meter NISSAN 300ZX 1984 Z31 Electrical System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 116, PDF Size: 3.42 MB

Page 1 of 116

ELECTRICAL SYSTEM

I

SECTION EL

CONTENTS

HOW TO READ DIAGRAMS

STANDARDIZED RELAY

POWER SUPPLY ROUTING

BATTERY.

.. ..

STARTING SYSTEM .

STARTING SYSTEM -Starter -

CHARGING SYSTEM .

CHARGING SYSTEM - Alternator

COMB IN AT1 ON SWITCH

INSTRUMENT SWITCH

HEADLAMP

EXTERIOR LAMP,

INTERIOR LAMP

.

..

..

..

..

..

... ......

..

.. ....

..

.. ...

EL- 2

EL- 3

EL- 4

EL- 6

EL- 9

EL-

10

EL- 15

EL- 17

EL- 23

EL- 25

EL- 26

EL- 34

EL- 38

METER AND GAUGES - Digital Type Combination Meter . . EL- 41

METER AND GAUGES - Digital Type Combination Gauge . .. .. EL- 57

METER AND GAUGES - Needle Type Combination Meter .. . EL- 65

METER AND GAUGES

- Needle Type Combination Gauge.. .... EL- 68

WARNING LAMPS AND CHIME. .......... ... .... EL- 71

VOICE WARNING SYSTEM

... ... EL- 76

TIME CONTROL SYSTEM ... EL- 81

WIPER AND WASHER .... .... ... ... . EL- 89

HORN, CIGARETTE LIGHTER, CLOCK . . ......... EL- 92

REAR WINDOW DEFOGGER

... .. ... ....... EL- 93

AUDIO AND POWER ANTENNA

,. . .... .. . EL- 95

AUTOMATIC SPEED CONTROL DEVICE (AS

C D ) . ... , . EL- 97

LOCATION OF ELECTRICAL UNITS

... .. .. .. EL-104

HARNESS LAYOUT

. . .. .. .. . EL-107

Page 2 of 116

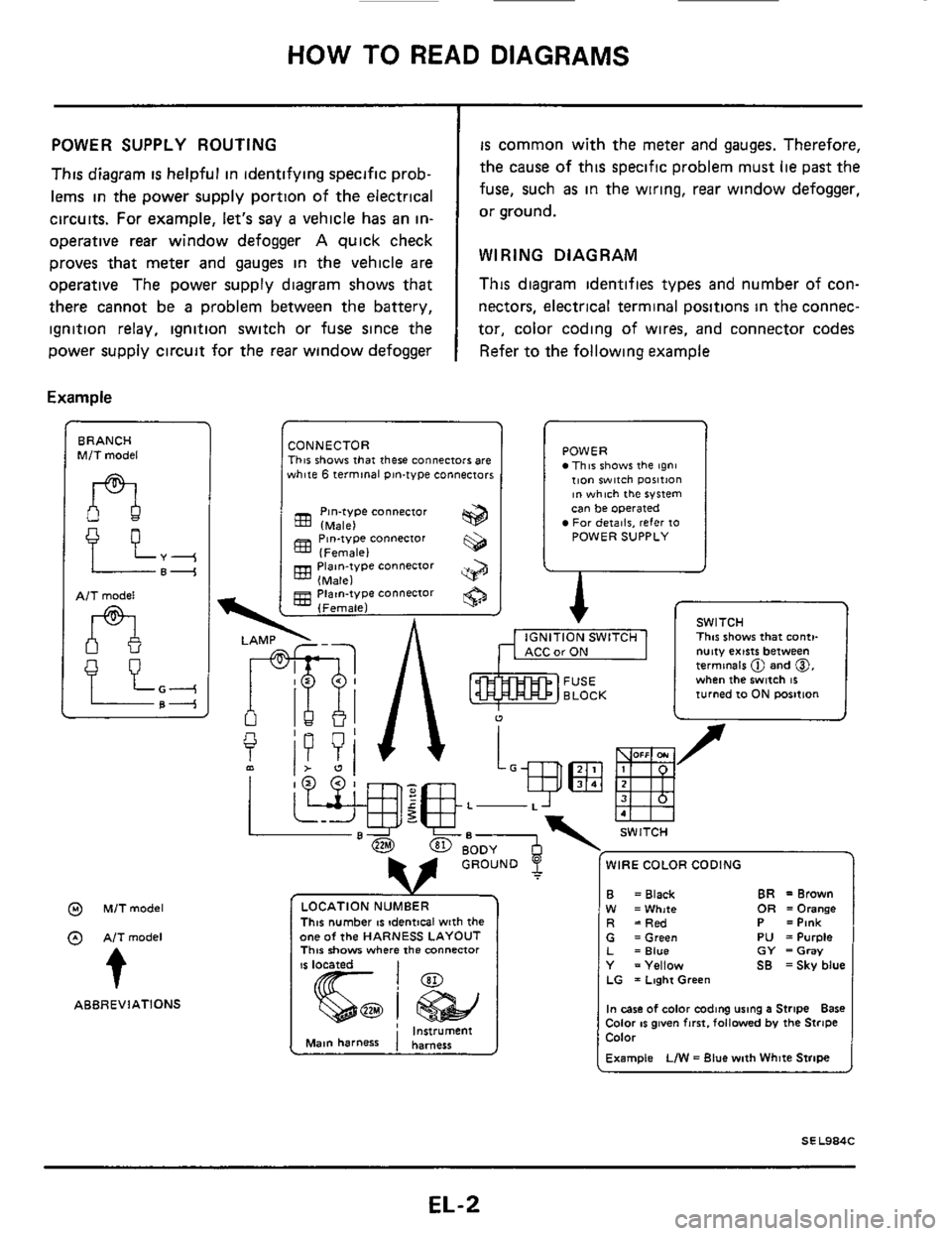

HOW TO READ DIAGRAMS

I

POWER SUPPLY ROUTING

This diagram is helpful in identifying specific prob-

lems

in the power supply portion of the electrical

circuits. For example, let's say

a vehicle has an in-

operative

rear window defogger A quick check

proves that meter and

gauges in the vehicle are

operative The power supply diagram shows that

there cannot be

a problem between the battery,

ignition relay, ignition switch or fuse since the

power supply circuit for the

rear window defogger

Example

BRANCH M/T model

AlT model

n

@ M/Tmodel

@ AITmodel

t

ABBREVIATIONS

is common with the meter and gauges. Therefore,

the cause of this specific problem must

lie past the

fuse, such

as in the wiring, rear window defogger,

or ground.

WIRING DIAGRAM

This diagram identifies types and number of con-

nectors, electrical

terminal positions in the connec-

tor, color coding of wires, and connector codes

Refer to the following example

CONNECTOR This shows that there connectors are white 6 terminal pin-type connectors

Pin-type connector (Male)

(Female)

(Male)

(Female)

833 Piaan-type connector

gg Piatn-type connector

POWER This shows the tgni tion witch ~osition ~n which the system can be operated For deiailr, refer 10 POWER SUPPLY

A r

I

1 v SWITCH ., , ,-,. -..,m I This shows that conti-

u

f

L-

WIRE COLOR CODING

This number IS !dentical with the one of the HARNESS LAYOUT This show where the mnnenor

CarON I nutty exists between termmels @ and 0, when the switch 16 turned 10 ON rmition

B W R

BR =Brown = Black OR =Orange =White =Red P =Pink G =Green PU =Purple L =Blue GY =Gray Y =Yellow SB =Sky blue LG = Laghi Green

In case of color coding using a Stripe Bare Color IS given fmt. followed by the Stripe Color

Example LIW = Blue with White Stripe

EL-2

Page 6 of 116

BATTERY

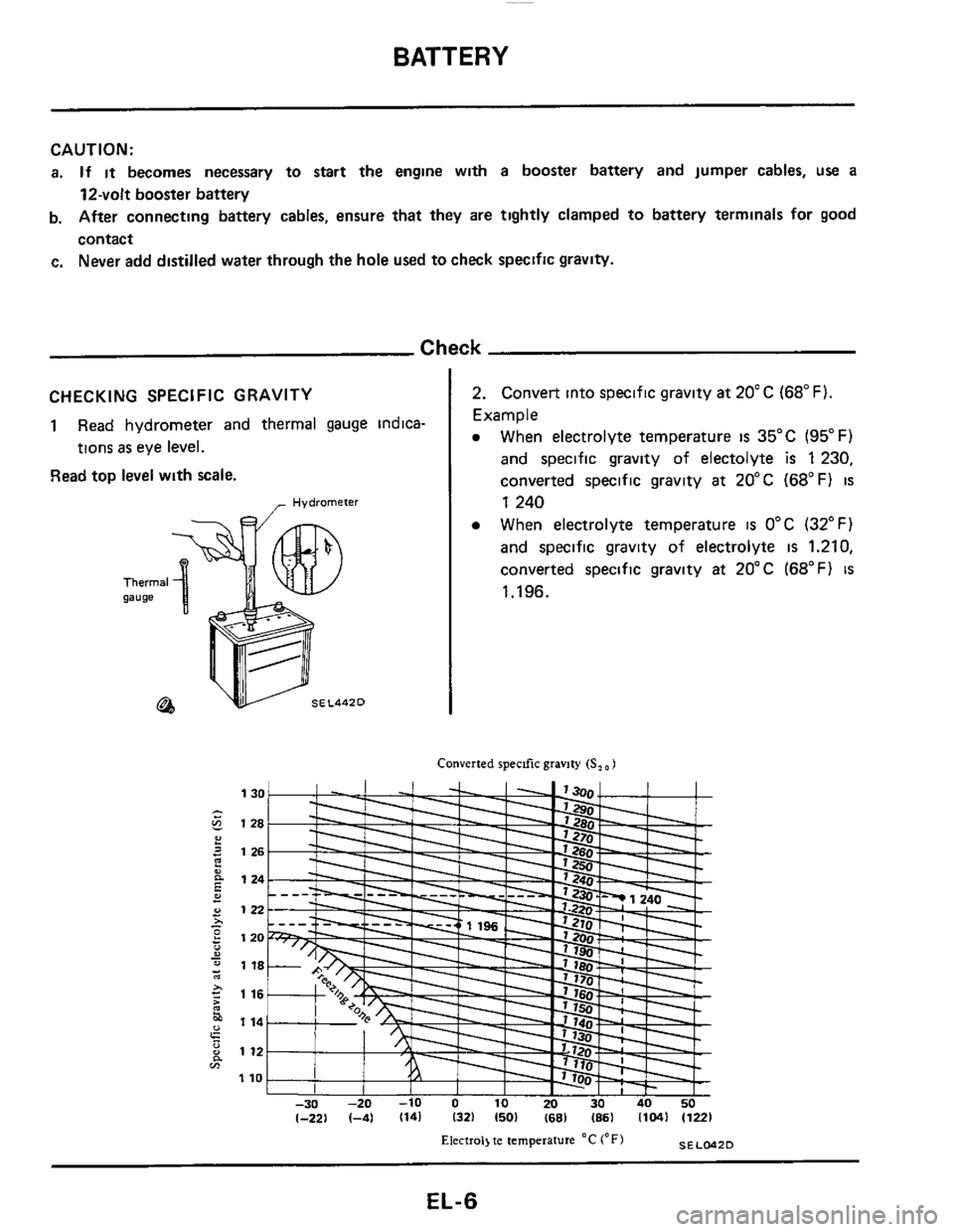

CHECKING SPECIFIC GRAVITY

1 Read hydrometer and thermal gauge indica-

tions

as eye level.

Read top level with scale.

CAUTION:

a. If it becomes necessary to start the engine with a booster battery and jumper cables, use a

12-volt booster battery

b. After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact

c. Never add distilled water through the hole used to check specific gravity.

2. Convert into specific gravity at 20°C (68°F)

Example

e When electrolyte temperature is 35°C (95°F)

and specific gravity of electolyte is 1230,

converted specific gravity

at 20°C (68°F) is

Check

- Hydrometer 1 240

When electrolyte temperature

is 0°C (32°F)

and specific gravity of electrolyte

is 1.210,

converted specific gravity

at 20°C (68°F) is

1.196.

Converted specific gravity (S, 1

1

1 , I I I I I 1- I -30 -20 -10 0 10 20 30 40 50 1-221 1-41 1141 132) 1501 1681 (86) (104) (1221

SELCdZD Electrol) te temperature "C ('F)

EL-6

Page 7 of 116

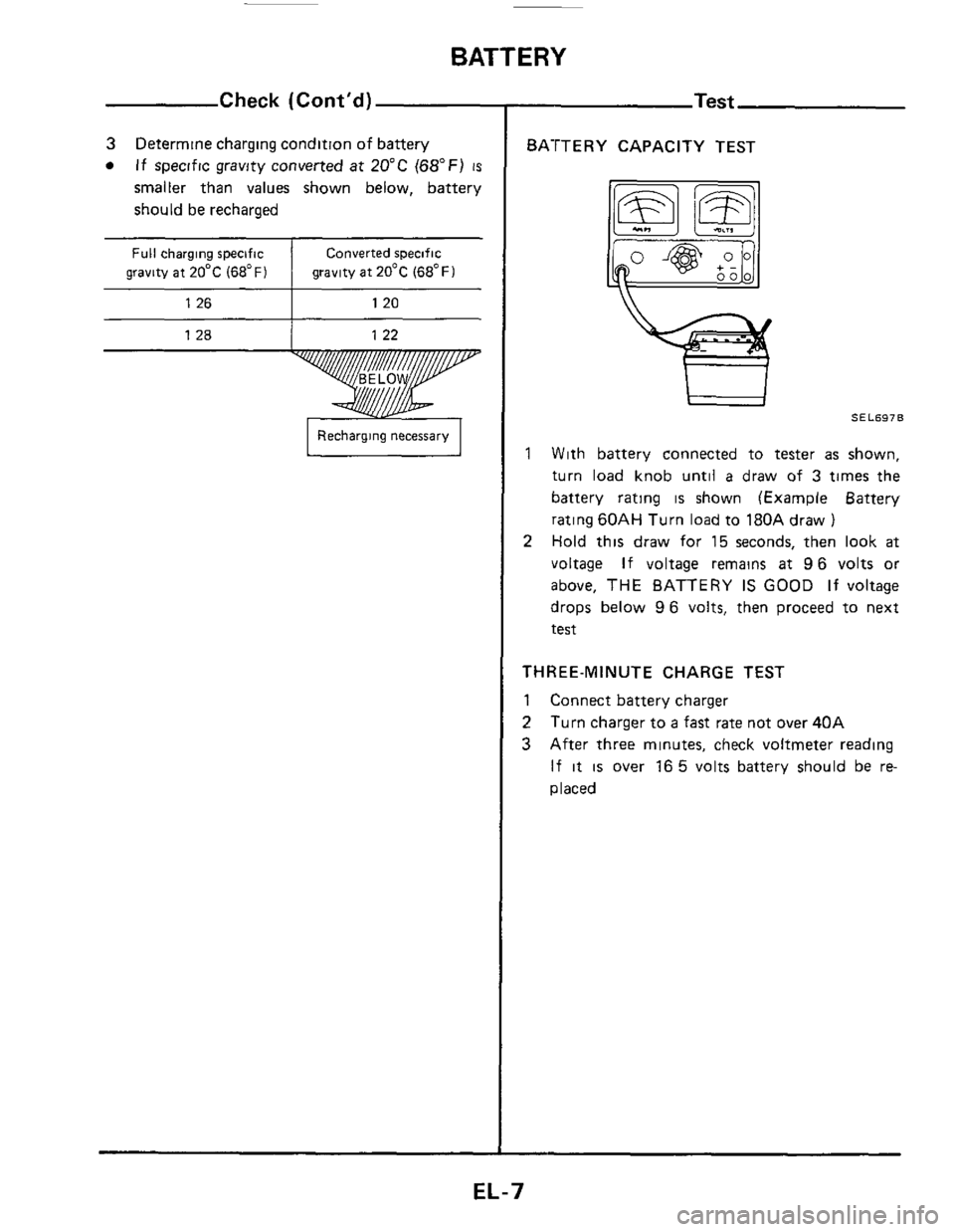

BATTERY

Full charging specific

gravity at 20°C

(68°F)

Check (Cont’d)

Converted specific

gravity at 20°C

(68°F)

1 26 I 120

I Recharging necessary I

BATTERY CAPACITY TEST

1 With battery connected to tester as shown,

turn load knob until

a draw of 3 times the

battery rating

is shown (Example Battery

rating

60AH Turn load to 180A draw )

Hold this draw for 15 seconds, then look at

voltage If voltage remains at 96 volts or

above,

THE BATTERY IS GOOD If voltage

drops below

96 volts, then proceed to next

test

2

THREE-MINUTE CHARGE TEST

1 Connect battery charger

2

3

Turn charger to a fast rate not over 40A

After three minutes, check voltmeter reading

If it is over 16 5 volts battery should be re-

placed

EL-7

Page 12 of 116

STARTING SYSTEM -Starter-

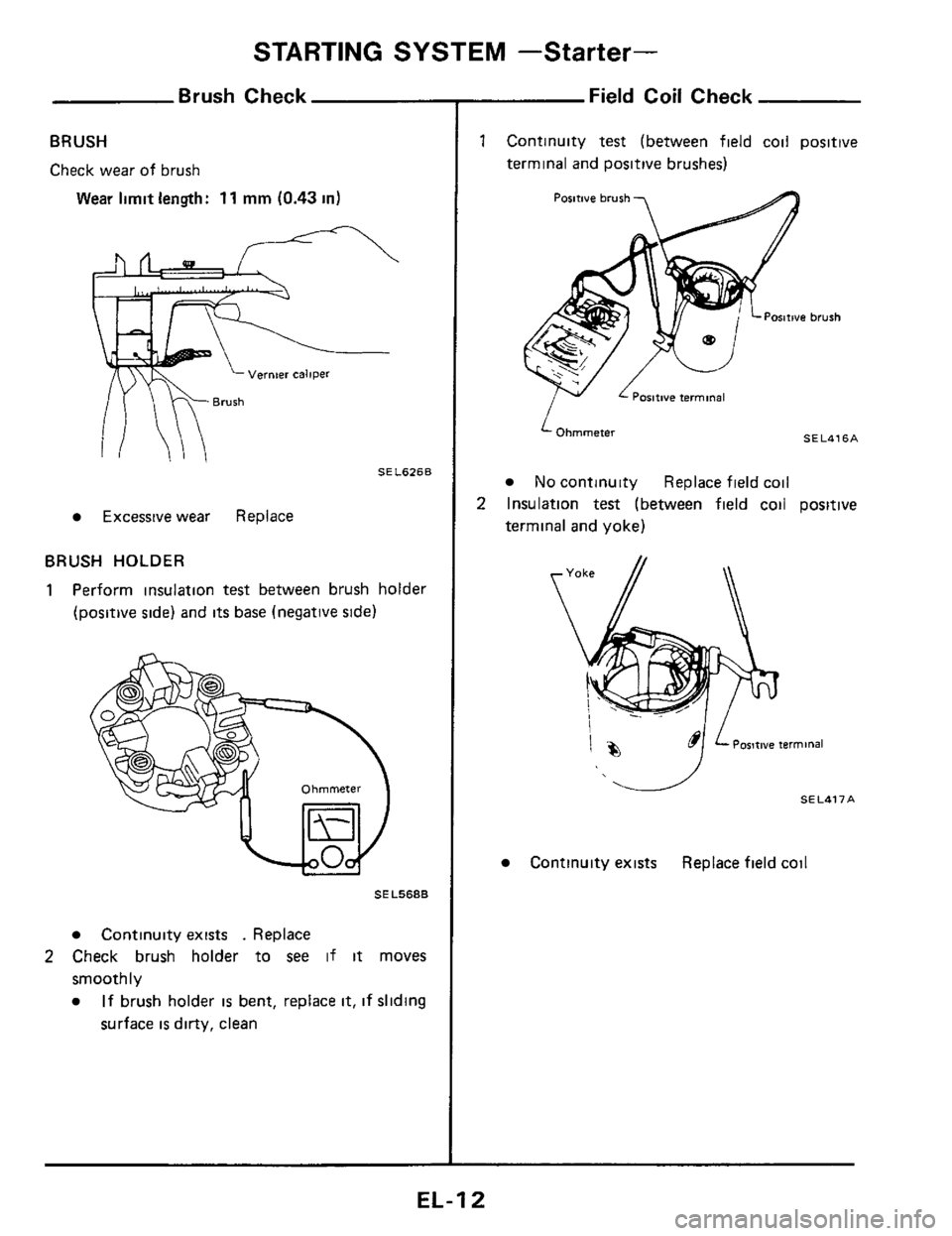

Brush Check

BRUSH

Check wear of brush

Wear limit length: 11 mm (0.43 in)

Vernier caliper

SEL626B

Excessive wear Replace

BRUSH HOLDER

1 Perform insulation test between brush holder

(positive side) and its base (negative side)

SE L568B

Continuity exists . Replace

smoothly

2 Check brush holder to see if it moves

If brush holder is bent, replace it, if sliding

surface

is dirty, clean

Field Coil Check

Continuity test (between field coil positive

terminal and positive brushes)

ositive terminal

‘Ohmmeter

No continuity Replace fielk ~

SELUq6A

:oil

Insulation test (between field coil positive

terminal

and yoke)

Postwe terminal

I

1%

Continuity exists Replace field coil

EL-I 2

Page 13 of 116

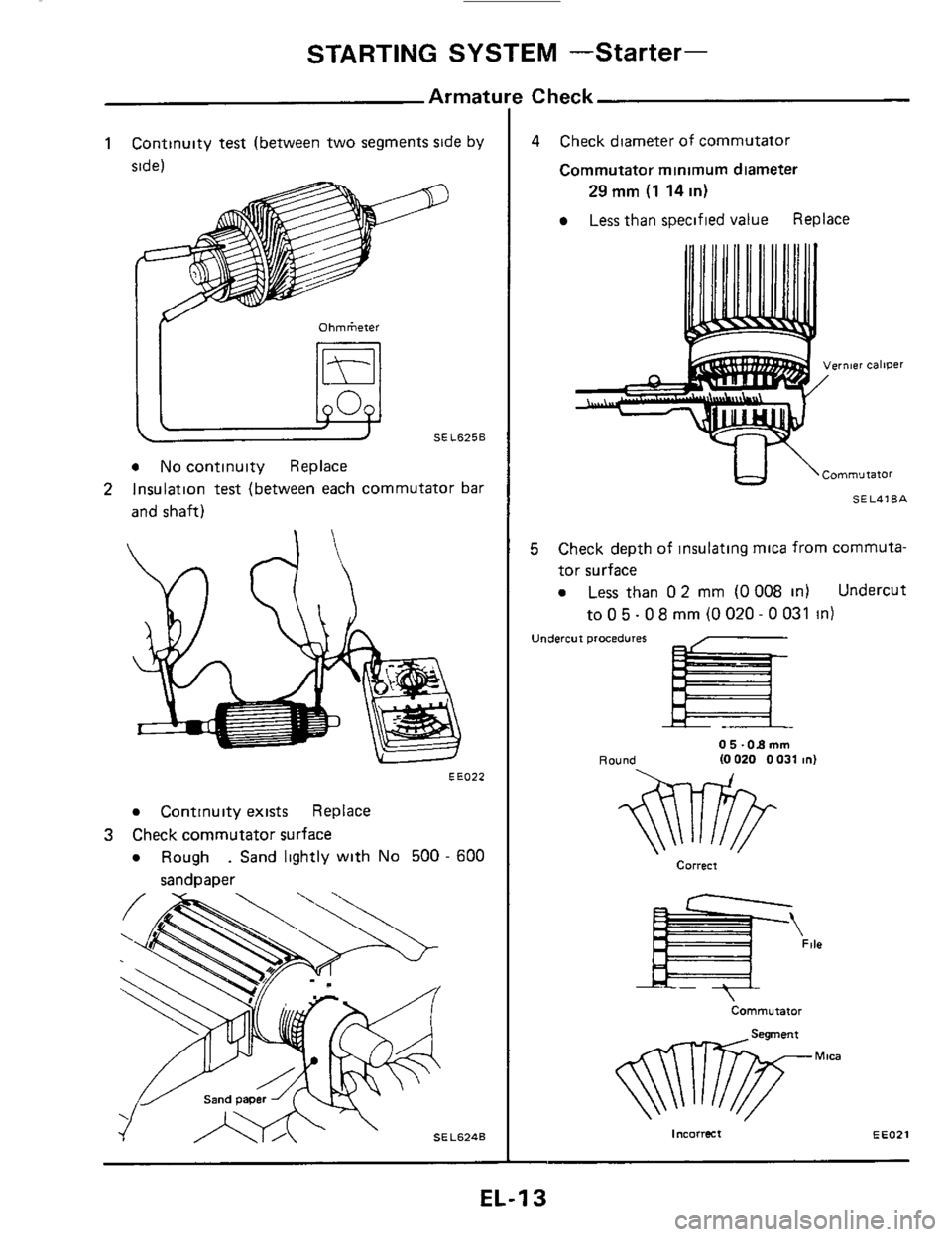

STARTING SYSTEM -Starter-

1 Continuity test (between two segments side by

side)

IY Ohrnketer

a No continuity Replace

Insulation

test (between each commutator bar

and shaft) 2

EE022

a Continuity exists Replace

a Rough . Sand lightly with No 500 - 600

3 Check commutator surface

sandpaper

! Check

4 Check diameter of commutator

Commutator minimum diameter

Less than specified value Replace

29 mm (1 14 in)

vernier caliper

tJ \Cornmurator

SEL418A

5 Check depth of insulating mica from commuta-

tor surface

a Less than 0 2 mm (0 008 in) Undercut

to 0 5.0 8 mrn (0 020 - 0 031 in)

Undercut procedures

Round 0 5 -08 mm (0 020 0 031 in)

Correct

Commutator

incorrect EEOZI

EL-1 3

Page 14 of 116

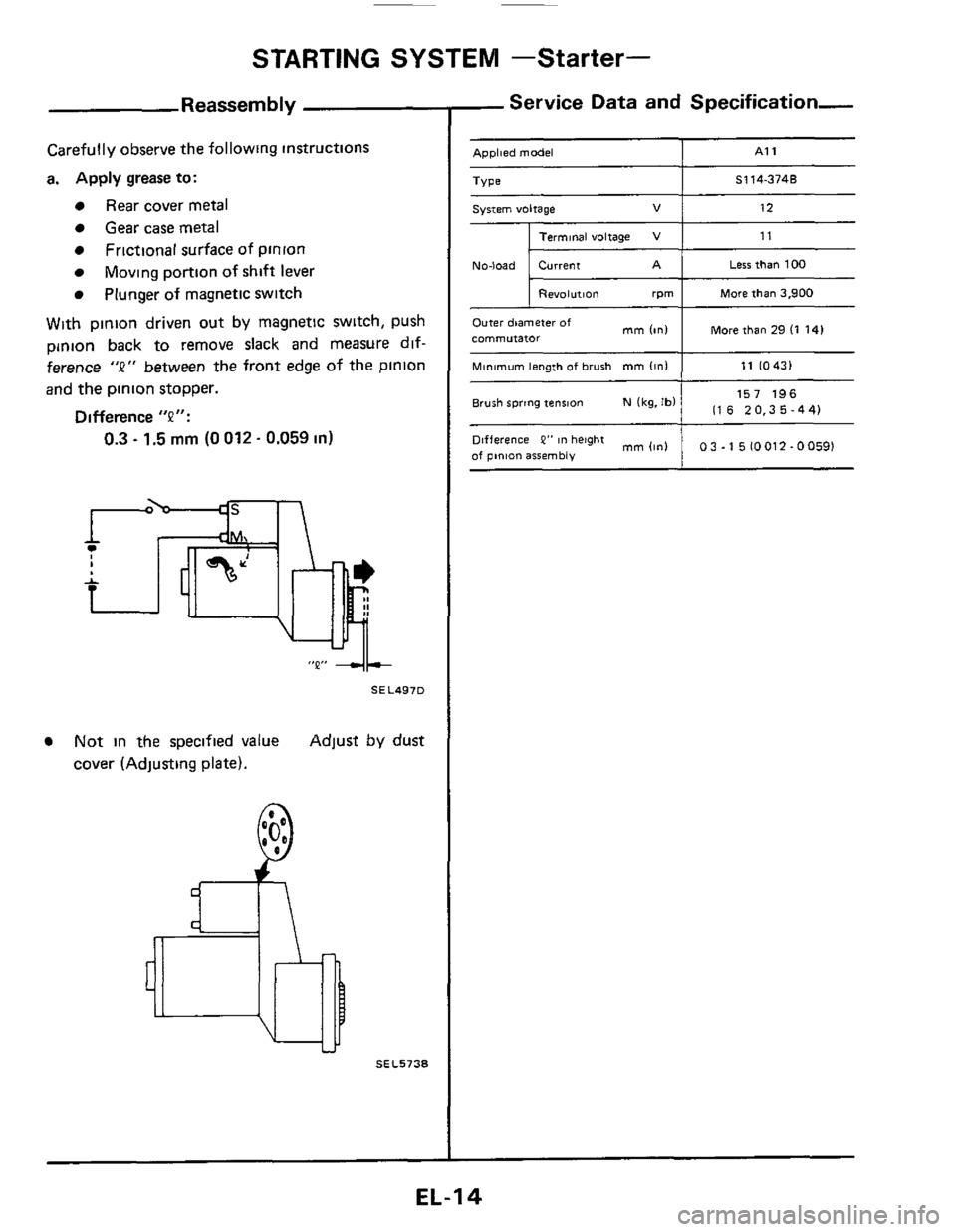

STARTING SYSTEM -Starter-

Minimum length of brush mm (In)

Reassembly

11 10431

Carefully observe the following instructions

a. Apply grease

to:

Rear cover metal

Gear case metal

Frictional surface of pinion

Plunger of magnetic switch

Moving portion of shift lever

With pinion driven out by magnetic switch, push

pinion back to remove slack and measure dif-

ference

"2" between the front edge of the pinion

and the pinion stopper.

Difference "P":

0.3 - 1.5 mm (0 012. 0.059 in)

"Q" 4+

SEL497D

Not in the specified value Adjust by dust

cover (Adjusting plate).

SEL5738

- Service Data and Specification-

- Applied model I A1 1

Less than 100 -

I Revolution rpm I Mare than 3.900

I More than 29 (1 141 Outer diameter of commutator mm (in1

157 196

1 116 20.35-44) Brush spring tension N (kg. Ibl

mm(in1 1 03-1510012-00591 Difference P" in height

of pinion assembly

EL-I 4

Page 16 of 116

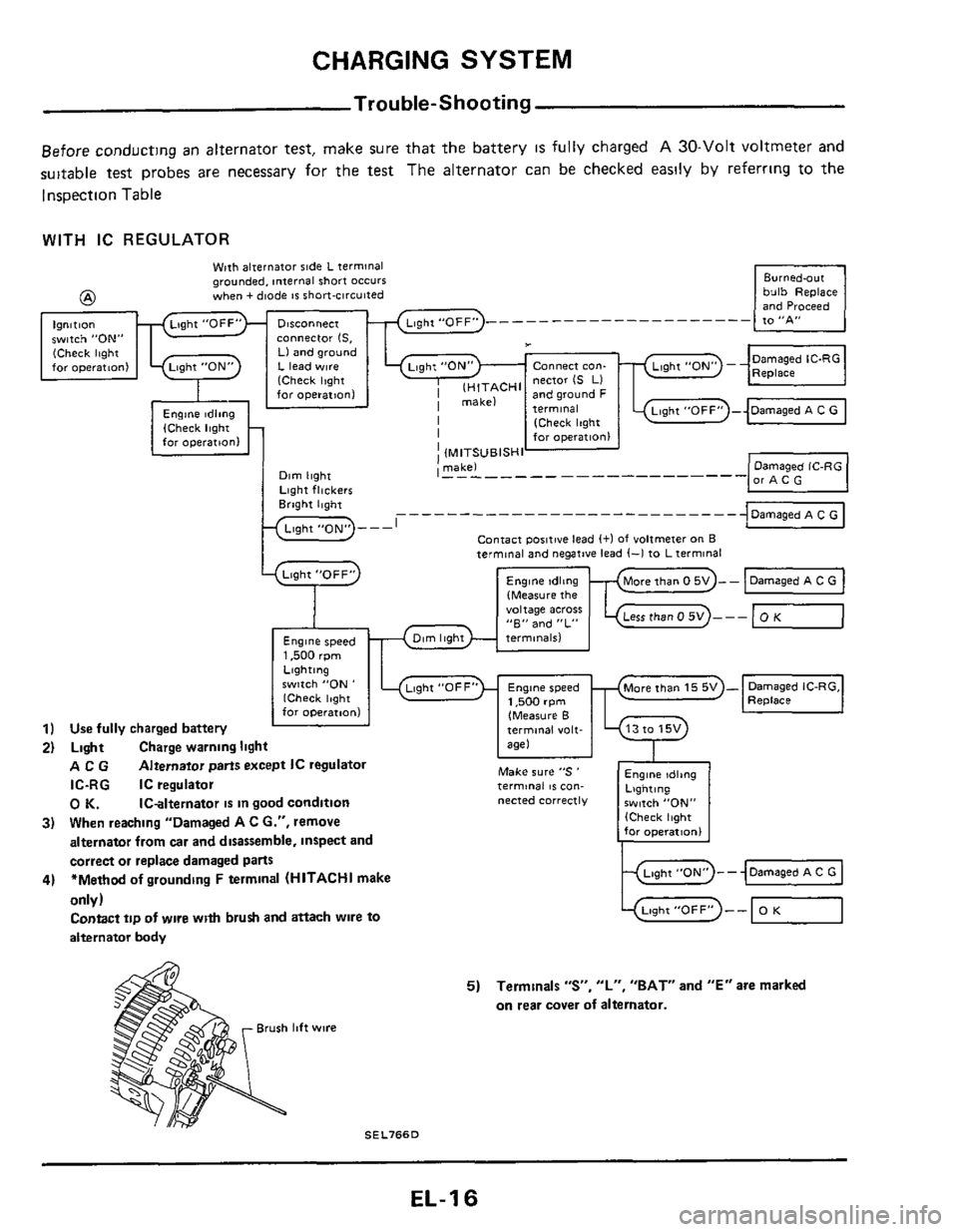

CHARGING SYSTEM

Make sure "S ' termmal 8s con- IC-RG IC regulator

When reaching "Damaged

A C G.", remove

0 K. IC-alternator 16 In good condltlon nected COrreCtly

Trouble-Shooting

Before conducting an alternator test, make sure that the battery IS fully charged A 30-Volt voltmeter and

suitable test probes are necessary for the test The alternator can

be checked easily by referrmg to the

Inspection Table

Engine tdltng Lighting $witch "ON,, (Check light for operatlonl

WITH IC REGULATOR

bulb Replace and Proceed -

Wpth alternator side L terminal grounded, internal short occurs when + diode IS short-circuited @

Ignition witch "ON" cOnneCtor IS. (Check light Ll and ground for operatton1 L lead w~re Connect con-

I lH,TACHl nector IS LI far operation1 and ground F

I [Check Itght I for operation1

I (MITSUBISHI ' makel I - - - - - - - - - - - - -------- -

J

..........................

Contact poiitwe lead (+I of voltmeter on B

Lqht "OFF"

9

Engine speed 1,500 rpm

terminal and negative lead (-1 to L terminal

(Measure the "oltage acres "E" and "L"

only)

Contact tip of wlre with brush and attach wire to

alternator body -0 Light"0FF" -- OK

5) Terminals "S", "L", "BAT" and "E" are marked

on rear cover

of alternator.

Brush lift wire

SEL766D

EL-1 6

Page 18 of 116

____ ____

CHARGING SYSTEM -Alternator-

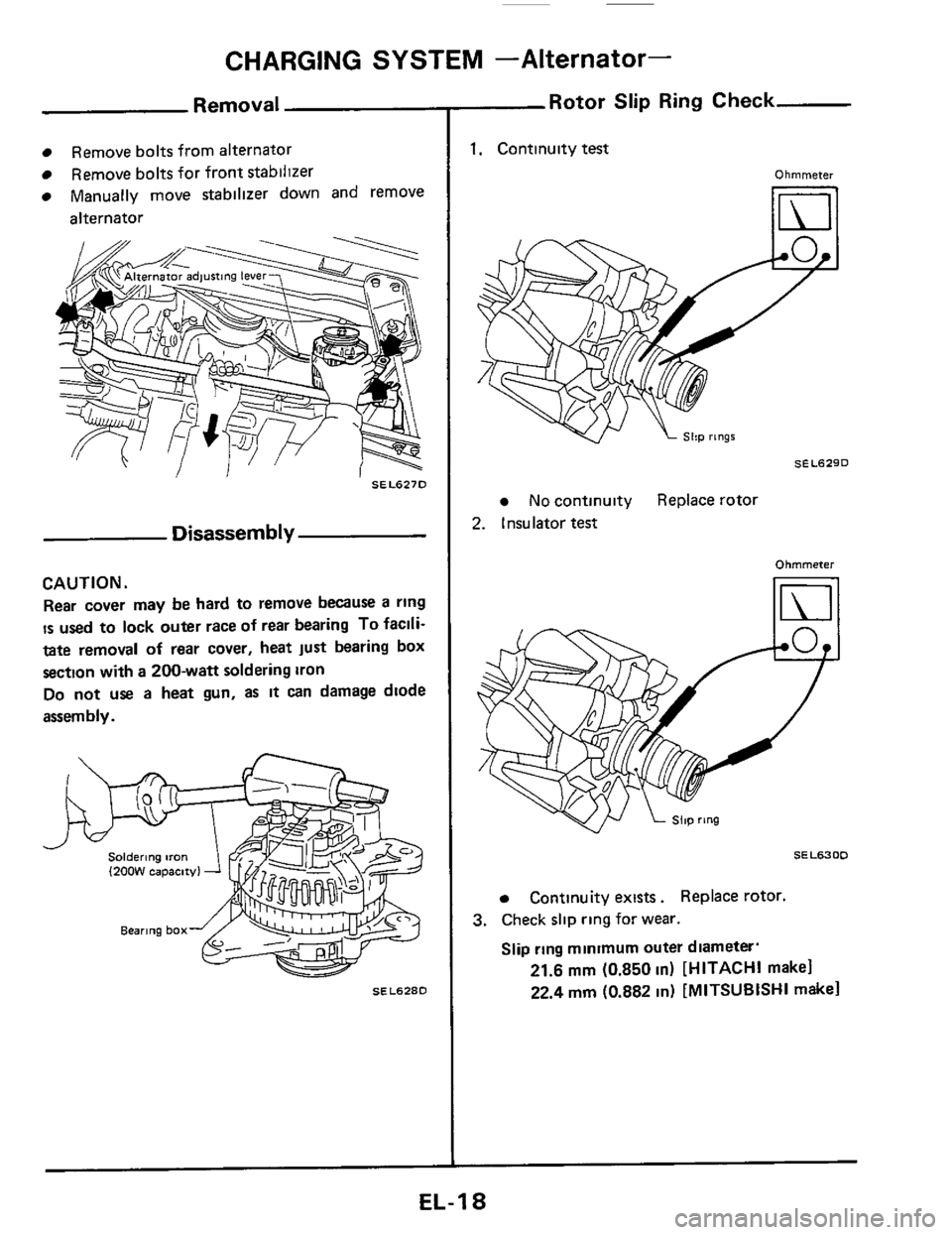

Removal

Remove bolts from alternator

Remove bolts for front stabilizer

Manually

move stabilizer down and remove

alternator

SEL627D

Disassembly

CAUTION.

Rear cover may be hard to remove because a ring

IS used to lock outer race of rear bearing To facili-

tate removal of rear cover, heat just bearing box

section with

a 200-wan soldering iron

Do not use a heat gun, as it can damage diode

assembly.

SEL628D

Rotor Slip Ring Check

1. Continuity test

Ohmmeter

SEL629D

No continuity Replace rotor

2. Insulator test

Ohmmeter

IWI

SEL630D

Continuity exists. Replace rotor.

3. Check slip ring for wear.

Slip ring minimum outer diameter.

21.6 mm (0.850 in) [HITACHI makel

22.4

mm (0.882 in) [MITSUBISHI makel

EL-I 8

Page 20 of 116

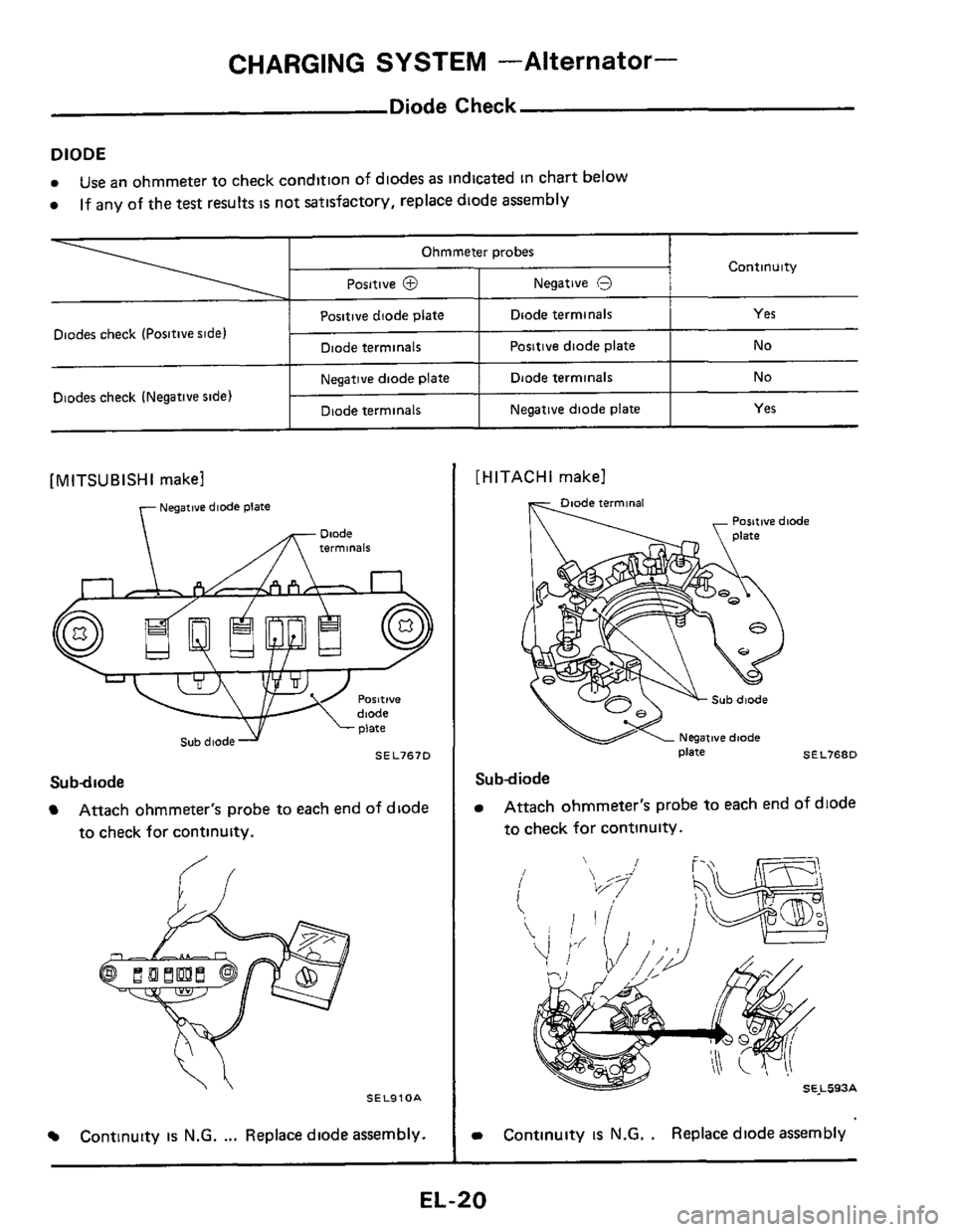

CHARGING SYSTEM -Alternator-

Ohmmeter probes

~ositive 0 Negative 8

Positive diode plate Diode terminals

Diode terminals Positive diode plate

Negative diode plate Diode terminals

Diode terminals Negative diode plate

Diodes check (Positive side)

Diodes check (Negative side)

Diode Check

Continuity

Yes

No

No

Yes

[ MlTSUBlSHl makel

Negatwe diode plate

piate

SEL767D Sub dlode

Subdiode

Attach ohmmeter's probe to each end of diode

to check for continuity.

SEL910A

Continuity is N.G. ... Replace diode assembly.

[HITACHI makel

SEL768D

Subdiode

Attach ohmmeter's probe to each end of diode

to check for continulty.

Continuity is N.G. . Replace diode assembly

EL-20