torque MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1787 of 2103

S T E E R I N G

POWER PRESSURE

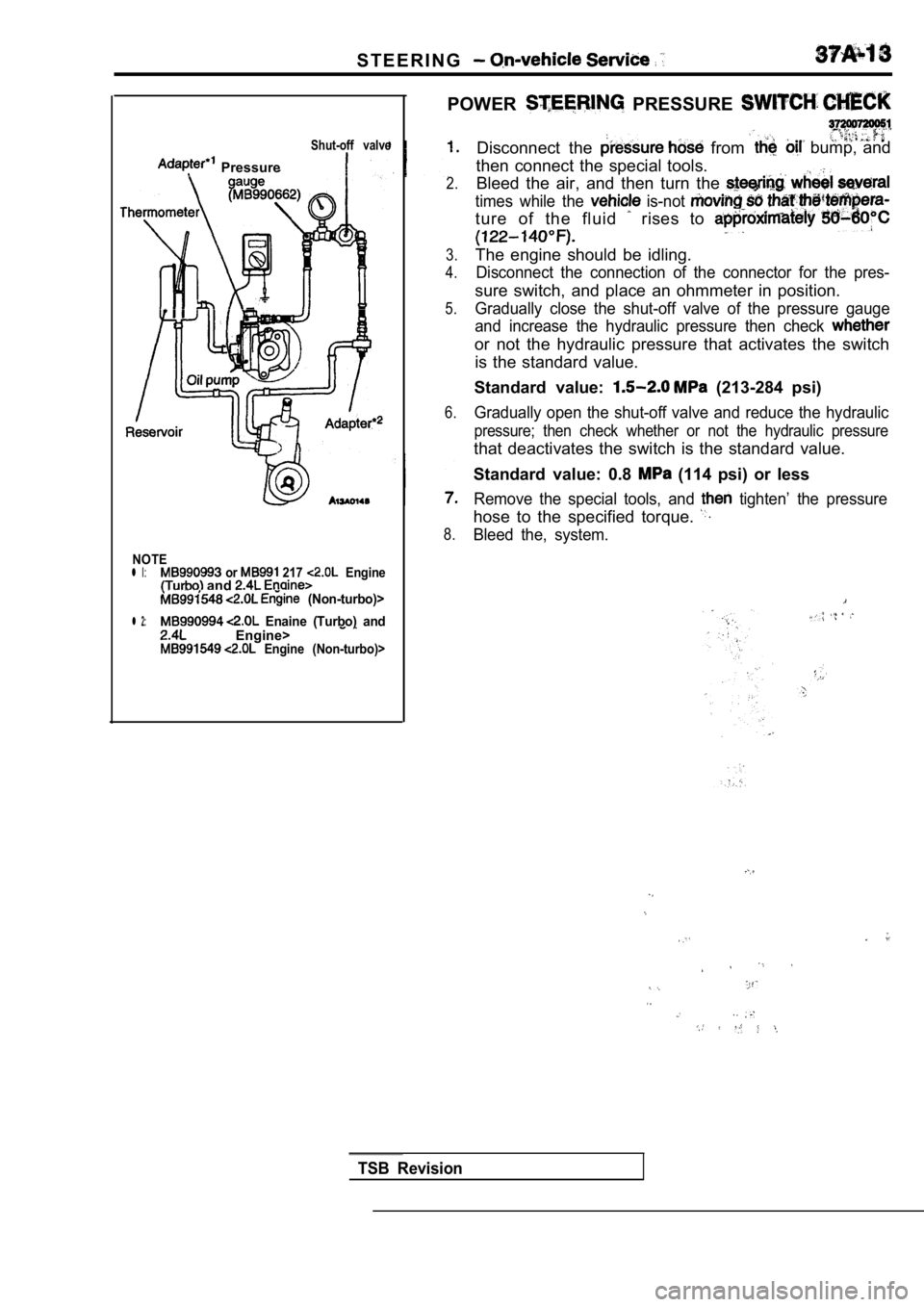

Shut-off valve

Pressure

2.

3.

4.

Disconnect the from bump, and

then connect the special tools. Bleed the air, and then turn the

times while the is-not

ture of the fluid rises to

The engine should be idling.

5.

Disconnect the connection of the connector for the pres-

sure switch, and place an ohmmeter in position.

Gradually close the shut-off valve of the pressure gauge

and increase the hydraulic pressure then check

or not the hydraulic pressure that activates the sw itch

is the standard value.

Standard value:

(213-284 psi)

6.Gradually open the shut-off valve and reduce the hy draulic

pressure; then check whether or not the hydraulic p ressure

that deactivates the switch is the standard value.

Standard value: 0.8

(114 psi) or less

8.

Remove the special tools, and tighten’ the pressure

hose to the specified torque.

Bleed the, system.

NOTEl l or 217 Engine and (Non-turbo)>

l 2: Enaine (Turbo) and Engine> Engine (Non-turbo)>

TSB Revision

Page 1796 of 2103

S T E E R I N G

TSB Revision

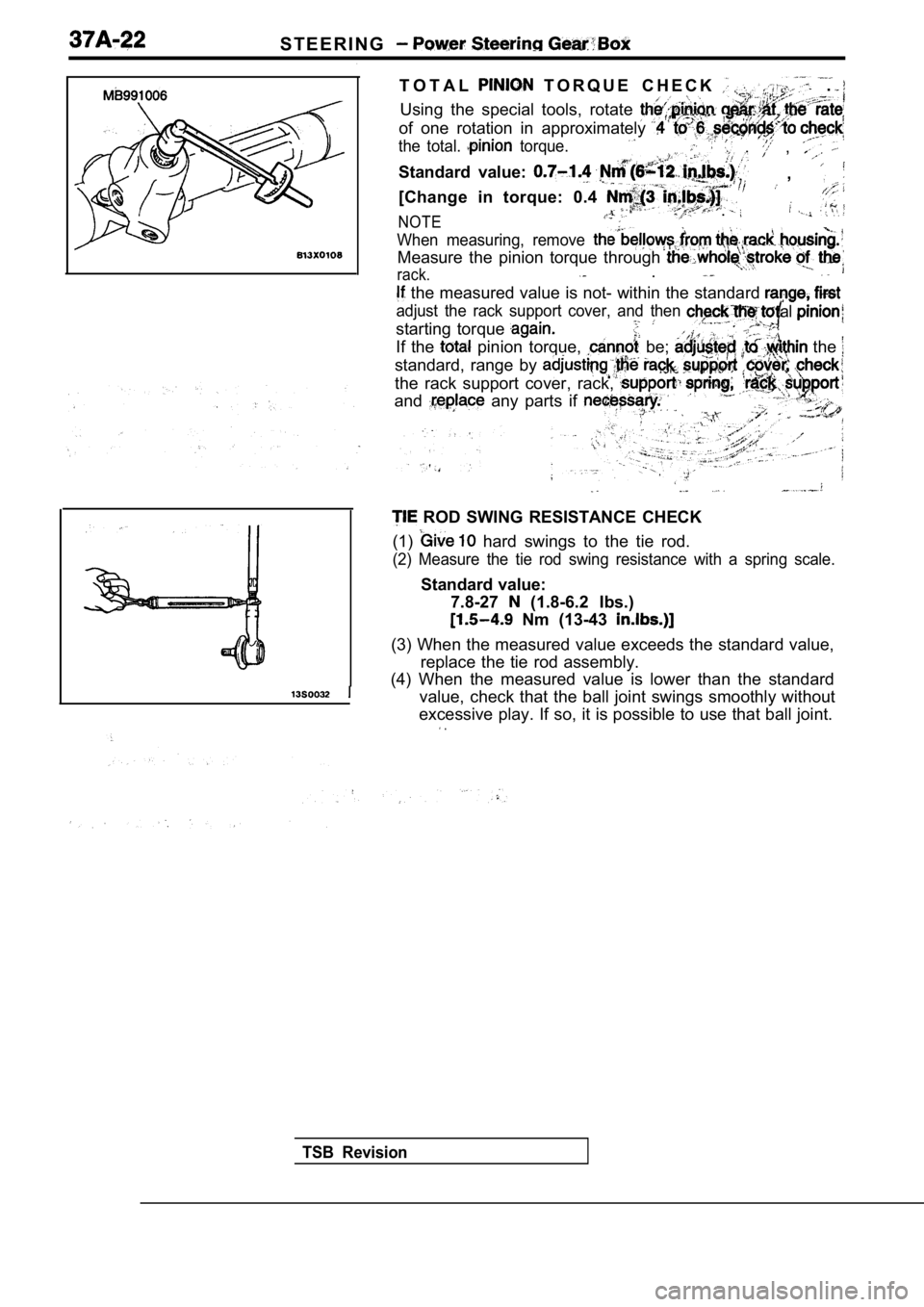

T O T A L T O R Q U E C H E C K .

Using the special tools, rotate

of one rotation in approximately

the total. torque. , ,

Standard value: ,

[Change in torque: 0.4

NOTE.

When measuring, remove

Measure the pinion torque through

rack. .

the measured value is not- within the standard

adjust the rack support cover, and then

starting torque

al

If the pinion torque, be; the

standard, range by

the rack support cover, rack,

and any parts if

ROD SWING RESISTANCE CHECK

(1)

hard swings to the tie rod.

(2) Measure the tie rod swing resistance with a spr ing scale.

Standard value:

7.8-27

(1.8-6.2 Ibs.)

Nm (13-43

(3) When the measured value exceeds the standard va lue,

replace the tie rod assembly.

(4) When the measured value is lower than the stand ard

value, check that the ball joint swings smoothly wi thout

excessive play. If so, it is possible to use that b all joint.

.

Page 1797 of 2103

Power Steering Gear

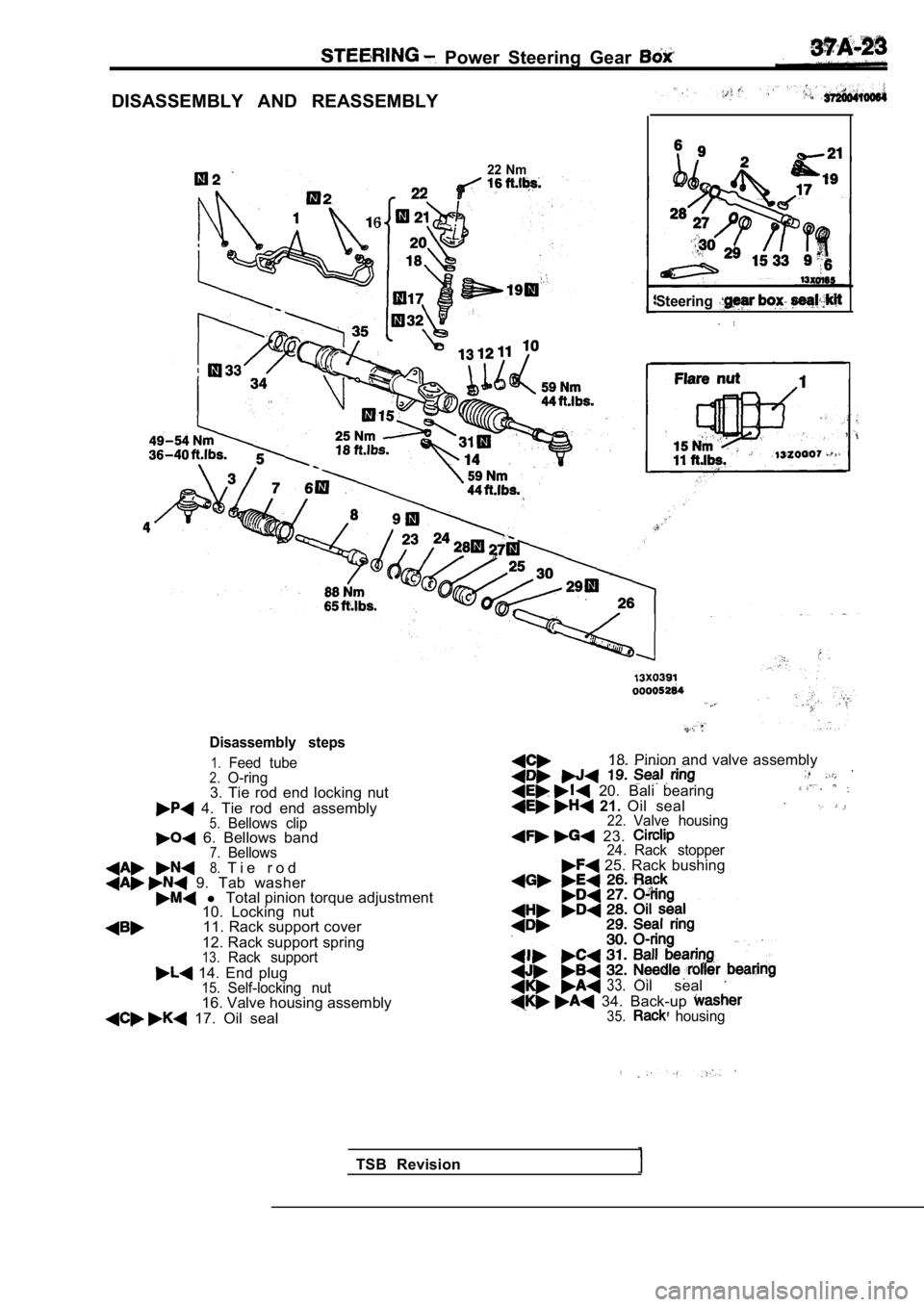

DISASSEMBLY AND REASSEMBLY

6

22 Nm

Steering

Disassembly steps

1.Feed tube2.O-ring3. Tie rod end locking nut

4. Tie rod end assembly5.Bellows clip 6. Bellows band7.Bellows8.T i e r o d 9. Tab washer l Total pinion torque adjustment

10. Locking nut

11. Rack support cover

12. Rack support spring

13.Rack support

14. End plug15.Self-locking nut16. Valve housing assembly

17. Oil seal 18. Pinion and valve assembly

20. Bali bearing 21.

Oil seal22.Valve housing

23. 24. Rack stopper 25. Rack bushing

33.Oil seal

34. Back-up 35. housing

TSB Revision

Page 1804 of 2103

STEERING Power Steering Gear Box

Bellows band

Concave

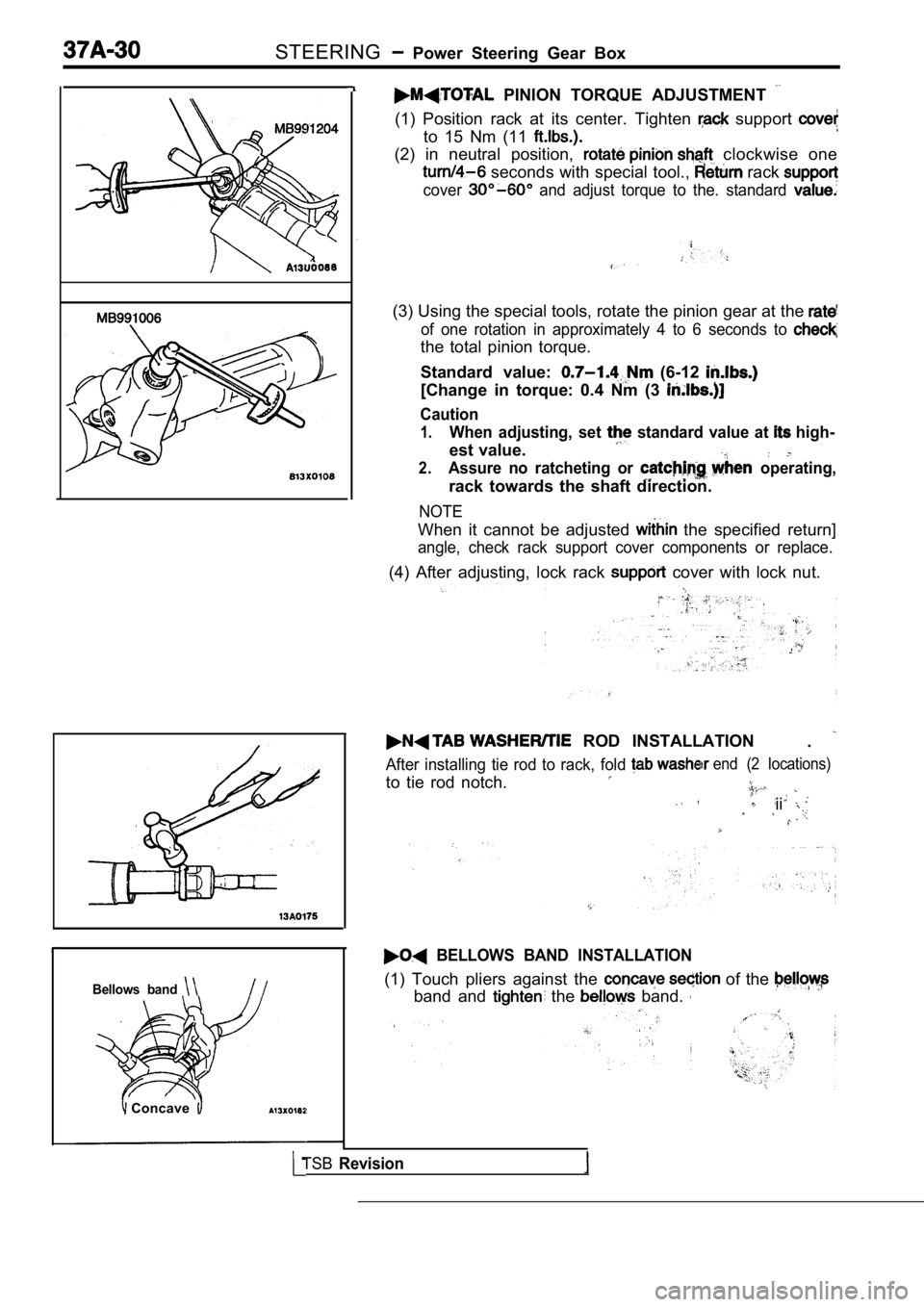

PINION TORQUE ADJUSTMENT

(1) Position rack at its center. Tighten support

to 15 Nm (11

(2) in neutral position, clockwise one

seconds with special tool., rack

cover and adjust torque to the. standard

(3) Using the special tools, rotate the pinion gear at the

of one rotation in approximately 4 to 6 seconds to

the total pinion torque.

Standard value:

(6-12

[Change in torque: 0.4 Nm (3

Caution

1.When adjusting, set standard value at high-

est value.

2.Assure no ratcheting or operating,

rack towards the shaft direction.

NOTE

When it cannot be adjusted the specified return]

angle, check rack support cover components or repla ce.

(4) After adjusting, lock rack cover with lock nut.

ROD INSTALLATION

.

After installing tie rod to rack, fold

to tie rod notch.

end (2 locations)

ii

BELLOWS BAND INSTALLATION

(1) Touch pliers against the of the

band and the band.

TSBRevision

Page 1838 of 2103

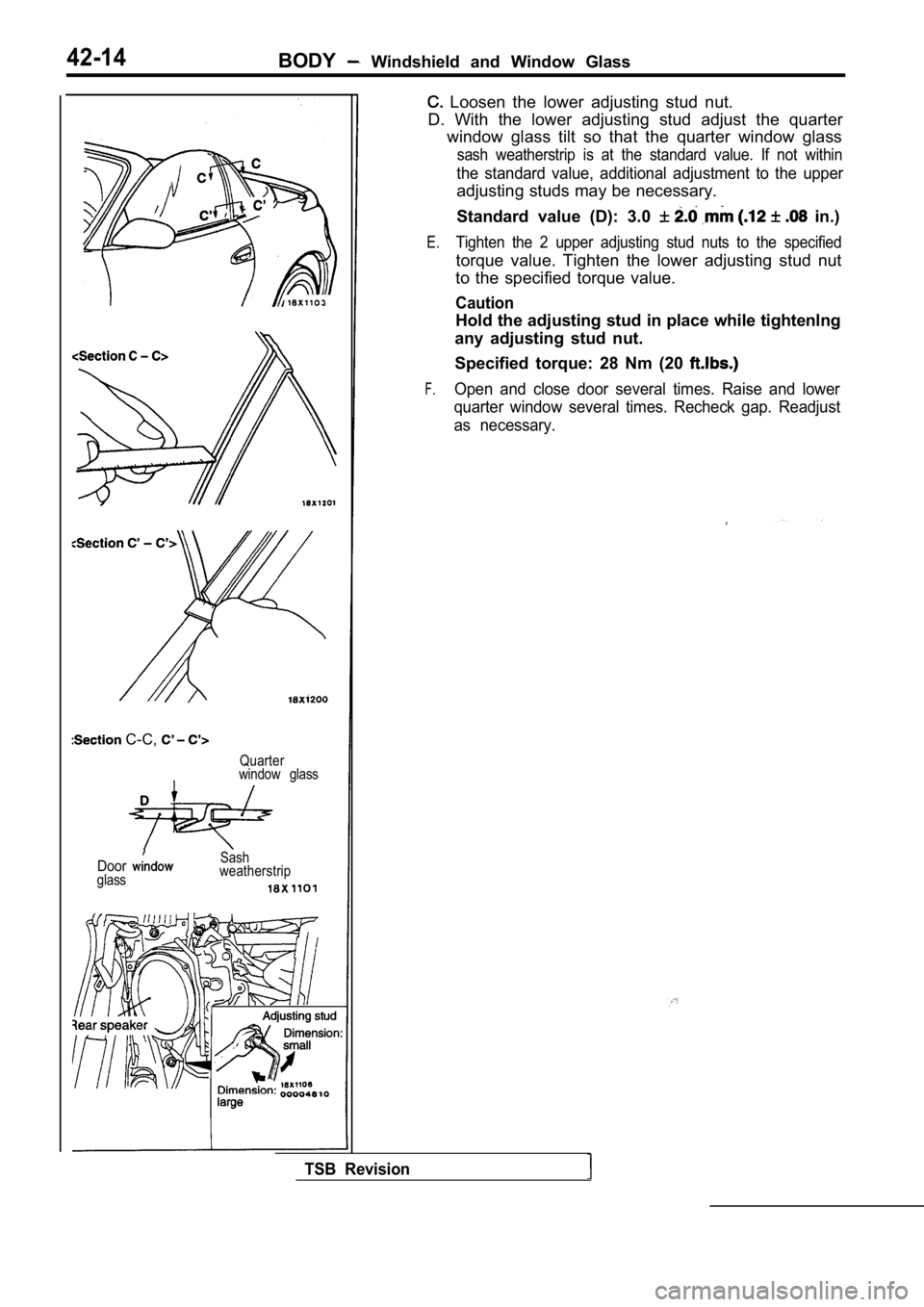

42-14BODY Windshield and Window Glass

C-C,

Quarter

window glass

Doorglass Sash

weatherstrip

Loosen the lower adjusting stud nut.

D. With the lower adjusting stud adjust the quarter window glass tilt so that the quarter window glass

sash weatherstrip is at the standard value. If not within

the standard value, additional adjustment to the upper

adjusting studs may be necessary.

Standard value (D): 3.0

in.)

E.Tighten the 2 upper adjusting stud nuts to the spec ified

torque value. Tighten the lower adjusting stud nut

to the specified torque value.

Caution

Hold the adjusting stud in place while tightenlng

any adjusting stud nut.

Specified torque: 28 Nm (20

F.Open and close door several times. Raise and lower

quarter window several times. Recheck gap. Readjust

as necessary.

TSB Revision

Page 1976 of 2103

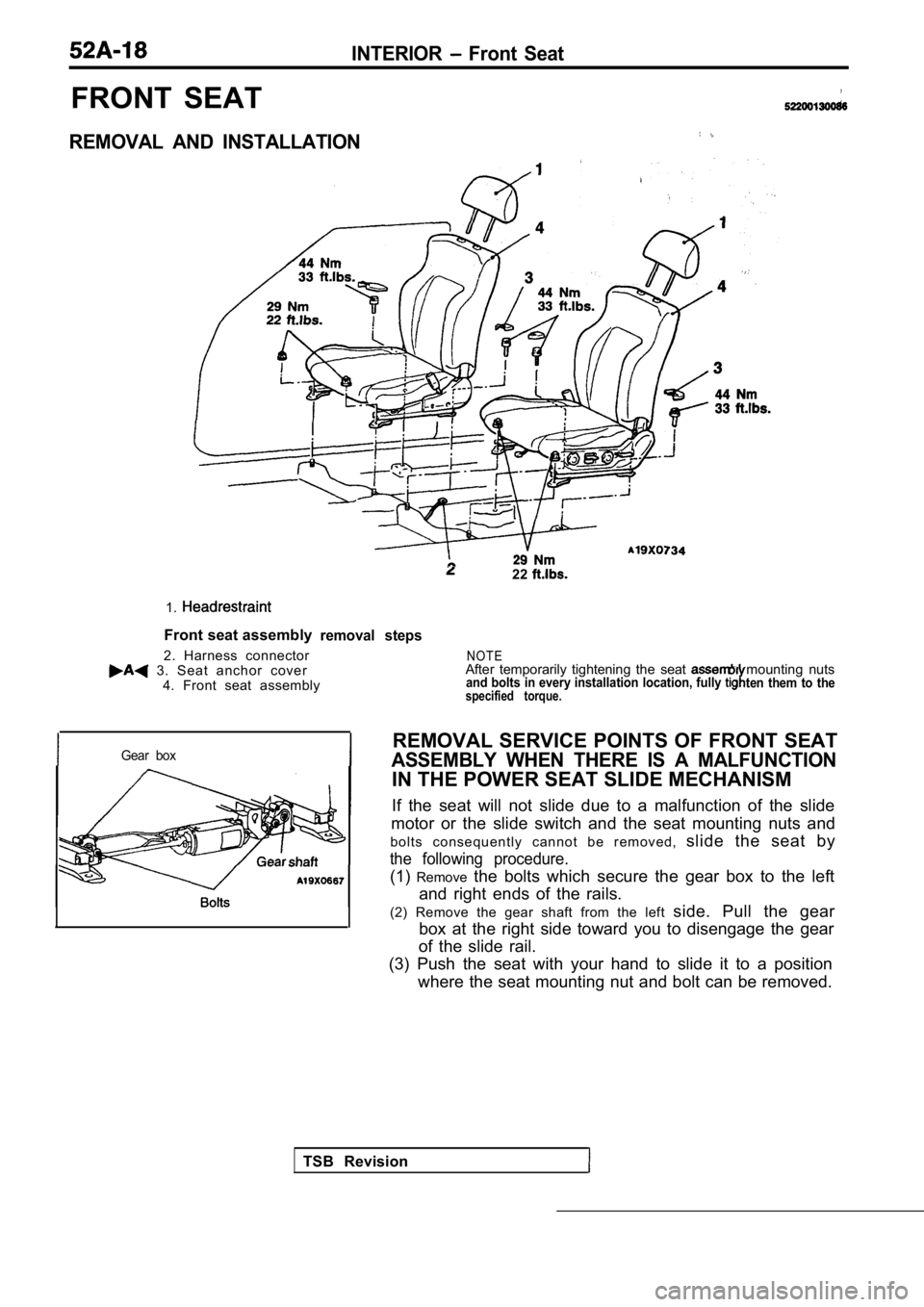

INTERIOR Front Seat

FRONT SEAT

REMOVAL AND INSTALLATION

1.

Front seat assembly

2. Harness connector

3. Seat anchor cover 4. Front seat assembly

22

removal steps

Gear box

TSB Revision

N O T EAfter temporarily tightening the seat mounting nutsand bolts in every installation location, fully ten them to thespecified torque.

REMOVAL SERVICE POINTS OF FRONT SEAT

ASSEMBLY WHEN THERE IS A MALFUNCTION

IN THE POWER SEAT SLIDE MECHANISM

If the seat will not slide due to a malfunction of the slide

motor or the slide switch and the seat mounting nut s and

b o l t s c o n s e q u e n t l y c a n n o t b e r e m o v e d , slide the seat by

the following procedure.

(1)Remove the bolts which secure the gear box to the left

and right ends of the rails.

(2) Remove the gear shaft from the left side. Pull the gear

box at the right side toward you to disengage the g ear

of the slide rail.

(3) Push the seat with your hand to slide it to a p osition

where the seat mounting nut and bolt can be removed .

Page 2056 of 2103

6HEATER, AIR

AND VENTILATION On-vehicle Service

COMPRESSOR NOISE CHECK

You must first know the conditions when the noise occurs. These conditions are: weather, vehicle speed,

in gear or neutral, engine temperature or any other special conditions.

Noises that develop during A/C operation can often be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be caus ed by loose bolts, nuts, mounting brackets, or a

loose clutch assembly. Verify accessory drive belt tension (power steering or generator).

Improper accessory drive belt tension can cause a m isleading noise when the compressor is engaged

and little or no noise when the compressor is disen gaged.

Drive belts are speed-sensitive. That is, at differ ent engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often mis taken for mechanical problems within the compressor .

ADJUSTMENT

1. Select a quiet area for testing. Duplicate conditions as much as possible. Switch compressor on

and off several times to clearly identify compresso r noise. To duplicate high ambient

head pressure), restrict air flow through condenser . Install manifold gauge set sure discharge

pressure doesn’t exceed 2,070 (300 psi).

2. Tighten all compressor mounting bolts, clutch mo unting bolt, and compressor drive belt. Check to

assure clutch coil is tight (no rotation or wobble) .

3. Check refrigerant hoses for rubbing or interfere nce that can cause unusual noises.

4. Check refrigerant charge. (Refer to

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mountin g bolts and retorque. Repeat Step 1.

7. If noise continues, replace compressor and repea t Step 1.

Revision

Page 2081 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual and Tension

Engine (Non-turbo)>

Bolt mm in.)]

Socket

Deep socket

(14 mm

in.)]

TSB

HUB REMOVAL

(1) Remove the clutch hub mounting bolt.

(2) Tighten a

mm in.) bolt into the ho MITSUBISHI SPYDER 1990 Service Repair Manual and Tension

Engine (Non-turbo)>

Bolt mm in.)]

Socket

Deep socket

(14 mm

in.)]

TSB

HUB REMOVAL

(1) Remove the clutch hub mounting bolt.

(2) Tighten a

mm in.) bolt into the ho](/img/19/57345/w960_57345-2080.png)

and Tension

Engine (Non-turbo)>

Bolt mm in.)]

Socket

Deep socket

(14 mm

in.)]

TSB

HUB REMOVAL

(1) Remove the clutch hub mounting bolt.

(2) Tighten a

mm in.) bolt into the hole of the

clutch hub to remove the serration assembly the shaft

and the clutch hub.

SEAL INSTALLATION

Use a 21 mm in.) socket to install the shaft seal so

that the O-ring assembly side is facing the front h ousing.

FELT, FELT HOLDER INSTALLATION

After installing the felt in the felt holder, them to the

front housing using a 14 mm

deep socket.

FRONT HOUSING INSTALLATION

(1) Apply compressor oil to the shaft.

Compressor oil: ND-OIL 8

(2) Install the front housing without damaging the shaft seal

lip.

(3) After installing the front housing, install the clutch hub

mounting bolt to the shaft, and check that the breakaway

torque is within the torque value.

Breakaway torque:

Nm (4 or less

Page 2093 of 2103

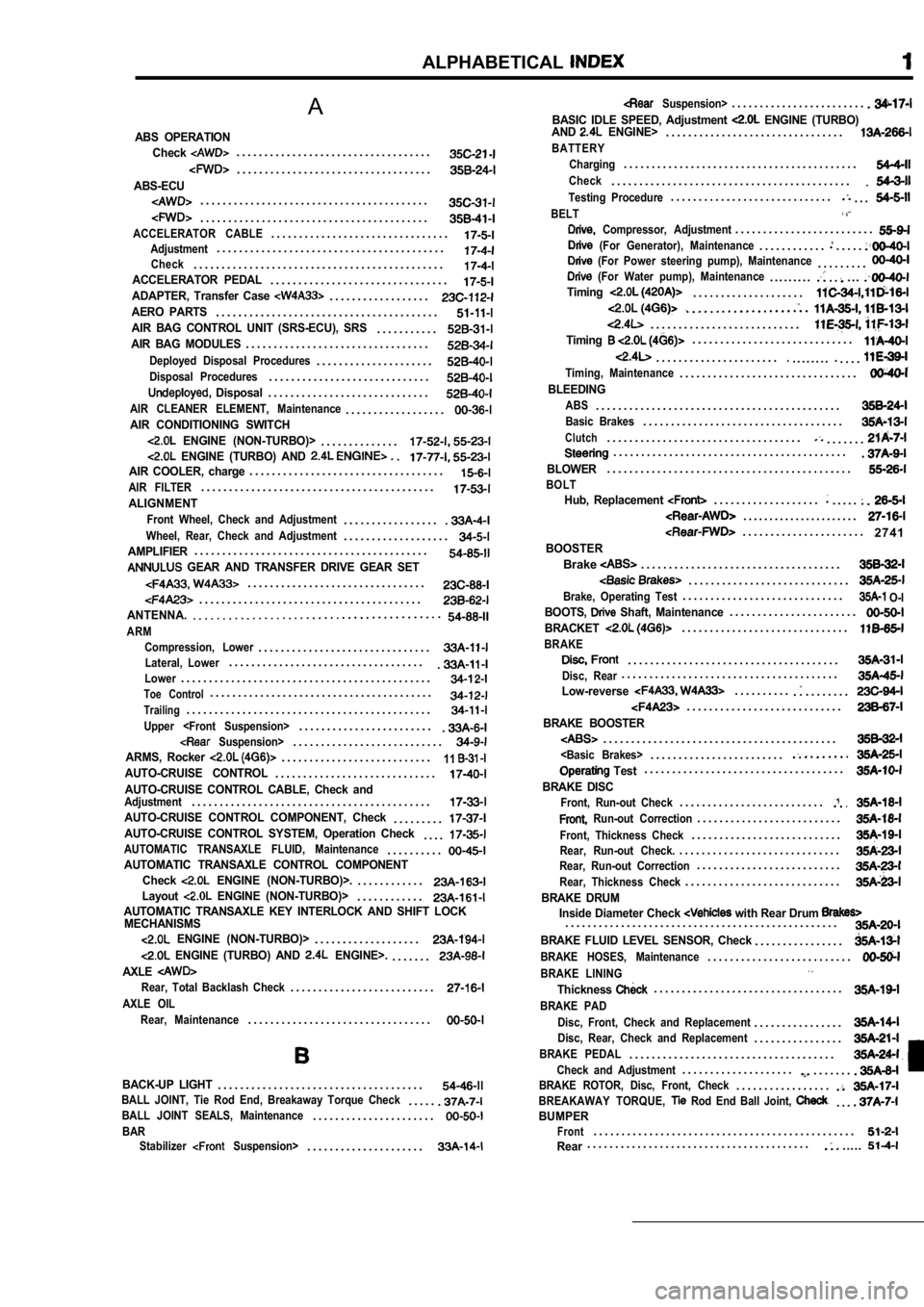

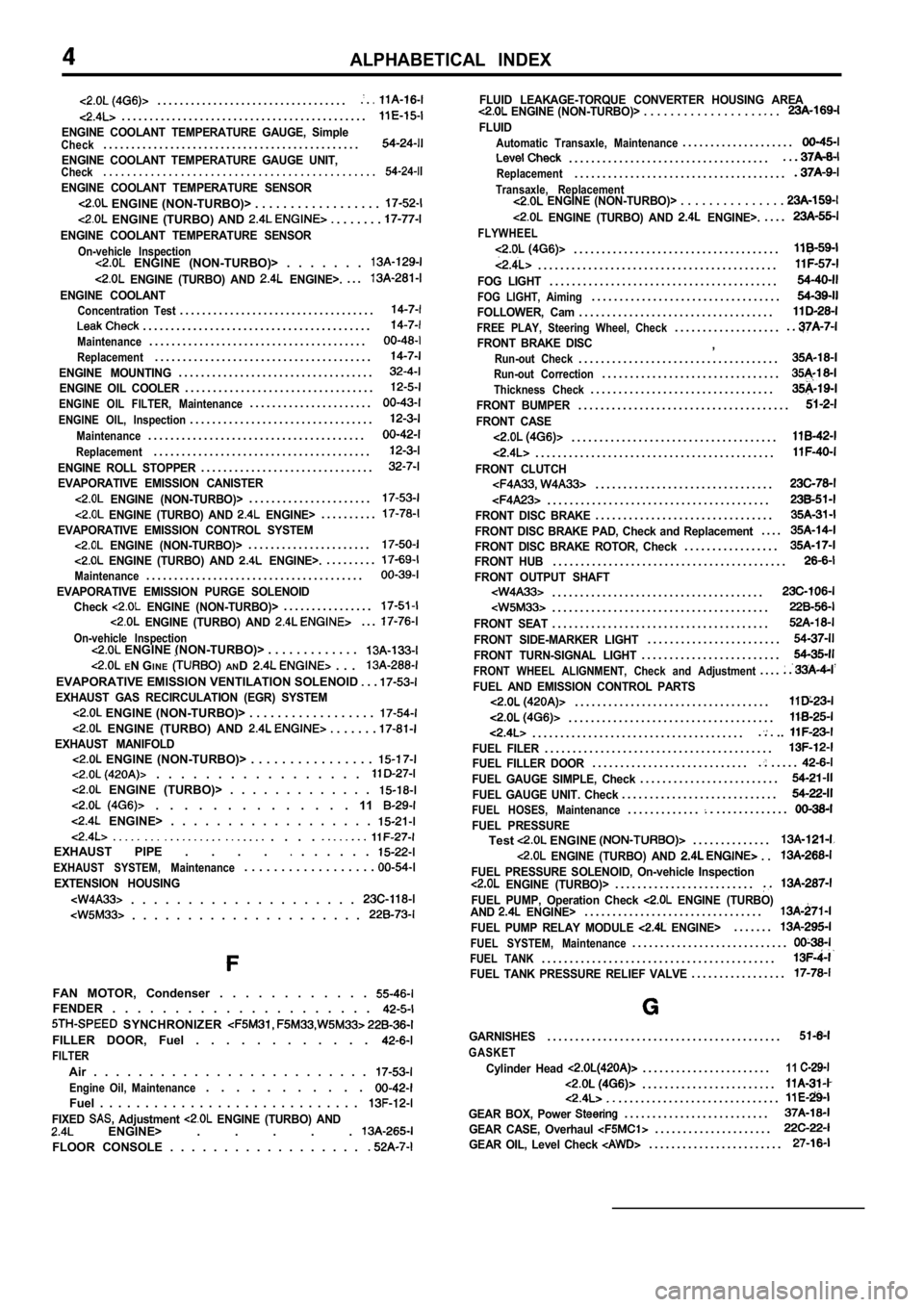

ALPHABETICAL

A

ABS OPERATIONCheck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABS-ECU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ACCELERATOR CABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ACCELERATOR PEDAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADAPTER, Transfer Case . . . . . . . . . . . . . . . . . .

AERO PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR BAG CONTROL UNIT (SRS-ECU), SRS. . . . . . . . . . .AIR BAG MODULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deployed Disposal Procedures. . . . . . . . . . . . . . . . . . . . .

Disposal Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR CLEANER ELEMENT, Maintenance. . . . . . . . . . . . . . . . . .AIR CONDITIONING SWITCH

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . ENGINE (TURBO) AND .AIR COOLER, charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR FILTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALIGNMENT

Front Wheel, Check and Adjustment. . . . . . . . . . . . . . . . .

Wheel, Rear, Check and Adjustment. . . . . . . . . . . . . . . . . . .AMPLIFIER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR AND TRANSFER DRIVE GEAR SET

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANTENNA.

ARM Compression, Lower

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lateral, Lower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toe Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper

Suspension>. . . . . . . . . . . . . . . . . . . . . . . . . . .ARMS, Rocker . . . . . . . . . . . . . . . . . . . . . . . . . . .11AUTO-CRUISE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUTO-CRUISE CONTROL CABLE, Check andAdjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUTO-CRUISE CONTROL COMPONENT, Check. . . . . . . . .AUTO-CRUISE CONTROL SYSTEM, Operation Check. . . .AUTOMATIC TRANSAXLE FLUID, Maintenance. . . . . . . . . .AUTOMATIC TRANSAXLE CONTROL COMPONENTCheck

ENGINE (NON-TURBO)>.. . . . . . . . . . . .Layout ENGINE (NON-TURBO)>. . . . . . . . . . . .AUTOMATIC TRANSAXLE KEY INTERLOCK AND SHIFT LOCKMECHANISMS

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . . . . .AXLE

Rear, Total Backlash Check. . . . . . . . . . . . . . . . . . . . . . . . . .

AXLE OIL

Rear, Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BACK-UP LIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BALL JOINT, Tie Rod End, Breakaway Torque Check. . . . .BALL JOINT SEALS, Maintenance. . . . . . . . . . . . . . . . . . . . . .

BARStabilizer Suspension>. . . . . . . . . . . . . . . . . . . . .

Suspension>. . . . . . . . . . . . . . . . . . . . . . . .

BASIC IDLE SPEED, Adjustment ENGINE (TURBO)

AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BATTERY

Charging

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..Testing Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .

BELT

Compressor, Adjustment. . . . . . . . . . . . . . . . . . . . . . . . .

(For Generator), Maintenance. . . . . . . . . . . .. . . . . (For Power steering pump), Maintenance. . . . . . . . . (For Water pump), Maintenance. . . . . . . . .. .. . .Timing. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . ... . . . . . . . .

. . . .Timing, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLEEDING

ABS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLOWER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BOLTHub, Replacement . . . . . . . . . . . . . . . . . . .. . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . 2 7 4 1

BOOSTER

Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake, Operating Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . O-IBOOTS, Shaft, Maintenance. . . . . . . . . . . . . . . . . . . . . . .

BRACKET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disc, Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low-reverse. . . . . . . . . .. . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE BOOSTER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE DISC

Front, Run-out Check. . . . . . . . . . . . . . . . . . . . . . . . . .. Run-out Correction. . . . . . . . . . . . . . . . . . . . . . . . . .

Front, Thickness Check. . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear, Run-out Check.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear, Run-out Correction. . . . . . . . . . . . . . . . . . . . . . . . . .

Rear, Thickness Check. . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE DRUM

Inside Diameter Check with Rear Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE FLUID LEVEL SENSOR, Check. . . . . . . . . . . . . . . .

BRAKE HOSES, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE LINING

Thickness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE PAD

Disc, Front, Check and Replacement

. . . . . . . . . . . . . . . .Disc, Rear, Check and Replacement. . . . . . . . . . . . . . . .

BRAKE PEDAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check and Adjustment. . . . . . . . . . . . . . . . . . . .. . . . . . .BRAKE ROTOR, Disc, Front, Check. . . . . . . . . . . . . . . . .BREAKAWAY TORQUE, Rod End Ball Joint, . . .BUMPERFront. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......

Page 2096 of 2103

ALPHABETICAL INDEX

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE COOLANT TEMPERATURE GAUGE, SimpleCheck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE COOLANT TEMPERATURE GAUGE UNIT,Check. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

ENGINE COOLANT TEMPERATURE SENSOR

ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND . . . . . . .

ENGINE COOLANT TEMPERATURE SENSOR

On-vehicle Inspection ENGINE (NON-TURBO)> . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . .

ENGINE COOLANTConcentration Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE OIL COOLER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE OIL FILTER, Maintenance. . . . . . . . . . . . . . . . . . . . . .

ENGINE OIL, Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE ROLL STOPPER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVAPORATIVE EMISSION CANISTER

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>. . . . . . . . . .

EVAPORATIVE EMISSION CONTROL SYSTEM ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . . . . . . .

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EVAPORATIVE EMISSION PURGE SOLENOID

Check ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . .

ENGINE (TURBO) AND . . .

On-vehicle Inspection ENGINE (NON-TURBO)> . . . . . . . . . . . . .

EN G INE AND . . .

EVAPORATIVE EMISSION VENTILATION SOLENOID . .

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND . . . . . . EXHAUST MANIFOLD ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE (TURBO)> . . . . . . . . . . . . .

. . . . . . . . . . . . . . 11

ENGINE> . . . . . . . . . . . . . . . . . .

. . . . EXHAUST PIPE . . . . . . . . . .

EXHAUST SYSTEM, Maintenance. . . . . . . . . . . . . . . . . .

EXTENSION HOUSING

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

FAN MOTOR, Condenser . . . . . . . . . . . . FENDER . . . . . . . . . . . . . . . . . . . . .

SYNCHRONIZER

FILLER DOOR, Fuel . . . . . . . . . . . .

FILTER

Air . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil, Maintenance. . . . . . . . . . .

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIXED Adjustment ENGINE (TURBO) AND ENGINE> . . . . .

FLOOR CONSOLE . . . . . . . . . . . . . . . . . .

FLUID LEAKAGE-TORQUE CONVERTER HOUSING AREA ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . . . . .

FLUID

Automatic Transaxle, Maintenance. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle, Replacement ENGINE (NON-TURBO)> . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . .

FLYWHEEL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOG LIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOG LIGHT, Aiming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOWER, Cam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FREE PLAY, Steering Wheel, Check. . . . . . . . . . . . . . . . . . .

FRONT BRAKE DISC,Run-out Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Run-out Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thickness Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT BUMPER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT CASE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FRONT DISC BRAKE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT DISC BRAKE PAD, Check and Replacement. . . .

FRONT DISC BRAKE ROTOR, Check. . . . . . . . . . . . . . . . .FRONT HUB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT OUTPUT SHAFT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT SEAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT SIDE-MARKER LIGHT. . . . . . . . . . . . . . . . . . . . . . . .

FRONT TURN-SIGNAL LIGHT. . . . . . . . . . . . . . . . . . . . . . . . .

FRONT WHEEL ALIGNMENT, Check and Adjustment. . . .

FUEL AND EMISSION CONTROL PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

FUEL FILER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FUEL FILLER DOOR. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

FUEL GAUGE SIMPLE, Check. . . . . . . . . . . . . . . . . . . . . . . . .

FUEL GAUGE UNIT. Check. . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL HOSES, Maintenance. . . . . . . . . . . . .. . . . . . . . . . . . .

FUEL PRESSURETest ENGINE . . . . . . . . . . . . . .

ENGINE (TURBO) AND . .

FUEL PRESSURE SOLENOID, On-vehicle Inspection ENGINE (TURBO)>. . . . . . . . . . . . . . . . . . . . . . . . .

FUEL PUMP, Operation Check ENGINE (TURBO)

AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL PUMP RELAY MODULE ENGINE>. . . . . . .

FUEL SYSTEM, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUEL TANK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FUEL TANK PRESSURE RELIEF VALVE. . . . . . . . . . . . . . . . .

GARNISHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GASKET

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . .11

. . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR BOX, Power . . . . . . . . . . . . . . . . . . . . . . . . . .

GEAR CASE, Overhaul . . . . . . . . . . . . . . . . . . . . .

GEAR OIL, Level Check . . . . . . . . . . . . . . . . . . . . . . . .