clutch NISSAN 300ZX 1984 Z31 Automatic Transmission Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 99, PDF Size: 3.09 MB

Page 6 of 99

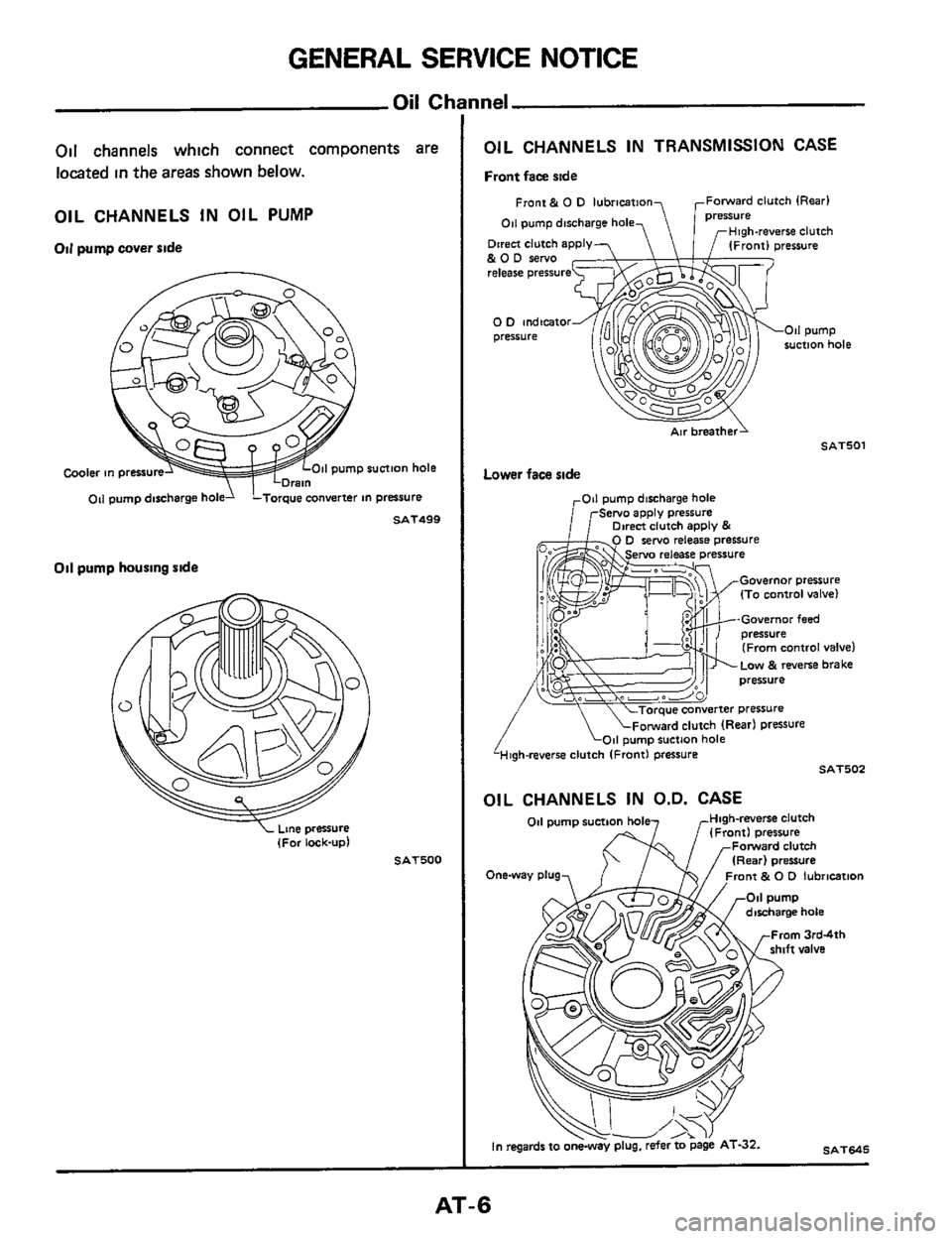

GENERAL SERVICE NOTICE

Oil Channel

Oil channels which connect components are

located in the

areas shown below.

OIL CHANNELS IN OIL PUMP

Oil pump cover ride

11 pump suction hole Cooler in pressure

011 pump discharge hold LTorque converter in pressure

Oil pump housing ride

ne oressure

SAT499

SAT500

OIL CHANNELS IN TRANSMISSION CASE

Front face rlde

Front & 0 D lubrication Forward clutch (Rear1

gh-reverse clutch

011 pump discharge hole

Direct clutch apply &OD sew0 release pressure

0 0 indicator pressure

SAT501

Lower face side

Governor pressure (To control valve)

Governor feed

(From control

valve)

LOW & reverse brake

High-reverse clutch IFrontl pressure SAT502

ii

OIL CHANNELS IN O.D. CASE

011 pump suction hole Hlgh-reverse clutch (Front1 pressure

Forward clutch

(Rear) Oresure

ront & 0 D lubrication

SAT645 In regards to oneway plug. refer to page AT-32.

AT-6

Page 7 of 99

GENERAL SERVICE NOTICE

I (Cont'd) Oil Cham

OIL CHANNELS IN DRUM SUPPORT OIL CHANNELS IN CONVERTER HOUSING

To lock-up ~ontrol valve

rDrain (E4N71Bl

clutch (Front)

Forward clutch

clutch pressure Front & 0 0 lubrmtmn

SAT706

3peration Mechanic:

In the E4N71B and 4N71B automatic transmission, each part operates as shown in the following table at

each gear select position

'arking

pawl

Htgh-

'everse

Front) Forward clutch (Rear) 0 D band servo Direct

clutch Range -

Release

ON ON

1 Reverse 1 ON 1 ION) ON

+-

ON I

I Neutral I ON I (ON) ON

T-

ON

-

ON

-

ON

ON

JT

I ION

'34

(0 D 1 ON I ON

Second I ON I (ON) ON

1 ON I (ON) 12

(Second) ON ON I ON

ON ord ON I I ON

The low & reverse brake IS applied In "1 I" range to prevent free wheeling when coasting and allows engine braking.

AT-7

Page 22 of 99

DISASSEMBLY

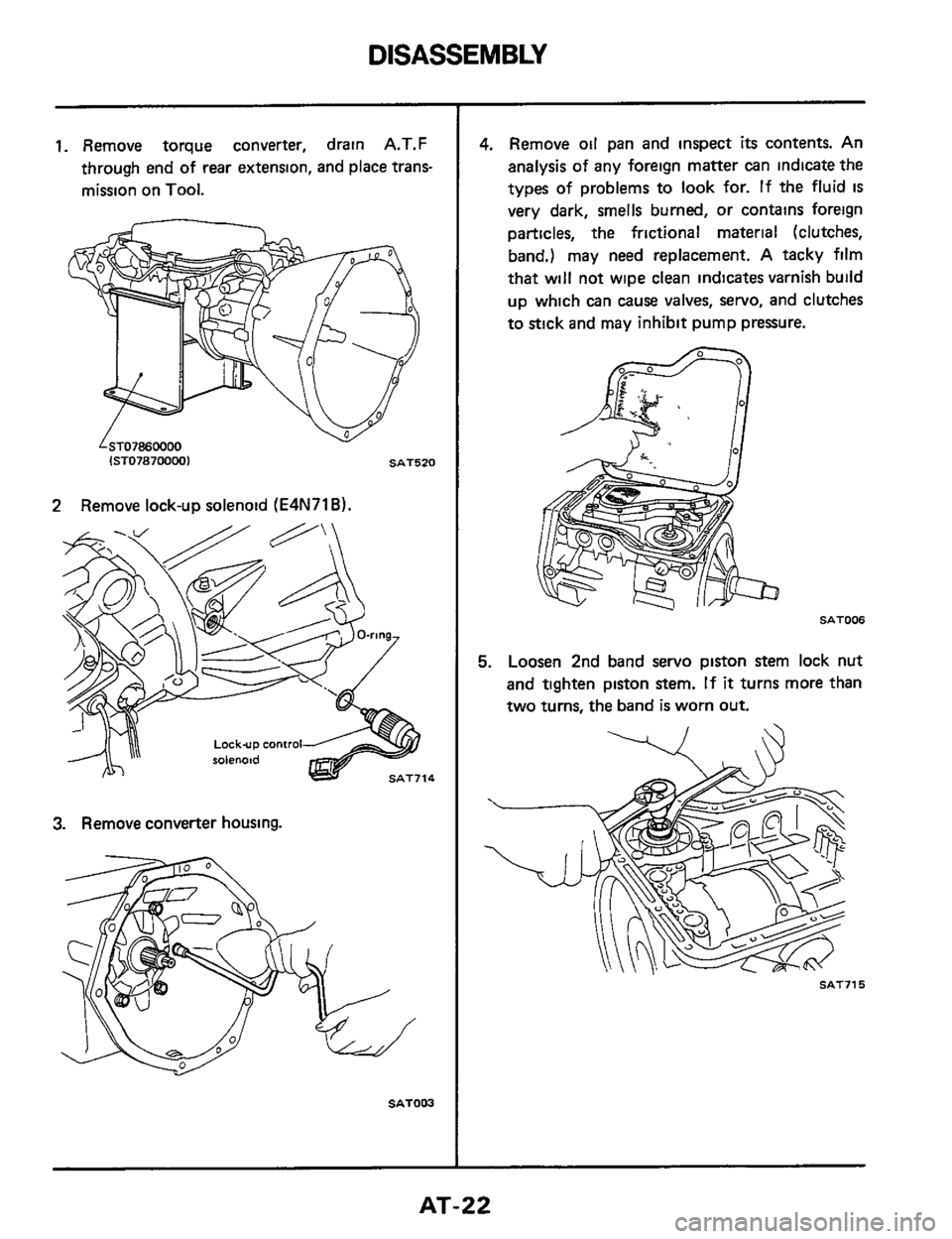

1. Remove torque converter, drain A.T.F

through end of

rear extension, and place trans-

mission on

Tool.

v

SAT520

2 Remove lock-up solenoid (E4N71B).

3. Remove converter housing.

SATOW

4. Remove oil pan and inspect its contents. An

analysis of any foreign matter can indicate the

types of problems to look for. If the fluid

IS

very dark, smells burned, or contains foreign

particles, the frictional material (clutches,

band.) may need replacement. A tacky film

that will not wipe clean indicates varnish bulld

up which can cause valves, servo, and clutches

to stick and may inhibit pump pressure.

SAT006

5. Loosen 2nd band servo piston stem lock nut

and tighten piston stem.

If it turns more than

two turns, the band

is worn out.

SAT71 5

AT-22

Page 23 of 99

DISASSEMBLY

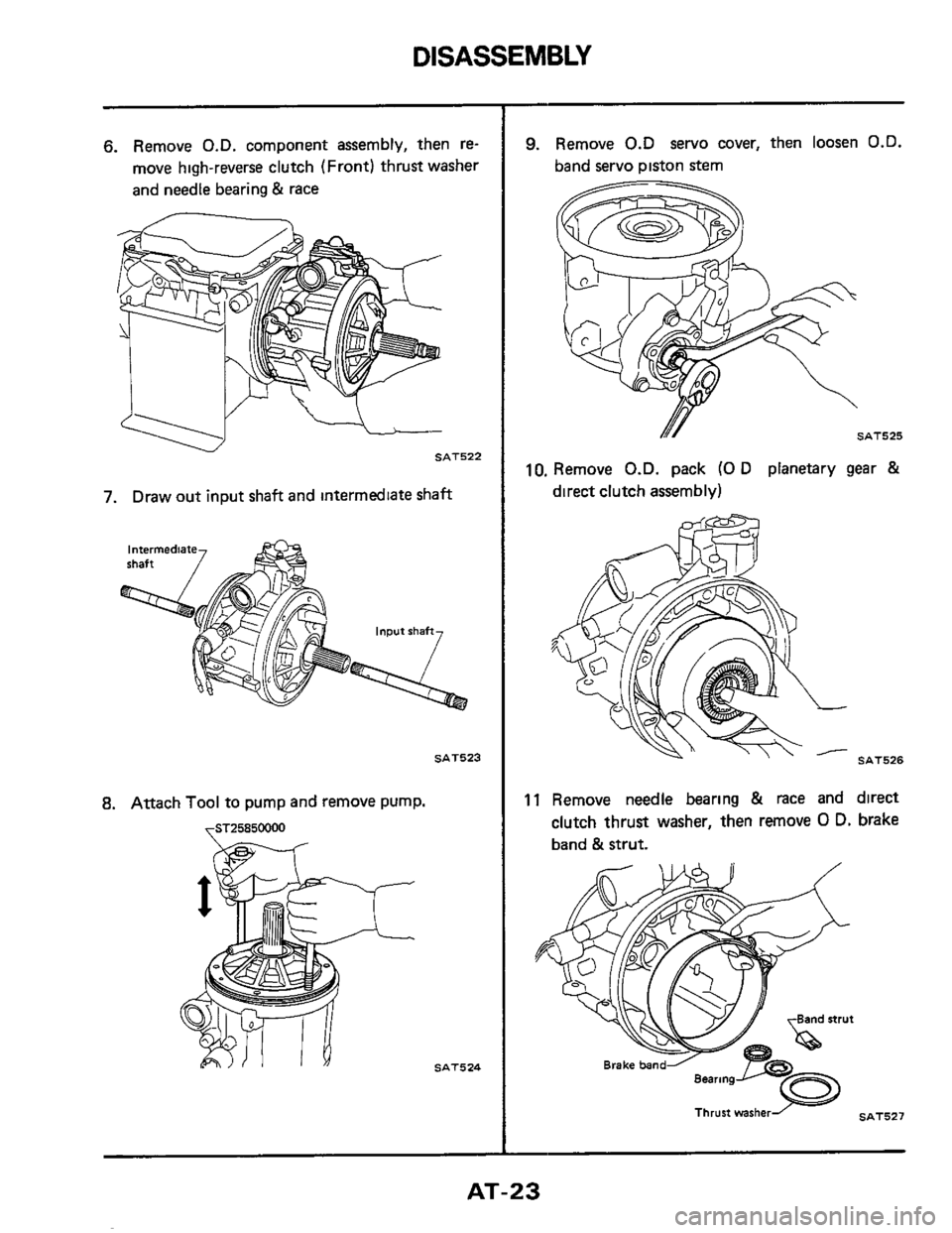

6. Remove O.D. component assembly, then re-

move high-reverse clutch (Front) thrust washer

and needle bearing

& race

7. Draw out input shaft and intermedtate shaft

8. Attach Tool to pump and remove pump.

SAT524

9. Remove 0.D servo cover, then loosen O.D.

band servo piston stem

SAT525

10. Remove O.D. pack (0 D planetary gear &

direct clutch assembly)

SAT526

11 Remove needle bearing & race and direct

clutch thrust washer, then remove

0 D. brake

band

& strut.

SAT527

AT-23

Page 25 of 99

DISASSEMBLY

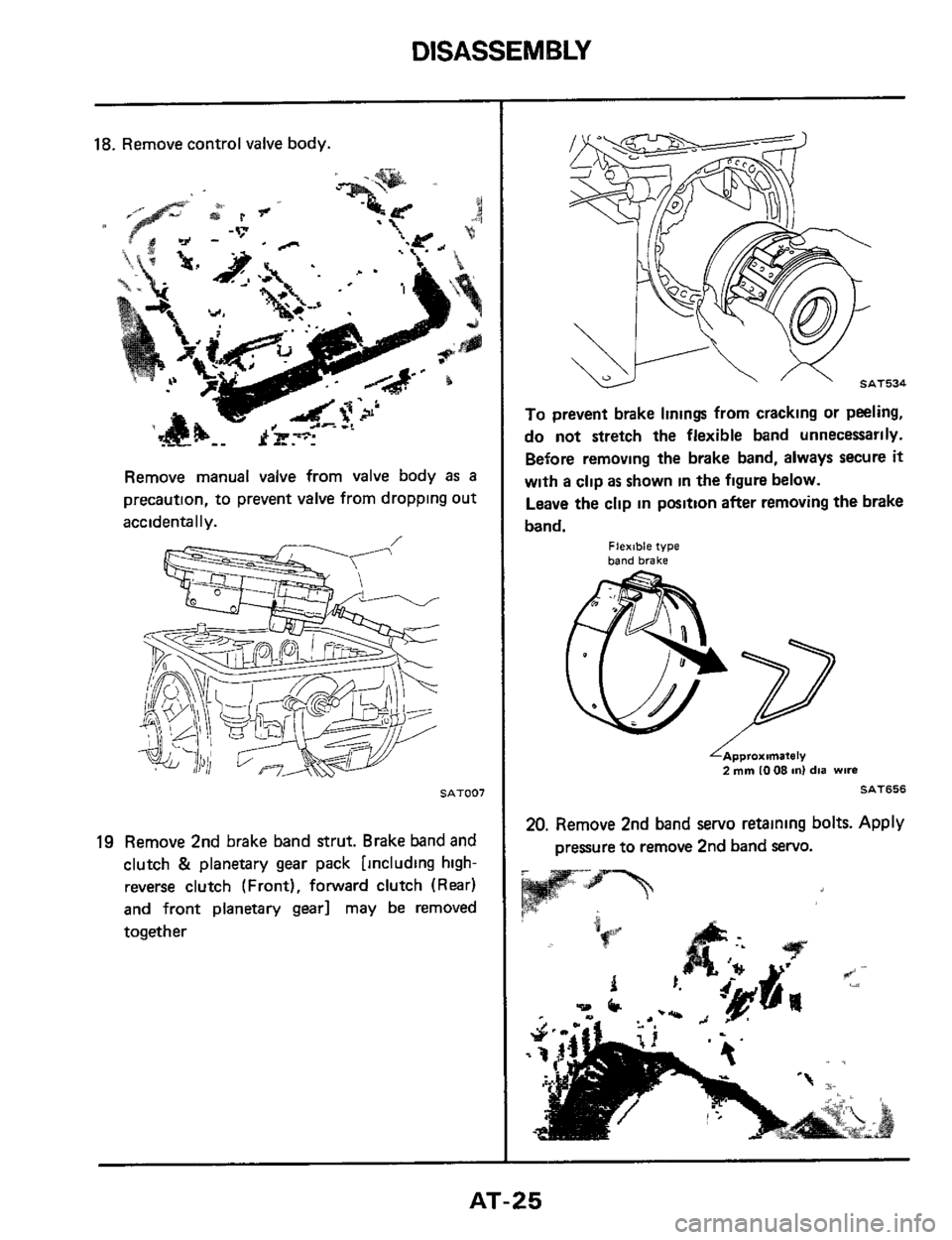

18. Remove control valve body.

Remove manual valve from valve body as a

precaution, to prevent valve from dropping out

accidentally.

SAT007

19 Remove 2nd brake band strut. Brake band and

clutch

& planetary gear pack [Including high-

reverse clutch (Front), forward clutch (Rear)

and front

planetary gear] may be removed

together

To prevent brake linings from cracking or peeling,

do not stretch the flexible band unnecessarily.

Before removing the brake band, always secure

it

with a clip as shown in the figure below.

Leave the clip

in position after removing the brake

band.

Flexible type band brake

2 mm 1008 In) dia wire

SAT656

20. Remove 2nd band servo retalning bolts. Apply

pressure to remove 2nd band =NO.

AT-25

Page 27 of 99

DISASSEMBLY

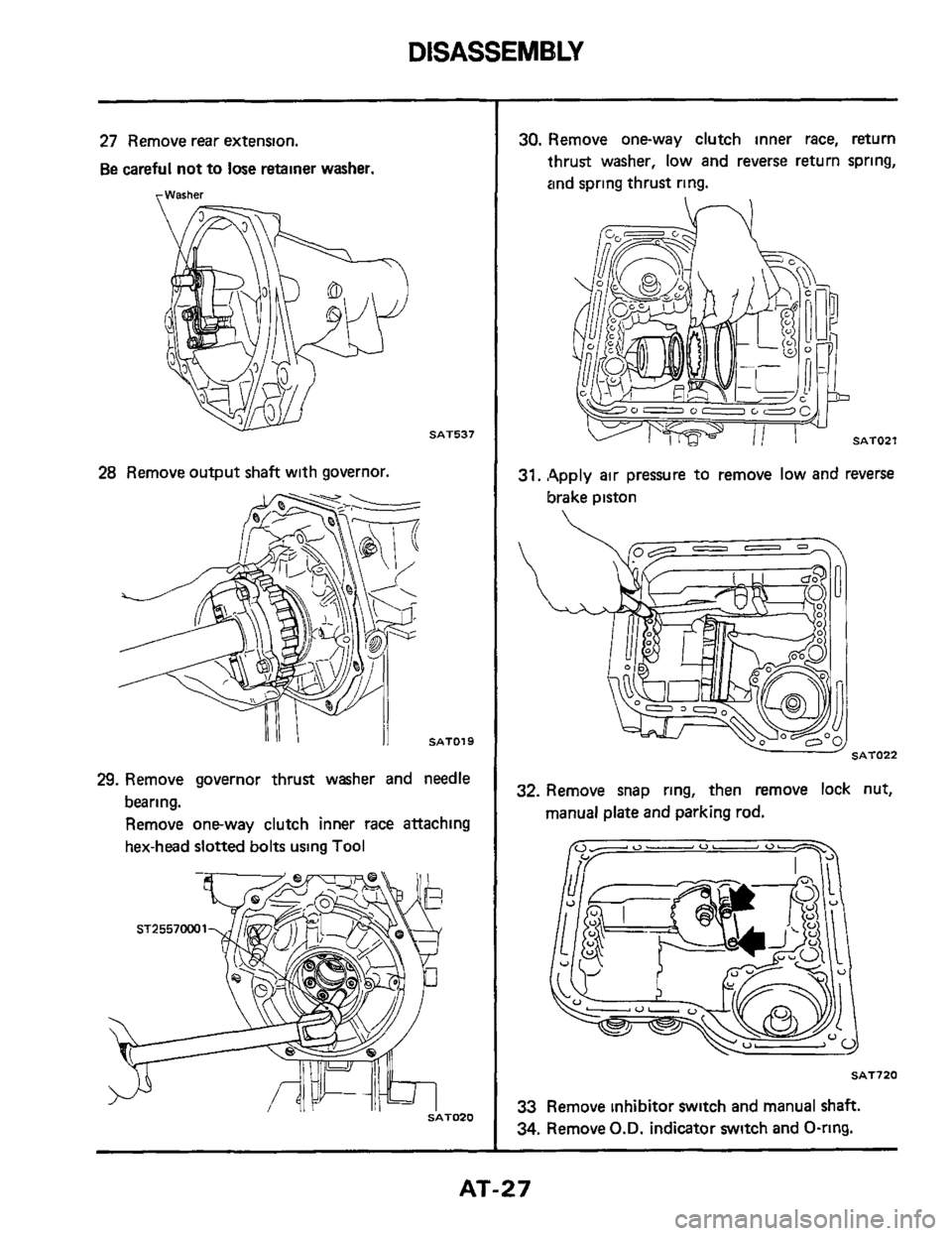

27 Remove rear extension.

Be careful not to lose retainer washer.

rWarher

SAT537

2% Remove output shaft with governor.

11 SAT019

29. Remove governor thrust washer and needle

bearing.

Remove one-way clutch inner race attaching

hex-head slotted bolts using

Tool

30. Remove one-way clutch inner race, return

thrust washer, low and reverse return spring,

and spring thrust ring.

31. ,Apply air pressure to remove low and reverse

brake piston

. ' SAT022

32. Remove snap ring, then remove lock nut,

manual plate and parking rod.

y- - " -

SAT720

33 Remove Inhibitor switch and manual shah.

34. Remove

O.D. indicator switch and O-ring.

AT-27

Page 37 of 99

REPAIR FOR COMPONENT PARTS

Control Valve Body (Cont’d)

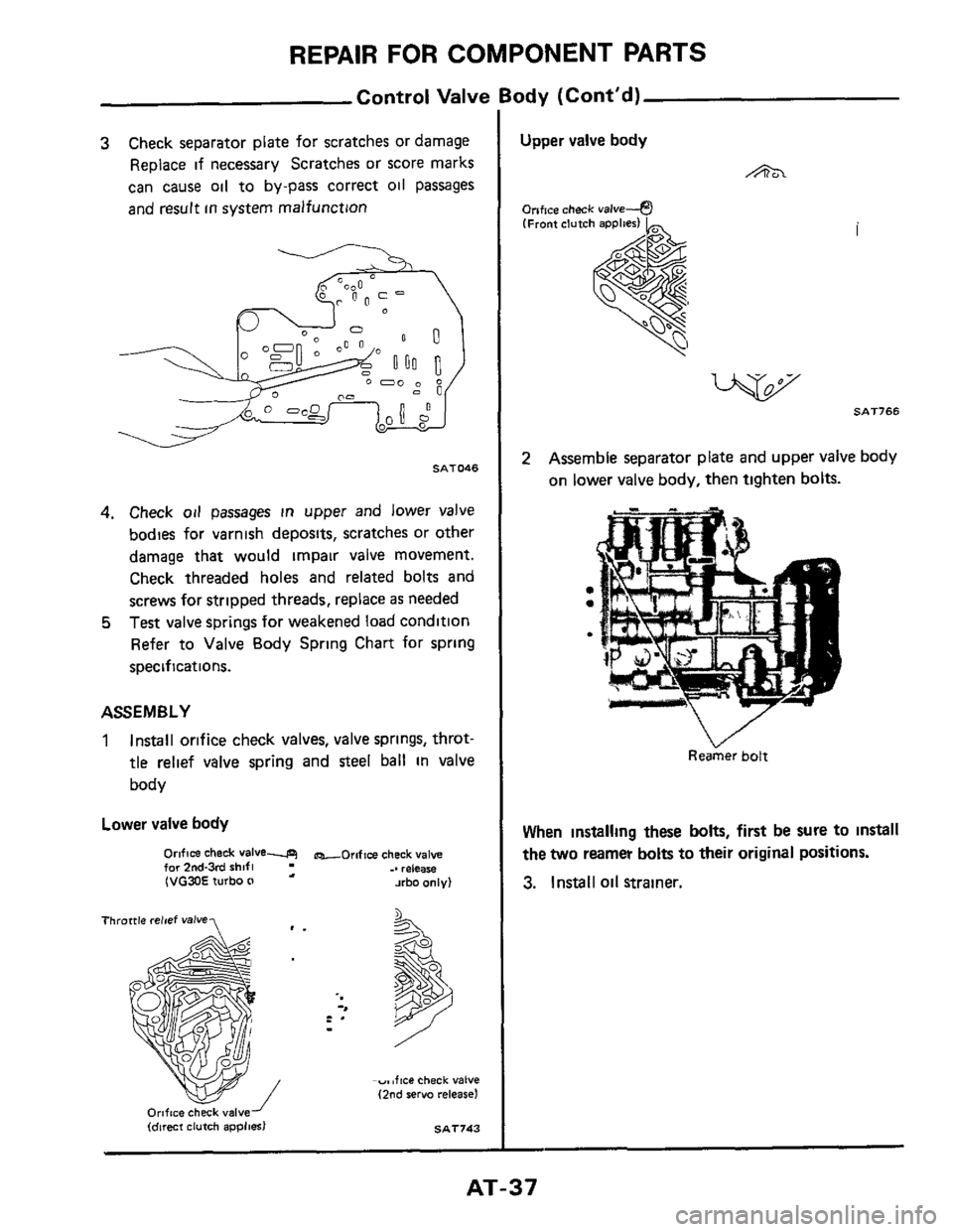

3 Check separator plate for scratches or damage

Replace if necessary Scratches or score marks

can cause oil to by-pass correct oil passages

and result in system malfunction

SAT046

4. Check oil passages in upper and lower valve

bodies for varnish deposits, scratches or other

damage that would impair valve movement.

Check threaded holes and related bolts and

screws for stripped threads, replace

as needed

Test valve springs for weakened load condition

Refer to Valve Body Spring Chart for spring

specifications.

5

ASSEMBLY

1 Install orifice check valves, valve springs, throt-

tle relief valve spring and steel ball in valve

body

Lower valve body

Orifice check Valve-P for 2nd-3rd rhifl .. reiea* (VG30E turbo (I a xbo only)

-oroftee check valve

Throttle relief valve,

Orifice chkk valveJ (direct clutch applies) SAT743

Upper valve body

A

Onfice check valve--@ (Front clutch applies) h

2 Assemble separator plate and upper valve body

on lower valve body, then tighten bolts.

ReaGer bolt

When installing these bolts, first be sure to install

the two reamer bolts to their original positions.

3. Install oil strainer.

AT-37

Page 39 of 99

REPAIR FOR COMPONENT PARTS

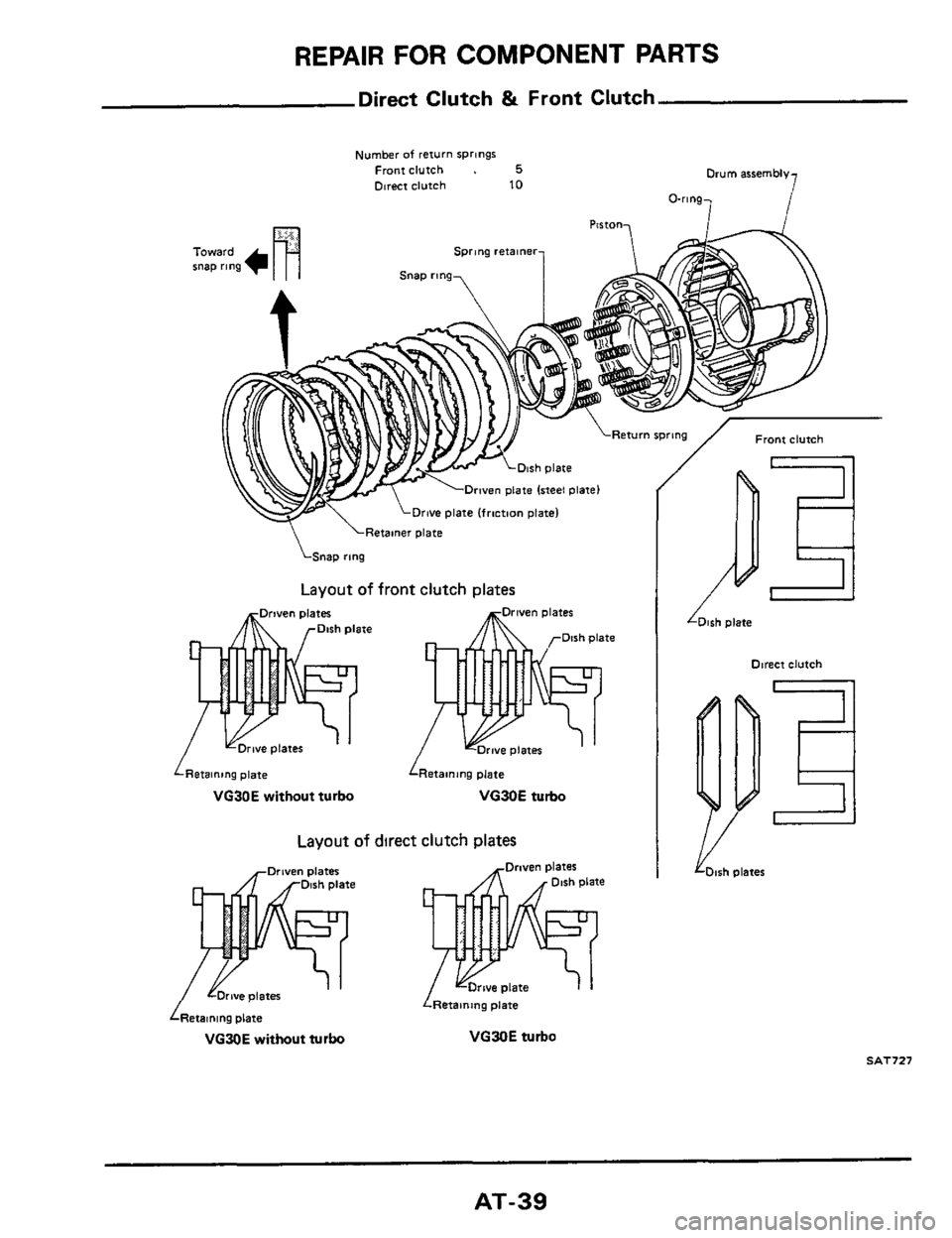

Direct Clutch & Front Clutch

Number of return springs Front clutch . 5 Dtr~t clutch 10 Drum assembly

O-ring, 1

Layout of direct clutch plates

Dish plater

VG30E without turbo VG30E turbo

SAT727

AT-39

Page 40 of 99

REPAIR FOR COMPONENT PARTS

Direct Clutch & Front Clutch (Cont'd)

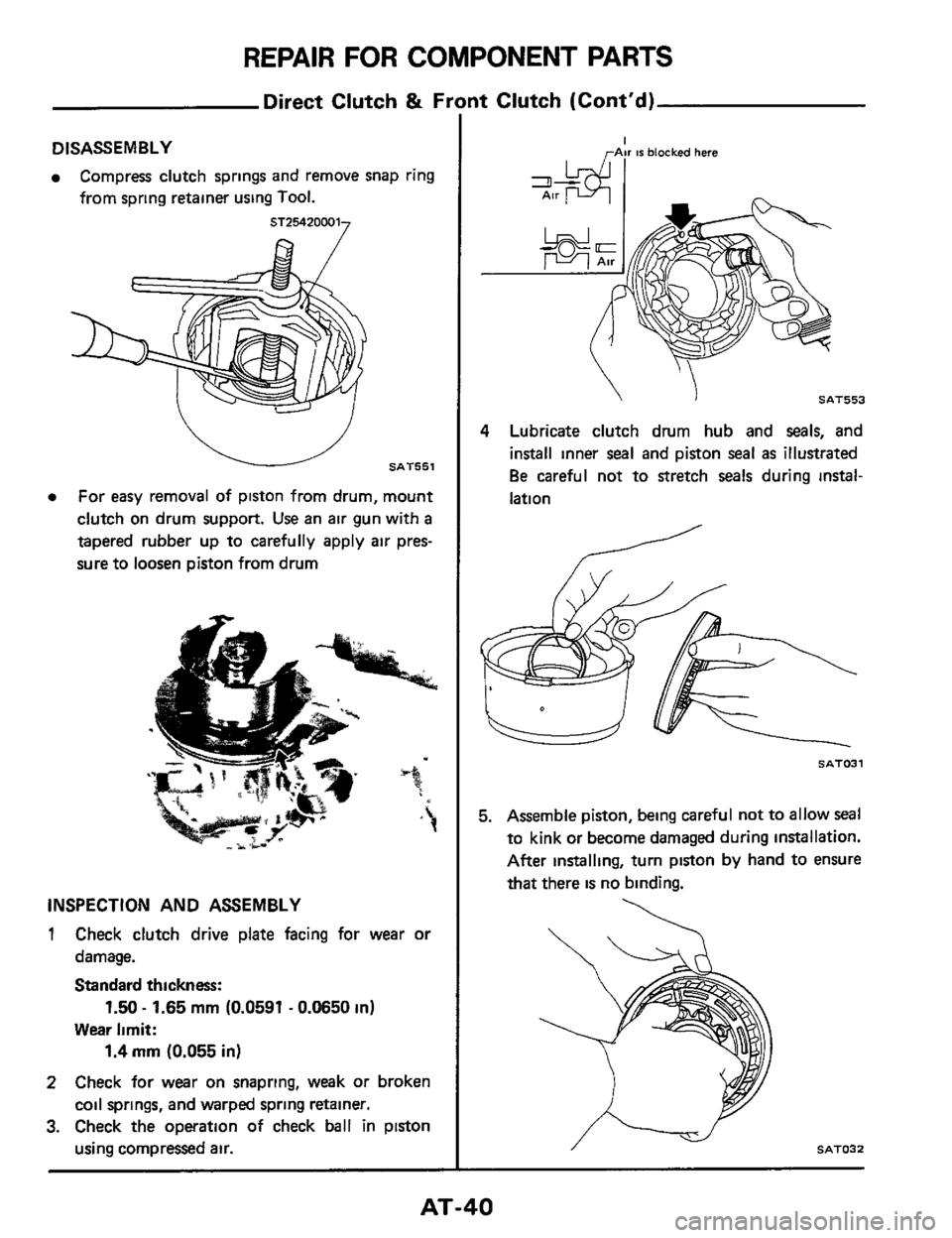

DISASSEMBLY

Compress clutch springs and remove snap ring

from spring retainer using

Tool.

e For easy removal of piston from drum, mount

clutch on drum support. Use an air gun with

a

tapered rubber up to carefully apply air pres-

sure to loosen piston from drum

INSPECTION AND ASSEMBLY

1 Check clutch drive plate facing for wear or

damage.

Standard thickness:

Wear limit:

2 Check for wear on snapring, weak or broken

coil springs, and warped spring retainer.

3. Check the operation of check ball in piston

using compressed air.

1.50 - 1.65 mrn (0.0591 - 0.0650 in)

1.4 mm (0.055 in)

LAW IS blocked here

SAT553

4 Lubricate clutch drum hub and seals, and

install inner

seal and piston seal as illustrated

Be careful not to stretch seals during instal-

lation

SAT031

5. Assemble piston, being careful not to allow seal

to kink or become damaged during installation.

After installing, turn piston

by hand to ensure

that there

is no binding.

/ .----icJ SAT032

AT-40

Page 41 of 99

REPAIR FOR COMPONENT PARTS

Thickness mm (in)

50(0197)

5

2 (0 2051

54(02131

5

6 (0 2201

5 8 (0 2281

6 0 IO 236)

6 2 10.244)

-

Direct Clutch & FI

Part number

31567-XZ900

31567-XZ901

31 567-X2902

31 567-XZ903

31 567-X2904

31 567-X2905

31567-XZ906

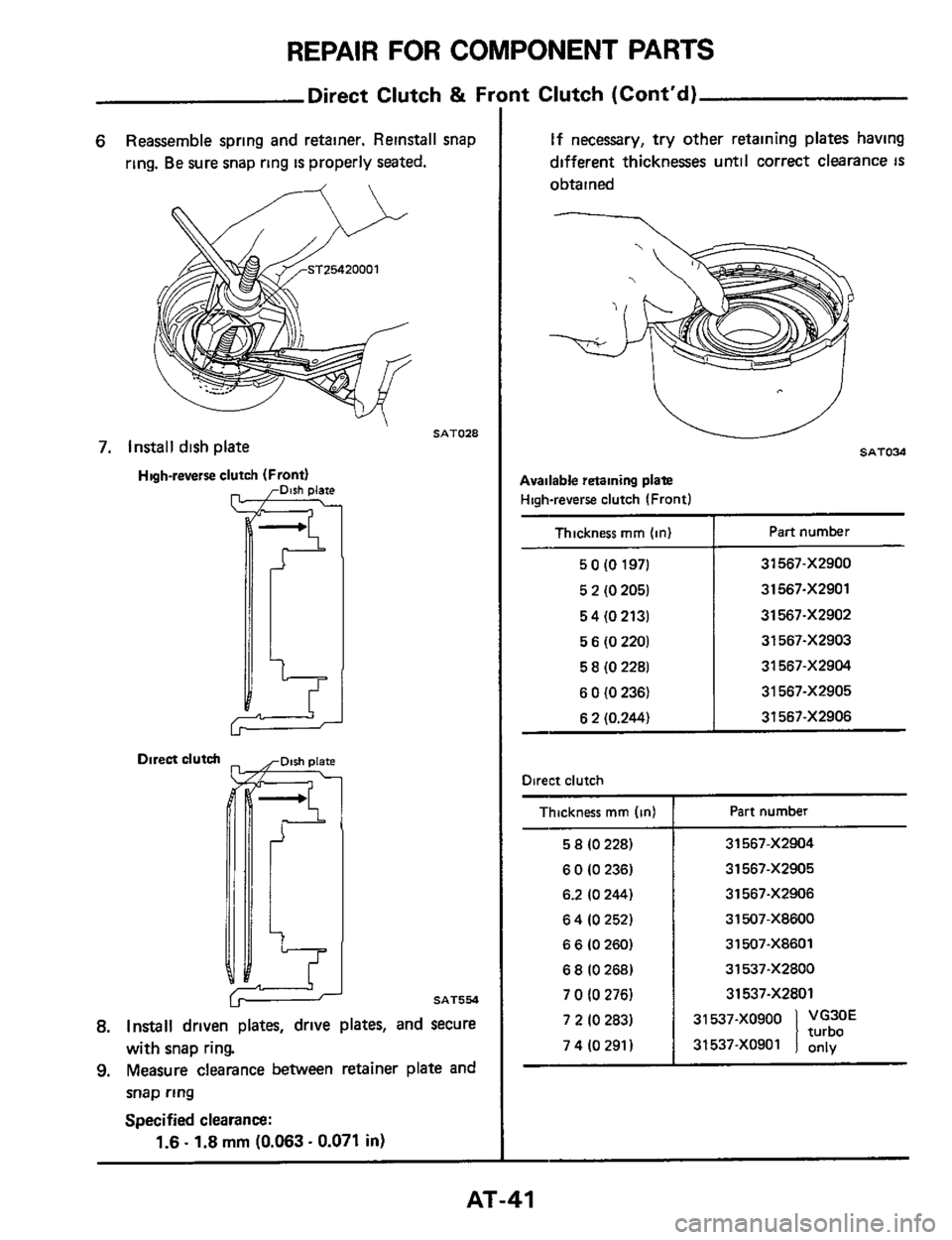

6 Reassemble spring and retainer. Reinstall snap

ring. Be sure snap ring IS properly seated.

Thickness mm (in1

5 8 IO 228)

6 0 IO 236)

6.2 (0 244)

6 4 (0 252)

6 6 IO 260)

6 8 IO 268)

7 0 IO 276)

-

SAT028

Part number

31567.X2904

31567-XZ905

31567-XZ906

31507-X8600

31507-X8601

31537-XZ800

31537-X2801

7. Install dish plate

High-reverse clutch (Front)

Direct clutch

SAT554

8. Install driven plates, drive plates, and secure

with snap ring.

9. Measure clearance between retainer plate and

snap ring

Specified clearance:

1.6. 1.8 mm (0.063.0.071 in)

it Clutch (Cont'd)

If necessary, try other retaining plates having

different thicknesses until correct clearance

IS

o bta i ned

Direct clutch

turbo 7 2 IO 283)

7410291)

AT-41