wiring NISSAN 300ZX 1984 Z31 Automatic Transmission Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 99, PDF Size: 3.09 MB

Page 61 of 99

ASSEMBLY

290 (1 142)

29 5 (1 161)

30 0 (1 1811

30 5 (1 201)

31 0 (1 220)

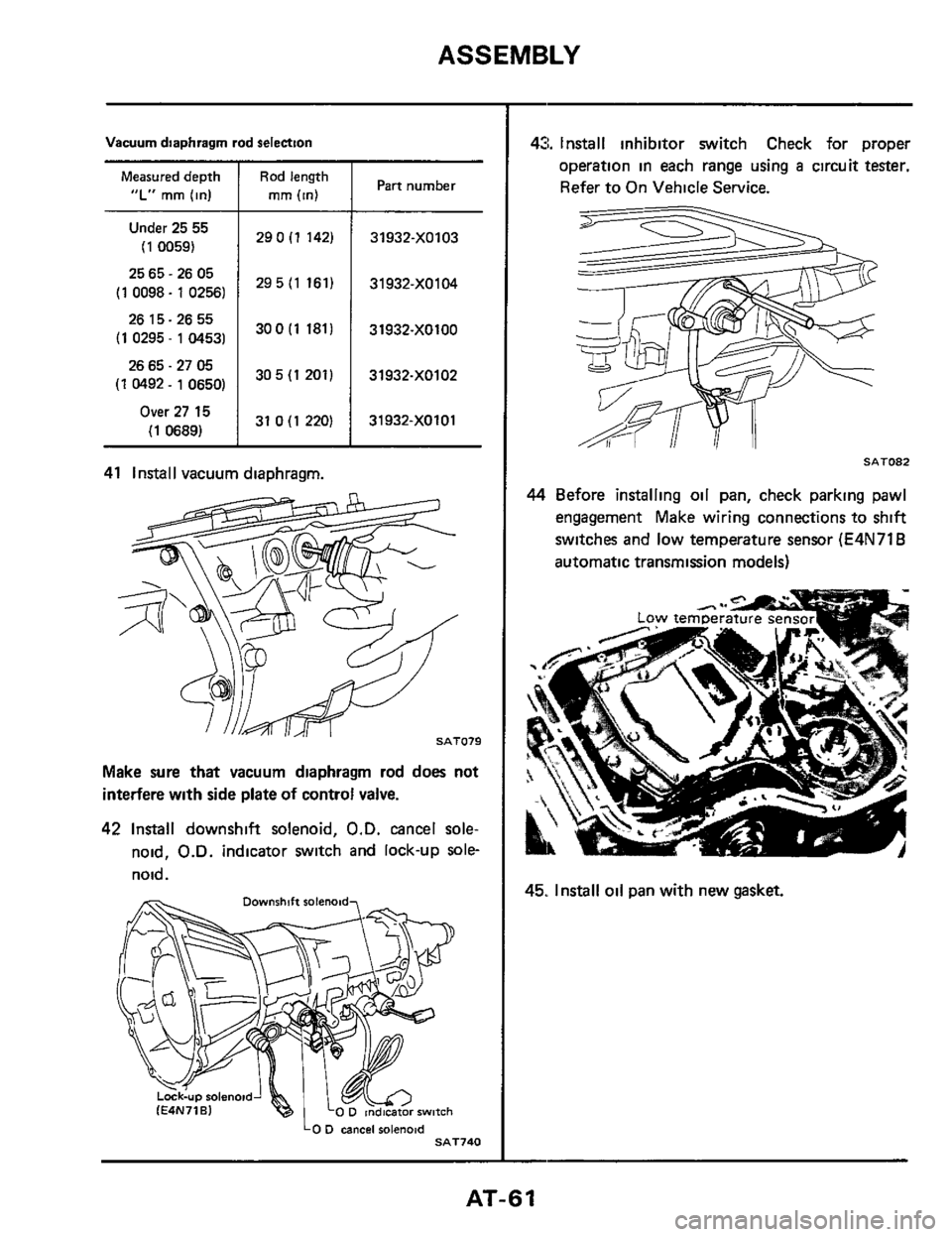

Vacuum diaphragm rod selection

31932-XO103

31932-X0104

31932-XOlOO

31932-X0102

31932-XOlOl

Measured depth

“L” mm (in)

Under 25 55

(1 0059)

25 65

- 26 05

(1

0098 - 1 02561

2615-2655

(1 0295 - 1 04531

26 65.27 05

(1 0492

- 1 0650)

Over 27 15

(1 0689)

Rod length

mm (in) Part number

41 Install vacuum diaphragm.

Make sure that vacuum diaphragm rod does not

interfere with side plate

of control valve.

42 Install downshift solenoid, O.D. cancel sole-

noid, O.D. indicator switch and lock-up sole-

noid.

LO D csncei rolenoid SAT740

43. Install inhibitor switch Check for proper

operation in each range using

a circuit tester.

Refer to On Vehicle Service.

Y li

SAT082

44 Before installing oil pan, check parking pawl

engagement Make wiring connections to shift

switches and low temperature sensor

(E4N71B

automatic transmission models)

45. Install oil pan with new gasket.

-

AT-61

Page 84 of 99

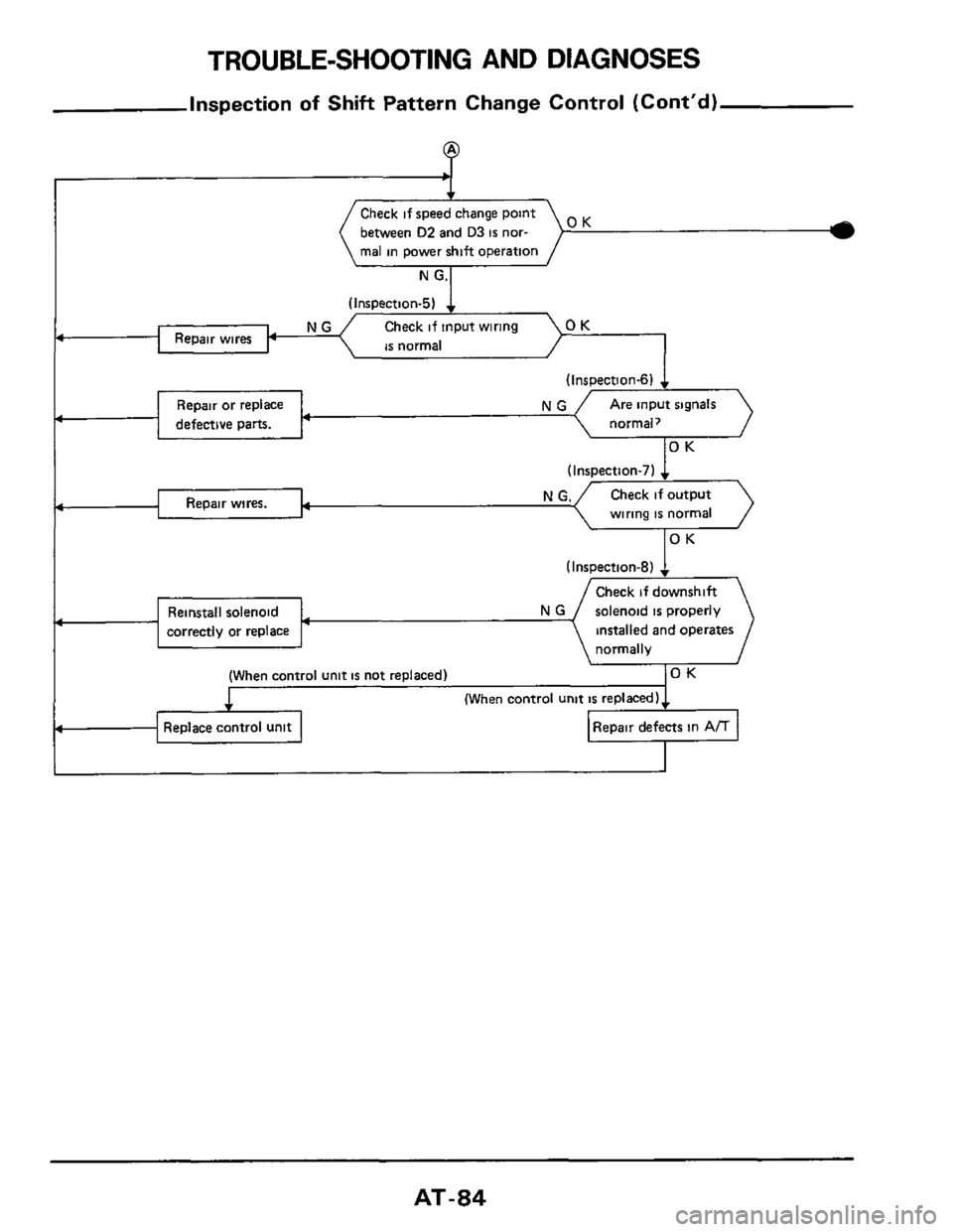

TROUBLE-SHOOTING AND DIAGNOSES

(Inspection-5)

Check if input wiring OK

L is normal Repair wires

(Inspection-6)

Repair or replace NG Are input signals

defective parts. normal? 4

OK

(Inspection-7)

Inspection of Shift Pattern Change Control (Cont'd)

(Inspection-8) 1

Check if downshift

Reinstall solenoid solenoid

is properly

correctly or replace installed and operates

normally

4

(When control unit is not replaced) OK

1 (When control unit is replaced)

4 Replace control unit

I 4

OK Check if speed change point

between

02 and D3 is nor-

mal in power shift operation

I N G.1

I. Repair wires.

AT-84

Page 85 of 99

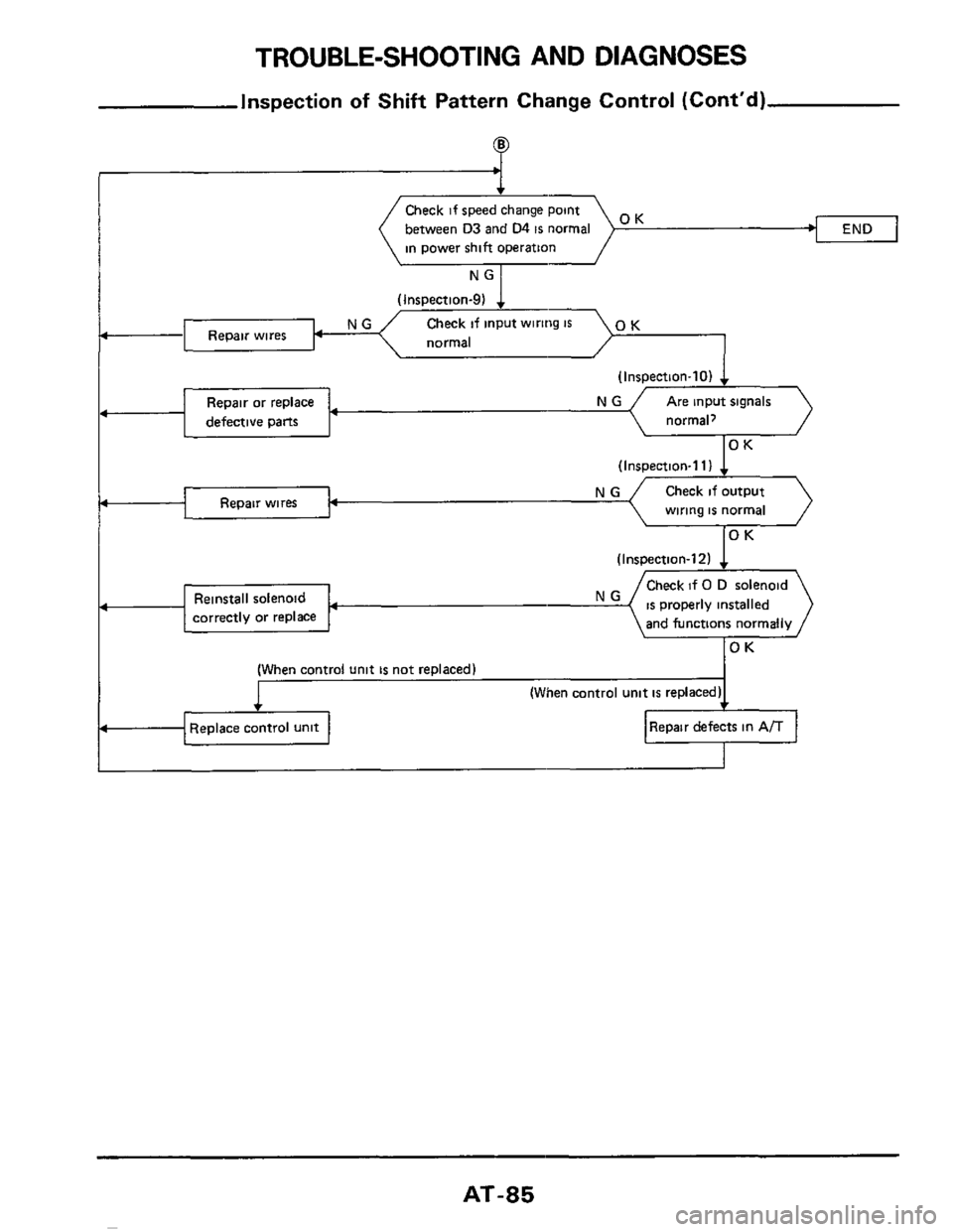

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Shift Pattern Change Control (Cont’d)

9

END OK Check if speed change point

between

D3 and D4 is normal

in power shift operation

(Inspection-9)

Check if input wiring is

normal

(Inspection-101

normal,

NG Repair wires

Repair or replace

defective pans

(Inspection.111 1

Check if output

wiring

is normal

(Inspection-12) 1

Check if 0 D solenoid

and functions normally Reinstall solenoid

correctly or replace

(When control unit is not replaced1

(When control unit is replaced)

Replace control unit

I-I-”7

Repair defects in A/T

P

AT-85

Page 86 of 99

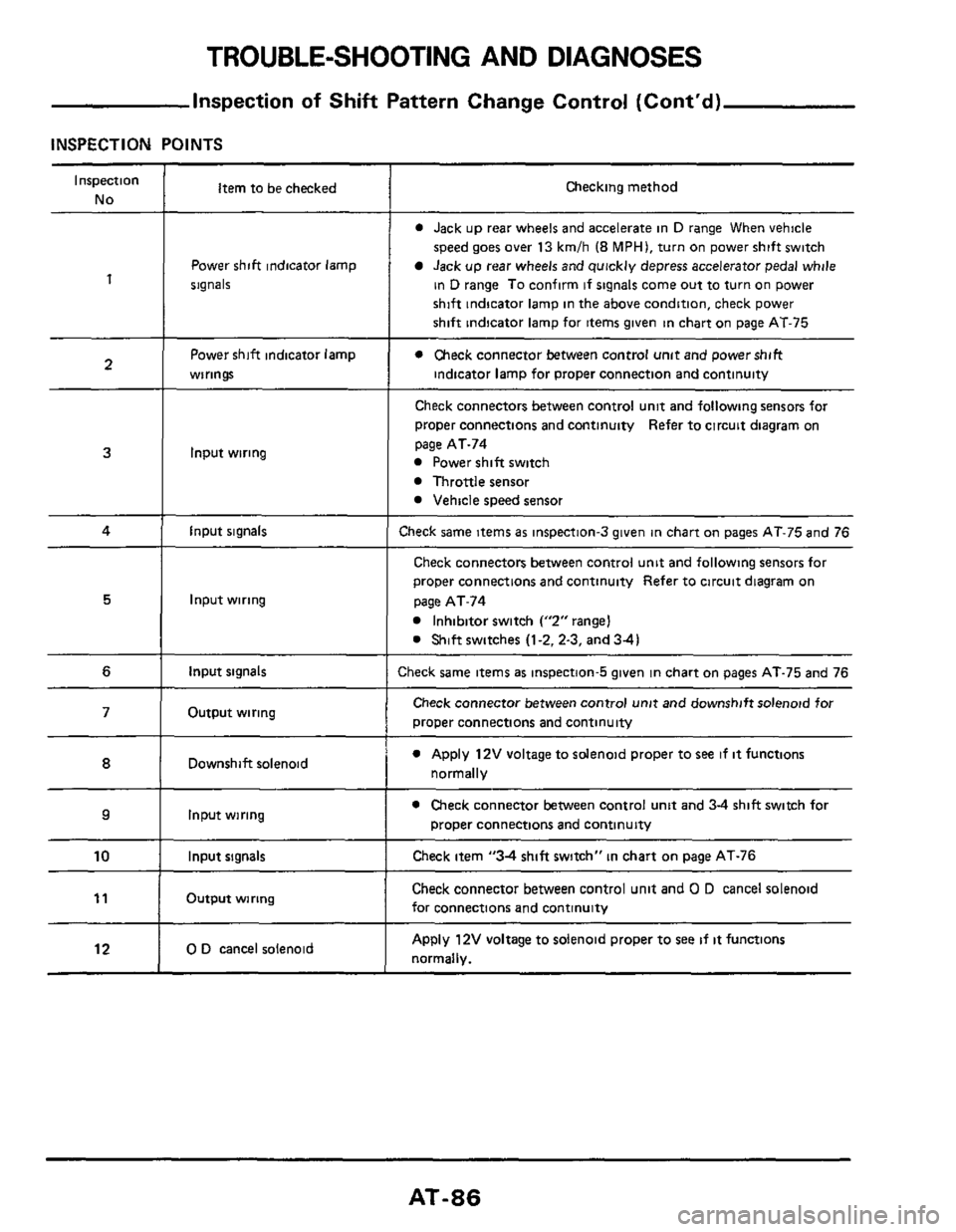

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Shift Pattern Change Control (Cont'd)

INSPECTION POINTS

Inspection

No

1

2

Item to be checked

Power shift indicator lamp

signals

Power shift indicator lamp

wirings

3

4 I input signals

Input wiring

5

6 I input signals

Input wiring

Output wiring 71

12

Downshift solenoid

Input wiring ~~

0 D cancel

solenoid

IO I Input signals

Output wiring l1 I

Checking method

0 Jack up rear wheels and accelerate in D range When vehicle

speed goes over 13 kmlh (8 MPHI, turn on power shift switch

Jack up rear wheels and quickly depress accelerator pedal while

in

D range To confirm if signals come out to turn on power

shift indicator lamp in the above condition, check power

shift indicator lamp for items given in chart

on page AT-75

0 Check connector between control unit and powershift

indicator lamp for proper connection and continuity

Check connectors between control unit and following sensors foi

proper connections and continuity Refer to circuit diagram on

page AT-74

Power shift switch

Throttle sensor

Vehicle speed sensor

:heck same items as inspection-3 given in chart on pages AT-75 and 76

Check connectors between control unit and following sensors for

proper wnnections and continuity Refer to circuit diagram on

page AT-74

Inhibitor switch Y2"rangeI

0 Shift switches (1-2.2-3, and 34)

:heck same items as inspection-5 given in chart on pages AT-75 and 76

Check connector between control unit and downshift solenoid for

proper connections and continuity

0 Apply 12V voltage to solenoid proper to see if it functions

normally

0 Check connector between control unit and 3-4 shift switch for

proper connections and continuity

Check item "34 shift switch" in chart on page AT-76

Check connector between control unit and 0 D cancel solenoid

for connections and continuity

Apply 12V voltage to solenoid proper to see if it functions

normally.

AT-86

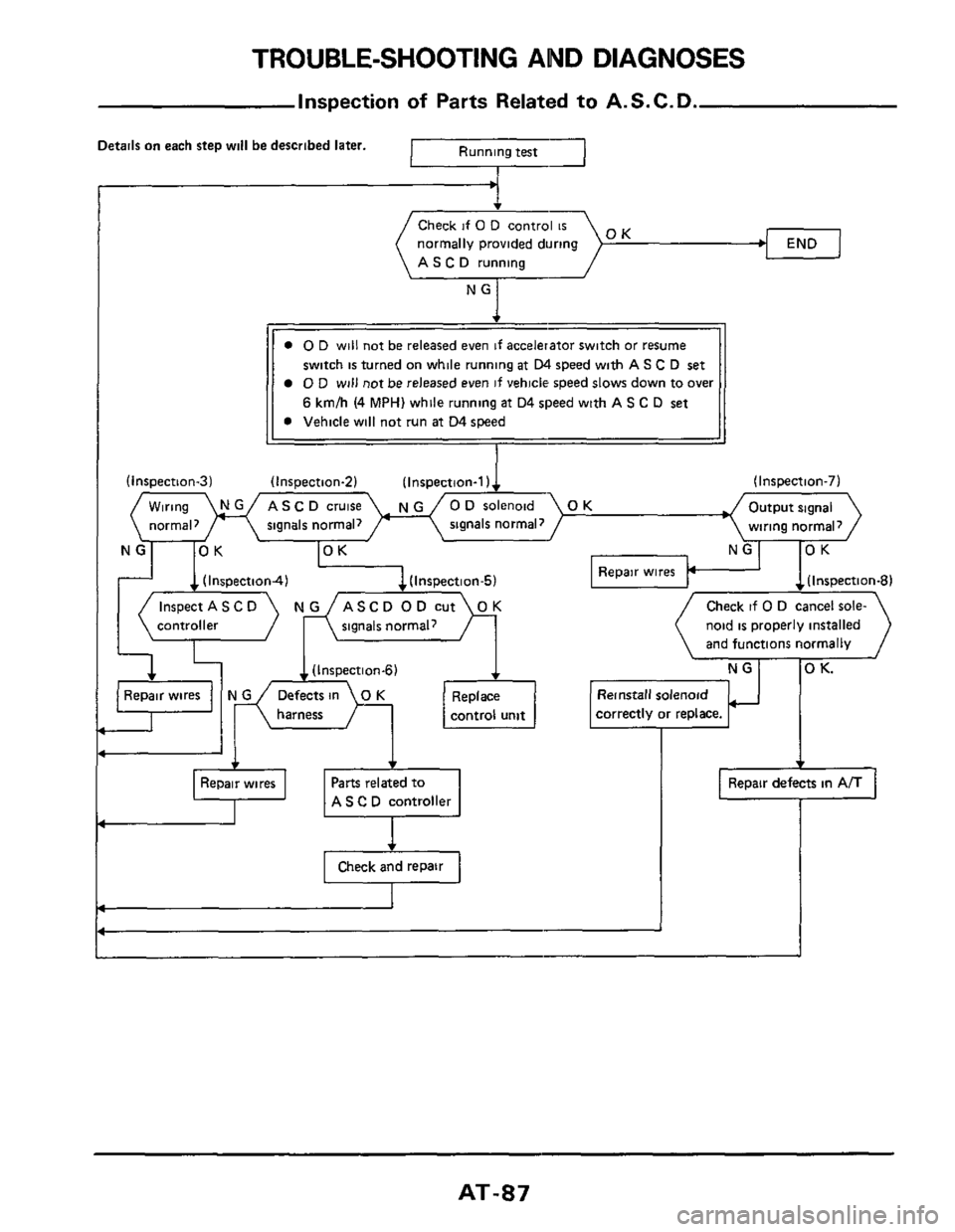

Page 87 of 99

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Parts Related to A. S. C. D.

I Running test Details on each step will be described later.

I

normally provided during

AS C D running

switch is turned on while running at D4 speed with AS C D set

0 D will not be released even if vehicle speed slows down to over

6 kmlh (4 MPHI while running at D4 speed with AS C D set

e Vehicle will not run at D4 speed

(Inspection-7)

Output signal

wiring normal?

(Inspection-3) (Inspection-2) (Inspection-1 I

0 D solenoid

signals normal,

wz) NGI 10 K lOK

controller signals normal?

Check if 0 D cancel sole-

noid

is properly installed

harness control unit correctly or replace.

Parts related to

AS C D controller

Check and repair

Repair defects in A/T

T

AT-87

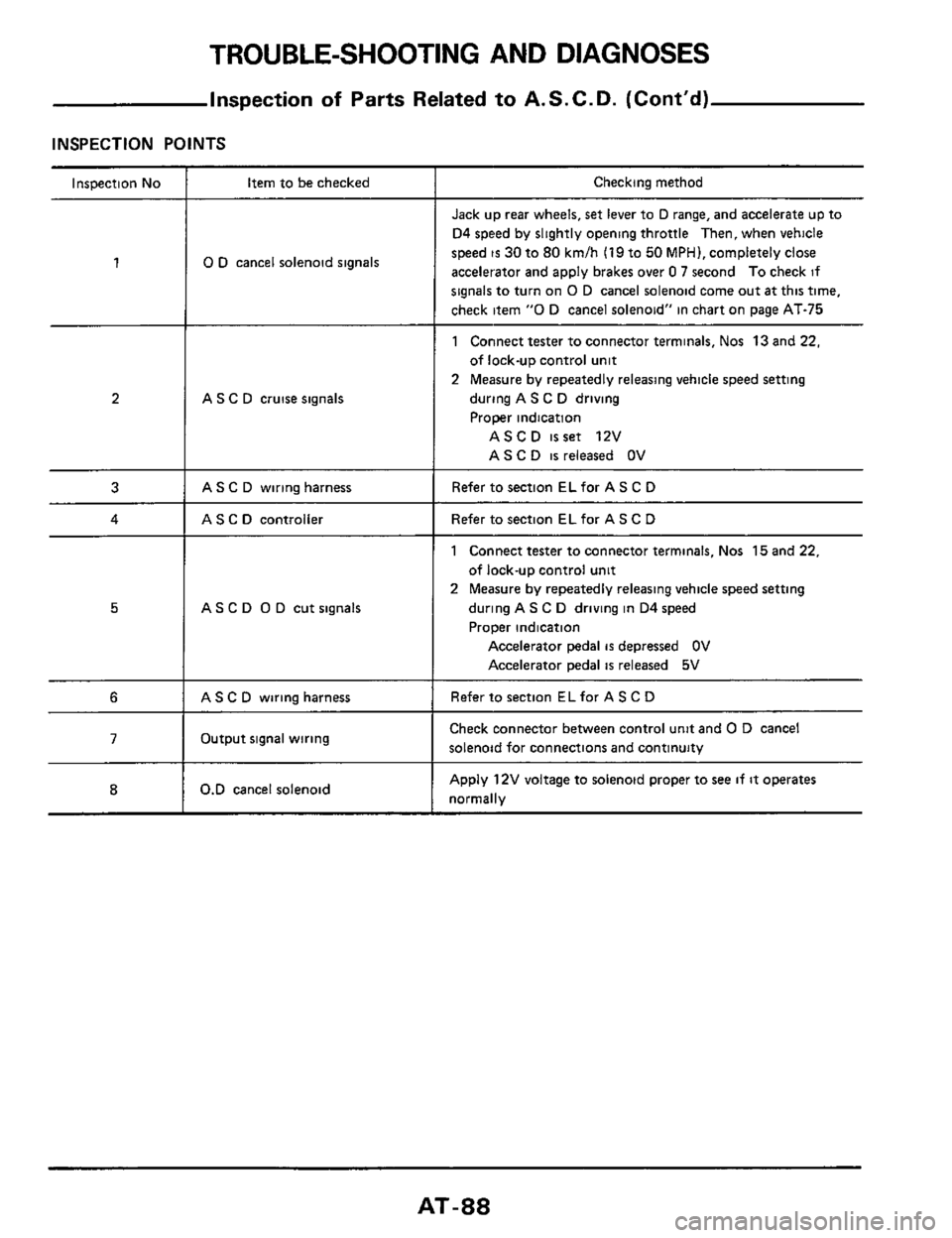

Page 88 of 99

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Parts Related to A. S. C. D. (Cont’d)

INSPECTION POINTS

Inspection No

1

2

3

4

5

6

7

8

Item to be checked

0 D cancel solenoid signals

A S C D cruise signals

AS C D wiring harness

AS C D controller

AS C D 0 D cut signals

AS C D wiring harness

Output signal wiring

0.D cancel solenoid

Checking method

Jack up rear wheels, set lever to D range, and accelerate up to

D4 speed by slightly opening throttle

Then, when vehicle

speed

is 30 to 80 kmlh (19 to 50 MPH), completely close

accelerator and apply brakes over

0 7 second To check if

signals to turn on 0 D cancel solenoid come out at this time,

check item

“0 D cancel solenoid” in chart on page AT-75

1 Connect tester to connector terminals, Nos 13 and 22,

of lock-up control unit

2 Measure by repeatedly releasing vehicle speed setting

during A S C D driving

Proper indication

ASCD isset 12V

AS C

D is released OV

Refer to section EL for A S C D

Refer to section EL for AS C D

1 Connect tester to connector terminals, Nos 15 and 22,

of lock-up control

unit

2 Measure by repeatedly releasing vehicle speed setting

during AS C

D driving in D4 speed

Proper indication

Accelerator pedal is depressed OV

Accelerator pedal

is released 5V

Refer to section ELfor A S C D

Check connector between control unit and 0 D cancel

solenoid for connections and continuity

Apply 12V voltage to solenoid proper to see if it operates

normally

AT-88

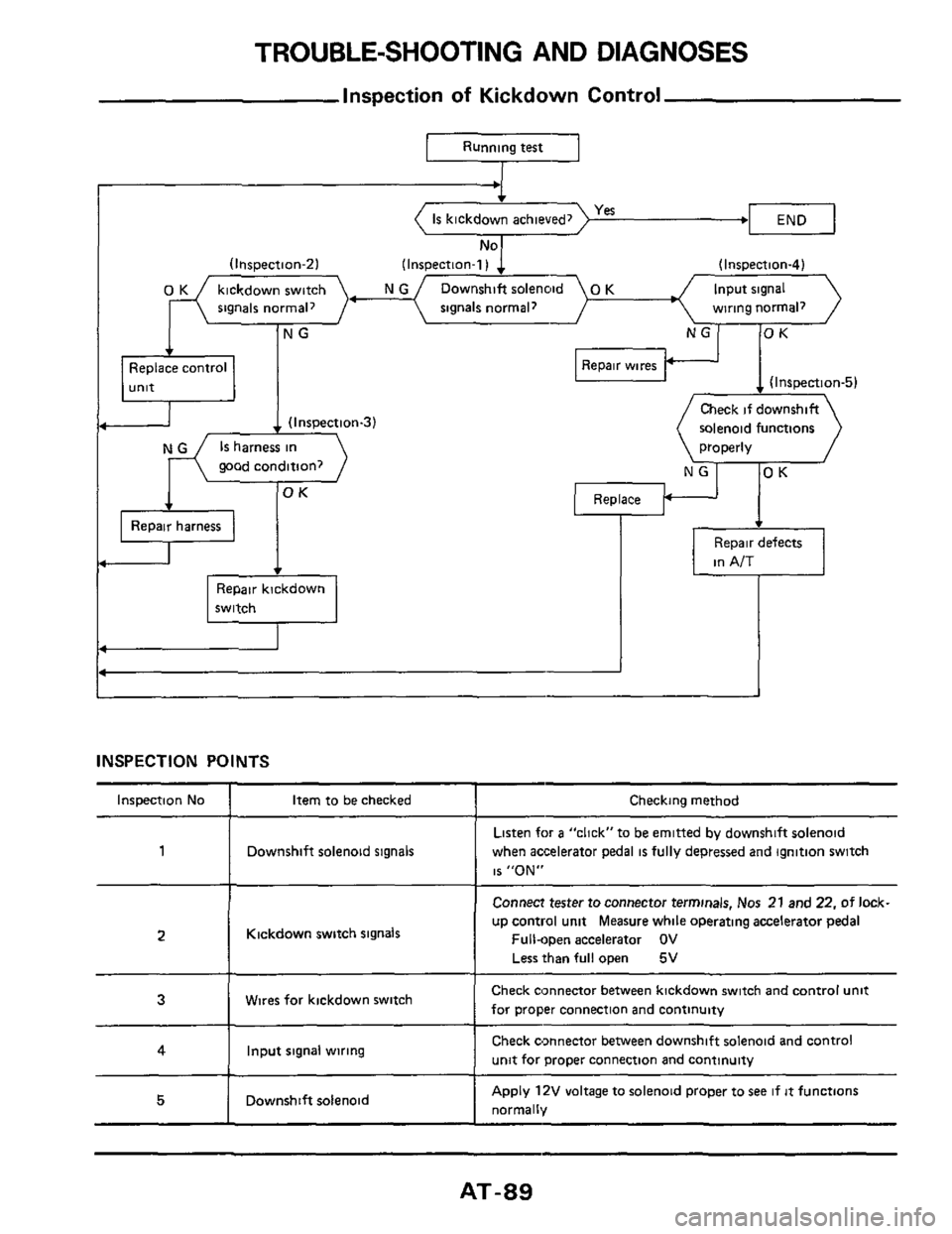

Page 89 of 99

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Kickdown Control

I Running test I

signals normal? signals normal? wiring normal?

Replace contrul

(I nspection-3)

good condition?

Repair harness

switch

I

Repair wires

(Inspection-5)

Check if downshift

solenoid functions

properly

Replace

in A/T I I

INSPECTION PO I NTS ~~

~

Inspection No Item to be checked Checking method

Listen for a “click“to be emitted by downshift solenoid

when accelerator pedal

is fully depressed and ignition switch

is “ON“

Downshift solenoid signals

I 1 Connect tester to connector terminals, Nus 21 and 22, of lock-

up control unit Measure while operating accelerator pedal

I Full-open accelerator OV 2 I Kickdown switch signals

Less than full open 5V

Check connector between kickdown switch and control unit

for moper connection and continuitv 3 1 Wires for kickdown switch

4 I Input signal wiring Check connector between downshift solenoid and control

unit for proper connection and continuity

Apply 12V voltage to solenoid proper to see if it functions

normally Downshift solenoid 5

AT-89