torque MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1715 of 2103

A B S

HYDRAULIC UNIT (HU) CHECK

Caution

35200170111

Turn the ignition switch off before connecting ordisconnecting the scan tool.

1.

up the vehicle and support the vehicle with rigid

racks placed at the specified jack-up points or pla ce the

wheels which are checked on the rollers of the brak ing

force tester.

Caution

1.The roller of the braking force tester and the tire

be dry during testing.

2.When testing the front brakes, apply the parking

brake, and when testing the rear brakes, stop the

front by chocking them.

2.Release the parking brake, and feel the drag force (drag

torque) on each road wheel.. __

When using the braking force tester, take a reading of’

the brake drag force.

3. Turn the ignition key to ‘the OFF position and

scan tool as shown in the diagram.

4.After checking that the shift lever or

lever is in neutral, start the engine.

NOTE

1.At this time, the ABS system will switch scan

tool mode -and the

warning light will

2.When the ABS has’ been interrupted by the -fail-saf e

function, the tool actuator testing cannot be

used.

5. Use the scan tool to force-drive the actuator.

TSB Revision

Page 1753 of 2103

Caution,

Turn the ignition switch off before

t h e

If the scan tool is disconnected while the ignition

switch

the diagnostic trouble codes will be memorized!

the warning’ light’ may

1. Jack up the vehicle and support: the vehicle with rigid;

racks at the specified jack-up place the

wheels which ‘are checked on. .therollers of the braking

force tester.

Caution

The roller of the braking force tester the

shouldbedry during

2. When parking!

the rear brakes, stop

them.,

2.Release the parking brake, and feel

torque) ‘each road wheel. .

using “the force tester, take “a

‘brake drag

Turn the ignition key to the

scan tool as the

lever is in neutral, start

1. At this time, the ABS

‘2.

mode and the

When the ABS has’

function, the scan tool actuator testing canbe

used.

5. Use the scan tool to force-drive the actuator.

6.Turn the wheel by check the change in

force when the brake is -depressed.

using the braking force tester, depress the brake

until braking force is at the following values,

and check to be sure that the braking force changes

to the brake drag force inspected in step 2 when the

actuator is force-driven.

Front wheel

Rear wheel

The result should be as shown in the following diagram.

7.If the result of inspection is abnormal, correct ac cording

to the “Diagnostic Table.”__ .

,

__

TSB

Page 1775 of 2103

CONTENTS

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . 2POWER STEERING GEAR . . . . . . . . . . 18

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3P O W E R S T E E R I N G H O S E ’ S

Engine . . . . .

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 7 Engine (Turbo) and . . . 47

Bleeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Checking Steering Wheel Return to Center

. . . .8

Fluid Level Check. . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fluid Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . .9

Oil Pump Test

. . . . . . . . . . . . . . . . . . . . .

Power Steering Pressure Switch Check

. . . . . . .13

Stationary Steering Effort Check. . . . . . . . . . . . . .8

Steering Angle Check. . . . . . . . . . . . . . . . . . . . . . . .7

Steering Wheel Free Play Check. . . . . . . . . . . . . . .7

Tie Rod End Ball Joint Breakaway Torque Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

POWER STEERING OIL PUMP

Engine (Non-turbo)> . . . . . . . . . . . . . . .

Engine (Turbo) and Engine> . . . 39

SEALANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . 3

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . .4

STEERING WHEEL AND

. . . . . . . . . . 14

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL (SRS) EQUIPPED

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead

the SRS inoperative).(2) Service or maintenance of any SRS component or component must be performed MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must this and especially its GROUP straint System (SRS) and GROUP 00 -Maintenance beginning any service or maintenance of any com-

ponent of the SRS or any

NOTEThe includes the following components: SRS light, air bag module, and interconnecting wiring.Other SRS-related components (that may have to be r emoved/installed in with service or maintenance) are indi-

cated in the table of contents by an asterisk

Page 1777 of 2103

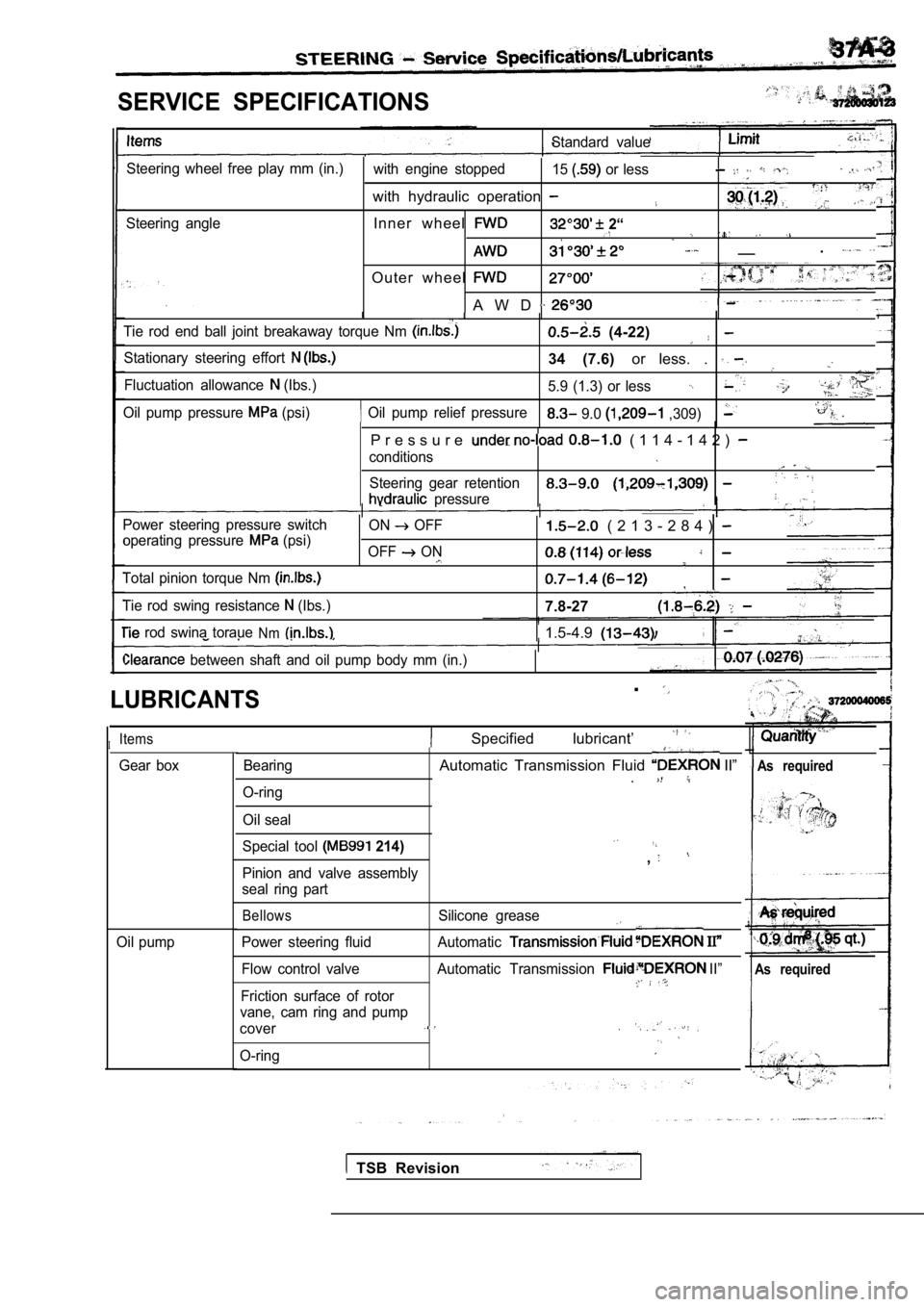

SERVICE SPECIFICATIONS

Standard value

Steering wheel free play mm (in.) with engine stopped15

or less,

with hydraulic operation

Steering angleInner wheel 2“

__

.

O u t e r w h e e l

A W D

Tie rod end ball joint breakaway torque Nm (4-22)

Stationary steering effort 34 (7.6) or less. .

Fluctuation allowance (Ibs.)

5.9 (1.3) or less

Oil pump relief pressureOil pump pressure (psi) 9.0 ,309)

P r e s s u r e ( 1 1 4 - 1 4 2 )

conditions

Steering gear retention

pressure

Power steering pressure switch

operating pressure

(psi)

Total pinion torque Nm

Tie rod swing resistance (Ibs.) ON

OFF

OFF

ON

( 2 1 3 - 2 8 4 )

7.8-27

rod swina toraueNm1.5-4.9

between shaft and oil pump body mm (in.)

LUBRICANTS

IItems

Bearing

O-ring

Oil seal

.

Specified lubricant’

Gear boxAutomatic Transmission Fluid II”

.As required

Oil pump Special tool

214)

Pinion and valve assembly

seal ring part

,

BellowsSilicone grease

Power steering fluid Automatic

Flow control valve Automatic Transmission II”

Friction surface of rotor

vane, cam ring and pump

cover.

O-ring

As required

TSB Revision

Page 1778 of 2103

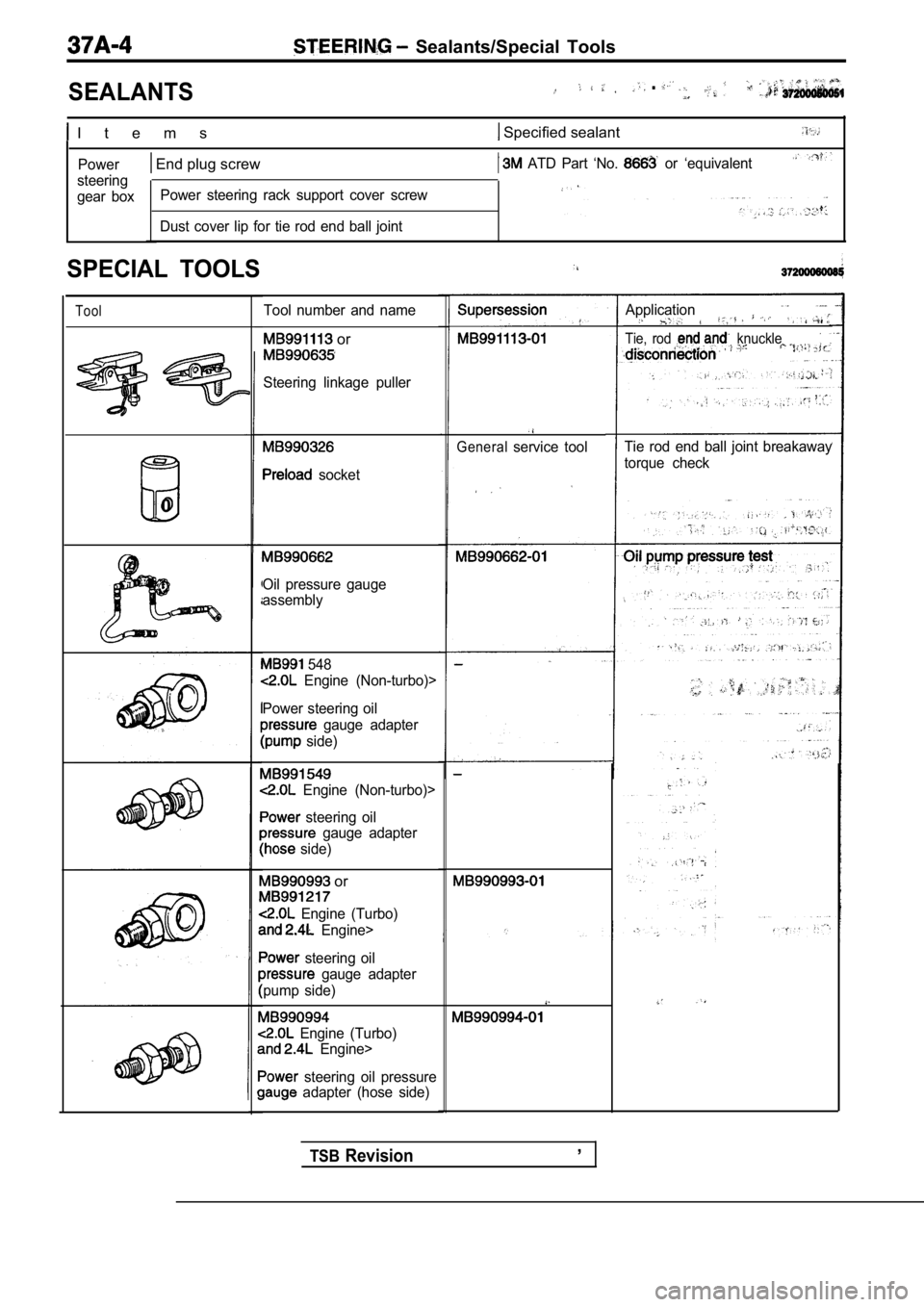

SEALANTS

Sealants/Special Tools

.

I t e m s Specified sealant

Power

steering

gear box End plug screw ATD Part ‘No. or ‘equivalent

Power steering rack support cover screw

Dust cover lip for tie rod end ball joint

SPECIAL TOOLS

Tool

0

Tool number and name

or

Steering linkage puller

socket

Oil pressure gauge

assembly

548

Engine (Non-turbo)>

Power steering oil

gauge adapter

side)

Engine (Non-turbo)>

steering oil

gauge adapter

side)

or

Engine (Turbo)

Engine>

steering oil

gauge adapter

pump side)

Engine (Turbo)

Engine>

steering oil pressure adapter (hose side)

Generalservice tool

TSBRevision,

Application

Tie, rod knuckle

Tie rod end ball joint breakaway

torque check

Page 1779 of 2103

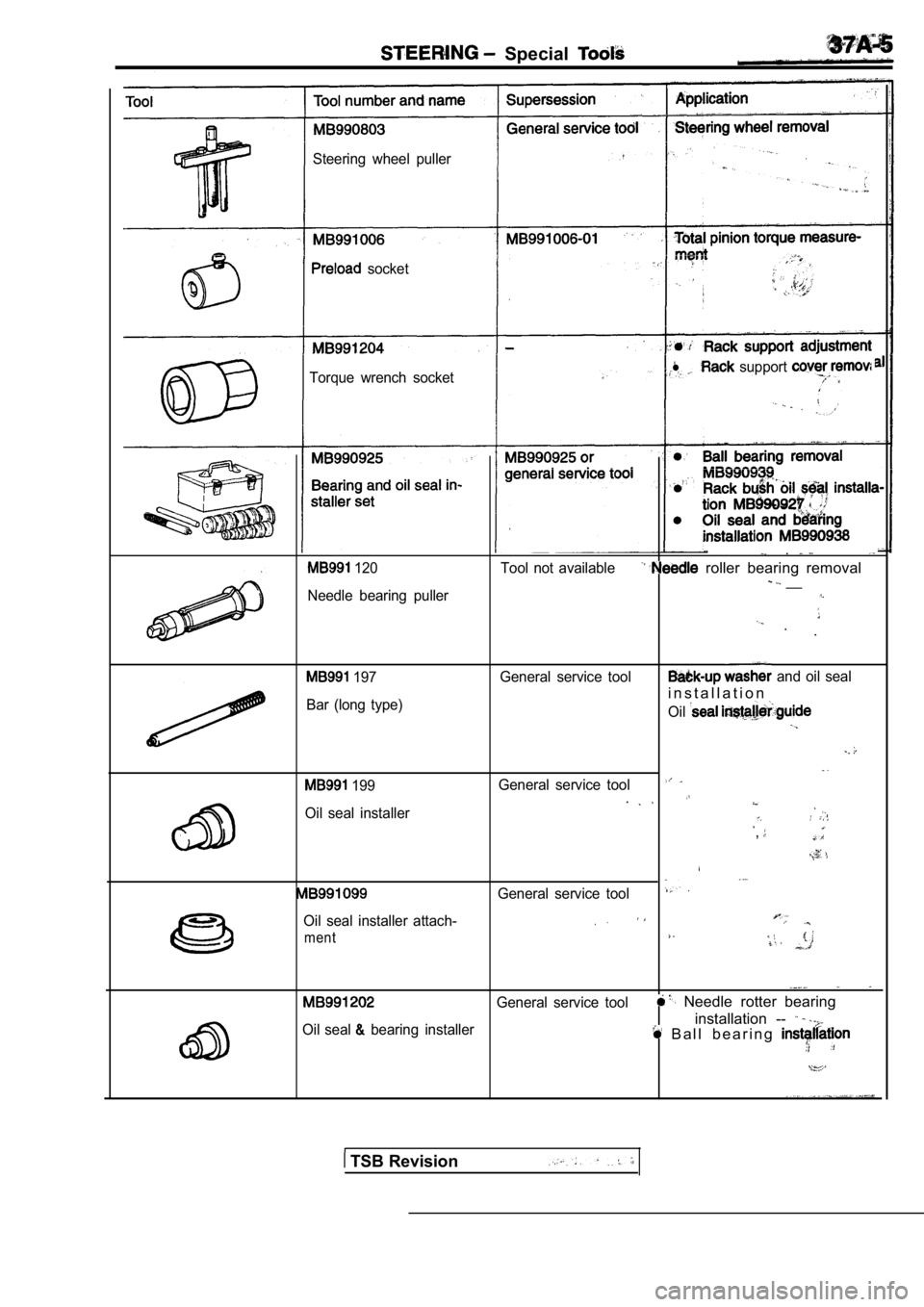

Special

Steering wheel puller

socket

Torque wrench socket

l support

120

Needle bearing puller

.

Tool not available roller bearing removal __

. .

197

Bar (long type) General service tool and oil seal

i n s t a l l a t i o n

Oil

199

Oil seal installerGeneral service tool

,

General service tool

Oil seal installer attach-

ment

General service tool Needle rotter bearing

Oil seal bearing installerinstallation -- B a l l b e a r i n g

TSB Revision

Page 1781 of 2103

STEERING On-vehicle”

TSB Revision

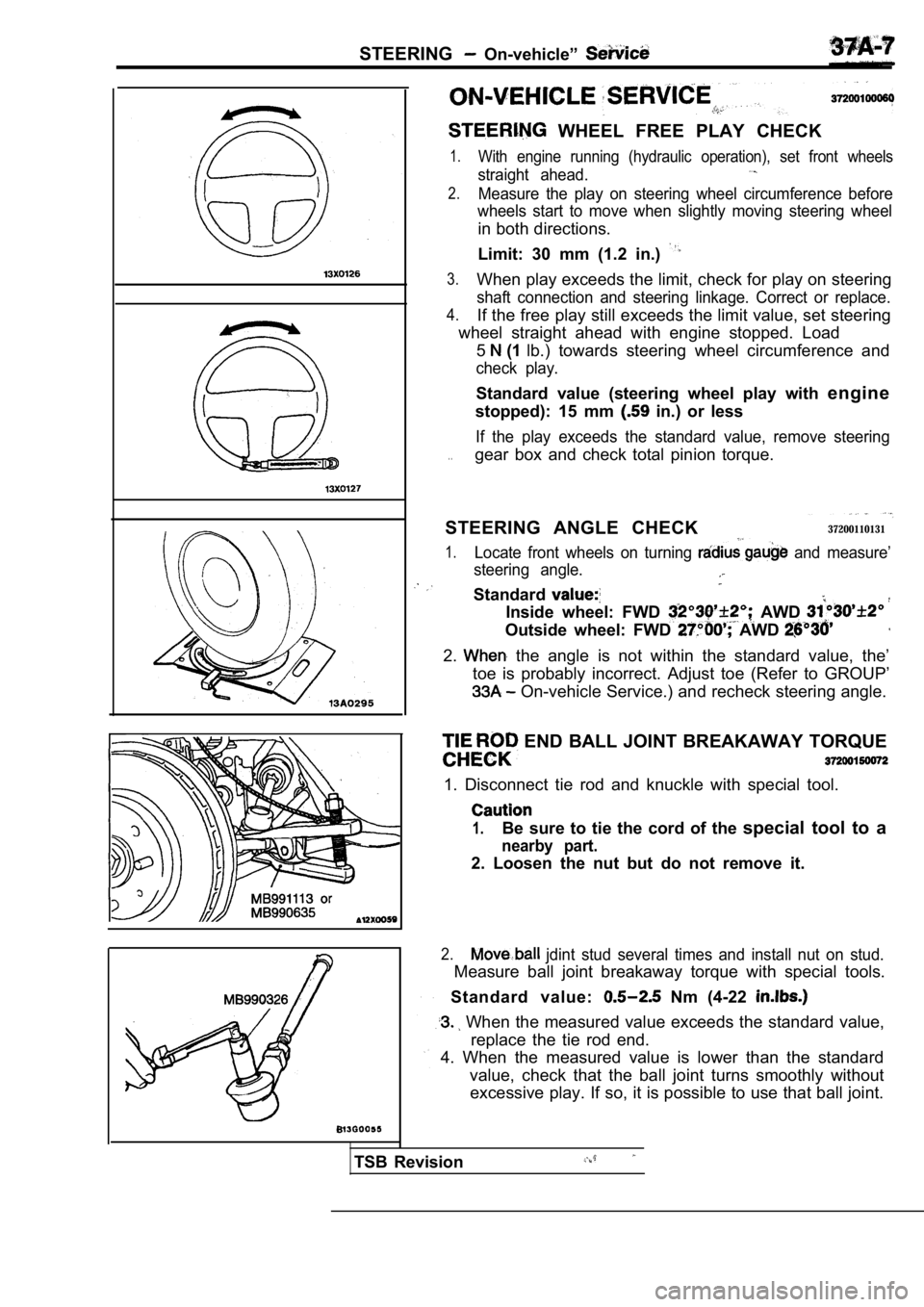

WHEEL FREE PLAY CHECK

1.With engine running (hydraulic operation), set front wheels

straight ahead.

2.Measure the play on steering wheel circumference be fore

wheels start to move when slightly moving steering wheel

in both directions.

Limit: 30 mm (1.2 in.)

3.When play exceeds the limit, check for play on steering

shaft connection and steering linkage. Correct or replace.

4.If the free play still exceeds the limit value, set steering

wheel straight ahead with engine stopped. Load

5

(1 lb.) towards steering wheel circumference and

check play.

Standard value (steering wheel play with engine

stopped): 15 mm

in.) or less

If the play exceeds the standard value, remove stee ring

. .gear box and check total pinion torque.

STEERING ANGLE CHECK

37200110131

1.Locate front wheels on turning and measure’

steering angle.

Standard

Inside wheel: FWD AWD

Outside wheel: FWD AWD

2. the angle is not within the standard value, the’

toe is probably incorrect. Adjust toe (Refer to GRO UP’

On-vehicle Service.) and recheck steering angle.

END BALL JOINT BREAKAWAY TORQUE

1. Disconnect tie rod and knuckle with special tool .

1.Be sure to tie the cord of the special tool to a

nearby part.

2. Loosen the nut but do not remove it.

2. jdint stud several times and install nut on stud.

Measure ball joint breakaway torque with special to ols.

Standard value:

Nm (4-22

When the measured value exceeds the standard value ,

replace the tie rod end.

4. When the measured value is lower than the standa rd

value, check that the ball joint turns smoothly wit hout

excessive play. If so, it is possible to use that b all joint.

Page 1784 of 2103

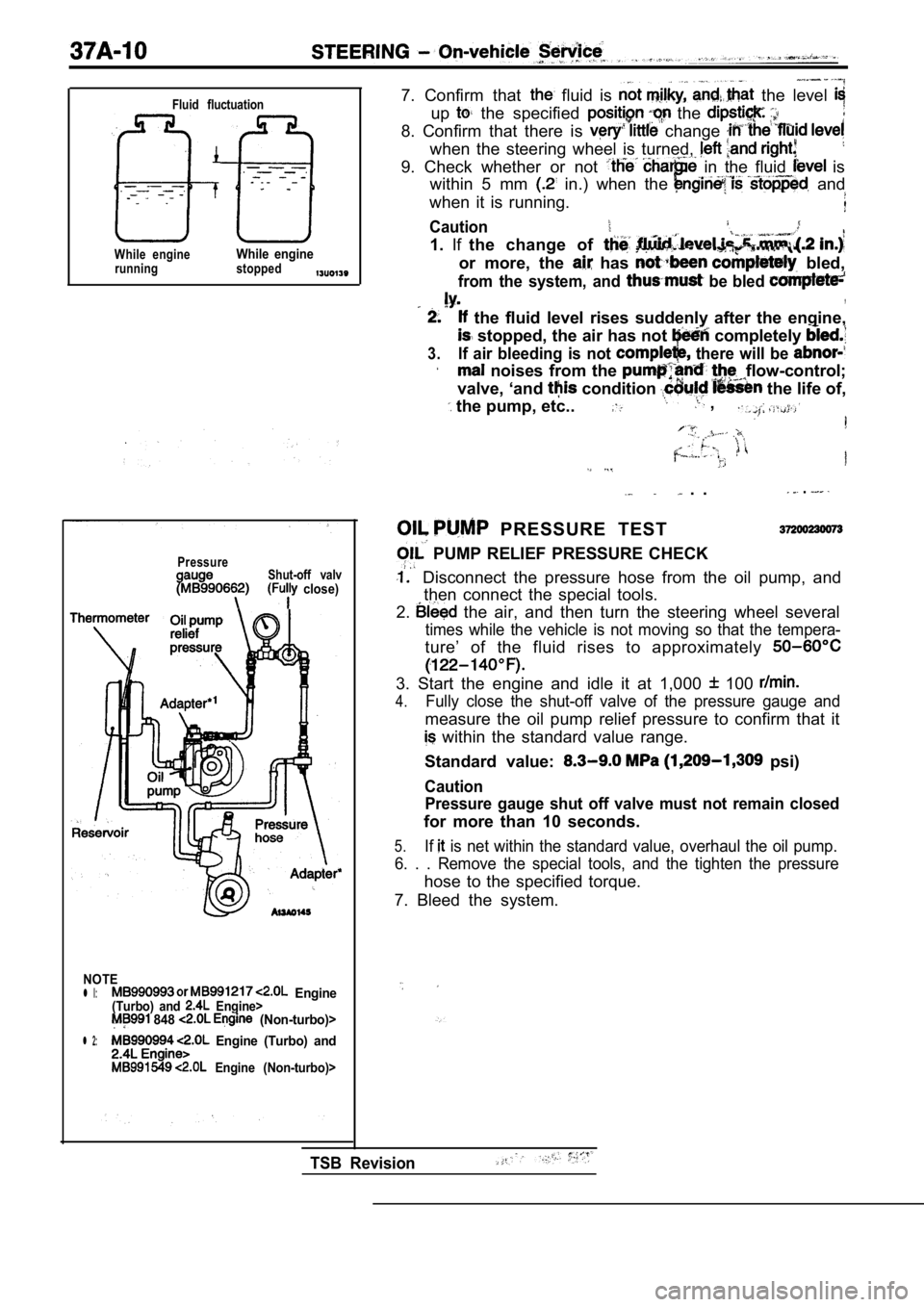

Fluid fluctuation

While engineWhile enginerunning stopped

PressureShut-off valv close)

NOTE

l l: Engine(Turbo) and Engine> 848 (Non-turbo)>

l 2: Engine (Turbo) and

Engine (Non-turbo)>

7. Confirm that fluid is the level

up the specified the

8. Confirm that there is change

when the steering wheel is turned,

9. Check whether or not in the fluid is

within 5 mm

in.) when the and

when it is running.

Caution

1. Ifthe change of

or more, the has bled,

from the system, and be bled ,

the fluid level rises suddenly after the engine,

stopped, the air has not completely

3.If air bleeding is not there will be

noises from the flow-control;

valve, ‘and

condition the life of,

the pump, etc.. ,

. . .

PRESSURE TEST

PUMP RELIEF PRESSURE CHECK

Disconnect the pressure hose from the oil pump, an d

then connect the special tools.

2.

the air, and then turn the steering wheel several

times while the vehicle is not moving so that the t empera-

ture’ of the fluid rises to approximately

3. Start the engine and idle it at 1,000 100

4.Fully close the shut-off valve of the pressure gaug e and

measure the oil pump relief pressure to confirm tha t it

within the standard value range.

Standard value:

psi)

Caution Pressure gauge shut off valve must not remain close d

for more than 10 seconds.

5.If is net within the standard value, overhaul the oil pump.

6. . . Remove the special tools, and the tighten th e pressure

hose to the specified torque.

7. Bleed the system.

TSB Revision

Page 1785 of 2103

STEERING On-vehicle’ Service

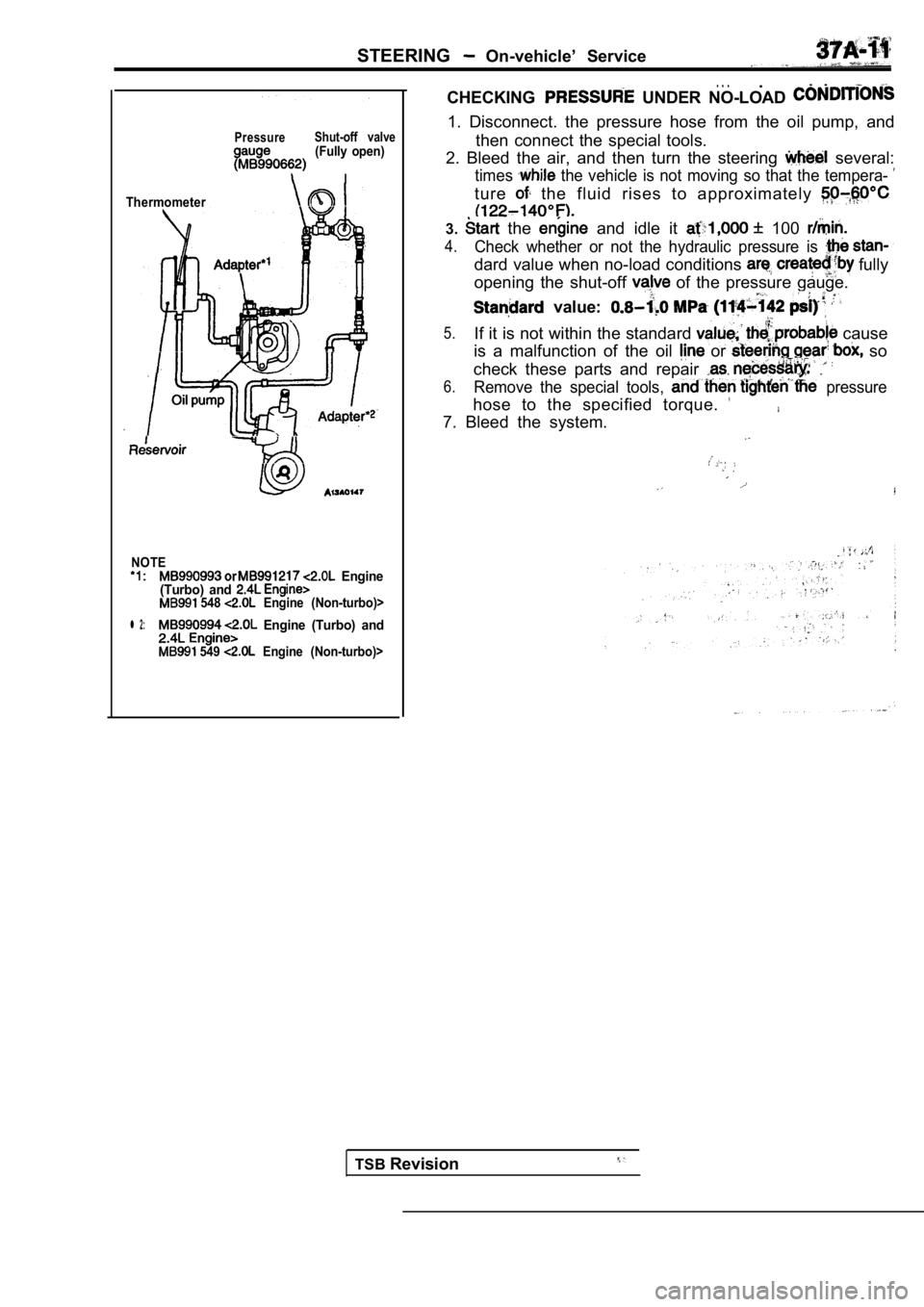

PressureShut-off valve(Fully open)

I

Thermometer

NOTE Engine

(Turbo) and

548 Engine (Non-turbo)>

l 2: Engine (Turbo) and

549 Engine (Non-turbo)>

. .. . ..

CHECKING

UNDER NO-LOAD

1. Disconnect. the pressure hose from the oil pump, and

then connect the special tools.

2. Bleed the air, and then turn the steering

several:

times the vehicle is not moving so that the tempera-

ture the fluid rises to approximately

3. the and idle it 100

4.Check whether or not the hydraulic pressure is

dard value when no-load conditions fully

opening the shut-off

of the pressure gauge.

value:

5.If it is not within the standard cause

is a malfunction of the oil

or so

6.

check these parts and repair

Remove the special tools, pressure

hose to the specified torque.

7. Bleed the system.

TSB Revision

Page 1786 of 2103

STEERING On-vehicle Service,.

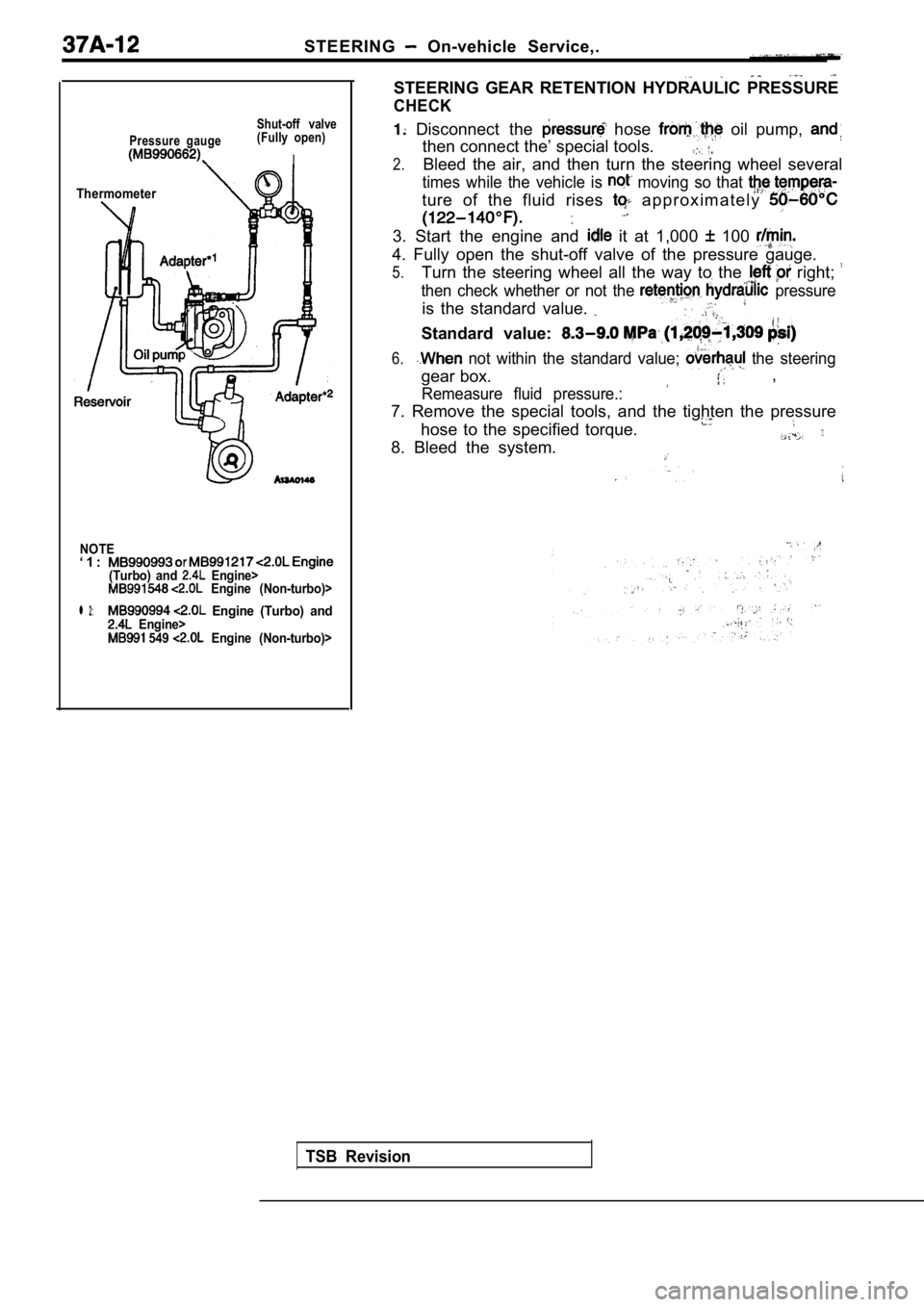

Shut-off valve

Pressure gauge (Fully open)

I

Thermometer

NOTE

‘ 1 :(Turbo) and Engine> Engine (Non-turbo)>

l 2: Engine (Turbo) and Engine> 549 Engine (Non-turbo)>

STEERING GEAR RETENTION HYDRAULIC PRESSURE

CHECK

Disconnect the hose oil pump,

then connect the’ special tools.

2.Bleed the air, and then turn the steering wheel sev eral

times while the vehicle is moving so that

ture of the fluid rises a p p r o x i m a t e l y

3. Start the engine and it at 1,000 100

4. Fully open the shut-off valve of the pressure ga uge.

5.Turn the steering wheel all the way to the right;

then check whether or not the pressure

is the standard value.

Standard value:

6. not within the standard value; the steering

gear box. ,

Remeasure fluid pressure.:

7. Remove the special tools, and the tighten the pr essure

hose to the specified torque.

8. Bleed the system.

TSB Revision