sensor MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1221 of 2103

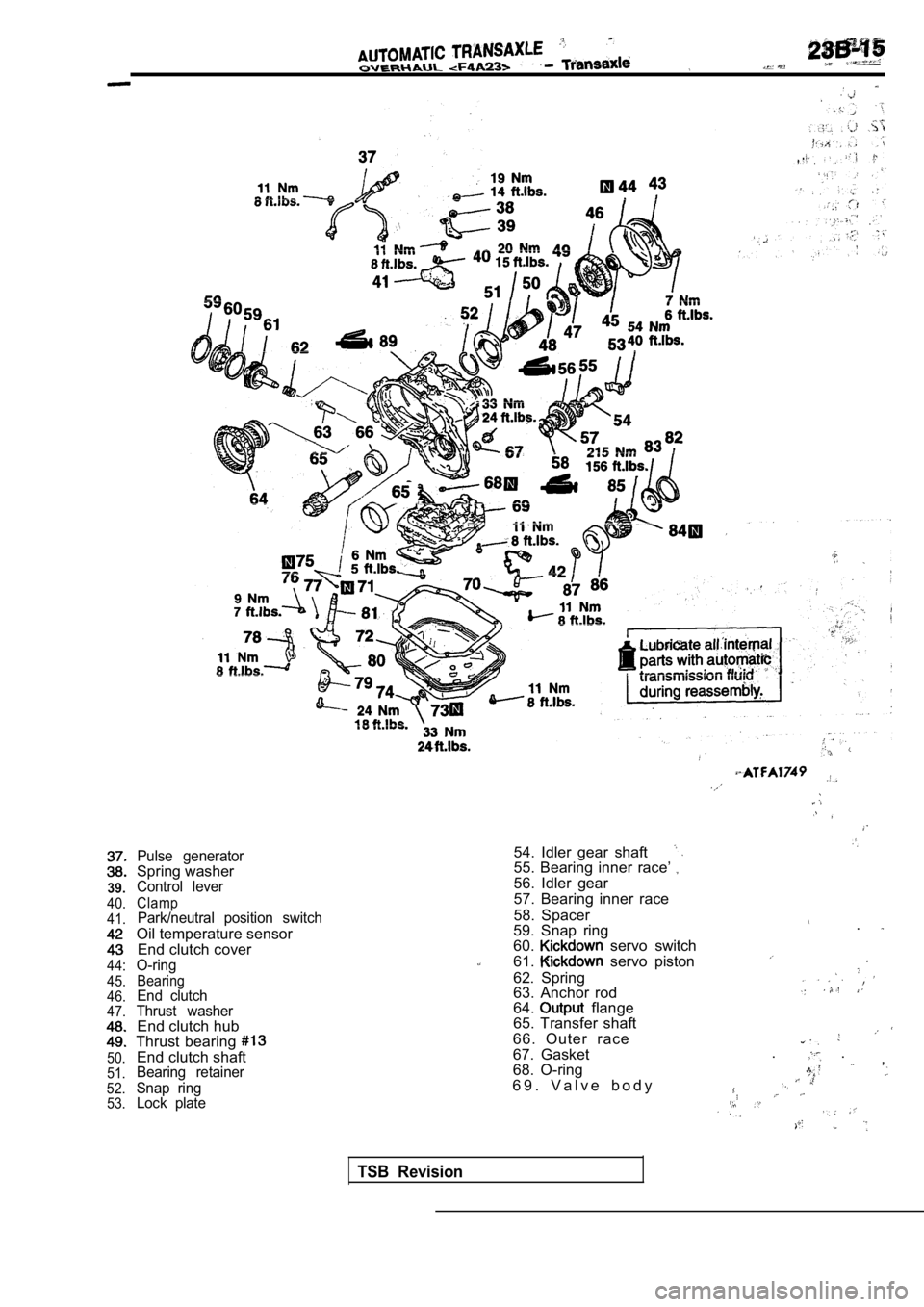

39.

40.

41.

44:

45.

46.

47.

50.

51.

52. 53.

Pulse generatorSpring washerControl lever

ClampPark/neutral position switch

Oil temperature sensor

End clutch cover

O-ring

BearingEnd clutch

Thrust washer

End clutch hub

Thrust bearing

End clutch shaftBearing retainer

Snap ring Lock plate

54. Idler gear shaft55. Bearing inner race’

56. Idler gear

57. Bearing inner race

58. Spacer

59. Snap ring .60. servo switch

61. servo piston

62. Spring

63. Anchor rod64. flange

65. Transfer shaft

66. Outer race

67. Gasket . .

,

68. O-ring

6 9 . V a l v e b o d y

TSB Revision

Page 1223 of 2103

A U T O M A T I C T R A N S A X L EOVERHAUL Transaxle

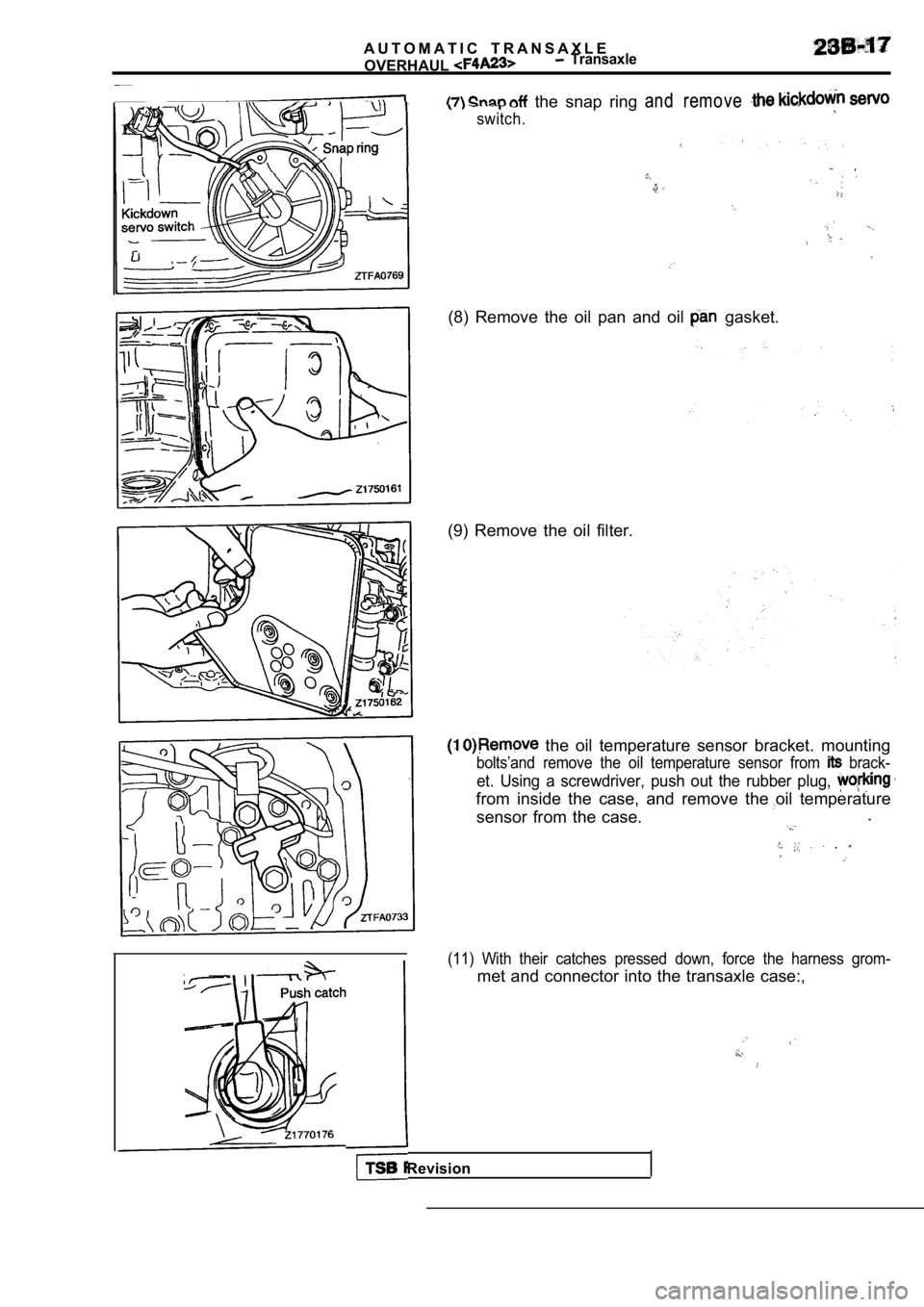

the snap ring and remove

switch.

(8) Remove the oil pan and oil gasket.

(9) Remove the oil filter.

the oil temperature sensor bracket. mounting

bolts’and remove the oil temperature sensor from brack-

et. Using a screwdriver, push out the rubber plug,

from inside the case, and remove the oil temperatur e

sensor from the case..

(11) With their catches pressed down, force the har

ness grom-

met and connector into the transaxle case:,

TSB Revision

Page 1304 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL,

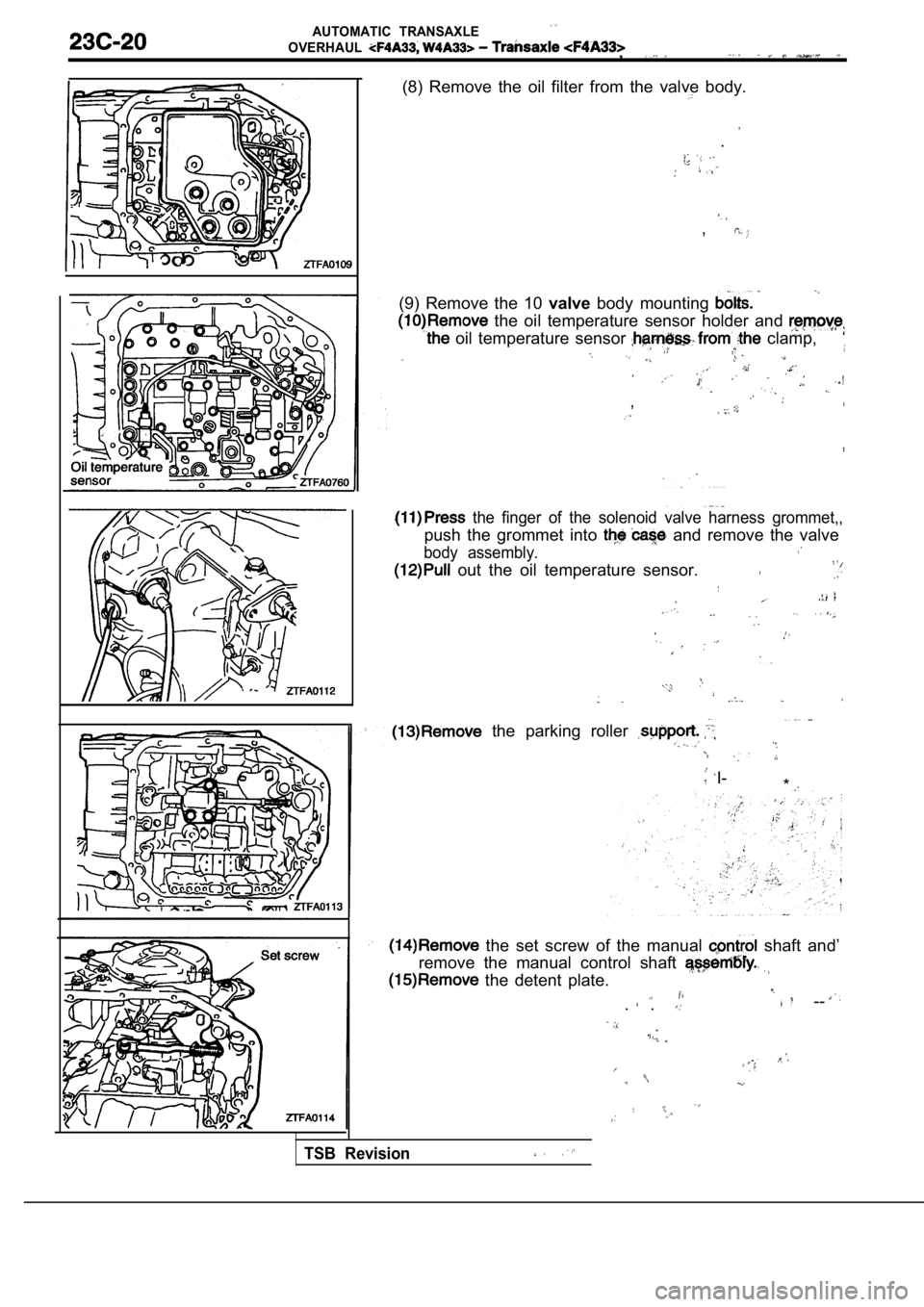

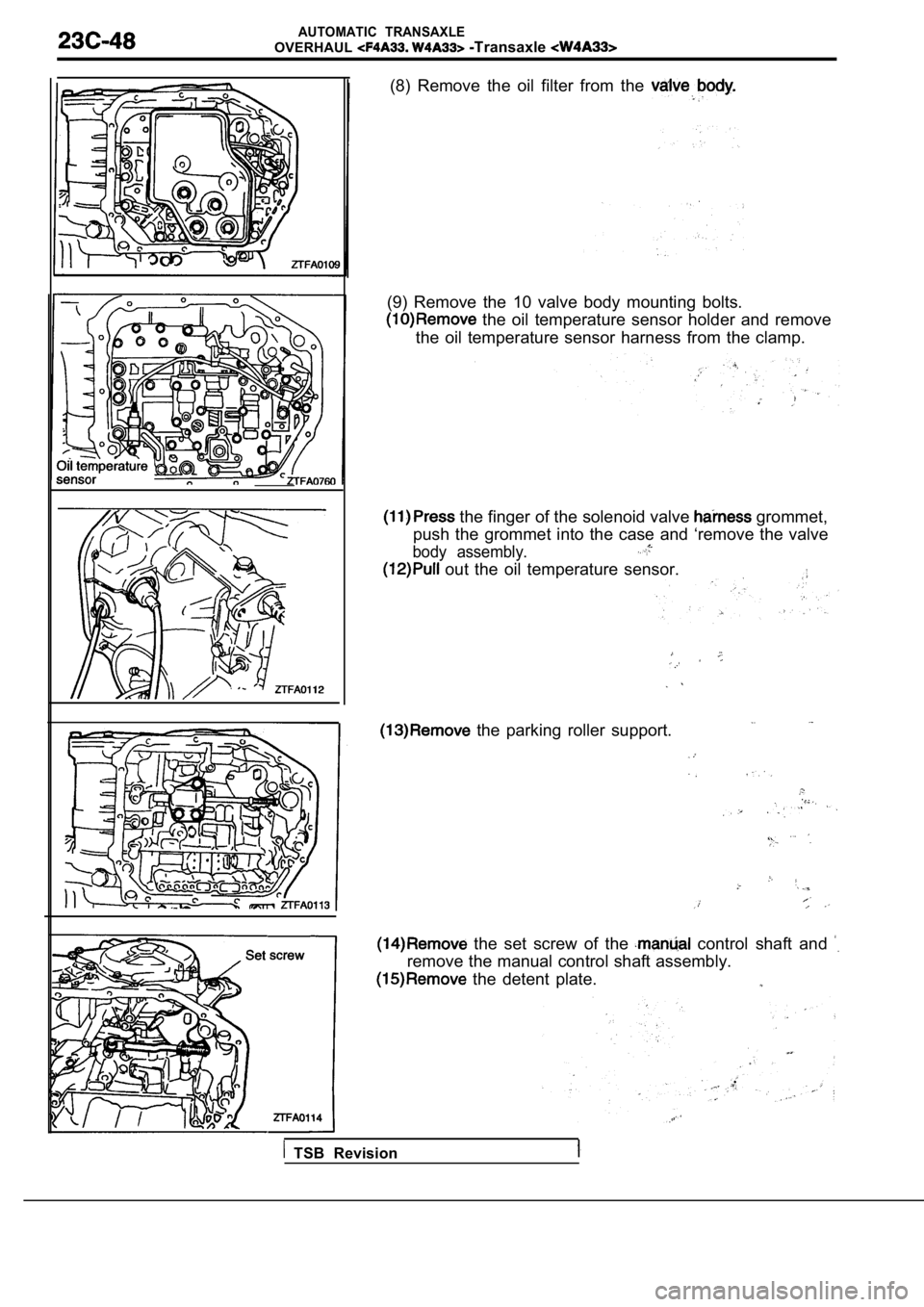

(8) Remove the oil filter from the valve body.

.

,

(9) Remove the 10 valvebody mounting

the oil temperature sensor holder and

oil temperature sensor clamp,

,

the finger of the solenoid valve harness grommet,,

push the grommet into and remove the valve

body assembly.

out the oil temperature sensor.

the parking roller

I-

*

the set screw of the manual shaft and’

remove the manual control shaft

the detent plate.

--. .

TSB Revision

Page 1325 of 2103

AUTOMATIC

OVERHAUL Transaxle

A

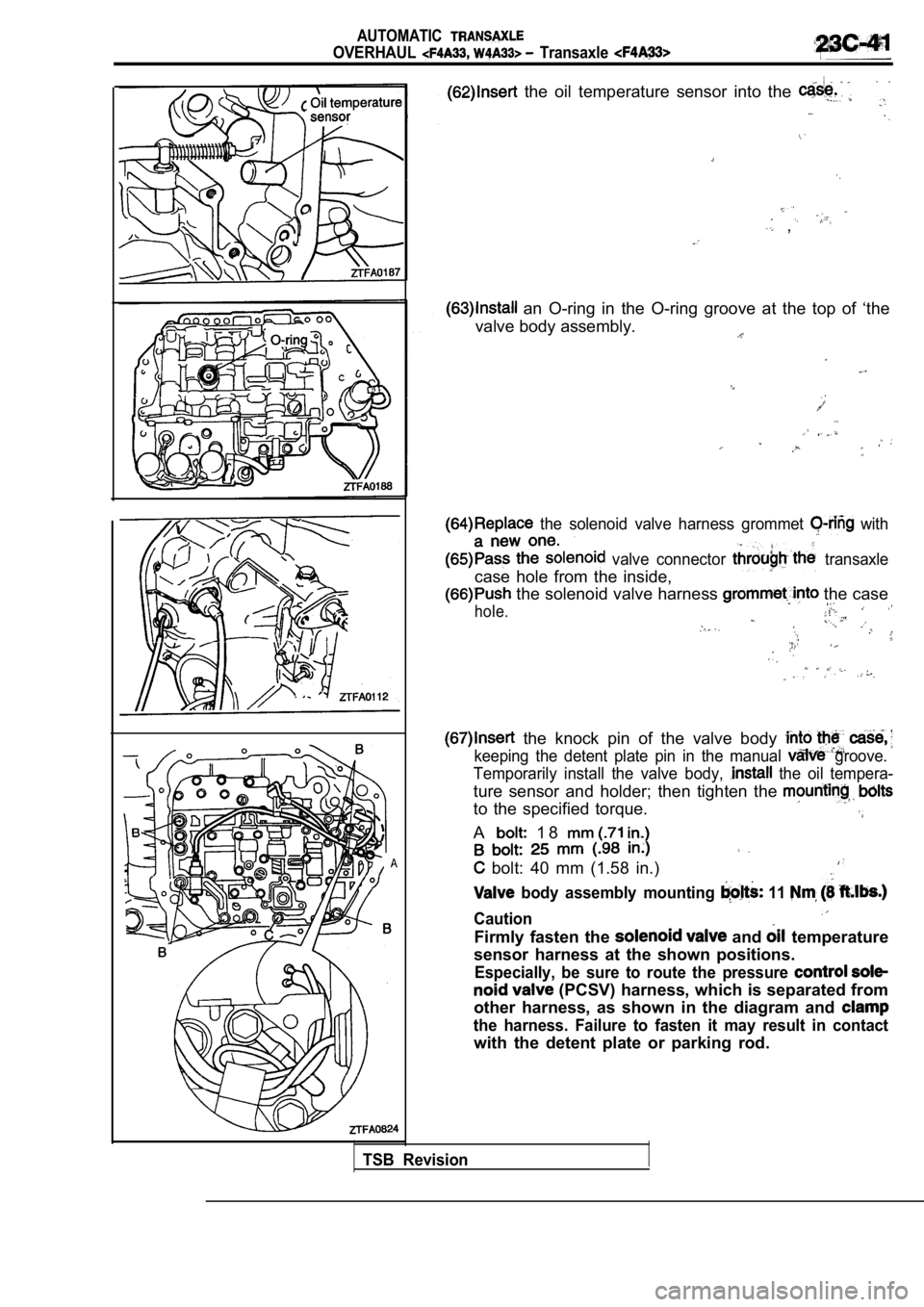

the oil temperature sensor into the

,

an O-ring in the O-ring groove at the top of ‘the

valve body assembly.

the solenoid valve harness grommet with

valve connector transaxle

case hole from the inside,

the solenoid valve harness the case

hole.

the knock pin of the valve body

keeping the detent plate pin in the manual groove.

Temporarily install the valve body,

the oil tempera-

ture sensor and holder; then tighten the

to the specified torque.

A 1 8

bolt: 40 mm (1.58 in.)

body assembly mounting 11

Caution

Firmly fasten the and temperature

sensor harness at the shown positions.

Especially, be sure to route the pressure

(PCSV) harness, which is separated from

other harness, as shown in the diagram and

the harness. Failure to fasten it may result in con tact

with the detent plate or parking rod.

TSB Revision

Page 1332 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL -Transaxle

(8) Remove the oil filter from the

(9) Remove the 10 valve body mounting bolts.

the oil temperature sensor holder and remove

the oil temperature sensor harness from the clamp.

the finger of the solenoid valve grommet,

push the grommet into the case and ‘remove the valv e

body assembly.

out the oil temperature sensor.

the parking roller support.

the set screw of the control shaft and

remove the manual control shaft assembly.

the detent plate.

TSB Revision

Page 1356 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL -Transaxle

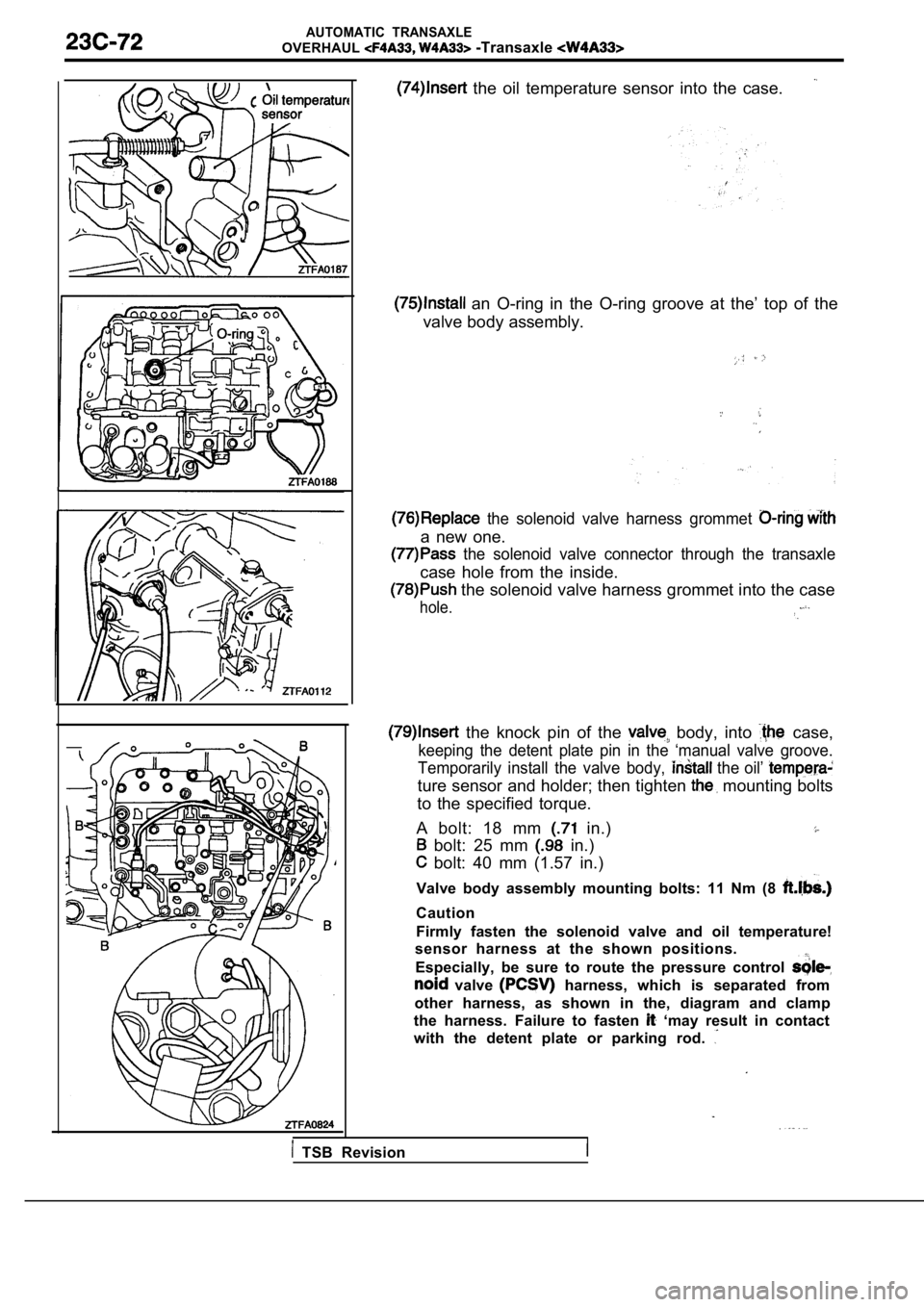

the oil temperature sensor into the case.

an O-ring in the O-ring groove at the’ top of the

valve body assembly.

the solenoid valve harness grommet

a new one.

the solenoid valve connector through the transaxle

case hole from the inside.

the solenoid valve harness grommet into the case

hole.

the knock pin of the body, into case,

keeping the detent plate pin in the ‘manual valve g roove.

Temporarily install the valve body,

the oil’

ture sensor and holder; then tighten mounting bolts

to the specified torque.

A bolt: 18 mm

in.)

bolt: 25 mm in.)

bolt: 40 mm (1.57 in.)

Valve body assembly mounting bolts: 11 Nm (8

Caution

Firmly fasten the solenoid valve and oil temperatur e!

sensor harness at the shown positions.

Especially, be sure to route the pressure control

valve harness, which is separated from

other harness, as shown in the, diagram and clamp

the harness. Failure to fasten

‘may result in contact

with the detent plate or parking rod.

TSB Revision

Page 1404 of 2103

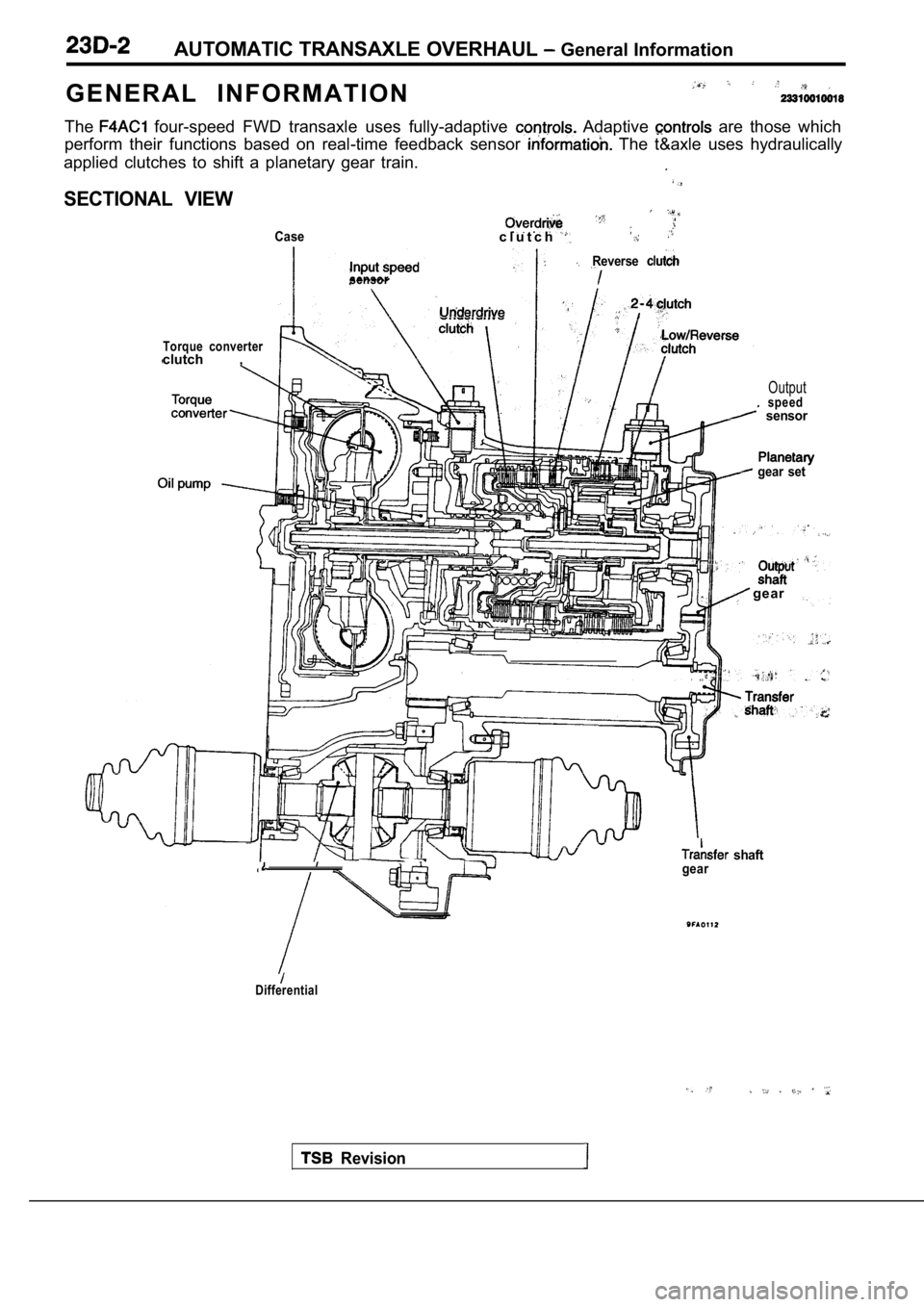

AUTOMATIC TRANSAXLE OVERHAUL General Information

G E N E R A L I N F O R M A T I O N

The four-speed FWD transaxle uses fully-adaptive Adaptive are those which

perform their functions based on real-time feedback sensor

The t&axle uses hydraulically

applied clutches to shift a planetary gear train.

SECTIONAL VIEW

Casec l u t c h

sensor

Torque converterclutch ,

Reverse

Outputspeed sensor

gear set

Revision

gear

shaftgear

Differential

Page 1417 of 2103

AUTOMATIC TRANSAXLE OVERHAUL Transaxle

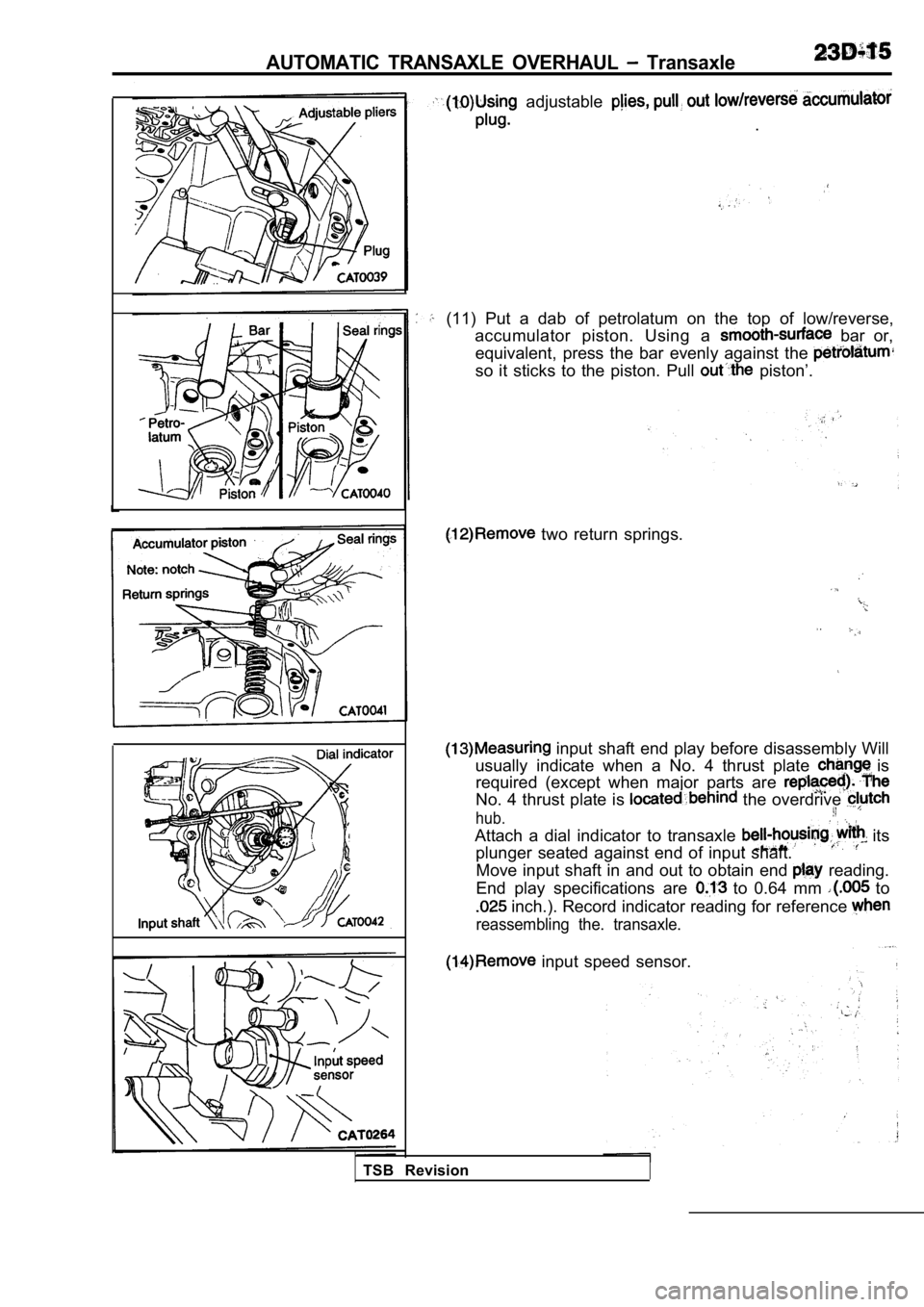

adjustable

.

(11) Put a dab of petrolatum on the top of low/reve rse,

accumulator piston. Using a

bar or,

equivalent, press the bar evenly against the

so it sticks to the piston. Pull piston’.

two return springs.

input shaft end play before disassembly Will

usually indicate when a No. 4 thrust plate

is

required (except when major parts are

No. 4 thrust plate is the overdrive

hub.

Attach a dial indicator to transaxle its

plunger seated against end of input shaft.

Move input shaft in and out to obtain end

reading.

End play specifications are

to 0.64 mm to

inch.). Record indicator reading for reference

reassembling the. transaxle.

input speed sensor.

TSB Revision

Page 1446 of 2103

AUTOMATIC TRANSAXLE OVERHAUL Transaxle

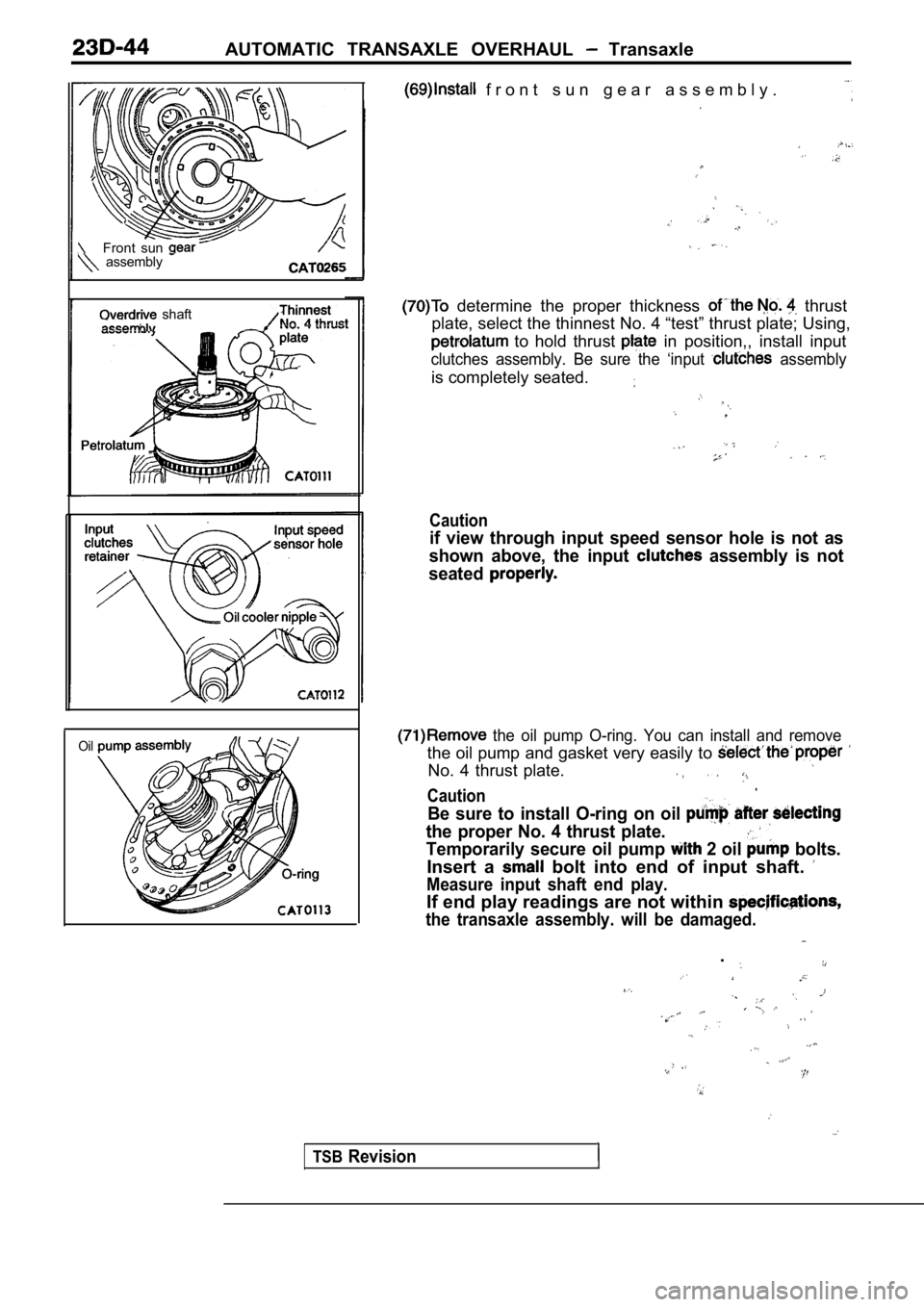

f r o n t s u n g e a r a s s e m b l y .

Front sun assembly

shaft

Oil

determine the proper thickness thrust

plate, select the thinnest No. 4 “test” thrust plat e; Using,

to hold thrust in position,, install input

clutches assembly. Be sure the ‘input assembly

is completely seated.

Caution

if view through input speed sensor hole is not as

shown above, the input

assembly is not

seated

the oil pump O-ring. You can install and remove

the oil pump and gasket very easily to

No. 4 thrust plate..Caution

Be sure to install O-ring on oil

the proper No. 4 thrust plate.

Temporarily secure oil pump 2 oil bolts.

Insert a bolt into end of input shaft.

Measure input shaft end play.

If end play readings are not within

the transaxle assembly. will be damaged.

.

TSBRevision

Page 1467 of 2103

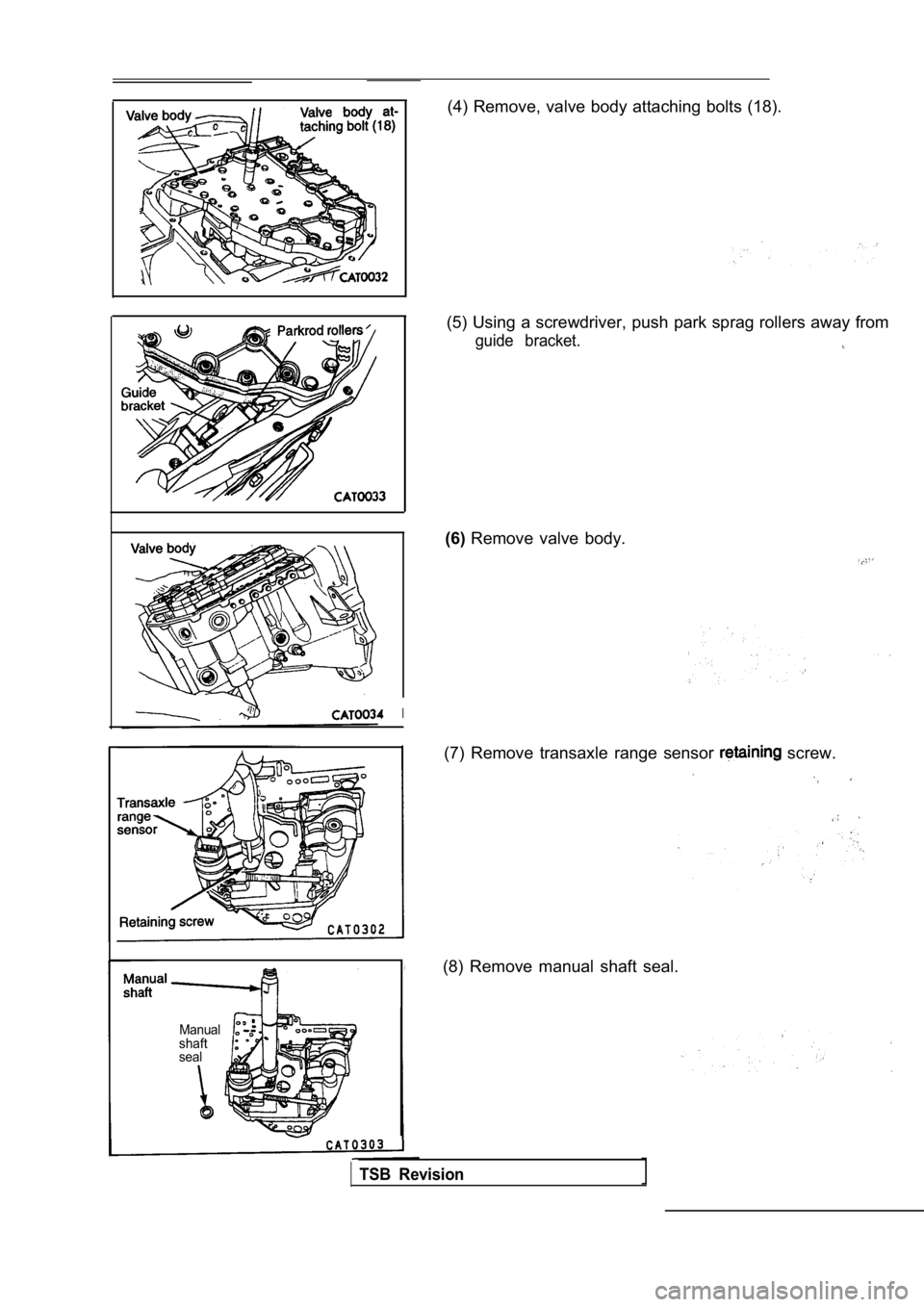

(4) Remove, valve body attaching bolts (18).

I

Manual

shaft

seal

(5) Using a screwdriver, push park sprag rollers aw ay from

guide bracket.

(6)Remove valve body.

(7) Remove transaxle range sensor

screw.

(8) Remove manual shaft seal.

TSB Revision