NISSAN 300ZX 1984 Z31 Front Suspension User Guide

Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 24, PDF Size: 0.68 MB

Page 11 of 24

TENSION ROD AND STABILIZER BAR

Removal and Installation

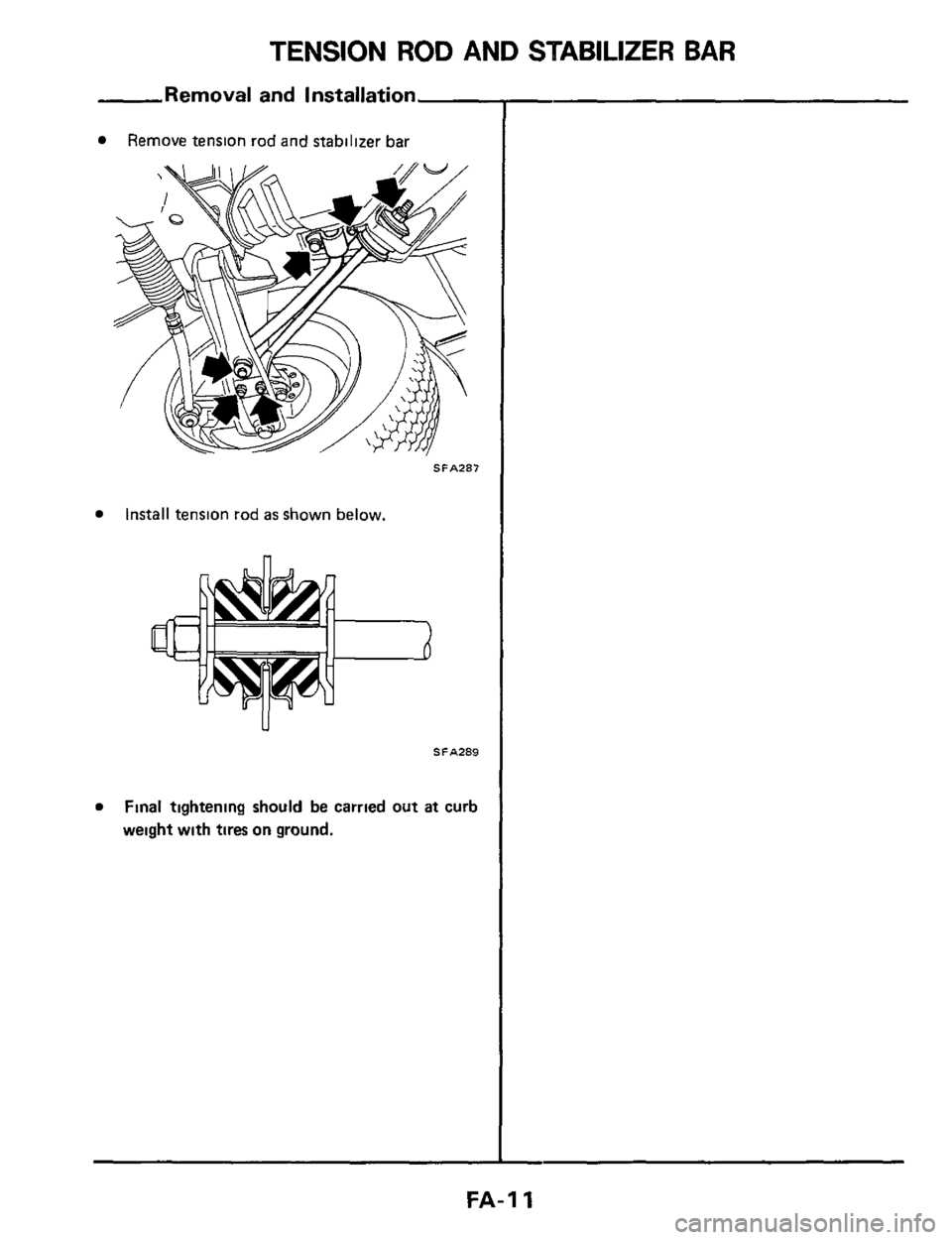

Remove tension rod and stabilizer bar

SFA287

Install tension rod as shown below.

SFA289

Final tightening should be carried out at curb

weight with tires on ground.

FA-I 1

Page 12 of 24

TRANSVERSE LINK AND LOWER BALL JOINT

Removal ar

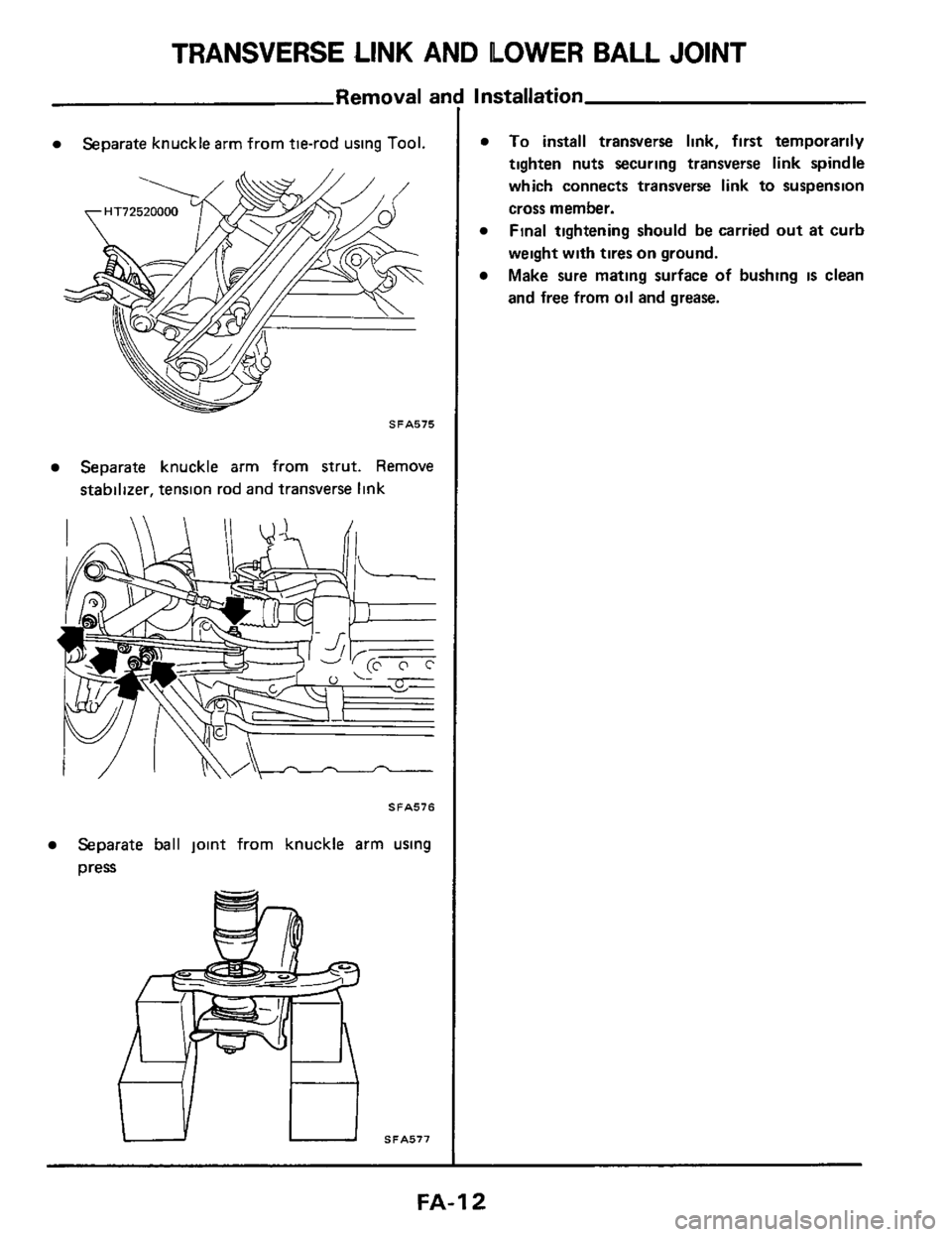

Separate knuckle arm from tie-rod using Tool.

SFA575

Separate knuckle arm from strut. Remove

stabilizer, tension rod and transverse link

SFA576

Separate ball joint from knuckle arm using

press

SFA577

Installation

To install transverse link, first temporarily

tighten nuts securing transverse

link spindle

which connects transverse

link to suspension

cross member.

Final tightening should be carried out at curb

weight with tires

on ground.

Make sure mating surface of bushing

is clean

and free from oil and grease.

FA-I 2

Page 13 of 24

TRANSVERSE LINK AND LOWER BALL JOINT

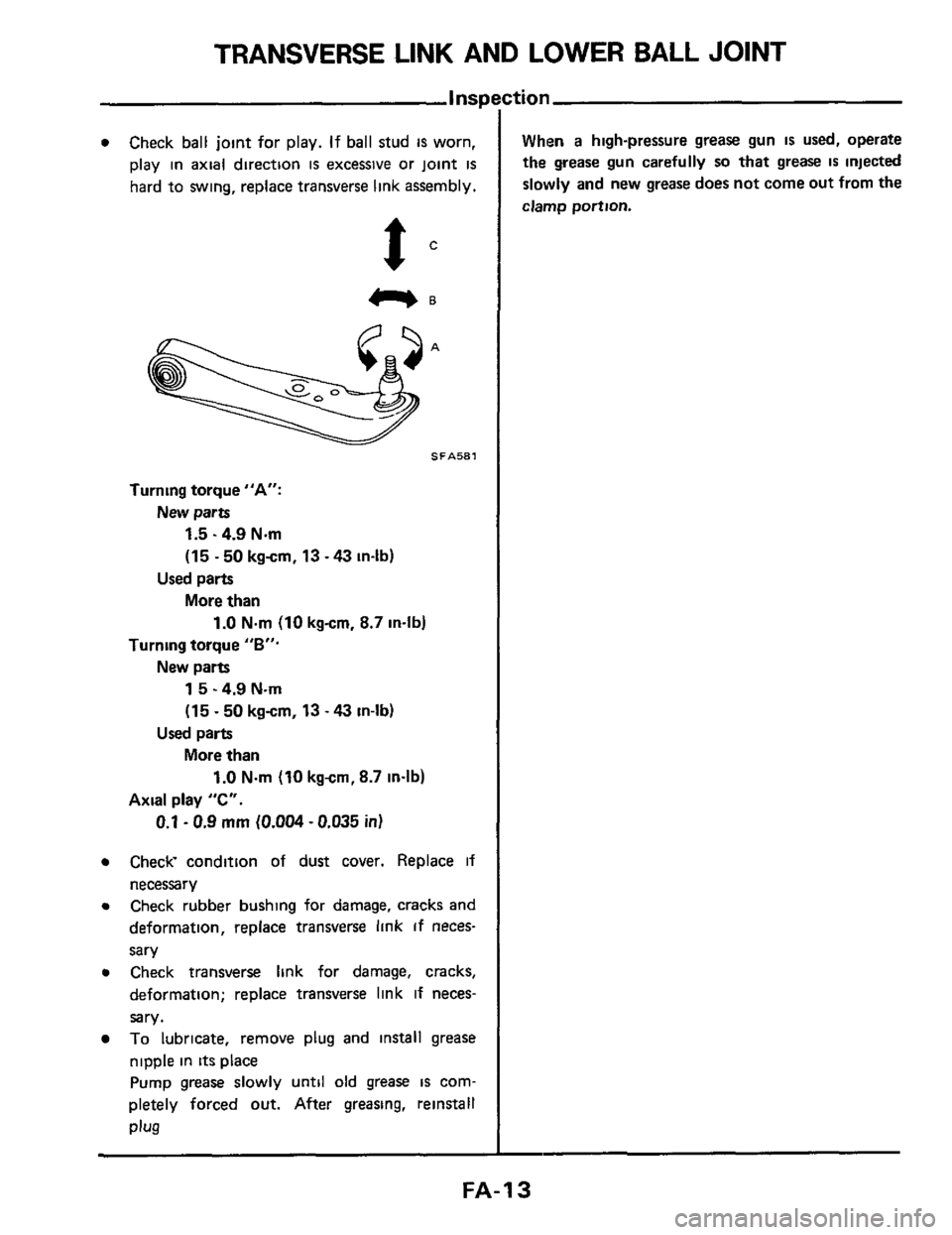

0 Check ball joint for play. If ball stud IS worn,

play in axial direction

is excessive or joint is

hard to swing, replace transverse link assembly.

e 2.

Turning torque "A:

1.5.4.9 Nm

(15

- 50 kgcm, 13 - 43 in-lb)

More

than

New parts

Used parts

1.0 Nm (10 kgcm. 8.7 in-11~.

Turning torque "B".

1 5 - 4.9 N.m

(15

~ 50 kgcm, 13 - 43 in-lb)

More

than

New parts

Used parts

1.0 N.m (10 kgcm, 8.7 in-lb)

Axial play "C".

0.1 - 0.9 mm (0.004 - 0.035 in)

0 Check condition of dust cover. Replace if

necessary

0 Check rubber bushing for damage, cracks and

deformation, replace transverse link If neces-

sary

0 Check transverse link for damage, cracks,

deformation; replace transverse link if neces-

sary.

To lubricate, remove plug and install grease

nipple in

its place

Pump

grease slowly until old grease is com-

pletely forced out. After greasing, reinstall

Plug

:tion

When a high-pressure grease gun IS used, operate

the grease gun carefully so that grease IS injected

slowly and new grease

does not come out from the

clamp portion.

FA-I 3

Page 14 of 24

SUSPENSION CROSSMEMBER

Removal and Installation

Precaution

Support engine weight to remove

load from engine

mounting.

Inspection

Check suspension crossmember for deformation or

cracking. Replace

if necessary.

FA-I 4

Page 15 of 24

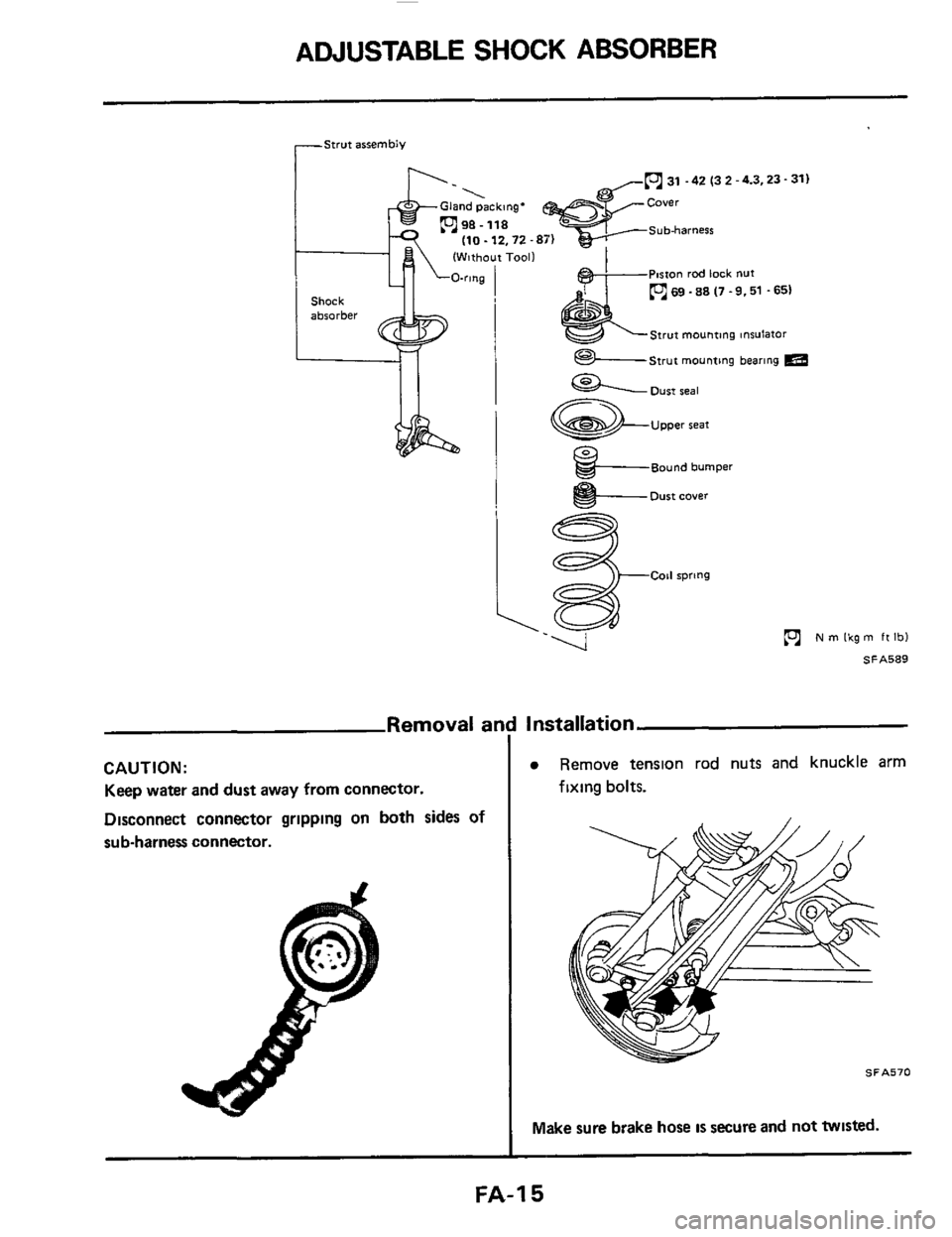

ADJUSTABLE SHOCK ABSORBER

rStwt assembly

31 -42 (3 2 -4.3,23- 31)

(Without Tool1

P~rton rod lock nut

69 .88 (7 .9.51 .651

Strut mounting tnsulator

Strut mounting bearing m

31 -42 (3 2 -4.3.23- 31)

Strut mounting tnsulator

im

Shock

absorber

Oust seal

Upper seat

Bound bumper

I e- Dust cover

ie

N m Ikg m ft Ibl

SA589

Removal ar

CAUTION:

Keep water and dust away from connector.

Disconnect connector grlpplng

on both sides of

sub-harness connector.

Installation

Remove tenslon rod nuts and knuckle arm

fixing bolts.

SFA570

Make sure brake hose IS secure and not twisted.

FA-I 5

Page 16 of 24

ADJUSTABLE SHOCK ABSORBER

-Removal and Installation (Cont'dL

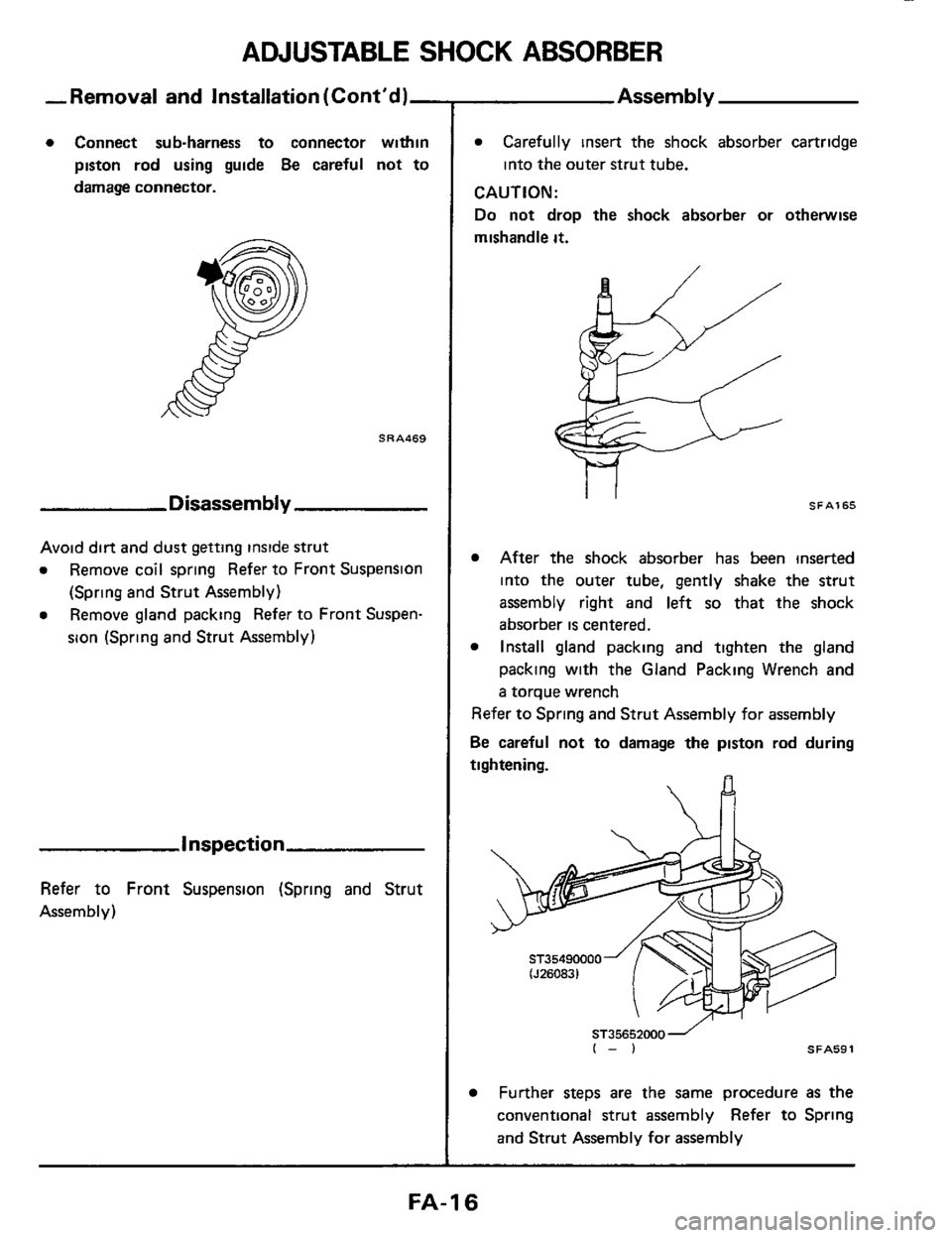

0 Connect sub-harness to connector within

piston rod using guide

Be careful not to

damage connector.

SRA469

Disassembly

Avoid dirt and dust getting inside strut

0 Remove coil spring Refer to Front Suspension

0 Remove gland packing Refer to Front Suspen-

(Spring and Strut Assembly)

sion (Spring and Strut Assembly)

Inspection

Refer to Front Suspension (Spring and Strut

Assembly)

0 Carefully insert the shock absorber cartridge

into the outer strut tube.

CAUTION:

Do not drop the shock absorber or otherwise

mishandle

it.

SFA165

After the shock absorber has been inserted

into the outer tube, gently shake the strut

assembly right and left

so that the shock

absorber

is centered.

Install gland packing and tighten the gland

packing with the Gland Packing Wrench and

a torque wrench

Refer to Spring and Strut Assembly for assembly

Be careful not to damage the piston rod during

tightening.

ST35652000- I-) SFA591

Further steps are the same procedure as the

conventional strut assembly Refer to Spring

and Strut Assembly for assembly

FA-I 6

Page 17 of 24

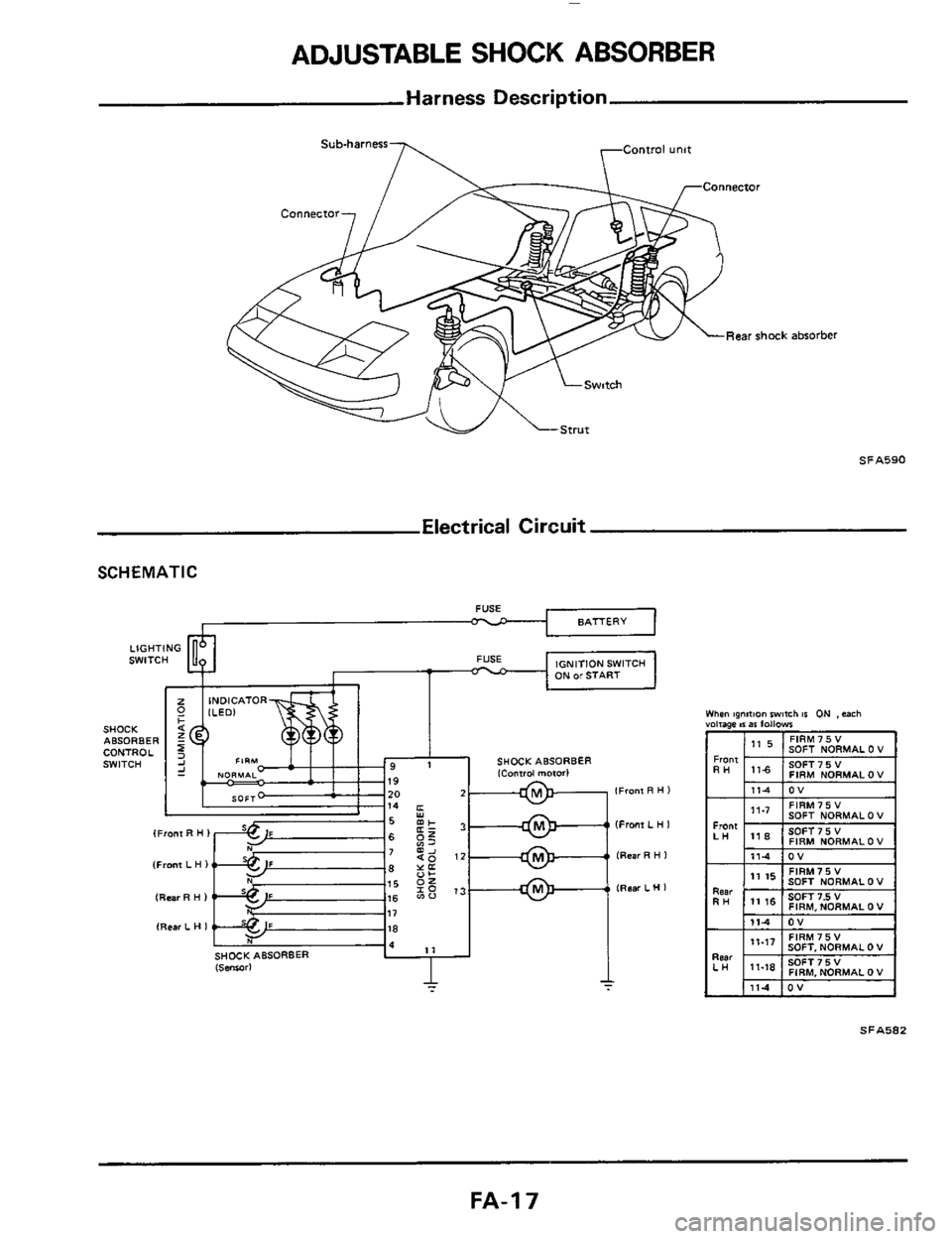

ADJUSTABLE SHOCK ABSORBER

Harness Description

Sub-harness

Rear shock absorber

SFA590

Electrical Circuit

SCHEMATIC

I I l,* I"" I

SOFT NORMAL 0 V

SOFT 7 5 V FIRM NORMAL 0 V

I 111-4 IOV I

SFAS82

FA-I 7

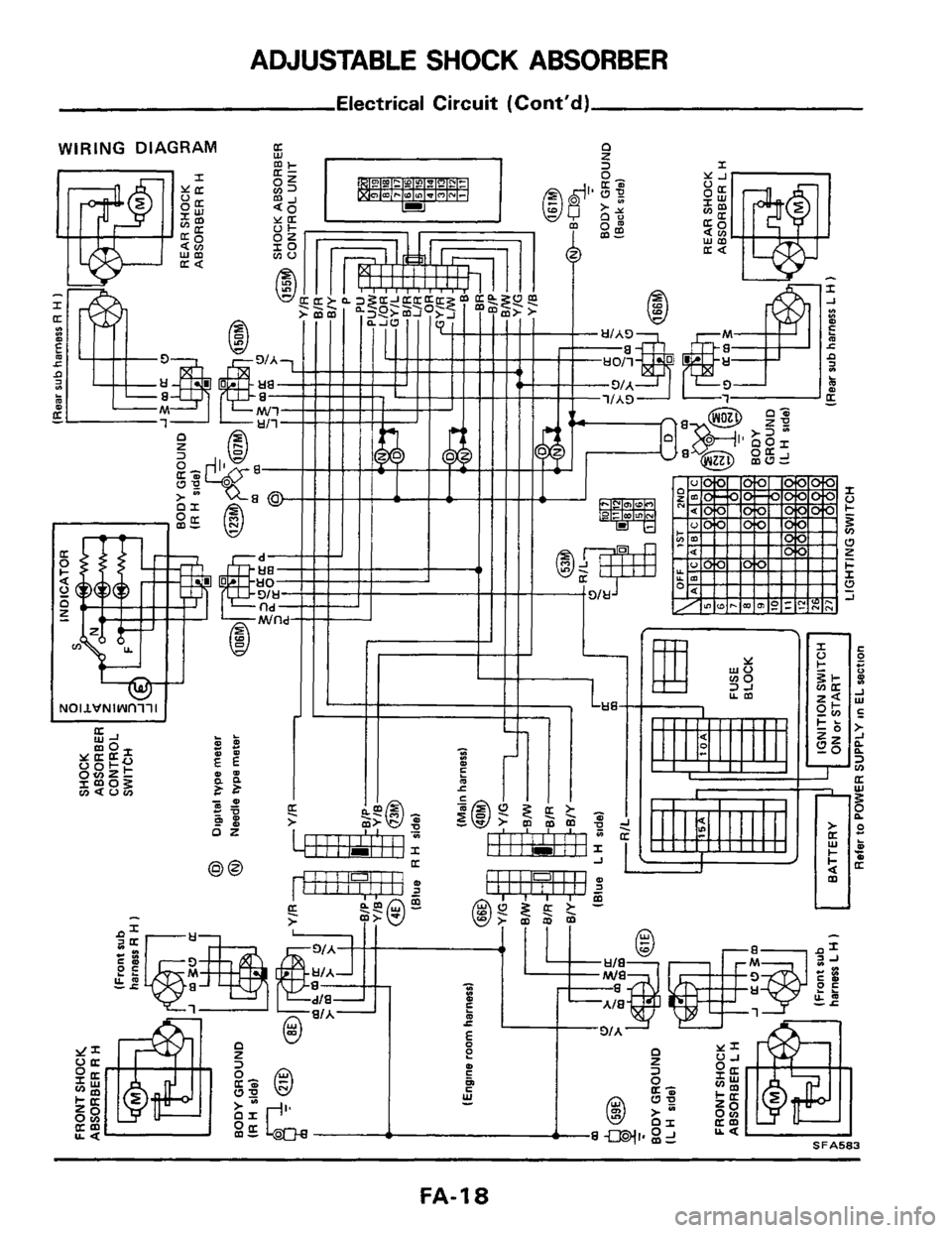

Page 18 of 24

I I

FA-I 8

Page 19 of 24

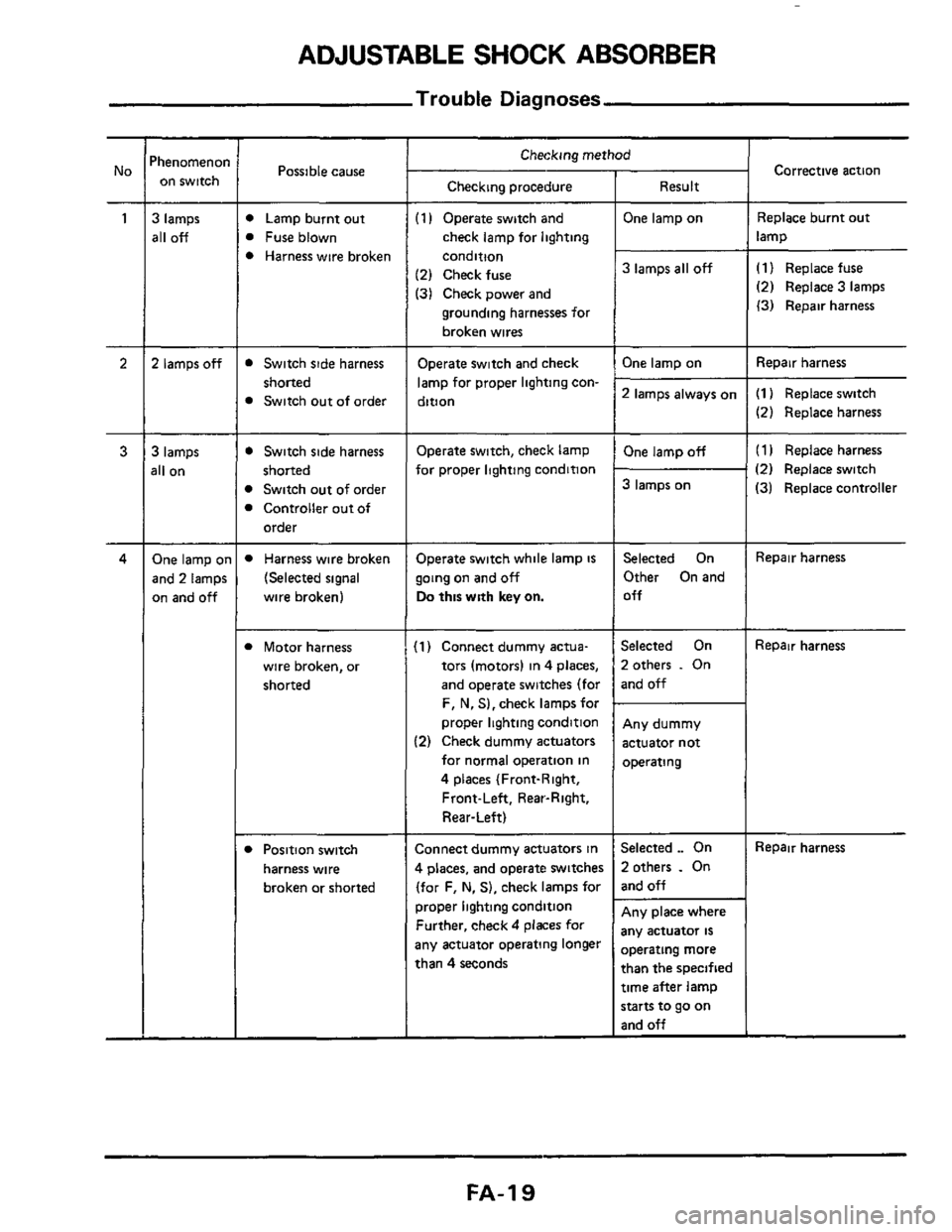

ADJUSTABLE SHOCK ABSORBER

Trouble Diagnoses

Possible cause

D Lamp burnt out

B Fuse blown

B Harness wire broken

Checking procedure

(1 I Operate switch and

check lamp for lighting

condition

(2) Check fuse

(31 Check power and

grounding harnesses for

broken wires ~~~~~~

Switch

side harness

shorted

Switch out of order

D Switch side harness

B Switch out of order

B Controller out of

shorted

order

Operate switch and check

lamp for proper lighting con-

dition

Operate switch, check lamp

for proper lighting condition

D Harness wire broken

(Selected signal

wire broken)

Operate switch while lamp is

going on and off

Do this with key on.

Corrective action

I Checking method 'henomenoi

on switch

3 lamps

all off

2 lamps off

Result

One lamp on

Replace burnt out

lamp

3 lamps all off (1) Replace fuse

(2) Replace 3 lamps

(3) Repair harness ~~

Repair

harness One lamp on

2 lamps always on (1) Replace switch

(2) Replace harness

(1 I Replace harness

(2) Replace switch

(31 Replace controller

3 lamps

311 on

One lamp off

3 lamps on

One lamp 01

and 2 lamps

on and

off

Selected On

Other On and

Off Repair harness

B Motor harness

wire broken, or

shorted

(1) Connect dummy actua-

tors (motors) in 4 places,

and operate switches (for

F, N, S),check lampsfor

proper lighting condition

(2) Check dummy actuators

for normal operation in

4 places (Front-Right,

Front-Left, Rear-Right,

Rear-Left)

Selected On

2otherr

. On

and off

Repair harness

Any dummy

actuator not

operating ~ ~~

Connect

dummy actuators in

4 places, and operate switches

(for F,

N. S), check lamps for

proper lighting condition

Further, check

4 places for

any actuator operating longer

than

4 seconds

Selected ._ On

2 others . On

and off

Repair harness D Position switch

harness wire

broken or shorted

Any place where

any actuator

is

Dperating more

than the specified

time after lamp

starts to go on

and off

FA-I 9

Page 20 of 24

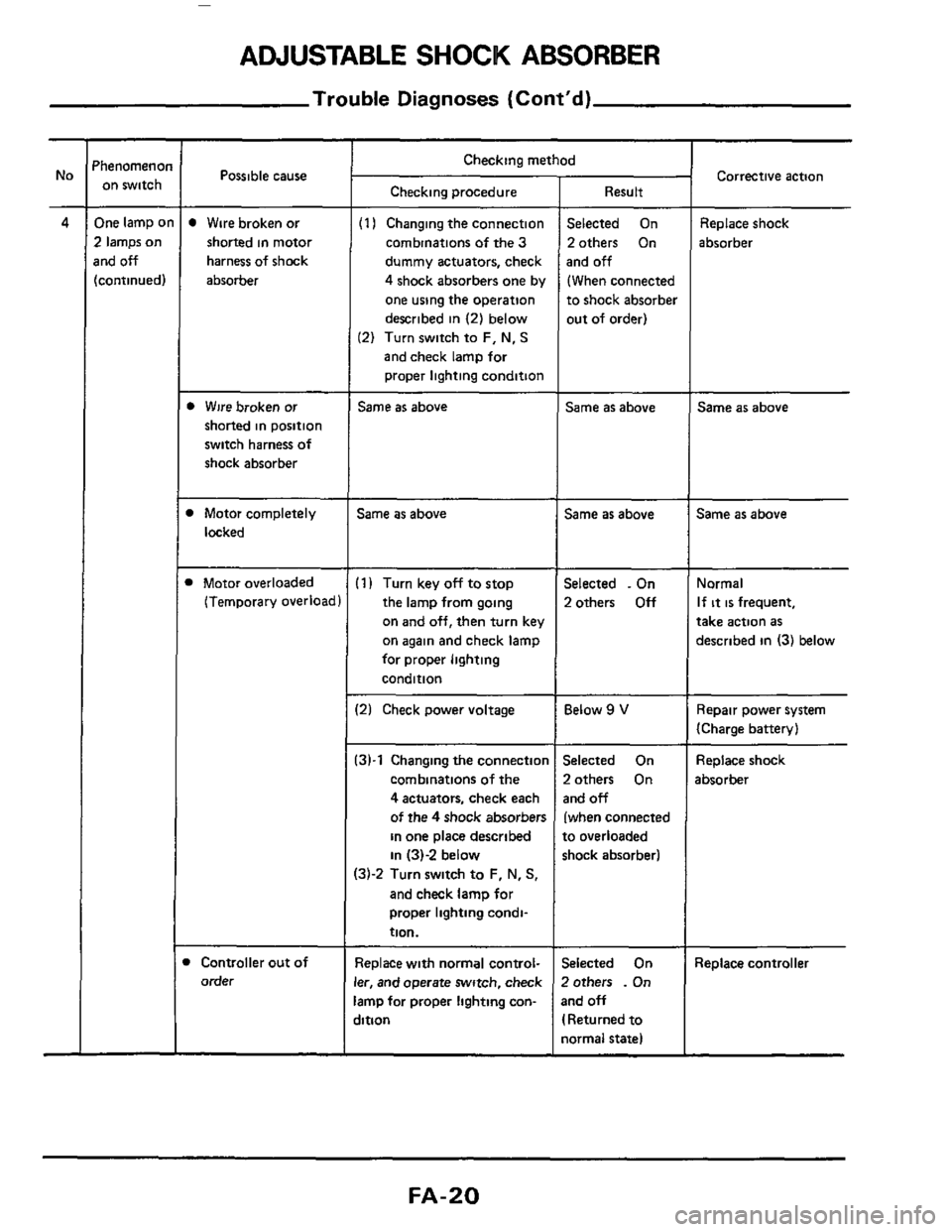

ADJUSTABLE SHOCK ABSORBER

Trouble Diagnoses (Cont'd)

'henomenoi on switch

One lamp o

2 lamps on

rnd off

[continued)

Possible cause ~

Wire

broken or

shorted in motor

harness of shock

absorber

b Wire broken or

shorted in position

switch harness of

shock absorber

1 Motor completely

locked

1 Motor overloaded

(Temporary overload

Controller out of

order

Checking method

Checking procedure

(1 I Changing the connection

combinations

of the 3

dummy actuators, check

4 shock absorbers one by

one using the operation

described

in (2) below

(2) Turn switch to F, N, S

and check lamp for

proper lighting condition

Same as above

Same as above

(1) Turn key off to stop

the lamp from going

on

and off, then turn key

on again and check lamp

for proper lighting

condition

12) Check power voltage

:3)-1 Changing the connectior

combinations of the

4 actuators, check each

of the

4 shock absorbers

in one place described

in 131-2 below

13j-2 Turn switch to F, N, S,

and check lamp for

proper lighting condi-

tion.

Replace with normal control-

er, and operate switch, check

amp for proper lighting con-

jition

Result

Selected On

2others On

and

off

(When connected

to shock absorber

out of order)

Same as above

Same as above

Selected . On

2others

Off

Below 9 V

Selected On

2others On

and off

(when connected

to overloaded

shock absorber1

jelected On

Zothers

. On

3nd off

I Returned to

iormal state)

Corrective action

Replace shock

absorber

Same as above

Same as above

Normal

If it is frequent,

take action as

described in (3) below

Repair power system

(Charge battery)

Replace shock

absorber

Replace controller

FA-20