NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: height, window, change wheel, driver seat adjustment, phone, bolt pattern, lights

Page 1201 of 2898

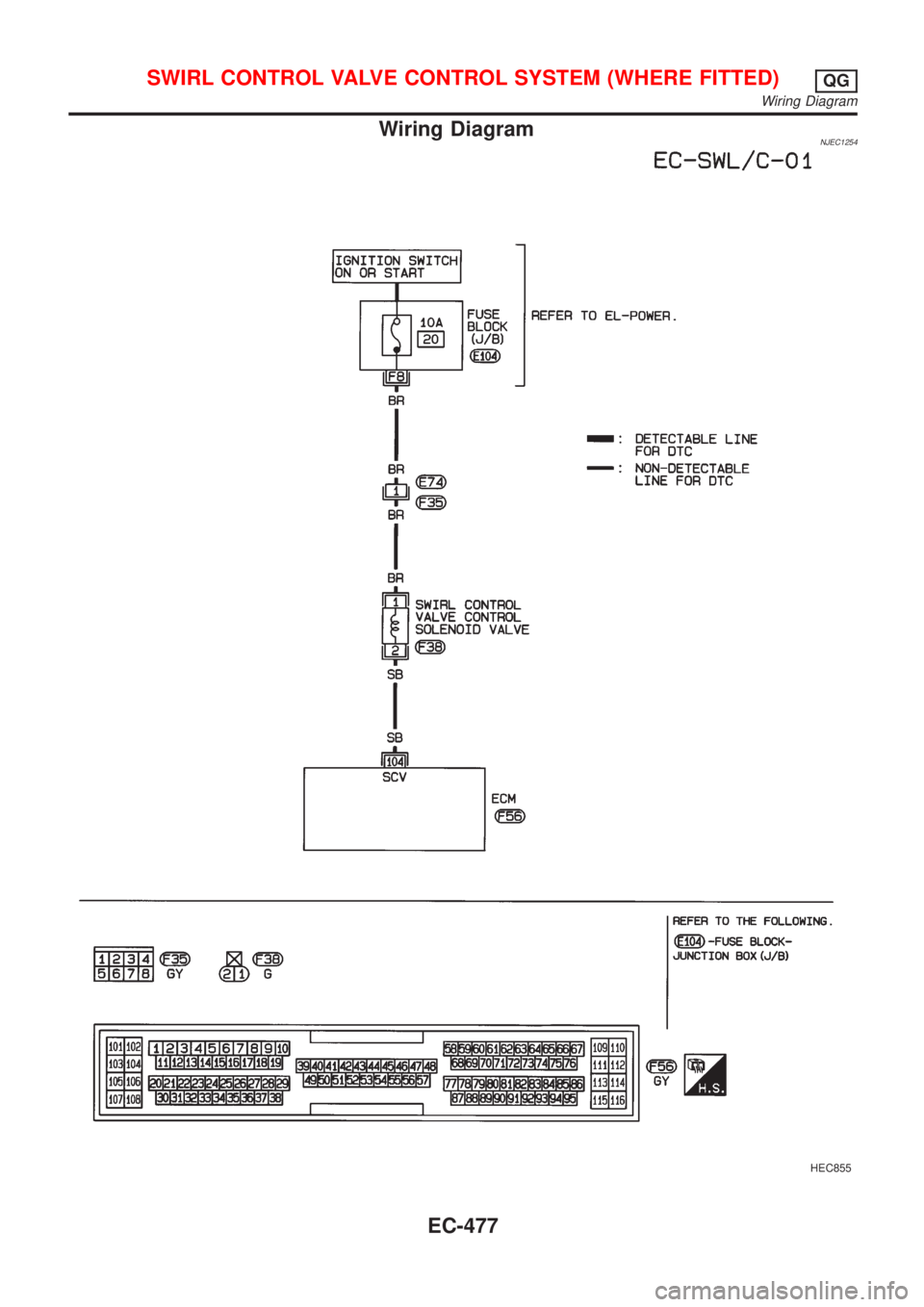

Wiring DiagramNJEC1254

HEC855

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Wiring Diagram

EC-477

Page 1202 of 2898

Diagnostic ProcedureNJEC1255

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

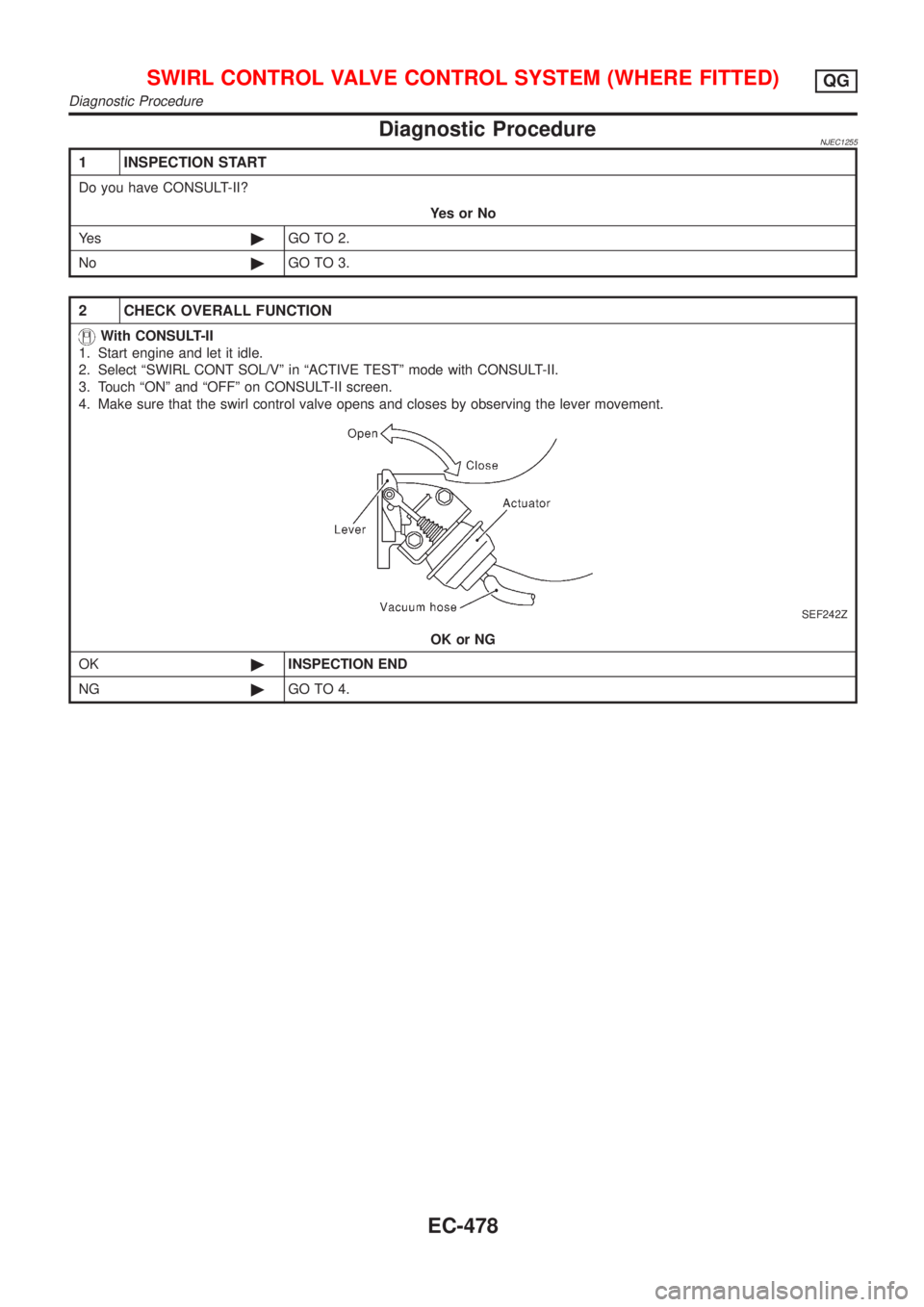

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine and let it idle.

2. Select ªSWIRL CONT SOL/Vº in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªONº and ªOFFº on CONSULT-II screen.

4. Make sure that the swirl control valve opens and closes by observing the lever movement.

SEF242Z

OK or NG

OK©INSPECTION END

NG©GO TO 4.

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure

EC-478

Page 1203 of 2898

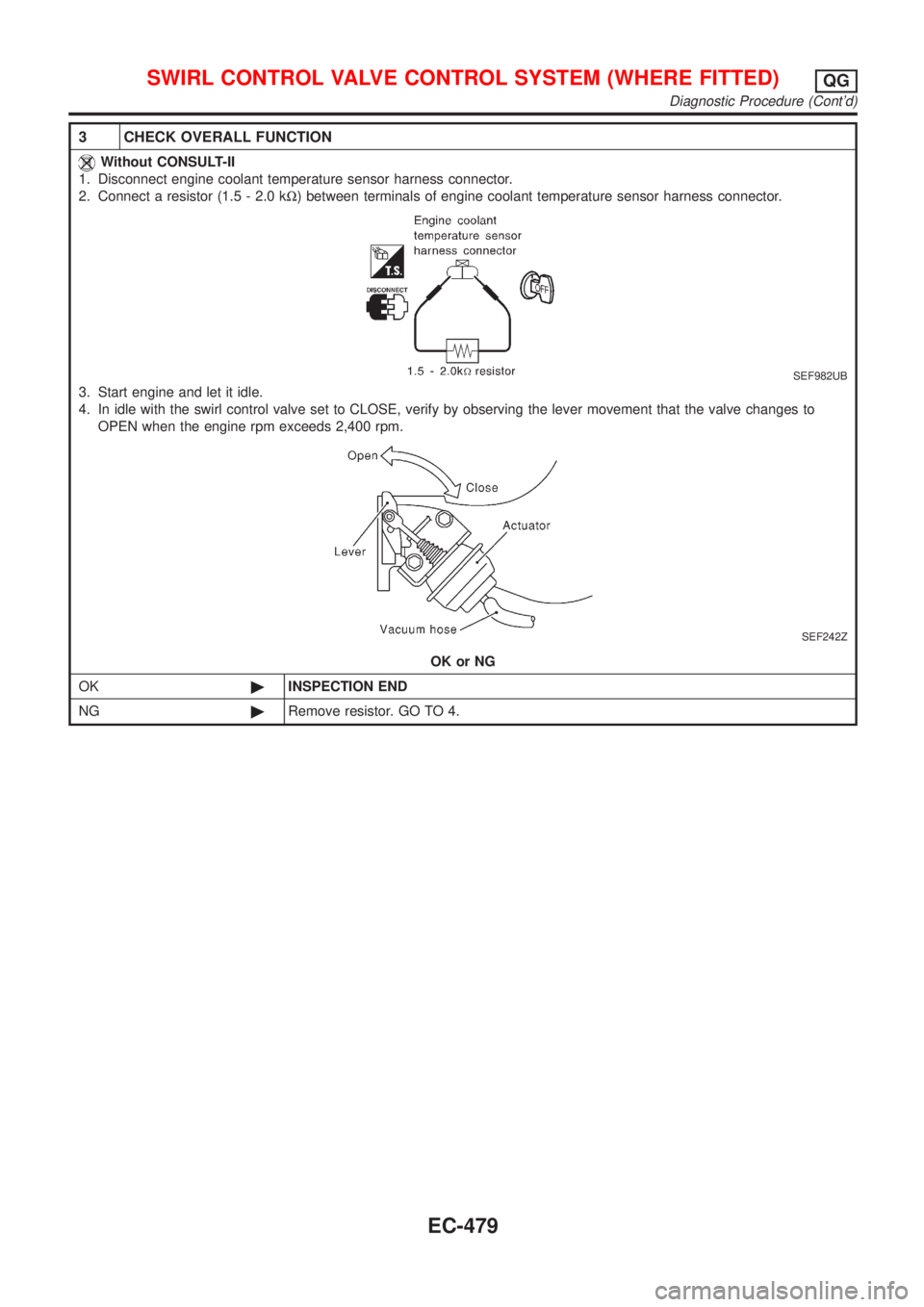

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Disconnect engine coolant temperature sensor harness connector.

2. Connect a resistor (1.5 - 2.0 kW) between terminals of engine coolant temperature sensor harness connector.

SEF982UB

3. Start engine and let it idle.

4. In idle with the swirl control valve set to CLOSE, verify by observing the lever movement that the valve changes to

OPEN when the engine rpm exceeds 2,400 rpm.

SEF242Z

OK or NG

OK©INSPECTION END

NG©Remove resistor. GO TO 4.

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-479

Page 1204 of 2898

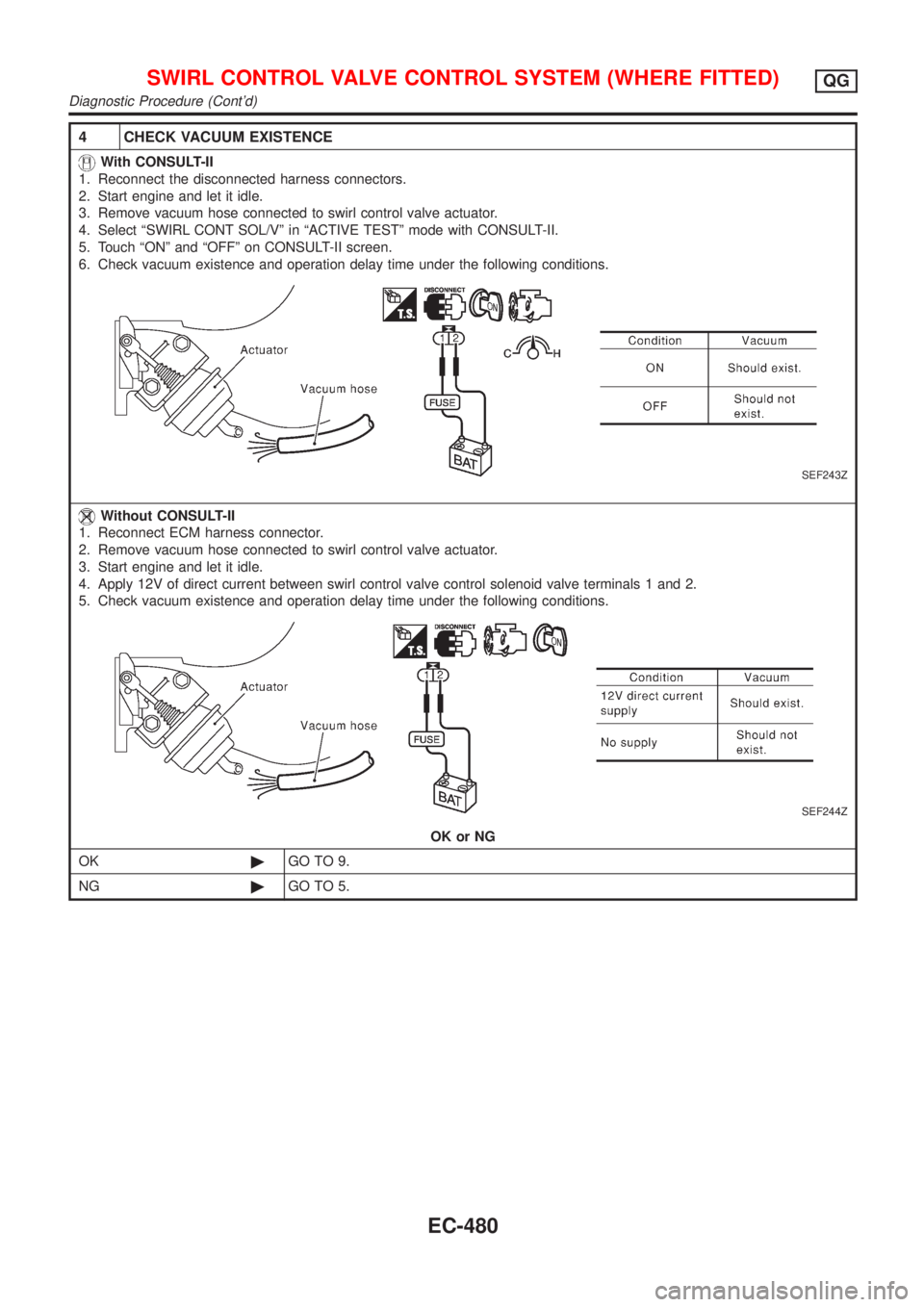

4 CHECK VACUUM EXISTENCE

With CONSULT-II

1. Reconnect the disconnected harness connectors.

2. Start engine and let it idle.

3. Remove vacuum hose connected to swirl control valve actuator.

4. Select ªSWIRL CONT SOL/Vº in ªACTIVE TESTº mode with CONSULT-II.

5. Touch ªONº and ªOFFº on CONSULT-II screen.

6. Check vacuum existence and operation delay time under the following conditions.

SEF243Z

Without CONSULT-II

1. Reconnect ECM harness connector.

2. Remove vacuum hose connected to swirl control valve actuator.

3. Start engine and let it idle.

4. Apply 12V of direct current between swirl control valve control solenoid valve terminals 1 and 2.

5. Check vacuum existence and operation delay time under the following conditions.

SEF244Z

OK or NG

OK©GO TO 9.

NG©GO TO 5.

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-480

Page 1205 of 2898

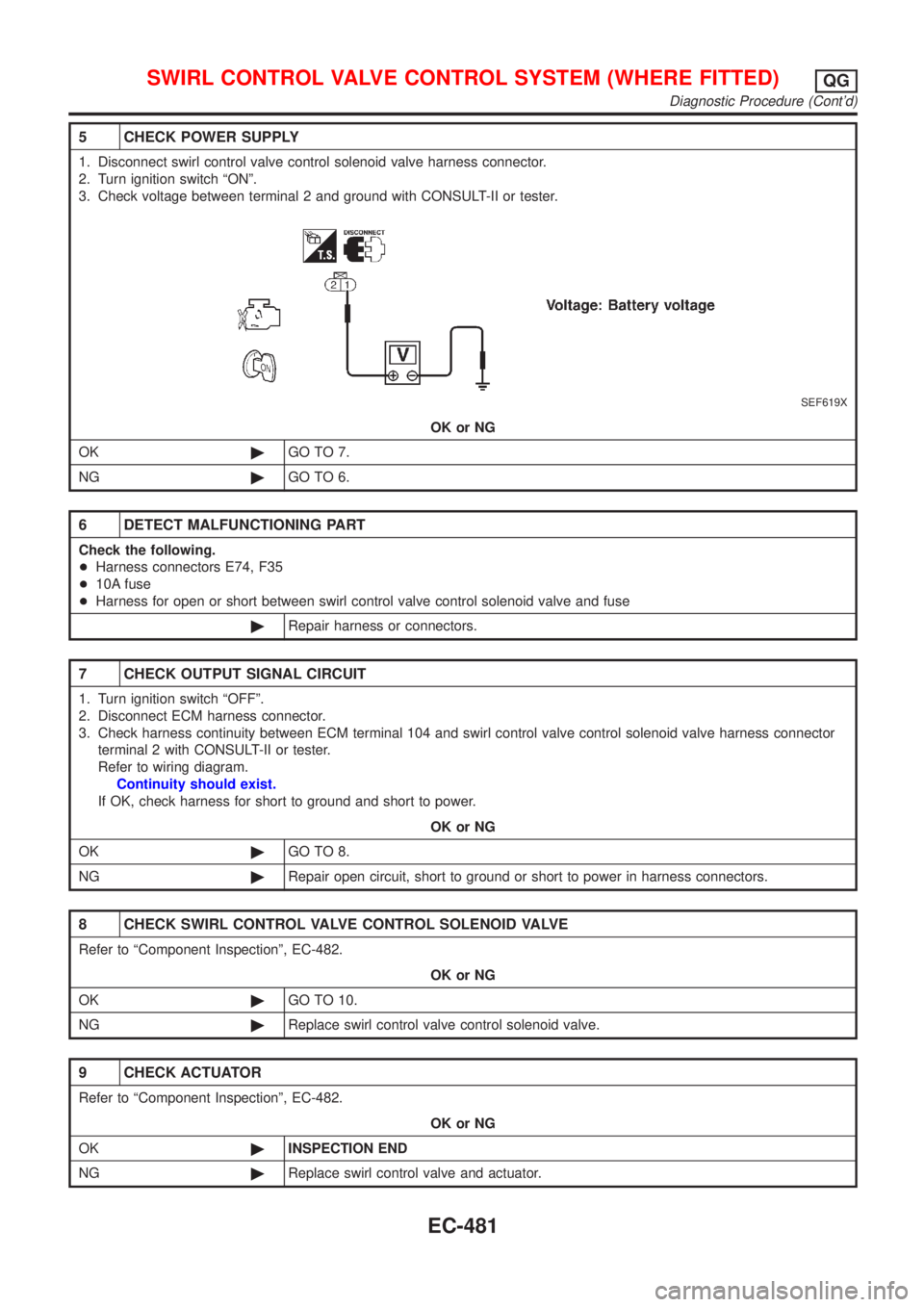

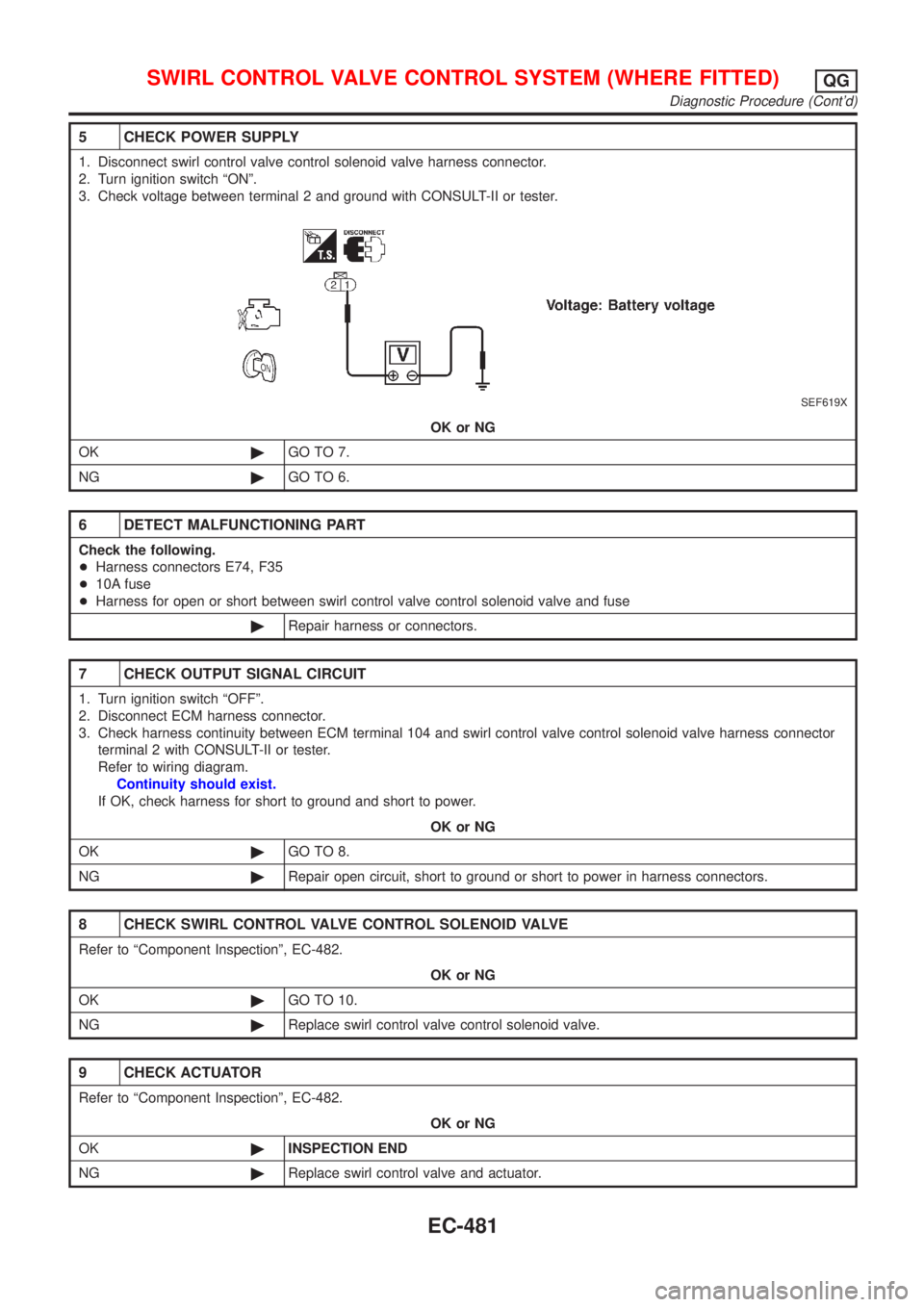

5 CHECK POWER SUPPLY

1. Disconnect swirl control valve control solenoid valve harness connector.

2. Turn ignition switch ªONº.

3. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF619X

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E74, F35

+10A fuse

+Harness for open or short between swirl control valve control solenoid valve and fuse

©Repair harness or connectors.

7 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 104 and swirl control valve control solenoid valve harness connector

terminal 2 with CONSULT-II or tester.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©Repair open circuit, short to ground or short to power in harness connectors.

8 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Refer to ªComponent Inspectionº, EC-482.

OK or NG

OK©GO TO 10.

NG©Replace swirl control valve control solenoid valve.

9 CHECK ACTUATOR

Refer to ªComponent Inspectionº, EC-482.

OK or NG

OK©INSPECTION END

NG©Replace swirl control valve and actuator.

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-481

Page 1206 of 2898

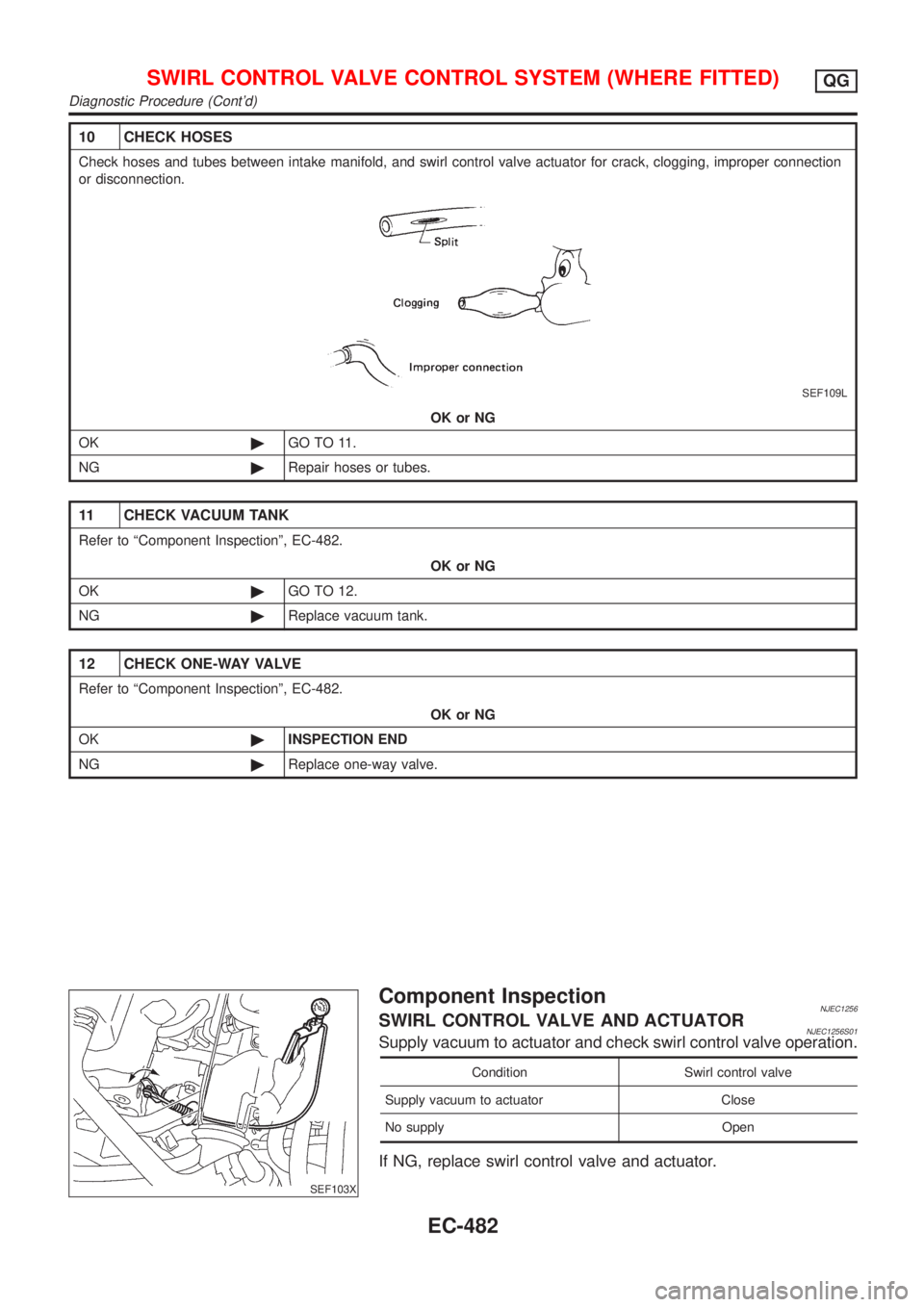

10 CHECK HOSES

Check hoses and tubes between intake manifold, and swirl control valve actuator for crack, clogging, improper connection

or disconnection.

SEF109L

OK or NG

OK©GO TO 11.

NG©Repair hoses or tubes.

11 CHECK VACUUM TANK

Refer to ªComponent Inspectionº, EC-482.

OK or NG

OK©GO TO 12.

NG©Replace vacuum tank.

12 CHECK ONE-WAY VALVE

Refer to ªComponent Inspectionº, EC-482.

OK or NG

OK©INSPECTION END

NG©Replace one-way valve.

SEF103X

Component InspectionNJEC1256SWIRL CONTROL VALVE AND ACTUATORNJEC1256S01Supply vacuum to actuator and check swirl control valve operation.

Condition Swirl control valve

Supply vacuum to actuator Close

No supply Open

If NG, replace swirl control valve and actuator.

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-482

Page 1207 of 2898

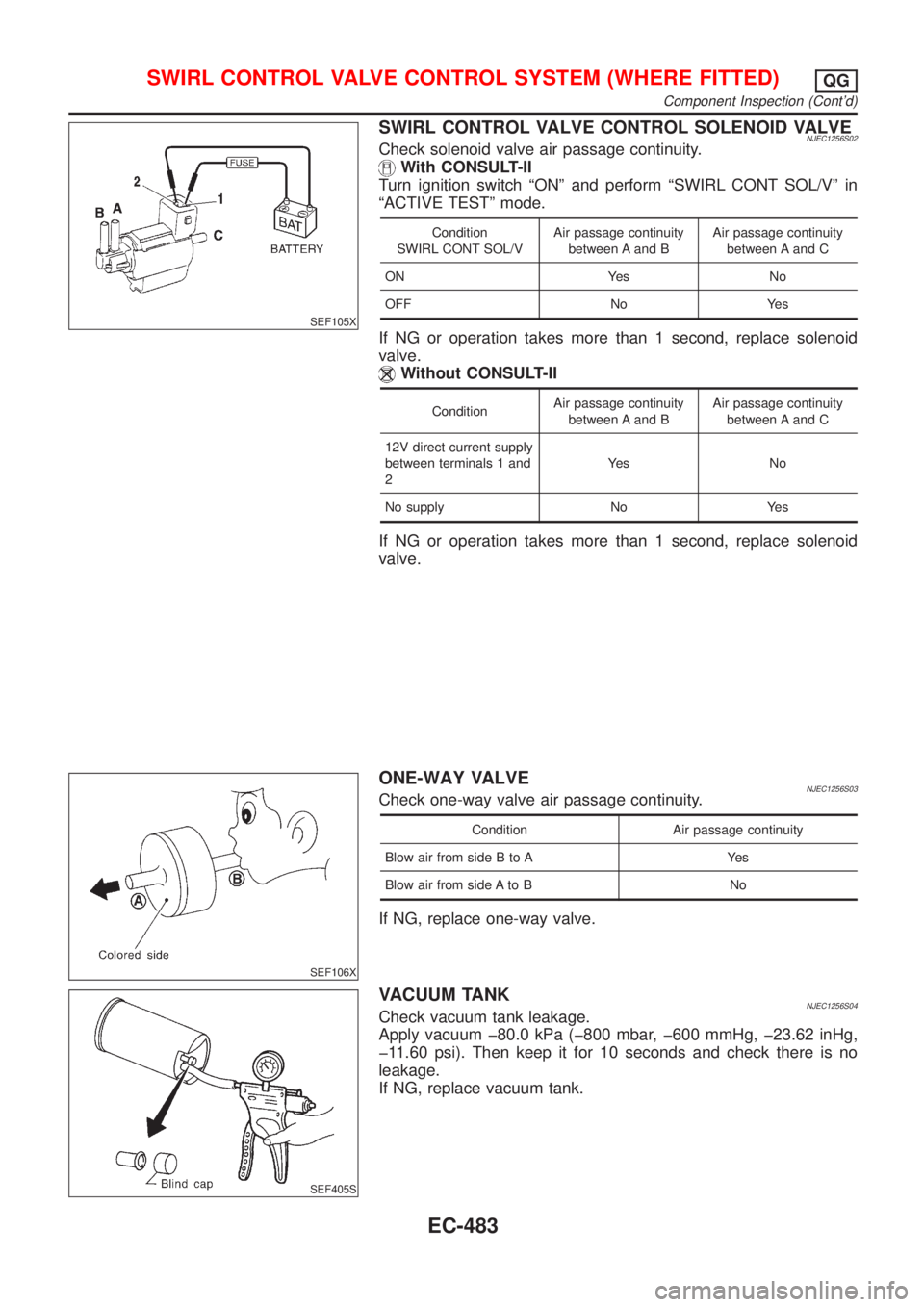

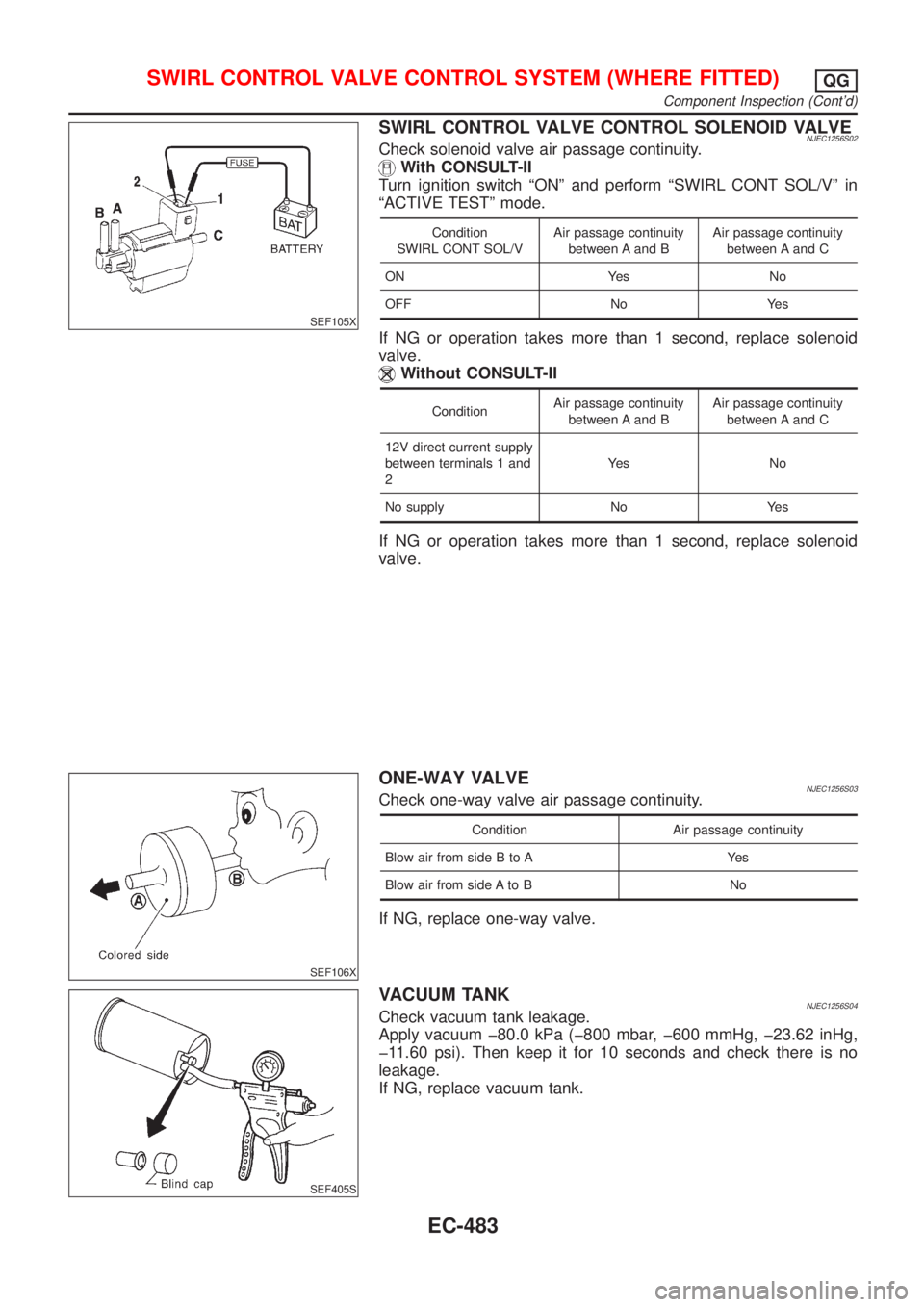

SEF105X

SWIRL CONTROL VALVE CONTROL SOLENOID VALVENJEC1256S02Check solenoid valve air passage continuity.

With CONSULT-II

Turn ignition switch ªONº and perform ªSWIRL CONT SOL/Vº in

ªACTIVE TESTº mode.

Condition

SWIRL CONT SOL/VAir passage continuity

between A and BAir passage continuity

between A and C

ON Yes No

OFF No Yes

If NG or operation takes more than 1 second, replace solenoid

valve.

Without CONSULT-II

ConditionAir passage continuity

between A and BAir passage continuity

between A and C

12V direct current supply

between terminals 1 and

2Ye s N o

No supply No Yes

If NG or operation takes more than 1 second, replace solenoid

valve.

SEF106X

ONE-WAY VALVENJEC1256S03Check one-way valve air passage continuity.

Condition Air passage continuity

Blow air from side B to A Yes

Blow air from side A to B No

If NG, replace one-way valve.

SEF405S

VACUUM TANKNJEC1256S04Check vacuum tank leakage.

Apply vacuum þ80.0 kPa (þ800 mbar, þ600 mmHg, þ23.62 inHg,

þ11.60 psi). Then keep it for 10 seconds and check there is no

leakage.

If NG, replace vacuum tank.

SWIRL CONTROL VALVE CONTROL SYSTEM (WHERE FITTED)QG

Component Inspection (Cont'd)

EC-483

Page 1208 of 2898

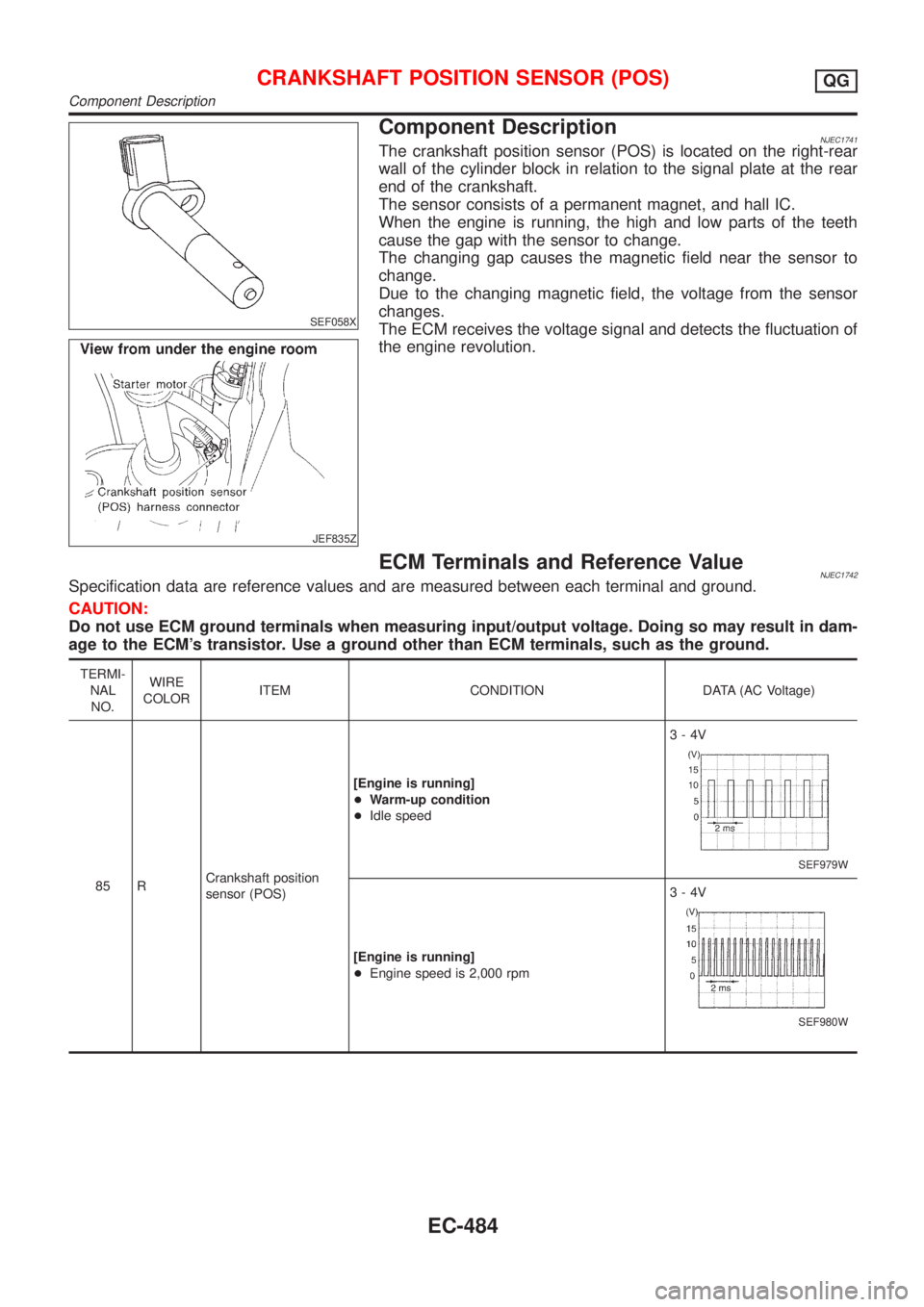

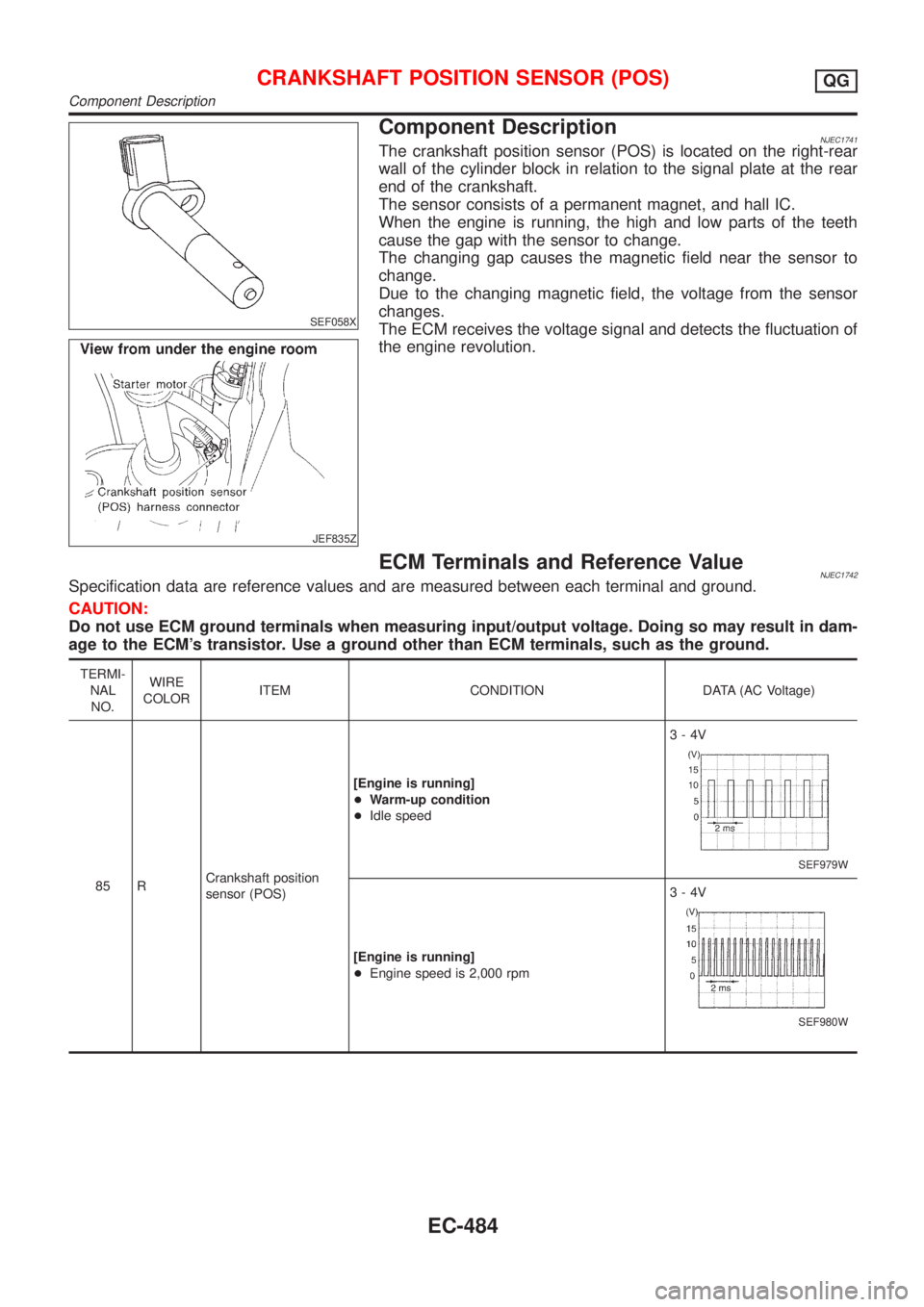

SEF058X

JEF835Z

Component DescriptionNJEC1741The crankshaft position sensor (POS) is located on the right-rear

wall of the cylinder block in relation to the signal plate at the rear

end of the crankshaft.

The sensor consists of a permanent magnet, and hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

the engine revolution.

ECM Terminals and Reference ValueNJEC1742Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (AC Voltage)

85 RCrankshaft position

sensor (POS)[Engine is running]

+Warm-up condition

+Idle speed3-4V

SEF979W

[Engine is running]

+Engine speed is 2,000 rpm3-4V

SEF980W

CRANKSHAFT POSITION SENSOR (POS)QG

Component Description

EC-484

Page 1209 of 2898

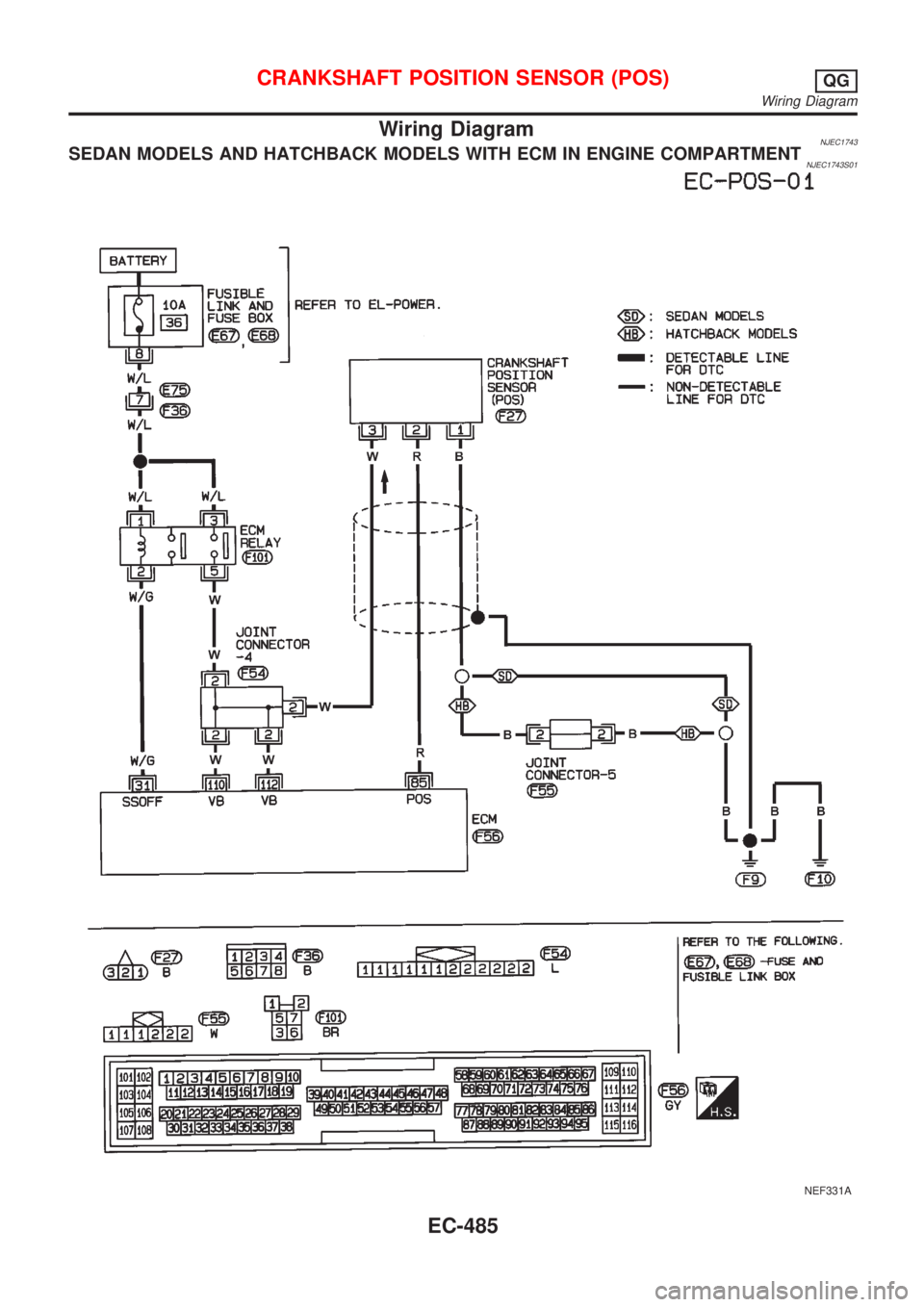

Wiring DiagramNJEC1743SEDAN MODELS AND HATCHBACK MODELS WITH ECM IN ENGINE COMPARTMENTNJEC1743S01

NEF331A

CRANKSHAFT POSITION SENSOR (POS)QG

Wiring Diagram

EC-485

Page 1210 of 2898

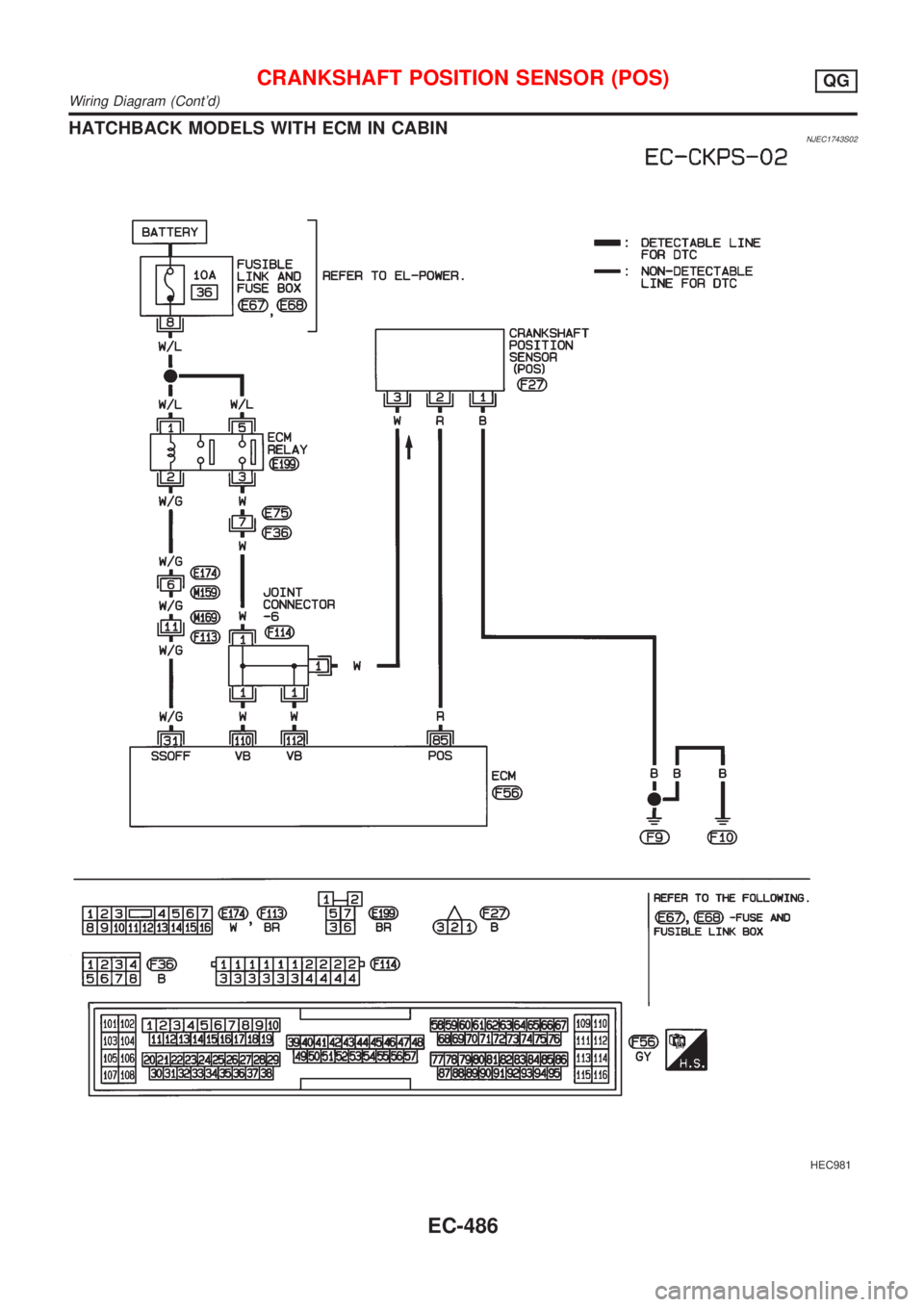

HATCHBACK MODELS WITH ECM IN CABINNJEC1743S02

HEC981

CRANKSHAFT POSITION SENSOR (POS)QG

Wiring Diagram (Cont'd)

EC-486

Trending: compression ratio, coolant reservoir, seat memory, radiator, heater, flat tire, wheel alignment