torque MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1612 of 2103

FRONT SUSPENSION

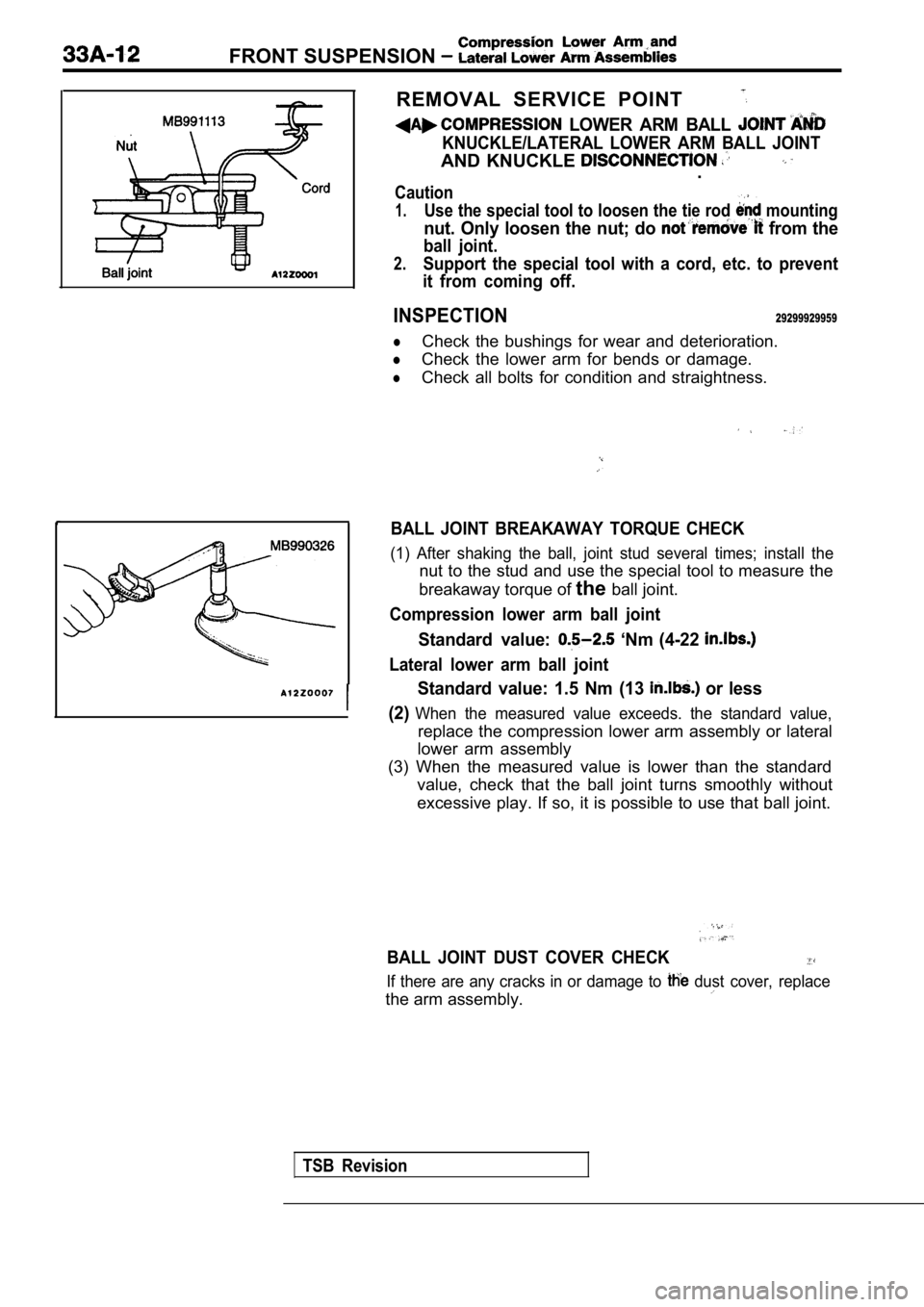

REMOVAL SERVICE POINT

LOWER ARM BALL

KNUCKLE/LATERAL LOWER ARM BALL JOINT

AND KNUCKLE .

Caution

1.Use the special tool to loosen the tie rod mounting

nut. Only loosen the nut; do from the

ball joint.

2.Support the special tool with a cord, etc. to prevent

it from coming off.

INSPECTION29299929959

lCheck the bushings for wear and deterioration.

lCheck the lower arm for bends or damage.

lCheck all bolts for condition and straightness.

BALL JOINT BREAKAWAY TORQUE CHECK

(1) After shaking the ball, joint stud several time s; install the

nut to the stud and use the special tool to measure the

breakaway torque of theball joint.

Compression lower arm ball joint

Standard value: ‘Nm (4-22

Lateral lower arm ball joint

Standard value: 1.5 Nm (13 or less

(2)

When the measured value exceeds. the standard value ,

replace the compression lower arm assembly or lateral

lower arm assembly

(3) When the measured value is lower than the stand ard

value, check that the ball joint turns smoothly wit hout

excessive play. If so, it is possible to use that b all joint.

BALL JOINT DUST COVER CHECK

If there are any cracks in or damage to dust cover, replace

the arm assembly.

TSB Revision

Page 1615 of 2103

FRONT SUSPENSION , ,

Al

Clip ring ends onopposite side also possible)

STABILIZER LINK BALL JOINT BREAKAWAY

CHECK

(1) After shaking the ball joint stud several times, install the

nut to the stud and use the special tool to measure the

breakaway torque of the ball joint.

Standard value: Nm (4-13

(2) When the measured value exceeds the standard va lue,

replace the stabilizer link.

(3) When the measured value is lower than the standard

value, check that the ball joint turns smoothly wit hout

excessive play. If so, it is possible to use that b all joint.

BALL JOINT DUST COVER CHECK

If there are any cracks in or damage to the dust co ver, replace

the stabilizer link.

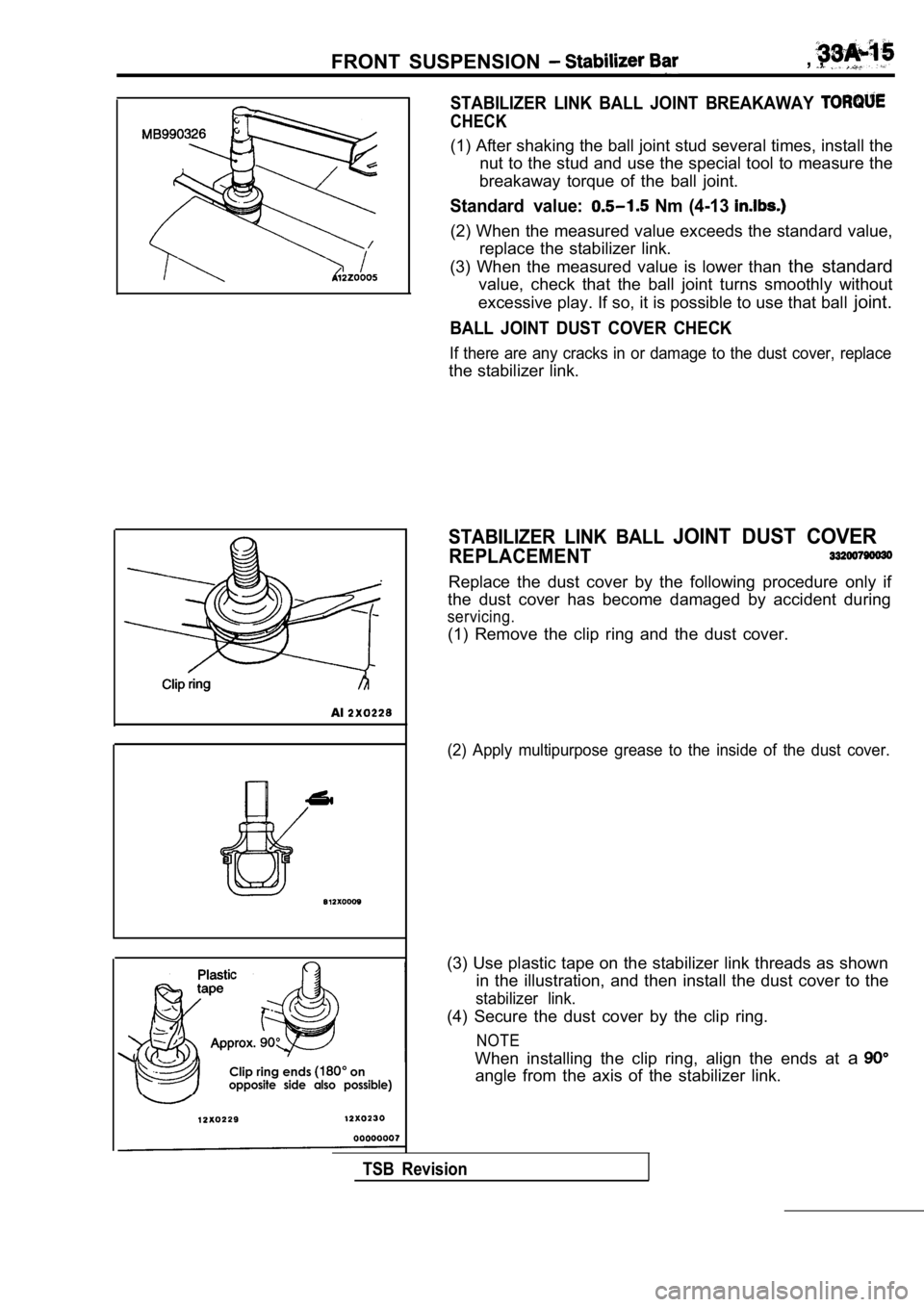

STABILIZER LINK BALL JOINT DUST COVER

REPLACEMENT

Replace the dust cover by the following procedure o nly if

the dust cover has become damaged by accident durin g

servicing.

(1) Remove the clip ring and the dust cover.

(2) Apply multipurpose grease to the inside of the dust cover.

(3) Use plastic tape on the stabilizer link threads as shown

in the illustration, and then install the dust cove r to the

stabilizer link.

(4) Secure the dust cover by the clip ring.

NOTE

When installing the clip ring, align the ends at a

angle from the axis of the stabilizer link.

TSB Revision

Page 1620 of 2103

REAR SUSPENSION Service Specifications/Special tools, , .

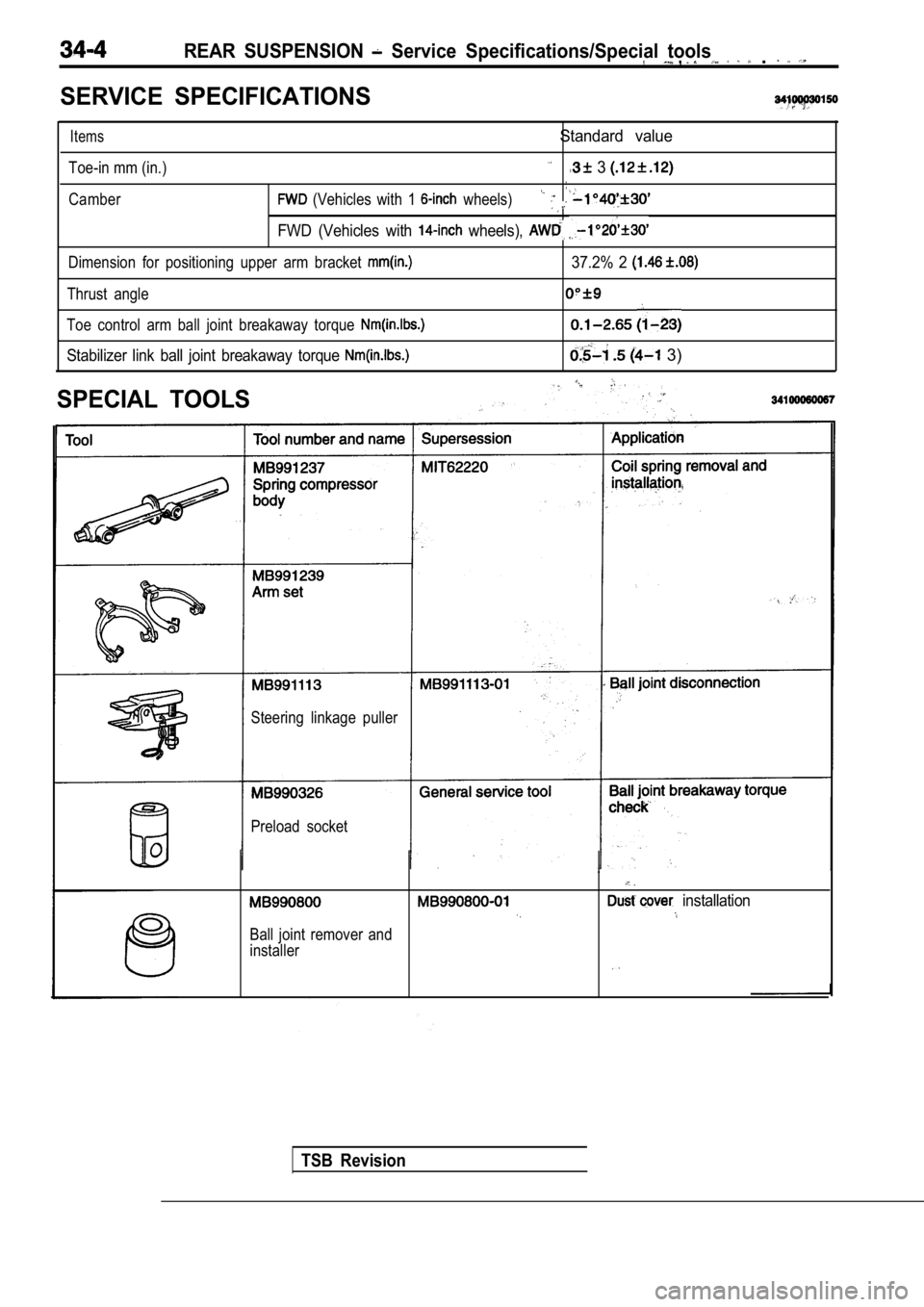

SERVICE SPECIFICATIONS

Items

Toe-in mm (in.)

Standard value

3

Camber (Vehicles with 1 wheels)

FWD (Vehicles with wheels),

Dimension for positioning upper arm bracket

Thrust angle

Toe control arm ball joint breakaway torque

Stabilizer link ball joint breakaway torque

SPECIAL TOOLS

37.2% 2

3)

Steering linkage puller

Preload socket

.

installation

Ball joint remover and

installer

TSB Revision

Page 1629 of 2103

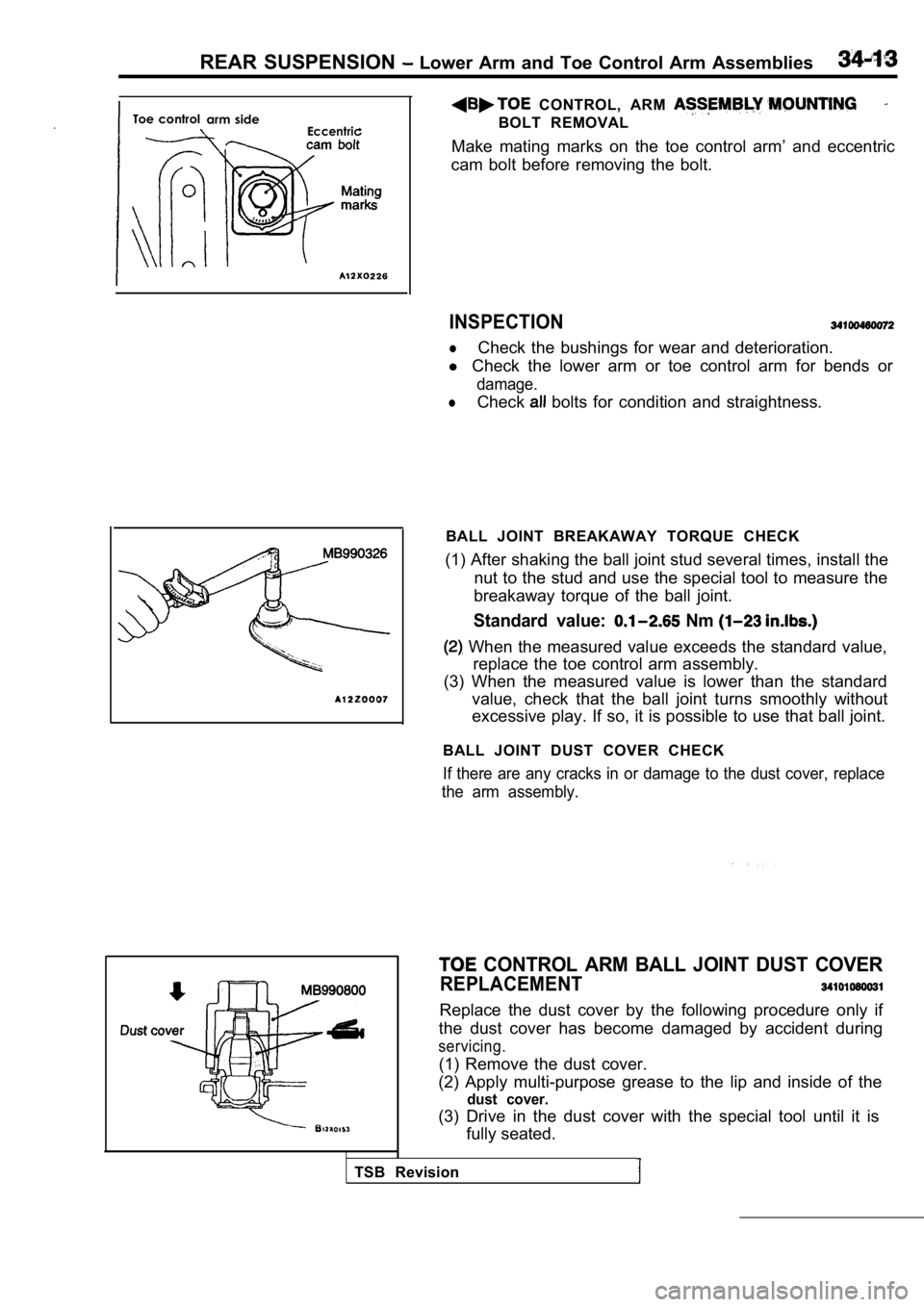

REAR SUSPENSION Lower Arm and Toe Control Arm Assemblies

Toe controlarm sideEccentric

CONTROL, ARM

BOLT REMOVAL

Make mating marks on the toe control arm’ and eccen tric

cam bolt before removing the bolt.

INSPECTION

lCheck the bushings for wear and deterioration.

l Check the lower arm or toe control arm for bends or

damage.

lCheck bolts for condition and straightness.

BALL JOINT BREAKAWAY TORQUE CHECK

(1) After shaking the ball joint stud several times , install the

nut to the stud and use the special tool to measure the

breakaway torque of the ball joint.

Standard value: Nm

When the measured value exceeds the standard value ,

replace the toe control arm assembly.

(3) When the measured value is lower than the stand ard

value, check that the ball joint turns smoothly wit hout

excessive play. If so, it is possible to use that b all joint.

BALL JOINT DUST COVER CHECK

If there are any cracks in or damage to the dust co ver, replace

the arm assembly.

CONTROL ARM BALL JOINT DUST COVER

REPLACEMENT

Replace the dust cover by the following procedure o nly if

the dust cover has become damaged by accident durin g

servicing.

(1) Remove the dust cover.

(2) Apply multi-purpose grease to the lip and insid e of the

dust cover.

(3) Drive in the dust cover with the special tool u ntil it is

fully seated.

TSB Revision

Page 1634 of 2103

S U S P E N S I O N B a r

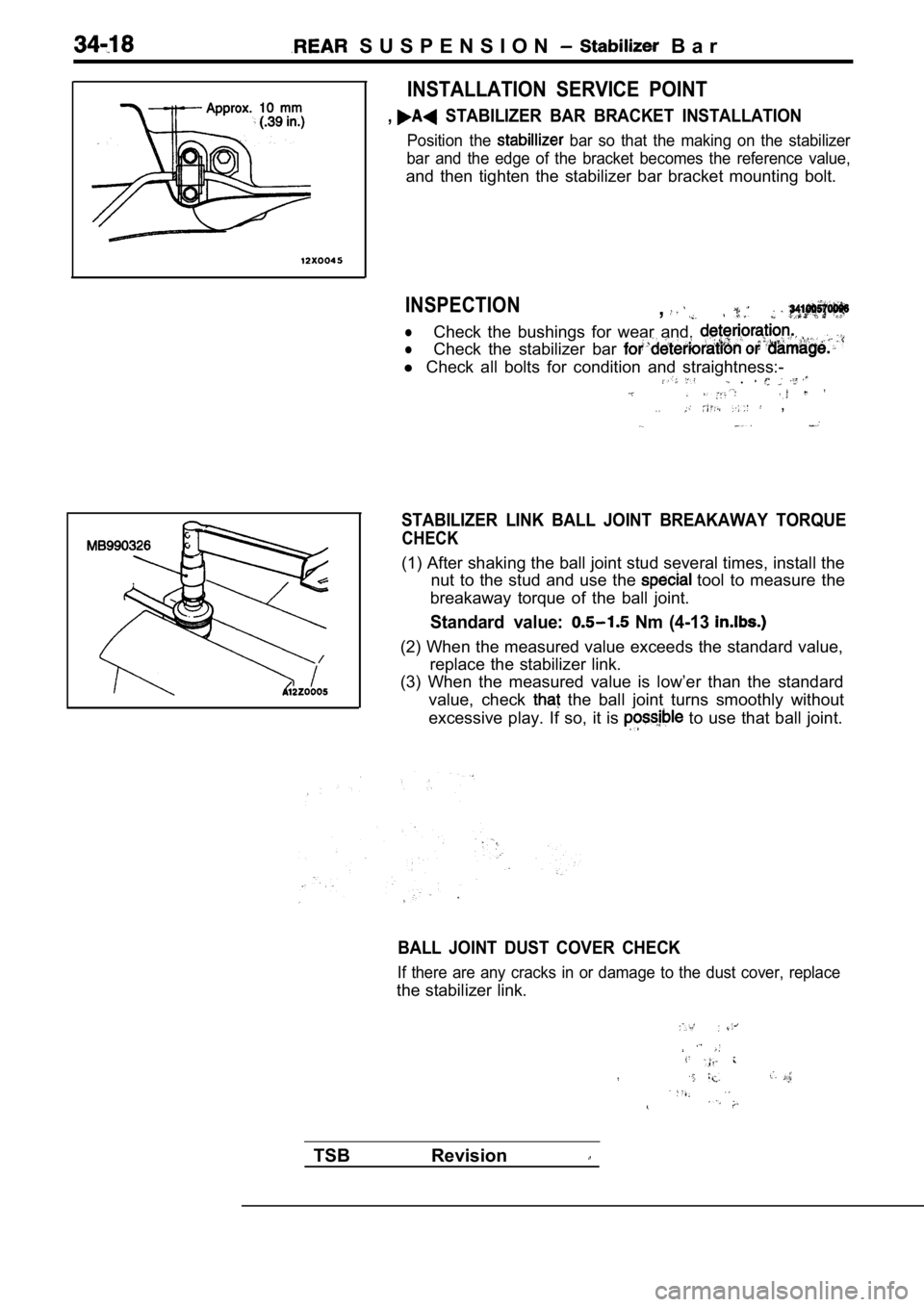

INSTALLATION SERVICE POINT

, STABILIZER BAR BRACKET INSTALLATION

Position the bar so that the making on the stabilizer

bar and the edge of the bracket becomes the referen ce value,

and then tighten the stabilizer bar bracket mounting bolt.

INSPECTION,

lCheck the bushings for wear and,

lCheck the stabilizer bar

l Check all bolts for condition and straightness:- .

. . ,

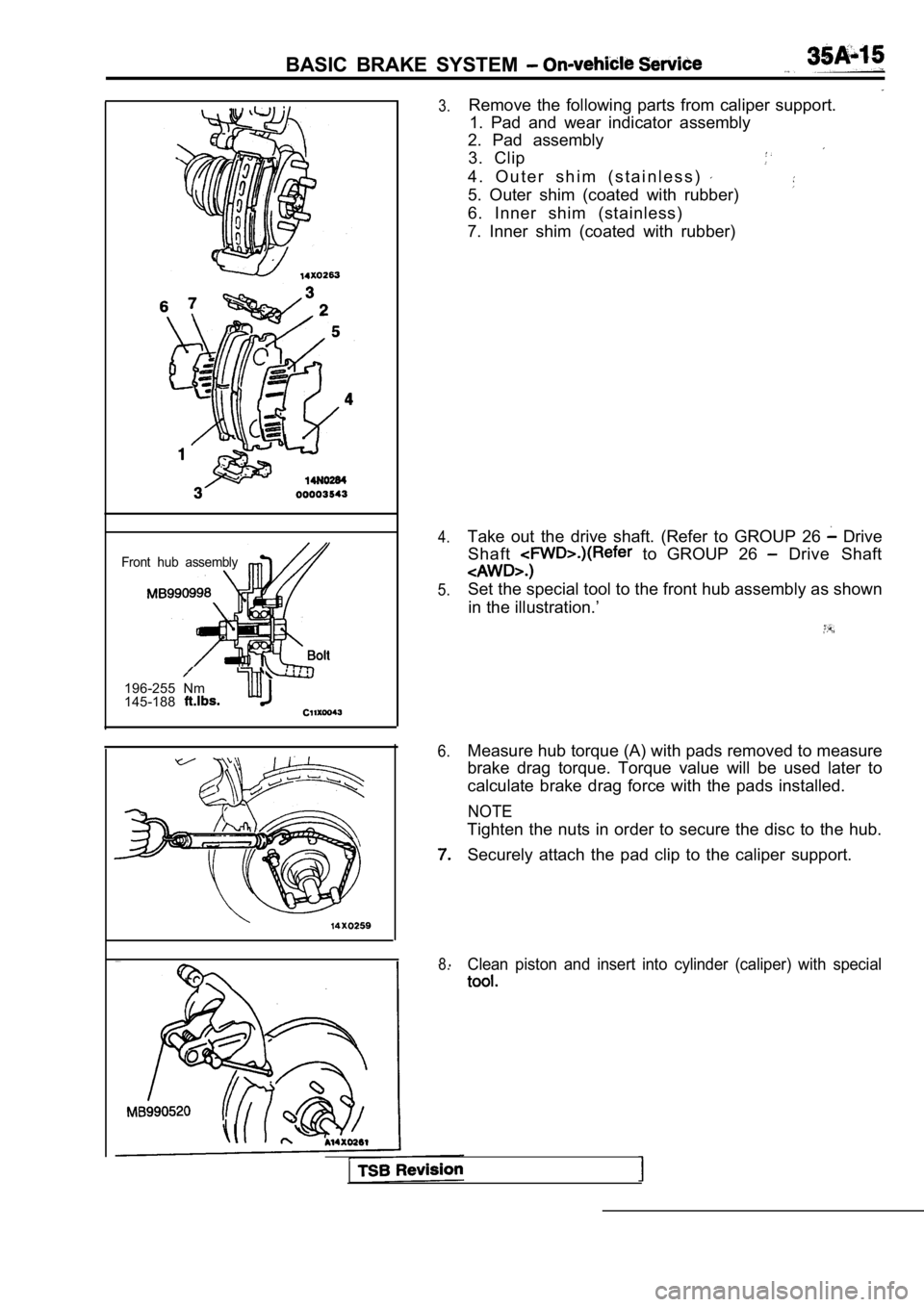

STABILIZER LINK BALL JOINT BREAKAWAY TORQUE

CHECK

(1) After shaking the ball joint stud several times , install the

nut to the stud and use the

tool to measure the

breakaway torque of the ball joint.

Standard value: Nm (4-13

(2) When the measured value exceeds the standard va lue,

replace the stabilizer link.

(3) When the measured value is low’er than the stan dard

value, check

the ball joint turns smoothly without

excessive play. If so, it is

to use that ball joint.

BALL JOINT DUST COVER CHECK

If there are any cracks in or damage to the dust co ver, replace

the stabilizer link.

TSB Revision

Page 1653 of 2103

BASIC BRAKE SYSTEM

Front hub assembly

196-255 Nm

145-188

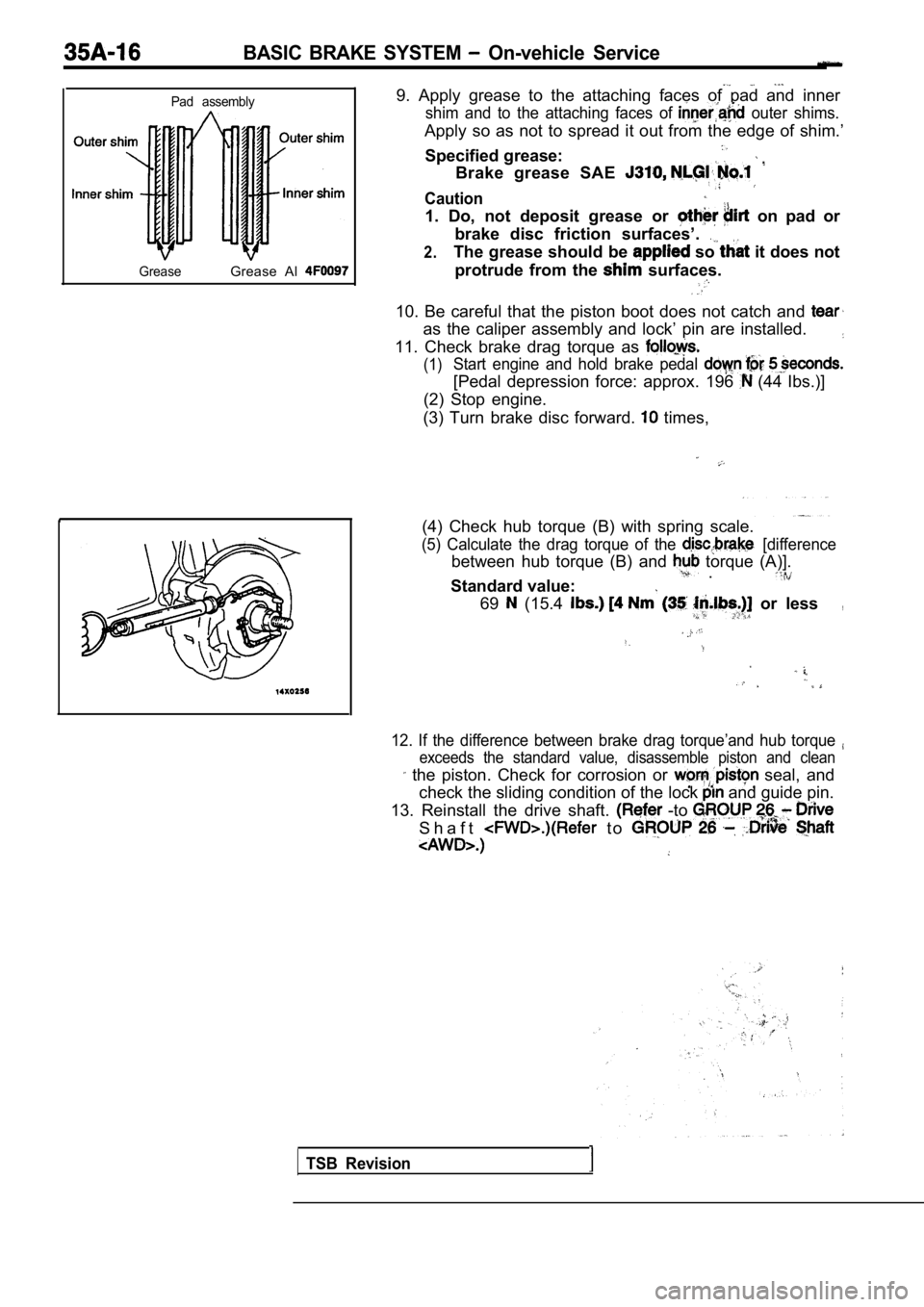

3.

4.

5.

6.

8.

Remove the following parts from caliper support. 1. Pad and wear indicator assembly

2. Pad assembly

3. Clip

4 . O u t e r s h i m ( s t a i n l e s s )

5. Outer shim (coated with rubber)

6. Inner shim (stainless)

7. Inner shim (coated with rubber)

Take out the drive shaft. (Refer to GROUP 26

Drive

Shaft

to GROUP 26 Drive Shaft

Set the special tool to the front hub assembly as s hown

in the illustration.’

Measure hub torque (A) with pads removed to measure

brake drag torque. Torque value will be used later to

calculate brake drag force with the pads installed.

NOTE

Tighten the nuts in order to secure the disc to the hub.

Securely attach the pad clip to the caliper support .

Clean piston and insert into cylinder (caliper) with special

Page 1654 of 2103

BASIC BRAKE SYSTEM On-vehicle Service

Pad assembly

Grease

Grease Al

9. Apply grease to the attaching faces of pad and i nner

shim and to the attaching faces of outer shims.

Apply so as not to spread it out from the edge of shim.’

Specified grease:

Brake grease SAE

Caution

1. Do, not deposit grease or on pad or

brake disc friction surfaces’.

2.The grease should be so it does not

protrude from the

surfaces.

10. Be careful that the piston boot does not catch and

as the caliper assembly and lock’ pin are installed.

11. Check brake drag torque as

(1)Start engine and hold brake pedal

[Pedal depression force: approx. 196 (44 Ibs.)]

(2) Stop engine.

(3) Turn brake disc forward.

times,

(4) Check hub torque (B) with spring scale.

(5) Calculate the drag torque of the [difference

between hub torque (B) and torque (A)]. .

Standard value:

69 (15.4 or less,

12. If the difference between brake drag torque’and hub torque

exceeds the standard value, disassemble piston and clean

the piston. Check for corrosion or seal, and

check the sliding condition of the lock

and guide pin.

13. Reinstall the drive shaft.

-to

S h a f t t o

TSB Revision

Page 1660 of 2103

BASIC BRAKE SYSTEM On-vehicle Service

TSB Revision

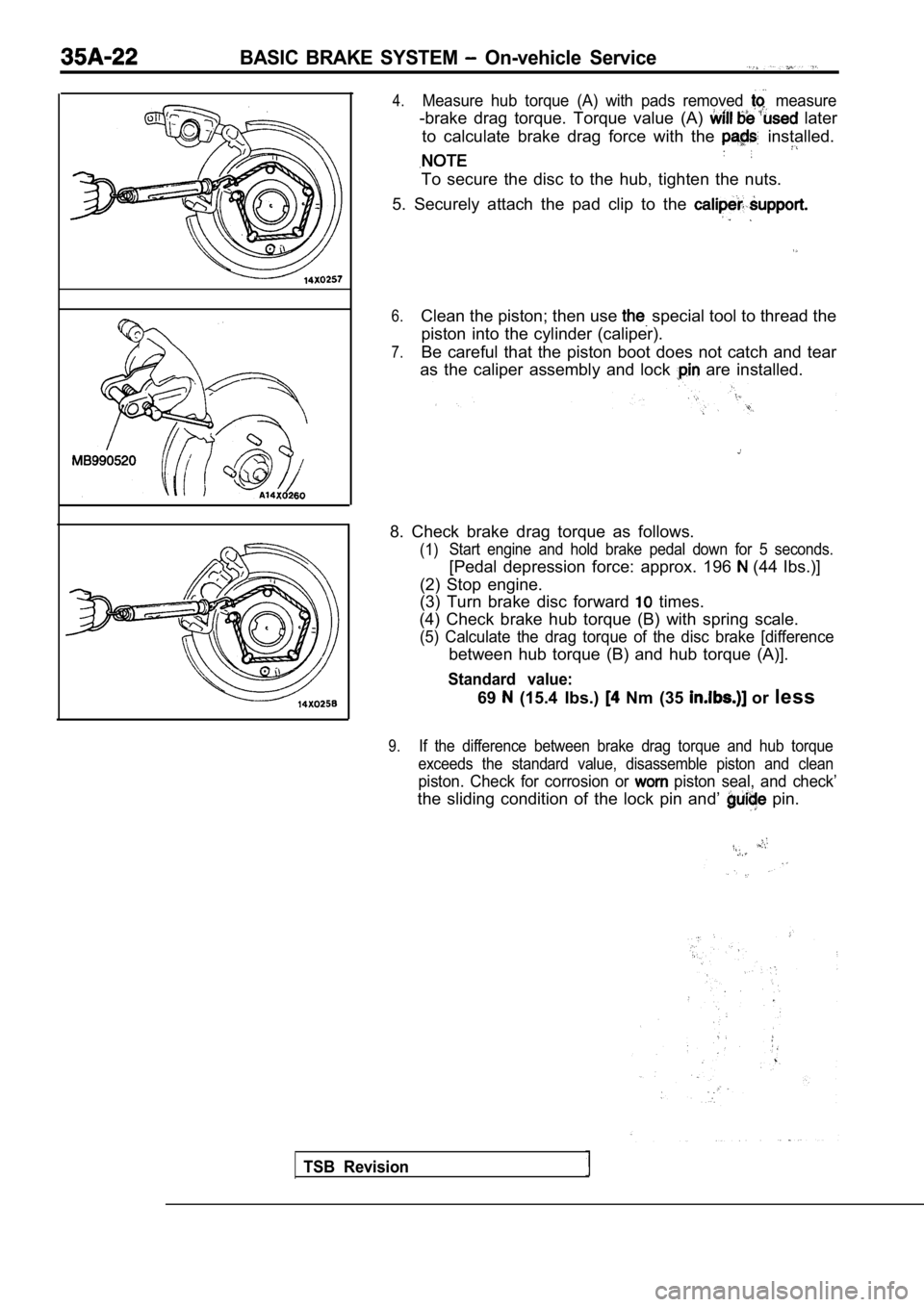

4.Measure hub torque (A) with pads removed measure

-brake drag torque. Torque value (A) later

to calculate brake drag force with the

installed.

To secure the disc to the hub, tighten the nuts.

5. Securely attach the pad clip to the

6.Clean the piston; then use special tool to thread the

piston into the cylinder (caliper).

7.Be careful that the piston boot does not catch and tear

as the caliper assembly and lock

are installed.

8. Check brake drag torque as follows.

(1) Start engine and hold brake pedal down for 5 second

s.

[Pedal depression force: approx. 196 (44 Ibs.)]

(2) Stop engine.

(3) Turn brake disc forward

times.

(4) Check brake hub torque (B) with spring scale.

(5) Calculate the drag torque of the disc brake [di fference

between hub torque (B) and hub torque (A)].

Standard value:

69 (15.4 Ibs.) Nm (35 or less

9.If the difference between brake drag torque and hub torque

exceeds the standard value, disassemble piston and clean

piston. Check for corrosion or piston seal, and check’

the sliding condition of the lock pin and’ pin.

Page 1669 of 2103

BASIC SYSTEM Front

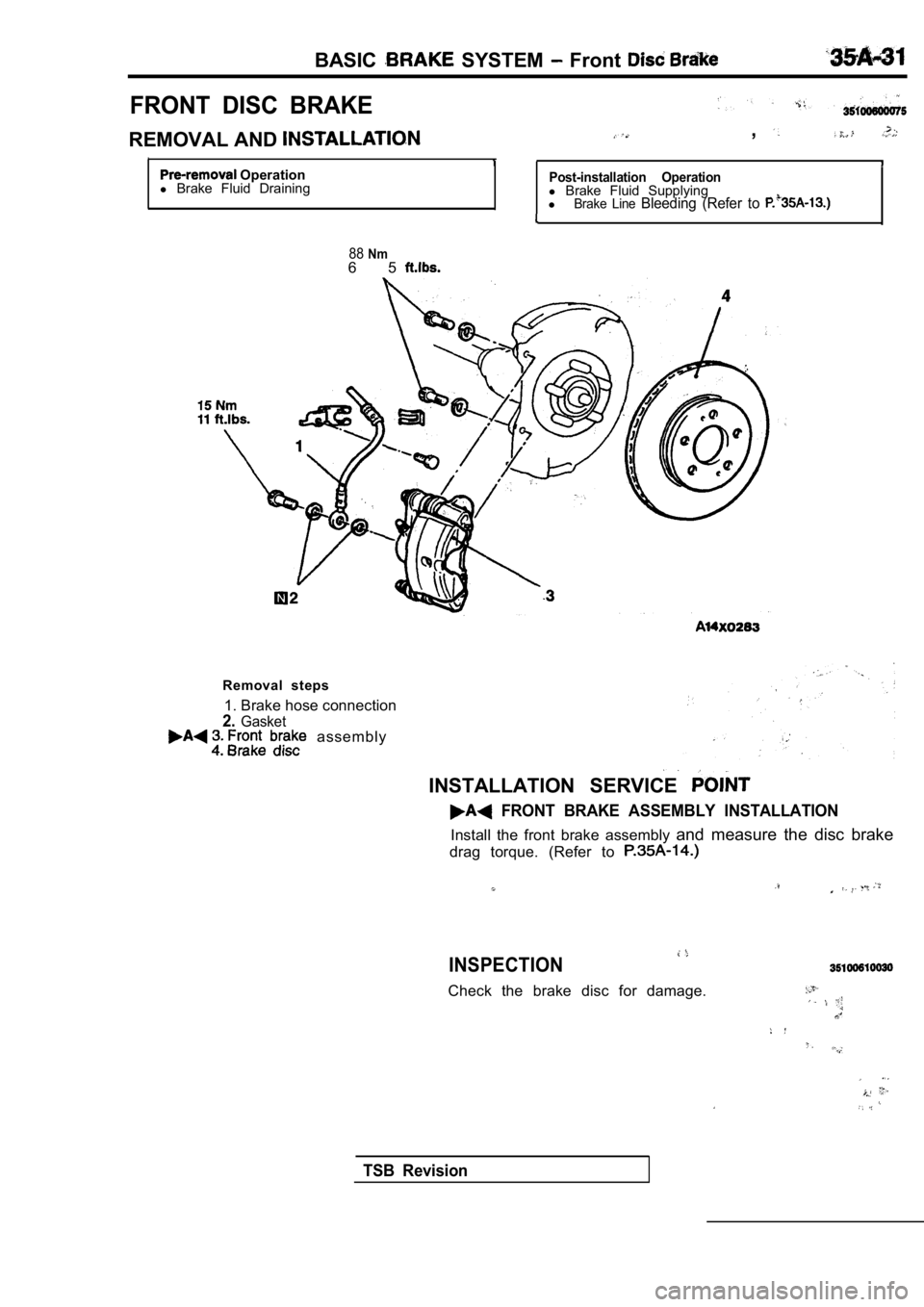

FRONT DISC BRAKE

REMOVAL AND ,

I1I Operation

l Brake Fluid DrainingPost-installation Operationl Brake Fluid Supplying

lBrake Line Bleeding (Refer to

I

88Nm6 5

Removal steps

1. Brake hose connection

2.Gasket assembly

INSTALLATION SERVICE

FRONT BRAKE ASSEMBLY INSTALLATION

Install the front brake assembly and measure the disc brake

drag torque. (Refer to

INSPECTION

Check the brake disc for damage.

TSB Revision

Page 1683 of 2103

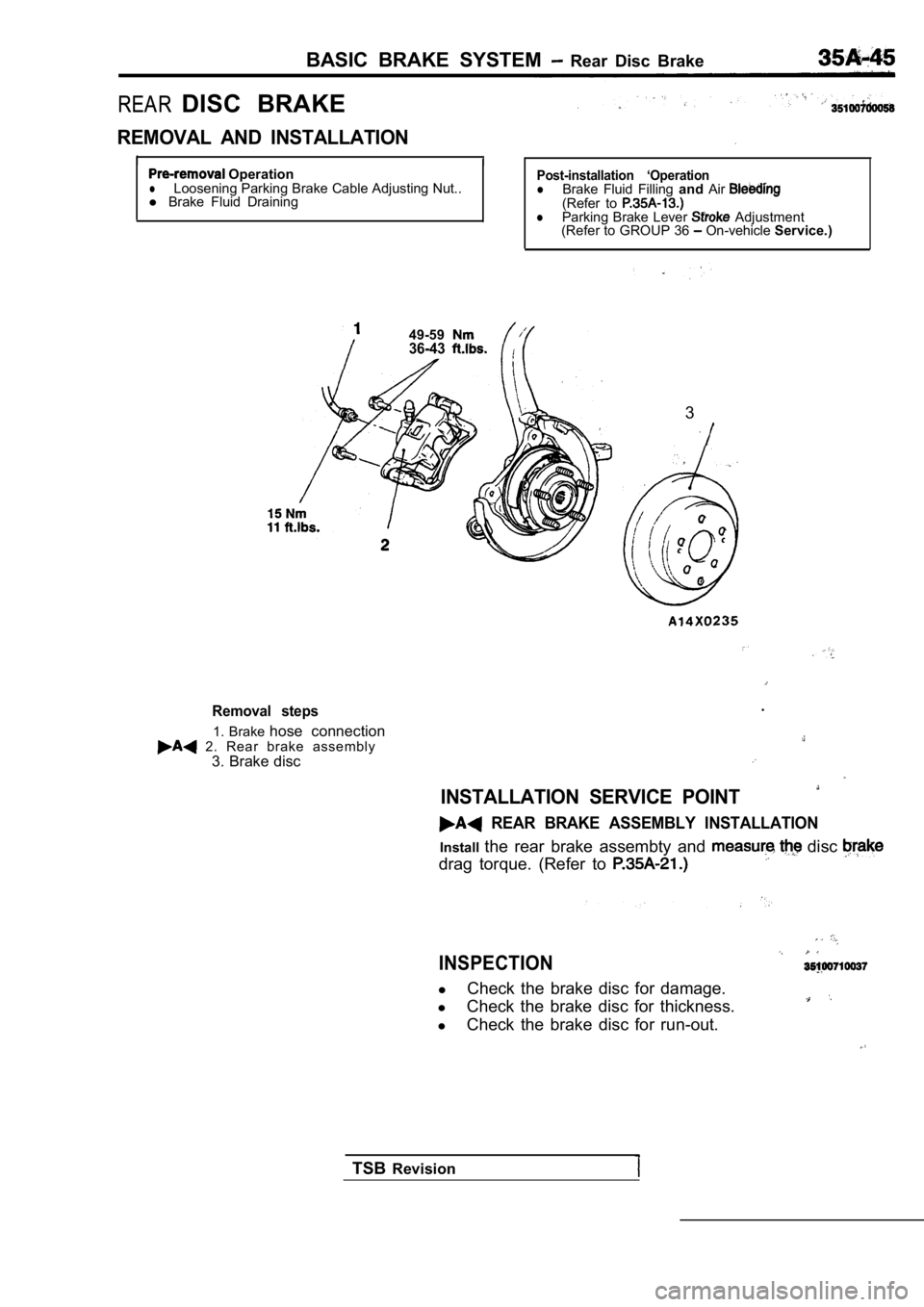

BASIC BRAKE SYSTEM Rear Disc Brake

REAR DISC BRAKE

REMOVAL AND INSTALLATION

I

I OperationlLoosening Parking Brake Cable Adjusting Nut..

l Brake Fluid DrainingPost-installation ‘OperationlBrake Fluid Filling andAir(Refer to lParking Brake Lever Adjustment

(Refer to GROUP 36 On-vehicle Service.)

49-59

36-43

3

Removal steps

1. Brake hose connection 2. Rear brake assembly

3. Brake disc .

INSTALLATION SERVICE POINT

REAR BRAKE ASSEMBLY INSTALLATION

Install

the rear brake assembty and disc

drag torque. (Refer to

INSPECTION

lCheck the brake disc for damage.

l Check the brake disc for thickness.

l Check the brake disc for run-out.

TSB Revision