MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 491 of 2103

ENGINE (NON-TURBO)> Troubleshooting

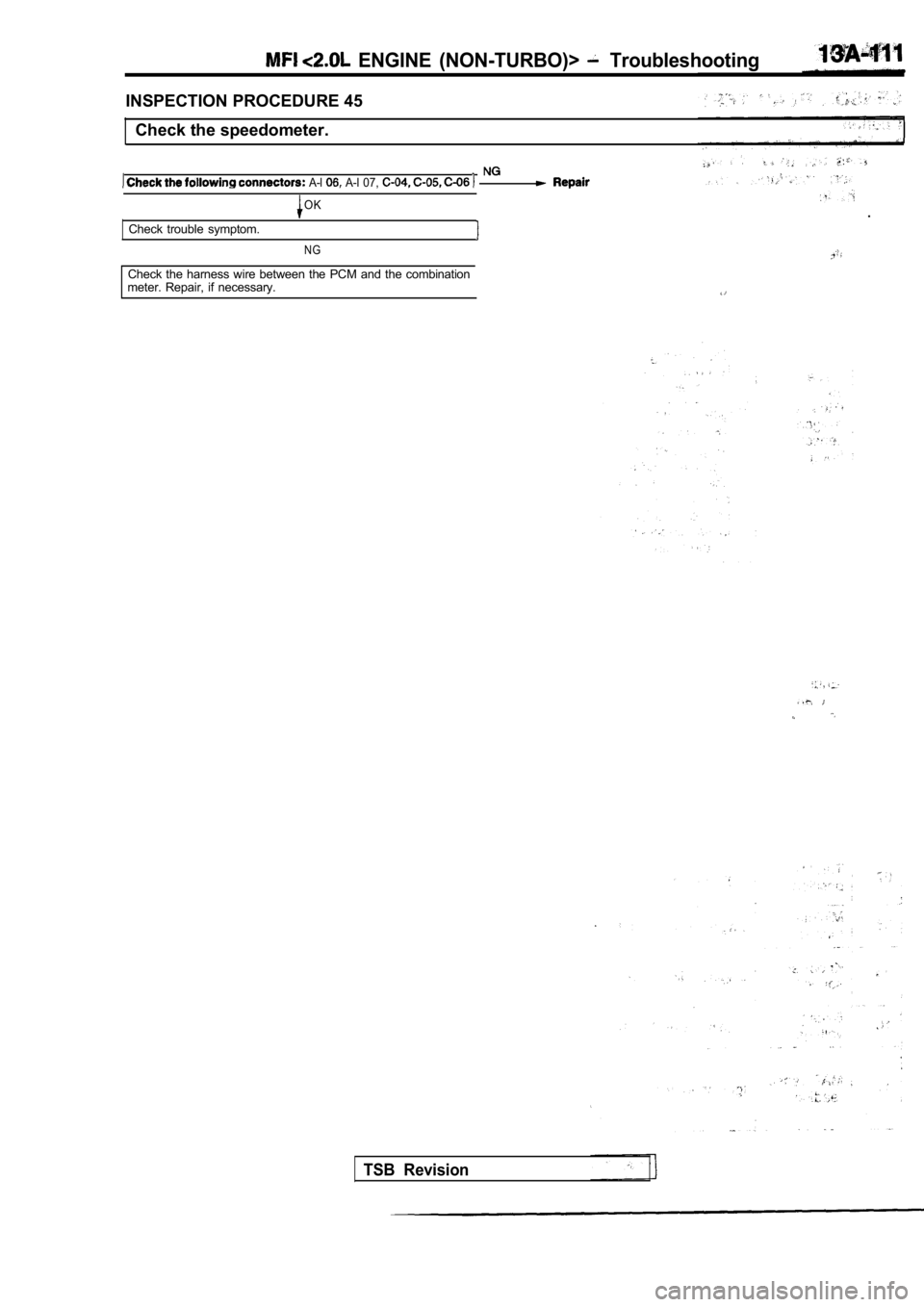

INSPECTION PROCEDURE 45Check the speedometer.

A-l A-l 07,

OK

Check trouble symptom.

NG

Check the harness wire between the PCM and the comb ination

meter. Repair, if necessary.

TSB Revision

.

Page 492 of 2103

ENGINE (NON-TURBO)> Troubleshooting

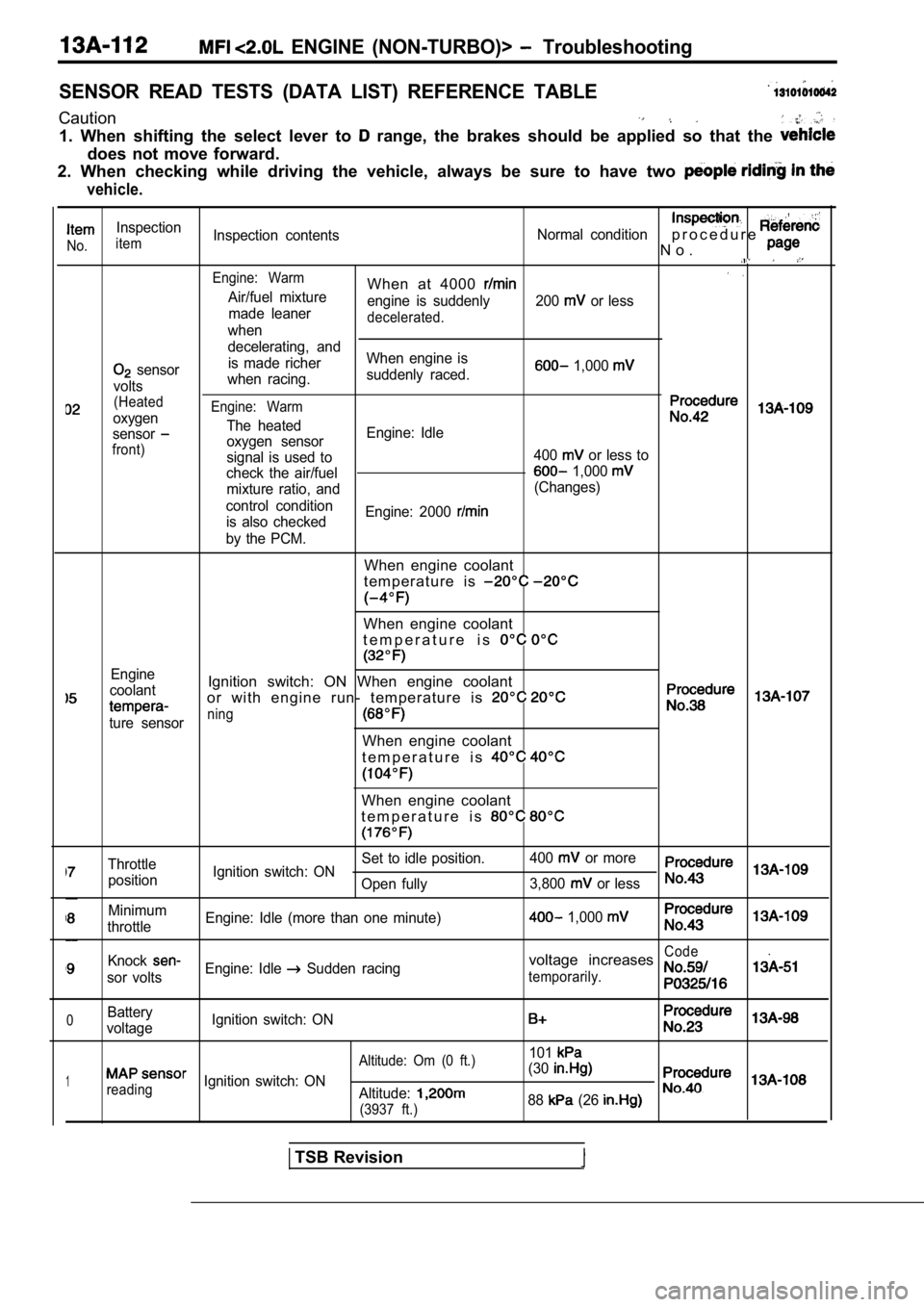

SENSOR READ TESTS (DATA LIST) REFERENCE TABLE

Caution

1. When shifting the select lever to range, the brakes should be applied so that the

does not move forward.

2. When checking while driving the vehicle, always be sure to have two

vehicle.

Inspection

No.itemInspection contents

Normal conditionp r o c e d u r e

N o .

Engine: WarmWhen at 4000 Air/fuel mixture

engine is suddenly 200 or less

made leaner

decelerated.when

decelerating, and

sensor is made richer

When engine is 1,000

voltswhen racing.

suddenly raced.

(Heated

oxygenEngine: Warm

The heatedsensoroxygen sensor Engine: Idlefront)signal is used to

400 or less to

check the air/fuel

1,000

mixture ratio, and (Changes)

control condition is also checked Engine: 2000

by the PCM.

When engine coolant

t e m p e r a t u r e i s

When engine coolant

t e m p e r a t u r e i s

Engine

coolantIgnition switch: ON When engine coolant

or with engine run- temperature is

ture sensorning

When engine coolant

t e m p e r a t u r e i s

When engine coolant

t e m p e r a t u r e i s

Throttle Set to idle position.

400 or more

position Ignition switch: ON

Open fully 3,800

or less

Minimum

throttle Engine: Idle (more than one minute) 1,000

KnockCode

sor voltsEngine: Idle Sudden racingvoltage increases

temporarily.

0Battery

voltage Ignition switch: ON

101

1

Altitude: Om (0 ft.)

reading

Ignition switch: ON (30Altitude:

(3937 ft.)88 (26

TSB Revision

Page 493 of 2103

ENGINE (NON-TURBO)>

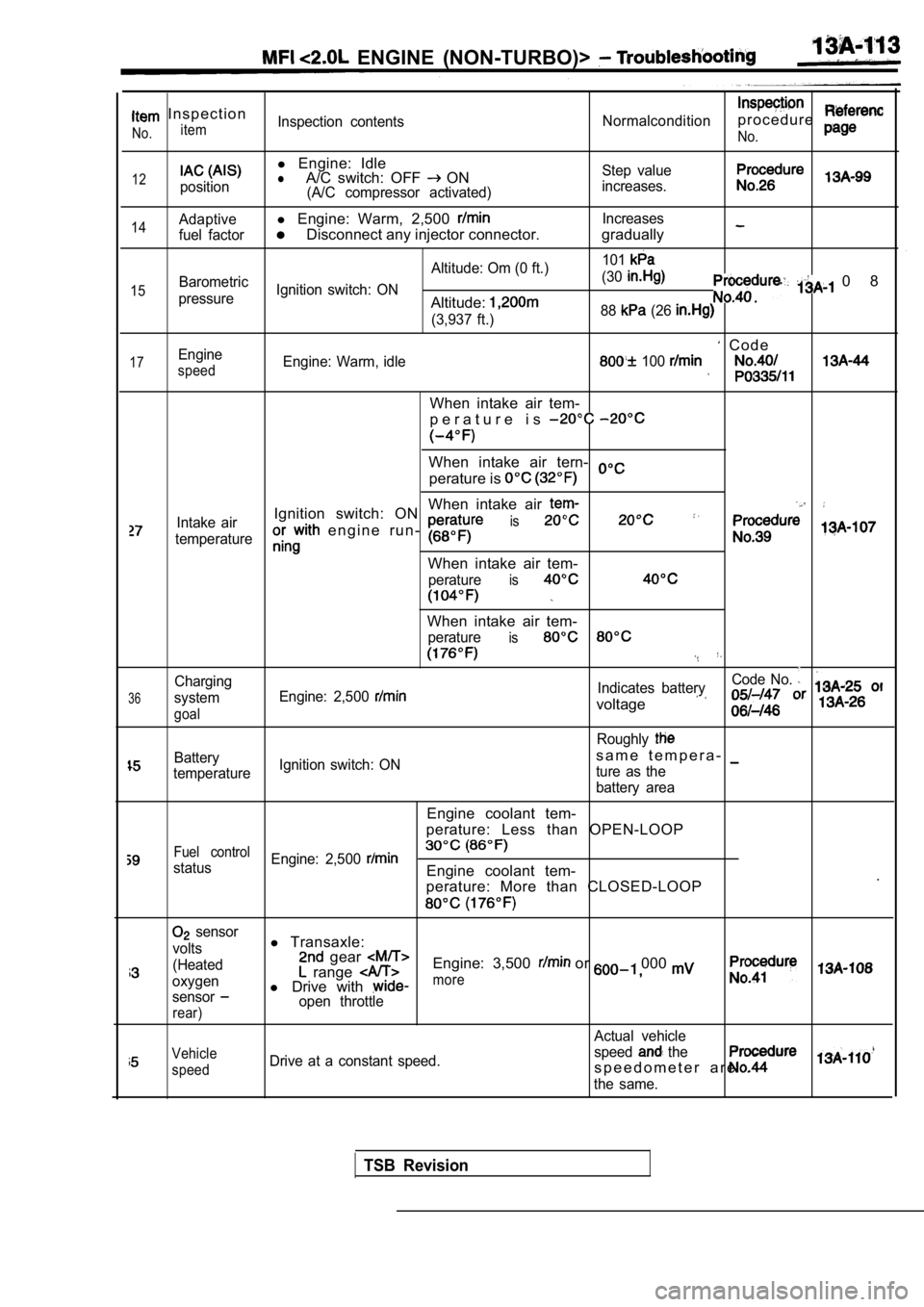

I n s p e c t i o n

itemNo.Inspection contentsNormalconditionp r o c e d u r e

No.

12position

l Engine: IdlelA/C switch: OFF ON(A/C compressor activated) Step value

increases.

14

15

17

Adaptivel Engine: Warm, 2,500 Increases

fuel factor

Disconnect any injector connector. gradually

Altitude: Om (0 ft.) 101Barometric

Ignition switch: ON (30

pressureAltitude:

0 8

(3,937 ft.)

88 (26

C o d eEngine

speedEngine: Warm, idle 100

When intake air tem-

p e r a t u r e i s

When intake air tern-

perature is

When intake air

Intake airIgnition switch: ON

e n g i n e r u n - is

temperature

When intake air tem-

peratureis

36

Charging

system

goal

When intake air tem-

peratureis

Code No.

Engine: 2,500 Indicates battery

voltage

Roughly

Batterys a m e t e m p e r a -

temperature Ignition switch: ON

ture as the

battery area

Engine coolant tem-

perature: Less than OPEN-LOOP

Fuel control

status Engine: 2,500 Engine coolant tem-

.

perature: More than CLOSED-LOOP

sensor

volts

(Heated

oxygen

sensor

rear)

l Transaxle: gear Engine: 3,500 or 000 range l Drive with more

open throttle

Actual vehicle

Vehicle

speedDrive at a constant speed. speed the

s p e e d o m e t e r a r e .

the same.

TSB Revision

Page 494 of 2103

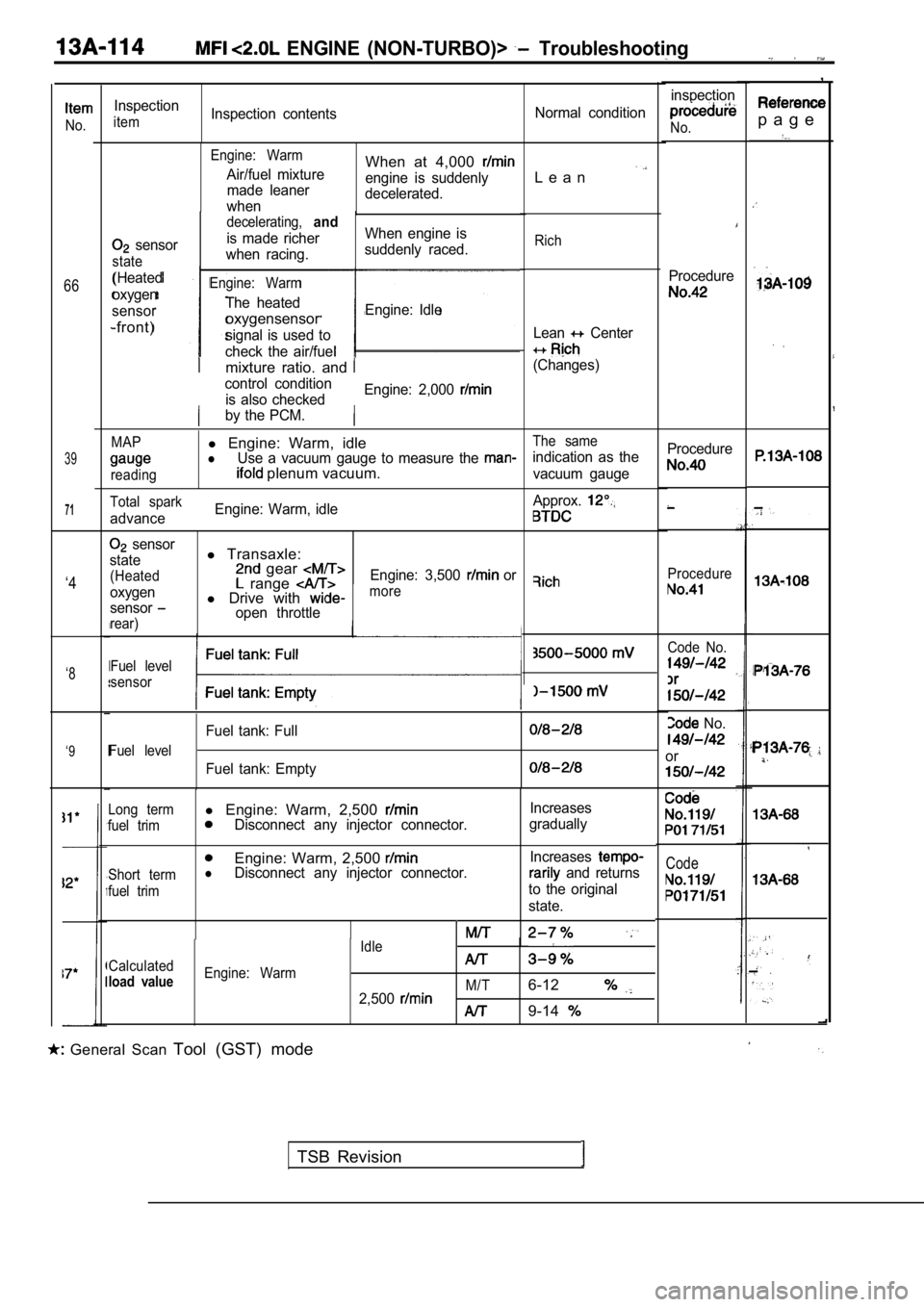

ENGINE (NON-TURBO)> Troubleshooting

,

p a g eNo.

66

39

71

inspection

No.

Procedure

Inspection

itemInspection contentsNormal condition

Engine: Warm

Air/fuel mixture

made leaner

whenWhen at 4,000

engine is suddenly

decelerated.L e a n

sensor

state

(Heated

oxygen

sensor

-front)

decelerating,and

is made richer When engine is

when racing. suddenly raced.

Engine: Warm

The heated

oxygensensorEngine: Idle

signal is used to

check the air/fuel

Rich

Lean Center

(Changes)mixture ratio. and

control condition is also checked Engine: 2,000

by the PCM.

MAPl

Engine: Warm, idleThe same

lUse a vacuum gauge to measure the indication as the

reading plenum vacuum.vacuum gauge Procedure

Procedure

Total spark

advance

Engine: Warm, idle

Approx.

sensor

state

(Heated

oxygen

sensor

rear)

l Transaxle: gear range l Drive with open throttle Engine: 3,500

or‘4more

Code No.

No.

or

Fuel level

sensor‘8

Fuel level

Fuel tank: Full

Fuel tank: Empty

‘9

Code

Long terml

Engine: Warm, 2,500 Increases

fuel trimDisconnect any injector connector. gradually

Engine: Warm, 2,500

Short termlDisconnect any injector connector. Increases and returns

fuel trimto the original

state.

Idle

Calculated

load valueEngine: Warm M/T

2,5006-12

9-14

General Scan Tool (GST) mode

TSB Revision

Page 495 of 2103

ENGINE

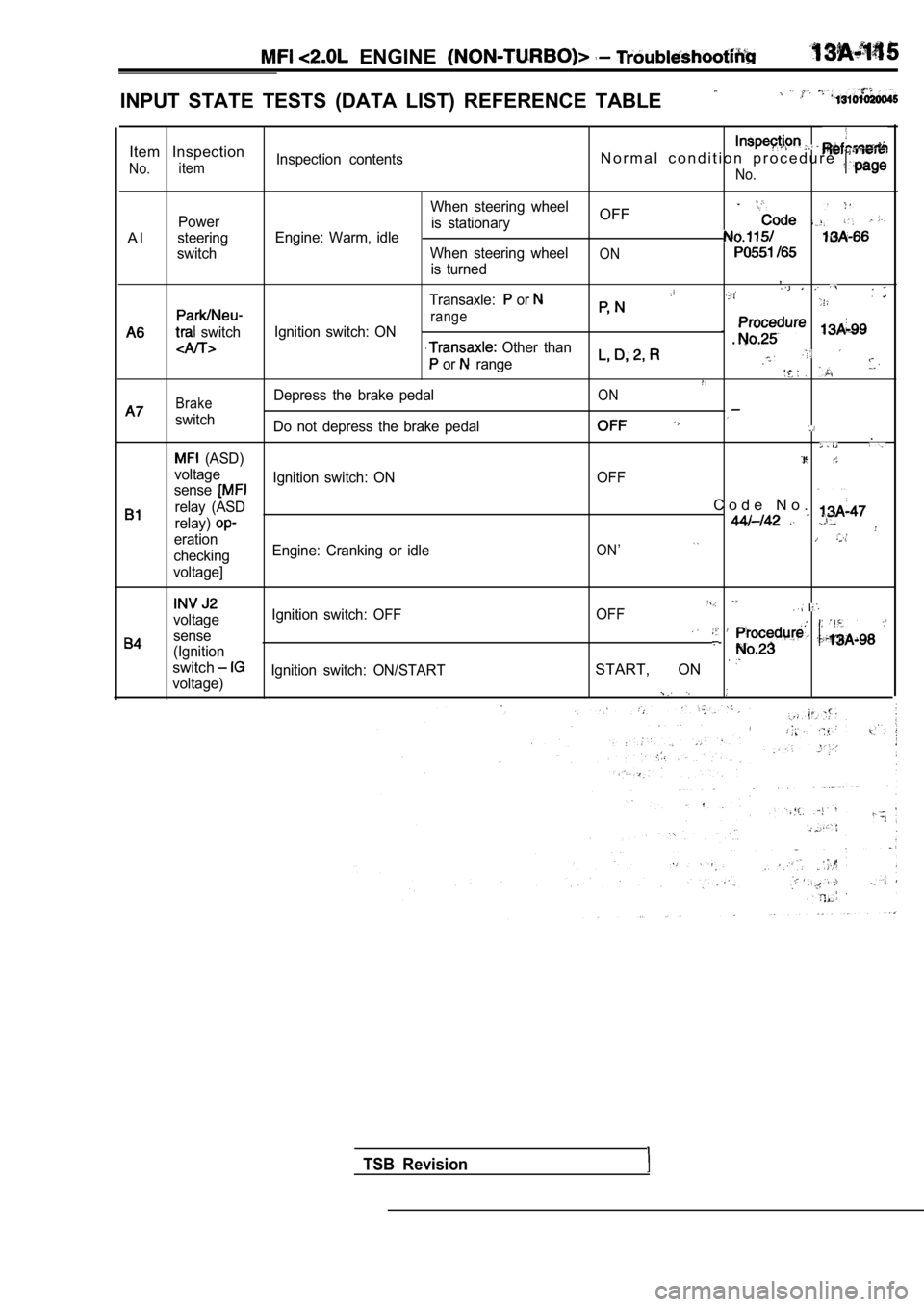

INPUT STATE TESTS (DATA LIST) REFERENCE TABLE

Item Inspection

No.itemInspection contentsN o r m a l c o n d i t i o n p r o c e d u r e

No.

A l

Power

steering

switch

switch

When steering wheel

is stationaryOFF

Engine: Warm, idle

When steering wheelONis turned,

Transaxle: or

rangeIgnition switch: ON

Other than

or range

BrakeDepress the brake pedalON

switch Do not depress the brake pedal.

(ASD)

voltage OFF

senseIgnition switch: ON

relay (ASD

C o d e N o .

relay)

erationON’checking Engine: Cranking or idle

voltage]

voltage Ignition switch: OFF

OFF

sense

(Ignition

switchSTART, ON voltage)Ignition switch: ON/START

TSB Revision

Page 496 of 2103

ENGINE (NON-TURBO)> , ,

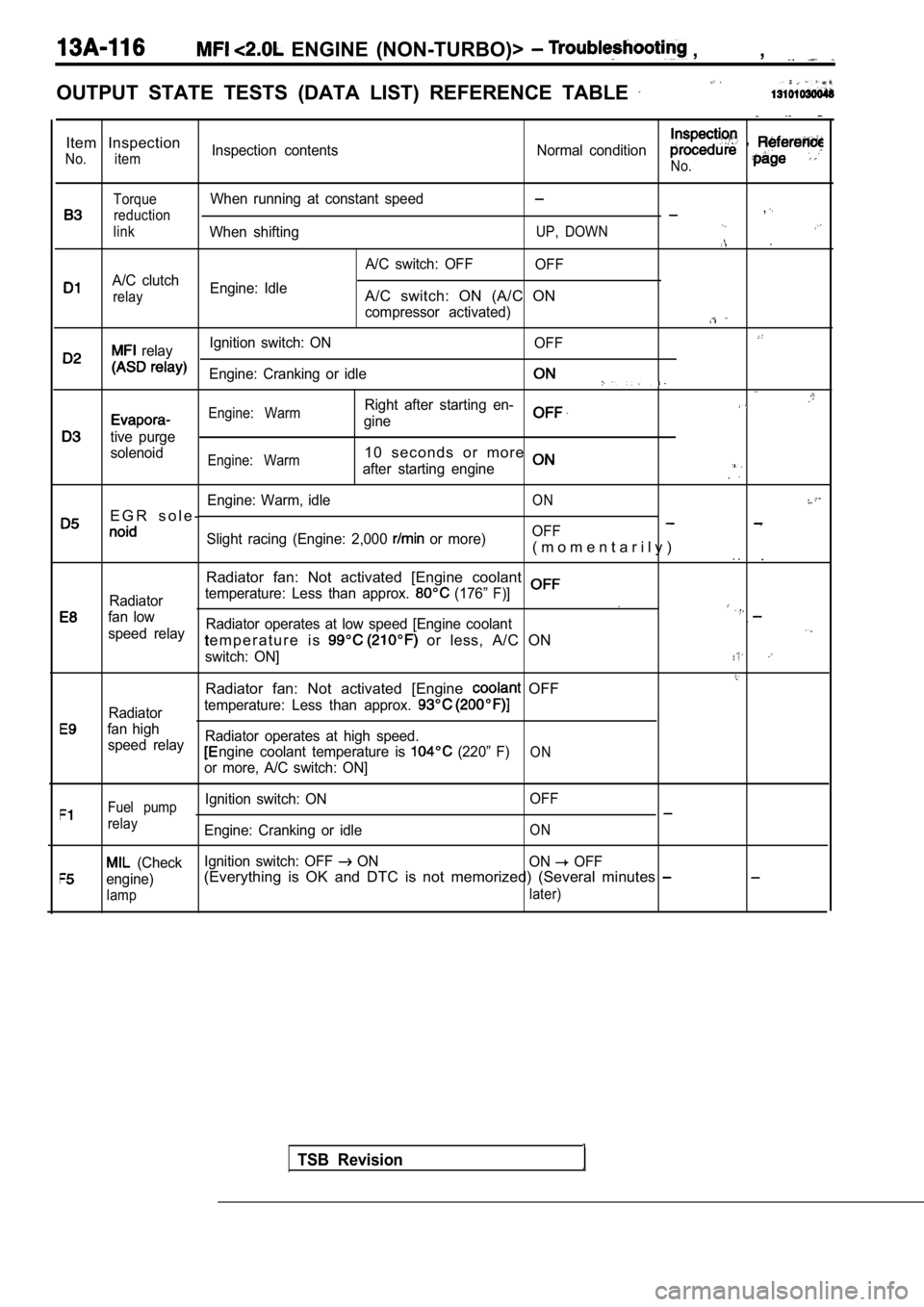

OUTPUT STATE TESTS (DATA LIST) REFERENCE TABLE

Item Inspection

No. itemInspection contentsNormal condition ,

No.

TorqueWhen running at constant speed

reduction,

linkWhen shiftingUP, DOWN

A/C switch: OFFOFF

A/C clutch

relayEngine: IdleA/C switch: ON (A/C ON

compressor activated)

relayIgnition switch: ON

OFF

Engine: Cranking or idle

Engine: WarmRight after starting en-

gine

tive purge

solenoid

Engine: Warm1 0 s e c o n d s o r m o r e

after starting engine

Engine: Warm, idleON

E G R s o l e -OFFSlight racing (Engine: 2,000 or more)( m o m e n t a r i l y ). ..

Radiator fan: Not activated [Engine coolant

Radiator temperature: Less than approx. (176” F)]

fan lowRadiator operates at low speed [Engine coolantspeed relaye m p e r a t u r e i s or less, A/C ON

switch: ON]

Radiator fan: Not activated [Engine OFF

Radiatortemperature: Less than approx.

fan high

speed relay Radiator operates at high speed.

ngine coolant temperature is (220” F)ON

or more, A/C switch: ON]

Fuel pumpIgnition switch: ON

OFF

relayEngine: Cranking or idleON

(CheckIgnition switch: OFF ON

ON OFF

engine)(Everything is OK and DTC is not memorized) (Severa l minutes

lamp later)

TSB Revision

Page 497 of 2103

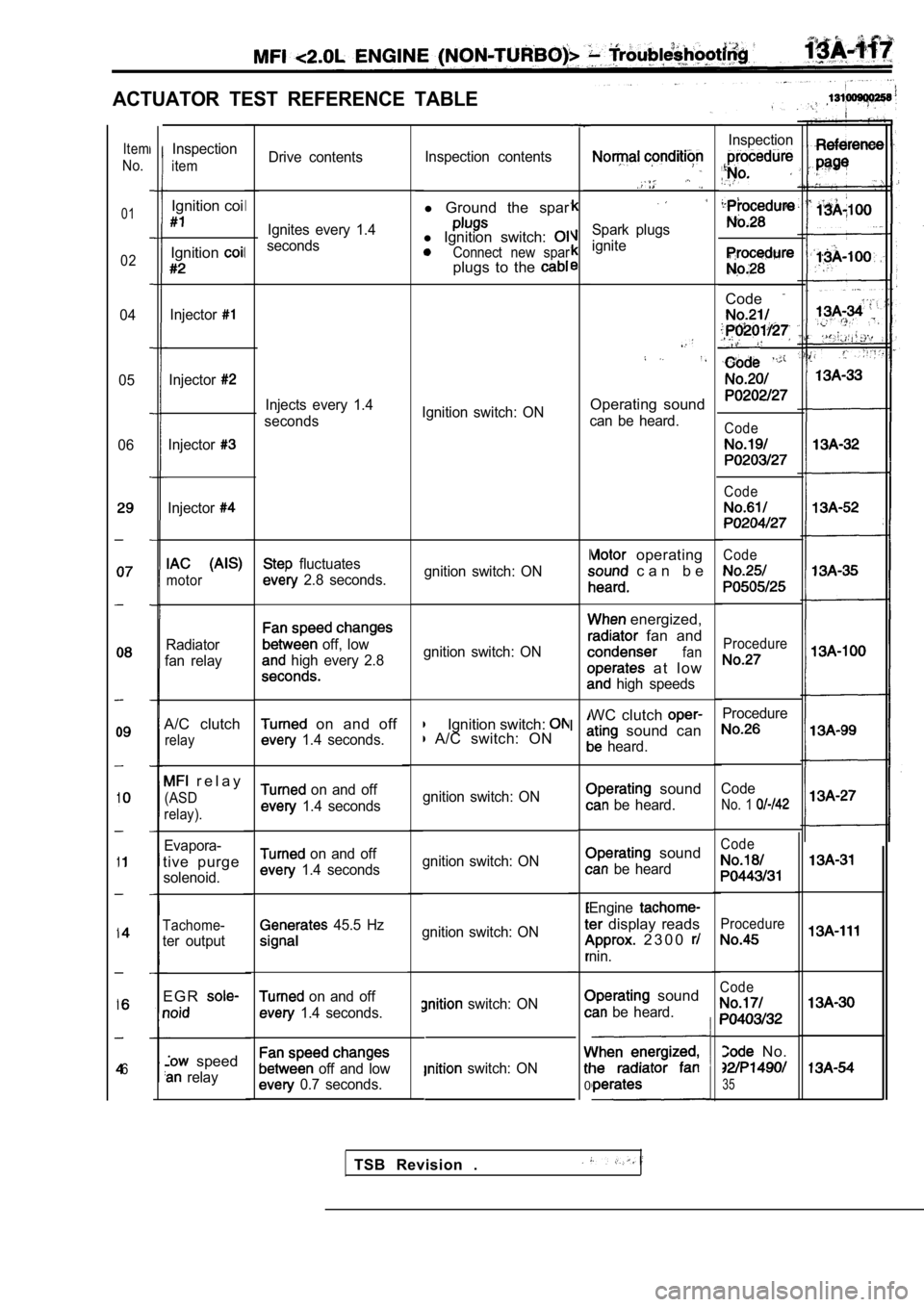

ACTUATOR TEST REFERENCE TABLE

Drive contentsInspection contents

l

Ground the spar

l Ignition switch: Connect new sparplugs to the

Spark plugs

ignite

Ignition switch: ONOperating sound

can be heard.

gnition switch: ON

operating

c a n b e

gnition switch: ON

energized,

fan and

fan

a t l o w

high speeds

Ignition switch: A/C switch: ON WC clutch sound can

heard.

gnition switch: ON

sound

be heard.

gnition switch: ON

sound

be heard

gnition switch: ON Engine

display reads

2 3 0 0

nin.

switch: ON

switch: ON

I

I

0

sound

be heard.

Item

No.

01

02

04

05

06

6

Inspection

Code

,

Code

Code

Code

Procedure

Procedure

Code

No. 1

Code

Procedure

Code

No.

35

Inspection

item

Ignition coi

Ignition

Injector

Injector

Injector

Injector

motor

Radiator

fan relay

A/C clutch

relay

r e l a y

(ASD

relay).

Evapora-

tive purge

solenoid.

Tachome-

ter output

E G R

speed

relay Ignites every 1.4

seconds

I

I

Injects every 1.4

seconds

fluctuates

2.8 seconds.

off, low

high every 2.8

on and off

1.4 seconds.

on and off

1.4 seconds

on and off

1.4 seconds

45.5 Hz

on and off

1.4 seconds.

off and low

0.7 seconds.

TSB Revision .

Page 498 of 2103

ENGINE

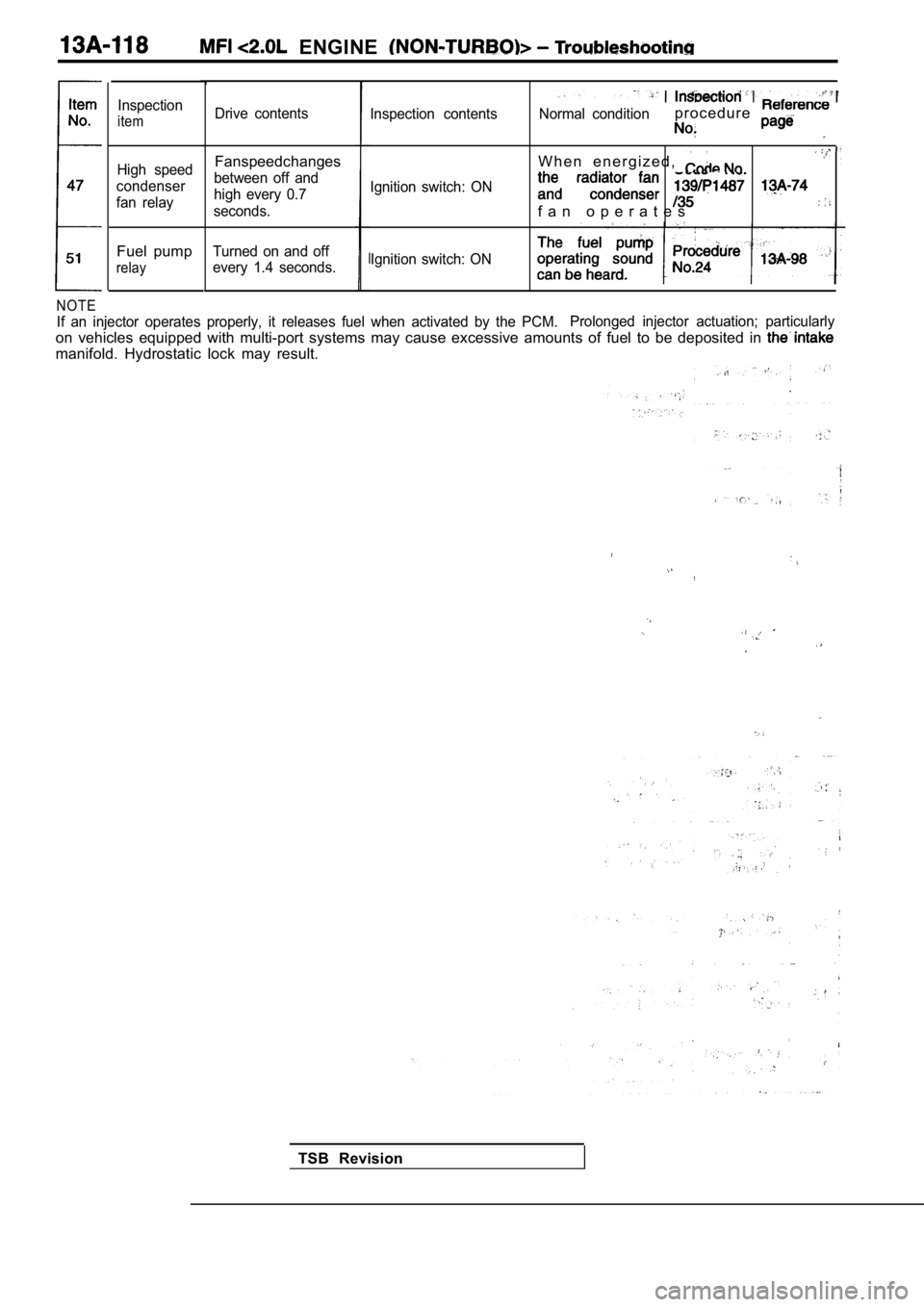

NOTE

If an injector operates properly, it releases fuel when activated by the PCM.Prolonged injector actuation; particularly

on vehicles equipped with multi-port systems may ca

use excessive amounts of fuel to be deposited in

manifold. Hydrostatic lock may result.

Inspection

item

High speed

condenser

fan relay

Fuel pump

relay

Drive contents

Fanspeedchanges

between off and

high every 0.7

seconds.

Turned on and off

every 1.4 seconds. Inspection contents

Ignition switch: ON

Ignition switch: ON Normal condition

p r o c e d u r e

W h e n e n e r g i z e d ,

f a n o p e r a t e s

TSB Revision

Page 499 of 2103

ENGINE (NON-TURBO)>

ON-VEHICLE SERVICE

THROTTLE BODY MINIMUM AIR FLOW

CHECK

1.Start the engine and warm it up until the engine co olant

is heated to

or higher and then stop the

engine.

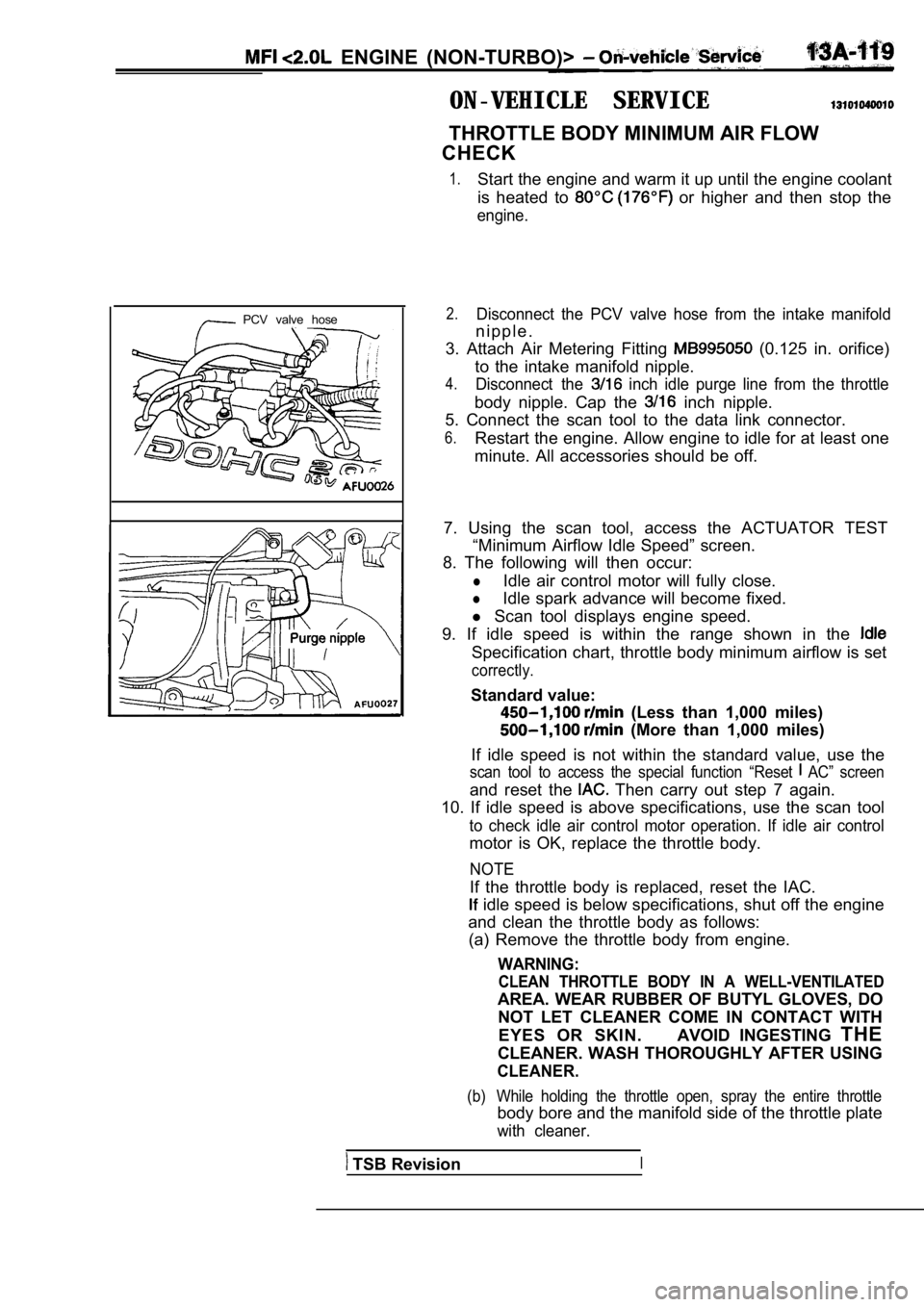

PCV valve hose2.Disconnect the PCV valve hose from the intake manif old

n i p p l e .

3. Attach Air Metering Fitting

(0.125 in. orifice)

to the intake manifold nipple.

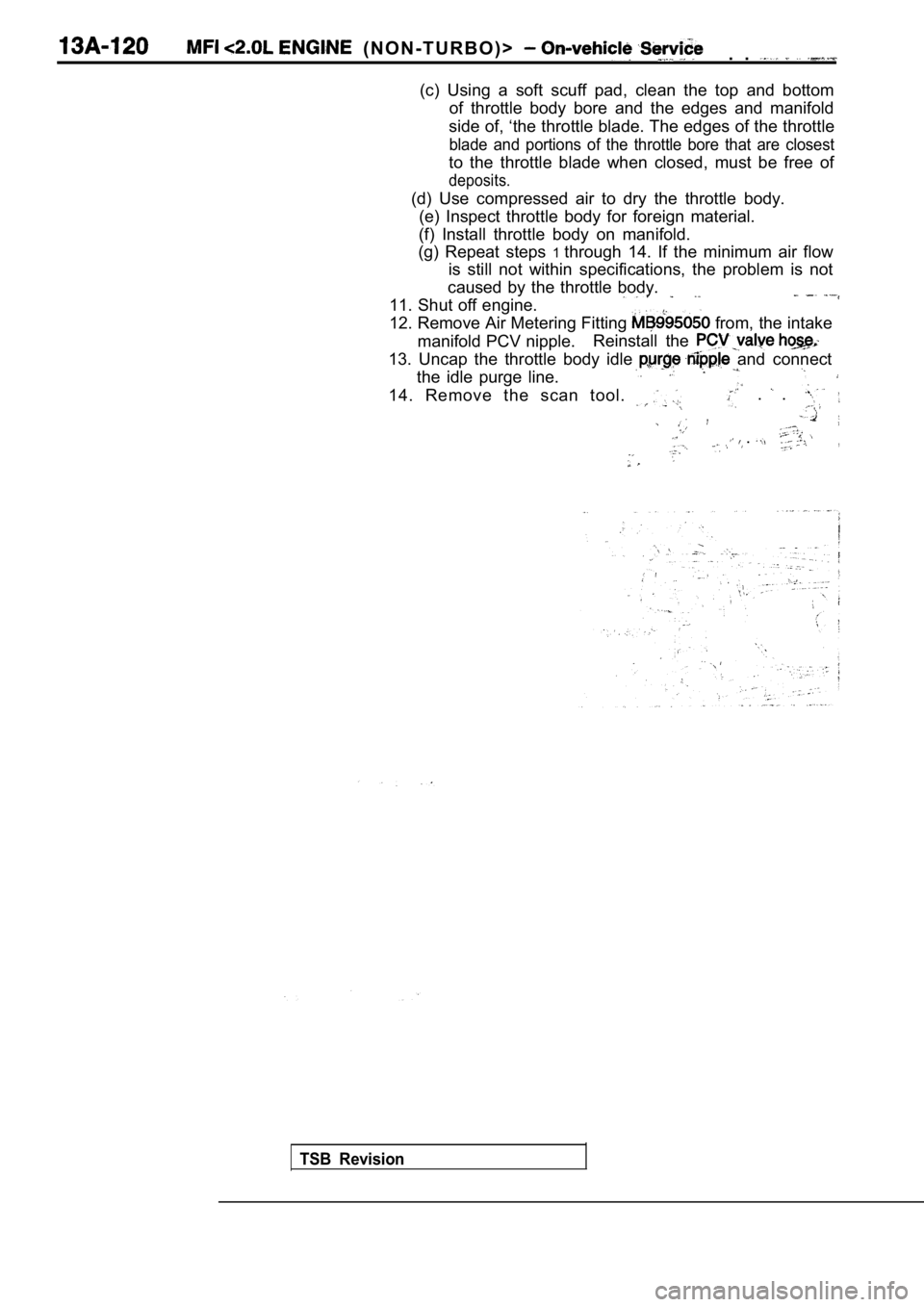

4.Disconnect the inch idle purge line from the throttle

body nipple. Cap the inch nipple.

5. Connect the scan tool to the data link connector .

6.Restart the engine. Allow engine to idle for at least one

minute. All accessories should be off.

7. Using the scan tool, access the ACTUATOR TEST “Minimum Airflow Idle Speed” screen.

8. The following will then occur:

lIdle air control motor will fully close.

lIdle spark advance will become fixed.

l Scan tool displays engine speed.

9. If idle speed is within the range shown in the

Specification chart, throttle body minimum airflow is set

correctly.

Standard value:

(Less than 1,000 miles)

(More than 1,000 miles)

If idle speed is not within the standard value, use the

scan tool to access the special function “Reset AC” screen

and reset the Then carry out step 7 again.

10. If idle speed is above specifications, use the scan tool

to check idle air control motor operation. If idle air control

motor is OK, replace the throttle body.

NOTE

If the throttle body is replaced, reset the IAC.

idle speed is below specifications, shut off the e ngine

and clean the throttle body as follows: (a) Remove the throttle body from engine.

WARNING:

CLEAN THROTTLE BODY IN A WELL-VENTILATED

AREA. WEAR RUBBER OF BUTYL GLOVES, DO

NOT LET CLEANER COME IN CONTACT WITH

EYES OR SKIN. AVOID INGESTING THE

CLEANER. WASH THOROUGHLY AFTER USING

CLEANER.

(b) While holding the throttle open, spray the entir e throttle

body bore and the manifold side of the throttle plate

with cleaner.

TSB RevisionI

Page 500 of 2103

( N O N - T U R B O ) > . .

(c) Using a soft scuff pad, clean the top and bottom

of throttle body bore and the edges and manifold

side of, ‘the throttle blade. The edges of the thro ttle

blade and portions of the throttle bore that are cl osest

to the throttle blade when closed, must be free of

deposits.

(d) Use compressed air to dry the throttle body.

(e) Inspect throttle body for foreign material.

(f) Install throttle body on manifold.

(g) Repeat steps 1through 14. If the minimum air flow

is still not within specifications, the problem is not

caused by the throttle body.

11. Shut off engine.

12. Remove Air Metering Fitting from, the intake

manifold PCV nipple. Reinstall the

13. Uncap the throttle body idle and connect

the idle purge line.

14. Remove the scan tool. . .

. ,

TSB Revision