compression ratio MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 62 of 2103

ENGINE General Information

GENERAL INFORMATION

Items SpecificationsI

Number of cylinders

Bore mm (in.)

Stroke mm (in.)

In-line DOHC

85.0

(3.28)

Piston displacement

Compression ratio

Firing order

Counterbalance shaft8.5

Equipped

Valve timing Intake valve

Exhaust valve Opens

Closes

Opens

Closes 21 “BTDC

.

Lubrication systemIPressure feed-full flow , ,I

Oil pump type

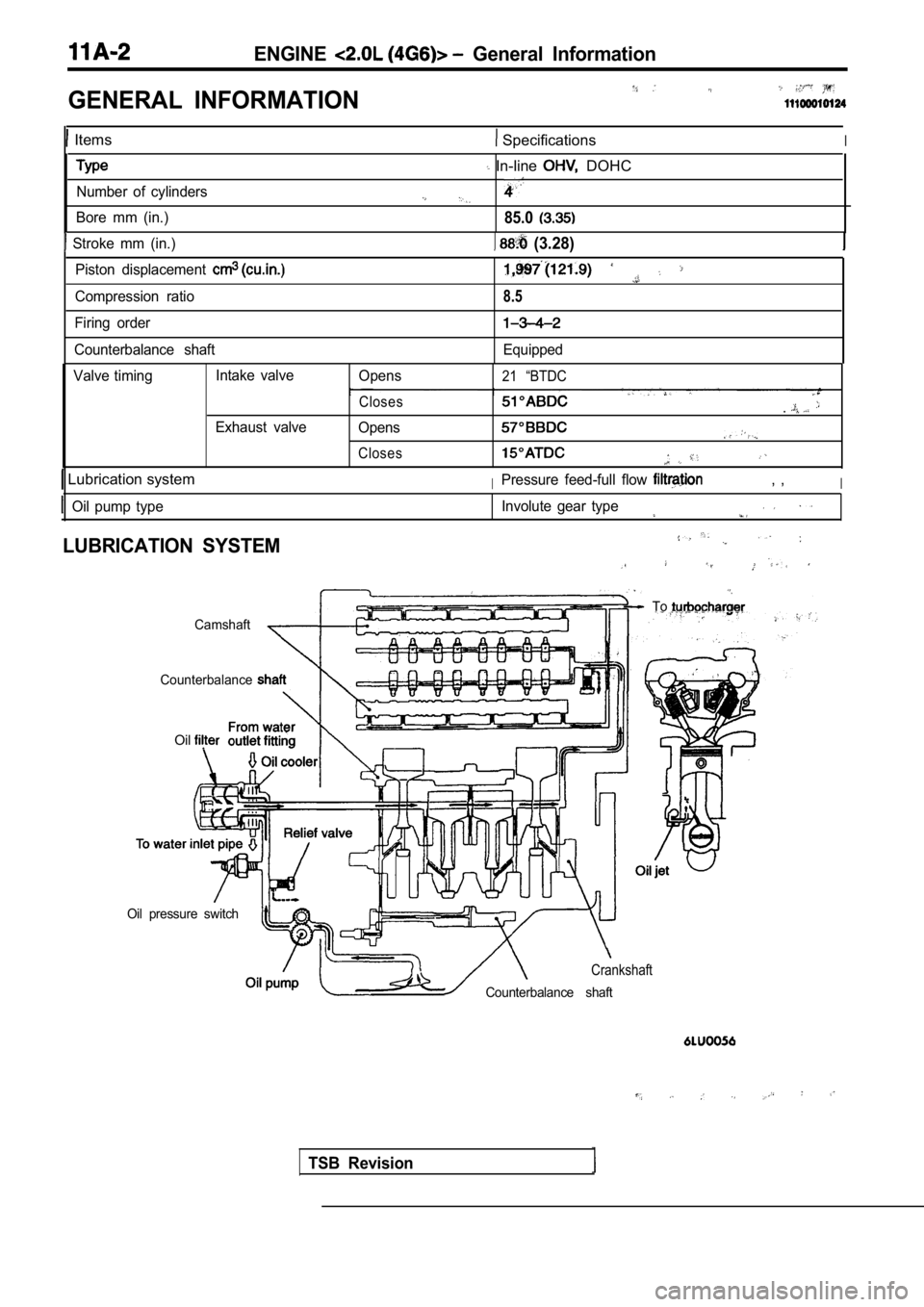

LUBRICATION SYSTEM

Involute gear type

To

Camshaft

Counterbalance

TSB Revision

Oil

Oil pressure switch

Crankshaft

Counterbalance shaft

Page 66 of 2103

ENGINE,

TROUBLESHOOTING

Oil filter cloggedInstall new filter

Oil pump gears or cover wornReplace gears cover

Thin or diluted engine oil Change engine oil to correct viscosity

Oil relief valve stuck (open) Repair relief valve

Excessive bearing clearanceReplace bearings

pressure too high Oil relief valve stuck (closed) Repair relief valve

Joisy valves Incorrect lash adjuster Bleed air or rep lace lash adjuster

Thin or diluted engine oil (low oil pressure)

Change engine oil ,

Valve stem or valve guide worn or damaged Replace va lve guide

rod noise/Insufficient oil supplyCheck engine oil level

nain bearing noise Low oil pressure Refer

pressure drop”

Thin or diluted engine oil Change engine oil

Excessive bearing clearance Replace bearings

belt noiseIncorrect belt tension Adjust belt tension and/or replace tim-ing belt

engine Loose engine roll stopper (Front, Rear)Retighten

ng and vibration

Loose transaxle mount bracketRetighten

Loose engine mount bracketRetighten

Loose center memberRetighten

Broken transaxle mount insulatorReplace

Broken engine mount insulatorReplace

Broken roll stopper insulatorReplace

Symptom

Probable cause

Remedy.

Compression too low Cylinder head gasket blownReplace gasket

Piston ring worn or damagedReplace rings

Piston or cylinder worn

Repair or replace piston cylinder

block

Valve seat worn or damagedRepair or replace valve and/or

Oil pressure drop Engine oil level too low Check engine oil level

Oil pressure switch faulty

pressure switch

TSB Revision

Page 72 of 2103

ENGINE On-vehicle

Caution

1.Keep away from the spark plug hole when crank-

ing.

2. If compression is measured with water, oil, fuel,

etc., that has come from cracks inside the cylinder ,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

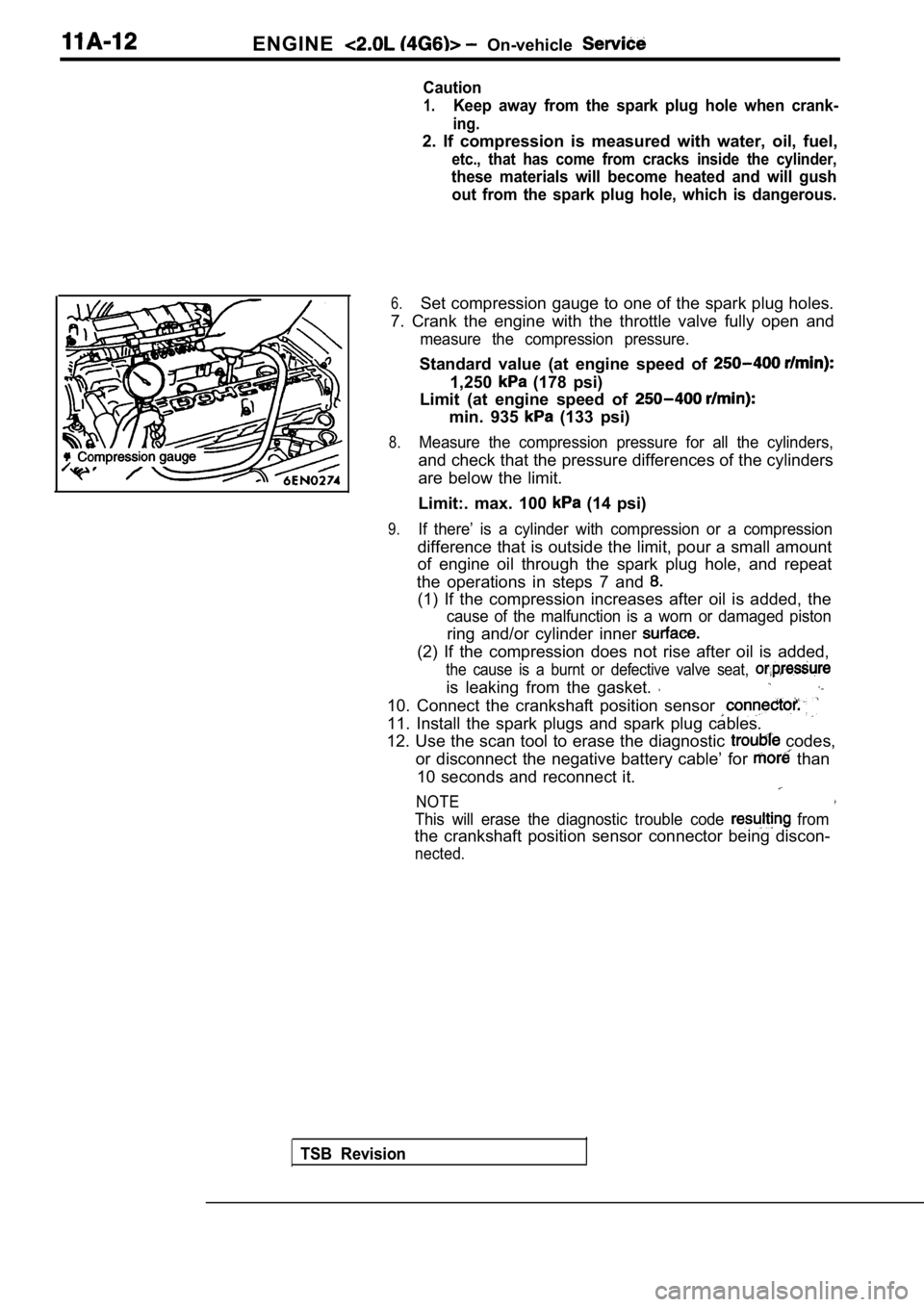

6.Set compression gauge to one of the spark plug hole s.

7. Crank the engine with the throttle valve fully o pen and

measure the compression pressure.

Standard value (at engine speed of

1,250 (178 psi)

Limit (at engine speed of

min. 935 (133 psi)

8.Measure the compression pressure for all the cylind ers,

and check that the pressure differences of the cylinders

are below the limit.

Limit:. max. 100

(14 psi)

9.If there’ is a cylinder with compression or a compr ession

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repe at

the operations in steps 7 and

(1) If the compression increases after oil is added , the

cause of the malfunction is a worn or damaged pisto n

ring and/or cylinder inner

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat,

is leaking from the gasket.

10. Connect the crankshaft position sensor

11. Install the spark plugs and spark plug cables.

12. Use the scan tool to erase the diagnostic

codes,

or disconnect the negative battery cable’ for

than

10 seconds and reconnect it.

NOTE

This will erase the diagnostic trouble code from

the crankshaft position sensor connector being disc on-

nected.

TSB Revision

Page 74 of 2103

ENGINE On-vehicle Service

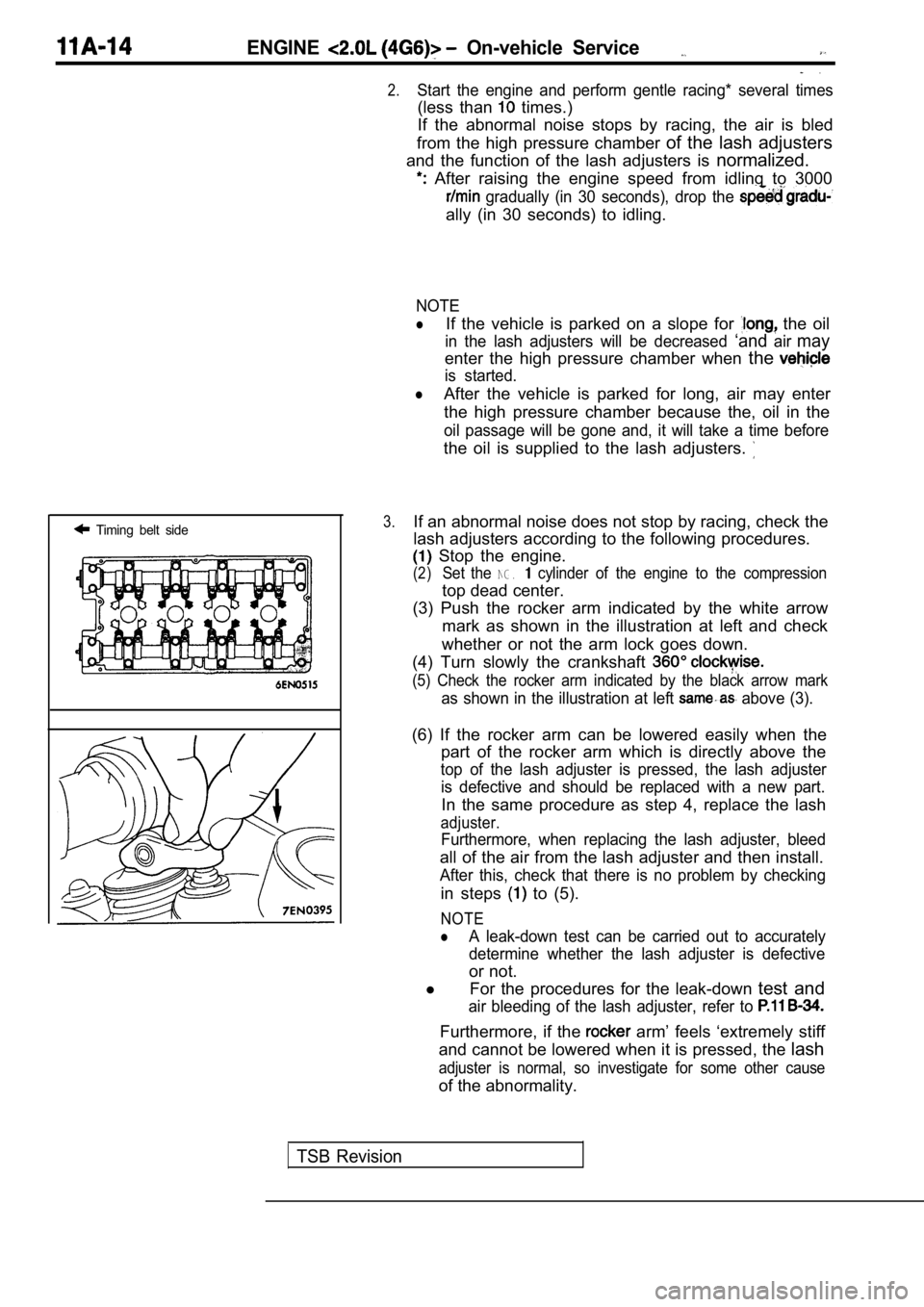

Timing belt side

.

2.Start the engine and perform gentle racing* several times

(less than times.)

If the abnormal noise stops by racing, the air is b led

from the high pressure chamber of the lash adjusters

and the function of the lash adjusters is normalized.

After raising the engine speed from idling to 3000

gradually (in 30 seconds), drop the

ally (in 30 seconds) to idling.

NOTE

lIf the vehicle is parked on a slope for the oil

in the lash adjusters will be decreased ‘andairmay

enter the high pressure chamber when the

is started.

lAfter the vehicle is parked for long, air may enter

the high pressure chamber because the, oil in the

oil passage will be gone and, it will take a time b efore

the oil is supplied to the lash adjusters.

3.If an abnormal noise does not stop by racing, check the

lash adjusters according to the following procedure s.

Stop the engine.

(2)Set the NG. cylinder of the engine to the compression

top dead center.

(3) Push the rocker arm indicated by the white arro w

mark as shown in the illustration at left and check

whether or not the arm lock goes down.

(4) Turn slowly the crankshaft

(5) Check the rocker arm indicated by the black arr ow mark

as shown in the illustration at left above (3).

(6) If the rocker arm can be lowered easily when th e

part of the rocker arm which is directly above the

top of the lash adjuster is pressed, the lash adjus ter

is defective and should be replaced with a new part .

In the same procedure as step 4, replace the lash

adjuster.

Furthermore, when replacing the lash adjuster, bleed

all of the air from the lash adjuster and then install.

After this, check that there is no problem by check ing

in steps to (5).

NOTE

lA leak-down test can be carried out to accurately

determine whether the lash adjuster is defective

or not.

l For the procedures for the leak-down test and

air bleeding of the lash adjuster, refer to

Furthermore, if the arm’ feels ‘extremely stiff

and cannot be lowered when it is pressed, the lash

adjuster is normal, so investigate for some other c ause

of the abnormality.

TSB Revision

Page 85 of 2103

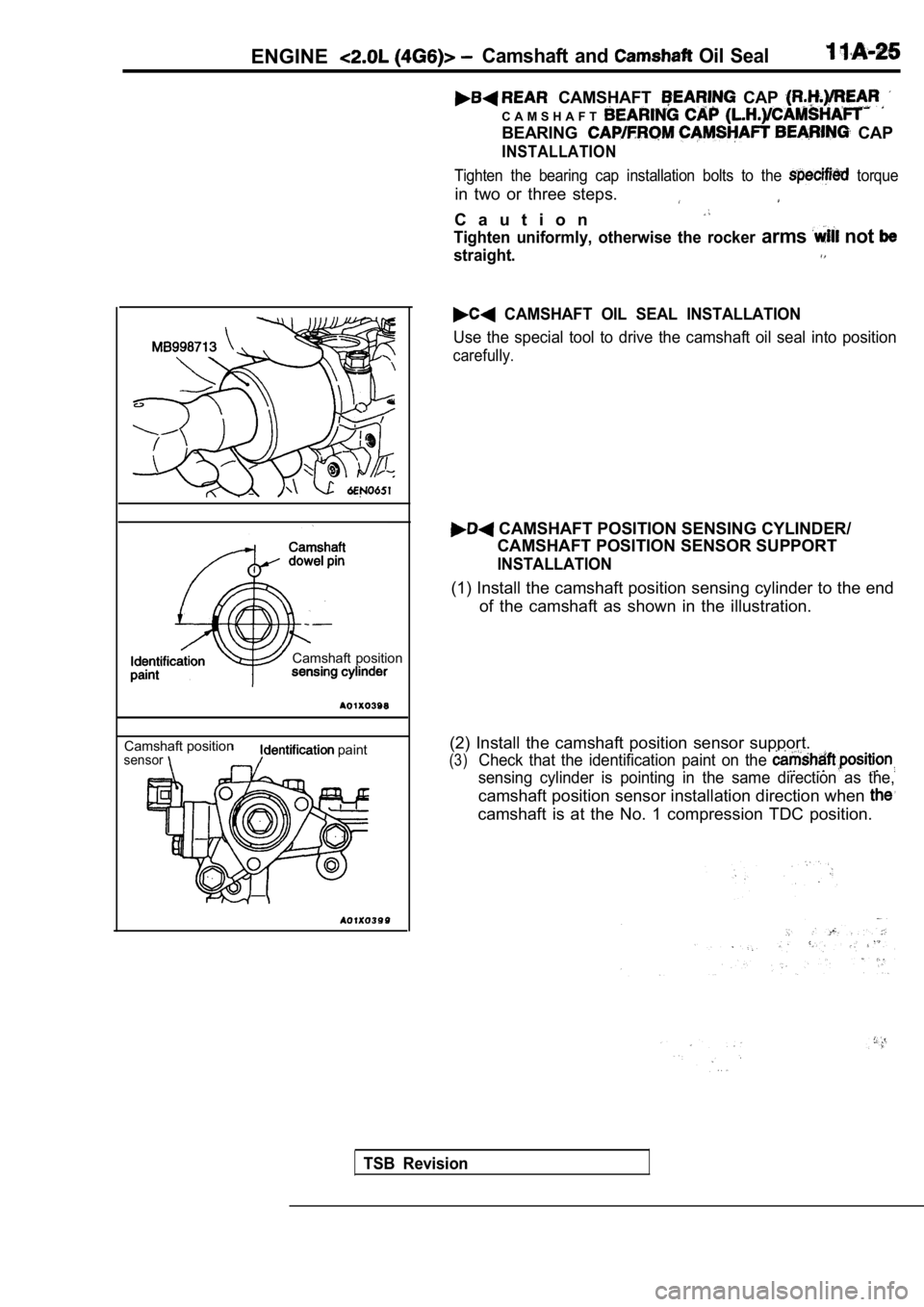

ENGINECamshaft and Oil Seal

CAMSHAFT CAP

C A M S H A F T

BEARING CAP

INSTALLATION

Tighten the bearing cap installation bolts to the torque

in two or three steps.

C a u t i o n

Tighten uniformly, otherwise the rocker arms not

straight.

Camshaft position

Camshaft positionsensor paint

CAMSHAFT OIL SEAL INSTALLATION

Use the special tool to drive the camshaft oil seal into position

carefully.

CAMSHAFT POSITION SENSING CYLINDER/

CAMSHAFT POSITION SENSOR SUPPORT

INSTALLATION

(1) Install the camshaft position sensing cylinder to the end

of the camshaft as shown in the illustration.

(2) Install the camshaft position sensor support.

(3)Check that the identification paint on the

sensing cylinder is pointing in the same direction as the,

camshaft position sensor installation direction when

camshaft is at the No. 1 compression TDC position.

TSB Revision

Page 106 of 2103

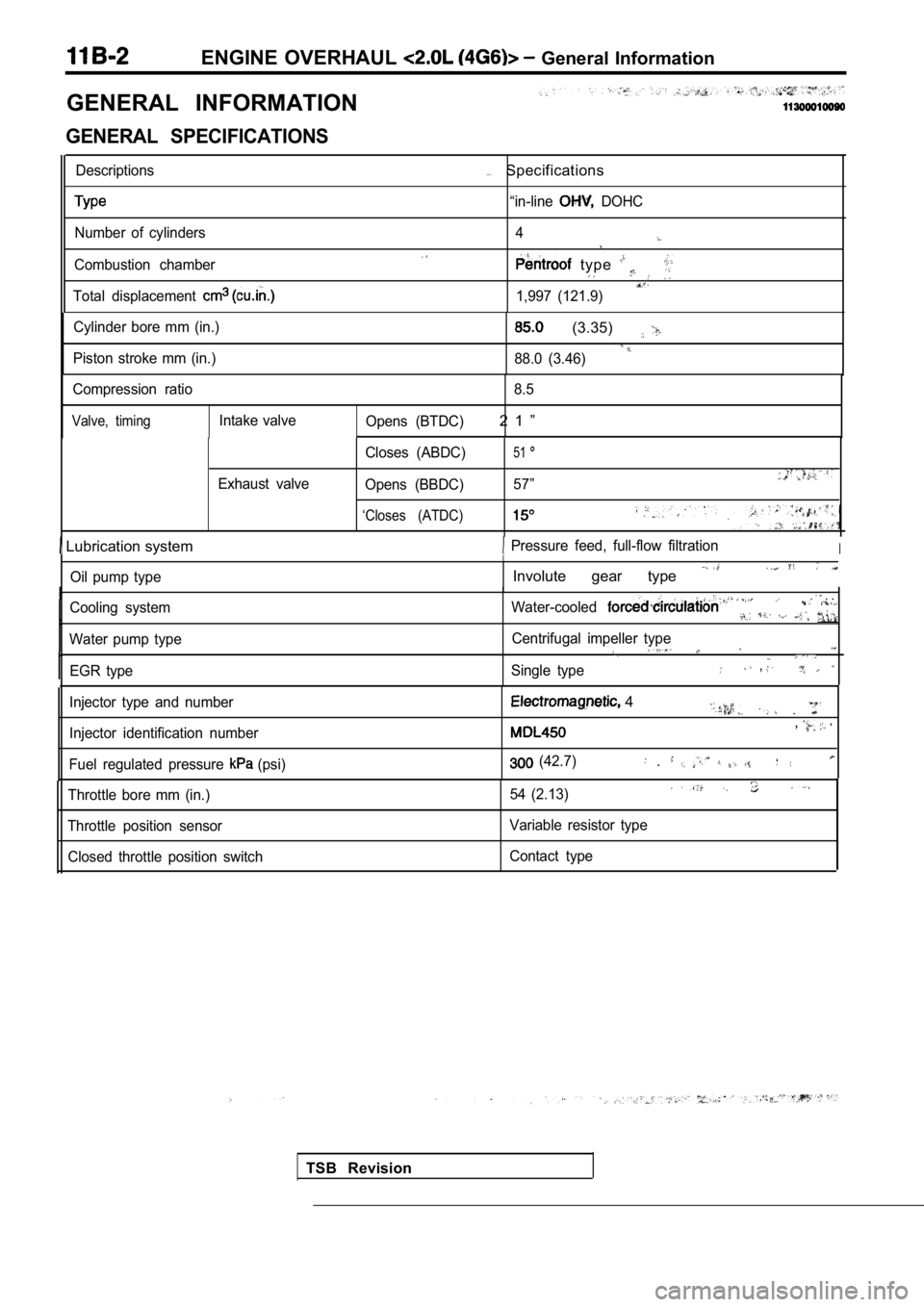

ENGINE OVERHAUL General Information

GENERAL INFORMATION

GENERAL SPECIFICATIONS

Descriptions

Number of cylinders

Combustion chamber

Total displacement

. . .Specifications

“in-line DOHC

4

type

1,997 (121.9)

Cylinder bore mm (in.)

Piston stroke mm (in.)

(3.35)

88.0 (3.46)

Compression ratio 8.5

Valve, timingIntake valve

Opens (BTDC)2 1 ”

Exhaust valve Closes (ABDC)

51

Opens (BBDC)

57”

‘Closes (ATDC)

Lubrication system Pressure feed, full-flow filtrationI

Oil pump type

Cooling system

Water pump type EGR type

I

Involute gear type

Water-cooled . .

Centrifugal impeller type

Single type,

TSB Revision

Injector type and number

Injector identification number

Fuel regulated pressure

(psi)

4

,

(42.7) .

Throttle bore mm (in.)

Throttle position sensor Closed throttle position switch 54 (2.13)

Variable resistor type

Contact type

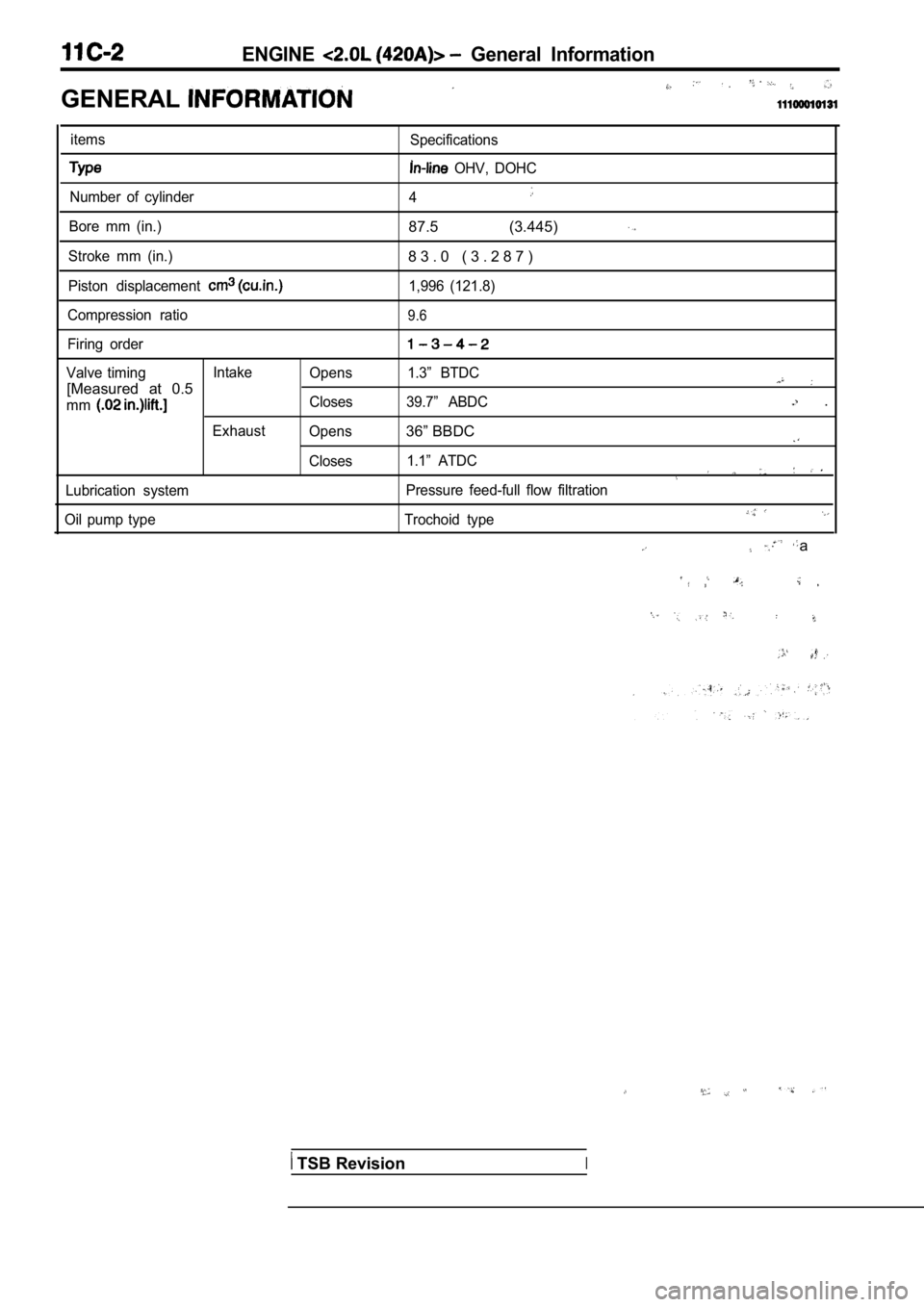

Page 172 of 2103

ENGINE General Information

GENERAL

itemsSpecifications

OHV, DOHC

Number of cylinder 4

Bore mm (in.)87.5 (3.445)

Stroke mm (in.)8 3 . 0 ( 3 . 2 8 7 )

Piston displacement 1,996 (121.8)

Compression ratio

9.6

Firing order

Valve timing Intake

Opens 1.3” BTDC

[Measured at 0.5

mmCloses 39.7” ABDC .

Exhaust Opens36” BBDC

Closes 1.1” ATDC

Lubrication system Pressure feed-full flow filtration

Oil pump type Trochoid type

a

TSB RevisionI

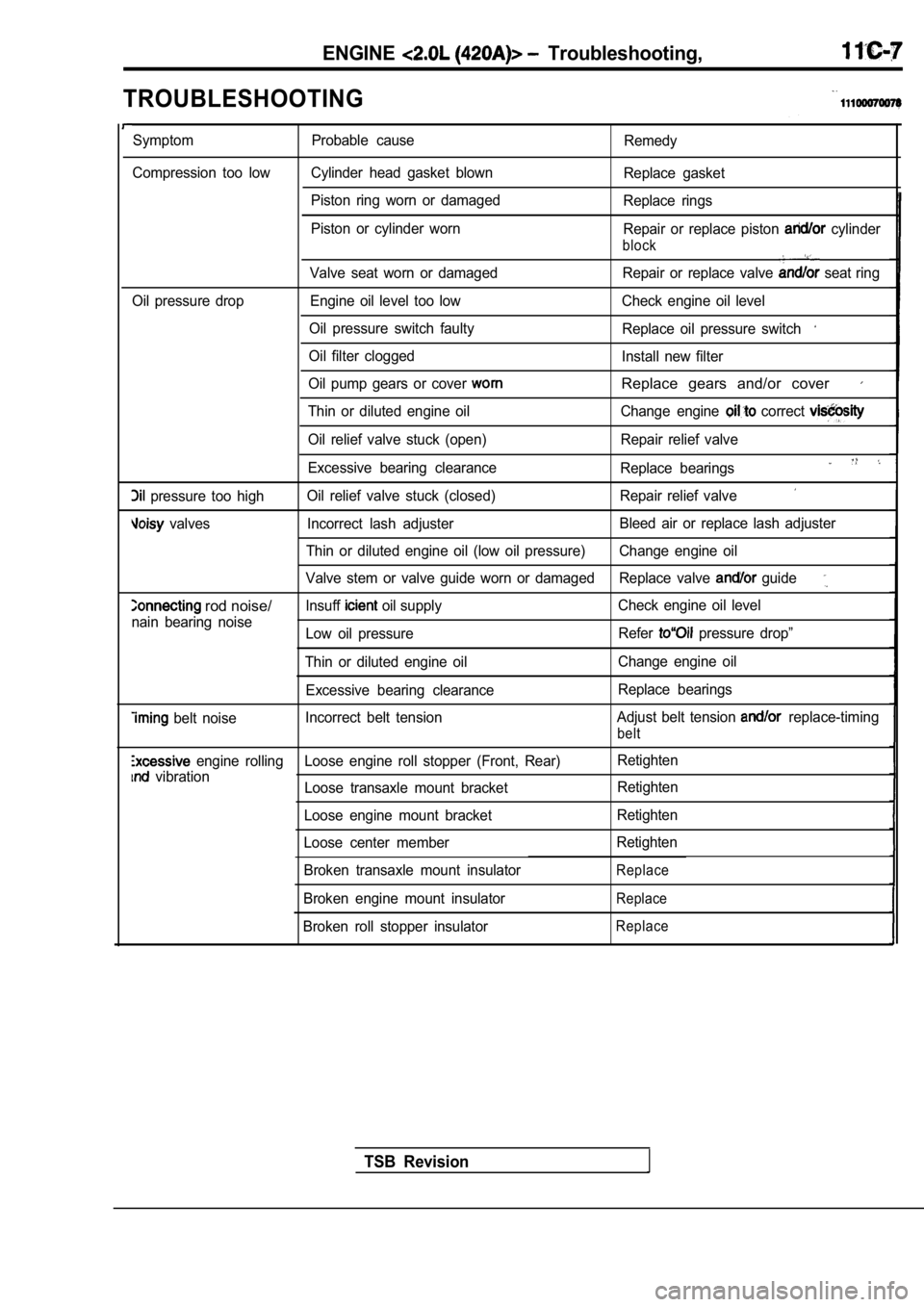

Page 177 of 2103

ENGINE Troubleshooting,

TROUBLESHOOTING

Symptom Probable causeRemedy

Compression too low Cylinder head gasket blown Replace gasket

Piston ring worn or damaged Replace rings

Piston or cylinder worn Repair or replace piston

cylinder

block

Valve seat worn or damaged Repair or replace valve seat ring

Oil pressure drop Engine oil level too low Check engi ne oil level

Oil pressure switch faulty Replace oil pressure switch

Oil filter clogged

Install new filter

Oil pump gears or cover

Replace gears and/or cover

Thin or diluted engine oil Change engine correct

Oil relief valve stuck (open) Repair relief valve

Excessive bearing clearance Replace bearings

pressure too highOil relief valve stuck (closed) Repair relief valve

valves Incorrect lash adjuster Bleed air or replace lash adjuster

Thin or diluted engine oil (low oil pressure) Change engine oil

Valve stem or valve guide worn or damaged Replace va lve

guide

rod noise/lnsuff oil supplyCheck engine oil level

nain bearing noise Low oil pressure Refer

pressure drop”

Thin or diluted engine oil Change engine oil

Excessive bearing clearance Replace bearings

belt noiseIncorrect belt tension

Adjust belt tension replace-timing

belt

engine rolling Loose engine roll stopper (Front, Re

ar)Retighten

vibration

Loose transaxle mount bracket Retighten

Loose engine mount bracket Retighten

Loose center member Retighten

Broken transaxle mount insulator

Replace

Broken engine mount insulatorReplace

Broken roll stopper insulatorReplace

TSB Revision

Page 182 of 2103

E N G I N E On-vehicle Service’

5. Cover the spark plug hole with a shop towel etc. , and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

. Caution

1.Keep away from the spark plug hole when crank-

ing.

2. If compression is measured with water, oil, fuel ,

etc., that has come from cracks inside the cylinder ,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

6.Set compression gauge to one of the spark plug hole s.

7. Crank the engine with the throttle valve fully o pen and

measure the compression pressure.

Standard value (at engine speed of

p s i )

Limit (at engine speed of

min. 689 (100 psi)

8.Measure the compression pressure for all the cylind ers,

and check that the pressure differences of the cylinders

are below the limit.

Limit:

NOTE

The limit value can be derived by calculating the d ifference

between the maximum and minimum values for the

compression pressure and dividing this value by the

maximum value.

9.If there is a cylinder with compression or a compre ssion

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps 7 and 8. (1) If the compression increases after oil is added , the

cause of the malfunction is a worn or damaged pisto n

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is a dded,

the cause is a burnt or defective valve seat, or pr essure

is leaking from the gasket.

10. Connect the

relay (ASD relay) connector.

11. Install the spark plug and spark plug cable.

12. Use the scan tool to erase the diagnostic troub le codes.

NOTE

This will erase the diagnostic trouble code resulti ng

the relay (ASD relay) being disconnected.

TSB Revision

Page 208 of 2103

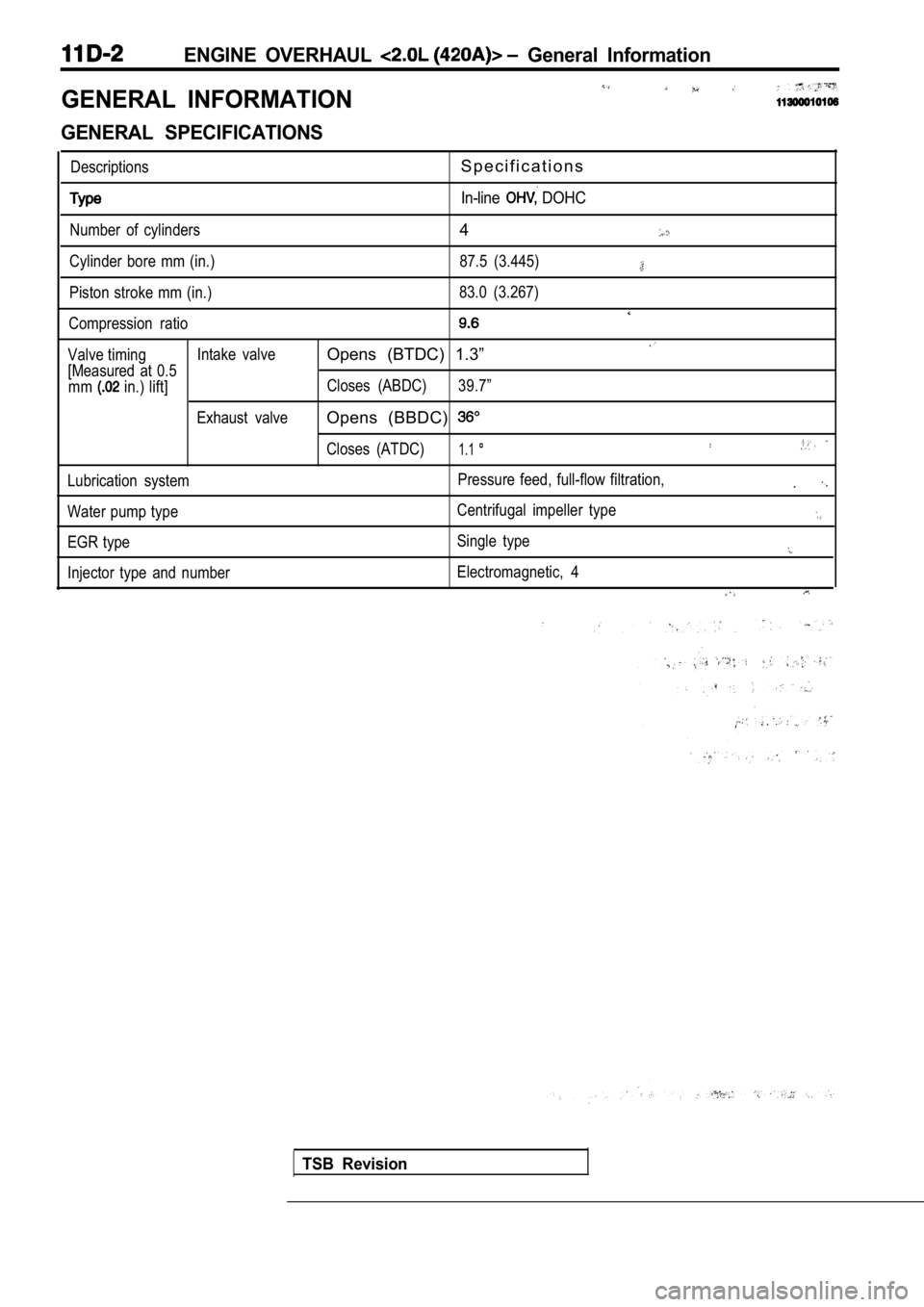

ENGINE OVERHAUL General Information

GENERAL INFORMATION

GENERAL SPECIFICATIONS

DescriptionsS p e c i f i c a t i o n s

In-line DOHC

Number of cylinders

Cylinder bore mm (in.)

Piston stroke mm (in.)

Compression ratio

Valve timing Intake valve

[Measured at 0.5 mm

in.) lift]

Exhaust valve

Lubrication system

Water pump type

EGR type

Injector type and number

4

87.5 (3.445)

83.0 (3.267)

Opens (BTDC) 1.3”

Closes (ABDC) 39.7”

Opens (BBDC)

Closes (ATDC)1.1

Pressure feed, full-flow filtration,

Centrifugal impeller type

Single type

Electromagnetic, 4

TSB Revision