tow NISSAN 300ZX 1984 Z31 Manual Transmission Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 34, PDF Size: 1.29 MB

Page 24 of 34

5SPEED TRANSMISSION [Model: BW T-5 (FS5R90A)I

4 Remove shifter shaft through rear

of case cover

5 Slide selector plates from shift

fork assembhes

. __ - - . . I

INSPECTION

1 Clean with solvent and check for

wear, scratches, projections, damage,

breakage

or other faulty conditions

Replace any part whch is worn or

damaged

2 Inspect shft fork inserts for wear

or damage Replace if necessary

ASSEMBLY

I Assemble selector plates to sluft

fork assembhes

2 Install shifter shaft through open-

mg m rear of case cover and assemble

to

1-2 duft fork, mterlock plate,

strkmg lever and

3-4 sluft fork

Install shfter shaft roll pin

to stnkmg

lever

3 Apply a contmuous bead of

sealant to case cover matlng surface

4 Install cover to case

5 Apply sealant to threads and

install two ahgnment dowels into

cover

6 Apply sealant to threads and

install case cover bolts

@ : 8.1 - 14.7 N m

(0.83 - 1.5 kg-m,

6.0 - 10 8 ft-lb)

7 Install rear extension Refer to

rear extension for assembly

TRANSMISSION CASE

DISASSEMBLY

1 Remove rear extenson Refer to

rear extension for disassembly

2 Remove case cover Refer to case

cover for disassembly

3 Remove back-up hght swltch

4 Remove retamer rmg and pivot

Pm

5 Remove funnel, thrust race, and

needle thrust beanng

6 Remove snap nng and thrust

race from rear

of 5th speed synchro-

nuer hub

MT-24

7 Remove pin from 5th speed hft

fork

8 Remove 5th speed shift fork,

synchronizer and counter gear

9 Remove front bearmg retamer

10 Remove mput shaft and mam

drive gear assembly Position flat area

of mam drive gear toward the counter

gear and remove

through the front

of the case

Page 25 of 34

SSPEED TRANSMISSION [Model: BW T-5 (FS5R90A)I

11 Remove mamshaft rear bearmg

race and remove mamshaft assembly

through top of case

I

12 Remove 5th speed shift rad,

reverse fork with 5th and reverse

relay lever, and spnng

13 Remove pm from reverse idler

shaft Remove reverse idler shaft

and gear

14 Rrmove snap nng and spacer

from rear of counter gear beanng

15. Remove counter gear rear beanng

by pressmg counter gear toward rear

of case untd bearmg is free Remove

bearing and spacer from rear of

counter gear

CAUTION:

When pressing out bearing, hold hand

under counter gear

so bearing does not

drop

16 Remove counter gear and front

thrust washer through top of case

11 Press front counter gear beanng

from case

This bearing should not be removed

unless replacement

is necessary.

INSPECTION

1 Clean with solvent and check for

cracks or pits

2 Check mating surfaces of trans-

mission case for small nicks, projec-

tions or sealant

The magnet at the bottom of the caSe

is held in place by a clip and a special

glue.

It should not be removed from

the case.

ASSEMBLY

1 Install front counter gear beanng

as follows

(1) Apply a

small bead of adheslve

agent to outside dlameter of bearmg

(2) Press bearmg into case untd the

front edge

is flush with the front edge

of the case

2 Install the counter gear thrust

washer into the case being sure

to abgn

the tang with the notch

m the case

Retam the washer

m the case with

a light coat of petroleum jelly

MT-25

3 Install the counter gear mto the

case and engage its front journal mto

the front bearmg

-' .".-:;-;' . -

.._. .." .

4 Install the rear counter gear bear-

ing as follows

(1) Install spacer to the rear of

counter gear

(2) Install beanng protector 5-33032

on the counter gear

Page 26 of 34

SSPEED TRANSMISSION [Model: BW T-5 (FS5R90A)I

(3) Install beanng over protector and

press mto case uslng bearmg mstaller

J-29895 When properly mstalled,

the beanng race

WIU protrude from the

case

3 12 to 3 22 mm (0 1228 to

0 1268 in)

(4) Install spacer and snap nng at

rear of beanng

5 Install reverse idler gear mto case

with shft fork groove toward the

rear Install reverse idler shaft, 0-rmg

and retammg pm

6 Install reverse fork with 5th and

reverse relay lever, 5th speed sluft

rad and spnng Install backup hght

switch

7 Instal mamshaft assembly mto the

case and mstall mamshaft rear bear-

mg race.

8 Install roller bearmgs mto the

mam drive gear Retaxn with petro-

leum jelly

9 Install mput shaft and

mam drive

gear assembly, needle thrust bearing,

thrust bearmg race and bloclung ring

into case

Be sure to align the flat arm of the

main drwe gear wlth the countergear

and

install carefully IO as not to dis-

lodge the roller bearings.

10 Remove at least 0 15 mm shuns

(0 0059 in) from under front bearing

race

in bearing retainer Install reman-

ing

shuns and race into retainer

11 Install front bearing retamer to

case

Be sure to position it so that

the

oll collector groove is up

@ : 15 - 27 Nm

(1.5 - 2.8 kg-m,

11-20h-lb)

12 Install 5th speed shift fork, 5th

speed counter gear and synchronuer as

a umt Ahgn

pm holes m duft fork

and

sluft rad and mstall retmmg pm

13 Install thrust race and snap rmg

to rear of 5th speed synchronuer hub

14 Install case cover Refer to case

cover for assembly

15 Install rear extension Refer to

rear extension for assembly

16 Push mput shaft to rear and

mount dial mdicator

so that its stem

rests aganst the front end of the

input shaft Zero indicator

17 Push output shaft forward and

read mdicator Record readmg for

calculation Remove mdicator

.-. ,

18 Remove beanng retamer and bear-

ing race Select proper thckness

sium

to provlde 0 13 to 025 mm (00051

to 0 0098 m) preload

Calculation Example

A

+ B = Shim size

(A) Indicator reading 0.10 rnm

(B) Desired preload 0.20 mm

Additional shim 0.30 mm

required

(deaance)

19 Apply a contmuous bead of

sealant

to bearing retamer matmg

surface and threads of bolts.

20 Install shuns and bearmg race

mto beanng retamer and lnstall the

beanng retainer as in Step 11

MT-26

Page 28 of 34

5SPEED TRANSMISSION [Model: BW T-5 (FS5R90A)I

3 Inspect cone surface for ex-

cessive wear

Shifting insert

Replace if worn excessively, worn

unevenly, or damaged

011 seals

1 Replace oll seal if seahng hp is

deformed or cracked Also discard

OII seal d spnng is out of position

Refer

to replacement of OII seals

2 Check contact between

od seal

lip and shaft, if necessary, replace

oil

seal and shaft as a set

ASSEMBLY

Synchronizers

1 Assemble couplmg sleeve to syn-

chronuer hub Make sure that the

sleeve &des freely on the hub

2 Posltion duftmg mserts mto 3

slots m synchroruzer hub with raised

portion facmg outward

3 hstd first msert SpMg wlth

hooked end engaged

to one of the

shft mserts

4 Install the second insert sprlng

on the opposlte side of the synchro-

nuer with the hooked end engaged

to the same msert but turned in the

opposite direction of the first sprmg

7 Install 3rd speed gear Press

3rd and

4th synchronuer onto front

of mainshaft using special

tool

J-25863-01 Be sure that the portion

of the hub with the extended hose

is toward the front

Mainshaft

1 Assemble the 1st and 2nd syn-

chronizer sleeve, mserts and springs

to the synchronuer hub

2 Install 2nd speed gear, thrust

washer and snap rmg

3 Install 1st speed gear

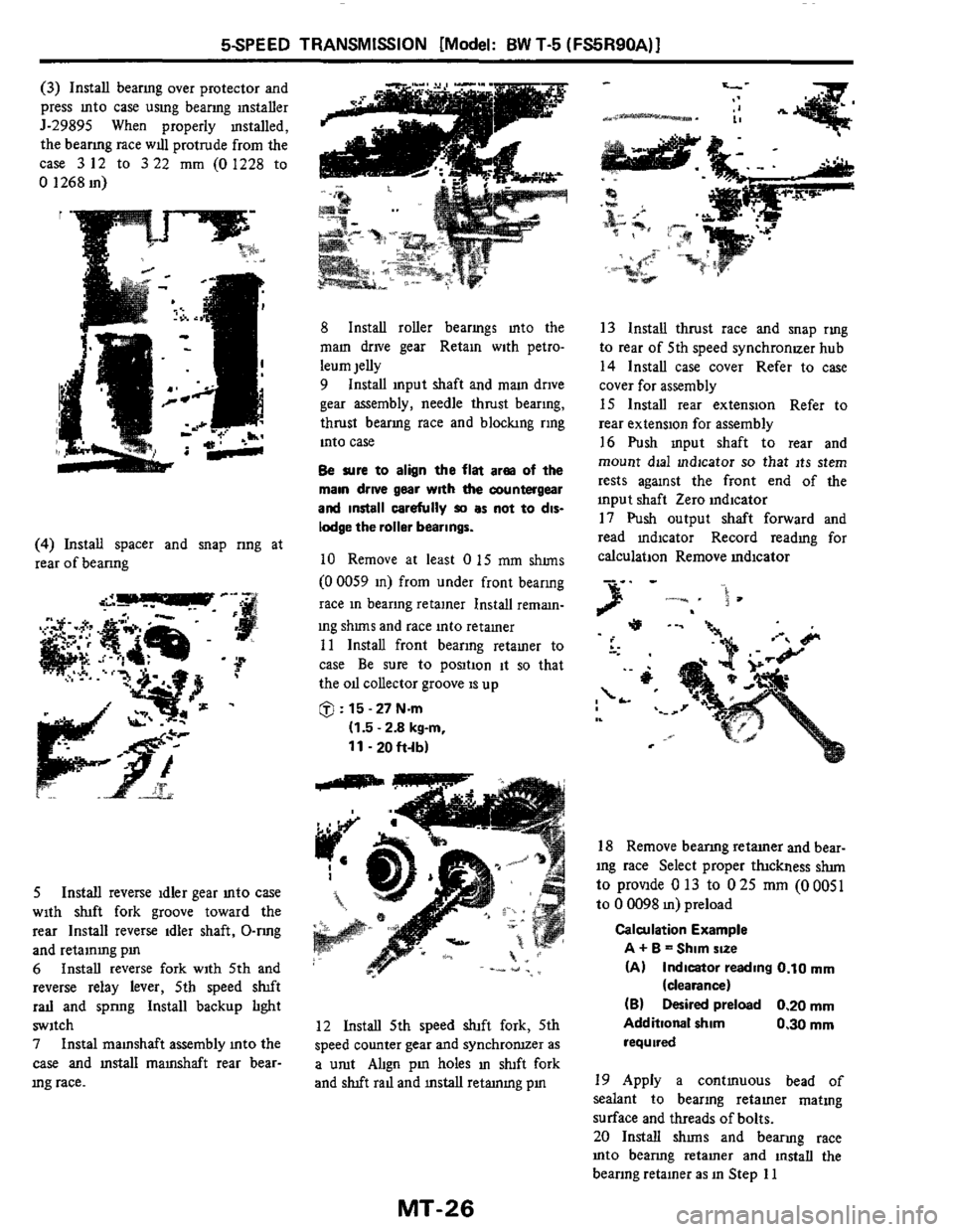

4 Install thrust washer positioning

pm into mmshaft

so that it projects

3 nun (0 12 in) from the bearmg

surface

5 Install thrust washer against 1st

speed gear, bemg certain that the

slot m the washer allgns mth the

Pm 6 Install rear beanng and press

5th speed gear onto mamshaft

usmg

special tool J-2.601041.

8 Install speedometer drive ball,

speedometer gear, and snap ring

9 Install transmission case Refer to

transmission case for assembly

10 Install case cover Refer to case

cover for assembly

11 Install rear extension Refer to

rear extension for assembly

REPLACEMENT OF

OIL SEALS

FRONT BEARING RETAINER

SEAL

It is necessary to remove transmission

unit from car Replace

all seal as

follows 1 Remove transmission Refer

to

removal

2

3 Dramall.

4 Remove front bearmg retamer

Wipe off dnt and grease

MT-28