ABS MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 5 of 2103

GENERAL How to Use This

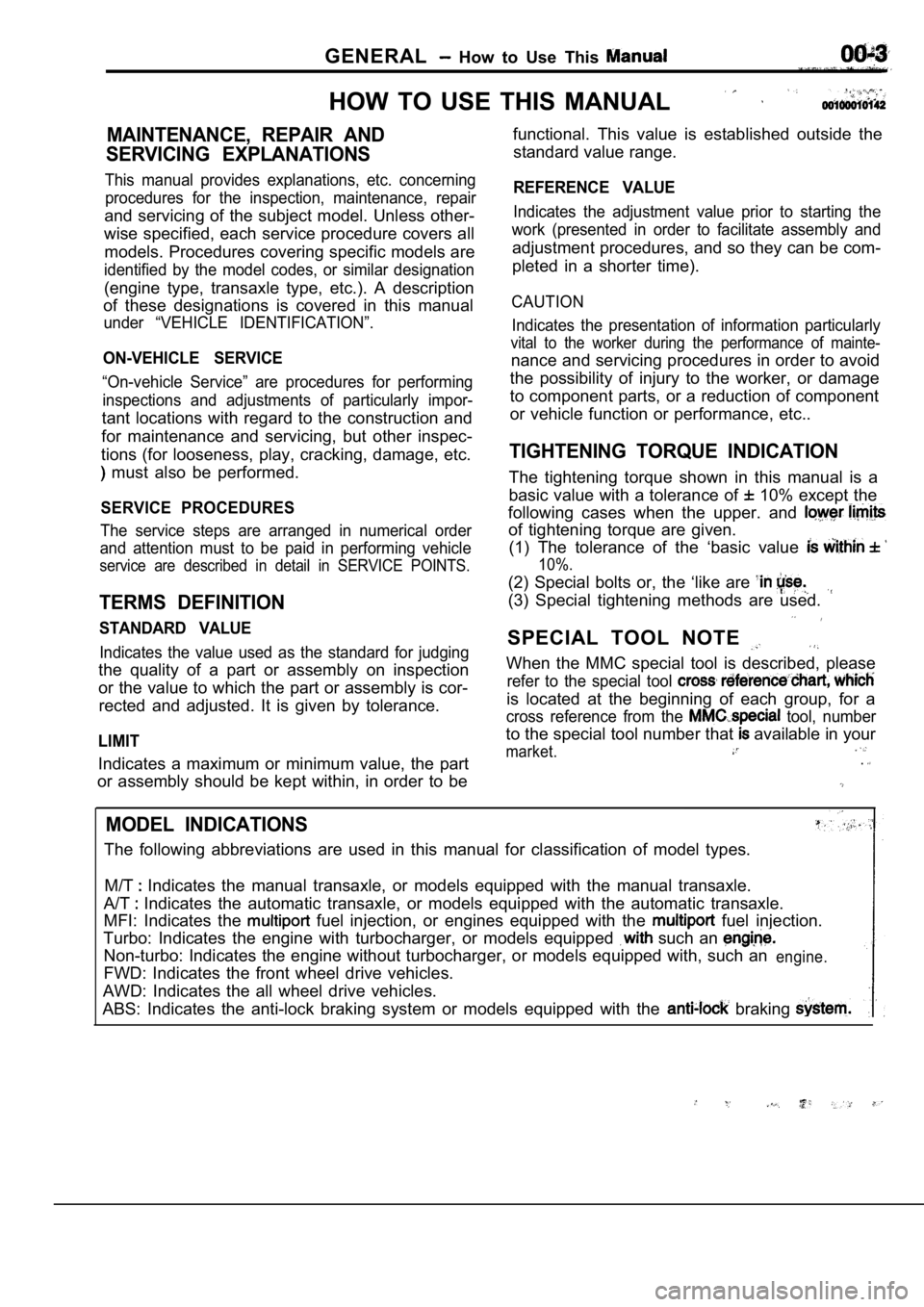

HOW TO USE THIS MANUAL

MAINTENANCE, REPAIR AND

SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all

models. Procedures covering specific models are

identified by the model codes, or similar designati on

(engine type, transaxle type, etc.). A description

of these designations is covered in this manual

under “VEHICLE IDENTIFICATION”.

ON-VEHICLE SERVICE

“On-vehicle Service” are procedures for performing

inspections and adjustments of particularly impor-

tant locations with regard to the construction and

for maintenance and servicing, but other inspec-

tions (for looseness, play, cracking, damage, etc.

must also be performed.

SERVICE PROCEDURES

The service steps are arranged in numerical order

and attention must to be paid in performing vehicle

service are described in detail in SERVICE POINTS.

TERMS DEFINITION

STANDARD VALUE

Indicates the value used as the standard for judgin g

the quality of a part or assembly on inspection

or the value to which the part or assembly is cor-

rected and adjusted. It is given by tolerance.

LIMIT

Indicates a maximum or minimum value, the part

or assembly should be kept within, in order to be functional. This value is established outside the

standard value range.

REFERENCE VALUE

Indicates the adjustment value prior to starting th e

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

CAUTION

Indicates the presentation of information particula rly

vital to the worker during the performance of maint e-

nance and servicing procedures in order to avoid

the possibility of injury to the worker, or damage

to component parts, or a reduction of component

or vehicle function or performance, etc..

TIGHTENING TORQUE INDICATION

The tightening torque shown in this manual is a

basic value with a tolerance of

10% except the

following cases when the upper. and

of tightening torque are given. (1) The tolerance of the ‘basic value

10%.

(2) Special bolts or, the ‘like are

(3) Special tightening methods are used.

SPECIAL TOOL NOTE

When the MMC special tool is described, please

refer to the special tool

is located at the beginning of each group, for a

cross reference from the tool, number

to the special tool number that available in your

market..

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

M/T

Indicates the manual transaxle, or models equipped with the manual transaxle.

A/T

Indicates the automatic transaxle, or models equip ped with the automatic transaxle.

MFI: Indicates the

fuel injection, or engines equipped with the fuel injection.

Turbo: Indicates the engine with turbocharger, or m odels equipped

such an

Non-turbo: Indicates the engine without turbocharger, or models equipped with, such anengine.

FWD: Indicates the front wheel drive vehicles.

AWD: Indicates the all wheel drive vehicles.

ABS: Indicates the anti-lock braking system or mode ls equipped with the

braking

Page 58 of 2103

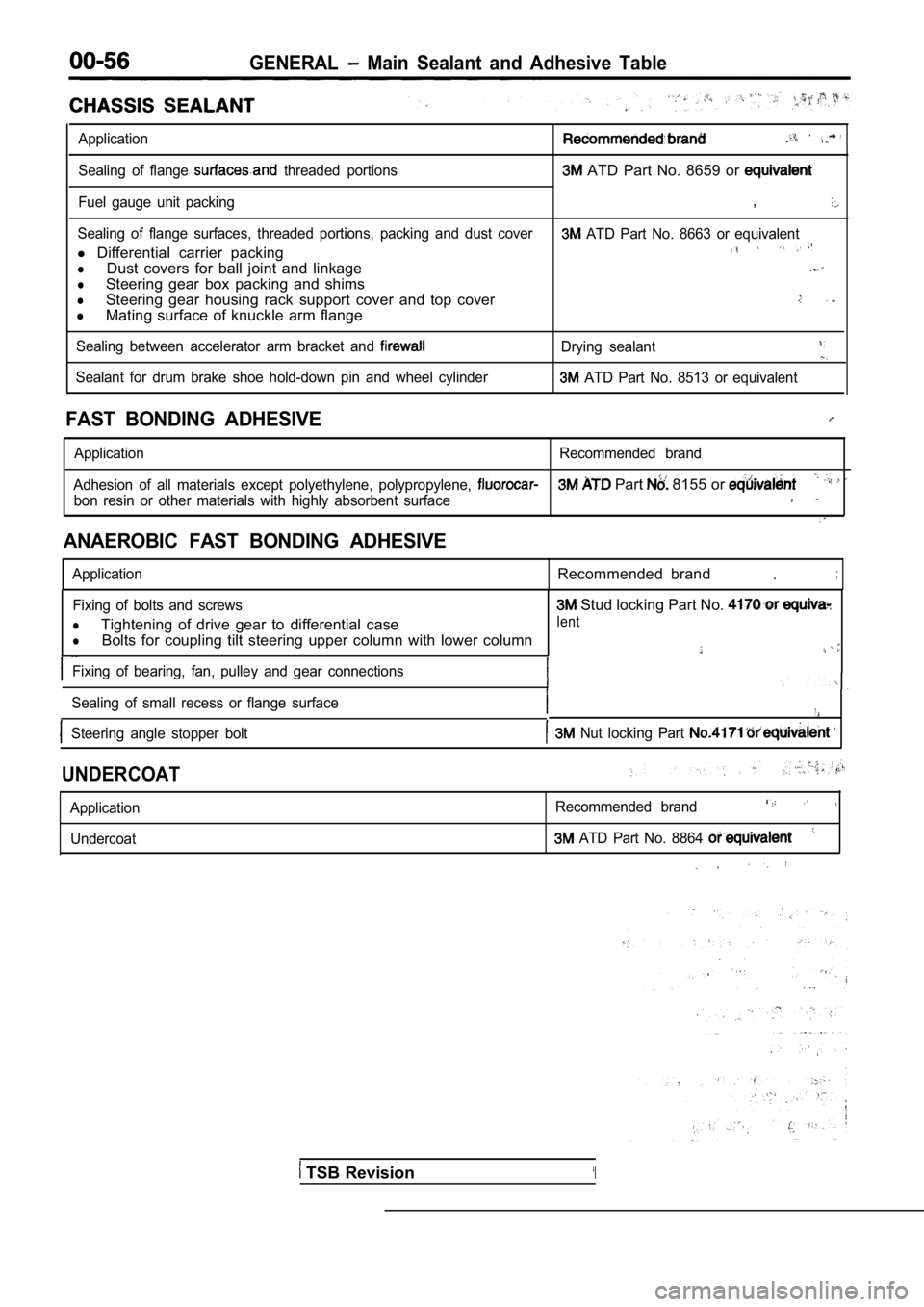

GENERAL Main Sealant and Adhesive Table

Application

Sealing of flange threaded portions ATD Part No. 8659 or

Fuel gauge unit packing,

Sealing of flange surfaces, threaded portions, packing and dust cover ATD Part No. 8663 or equivalent

l Differential carrier packing

lDust covers for ball joint and linkage

lSteering gear box packing and shims

lSteering gear housing rack support cover and top co ver

lMating surface of knuckle arm flange

Sealing between accelerator arm bracket and Drying sealant

Sealant for drum brake shoe hold-down pin and wheel cylinder ATD Part No. 8513 or equivalent

FAST BONDING ADHESIVE

Application Recommended brand

Adhesion of all materials except polyethylene, poly propylene,

Part 8155 or

bon resin or other materials with highly absorbent surface,

ANAEROBIC FAST BONDING ADHESIVE

ApplicationRecommended brand.

Fixing of bolts and screws

lTightening of drive gear to differential case

lBolts for coupling tilt steering upper column with lower column

Fixing of bearing, fan, pulley and gear connections

Sealing of small recess or flange surface

Steering angle stopper bolt Nut locking Part

Stud locking Part No.

lent

UNDERCOAT

Application Undercoat Recommended brand

ATD Part No. 8864

TSB Revision‘I

Page 213 of 2103

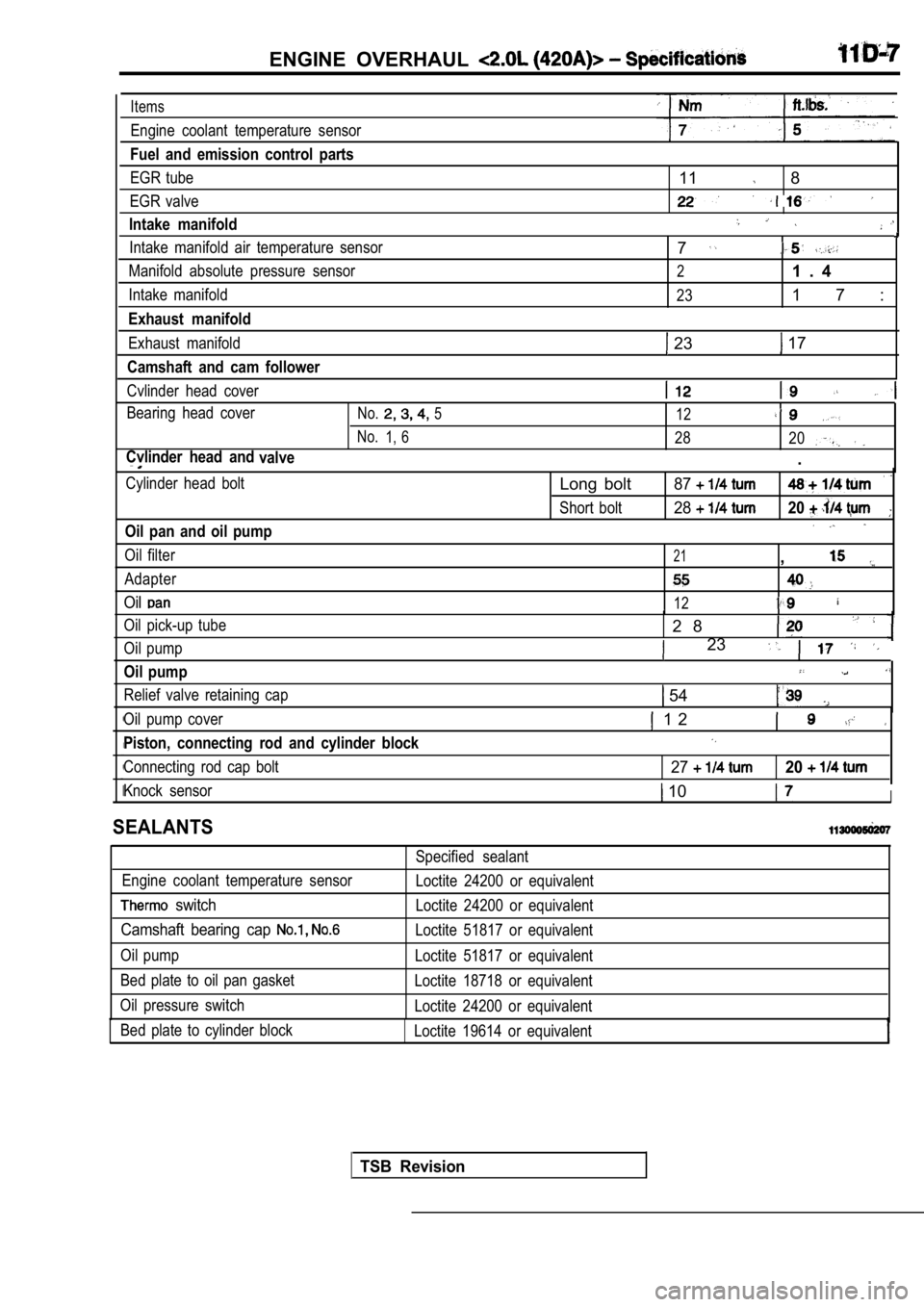

ENGINE OVERHAUL

Items

Engine coolant temperature sensor

Fuel and emission control parts

EGR tube

EGR valve

Intake manifold

11 8

Intake manifold air temperature sensor

Manifold absolute pressure sensor

Intake manifold

Exhaust manifold

Exhaust manifold

Camshaft and cam follower

Cvlinder head cover

Bearing head cover

No.5 12

No.1, 628 20

Cvlinder head and

valve.

7

21 . 4

231 7 :

23 17

Cylinder head bolt

Oil pan and oil pump

Oil filter

Adapter

Oil

Oil pick-up tube

Oil pump

Oil pump

Relief valve retaining cap

Long bolt87

Short bolt2820

21,

12

2 8

23

54

Oil pump cover

Piston, connecting rod and cylinder block

Connecting rod cap bolt

1 2

2720

Knock sensor 10I

SEALANTS

Engine coolant temperature sensor

switch

Camshaft bearing cap

Oil pump

Bed plate to oil pan gasket

Oil pressure switch Bed plate to cylinder block Specified sealant

Loctite 24200 or equivalent

Loctite 24200 or equivalent

Loctite 51817 or equivalent

Loctite 51817 or equivalent

Loctite 18718 or equivalent

Loctite 24200 or equivalent

Loctite 19614 or equivalent

TSB Revision

Page 214 of 2103

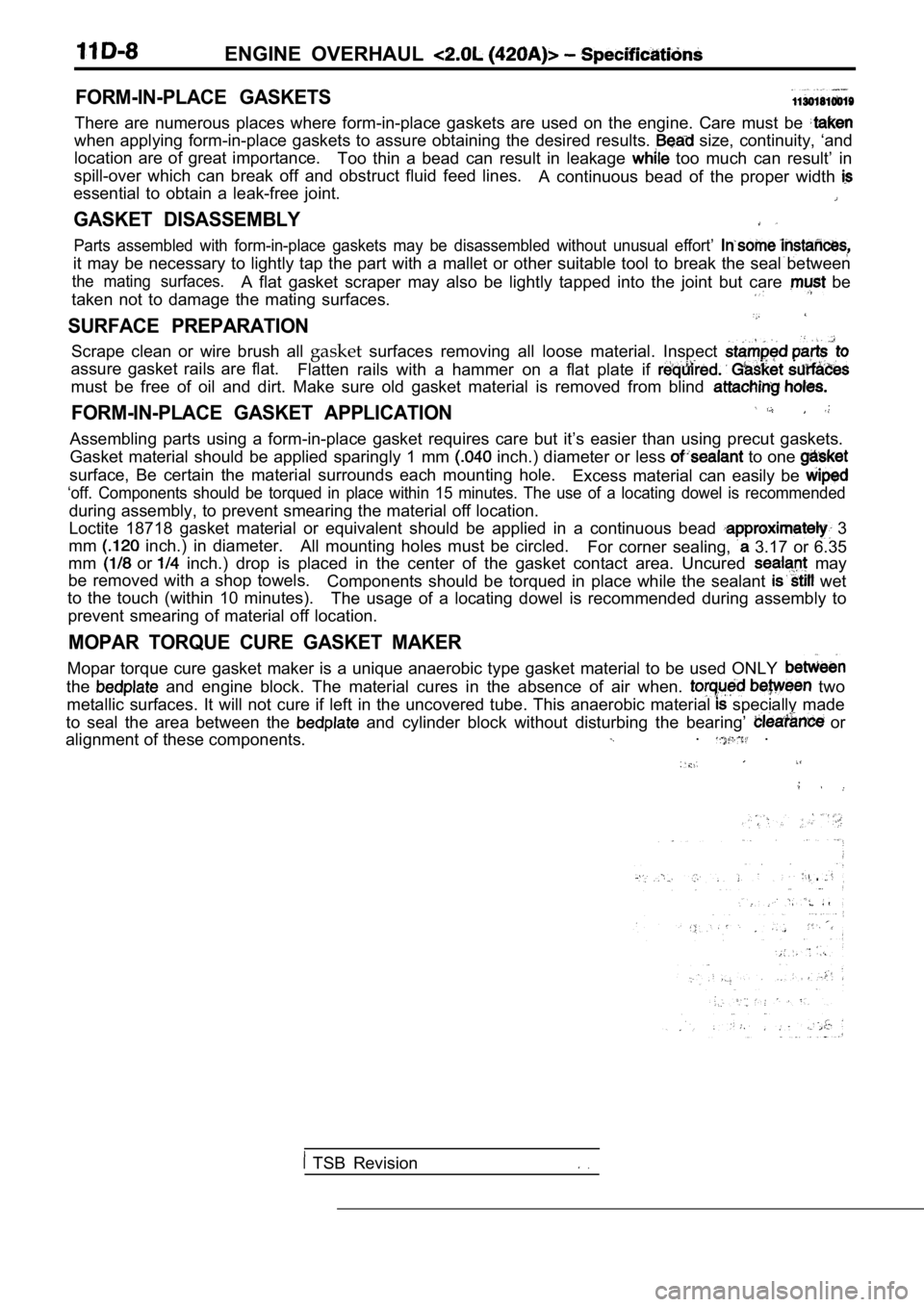

ENGINE OVERHAUL

FORM-IN-PLACE GASKETS

There are numerous places where form-in-place gaskets are used on the engine. Care must be

when applying form-in-place gaskets to assure obtaining the desired results. size, continuity, ‘and

location are of great importance. Too thin a bead can result in leakage

too much can result’ in

spill-over which can break off and obstruct fluid f eed lines.

A continuous bead of the proper width

essential to obtain a leak-free joint.

GASKET DISASSEMBLY

Parts assembled with form-in-place gaskets may be d isassembled without unusual effort’

it may be necessary to lightly tap the part with a mallet or other suitable tool to break the seal between

the mating surfaces.A flat gasket scraper may also be lightly tapped in to the joint but care be

taken not to damage the mating surfaces.

SURFACE PREPARATION

Scrape clean or wire brush all gasketsurfaces removing all loose material. Inspect

assure gasket rails are flat.

Flatten rails with a hammer on a flat plate if

must be free of oil and dirt. Make sure old gasket material is removed from blind

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket requires care but it’s easier than using precut gaskets.

Gasket material should be applied sparingly 1 mm

inch.) diameter or less to one

surface, Be certain the material surrounds each mou nting hole.

Excess material can easily be

‘off. Components should be torqued in place within 15 minutes. The use of a locating dowel is recommen ded

during assembly, to prevent smearing the material off location.

Loctite 18718 gasket material or equivalent should be applied in a continuous bead

3

mm

inch.) in diameter. All mounting holes must be circled.

For corner sealing, 3.17 or 6.35

mm

or inch.) drop is placed in the center of the gasket contact area. Uncured may

be removed with a shop towels. Components should be torqued in place while the sea lant

wet

to the touch (within 10 minutes). The usage of a locating dowel is recommended during assembly to

prevent smearing of material off location.

MOPAR TORQUE CURE GASKET MAKER

Mopar torque cure gasket maker is a unique anaerobi c type gasket material to be used ONLY

the and engine block. The material cures in the absenc e of air when. two

metallic surfaces. It will not cure if left in the uncovered tube. This anaerobic material

specially made

to seal the area between the

and cylinder block without disturbing the bearing’ or

alignment of these components.. .

TSB Revision

Page 231 of 2103

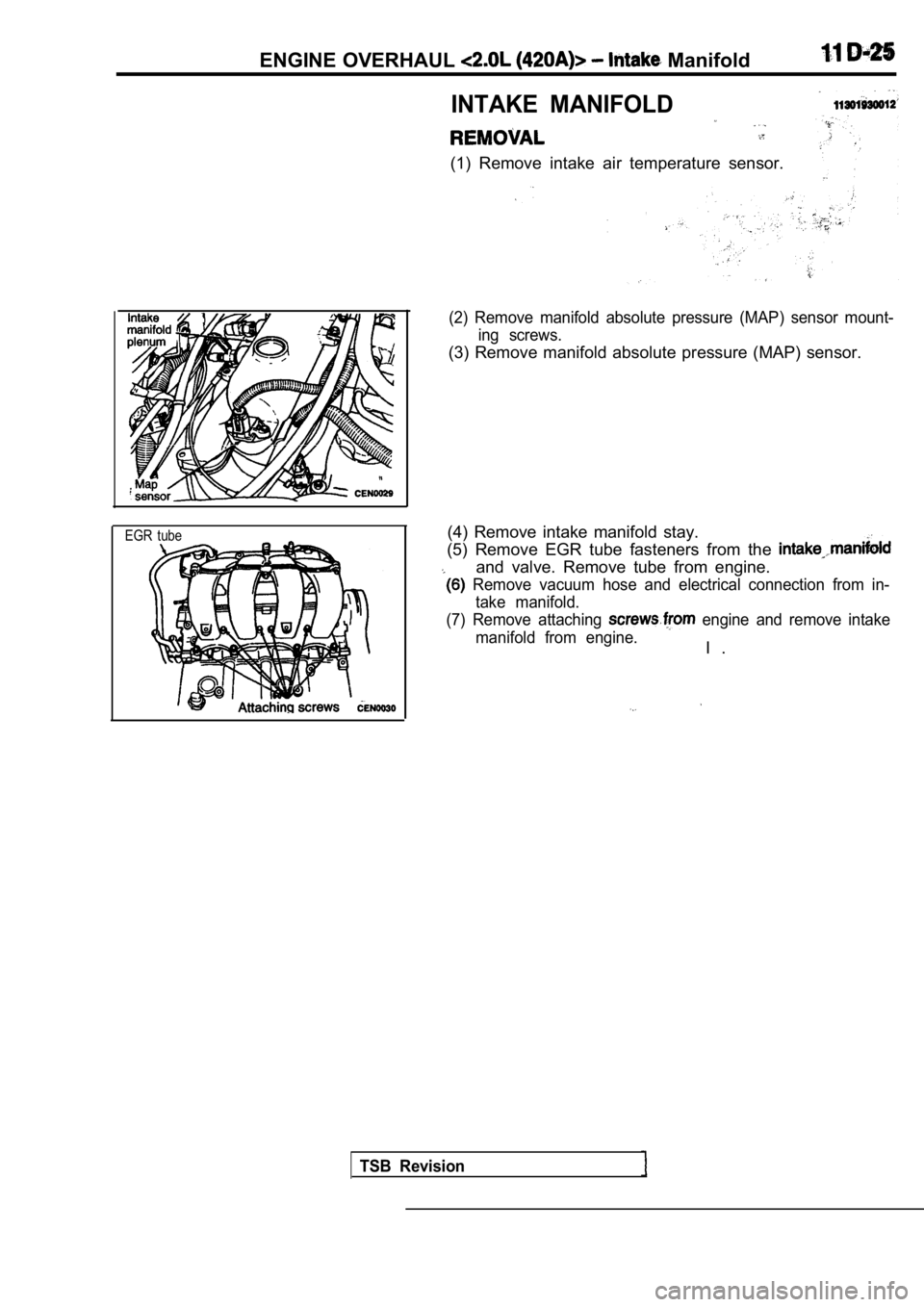

ENGINE OVERHAUL Manifold

EGR tube

INTAKE MANIFOLD

(1) Remove intake air temperature sensor.

(2) Remove manifold absolute pressure (MAP) sensor mount-

ing screws.

(3) Remove manifold absolute pressure (MAP) sensor.

(4) Remove intake manifold stay.

(5) Remove EGR tube fasteners from the

and valve. Remove tube from engine.

Remove vacuum hose and electrical connection from in-

take manifold.

(7) Remove attaching

engine and remove intake

manifold from engine.

I .

TSB Revision

Page 263 of 2103

ENGINE OVERHAUL

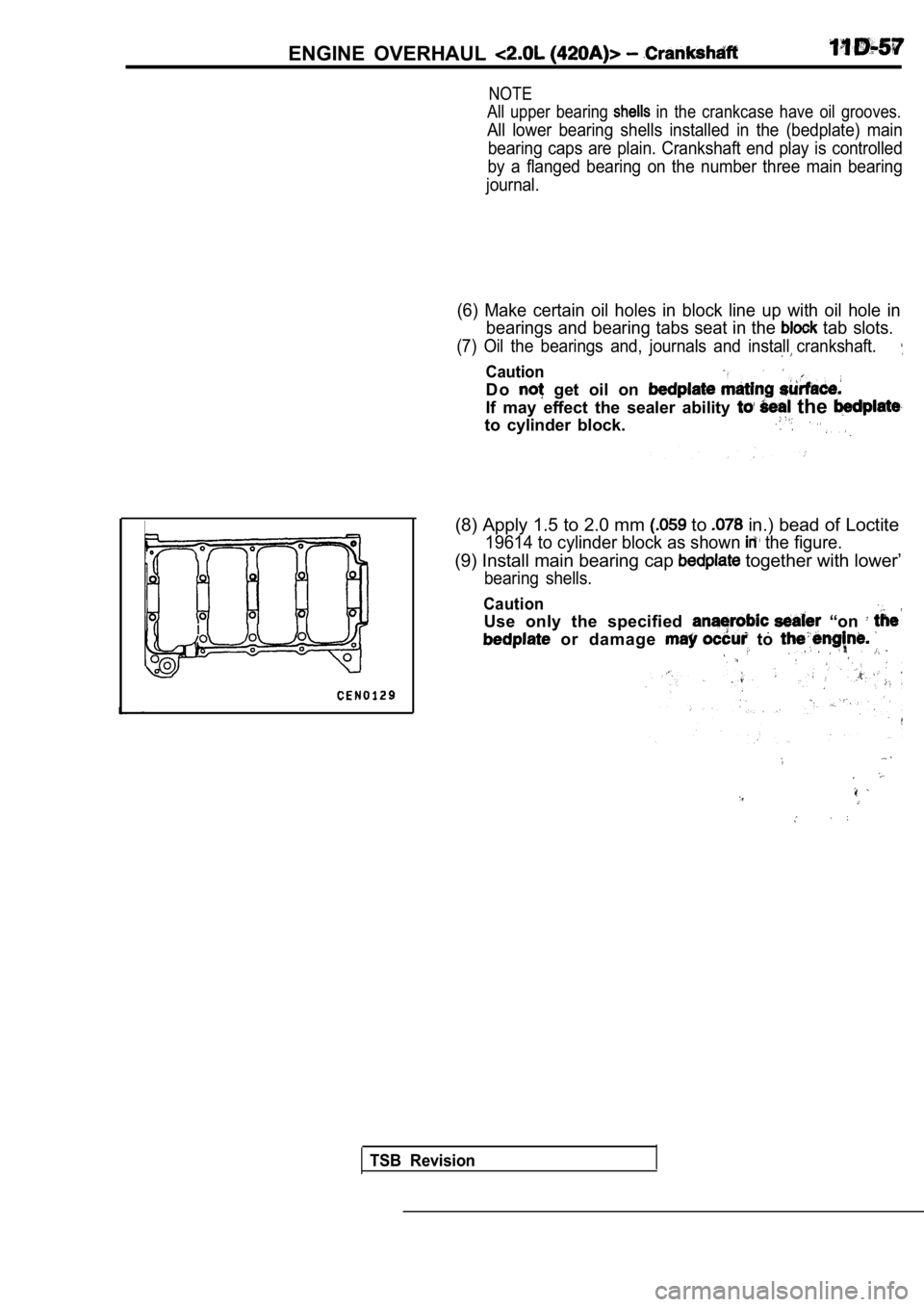

NOTE

All upper bearing

in the crankcase have oil grooves.

All lower bearing shells installed in the (bedplate ) main

bearing caps are plain. Crankshaft end play is cont rolled

by a flanged bearing on the number three main beari ng

journal.

(6) Make certain oil holes in block line up with oi l hole in

bearings and bearing tabs seat in the

tab slots.

(7) Oil the bearings and, journals and install cran kshaft.

Caution

D o get oil on

If may effect the sealer ability the

to cylinder block.

(8) Apply 1.5 to 2.0 mm to in.) bead of Loctite

19614 to cylinder block as shown the figure.

(9) Install main bearing cap together with lower’

bearing shells.

Caution

Use only the specified “on

or damage to

TSB Revision

Page 384 of 2103

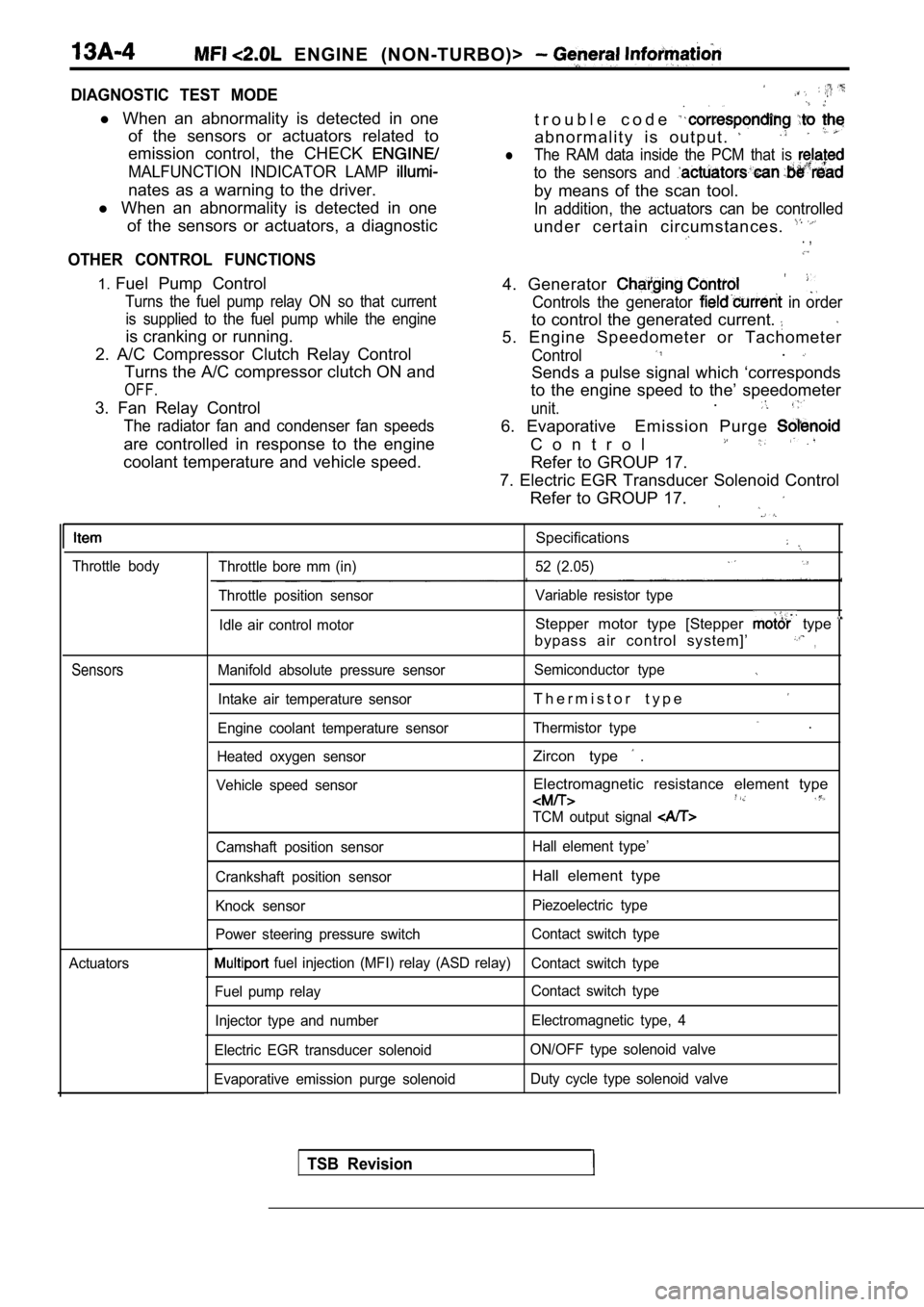

ENGINE (NON-TURBO)>

DIAGNOSTIC TEST MODE

l When an abnormality is detected in one

of the sensors or actuators related to

emission control, the CHECK

MALFUNCTION INDICATOR LAMP

nates as a warning to the driver.

l When an abnormality is detected in one

of the sensors or actuators, a diagnostic

OTHER CONTROL FUNCTIONS

t r o u b l e c o d e

a b n o r m a l i t y i s o u t p u t .

lThe RAM data inside the PCM that is

to the sensors and

by means of the scan tool.

In addition, the actuators can be controlled

under certain circumstances. . ,

1. Fuel Pump Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Compressor Clutch Relay Control Turns the A/C compressor clutch ON and

OFF.

3. Fan Relay Control

The radiator fan and condenser fan speeds

are controlled in response to the engine

coolant temperature and vehicle speed. 4. Generator

Controls the generator in order

to control the generated current.

5. Engine Speedometer or Tachometer

Control.

Sends a pulse signal which ‘corresponds

to the engine speed to the’ speedometer

unit..

6. Evaporative Emission Purge

C o n t r o l

Refer to GROUP 17.

7. Electric EGR Transducer Solenoid Control Refer to GROUP 17.

Throttle body

Sensors

Actuators

Specifications

Throttle bore mm (in) 52 (2.05)

Throttle position sensor Variable resistor type

Idle air control motor

Stepper motor type [Stepper type

bypass air control system]’,

Manifold absolute pressure sensor Semiconductor type

Intake air temperature sensorT h e r m i s t o r t y p e

Engine coolant temperature sensorThermistor type .

Heated oxygen sensorZircon type .

Vehicle speed sensorElectromagnetic resistance element type

TCM output signal

Camshaft position sensor Hall element type’

Crankshaft position sensor

Hall element type

Knock sensor Piezoelectric type

Power steering pressure switch Contact switch type

fuel injection (MFI) relay (ASD relay)

Contact switch type

Fuel pump relay Contact switch type

Injector type and number Electromagnetic type, 4

Electric EGR transducer solenoid ON/OFF type solenoid valve

Evaporative emission purge solenoid Duty cycle type solenoid valve

TSB Revision

Page 385 of 2103

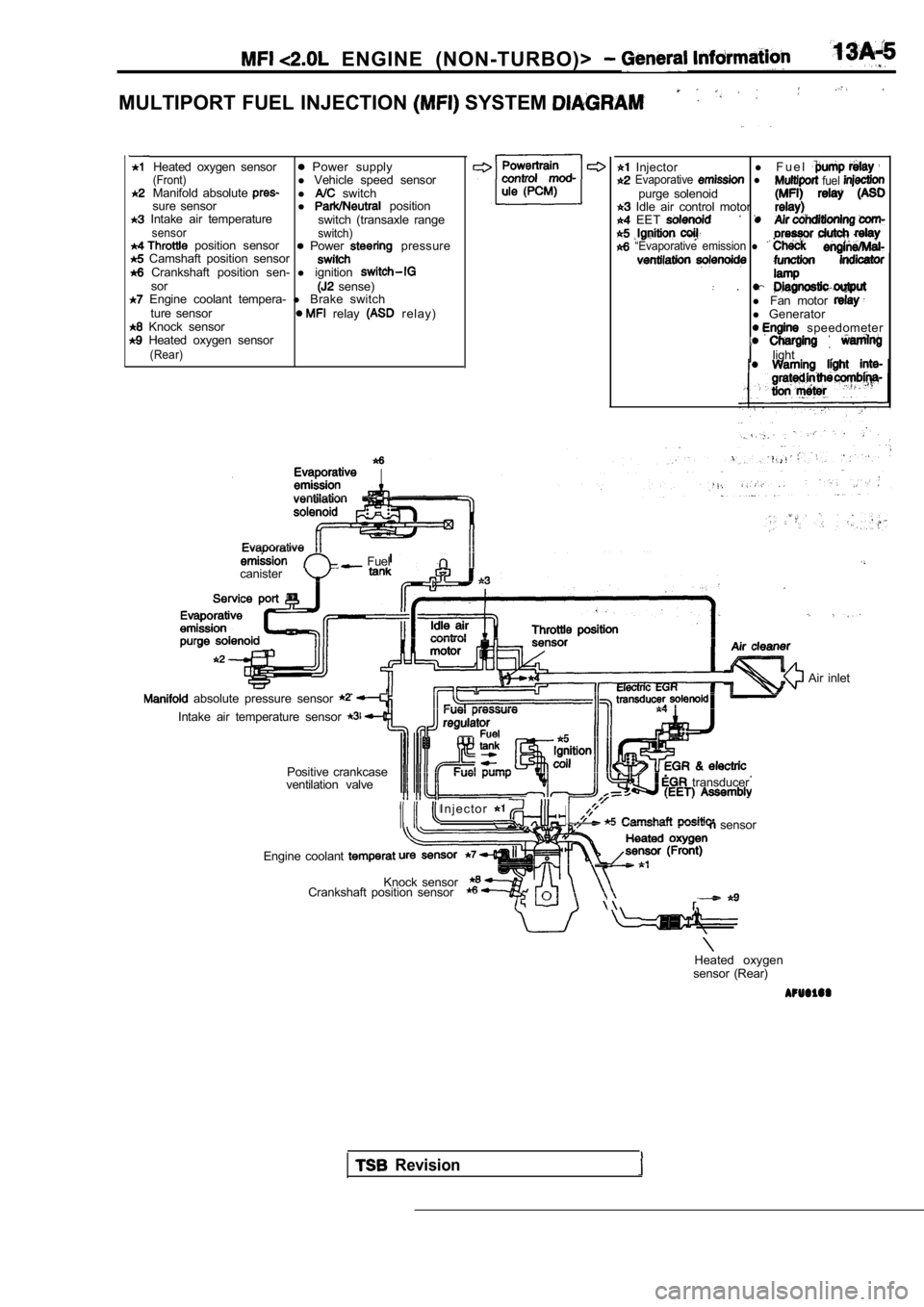

ENGINE (NON-TURBO)>

MULTIPORT FUEL INJECTION SYSTEM

Heated oxygen sensor Power supply(Front)l Vehicle speed sensor

Manifold absolute l switch

sure sensor l position Intake air temperature

switch (transaxle rangesensor switch) position sensor Power pressure Camshaft position sensor Crankshaft position sen- l ignitionsor sense) Engine coolant tempera- l Brake switch

ture sensor relay r e l a y ) Knock sensor Heated oxygen sensor(Rear)

Injector l

F u e l Evaporative l fuel purge solenoid Idle air control motor EET

“Evaporative emission l

.l Fan motor l Generator speedometer

light

.

Fuel

canister

absolute pressure sensor

Intake air temperature sensor

Positive crankcase

ventilation valve

I n j e c t o r

transducer

sensor

Engine coolant

Knock sensor

Crankshaft position sensor

Air inlet

Heated oxygen

sensor (Rear)

Revision

Page 530 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

OBD-IIDRIVE CYCLE.

All kinds of diagnostic trouble code can be monitor ed by carrying out a drive test in

with the following six drive cycle patterns. In other words, carrying out such a drive test

to reproduce any kind of which involves causing the check indicator

to illuminate and to check that the repair procedur e has eliminated the trouble that the check

engine/malfunction indicator lamp no longer illumin ates). In other words, doing such a drive allows

regenerate any kind of trouble which involves illuminating the check engine/malfunction indicator lamp

and to check the repair procedure has eliminated th e trouble (the check

indicator

lamp is no more illuminated).

Caution

Make sure that there are two people in the vehicle when

1. Catalytic converter monitor

Test conditions/procedure

1. All of the following conditions should be when the drive test is carried out.

(1) Outside air temperature: or higher

(2)

condition:

Selector lever position: range

l Overdrive switch: ON

lPower/economy changeover switch: Power,

(3) switch: OFF

2. Carry out one trip monitoring according to the f ollowing drive pattern (from’ starting

until ignition is turned off). (Takes approximately 20 minutes.)

the engine and quickly accelerate to a speed of 72 km/h (45 mph) or

Monitor pre-preparation period: drive for seconds or more the vehicle Speed,

at between 72 97 (45

during this period.60 mph). Braking (lasting several seconds) . .,

Decelerate until the vehicle speed is between 56 64 km/h (35 40 mph).

Monitoring period: drive for 90 seconds or more on

a level while maintaining the throttle.

opening angle at a constant angle (keeping throttle variations as small as absolutely possible)

and the vehicle speed at between 56

64 km/h (35 40 mph).

Fully close the throttle to make the vehicle decel erate. (Braking is allowed at this time.)

After the vehicle has been decelerating continuousl y for

seconds, quickly

to a speed of between 56 64 km/h (35 40 mph).

Repeat steps l 4 and

six times. (The procedure in steps and should be

total of six times.)

Decelerate to a stop. After the vehicle has stoppe d, turn the ignition

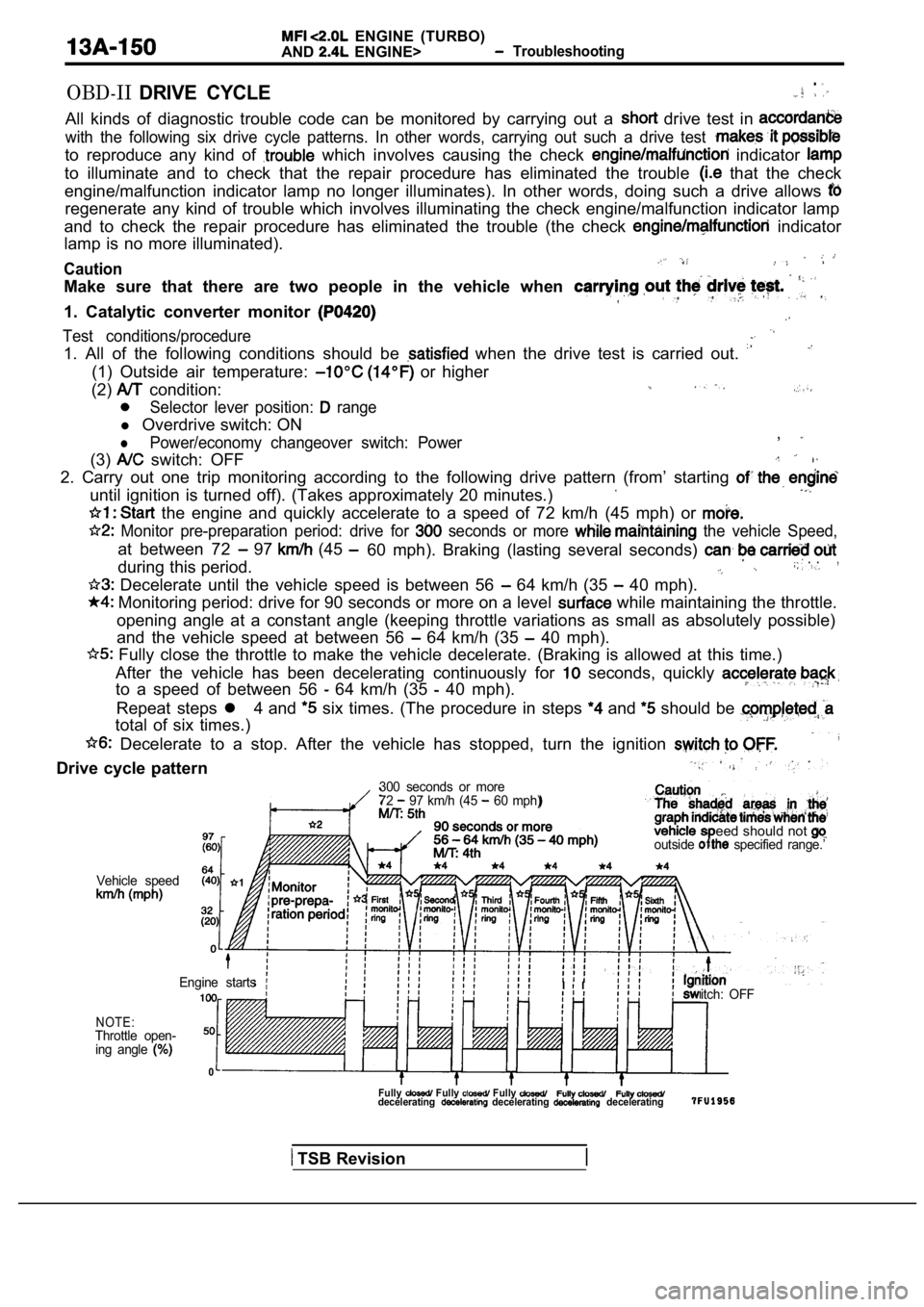

Drive cycle pattern

300 seconds or more

72 97 km/h (45 60 mph)

eed should not outside specified range.’

Vehicle speed

NOTE:Throttle open-ing angle

0

itch: OFF

Engine startsI I

Fully Fully Fully decelerating decelerating decelerating

TSB Revision

Page 531 of 2103

ENGINE (TURBO)

AND

ENGINE>

2. Evaporative emission control system leak monitor

Test conditions/procedure , . .

1. All of the following conditions should be satisfied ‘when the drive test is carried out.

(1) Engine coolant temperature: or lower engine

is stopped) ,

(2) Outside air temperature: or higher, or lower

(3) A/T condition: .

lSelector lever position: range .

l Overdrive switch: ON

l Power/economy changeover switch: Power

2. Carry out one trip monitoring according to the f ollowing drive pattern

until ignition is turned off). (Takes approximately 8 minutes.)

Check that both the engine coolant temperature’ an d air temperature ‘satisfy

in 1. above (when engine is stopped). ,

Monitor pre-preparation period: start the engine and accelerate’ 97

km/h (55 60 mph). Acceleration, deceleration and braking ca n be carried period.

Drive for 60 seconds or more while maintaining the vehicle speed

(55 60 mph). Braking and throttle ‘operations can be carried out this as

the vehicle speed remains within the specified rang e.

Monitoring period: drive for 150 seconds or more w hile maintaining the throttle opening’

at a constant angle (keeping throttle variations as small as absolutely possible) and the vehicle

speed at between 89

97 km/h (55 60 mph). Drive as consistently as possible during this

time, without making any sudden steering wheel’ mov ements.

Decelerate to a stop. After the vehicle has stopped, turn the ignition switch to OFF.

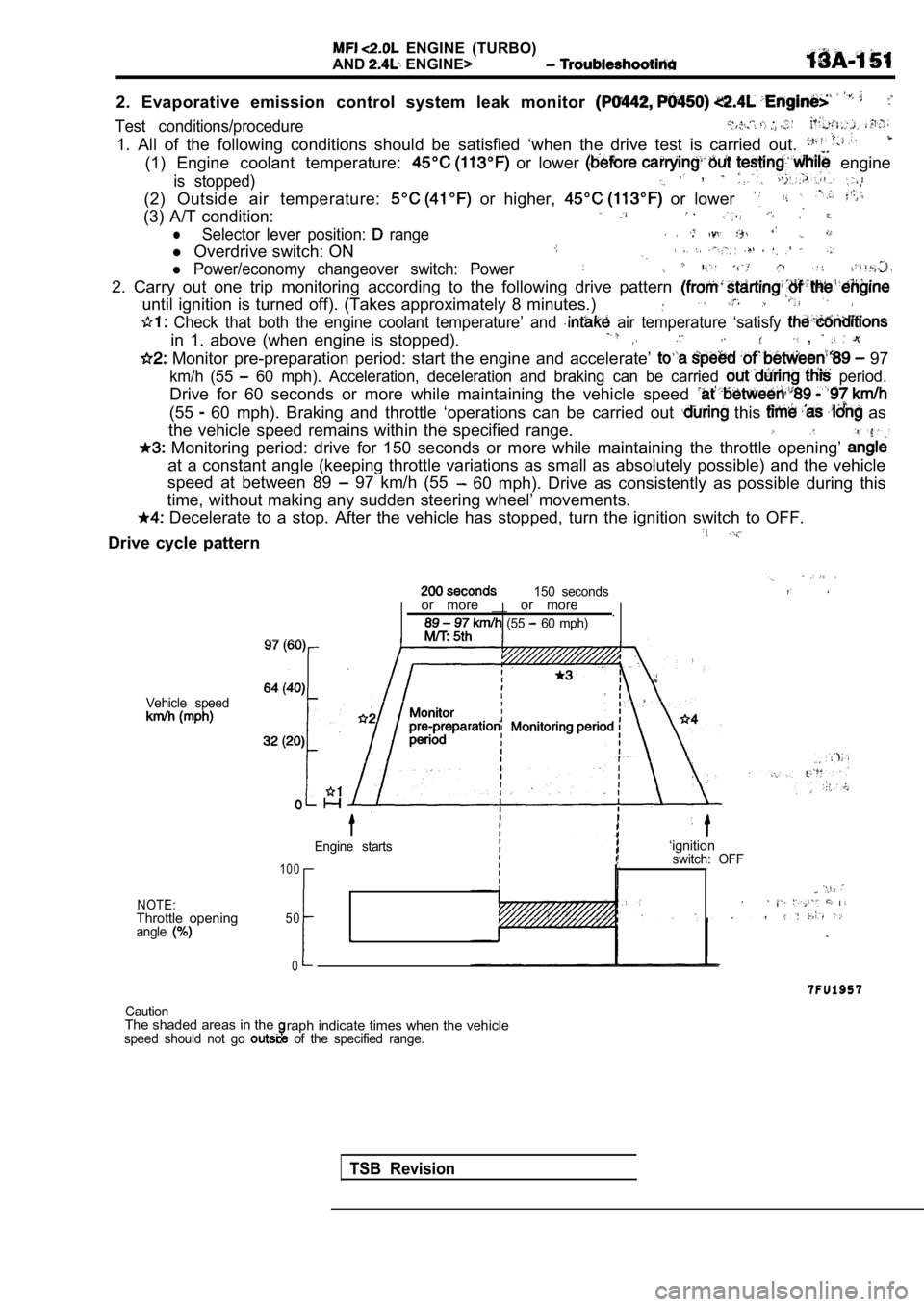

Drive cycle pattern

150 seconds

Vehicle speed

NOTE:Throttle openingangle

or more __ or more

.

(55 60 mph)

Engine starts

1 0 0

50

0

I

‘ignitionswitch: OFF

,

CautionThe shaded areas in theraph indicate times when the vehiclespeed should not go of the specified range.

TSB Revision