coolant temperature MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 812 of 2103

(Turbo) and Engine>

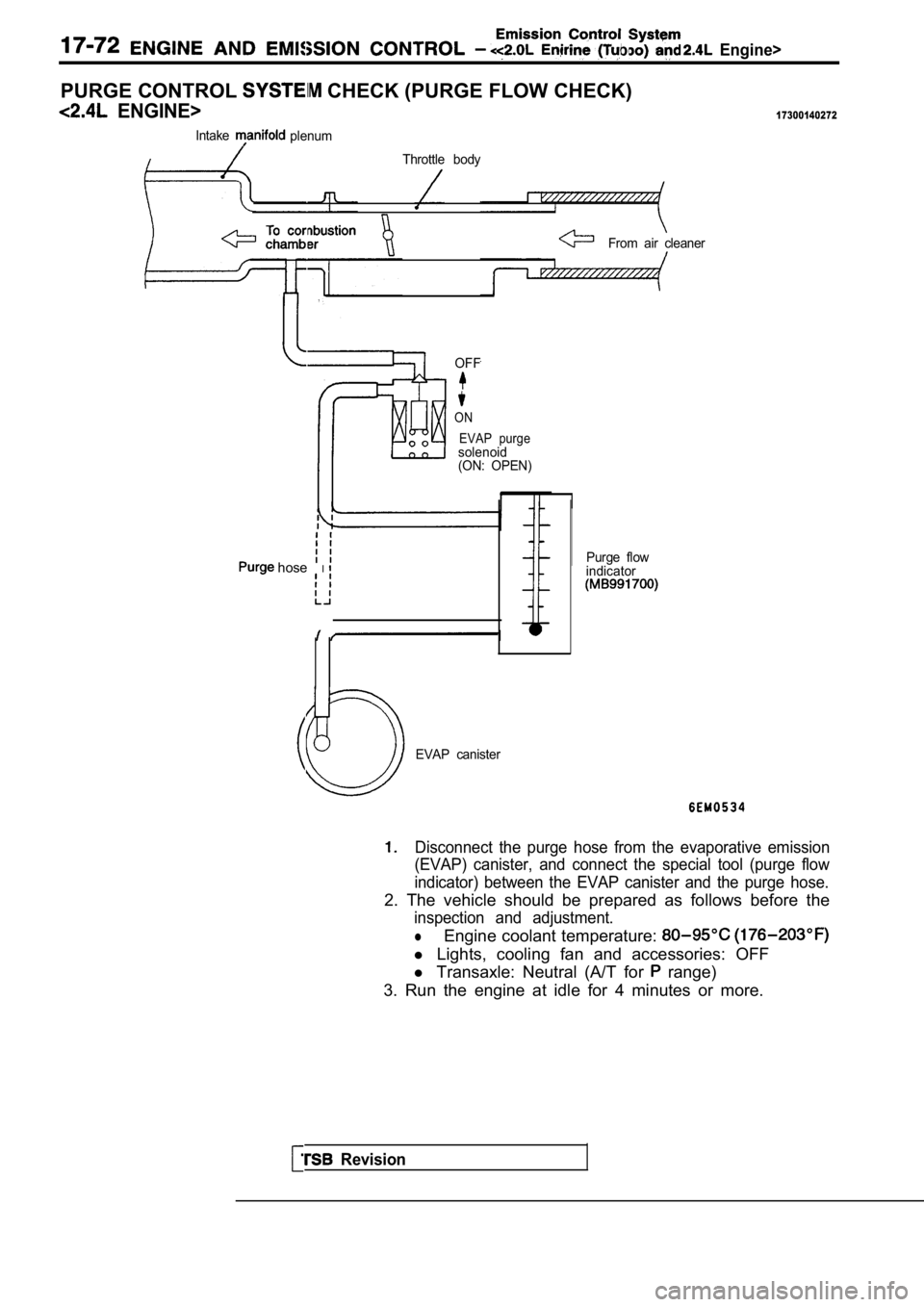

PURGE CONTROL CHECK (PURGE FLOW CHECK)

ENGINE>17300140272

IntakeplenumThrottle body

From air cleaner

OFF

ON EVAP purge

solenoid

(ON: OPEN)

hose IPurge flow

indicator

Revision

EVAP canister

Disconnect the purge hose from the evaporative emis sion

(EVAP) canister, and connect the special tool (purg e flow

indicator) between the EVAP canister and the purge hose.

2. The vehicle should be prepared as follows before the

inspection and adjustment.

lEngine coolant temperature:

l Lights, cooling fan and accessories: OFF

l Transaxle: Neutral (A/T for

range)

3. Run the engine at idle for 4 minutes or more.

Page 816 of 2103

AND C O N T R O L (Turbo) and Engine>

Valve

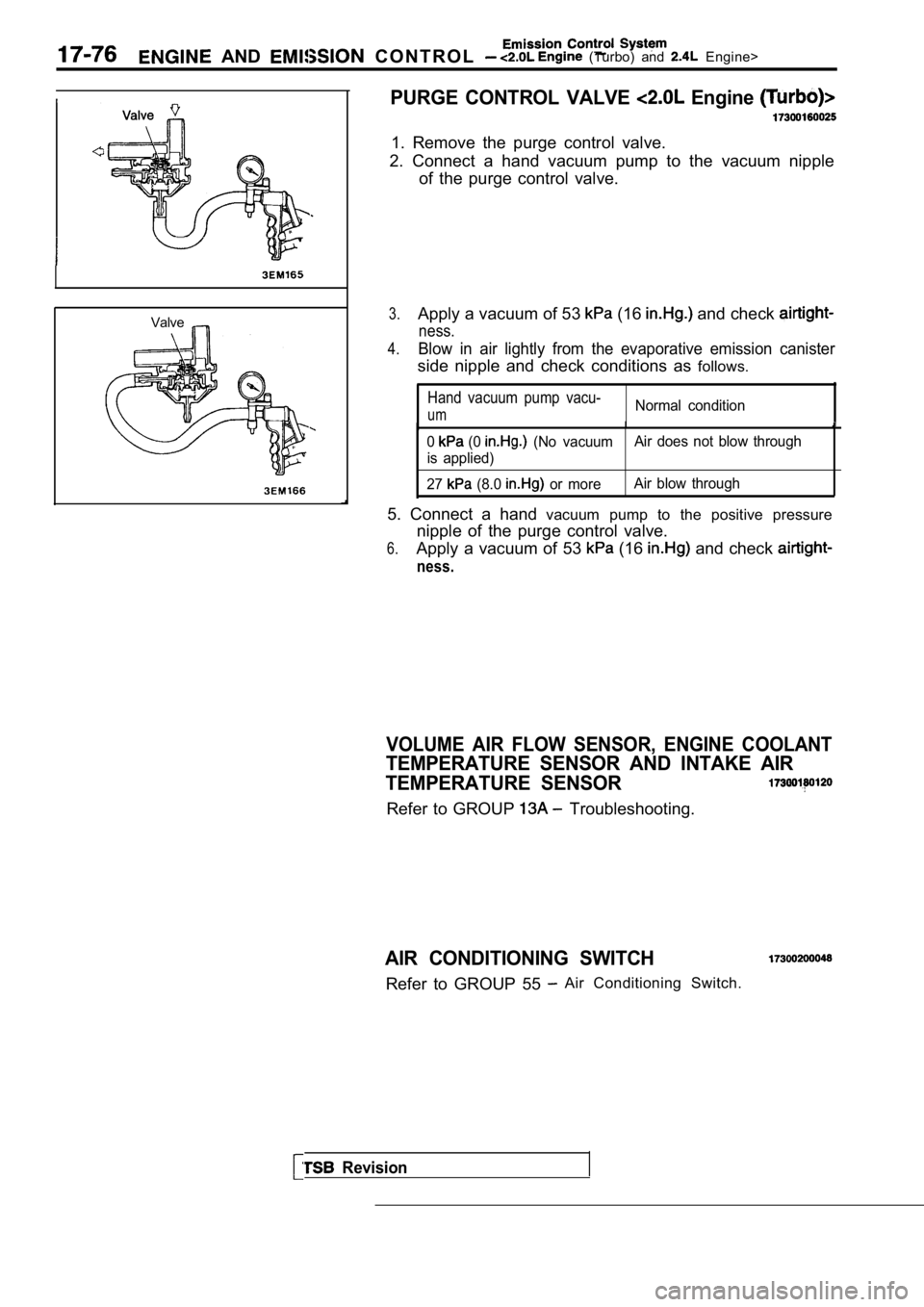

PURGE CONTROL VALVE Engine

1. Remove the purge control valve.

2. Connect a hand vacuum pump to the vacuum nipple of the purge control valve.

3.Apply a vacuum of 53 (16 and check

ness.

4.Blow in air lightly from the evaporative emission c anister

side nipple and check conditions as follows.

Hand vacuum pump vacu-

umNormal condition

0 (0 (No vacuumAir does not blow through

is applied)

27

(8.0 or more Air blow through

5. Connect a hand

vacuum pump to the positive pressure

nipple of the purge control valve.

6.Apply a vacuum of 53 (16 and check

ness.

Revision

VOLUME AIR FLOW SENSOR, ENGINE COOLANT

TEMPERATURE SENSOR AND INTAKE AIR

TEMPERATURE SENSOR

Refer to GROUP Troubleshooting.

AIR CONDITIONING SWITCH

Refer to GROUP 55 Air Conditioning Switch.

Page 820 of 2103

(Turbo) and Engine>

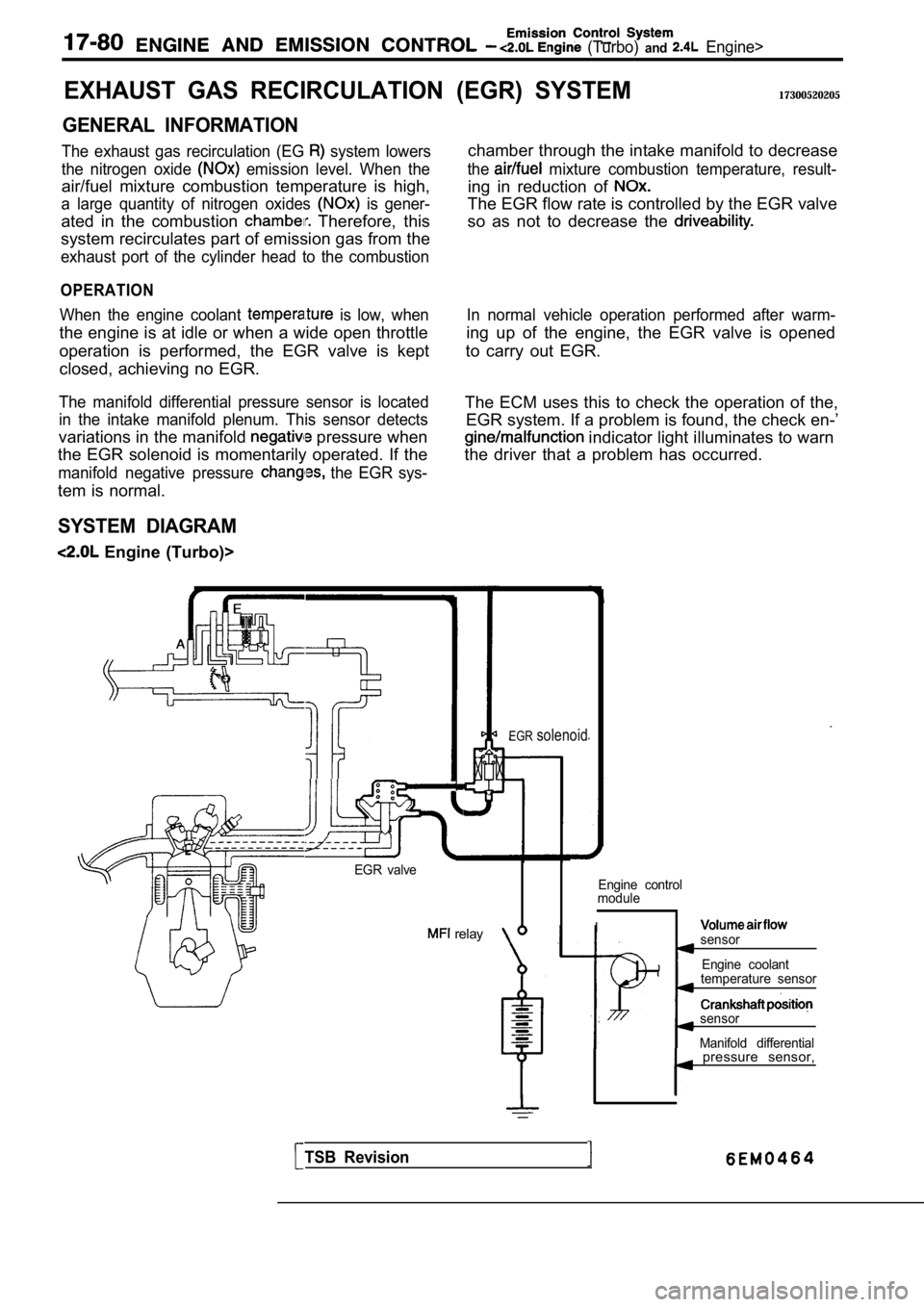

EXHAUST GAS RECIRCULATION

GENERAL INFORMATION

The exhaust gas recirculation (EG system lowers

the nitrogen oxide

emission level. When the

air/fuel mixture combustion temperature is high,

a large quantity of nitrogen oxides is gener-

ated in the combustion Therefore, this

system recirculates part of emission gas from the

exhaust port of the cylinder head to the combustion

OPERATION

When the engine coolant is low, when

the engine is at idle or when a wide open throttle

operation is performed, the EGR valve is kept

closed, achieving no EGR.

The manifold differential pressure sensor is locate d

in the intake manifold plenum. This sensor detects

variations in the manifold pressure when

the EGR solenoid is momentarily operated. If the

manifold negative pressure the EGR sys-

tem is normal.

SYSTEM DIAGRAM

Engine (Turbo)>

(EGR) SYSTEM17300520205

chamber through the intake manifold to decrease

the mixture combustion temperature, result-

ing in reduction of

The EGR flow rate is controlled by the EGR valve

so as not to decrease the

In normal vehicle operation performed after warm-

ing up of the engine, the EGR valve is opened

to carry out EGR.

The ECM uses this to check the operation of the, EGR system. If a problem is found, the check en-’

indicator light illuminates to warn

the driver that a problem has occurred.

EGR valve

relay

EGRsolenoid

Engine control

module

Isensor

Engine coolant

temperature sensor

sensor

Manifold differential

TSB Revision

pressure sensor,

Page 823 of 2103

Emission Control

ENGINE AND EMISSION CONTROL Engine

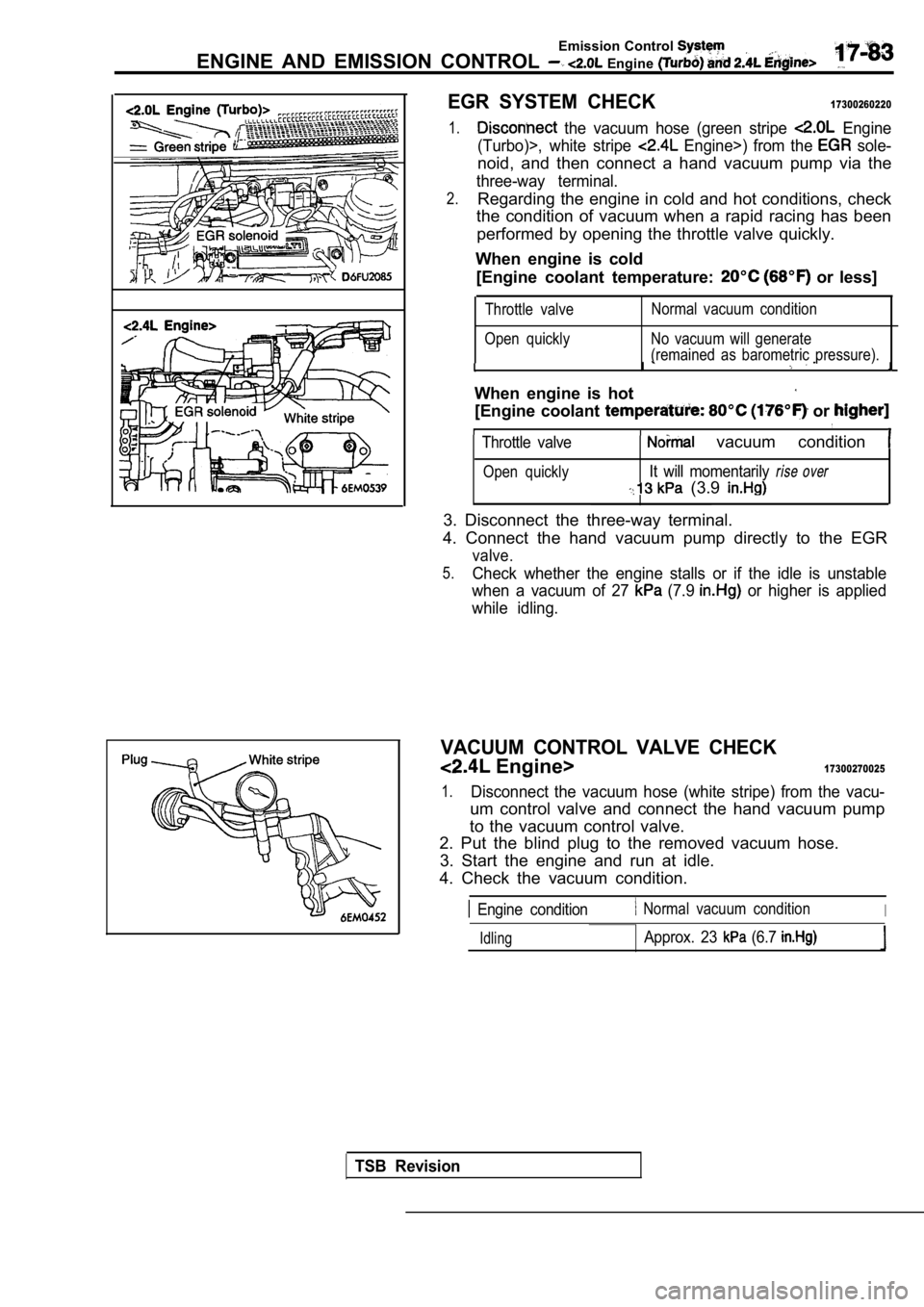

EGR SYSTEM CHECK17300260220

1. the vacuum hose (green stripe Engine

(Turbo)>, white stripe

Engine>) from the sole-

noid, and then connect a hand vacuum pump via the

three-way terminal.

2.Regarding the engine in cold and hot conditions, ch eck

the condition of vacuum when a rapid racing has bee n

performed by opening the throttle valve quickly.

When engine is cold [Engine coolant temperature:

or less]

Throttle valve

Open quickly Normal vacuum condition

No vacuum will generate

(remained as barometric pressure).

I

When engine is hot

[Engine coolant or

Throttle valve vacuum condition

Open quicklyIt will momentarily rise over

(3.9

3. Disconnect the three-way terminal.

4. Connect the hand vacuum pump directly to the EGR

valve.

5.Check whether the engine stalls or if the idle is u nstable

when a vacuum of 27

(7.9 or higher is applied

while idling.

VACUUM CONTROL VALVE CHECK

Engine>17300270025

1.Disconnect the vacuum hose (white stripe) from the vacu-

um control valve and connect the hand vacuum pump

to the vacuum control valve.

2. Put the blind plug to the removed vacuum hose.

3. Start the engine and run at idle.

4. Check the vacuum condition.

Engine condition Normal vacuum conditionI

IdlingApprox. 23 (6.7

TSB Revision

Page 1072 of 2103

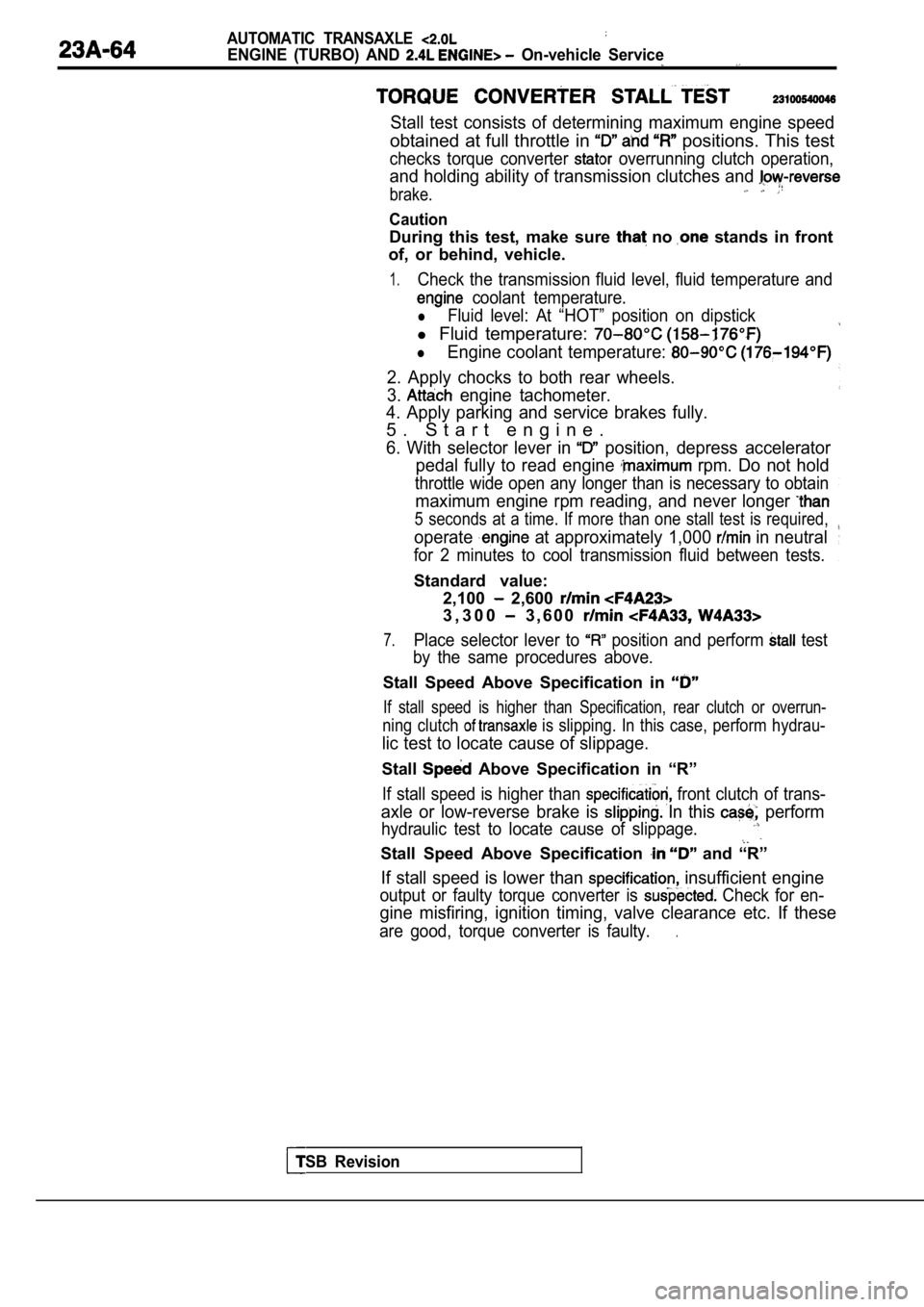

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND On-vehicle Service

Stall test consists of determining maximum engine speed

obtained at full throttle in positions. This test

checks torque converter overrunning clutch operation,

and holding ability of transmission clutches and

brake.

Caution

During this test, make sure no stands in front

of, or behind, vehicle.

1.Check the transmission fluid level, fluid temperatu re and

coolant temperature.

lFluid level: At “HOT” position on dipstick

l Fluid temperature:

lEngine coolant temperature:

2. Apply chocks to both rear wheels.

3.

engine tachometer.

4. Apply parking and service brakes fully.

5 . S t a r t e n g i n e .

6. With selector lever in position, depress accelerator

pedal fully to read engine

rpm. Do not hold

throttle wide open any longer than is necessary to obtain

maximum engine rpm reading, and never longer

5 seconds at a time. If more than one stall test is required,

operate at approximately 1,000 in neutral

for 2 minutes to cool transmission fluid between te sts.

Standard value:

TSB Revision

2,100 2,600

3 , 3 0 0 3 , 6 0 0

7.Place selector lever to position and perform test

by the same procedures above.

Stall Speed Above Specification in

If stall speed is higher than Specification, rear c lutch or overrun-

ning clutch is slipping. In this case, perform hydrau-

lic test to locate cause of slippage.

Stall Above Specification in “R”

If stall speed is higher than front clutch of trans-

axle or low-reverse brake is In this perform

hydraulic test to locate cause of slippage.

Stall Speed Above Specification and “R”

If stall speed is lower than insufficient engine

output or faulty torque converter is Check for en-

gine misfiring, ignition timing, valve clearance etc. If these

are good, torque converter is faulty..

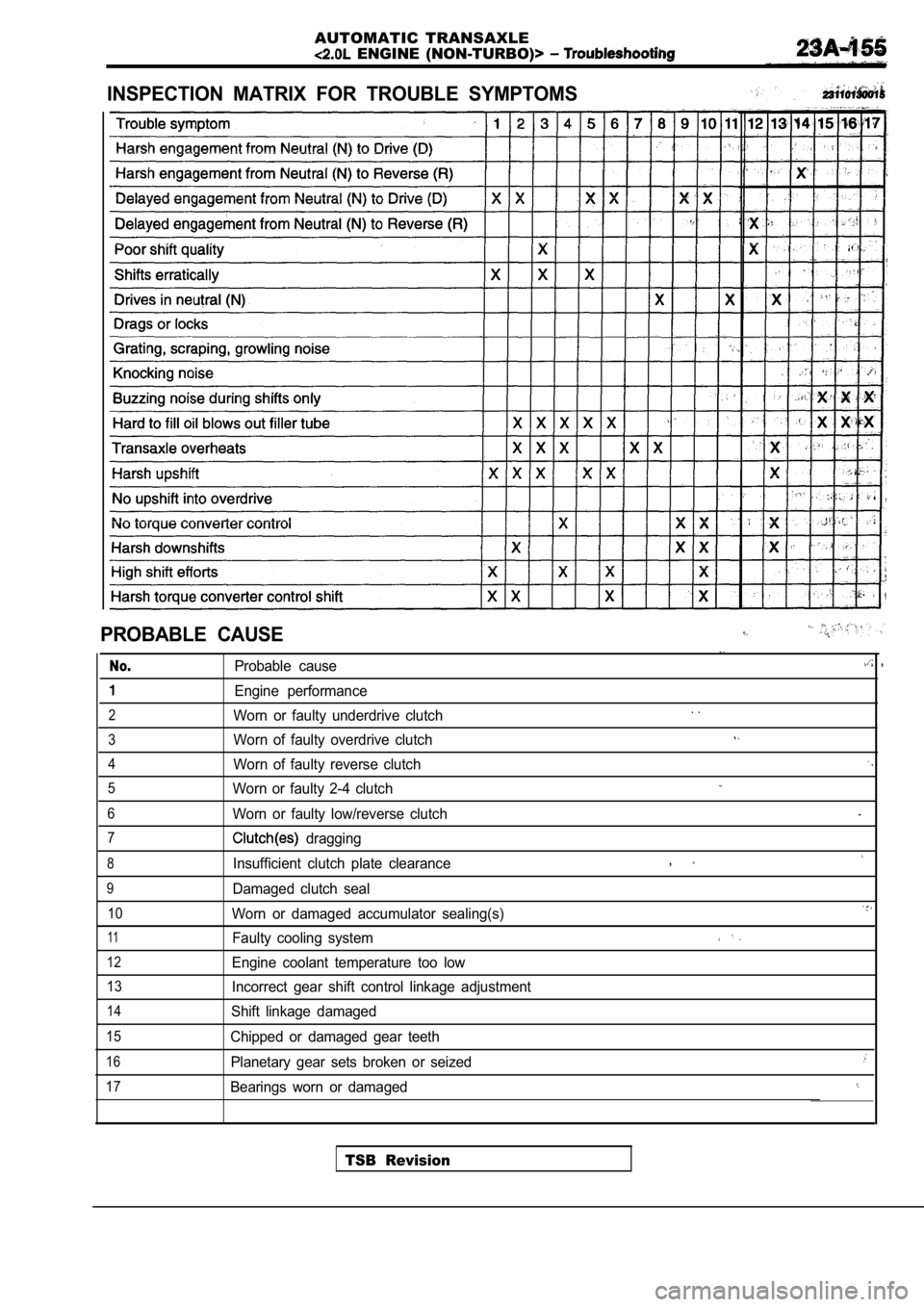

Page 1163 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)>

INSPECTION MATRIX FOR TROUBLE SYMPTOMS

PROBABLE CAUSE

No.Probable cause

Engine performance

2Worn or faulty underdrive clutch

3Worn of faulty overdrive clutch

4Worn of faulty reverse clutch

5Worn or faulty 2-4 clutch

6Worn or faulty low/reverse clutch

7 dragging

8Insufficient clutch plate clearance

9Damaged clutch seal

10Worn or damaged accumulator sealing(s)

11Faulty cooling system

12Engine coolant temperature too low

13Incorrect gear shift control linkage adjustment

14Shift linkage damaged

15Chipped or damaged gear teeth

16Planetary gear sets broken or seized

17Bearings worn or damaged

,

. .

,

TSB Revision

Page 1171 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)>: On-vehicle _ _

AUTOMATIC

COMPONENT CHECK

SPEED SENSOR

(1) Disconnect the input speed sensor connector.

(2) Measure the resistance

the input speed

side connector terminals 1 and 2.

Standard value:,

(3) If the resistance is outside the standard value , replace

the input speed sensor.

OUTPUT SPEED SENSOR CHECK

(1) Disconnect the output speed sensor connector.

(2) Measure the resistance between the input speed

side connector terminals 1 2.

Standard value:

(3) If the resistance is outside the standard value , replace

the output speed sensor.

TRANSAXLE RANGE SENSOR CONTINUITY CHECK

Refer to

OVERDRIVE SWITCH CONTINUITY CHECK

Refer to

POSITION SENSOR (TPS) CHECK

Refer to GROUP On-vehicle Inspection of Compo-

nents.

ENGINE COOLANT TEMPERATURE SENSOR CHECK

.

Refer to GROUP On-vehicle Inspection of

nents.

CRANKSHAFT CHECK

Refer to GROUP Troubleshooting.

ABSOLUTE PRESSURE SENSOR

Refer to On-vehicle Inspection of

nents.

Revision

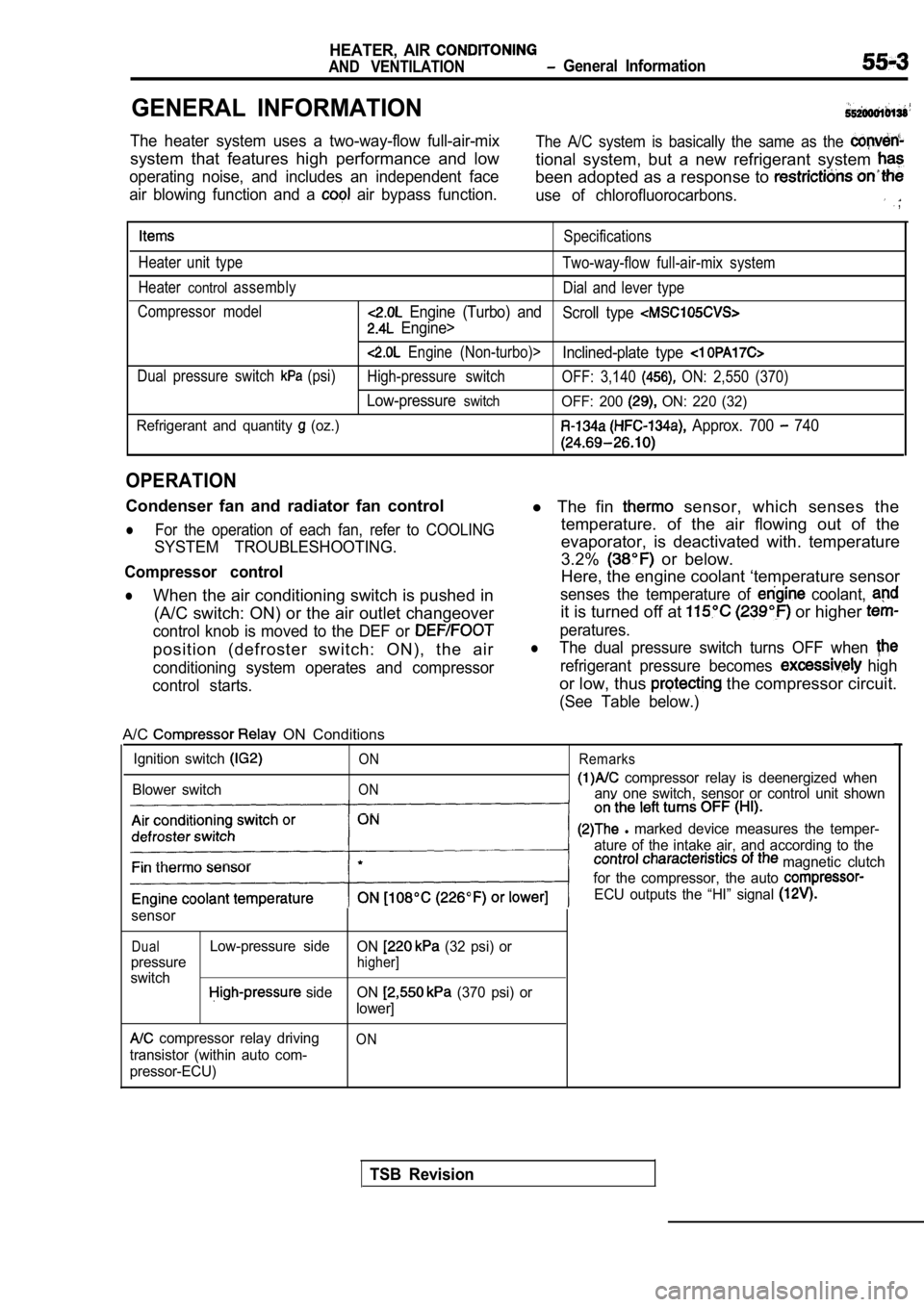

Page 2043 of 2103

HEATER, AIR

AND VENTILATION General Information

GENERAL INFORMATION

The heater system uses a two-way-flow full-air-mixThe A/C system is basically the same as the

system that features high performance and lowtional system, but a new refrigerant system

operating noise, and includes an independent facebeen adopted as a response to

air blowing function and a air bypass function.use of chlorofluorocarbons. ,

Specifications

Heater unit type Two-way-flow full-air-mix system

Heater

controlassembly Dial and lever type

Compressor model

Engine (Turbo) and Scroll type

Engine>

Engine (Non-turbo)>Inclined-plate type

Dual pressure switch (psi)High-pressure switch OFF: 3,140 ON: 2,550 (370)

Low-pressureswitchOFF: 200 ON: 220 (32)

Refrigerant and quantity

(oz.) Approx. 700 740

OPERATION

Condenser fan and radiator fan control

lFor the operation of each fan, refer to COOLING

SYSTEM TROUBLESHOOTING.

Compressor control

lWhen the air conditioning switch is pushed in (A/C switch: ON) or the air outlet changeover

control knob is moved to the DEF or

position (defroster switch: ON), the air

conditioning system operates and compressor

control starts.

l The fin sensor, which senses the

temperature. of the air flowing out of the

evaporator, is deactivated with. temperature

3.2%

or below.

Here, the engine coolant ‘temperature sensor

senses the temperature of coolant,

it is turned off at or higher

peratures.

lThe dual pressure switch turns OFF when

refrigerant pressure becomes high

or low, thus the compressor circuit.

(See Table below.)

A/C ON Conditions

Ignition switch

Blower switch

ON

ON Remarks

compressor relay is deenergized when

anv one switch, sensor or control unit shown

l marked device measures the temper-

ature of the intake air, and according to the

magnetic clutch

for the compressor, the auto

ECU outputs the “HI” signal

sensor

DualLow-pressure side ON (32 psi) or

pressure

higher]

switch side ON (370 psi) or

lower]

compressor relay driving

transistor (within auto com-

pressor-ECU)ON

TSB Revision

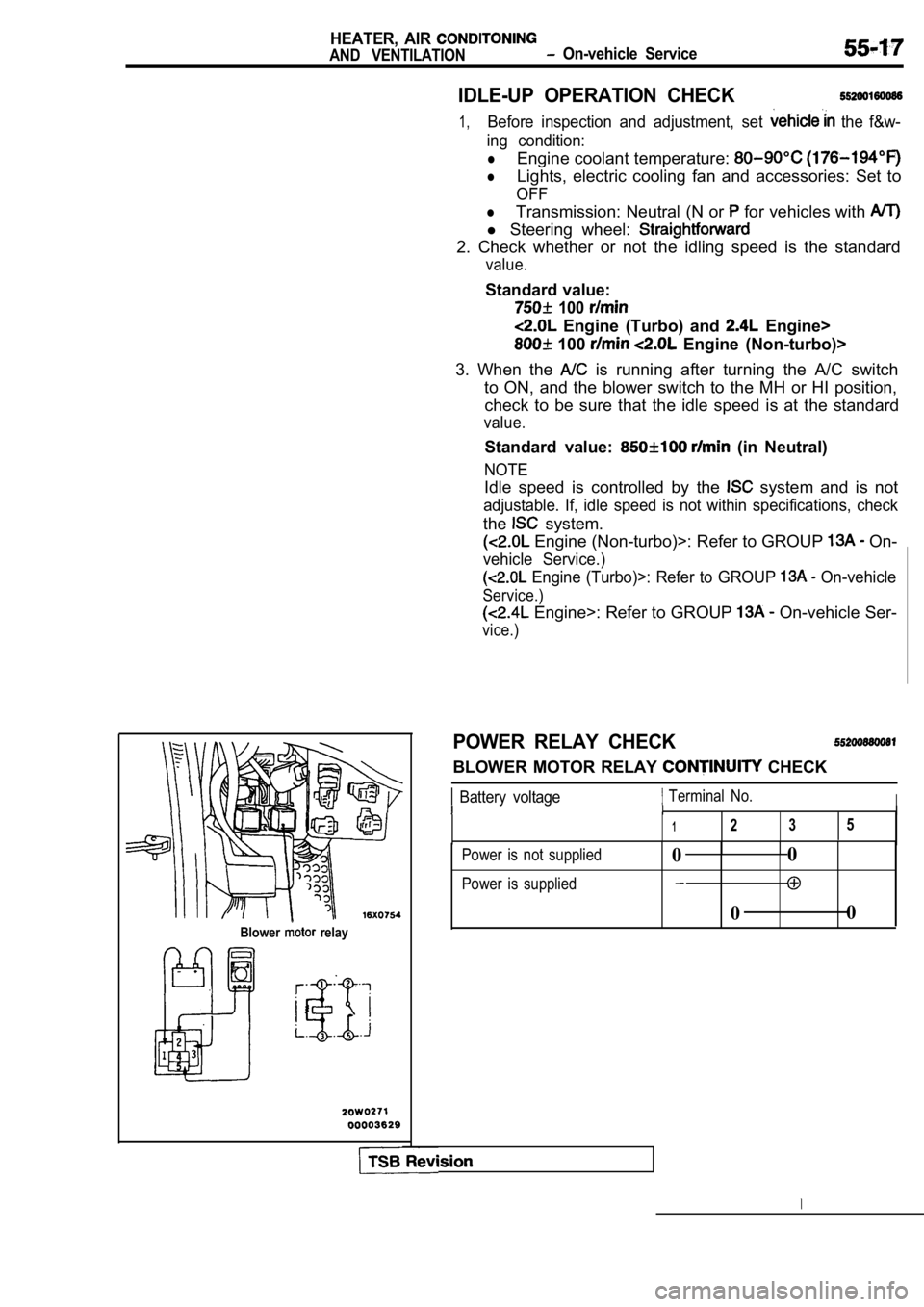

Page 2057 of 2103

HEATER, AIR

AND VENTILATION On-vehicle Service

IDLE-UP OPERATION CHECK

1,Before inspection and adjustment, set the f&w-

ing condition:

lEngine coolant temperature:

lLights, electric cooling fan and accessories: Set t o

OFF

lTransmission: Neutral (N or for vehicles with

l Steering wheel:

2. Check whether or not the idling speed is the sta ndard

value.

Blower relay

Standard value:

100

Engine (Turbo) and Engine>

100 Engine (Non-turbo)>

3. When the

is running after turning the A/C switch

to ON, and the blower switch to the MH or HI positi on,

check to be sure that the idle speed is at the stan dard

value.

Standard value: (in Neutral)

NOTE

Idle speed is controlled by the system and is not

adjustable. If, idle speed is not within specifications, check

the system.

Engine (Non-turbo)>: Refer to GROUP On-

vehicle Service.)

Engine (Turbo)>: Refer to GROUP On-vehicle

Service.)

Engine>: Refer to GROUP On-vehicle Ser-

vice.)

POWER RELAY CHECK

BLOWER MOTOR RELAY CHECK

Battery voltage Terminal No.III

1235

Power is not supplied

Power is supplied0 0

0 0

Page 2096 of 2103

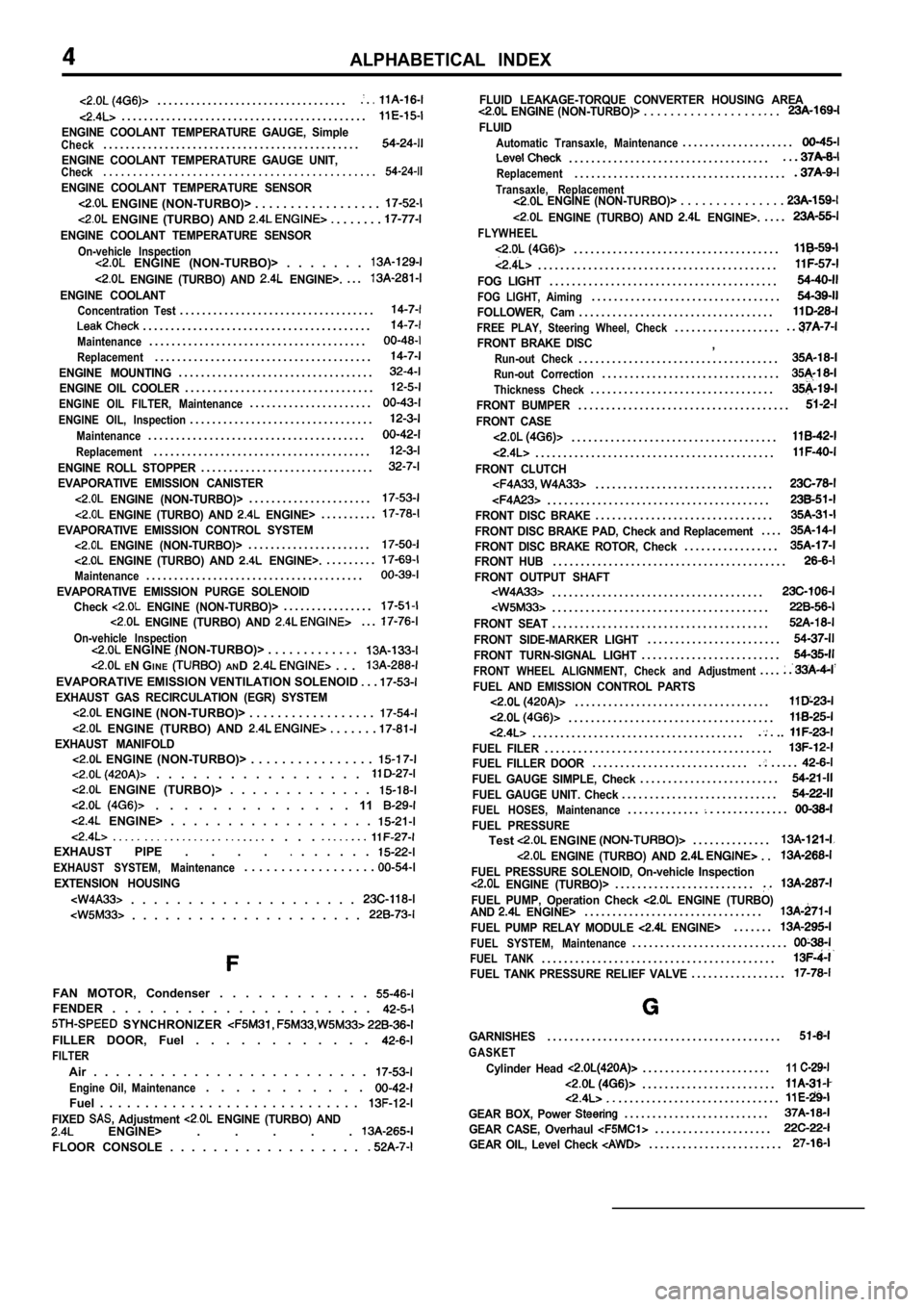

ALPHABETICAL INDEX

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE COOLANT TEMPERATURE GAUGE, SimpleCheck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE COOLANT TEMPERATURE GAUGE UNIT,Check. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

ENGINE COOLANT TEMPERATURE SENSOR

ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND . . . . . . .

ENGINE COOLANT TEMPERATURE SENSOR

On-vehicle Inspection ENGINE (NON-TURBO)> . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . .

ENGINE COOLANTConcentration Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE OIL COOLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE OIL FILTER, Maintenance. . . . . . . . . . . . . . . . . . . . . .

ENGINE OIL, Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE ROLL STOPPER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVAPORATIVE EMISSION CANISTER

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>. . . . . . . . . .

EVAPORATIVE EMISSION CONTROL SYSTEM ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . . . . . . .

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVAPORATIVE EMISSION PURGE SOLENOID

Check ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . .

ENGINE (TURBO) AND . . .

On-vehicle Inspection ENGINE (NON-TURBO)> . . . . . . . . . . . . .

EN G INE AND . . .

EVAPORATIVE EMISSION VENTILATION SOLENOID . .

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND . . . . . . EXHAUST MANIFOLD ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE (TURBO)> . . . . . . . . . . . . .

. . . . . . . . . . . . . . 11

ENGINE> . . . . . . . . . . . . . . . . . .

. . . . EXHAUST PIPE . . . . . . . . . .

EXHAUST SYSTEM, Maintenance. . . . . . . . . . . . . . . . . .

EXTENSION HOUSING

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

FAN MOTOR, Condenser . . . . . . . . . . . . FENDER . . . . . . . . . . . . . . . . . . . . .

SYNCHRONIZER

FILLER DOOR, Fuel . . . . . . . . . . . .

FILTER

Air . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil, Maintenance. . . . . . . . . . .

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIXED Adjustment ENGINE (TURBO) AND ENGINE> . . . . .

FLOOR CONSOLE . . . . . . . . . . . . . . . . . .

FLUID LEAKAGE-TORQUE CONVERTER HOUSING AREA ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . . . . .

FLUID

Automatic Transaxle, Maintenance. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle, Replacement ENGINE (NON-TURBO)> . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . .

FLYWHEEL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOG LIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOG LIGHT, Aiming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOWER, Cam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FREE PLAY, Steering Wheel, Check. . . . . . . . . . . . . . . . . . .

FRONT BRAKE DISC,Run-out Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Run-out Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thickness Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT BUMPER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT CASE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FRONT DISC BRAKE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT DISC BRAKE PAD, Check and Replacement. . . .

FRONT DISC BRAKE ROTOR, Check. . . . . . . . . . . . . . . . .FRONT HUB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT OUTPUT SHAFT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT SEAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT SIDE-MARKER LIGHT. . . . . . . . . . . . . . . . . . . . . . . .

FRONT TURN-SIGNAL LIGHT. . . . . . . . . . . . . . . . . . . . . . . . .

FRONT WHEEL ALIGNMENT, Check and Adjustment. . . .

FUEL AND EMISSION CONTROL PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

FUEL FILER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FUEL FILLER DOOR. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

FUEL GAUGE SIMPLE, Check. . . . . . . . . . . . . . . . . . . . . . . . .

FUEL GAUGE UNIT. Check. . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL HOSES, Maintenance. . . . . . . . . . . . .. . . . . . . . . . . . .

FUEL PRESSURETest ENGINE . . . . . . . . . . . . . .

ENGINE (TURBO) AND . .

FUEL PRESSURE SOLENOID, On-vehicle Inspection ENGINE (TURBO)>. . . . . . . . . . . . . . . . . . . . . . . . .

FUEL PUMP, Operation Check ENGINE (TURBO)

AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL PUMP RELAY MODULE ENGINE>. . . . . . .

FUEL SYSTEM, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL TANK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FUEL TANK PRESSURE RELIEF VALVE. . . . . . . . . . . . . . . . .

GARNISHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GASKET

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . .11

. . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR BOX, Power . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR CASE, Overhaul . . . . . . . . . . . . . . . . . . . . .

GEAR OIL, Level Check . . . . . . . . . . . . . . . . . . . . . . . .