MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 451 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ( N O N - T U R B O ) >

Scan tool 133

Code General scan tool Timing Belt Skipped 1 Tooth or

No.More

11 ,,

[Comment]l Timing belt improperly BackgroundlThe PCM uses voltage signal MITSUBISHI SPYDER 1990 Service Repair Manual ( N O N - T U R B O ) >

Scan tool 133

Code General scan tool Timing Belt Skipped 1 Tooth or

No.More

11 ,,

[Comment]l Timing belt improperly BackgroundlThe PCM uses voltage signal](/img/19/57345/w960_57345-450.png)

( N O N - T U R B O ) >

Scan tool 133

Code General scan tool Timing Belt Skipped 1 Tooth or

No.More

11 ,,

[Comment]l Timing belt improperly BackgroundlThe PCM uses voltage signals generated by the camsh aft position sensor and l C r a n k s h a f t s e n s o r

position sensors to determine engine synchronizatio n.

l lif these signals become out of sync, this DTC is pr oduced.

l Range of Check connected l With the engine running, every 44 ms an inhibit con dition is looked for as follows:lwide-open throttle, large change in MAP, cold engine, insufficient start to run time, Crankshaft position sensor eriy connected outside given windowslCamshaft’s relative position not lif an inhibit condition does not exist, the misalignment between the camshaft and crankshaftone of the following have been serviced:

is monitored.

Set Condition camshaft, timing. ten-

When the camshaft position sensor is offset from th e crankshaft position sensor one tooth

sprocket,or more.PCM the

NGCheck the following Repair

,Check the camshaft position sensor.

(Refer to GROUP 16 Ignition System.)

OK

Check the crankshaft position se

(Refer to GROUP 16 IgnitionSystem.)

OK

I

NG Repair

,

Check the timing belt. (Refer to GROUP 11

Timing Belt.)

Caution

When the following parts arereplaced with new ones, be sure to use the scan to

the camshaft position sensor with the crankshaft po sition sensor again or disconnect the negative

battery cable for 10 seconds or more:

camshaft, camshaft sprocket, timing belt, tensioner, cylinder head, head gasket, crankshaft sprocket,

crankshaft, cylinder block, etc.

TSB Revision

Page 452 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 135

No. No 5 Volts to MAP

14

[Comment]Background Open circuit

The

of 5 volts is to the MAP sensor. if this is extremely l Signal circuit MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 135

No. No 5 Volts to MAP

14

[Comment]Background Open circuit

The

of 5 volts is to the MAP sensor. if this is extremely l Signal circuit](/img/19/57345/w960_57345-451.png)

ENGINE (NON-TURBO)>

Scan tool 135

No. No 5 Volts to MAP

14

[Comment]Background Open circuit

The

of 5 volts is to the MAP sensor. if this is extremely l Signal circuit grounded ,lthe MAP sensor output deviates from standard .

Range of Check Before starting engine and immediately after stopp

ing engine

Set Condition ,

The output of MAP sensor is lower than the specified

Measure at the MAP sensor connector lDisconnect the connector, and measure at the harnes

s side.

l between 2 and ground

(ignition switch: ON)

O K :

OK

Check the harness wire connector. Repair, if necessary.

Check the following connectors: Repair

OK .

Check trouble symptom. .

N G, N GCheck the harness wire between the PCM and MAP Repairconnector.. .

OK

TSB Revision,

Page 453 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

Scan tool 136

Code General scan tool No 5 Volts to Throttle

No.Sensor

24

[Comment]

Backgroundl S e n s o r circuit grounded

lThe of 5 volts is to the TPS. if MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

Scan tool 136

Code General scan tool No 5 Volts to Throttle

No.Sensor

24

[Comment]

Backgroundl S e n s o r circuit grounded

lThe of 5 volts is to the TPS. if](/img/19/57345/w960_57345-452.png)

E N G I N E

Scan tool 136

Code General scan tool No 5 Volts to Throttle

No.Sensor

24

[Comment]

Backgroundl S e n s o r circuit grounded

lThe of 5 volts is to the TPS. if thisvoltage is extremely low, TPS l position sensor . Loss of output deviates from standard Range of Check

l Vehicle speed: More than 20 mph

l Engine speed: 1500

or more

l Manifold vacuum: Less than 13 (4 Set ConditionlThe output voltage of TPS is lower than the

l

Check the throttle position sensor (TPS) (Refer to

Measure at the throttle position sensor connector Check the following connectors: lDisconnect the connector, and measure at the harnes s sideOK

Check trouble symptom.

U K

Check the following connectors:

OK

NG

Check the wire between the PCM Repair, if necessary..

Repair

Check trouble symptom.

N G

Check the harness wire between the PC

OK

Replace the PCM.

Repair .

Scan tool 137

EATX Controller DTC Present cause

45.

[Comment] Sensors related to Background controlThe transaxle control module monitors the malfunctions of sensors and

actuatorsl TCMregarding the transaxle if any malfunction is detected, the TCM informs th e PCMl PCM failedby sending a Range of Check, Set Conditions

A malfunction is input from the TCM.,

Check the TCM (Refer to GROUP Troubleshooting.)

Revision

Page 454 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE Troubleshooting .

Scan tool 138

Code General scan tool

No. Not

25

[Comment]Range of Check

l Engine:

l Vehicle at rest and the brake appliedSet Conditionl speed differ MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE Troubleshooting .

Scan tool 138

Code General scan tool

No. Not

25

[Comment]Range of Check

l Engine:

l Vehicle at rest and the brake appliedSet Conditionl speed differ](/img/19/57345/w960_57345-453.png)

ENGINE Troubleshooting .

Scan tool 138

Code General scan tool

No. Not

25

[Comment]Range of Check

l Engine:

l Vehicle at rest and the brake appliedSet Conditionl speed differs from target idle by 200 for 12 seconds. l

Idle air control motor failed

l motor related circuit .

SCAN TOOL SENSOR READ TESTS (Data list)

12 position (Refer to Check the air control motor. (Refer to

OK

Check the throttle body minimum air flow. (Refer to

Code

No. R e l a y

General scan tool High Speed Radiator Fan Control

[Comment]

Background

lThe high speed radiator fan relay controls the high speed operation of the radiator fan.lOne side of the relay control coil is supplied with 12 volts when the switch is

turned to the ON position.

lThe circuit is completed when the other side of the relay coil is grounded by the PCM.lThe PCM grounds the relay control circuit depending on engine coolant temperature and/or A/C compressor condition, etc.

Range of Check

l Battery voltage: 10

or more

l Ignition switch: ON

Set Condition

lAn open or shorted condition is detected in the hig h speed radiator fan relay control circuitfor 3 seconds.

Probable cause

TSB Revision

l Relay open or l Ignition switch output lLow speed radiator fan relay control circuit

open or shorted

NGMeasure at the PCM connector Check the radiator fan circuit.lDisconnect the connector, and measure at harness side. Voltage between 69 and ground(Ignition switch: ON),.

OK: Battery positive voltage .,

l

Connect a jumper wire between 69 and ground(Ignition switch: ON)

OK: Radiator fan runs at high speed.

OK

Check the following connector: N G Repair

OK

Check trouble symptom.1

NG

Replace the PCM.

Page 455 of 2103

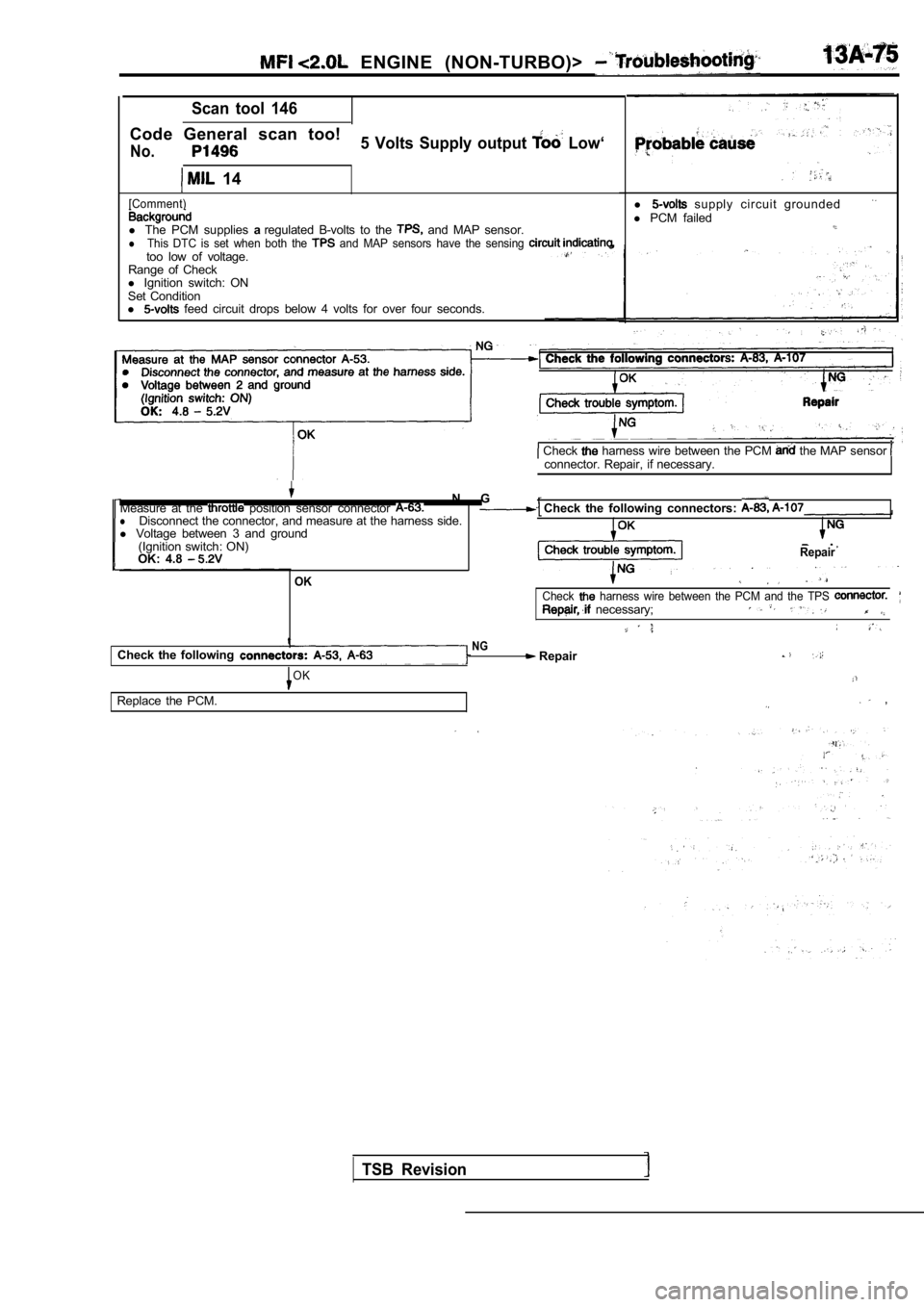

ENGINE (NON-TURBO)>

Scan tool 146

Code General scan too!

No.5 Volts Supply output Low‘

14

[Comment)

l The PCM supplies aregulated B-volts to the and MAP sensor.lThis DTC is set when both the and MAP sensors have the sensing too low of voltage.

Range of Check

l Ignition switch: ON

Set Condition

l

feed circuit drops below 4 volts for over four sec onds.l

supply circuit groundedl

PCM failed

Check harness wire between the PCM the MAP sensor connector. Repair, if necessary.

N G

Measure at the position sensor connector Check the following connectors: lDisconnect the connector, and measure at the harnes s side.

l Voltage between 3 and ground

(Ignition switch: ON)

OK: 4.8

Repair

OK

.

Check harness wire between the PCM and the TPS necessary;

NGCheck the following Repair

OK

Replace the PCM. ,

TSB Revision

Page 456 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

Scan tool 149

Code General scan tool Fuel Level Sending Unit Volts Too

No.Low

42

[Comment]l Sensor signal line is grounded. . Backgroundl Fuel level sensor failedl MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

Scan tool 149

Code General scan tool Fuel Level Sending Unit Volts Too

No.Low

42

[Comment]l Sensor signal line is grounded. . Backgroundl Fuel level sensor failedl](/img/19/57345/w960_57345-455.png)

E N G I N E

Scan tool 149

Code General scan tool Fuel Level Sending Unit Volts Too

No.Low

42

[Comment]l Sensor signal line is grounded. . Backgroundl Fuel level sensor failedlThe fuel level sensor, which is installed in the fu el tank, informs the PCM of fuel level(amount).Loss of supply. . lThe PCM does not carry out a specific OBD-II monito r when the fuel amount is small

or large.

Range of Checkl Battery positive voltage: 13 15 l Engine is runningSet ConditionsThe fuel level sensor output voltage is less than 0 .1 V.

Check the fuel gauge unit and its circuit. (Refer to GROUP 54

Combination Meters.)

OK1Check the following NG Repair

Check trouble symptom. Check the harness wire between the PCM and fuel lev

el sensor

Scan tool 150

Code General scan tool

Fuel Level Sending Unit Volts Too

No.High

42

[Comment]l Sensor is grounded.Backgroundl Fuel level sensor failedlThe fuel level sensor, which is installed in the fu el tank, informs the PCM of fuel levell Open sensor ground circuit(amount.)lThe PCM does not carry out a specific OBD-II monito r when the fuel amount is small

or large.

Range of Check

l Battery positive voltage: 13

15 l Engine is running

Set Conditions

The fuel level sensor output voltage is less than 4 .5 V.

TSB Revision

Check the fuel gauge unit and its circuit. to GROUP 54 Combination Meters.)

OK

Check the connectors: A-l 06 NG Repair

Check trouble symptom. Check the harness wire between the PCM and fuel lev

el sensor

connector.

the PCM.Repair

Page 457 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE Troubleshooting

[Comment]

Background

lThe fuel level sensor, which is installed in the fuel tank, informs the PCM of fuel level(amount).lThe PCM does not carry out a MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE Troubleshooting

[Comment]

Background

lThe fuel level sensor, which is installed in the fuel tank, informs the PCM of fuel level(amount).lThe PCM does not carry out a](/img/19/57345/w960_57345-456.png)

ENGINE Troubleshooting

[Comment]

Background

lThe fuel level sensor, which is installed in the fuel tank, informs the PCM of fuel level(amount).lThe PCM does not carry out a specific monitor when the fuel amount is small

or large.

Range of Check

l Battery positive voltage: 13

15 l Engine is running

Set Conditions

The fuel level signal does not change according to the fuel consumption by driving.Probable cause

l

Fuel level sensor failed

l PCM failed

Check the fuel gauge unit and its circuit.

(Refer to GROUP 54 Combination Meters.)

OK

N GCheck the following connectors: A-l 06 Repair

OK

Check trouble symptom.

N G

N G

Check the harness wire between the PCM and fuel lev el sensor Repairconnector.

OK

Replace the PCM.

Scan tool 153

Code General scan tool Battery Temperature Sensor

No.Voltage Too LowI

44

[Comment]

Background

Battery temperature input is used to adjust the gen erator charging rate based upon the ambient

temperature around the battery.

Range of Check

Ignition switch: ON

Set Conditions

The sensor voltage remains less than 0.3

for 3 seconds.

l Battery temperature sensor l PCM

Replace the

TSB Revision

Page 458 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

Scan tool 154

C o d e G e n e r a l s c a n t o o l T e m p e r a t u r e S e n s o r

No.Voltage Too High

44

[Comment]

Backgroundl Battery temperature sensor l PCM MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

Scan tool 154

C o d e G e n e r a l s c a n t o o l T e m p e r a t u r e S e n s o r

No.Voltage Too High

44

[Comment]

Backgroundl Battery temperature sensor l PCM](/img/19/57345/w960_57345-457.png)

E N G I N E

Scan tool 154

C o d e G e n e r a l s c a n t o o l T e m p e r a t u r e S e n s o r

No.Voltage Too High

44

[Comment]

Backgroundl Battery temperature sensor l PCM failedBattery temperature input is used to adjust the gen erator charging rate based upon the ambienttemperature around the battery.Range of CheckIgnition switch: ON

Set Conditions .

The sensor voltage remains more than 4.9 for 3 seconds.

Replace the PCM.

Scan tool 155

C o d e G e n e r a l s c a n t o o l U p s t r e a m S h o r t e d t o

No. G r o u n d

[Comment]

Background

lWhen the heated oxygen sensor temperature is low, t

he sensor has the same electrical

characteristics as an insulator.

lThe heated oxygen sensor output signal line is rest ricted to That is why the line voltageis approx. when the heated oxygen sensor temperature is low.lIf the heated oxygen sensor output signal line is grounded, its voltage will become low.

Range of Check

l Engine coolant temperature when the engine starts:

or less

l Within three seconds after the engine

Set Conditions

The heated oxygen sensor output signal line is or less.

TSB Revision

l

.

Upstream, heated oxygen sensor failed

Wiring harness and connectors failed PCM failed

NGCheck the harness wire between the PCM and upstream heated Repair

oxygen sensor connector.

OK

Replace the PCM.

Page 459 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ,

-- Scan tool 156,I

C o d e G e n e r a l s c a n t o o l D o w n s t r e a m to

No. G r o u n d

21

[Comment]l Downstream heated oxygen Backgroundl harness and connectors lWhen MITSUBISHI SPYDER 1990 Service Repair Manual ,

-- Scan tool 156,I

C o d e G e n e r a l s c a n t o o l D o w n s t r e a m to

No. G r o u n d

21

[Comment]l Downstream heated oxygen Backgroundl harness and connectors lWhen](/img/19/57345/w960_57345-458.png)

,

-- Scan tool 156,I

C o d e G e n e r a l s c a n t o o l D o w n s t r e a m to

No. G r o u n d

21

[Comment]l Downstream heated oxygen Backgroundl harness and connectors lWhen the heated oxygen sensor temperature is low, t he sensor has the same electrical

l PCM failed characteristics as an insulator.lThe heated oxygen sensor output signal line is That is is approx. when the heated oxygen sensor temperature is low.If the heated oxygen sensor output signal line is g rounded, will become lRange of checkl Engine coolant temperature when the engine starts: or lessl Within three seconds after the engine starts

Set Conditions

The heated oxygen sensor output signal line is

or less.

NGCheck the harness I .oxygen sensor connector.. , ,

OK

Replace the PCM.

11

[Comment]Background , connectedlAfter the engine has been started, the PCM maintain s an expected camshaft port l position

Scan tool 157,General scan toolIntermittent Loss of CMP CKP Probable cause

value. connectedlAt every crankshaft leading edge, this value is updated to reflect the expected

.Camshaft position sensor change in the cam level.

l lAt every crankshaft trailing edge, this value is compared to the true port level. sensor improperly lIf there is a disagreement between two values, then the diagnostic code isset.l sensor

Range of Check

l Engine: running

Set Condition

l Cam and crank signals have been out of sync, than times.

N GCheck the following connectors:. A-l 06

OK

__Check no cam sync. signal at PCM. (Refer to INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE

CODE.

Check no crank reference signal at PCM. (Refer to INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE

TSB Revision

Page 460 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 160

Code General scan tool EVAP Leak Monitor

No.Detected

31

[Comment]

Background

l The PCM monitors that the fuel tank, purge lines, e tc. are MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 160

Code General scan tool EVAP Leak Monitor

No.Detected

31

[Comment]

Background

l The PCM monitors that the fuel tank, purge lines, e tc. are](/img/19/57345/w960_57345-459.png)

ENGINE (NON-TURBO)>

Scan tool 160

Code General scan tool EVAP Leak Monitor

No.Detected

31

[Comment]

Background

l The PCM monitors that the fuel tank, purge lines, e tc. are well.

l

ventilation solenoid with the canister ventilation valve (incorporated in the lIf the fuel tank and purge lines are sealed the pressure will rise well by the solenoid specific timeslAfter the pressure rises well, the diaphragm inside the solenoid will not work any more.lIf the purge air leaks slightly, the solenoid will be activated more than specific times.

Range of Check, Set Condition

l The solenoid has been activated more than specific times.

‘ P r o b a b l e

I,

l Fuel tank cap screwed on l tank and purge lines, l Evaporative emission failed

l

l PCM failed’

NGCheck the evaporative Replace

(Refer to GROUP Emission Control System.)

OK

Check the evaporative emission purge solenoid.NG Replace

(Refer to GROUP 17 Emission Control System.)

OK

Check the fuel tank and purge line for leakage.

Scan tool 161

Code General scan tool EVAP Leak Monitor Large Leak

No. Detected

TSB Revision

[Comment]

l The PCM monitors that the fuel tank, purge lines, e tc. are well.

l

ventilation with the canister ventilation valve (incorporated in the solenoid) lIf the fuel tank and purge lines are sealed correct ly, the pressure will well by the solenoid specific times.lAfter the pressure rises well, the diaphragm inside the solenoid will not work any more.lIf the purge air leaks excessively, the solenoid should be activated much more than specific

times.

of Check. Set Condition

l been activated much more than specific times.

Probable cause

l Fuel tank filler cap screwed on lFuel tank and purge seated

l Evaporative solenoid

failed

l

l PCM ,

Check the evaporative emission ventilation solenoid .

(Refer to GROUP 17 Emission Control System.) Replace

NGCheck the evaporative emission purge solenoid. Replace

(Refer to GROUP 17 Emission Control System.)

OK

Check the fuel tank and line for I