torque MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1469 of 2103

AUTOMATIC TRANSAXLE OVERHAUL Valve Body

T/C control valve

spring plug

Regulator

valve spring

76

r e t a i n e r p l a t e w i t h

6.

Remove torque converter control valve and torque

converter clutch valve.

retainer

plateusingInstaller/Remover

17.

(15) Remove

Removeregulator valve.

TSB Revision

Page 1470 of 2103

AUTOMATIC TRANSAXLE OVERHAUL Valve Body

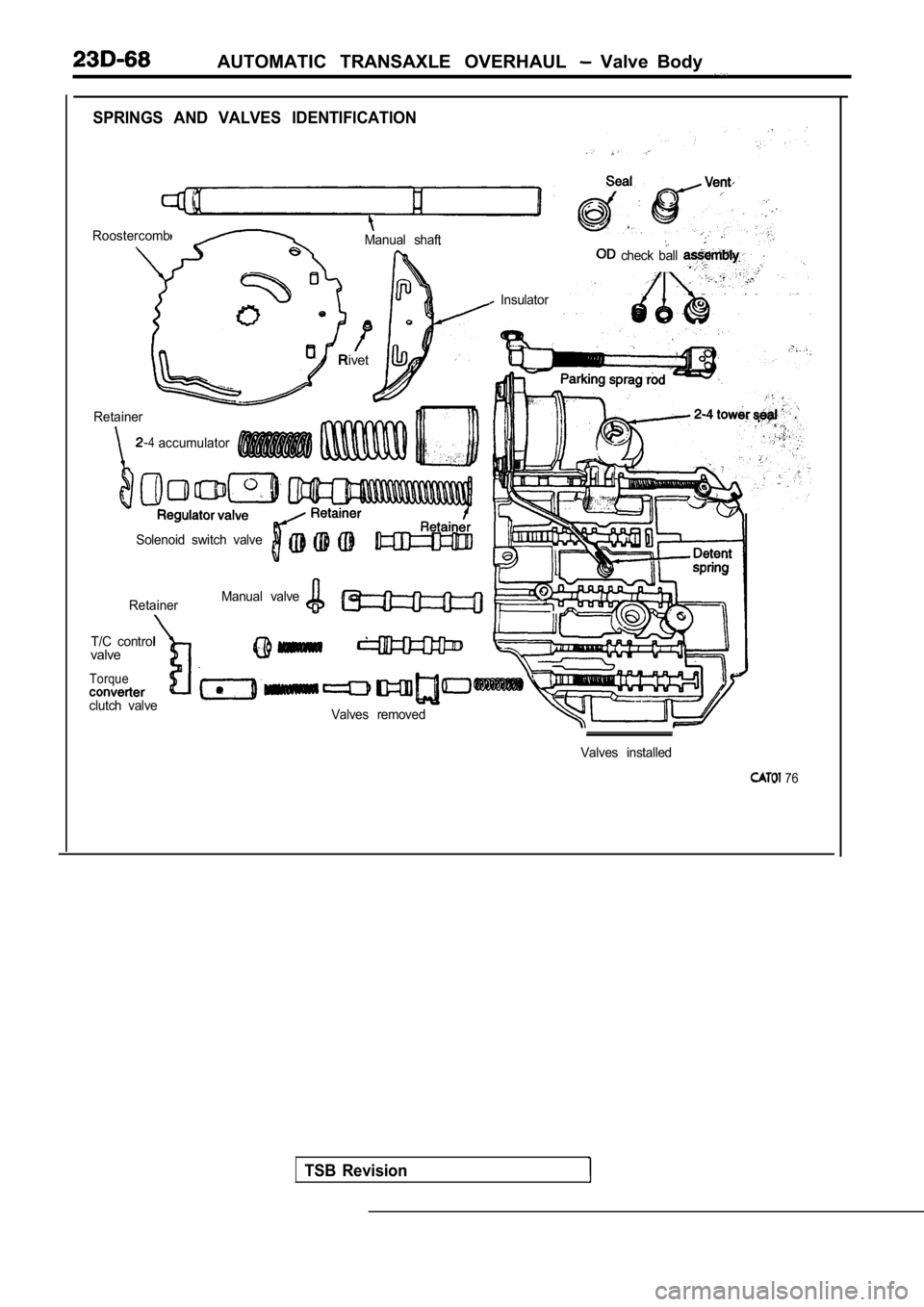

SPRINGS AND VALVES IDENTIFICATION

Roostercomb.Manual shaft

Retainer

-4

Rivet

Solenoid switch valve

Retainer

T/C control

valve

Torque

clutch valve Manual valve

Insulator

check ball

accumulator

Valves removed

TSB Revision

Valves installed

76

Page 1471 of 2103

AUTOMATIC TRANSAXLE OVERHAUL Body

Retainer

Check ball

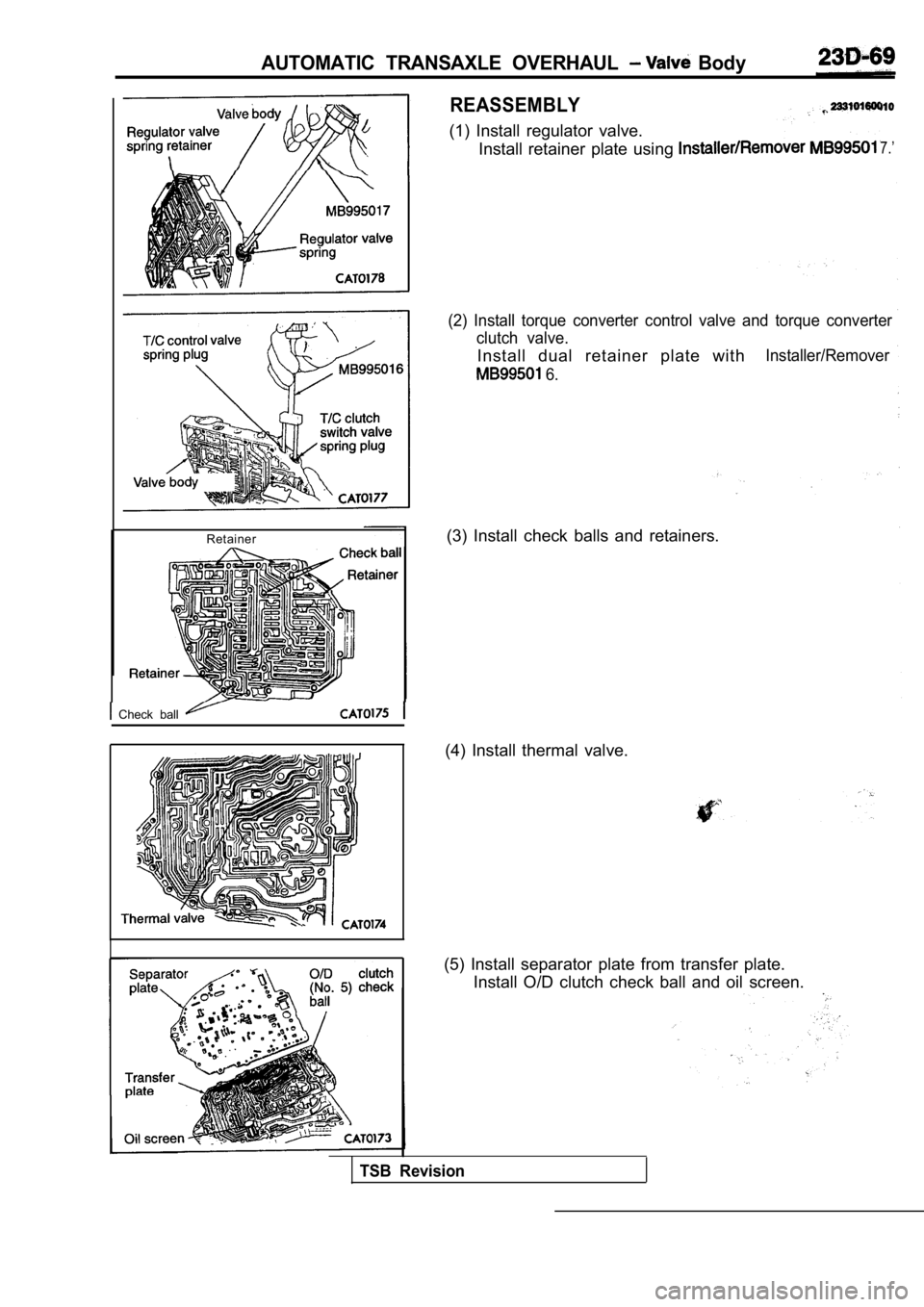

REASSEMBLY

(1) Install regulator valve.Install retainer plate using

7.’

(2) Install torque converter control valve and torq ue converter

clutch valve.

Install dual retainer plate withInstaller/Remover

6.

(3) Install check balls and retainers.

(4) Install thermal valve.

(5) Install separator plate from transfer plate. Install O/D clutch check ball and oil screen.

TSB Revision

Page 1483 of 2103

TRANSAXLE OVERHAUL Differential

Dial indicator

bracket

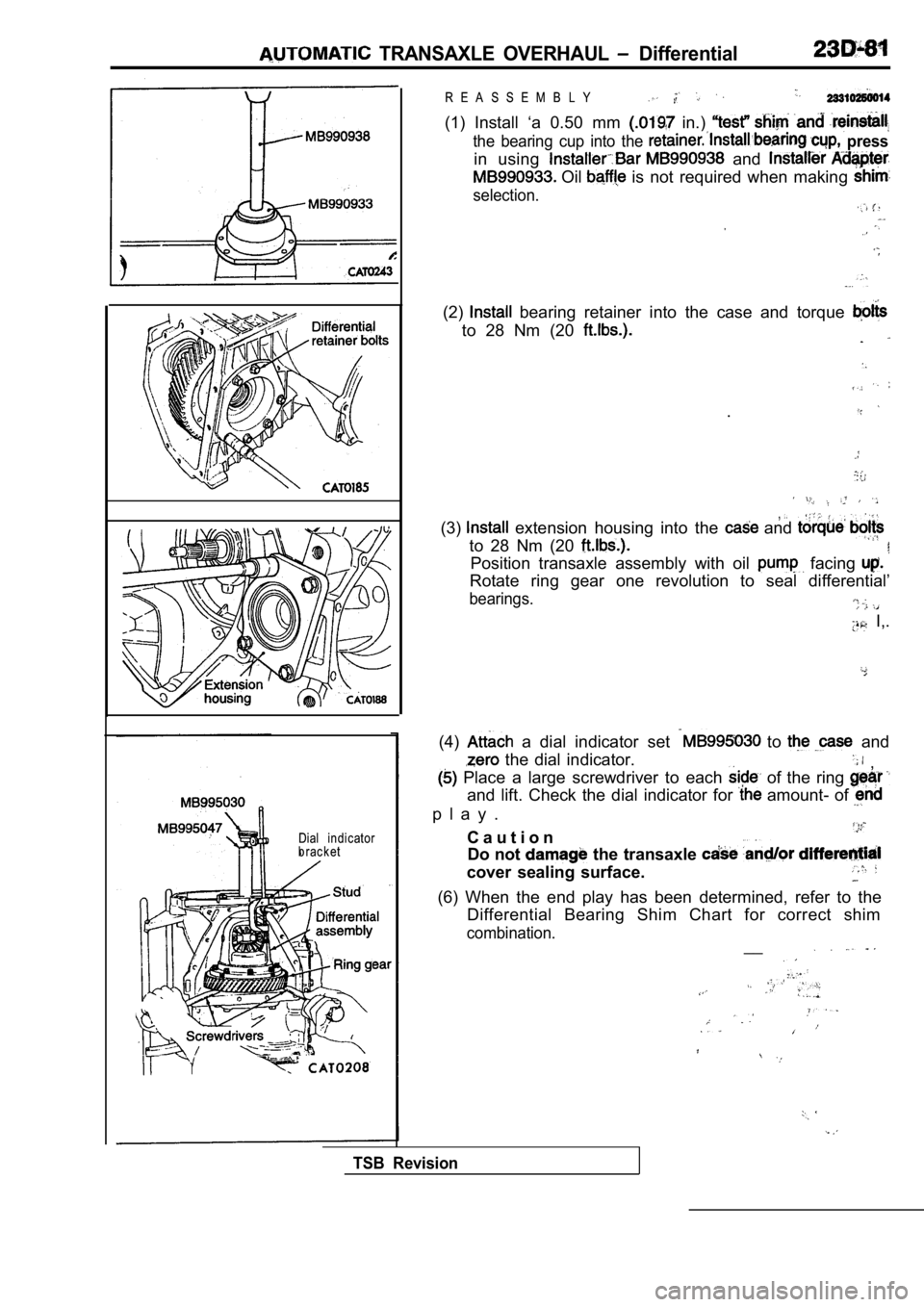

R E A S S E M B L Y

(1) Install ‘a 0.50 mm in.)

the bearing cup into the press

in using and

Oil is not required when making

selection.

(2) bearing retainer into the case and torque

to 28 Nm (20

.

,(3) extension housing into the and

to 28 Nm (20

Position transaxle assembly with oil facing

Rotate ring gear one revolution to seal differentia l’

bearings.

I,.

(4) a dial indicator set to and

the dial indicator., Place a large screwdriver to each of the ring

and lift. Check the dial indicator for amount- of

p l a y .

C a u t i o n

Do not

the transaxle

cover sealing surface.

TSB Revision

(6) When the end play has been determined, refer to the

Differential Bearing Shim Chart for correct shim

combination.__

Page 1486 of 2103

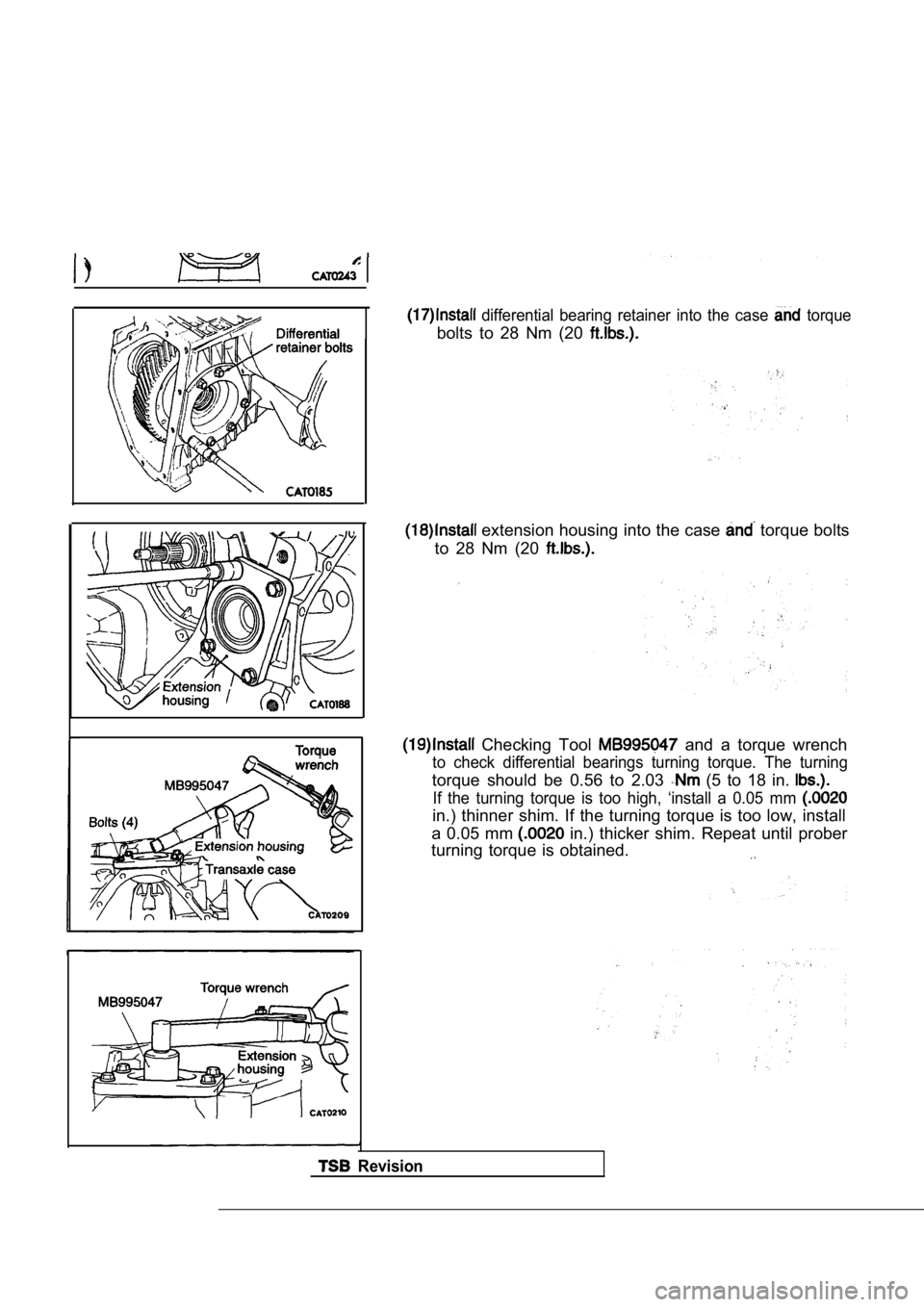

differential bearing retainer into the case torque

bolts to 28 Nm (20

extension housing into the case torque bolts

to 28 Nm (20

Checking Tool and a torque wrench

to check differential bearings turning torque. The turning

torque should be 0.56 to 2.03 (5 to 18 in.

If the turning torque is too high, ‘install a 0.05 mm

in.) thinner shim. If the turning torque is too low , install

a 0.05 mm

in.) thicker shim. Repeat until prober

turning torque is obtained.

Revision

Page 1488 of 2103

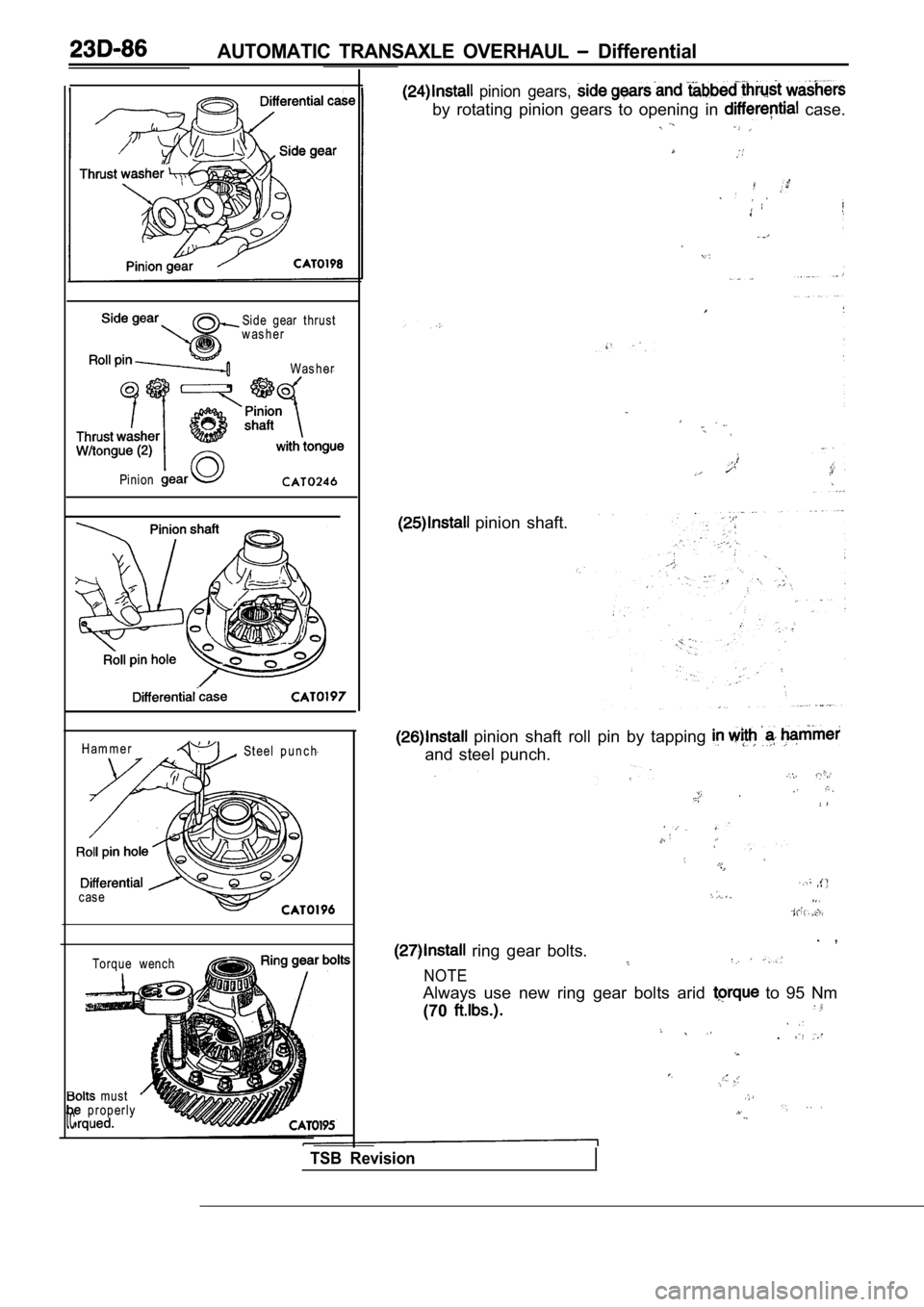

AUTOMATIC TRANSAXLE OVERHAUL Differential

Side gear thrust

w as h er

Was h er

Pinion

Ham m er

case

tc

Torque wench

pinion gears,

by rotating pinion gears to opening in case.

must properly

pinion shaft.

, St eel p u n c h

pinion shaft roll pin by tapping

and steel punch.

. , ring gear bolts.

NOTE

Always use new ring gear bolts arid to 95 Nm

(70

.

TSB Revision

Page 1506 of 2103

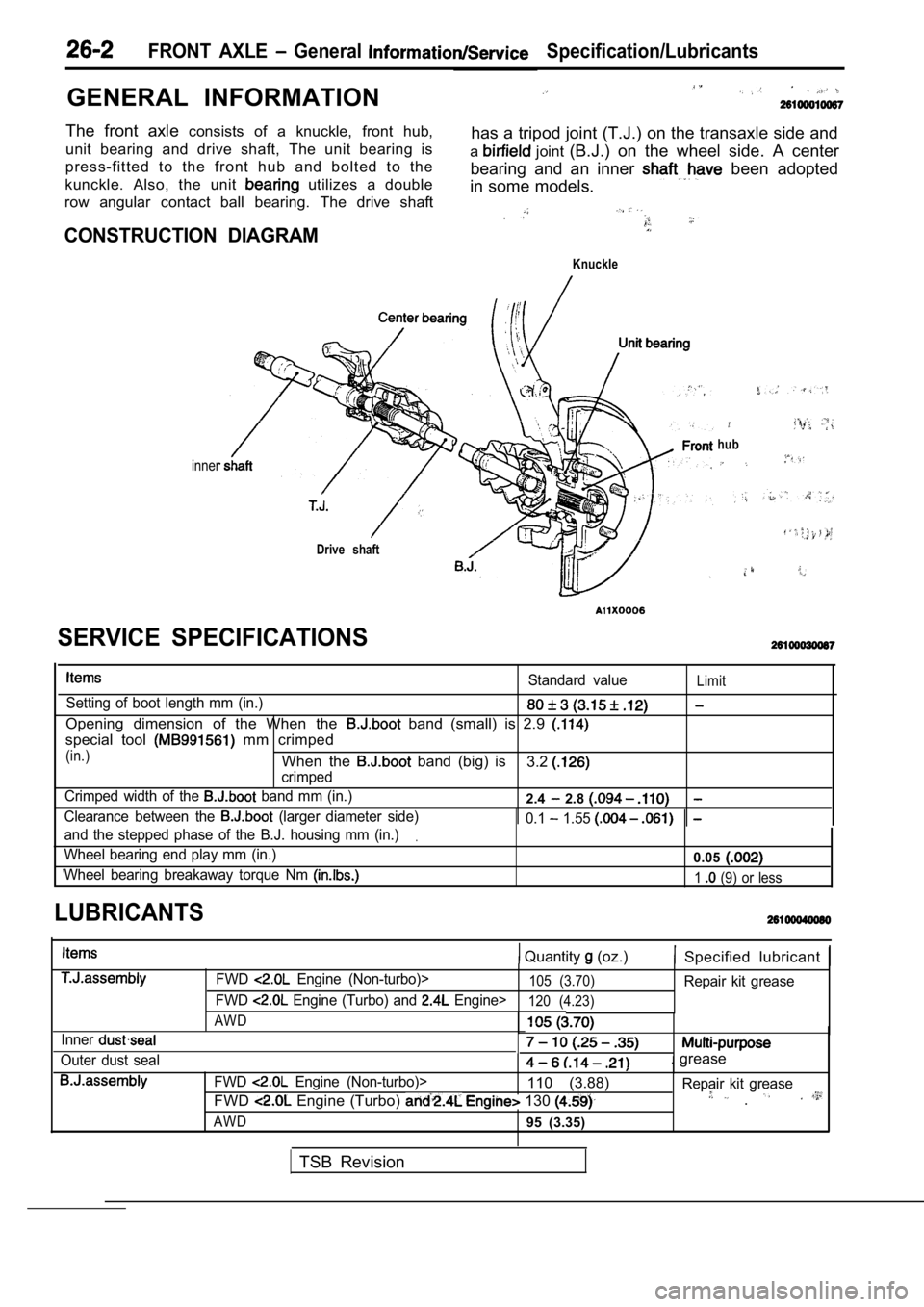

GENERAL INFORMATION

FRONT AXLE General Specification/Lubricants

The front axle consists of a knuckle, front hub,

unit bearing and drive shaft, The unit bearing is has a tripod joint (T.J.) on the transaxle side and

press-fitted to the front hub and bolted to the a

joint

(B.J.) on the wheel side. A center

kunckle. Also, the unit

utilizes a double bearing and an inner been adopted

in some models.

row angular contact ball bearing. The drive shaft

CONSTRUCTION DIAGRAM

Knuckle

inner

Drive shaft

hub

Standard valueLimit

Setting of boot length mm (in.)

Opening dimension of the When the band (small) is 2.9

special tool mm crimped

(in.)When the band (big) is

crimped3.2

Crimped width of the band mm (in.)2.4 2.8

Clearance between the (larger diameter side) 0.1 1.55

and the stepped phase of the B.J. housing mm (in.).

Wheel bearing end play mm (in.)0.05

Wheel bearing breakaway torque Nm 1 (9) or less

SERVICE SPECIFICATIONS

LUBRICANTS

Quantity (oz.) Specified lubricant

Inner

Outer dust sealFWD

Engine (Non-turbo)>105 (3.70)Repair kit grease

FWD

Engine (Turbo) and Engine>120 (4.23)

AWD

. grease

FWD Engine (Non-turbo)>110 (3.88) Repair kit grease

FWD Engine (Turbo) 130 .

AWD95 (3.35)

TSB Revision

Page 1507 of 2103

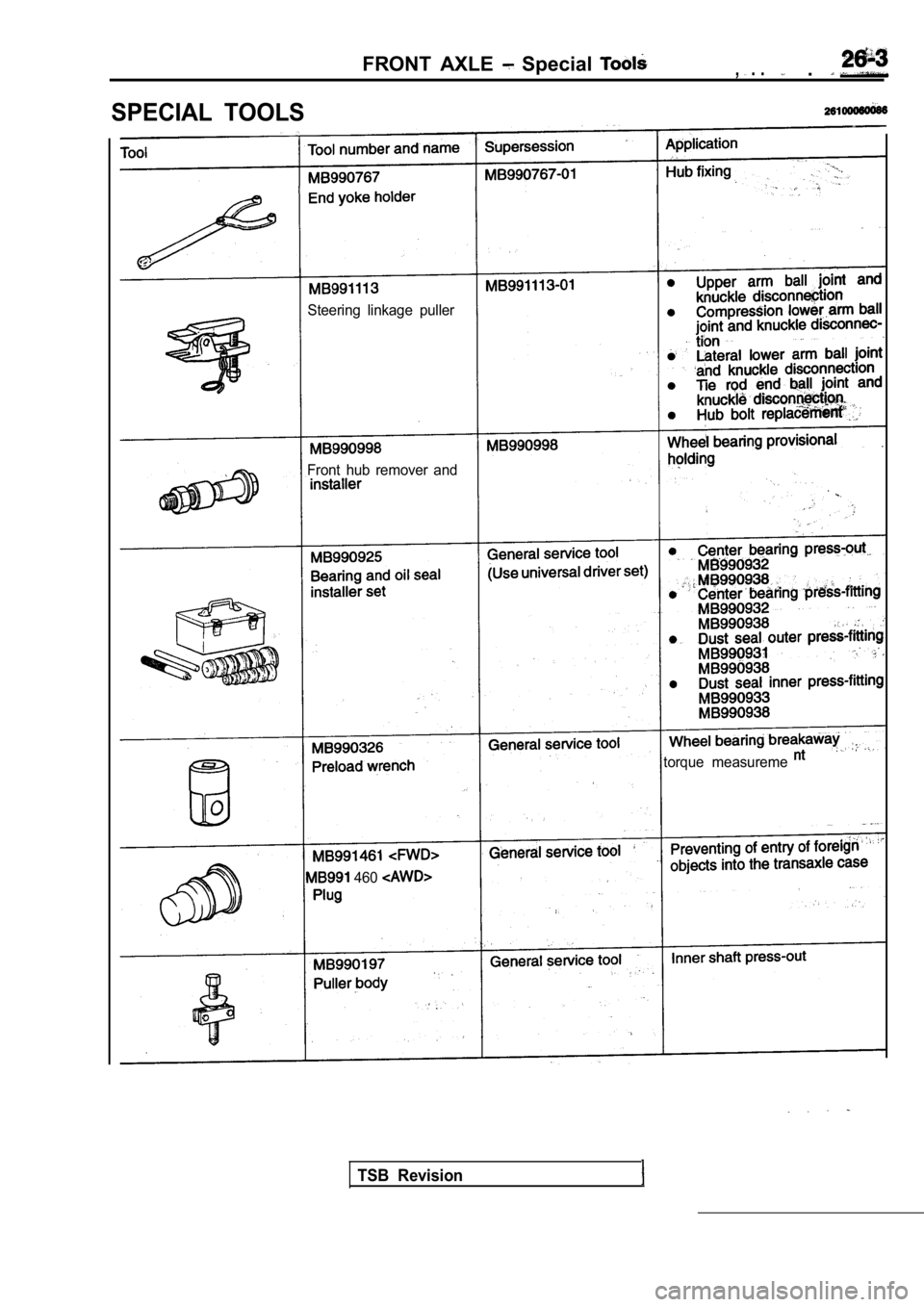

SPECIAL TOOLS

FRONT AXLE Special , . . .

Steering linkage puller

Front hub remover and

torque measureme

460

TSB Revision

Page 1511 of 2103

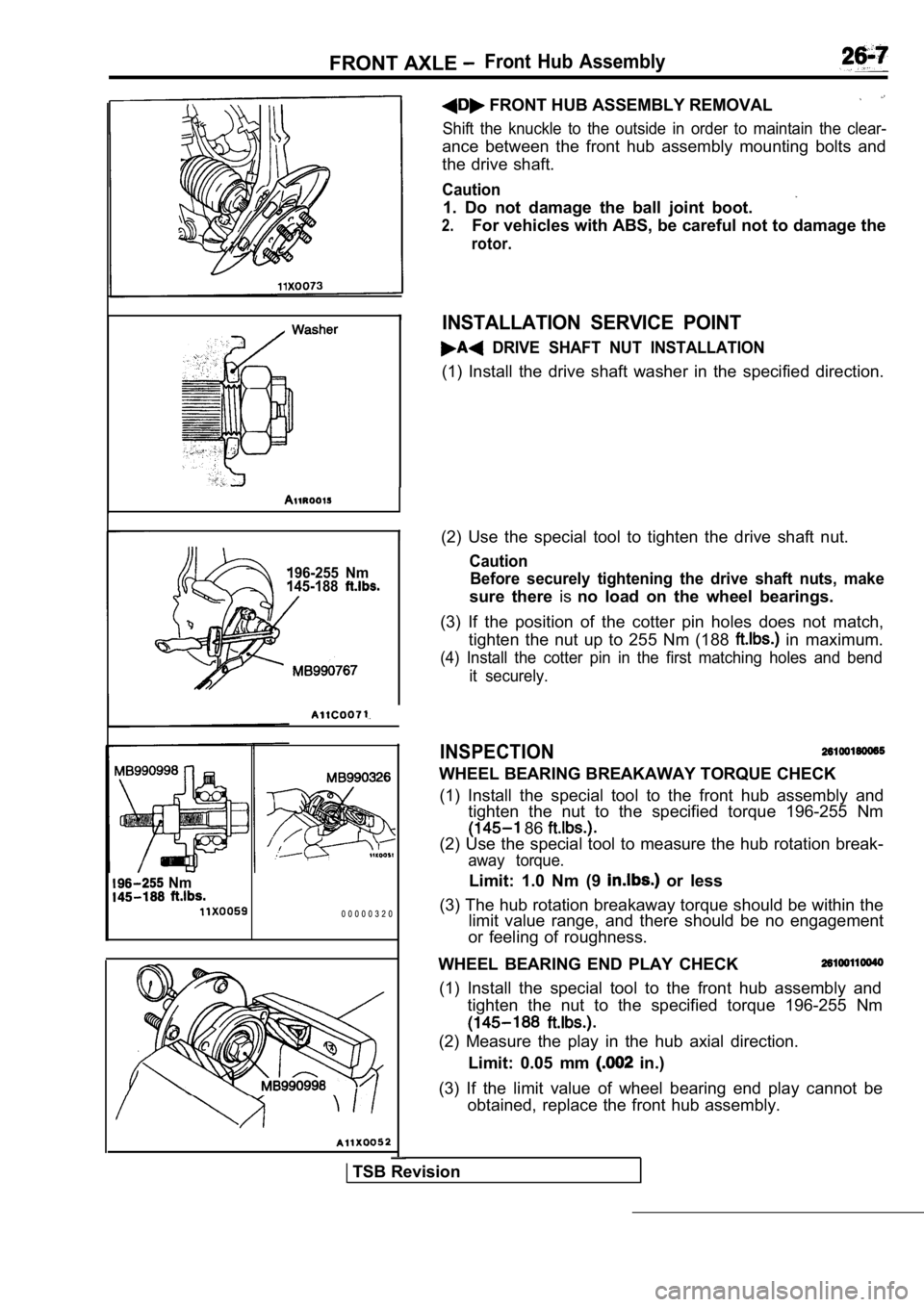

FRONT AXLE Front Hub Assembly

196-255 Nm

145-188

I(2) Use the special tool to tighten the drive shaft nut.

Caution

Before securely tightening the drive shaft nuts, ma ke

sure there isno load on the wheel bearings.

(3) If the position of the cotter pin holes does no t match,

tighten the nut up to 255 Nm (188

in maximum.

(4) Install the cotter pin in the first matching ho les and bend

it securely.

INSPECTION

WHEEL BEARING BREAKAWAY TORQUE CHECK

(1) Install the special tool to the front hub assem bly and

tighten the nut to the specified torque 196-255 Nm

86

(2) Use the special tool to measure the hub rotatio n break-

away torque.

Limit: 1.0 Nm (9 or less

(3) The hub rotation breakaway torque should be wit hin the

limit value range, and there should be no engagemen t

or feeling of roughness. Nm

0 0 0 0 0 3 2 0

FRONT HUB ASSEMBLY REMOVAL

Shift the knuckle to the outside in order to mainta in the clear-

ance between the front hub assembly mounting bolts and

the drive shaft.

Caution

1. Do not damage the ball joint boot.

2.For vehicles with ABS, be careful not to damage the

rotor.

INSTALLATION SERVICE POINT

DRIVE SHAFT NUT INSTALLATION

(1) Install the drive shaft washer in the specified direction.

WHEEL BEARING END PLAY CHECK

(1) Install the special tool to the front hub assem bly and

tighten the nut to the specified torque 196-255 Nm

(2) Measure the play in the hub axial direction.

Limit: 0.05 mm

in.)

(3) If the limit value of wheel bearing end play ca nnot be

obtained, replace the front hub assembly.

TSB Revision

Page 1553 of 2103

REAR AXLE Rear Assembly

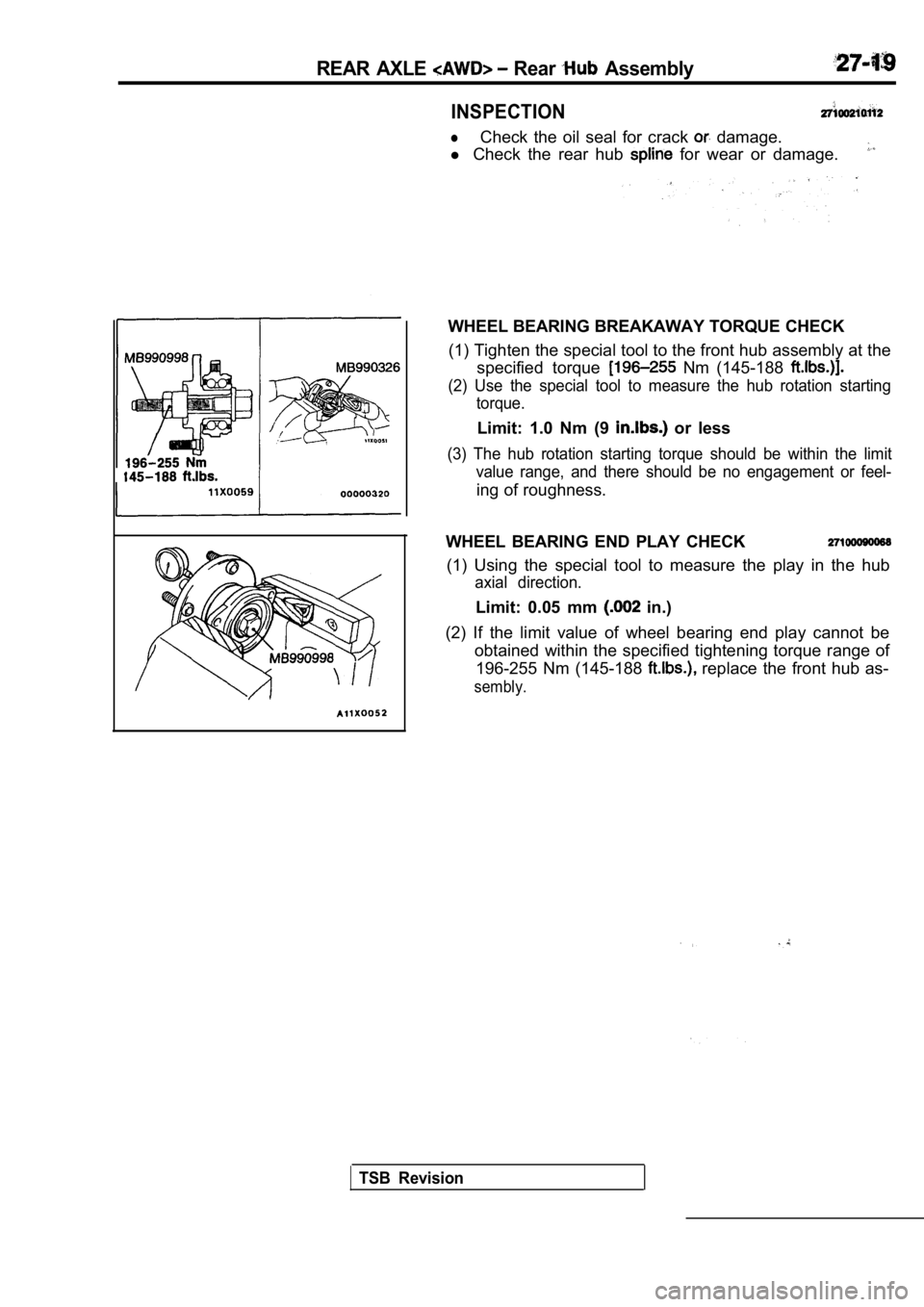

INSPECTION

lCheck the oil seal for crack damage.

l Check the rear hub

for wear or damage.

WHEEL BEARING BREAKAWAY TORQUE CHECK

(1) Tighten the special tool to the front hub assem bly at the

specified torque

Nm (145-188

(2) Use the special tool to measure the hub rotatio n starting

torque.

Limit: 1.0 Nm (9 or less

(3) The hub rotation starting torque should be with in the limit

value range, and there should be no engagement or f eel-

ing of roughness.

WHEEL BEARING END PLAY CHECK

(1) Using the special tool to measure the play in t he hub

axial direction.

Limit: 0.05 mm in.)

(2) If the limit value of wheel bearing end play ca nnot be

obtained within the specified tightening torque ran ge of

196-255 Nm (145-188

replace the front hub as-

sembly.

TSB Revision