NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1221 of 2898

3 CHECK OVERALL FUNCTION-II

With CONSULT-II

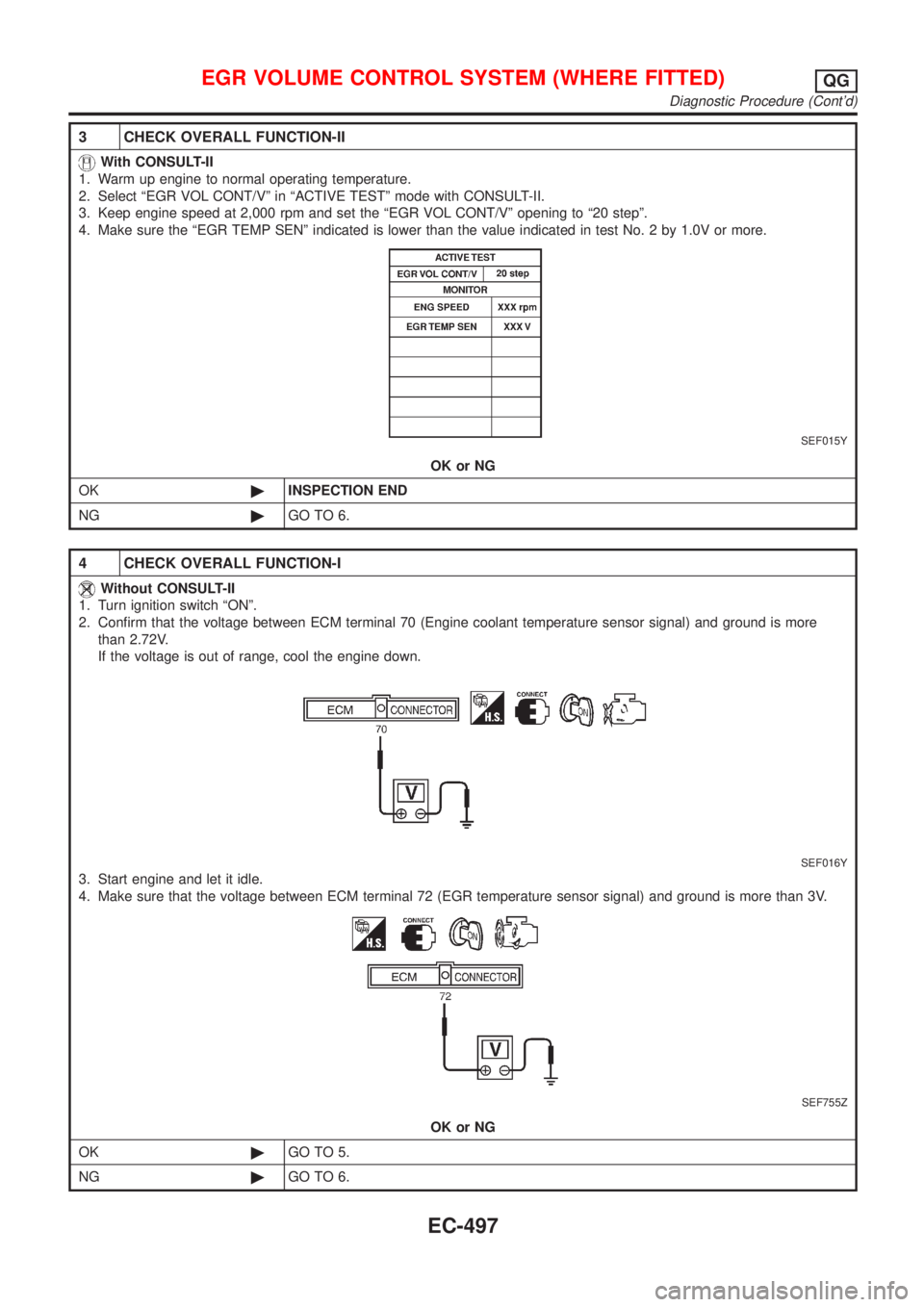

1. Warm up engine to normal operating temperature.

2. Select ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with CONSULT-II.

3. Keep engine speed at 2,000 rpm and set the ªEGR VOL CONT/Vº opening to ª20 stepº.

4. Make sure the ªEGR TEMP SENº indicated is lower than the value indicated in test No. 2 by 1.0V or more.

SEF015Y

OK or NG

OK©INSPECTION END

NG©GO TO 6.

4 CHECK OVERALL FUNCTION-I

Without CONSULT-II

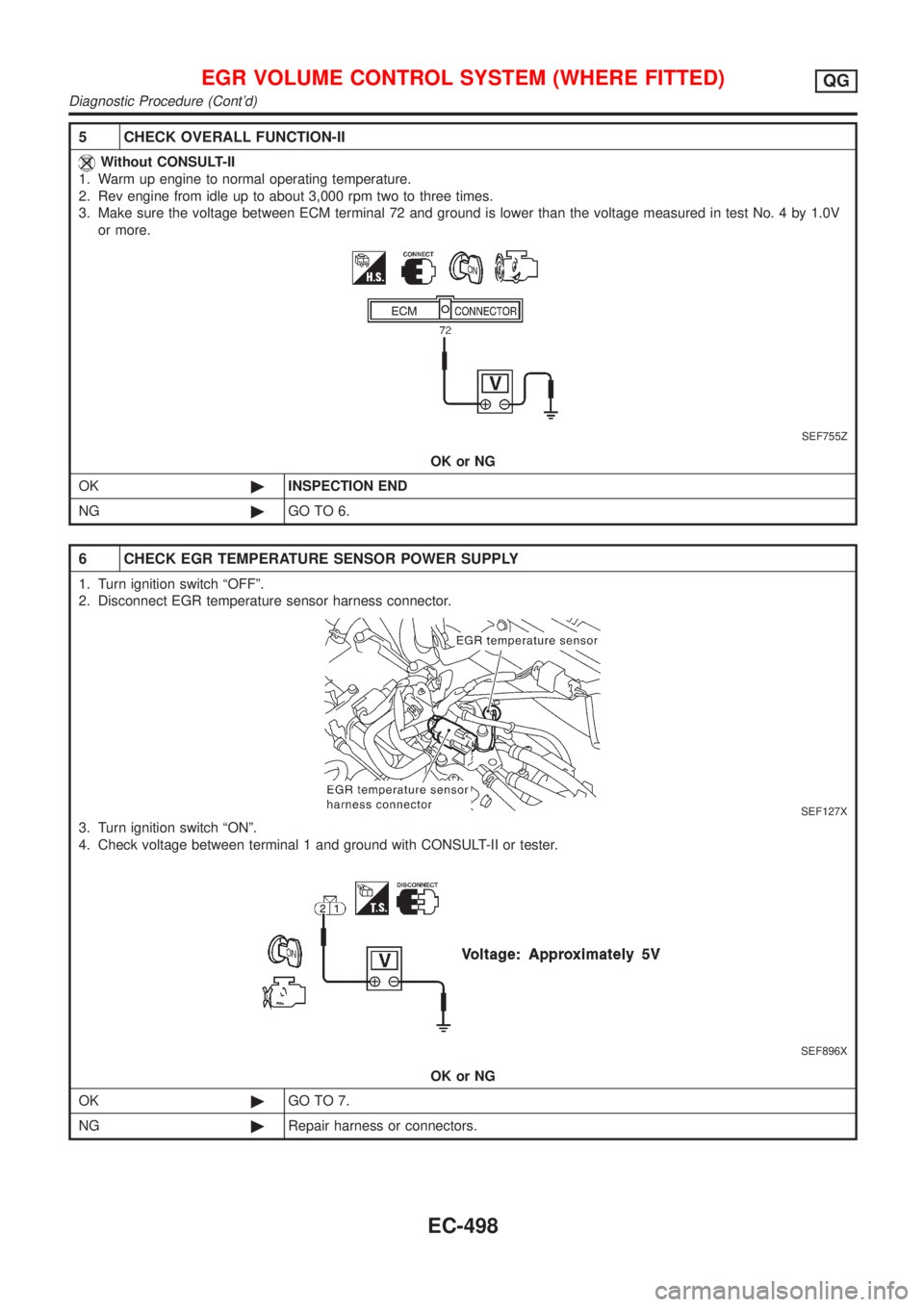

1. Turn ignition switch ªONº.

2. Confirm that the voltage between ECM terminal 70 (Engine coolant temperature sensor signal) and ground is more

than 2.72V.

If the voltage is out of range, cool the engine down.

SEF016Y

3. Start engine and let it idle.

4. Make sure that the voltage between ECM terminal 72 (EGR temperature sensor signal) and ground is more than 3V.

SEF755Z

OK or NG

OK©GO TO 5.

NG©GO TO 6.

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-497

Page 1222 of 2898

5 CHECK OVERALL FUNCTION-II

Without CONSULT-II

1. Warm up engine to normal operating temperature.

2. Rev engine from idle up to about 3,000 rpm two to three times.

3. Make sure the voltage between ECM terminal 72 and ground is lower than the voltage measured in test No. 4 by 1.0V

or more.

SEF755Z

OK or NG

OK©INSPECTION END

NG©GO TO 6.

6 CHECK EGR TEMPERATURE SENSOR POWER SUPPLY

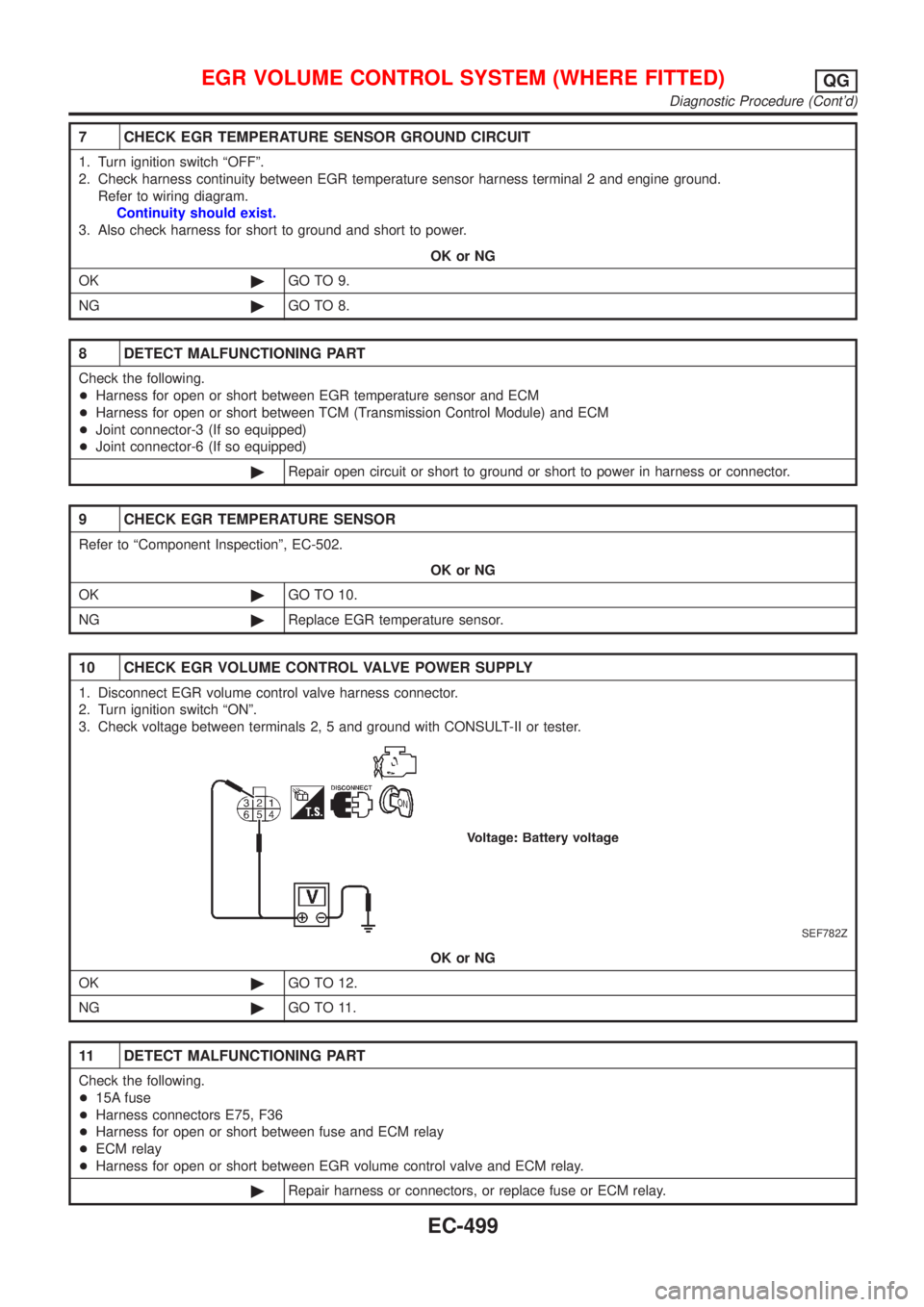

1. Turn ignition switch ªOFFº.

2. Disconnect EGR temperature sensor harness connector.

SEF127X

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEF896X

OK or NG

OK©GO TO 7.

NG©Repair harness or connectors.

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-498

Page 1223 of 2898

7 CHECK EGR TEMPERATURE SENSOR GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between EGR temperature sensor harness terminal 2 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness for open or short between EGR temperature sensor and ECM

+Harness for open or short between TCM (Transmission Control Module) and ECM

+Joint connector-3 (If so equipped)

+Joint connector-6 (If so equipped)

©Repair open circuit or short to ground or short to power in harness or connector.

9 CHECK EGR TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-502.

OK or NG

OK©GO TO 10.

NG©Replace EGR temperature sensor.

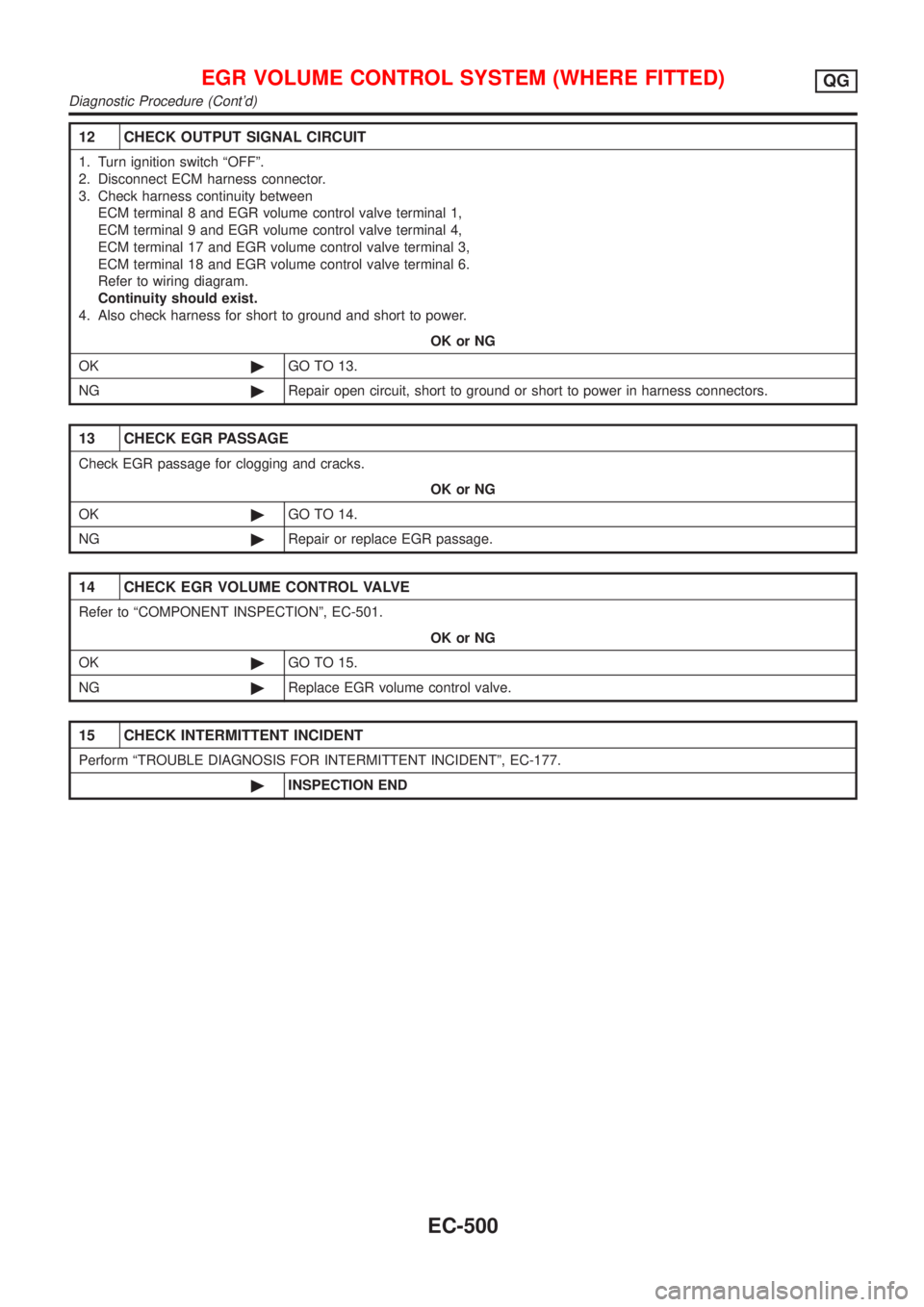

10 CHECK EGR VOLUME CONTROL VALVE POWER SUPPLY

1. Disconnect EGR volume control valve harness connector.

2. Turn ignition switch ªONº.

3. Check voltage between terminals 2, 5 and ground with CONSULT-II or tester.

SEF782Z

OK or NG

OK©GO TO 12.

NG©GO TO 11.

11 DETECT MALFUNCTIONING PART

Check the following.

+15A fuse

+Harness connectors E75, F36

+Harness for open or short between fuse and ECM relay

+ECM relay

+Harness for open or short between EGR volume control valve and ECM relay.

©Repair harness or connectors, or replace fuse or ECM relay.

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-499

Page 1224 of 2898

12 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM terminal 8 and EGR volume control valve terminal 1,

ECM terminal 9 and EGR volume control valve terminal 4,

ECM terminal 17 and EGR volume control valve terminal 3,

ECM terminal 18 and EGR volume control valve terminal 6.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 13.

NG©Repair open circuit, short to ground or short to power in harness connectors.

13 CHECK EGR PASSAGE

Check EGR passage for clogging and cracks.

OK or NG

OK©GO TO 14.

NG©Repair or replace EGR passage.

14 CHECK EGR VOLUME CONTROL VALVE

Refer to ªCOMPONENT INSPECTIONº, EC-501.

OK or NG

OK©GO TO 15.

NG©Replace EGR volume control valve.

15 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-500

Page 1225 of 2898

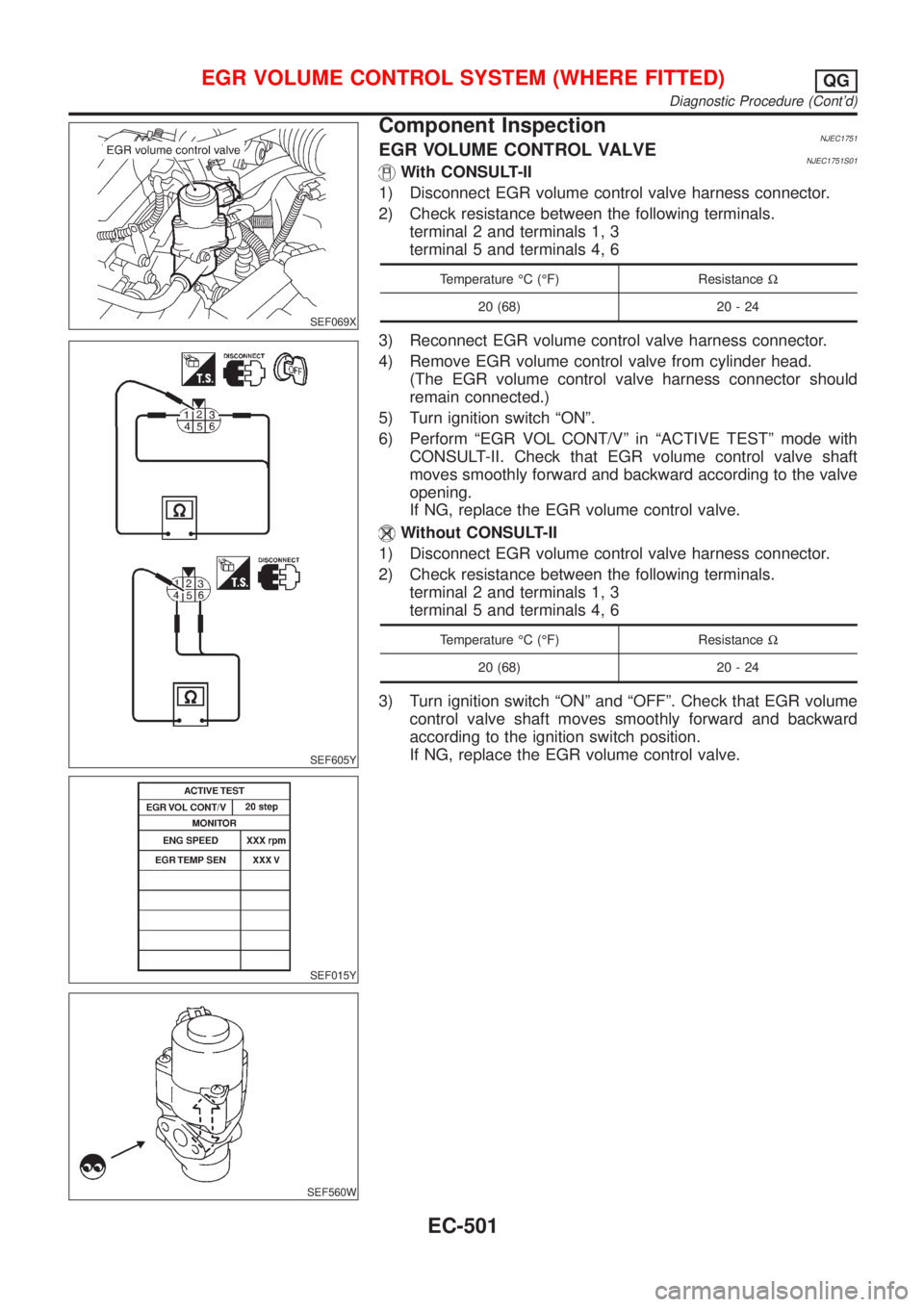

SEF069X

SEF605Y

SEF015Y

SEF560W

Component InspectionNJEC1751EGR VOLUME CONTROL VALVENJEC1751S01With CONSULT-II

1) Disconnect EGR volume control valve harness connector.

2) Check resistance between the following terminals.

terminal 2 and terminals 1, 3

terminal 5 and terminals 4, 6

Temperature ÉC (ÉF) ResistanceW

20 (68) 20 - 24

3) Reconnect EGR volume control valve harness connector.

4) Remove EGR volume control valve from cylinder head.

(The EGR volume control valve harness connector should

remain connected.)

5) Turn ignition switch ªONº.

6) Perform ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT-II. Check that EGR volume control valve shaft

moves smoothly forward and backward according to the valve

opening.

If NG, replace the EGR volume control valve.

Without CONSULT-II

1) Disconnect EGR volume control valve harness connector.

2) Check resistance between the following terminals.

terminal 2 and terminals 1, 3

terminal 5 and terminals 4, 6

Temperature ÉC (ÉF) ResistanceW

20 (68) 20 - 24

3) Turn ignition switch ªONº and ªOFFº. Check that EGR volume

control valve shaft moves smoothly forward and backward

according to the ignition switch position.

If NG, replace the EGR volume control valve.

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure (Cont'd)

EC-501

Page 1226 of 2898

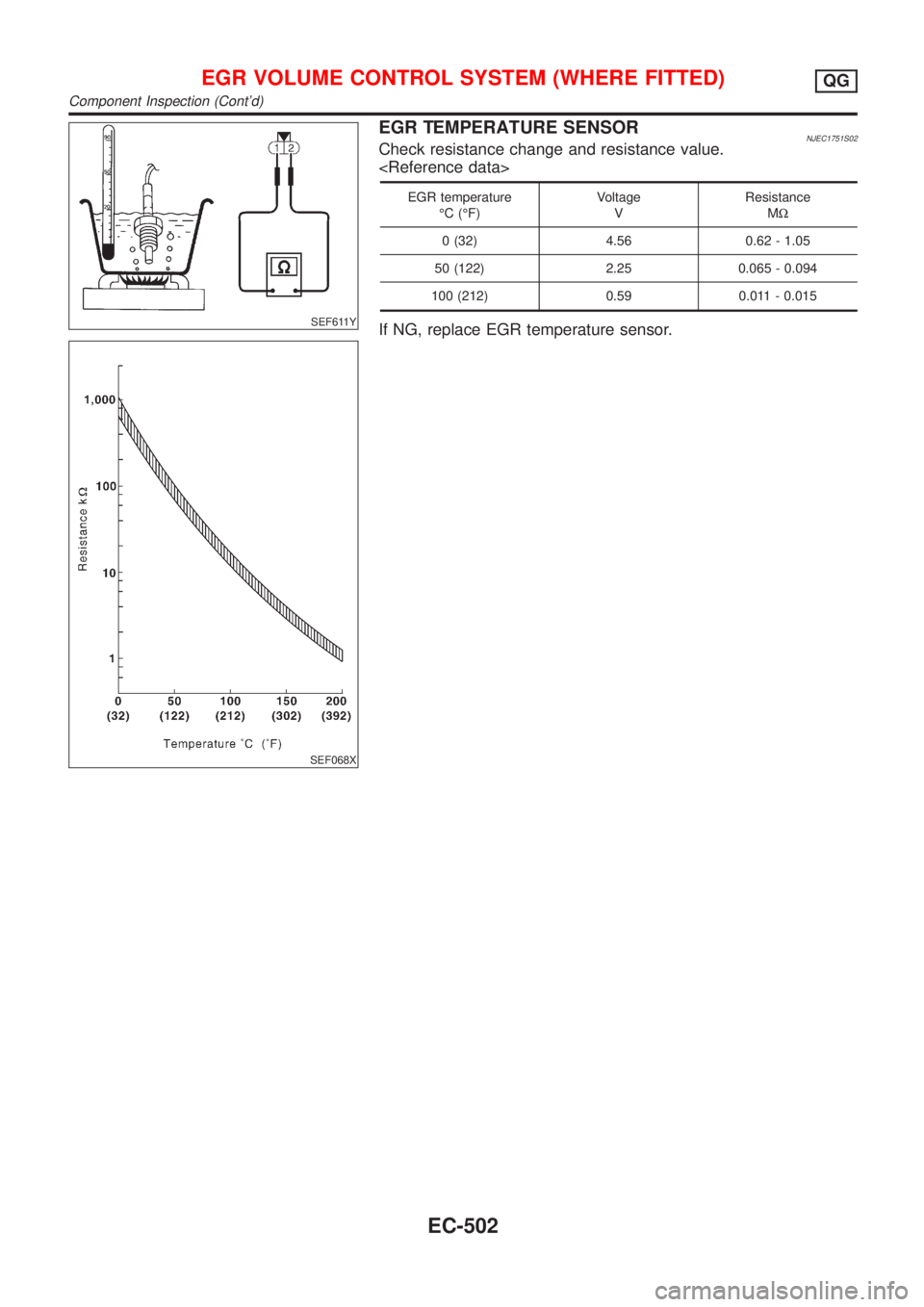

SEF611Y

SEF068X

EGR TEMPERATURE SENSORNJEC1751S02Check resistance change and resistance value.

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

If NG, replace EGR temperature sensor.

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Component Inspection (Cont'd)

EC-502

Page 1227 of 2898

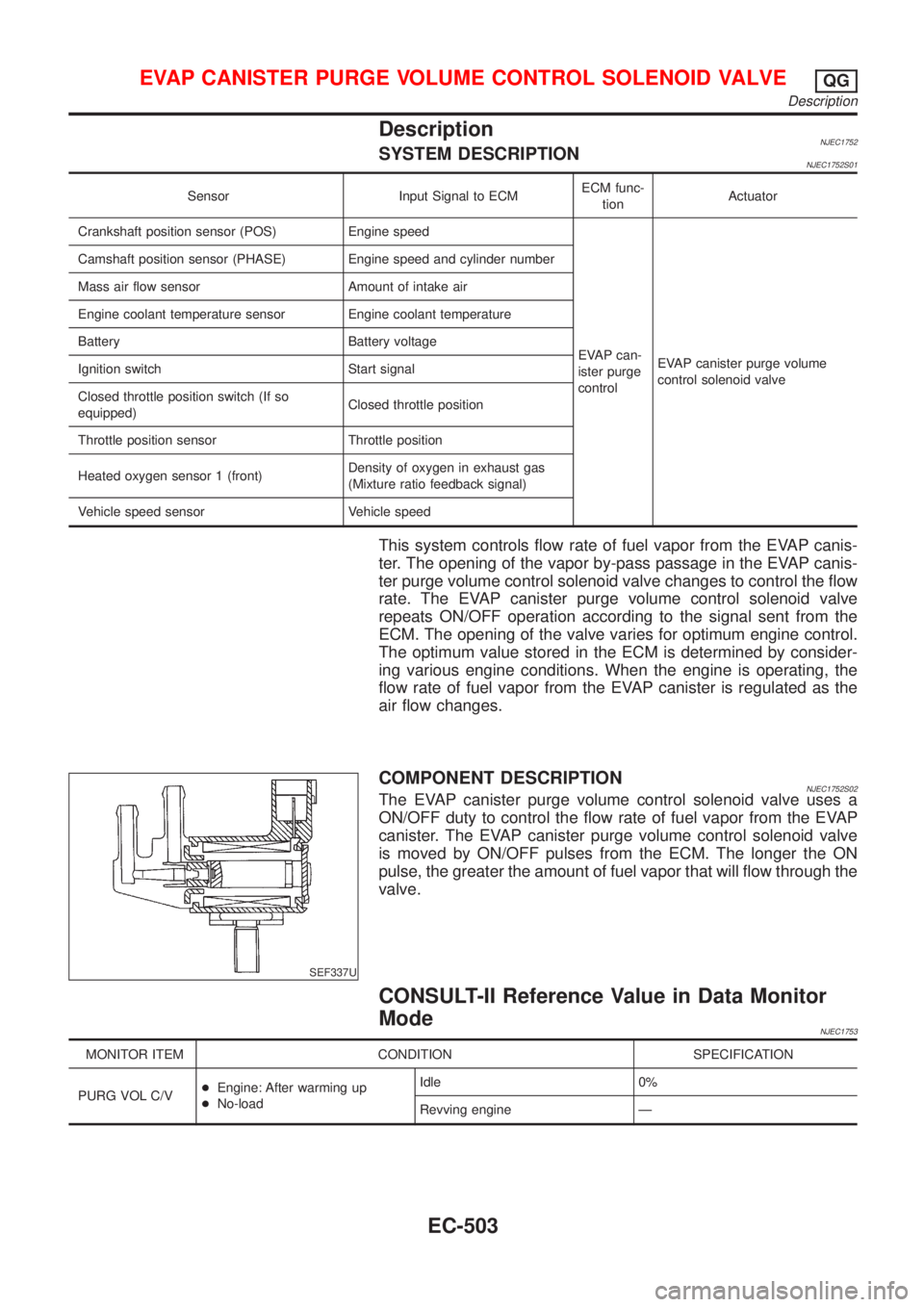

DescriptionNJEC1752SYSTEM DESCRIPTIONNJEC1752S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EVAP can-

ister purge

controlEVAP canister purge volume

control solenoid valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Battery Battery voltage

Ignition switch Start signal

Closed throttle position switch (If so

equipped)Closed throttle position

Throttle position sensor Throttle position

Heated oxygen sensor 1 (front)Density of oxygen in exhaust gas

(Mixture ratio feedback signal)

Vehicle speed sensor Vehicle speed

This system controls flow rate of fuel vapor from the EVAP canis-

ter. The opening of the vapor by-pass passage in the EVAP canis-

ter purge volume control solenoid valve changes to control the flow

rate. The EVAP canister purge volume control solenoid valve

repeats ON/OFF operation according to the signal sent from the

ECM. The opening of the valve varies for optimum engine control.

The optimum value stored in the ECM is determined by consider-

ing various engine conditions. When the engine is operating, the

flow rate of fuel vapor from the EVAP canister is regulated as the

air flow changes.

SEF337U

COMPONENT DESCRIPTIONNJEC1752S02The EVAP canister purge volume control solenoid valve uses a

ON/OFF duty to control the flow rate of fuel vapor from the EVAP

canister. The EVAP canister purge volume control solenoid valve

is moved by ON/OFF pulses from the ECM. The longer the ON

pulse, the greater the amount of fuel vapor that will flow through the

valve.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC1753

MONITOR ITEM CONDITION SPECIFICATION

PURG VOL C/V+Engine: After warming up

+No-loadIdle 0%

Revving engine Ð

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVEQG

Description

EC-503

Page 1228 of 2898

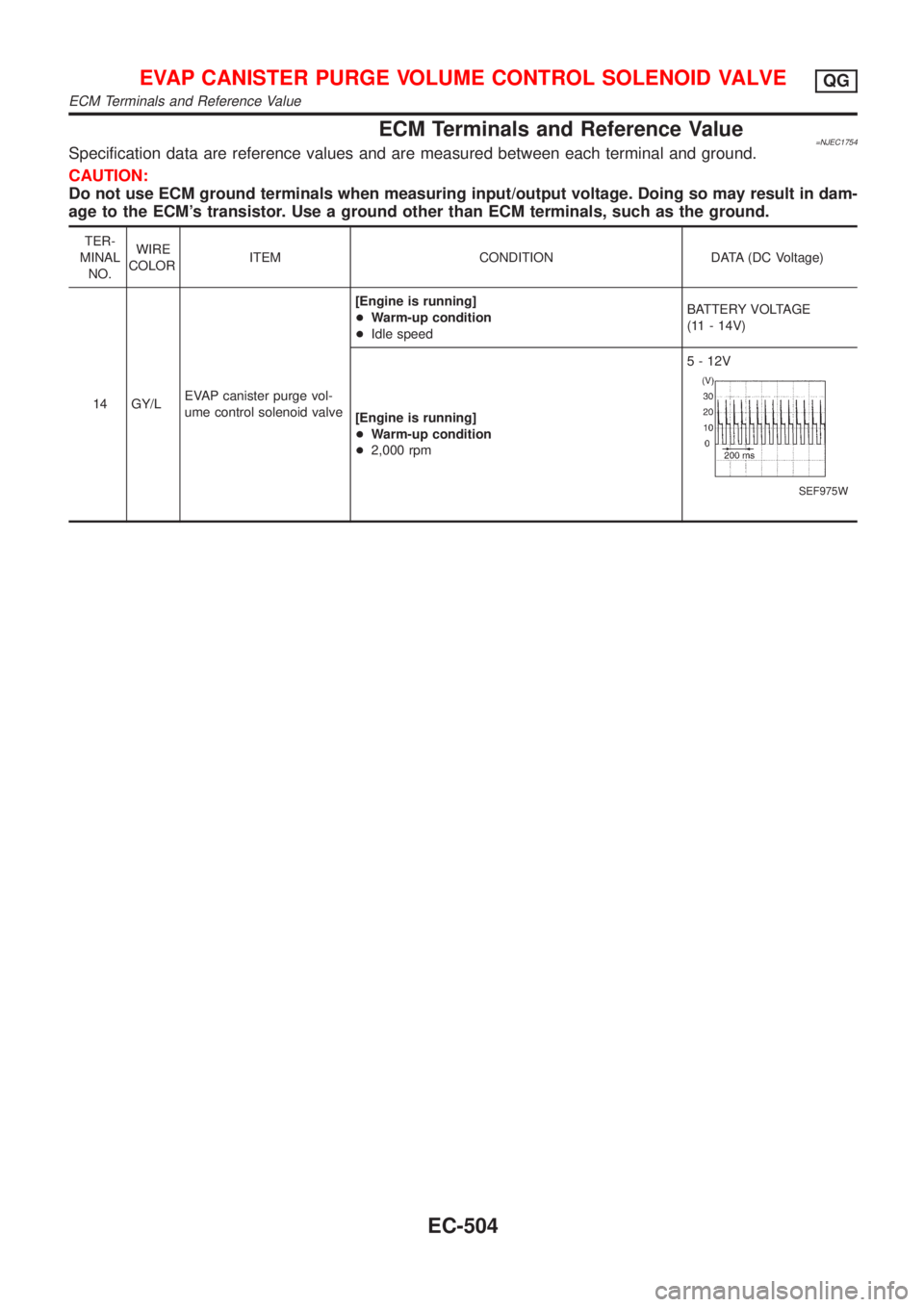

ECM Terminals and Reference Value=NJEC1754Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 GY/LEVAP canister purge vol-

ume control solenoid valve[Engine is running]

+Warm-up condition

+Idle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Warm-up condition

+2,000 rpm5 - 12V

SEF975W

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVEQG

ECM Terminals and Reference Value

EC-504

Page 1229 of 2898

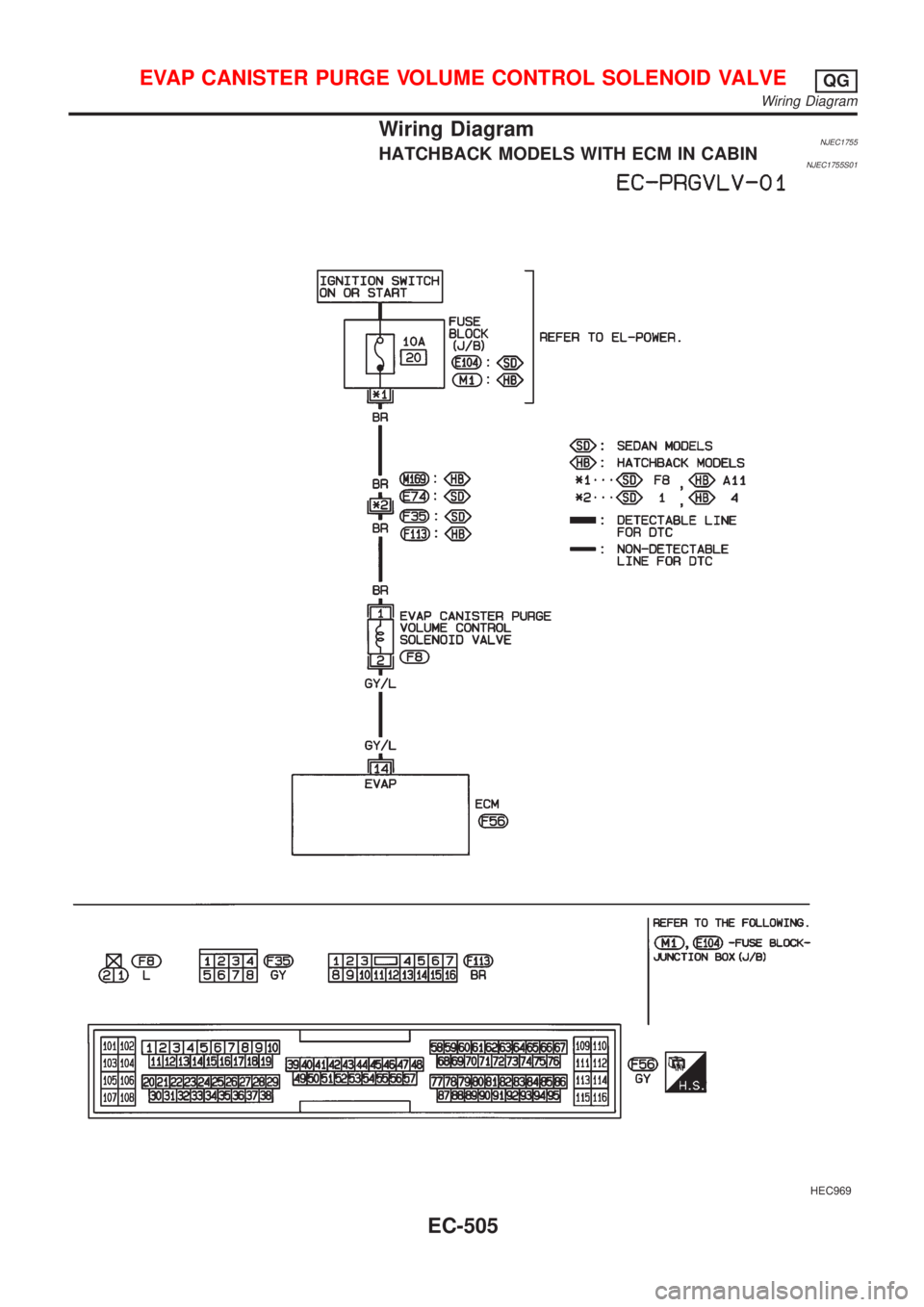

Wiring DiagramNJEC1755HATCHBACK MODELS WITH ECM IN CABINNJEC1755S01

HEC969

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVEQG

Wiring Diagram

EC-505

Page 1230 of 2898

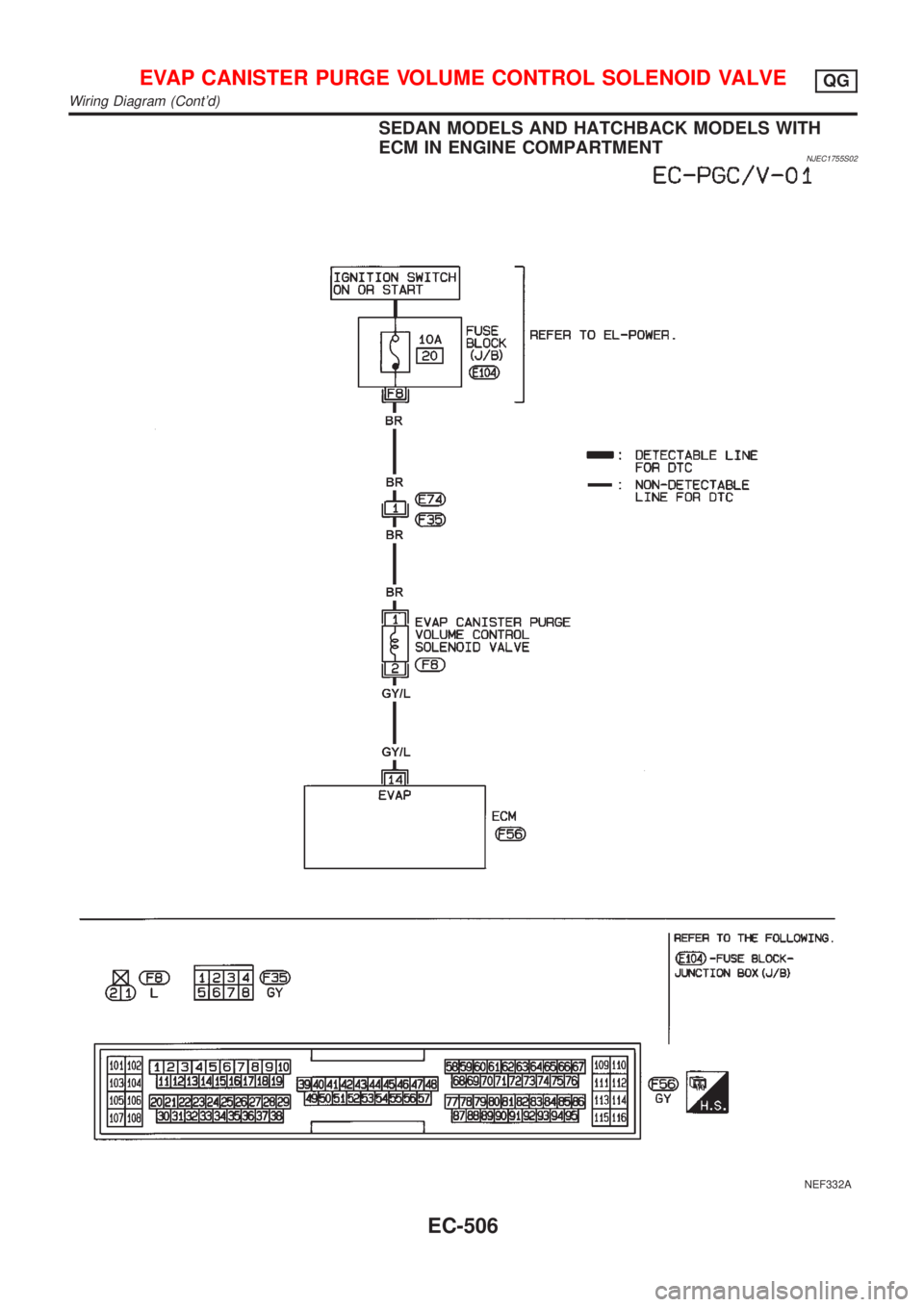

SEDAN MODELS AND HATCHBACK MODELS WITH

ECM IN ENGINE COMPARTMENT

NJEC1755S02

NEF332A

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVEQG

Wiring Diagram (Cont'd)

EC-506