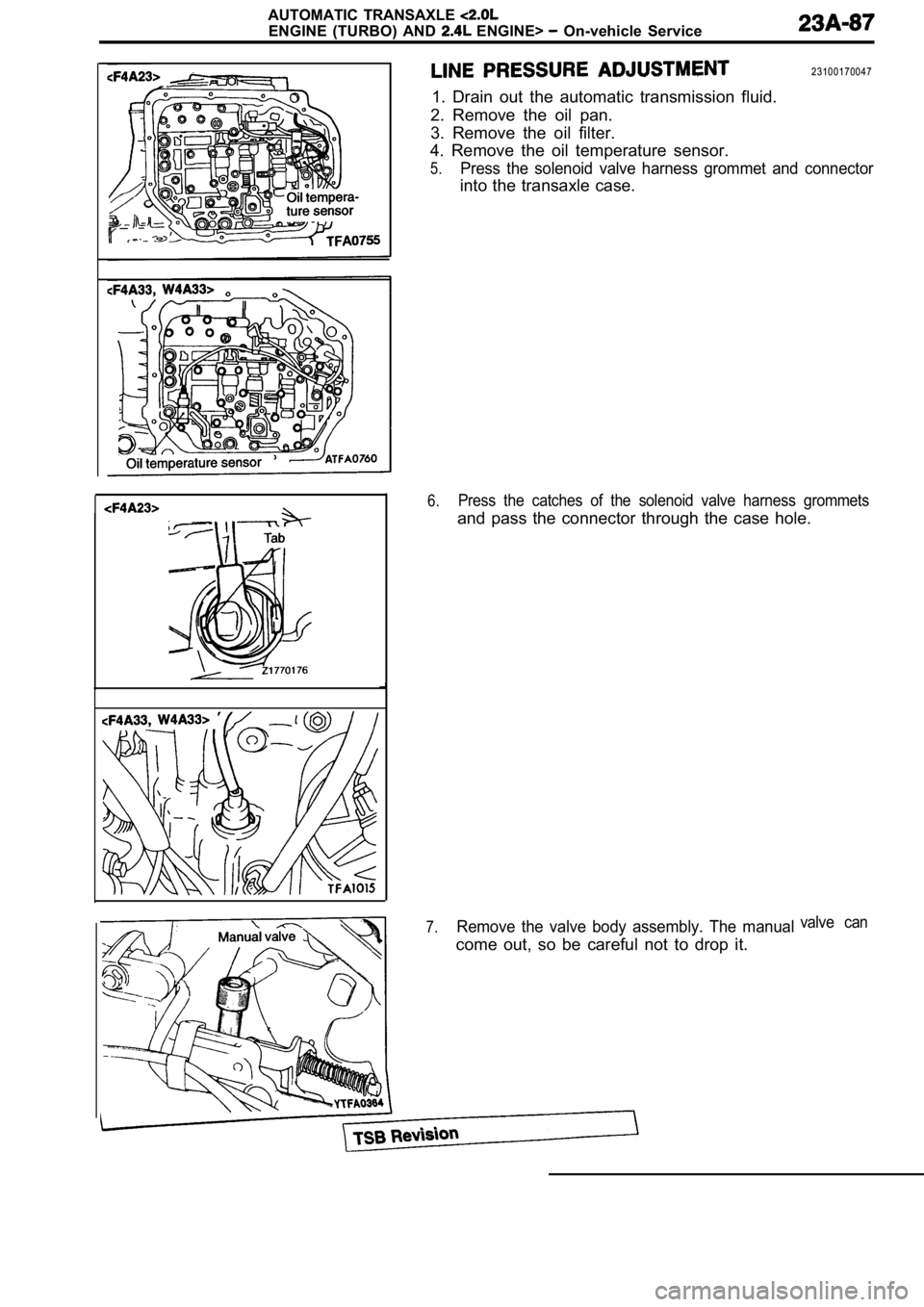

23100170047

1. Drain out the automatic transmission fluid.

2. Remove the oil pan.

3. Remove the oil filter.

4. Remove the oil temperature sensor.

5.Press the solenoid valve harness grommet and connec tor

into the transaxle case.

6.Press the catches of the solenoid valve harness grommets

and pass the connector through the case hole.

7.Remove the valve body assembly. The manual

come out, so be careful not to drop it.

valve can

Page 1096 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> On-vehicle Service

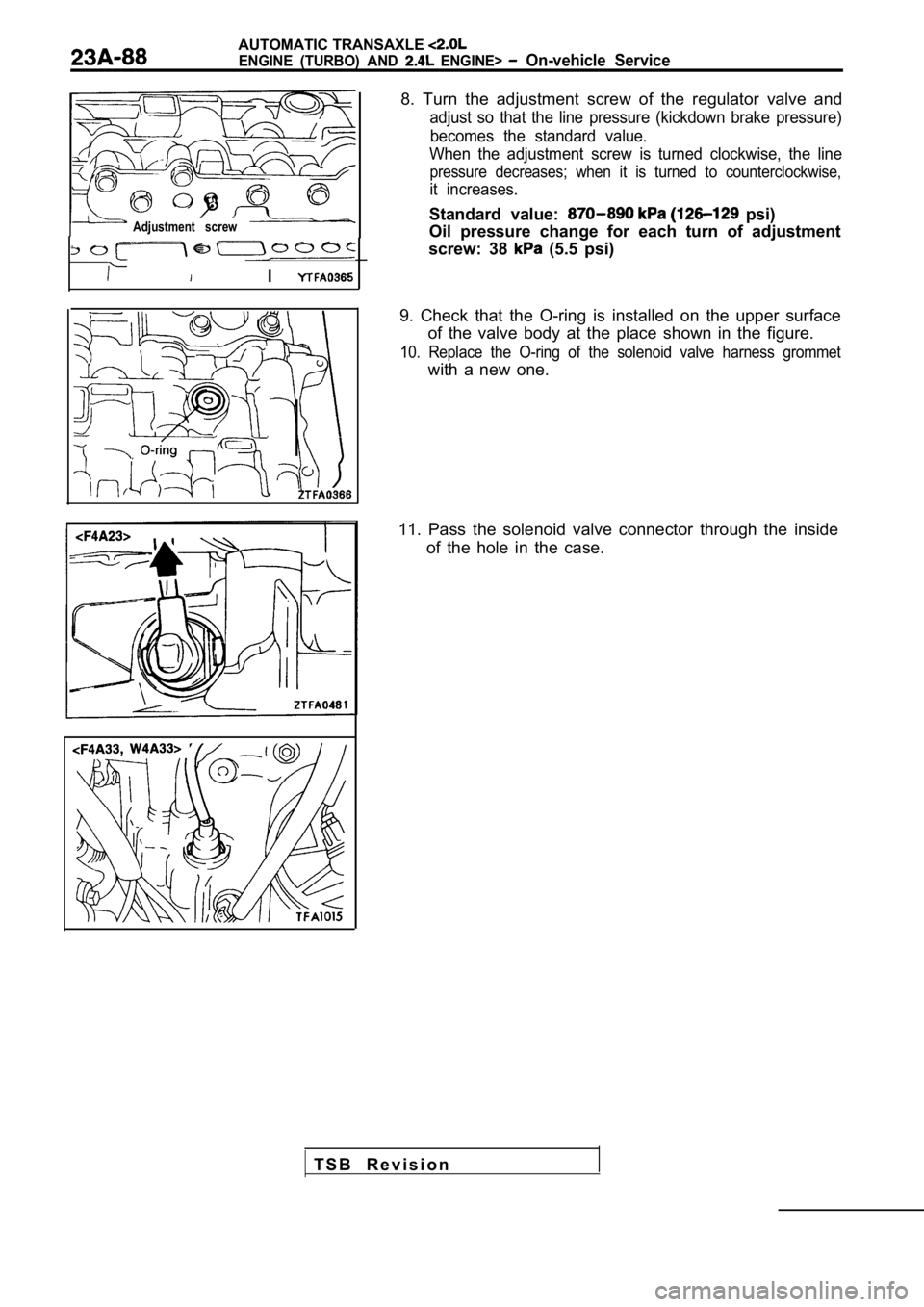

Adjustment screw

I

8. Turn the adjustment screw of the regulator valve and

adjust so that the line pressure (kickdown brake pressure)

becomes the standard value.

When the adjustment screw is turned clockwise, the line

pressure decreases; when it is turned to counterclockwise,

it increases.

Standard value: psi)

Oil pressure change for each turn of adjustment

screw: 38

(5.5 psi)

9. Check that the O-ring is installed on the upper surface

of the valve body at the place shown in the figure.

10. Replace the O-ring of the solenoid valve harnes s grommet

with a new one.

11. Pass the solenoid valve connector through the i nside

of the hole in the case.

T S B R e v i s i o n

Page 1097 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE>

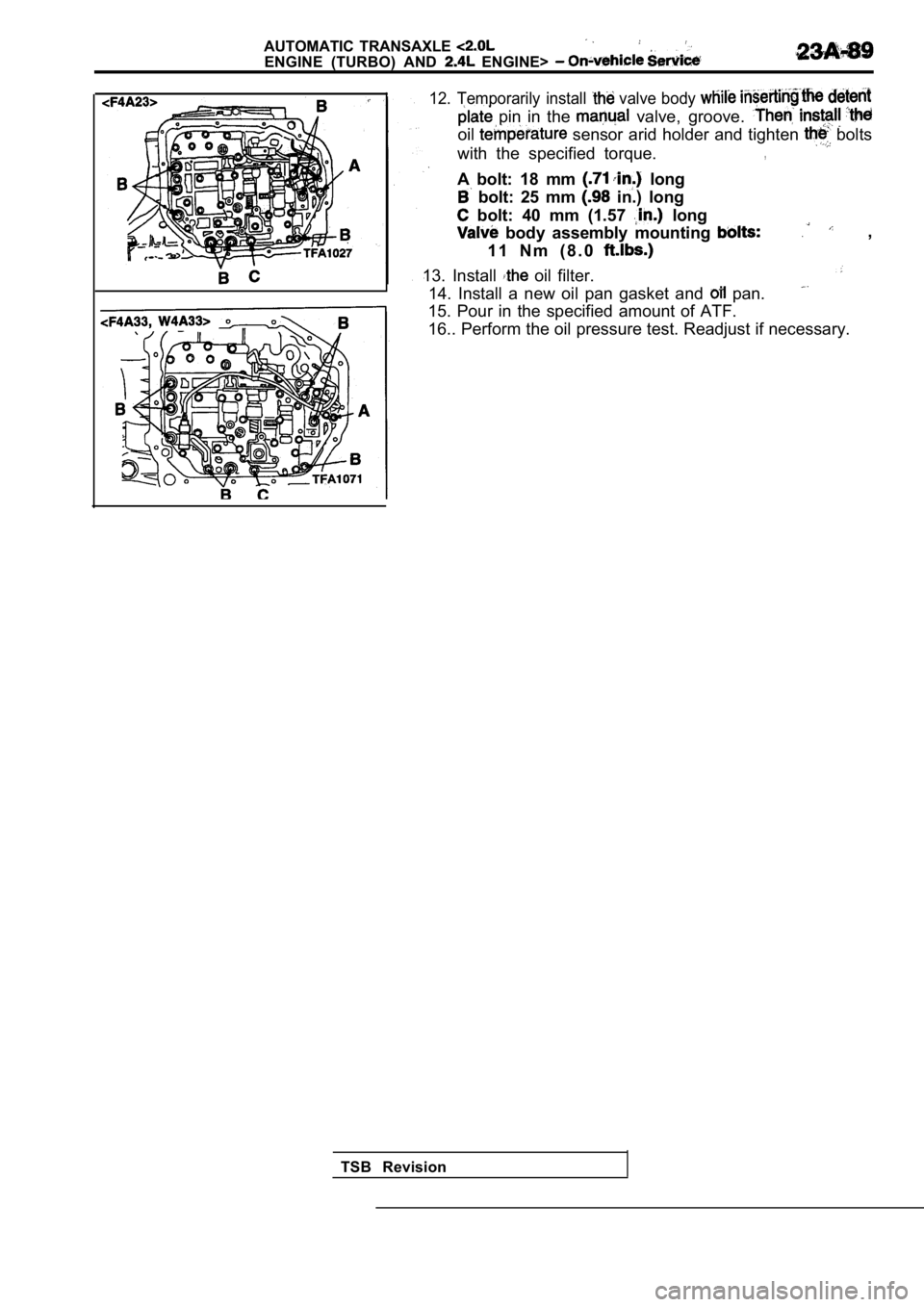

12. Temporarily install valve body

pin in the valve, groove.

oil sensor arid holder and tighten bolts

with the specified torque.,

A bolt: 18 mm long

bolt: 25 mm in.) long

bolt: 40 mm (1.57 long

body assembly mounting ,

1 1 N m ( 8 . 0

13. Install oil filter.

14. Install a new oil pan gasket and pan.

15. Pour in the specified amount of ATF.

16.. Perform the oil pressure test. Readjust if nec essary.

TSB Revision

Page 1098 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> On-vehicle

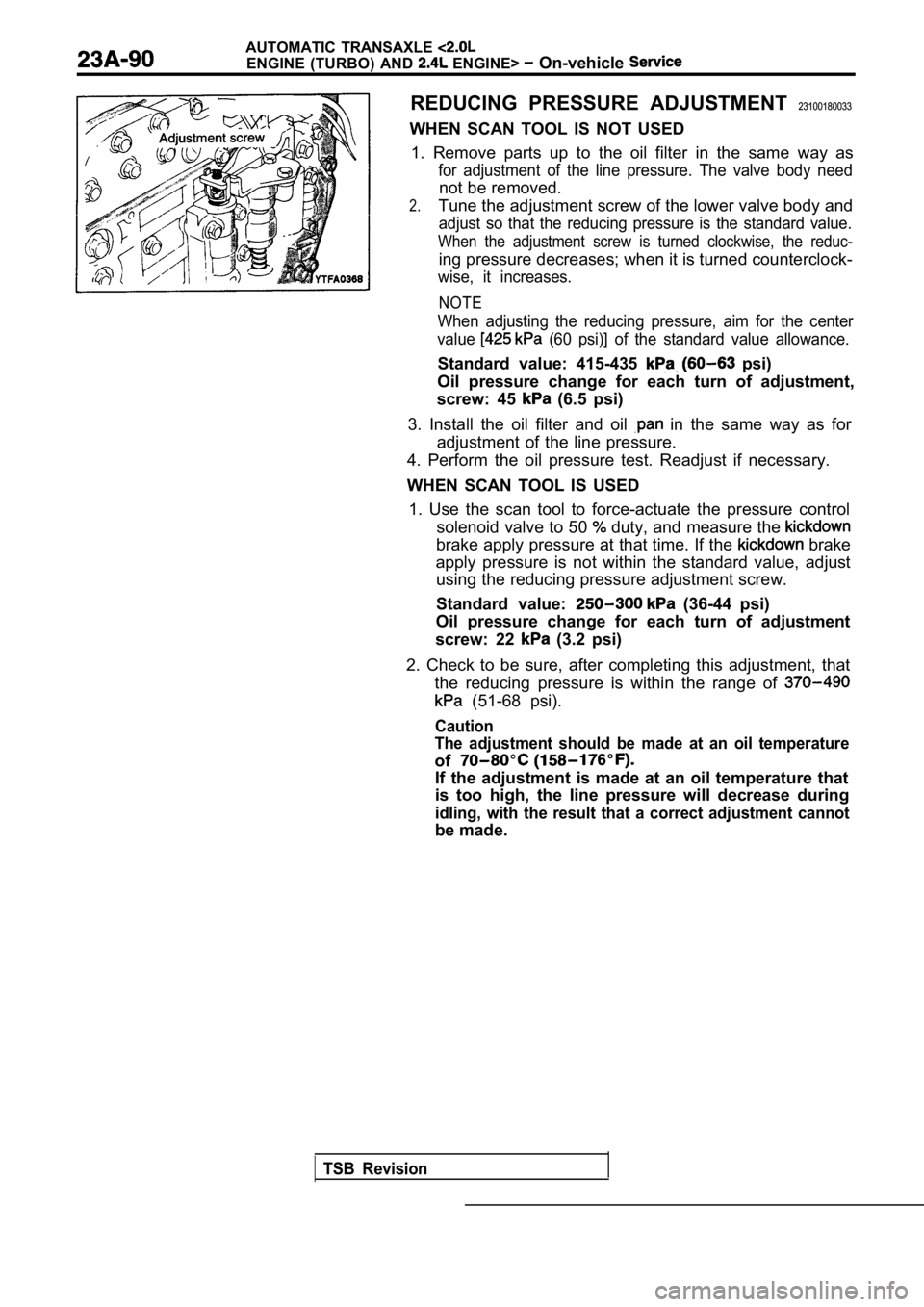

REDUCING PRESSURE ADJUSTMENT 23100180033

WHEN SCAN TOOL IS NOT USED 1. Remove parts up to the oil filter in the same wa y as

for adjustment of the line pressure. The valve body need

not be removed.

2.Tune the adjustment screw of the lower valve body a nd

adjust so that the reducing pressure is the standard value.

When the adjustment screw is turned clockwise, the reduc-

ing pressure decreases; when it is turned counterclock-

wise, it increases.

NOTE

When adjusting the reducing pressure, aim for the c enter

value

(60 psi)] of the standard value allowance.

Standard value: 415-435 psi)

Oil pressure change for each turn of adjustment,

screw: 45

(6.5 psi)

3. Install the oil filter and oil

in the same way as for

adjustment of the line pressure.

4. Perform the oil pressure test. Readjust if neces sary.

WHEN SCAN TOOL IS USED 1. Use the scan tool to force-actuate the pressure control

solenoid valve to 50

duty, and measure the

brake apply pressure at that time. If the brake

apply pressure is not within the standard value, ad just

using the reducing pressure adjustment screw.

Standard value:

(36-44 psi)

Oil pressure change for each turn of adjustment

screw: 22

(3.2 psi)

2. Check to be sure, after completing this adjustme nt, that

the reducing pressure is within the range of

(51-68 psi).

Caution

The adjustment should be made at an oil temperature

of

If the adjustment is made at an oil temperature tha t

is too high, the line pressure will decrease during

idling, with the result that a correct adjustment c annot

be made.

TSB Revision

Page 1099 of 2103

ENGINE (TURBO) AND ENGINE>

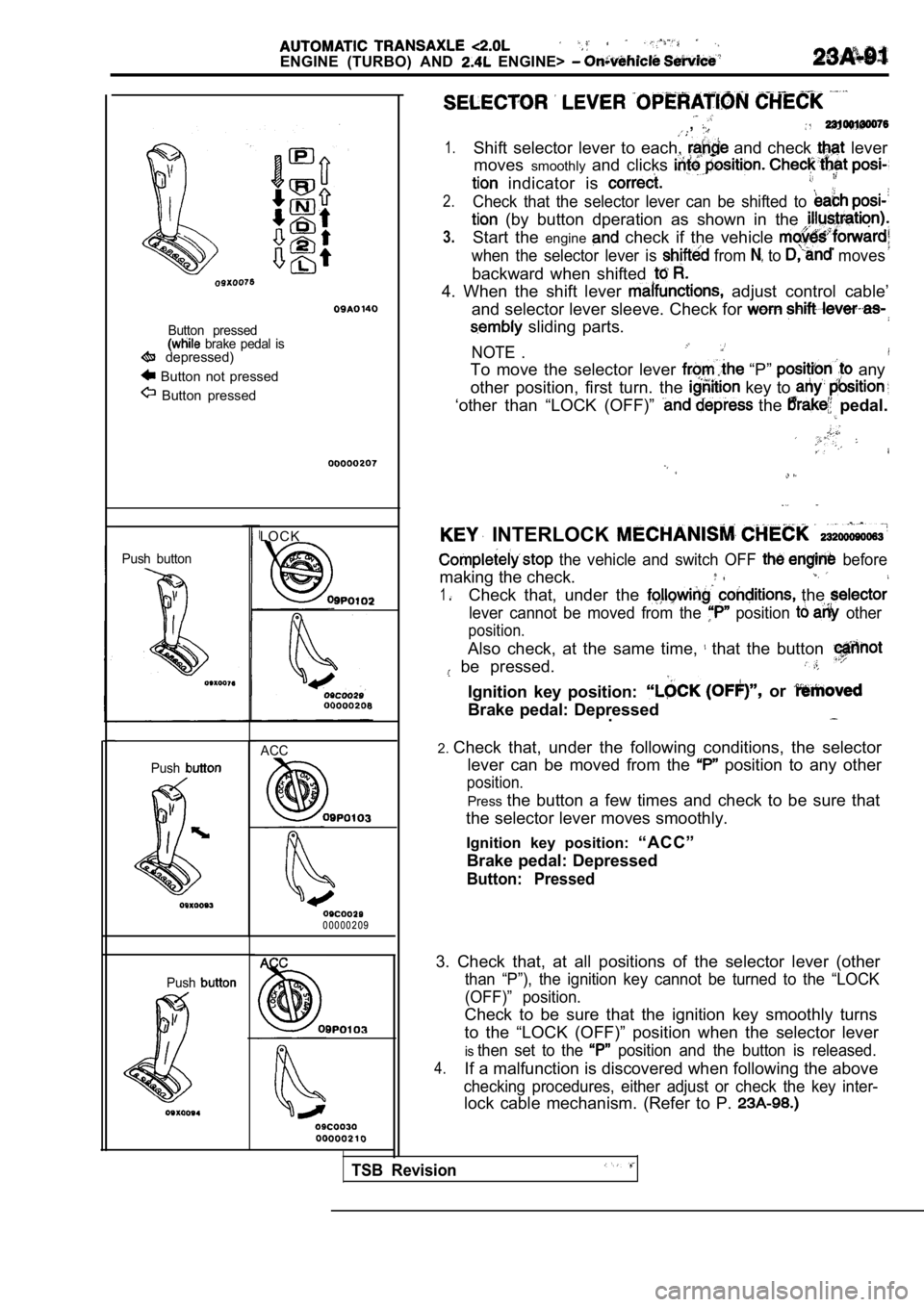

Button pressed brake pedal is depressed)

Button not pressed

Button pressed

Push buttonPush

Push

LOCK

ACC

0 0 0 0 0 2 0 9

,

1.Shift selector lever to each, and check lever

moves smoothly and clicks

indicator is

2.Check that the selector lever can be shifted to

(by button dperation as shown in the

3.Start the engine check if the vehicle

when the selector lever is from to moves

backward when shifted

4. When the shift lever adjust control cable’

and selector lever sleeve. Check for

sliding parts.

NOTE .

To move the selector lever “P” any

other position, first turn. the

key to

‘other than “LOCK (OFF)” the pedal.

. .

INTERLOCK

the vehicle and switch OFF before

making the check.

1Check that, under the the

lever cannot be moved from the position other

position.

Also check, at the same time, that the button

be pressed.

Ignition key position: or

Brake pedal: Depressed .

2.Check that, under the following conditions, the sel ector

lever can be moved from the

position to any other

position.

Press the button a few times and check to be sure that

the selector lever moves smoothly.

Ignition key position: “ACC”

Brake pedal: Depressed

Button: Pressed

TSB Revision

3. Check that, at all positions of the selector lev er (other

than “P”), the ignition key cannot be turned to the “LOCK

(OFF)” position.

Check to be sure that the ignition key smoothly tur ns

to the “LOCK (OFF)” position when the selector leve r

isthen set to the position and the button is released.

4.If a malfunction is discovered when following the above

checking procedures, either adjust or check the key inter-

lock cable mechanism. (Refer to P.

Page 1100 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> On-vehicle Service‘

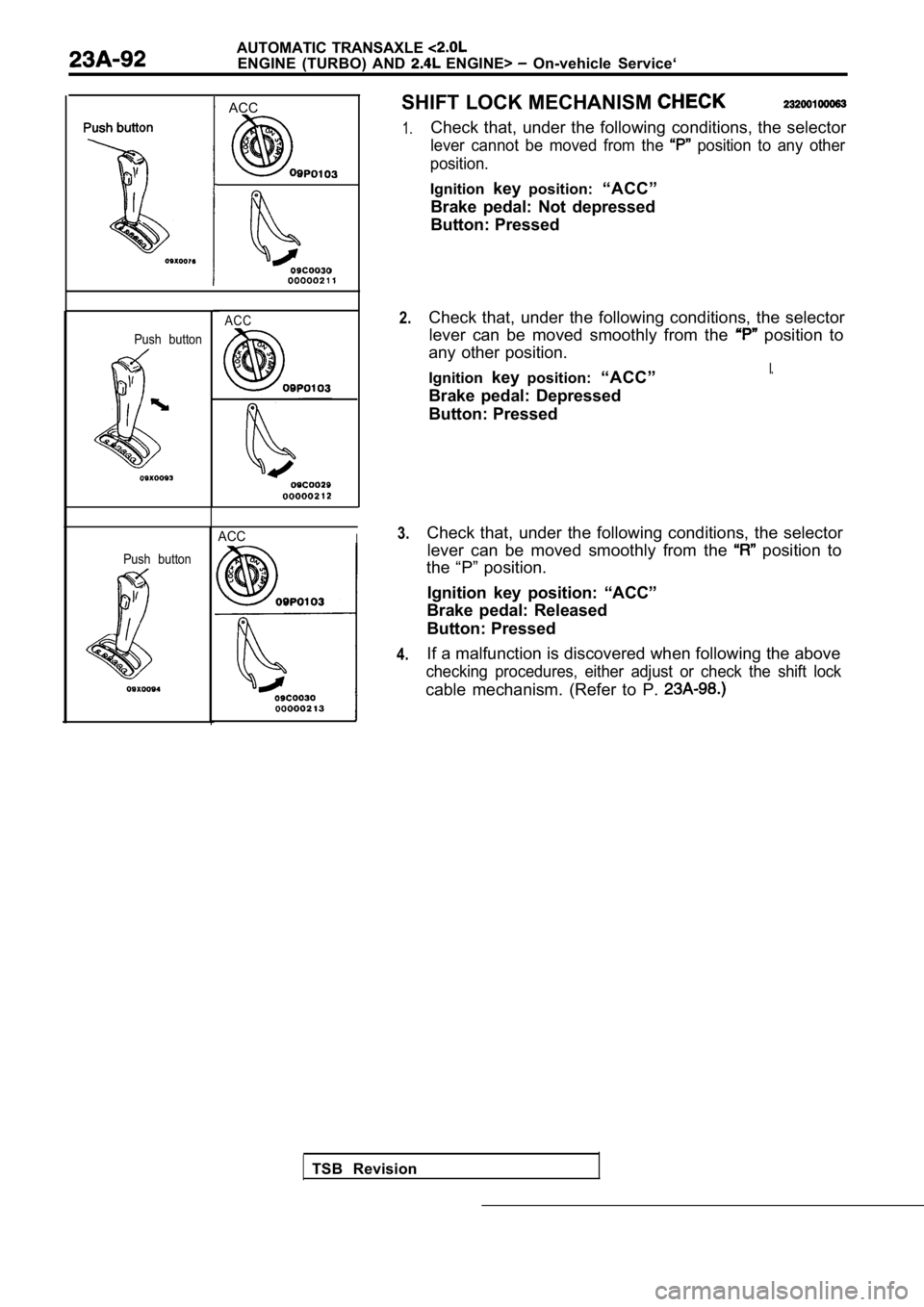

ACCSHIFT LOCK MECHANISM

1.

2.

3.

4.

Push button

Push button ACC

ACCI

TSB Revision Check that, under the following conditions, the sel

ector

lever cannot be moved from the position to any other

position.

Ignition keyposition: “ACC”

Brake pedal: Not depressed

Button: Pressed

Check that, under the following conditions, the sel ector

lever can be moved smoothly from the

position to

any other position.

Ignition keyposition: “ACC”

Brake pedal: Depressed

Button: Pressed

I.

Check that, under the following conditions, the sel ector

lever can be moved smoothly from the

position to

the “P” position.

Ignition key position: “ACC”

Brake pedal: Released

Button: Pressed

If a malfunction is discovered when following the a bove

checking procedures, either adjust or check the shi ft lock

cable mechanism. (Refer to P.