lock NISSAN 300ZX 1984 Z31 Front Suspension Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 24, PDF Size: 0.68 MB

Page 3 of 24

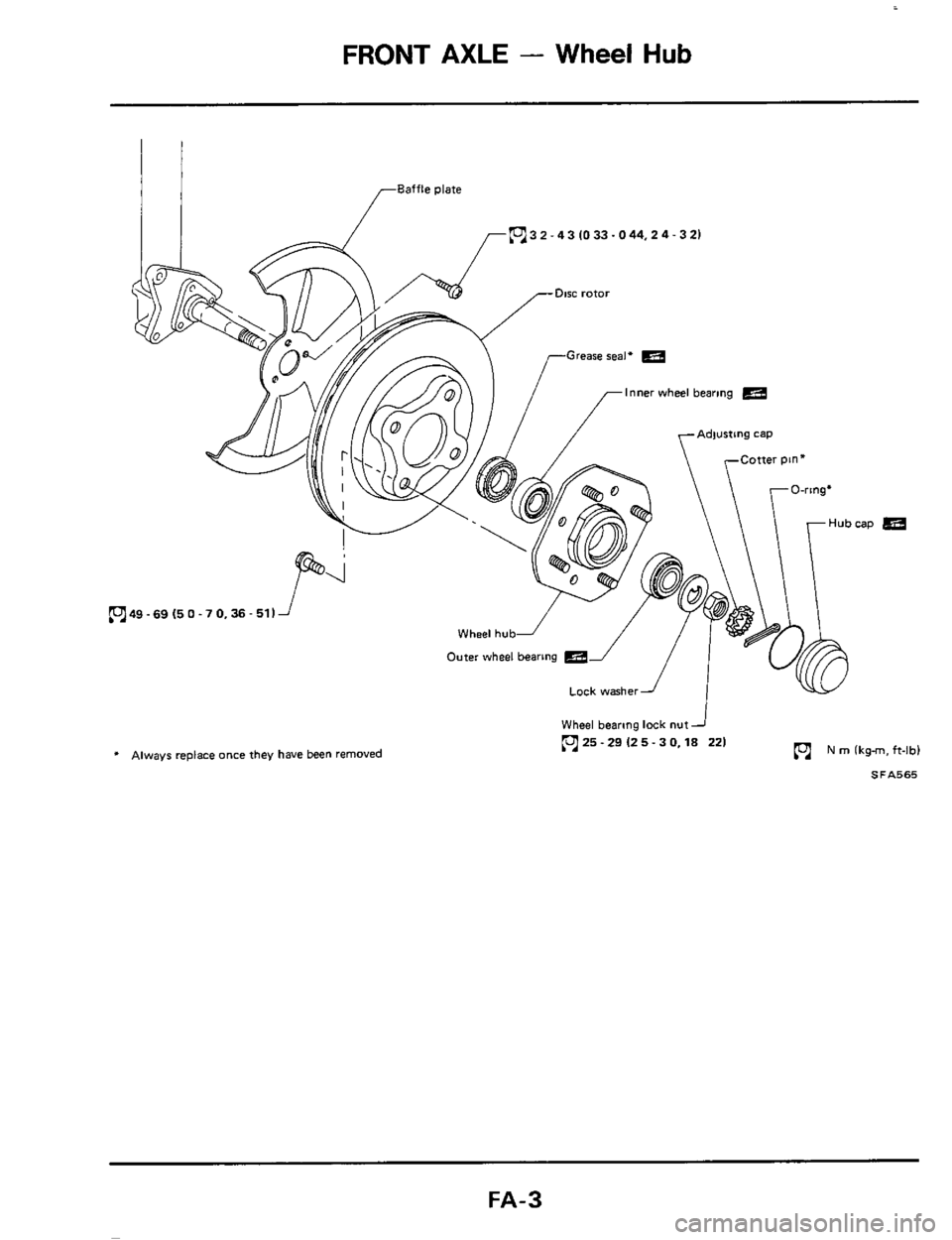

FRONT AXLE - Wheel Hub

Baffle plate

pj3 2 - 4 3 10 33.0 44,2 4 - 3 21

f

-Disc rotor

Inner wheel bearing

yAdwstlng cap

* Always replace once they have been removed N rn (kgm, ft-lb)

J

Lock washeri

Wheel bearing lock nut

25-29 125- 3 0,lS 221

SFA565

FA-3

Page 5 of 24

FRONT AXLE - Wheel Hub

Preload Adjustment

I

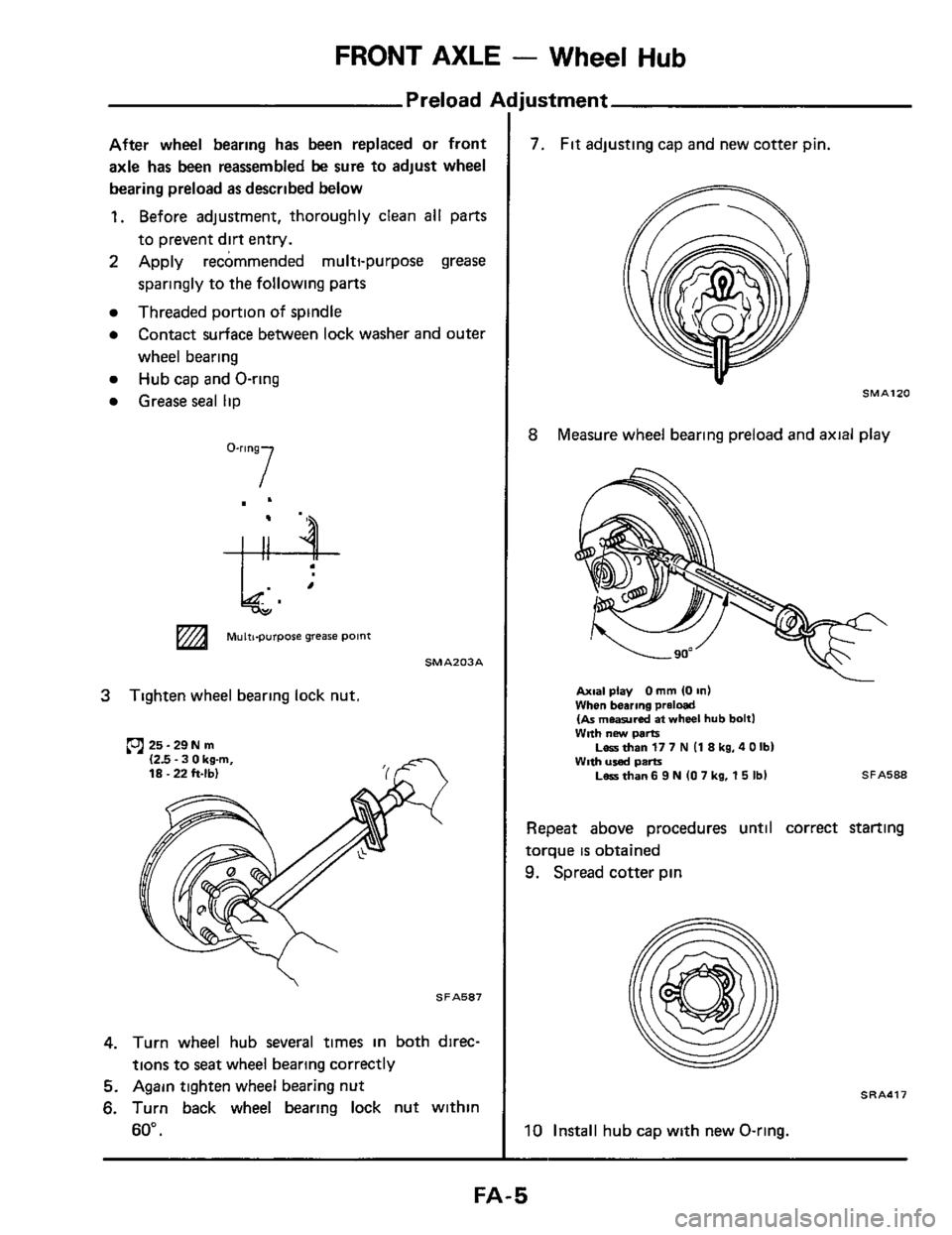

After wheel bearing has been replaced or front

axle

has been reassembled be sure to adjust wheel

bearing preload

as described below

1. Before adjustment, thoroughly clean all parts

to prevent

dirt entry.

2 Apply recommended multi-purpose grease

sparingly to the following parts

Threaded portion of spindle

Contact surface between lock washer and outer

wheel bearing

Hub cap and O-ring

Grease seal lip

O-'lng7

e- "

MulttpUrpOse grease point

SMAZO3A

3 Tighten wheel bearing lock nut,

25- 29N m 12.5 - 3 0 kgm, 18.22 h-lbl

SFAS87

4. Turn wheel hub several times in both direc-

tions to seat wheel bearing correctly

5. Again tighten wheel bearing nut

6. Turn back wheel bearing lock nut within

60".

7. Fit adjusting cap and new cotter pin,

SMAlZO

8 Measure wheel bearing preload and axial play

Axial play 0 mm IO In) When bearing preloal (As meamred at wheel hub bolt1 WRh new parts

With used parts ~errthanv7~ (iakg,aoIbl

Lerrthan6 9N (07 kg. 15 Ibl SFAS88

Repeat above procedures until correct starting

torque

is obtained

9. Spread cotter pin

SRA417

10 Install hub cap with new O-ring.

I

FA- 5

Page 6 of 24

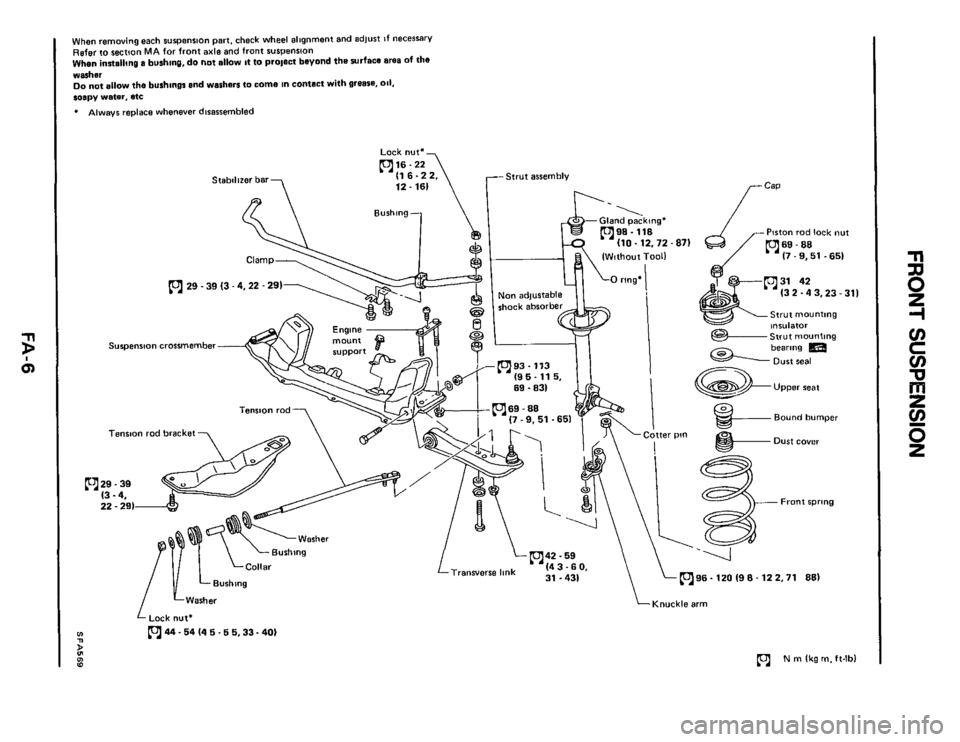

When removing each s~~pension part, check wheel allgnrnent and adlust If necessary

Refer to section MA for front axle and front suspension When innalling a bushing, do not allow It to prolect beyond the surface ares of the

warhsr

Do not allow the bushings and washers to come in conlact with grease. 011. soapy water. etc

* Always replace whenever disassembled

Strut assembly

Piston rad lock nut

(3 2.4 3,23 - 311

Strut mounting

Suspension crossmember

Tension rod bracket

m29-39

(3 - 4. 22.291

m96.120 19 8.12 2.71 881 Transverse link

LWasher

Lock nut*

m44- 54 (4 5.6 5,33- 40) m n

Knuckle arm

(c1 N m (kg m. ft-lbl g 0 10

n

8

z

-I

v)

c

v)

'cl

v)

z

e

5

Page 7 of 24

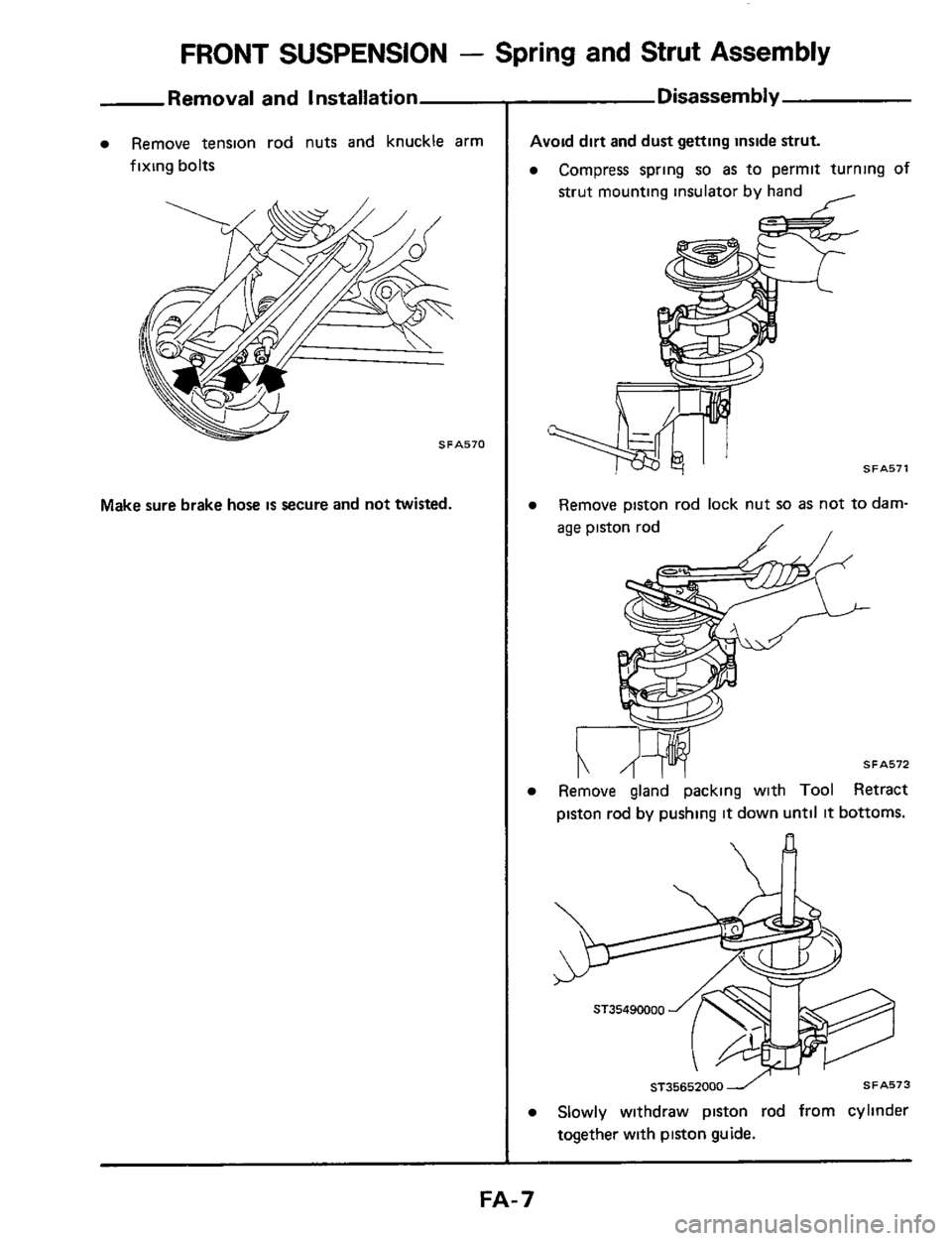

FRONT SUSPENSION - Spring and Strut Assembly

Removal and Installation

Remove tension rod nuts and knuckle arm

fixing bolts

Make sure brake hose is secure and not twisted.

Disassembly

Avoid dirt and dust getting inside strut.

Compress spring so as to permit turning of

strut mounting insulator by hand I

SFA571

Remove piston rod lock nut so as not to darn-

age piston rod / /

Remove gland packing with Tool Retract

piston rod

by pushing it down until it bottoms.

n

ST35652000 1 SFA573

Slowly withdraw piston rod from cylinder

together with piston guide.

FA- 7

Page 15 of 24

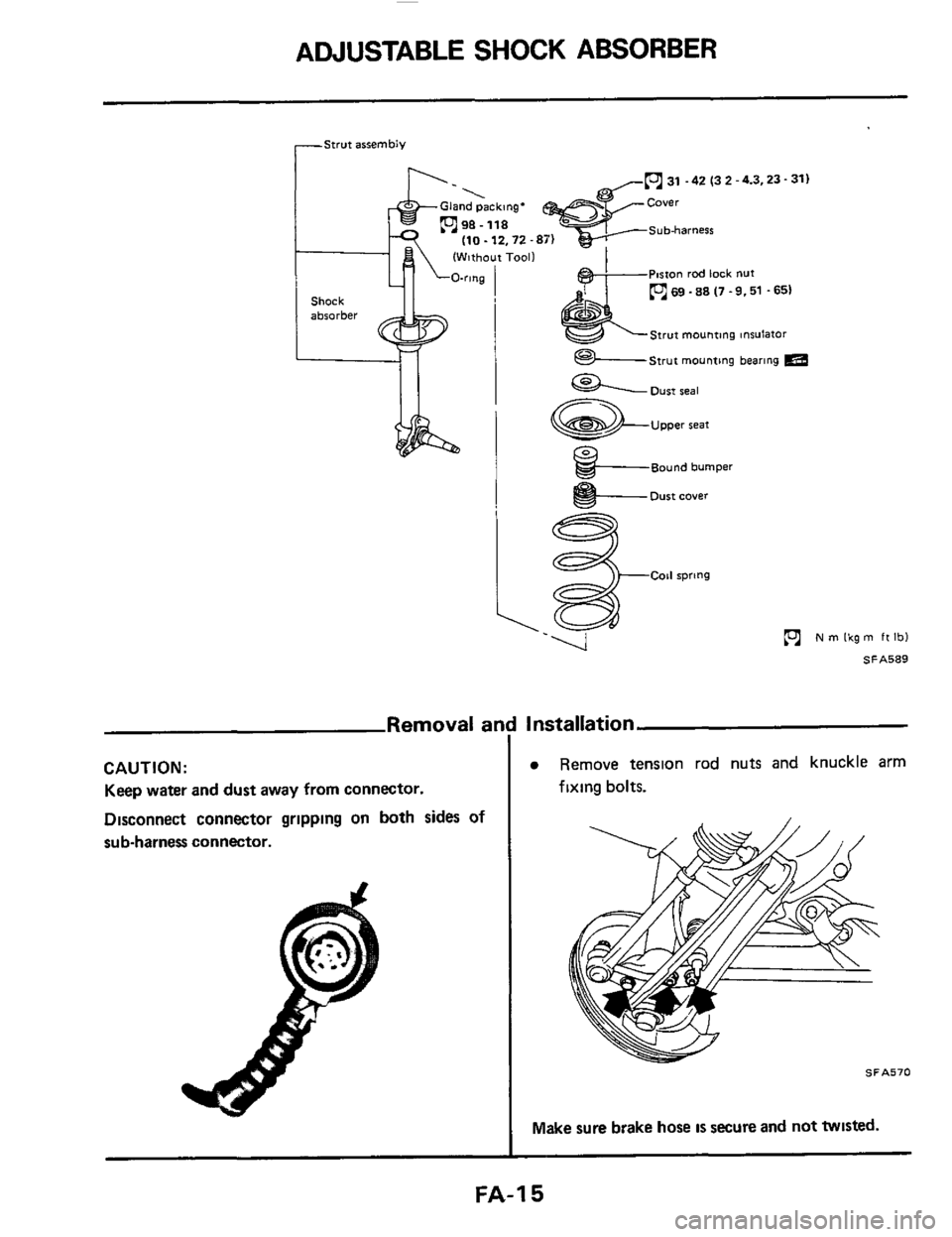

ADJUSTABLE SHOCK ABSORBER

rStwt assembly

31 -42 (3 2 -4.3,23- 31)

(Without Tool1

P~rton rod lock nut

69 .88 (7 .9.51 .651

Strut mounting tnsulator

Strut mounting bearing m

31 -42 (3 2 -4.3.23- 31)

Strut mounting tnsulator

im

Shock

absorber

Oust seal

Upper seat

Bound bumper

I e- Dust cover

ie

N m Ikg m ft Ibl

SA589

Removal ar

CAUTION:

Keep water and dust away from connector.

Disconnect connector grlpplng

on both sides of

sub-harness connector.

Installation

Remove tenslon rod nuts and knuckle arm

fixing bolts.

SFA570

Make sure brake hose IS secure and not twisted.

FA-I 5

Page 20 of 24

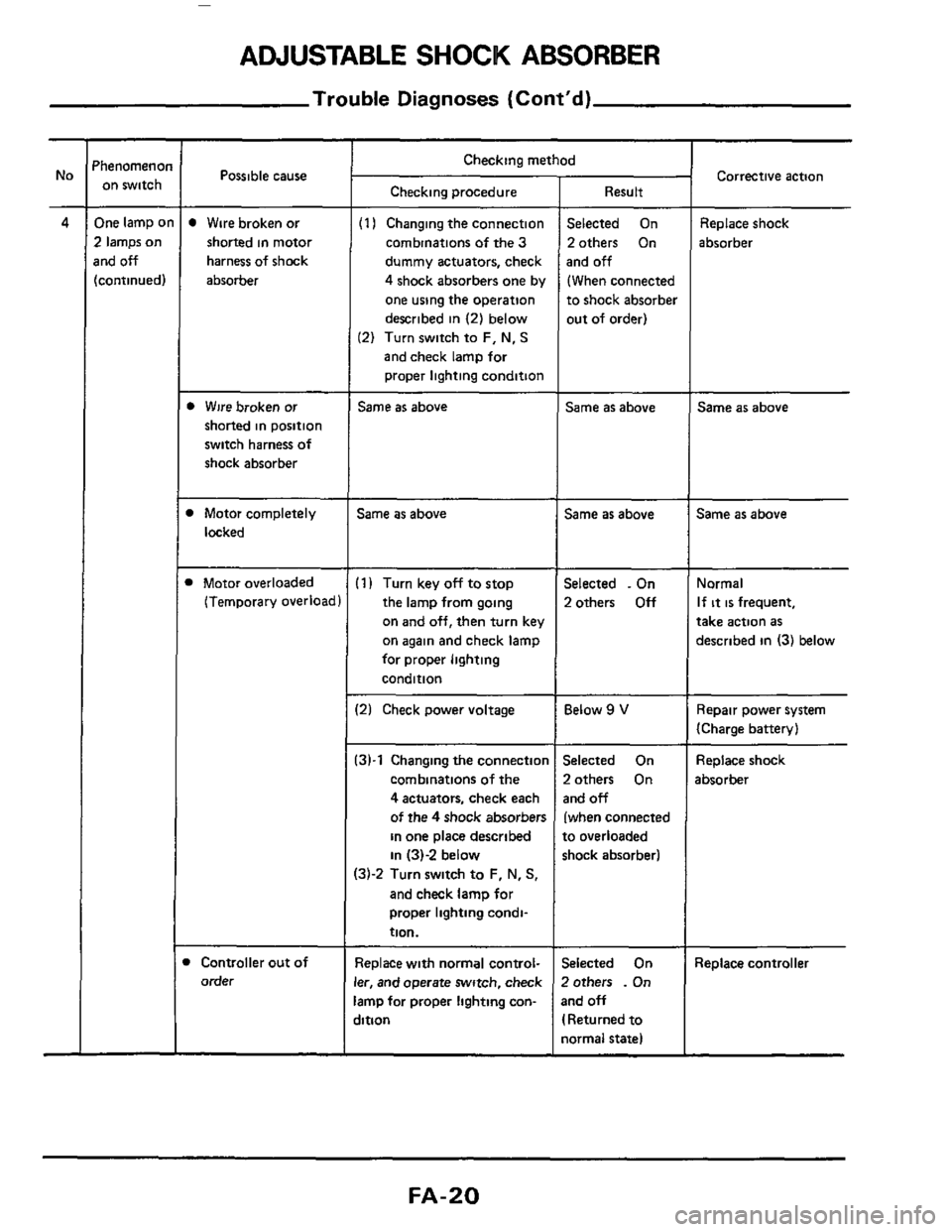

ADJUSTABLE SHOCK ABSORBER

Trouble Diagnoses (Cont'd)

'henomenoi on switch

One lamp o

2 lamps on

rnd off

[continued)

Possible cause ~

Wire

broken or

shorted in motor

harness of shock

absorber

b Wire broken or

shorted in position

switch harness of

shock absorber

1 Motor completely

locked

1 Motor overloaded

(Temporary overload

Controller out of

order

Checking method

Checking procedure

(1 I Changing the connection

combinations

of the 3

dummy actuators, check

4 shock absorbers one by

one using the operation

described

in (2) below

(2) Turn switch to F, N, S

and check lamp for

proper lighting condition

Same as above

Same as above

(1) Turn key off to stop

the lamp from going

on

and off, then turn key

on again and check lamp

for proper lighting

condition

12) Check power voltage

:3)-1 Changing the connectior

combinations of the

4 actuators, check each

of the

4 shock absorbers

in one place described

in 131-2 below

13j-2 Turn switch to F, N, S,

and check lamp for

proper lighting condi-

tion.

Replace with normal control-

er, and operate switch, check

amp for proper lighting con-

jition

Result

Selected On

2others On

and

off

(When connected

to shock absorber

out of order)

Same as above

Same as above

Selected . On

2others

Off

Below 9 V

Selected On

2others On

and off

(when connected

to overloaded

shock absorber1

jelected On

Zothers

. On

3nd off

I Returned to

iormal state)

Corrective action

Replace shock

absorber

Same as above

Same as above

Normal

If it is frequent,

take action as

described in (3) below

Repair power system

(Charge battery)

Replace shock

absorber

Replace controller

FA-20

Page 23 of 24

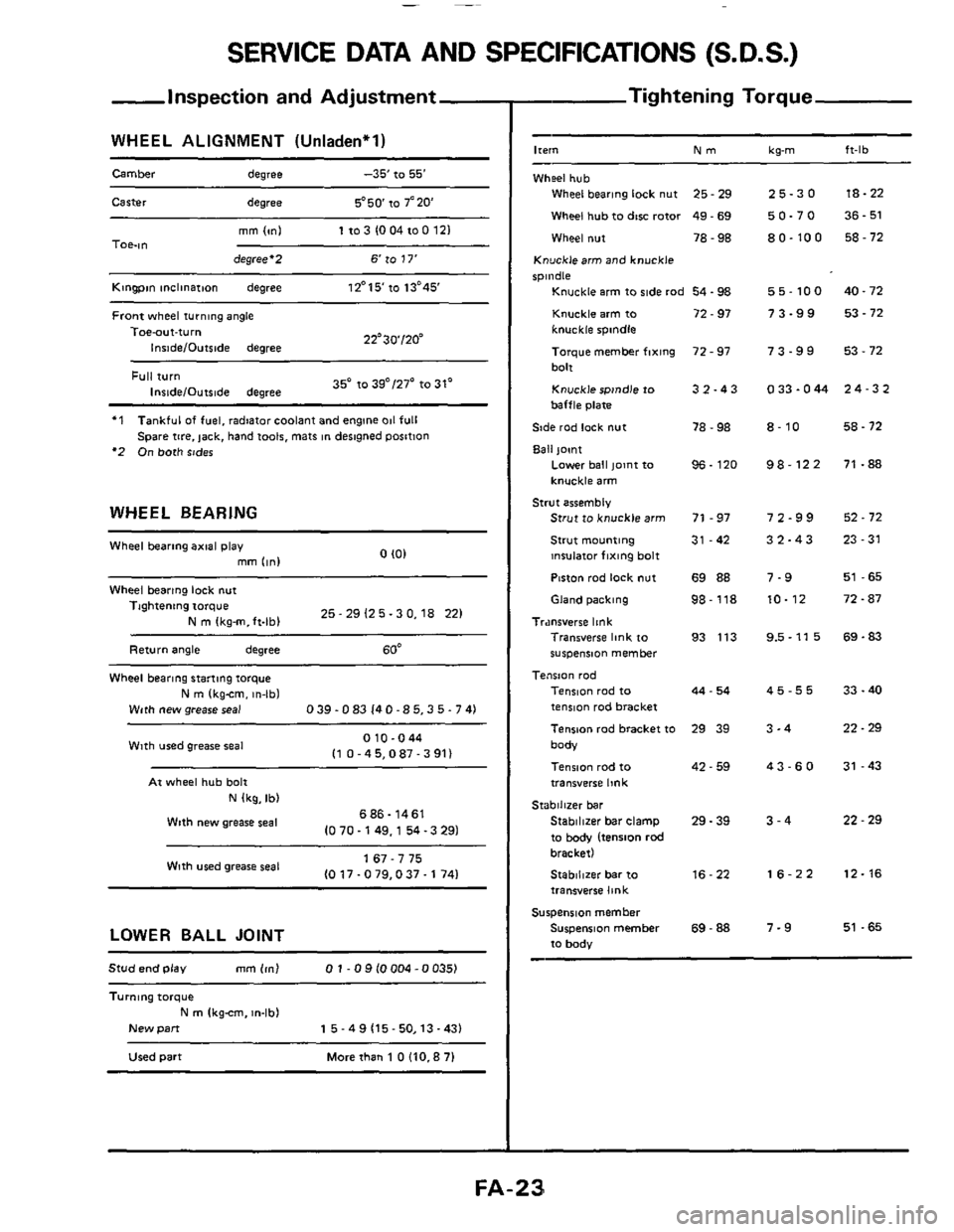

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

-Inspection and Adjustment

WHEEL ALIGNMENT (Unladen'l)

Camber degree -35' to 55'

Carter degree 5'50 to 7'20

mm lml 1103 1004100 121 TOe-ltl degree'2 6 to 17'

Kingpin inclinatmn degree 12'15'10 13'45'

Front wheel turning angle

22'30'120" Toe-aut-turn

Inside/Outslde degree

35' to 39"/27' to 31' Full turn InridelOutslde degree

'1

'2 On both sides

Tankful of fuel, radiator coolant and engine 011 full

Spare

tire. jack, hand t001s. mats in desngned position

WHEEL BEARING

0 I01 Wheel bearing axial play

mm (in1

Wheel bearing lock nut

25 - 29 12 5.3 0,18 221 Tightening torque

N m Ikg-m.ft-lbl

Return angle degree 60'

Wheel bearing stanmg torque

N m (kgcm. in-lbl

With new grease seal 0 39.0 83 14 0 -8 5,3 5.7 41

010-044 I1 0 -45,087 - 3 911 Wlth used grease seal

At wheel hub bolt

N (kg, Ib)

686- 1461

10 70.149,l 54 -3 291 Wtth new grease seal

1 67 - 7 75

10 17.0 79,037.1 741 With wed grease seal

LOWER BALL JOINT

Stud end play mm 1ml 0 1 - 0 9 10004 -0 0351

Turnlng torque

New pan

N m Ikgcm. m-lb)

1 5 - 4 9 (15- 50,13 -431

Used part Morethan 1 OllO.87l

- Tightening Torque

-

Ire," Nm kg-m ft-lb

Wheel hub

Wheel bearing lock nut 25 - 29

Wheel hub to dtw rotor 49 - 69

Wheel nut 78 - 98

Knucklearm and knuckle

spindle

Knuckle arm to ride rod 54.98

Knuckle arm to 72 - 97

knuckle spindle

Toique member fixing

bolt

Knuckle spindle to

baffle plate

Side rod lock

nut

Ball joint

72 - 97

3 2.4 3

78 - 98

Lower ball pint to

knuckle arm

Strut to knuckle arm 71 - 97

Strut mounting 31 -42

insulator fixing bolt

Piston rod

lock nut 69 88

96. 120

Strut assembly

Gland packing 98-118

Tr.mrverre link Transverse link to 93 113

wspeniion member

Tension rod Tension rod to

tenmn rod bracket

Tenson rad bracket

to 29 39

body

Tension rod

to

transverse link

Stabilizer bar clamp 29. 39

to body (tension rod bracket)

Stablllzer bar to 16-22

transverse link

Surpenrlon member

Suspension member

69 - 88

to body

44 - 54

42 - 59

Stabilizer bar

25-30

50-70

80-100

55-100

73-99

73-99

0 33.044

8-10

98-122

72-99

32-43

7-9

10-12

9.5-11 5

45-55

3-4

43-60

3-4

16-22

7-9

18-22

36

- 51

58

- 72

40.72 53

- 72

53 - 72

24-32

58.72

71 -88

52.72

23-31

51 -65

72.87

69.83

33 - 40

22.29

31 -43

22 - 29

12-16

51 -65