NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: length, tire type, heater, ABS, water pump, remove seats, oil pressure

Page 1261 of 2898

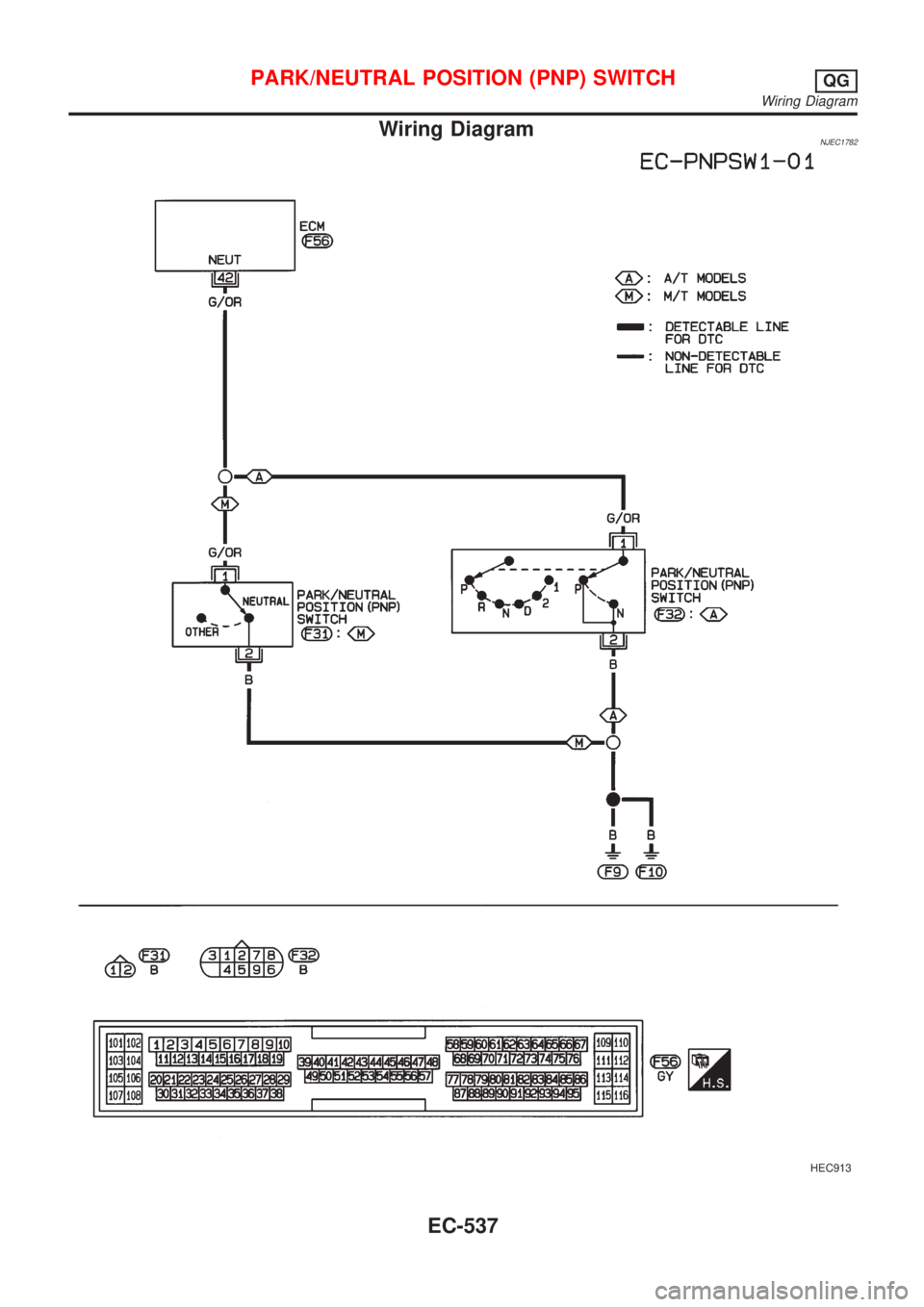

Wiring DiagramNJEC1782

HEC913

PARK/NEUTRAL POSITION (PNP) SWITCHQG

Wiring Diagram

EC-537

Page 1262 of 2898

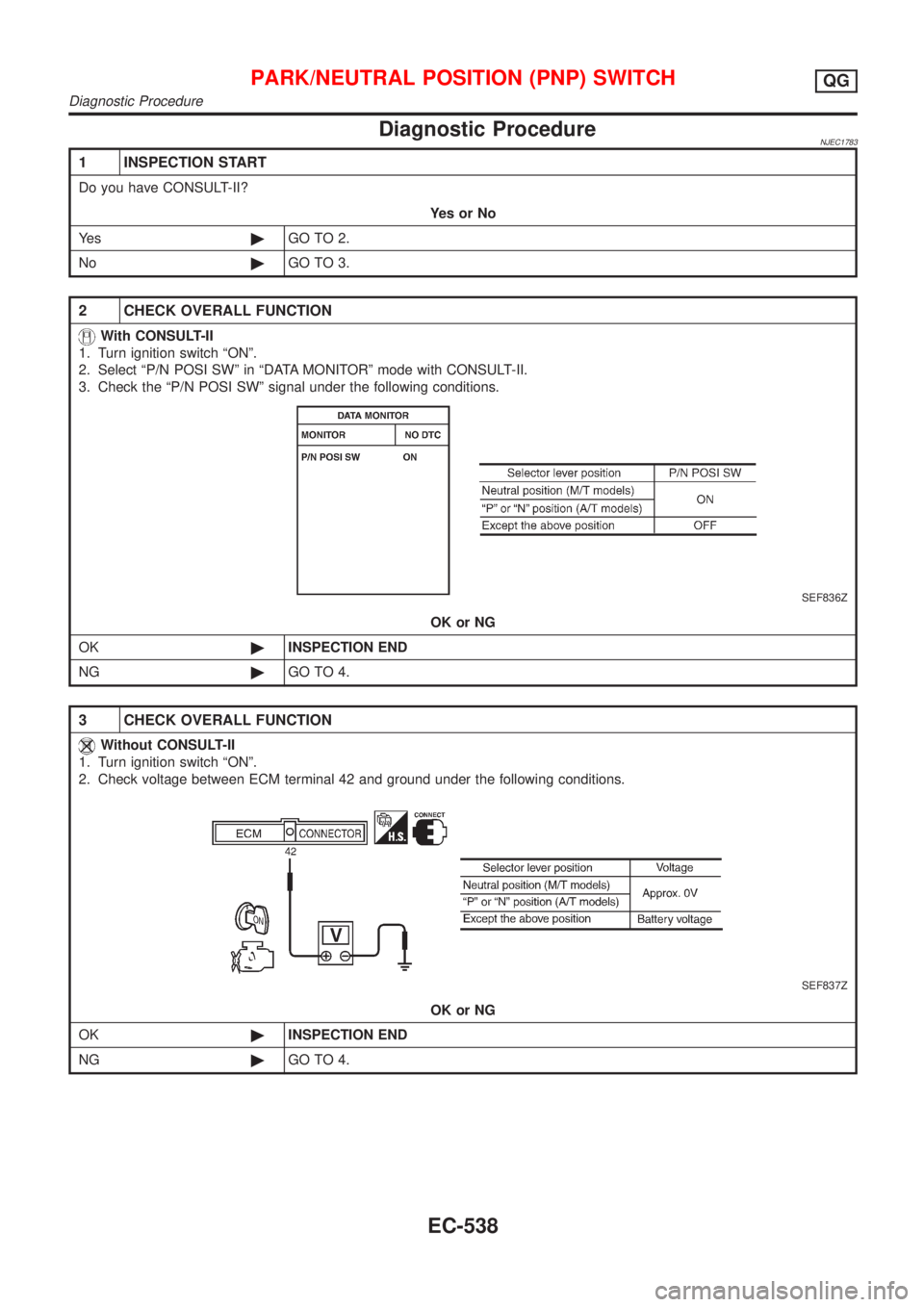

Diagnostic ProcedureNJEC1783

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªP/N POSI SWº in ªDATA MONITORº mode with CONSULT-II.

3. Check the ªP/N POSI SWº signal under the following conditions.

SEF836Z

OK or NG

OK©INSPECTION END

NG©GO TO 4.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 42 and ground under the following conditions.

SEF837Z

OK or NG

OK©INSPECTION END

NG©GO TO 4.

PARK/NEUTRAL POSITION (PNP) SWITCHQG

Diagnostic Procedure

EC-538

Page 1263 of 2898

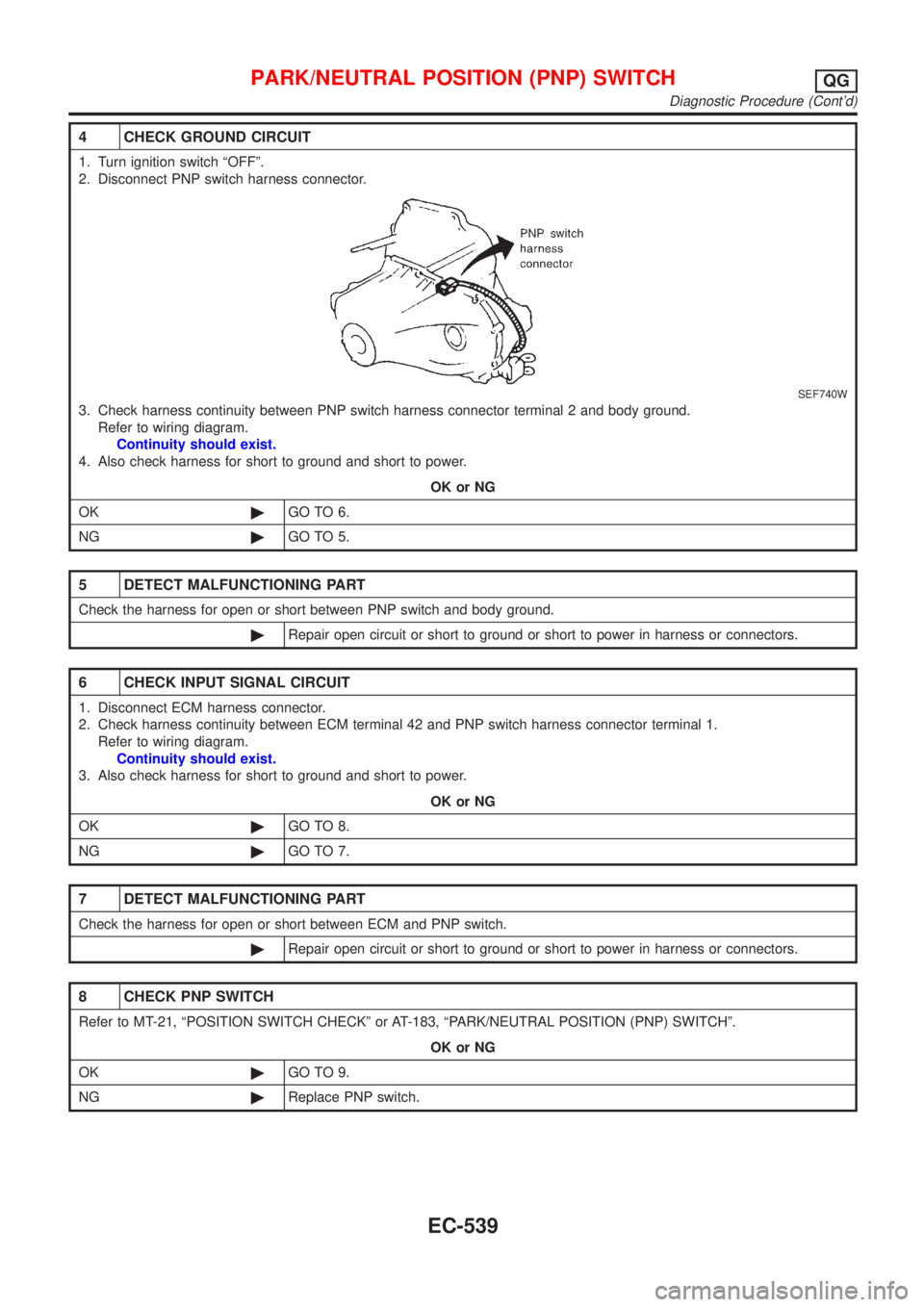

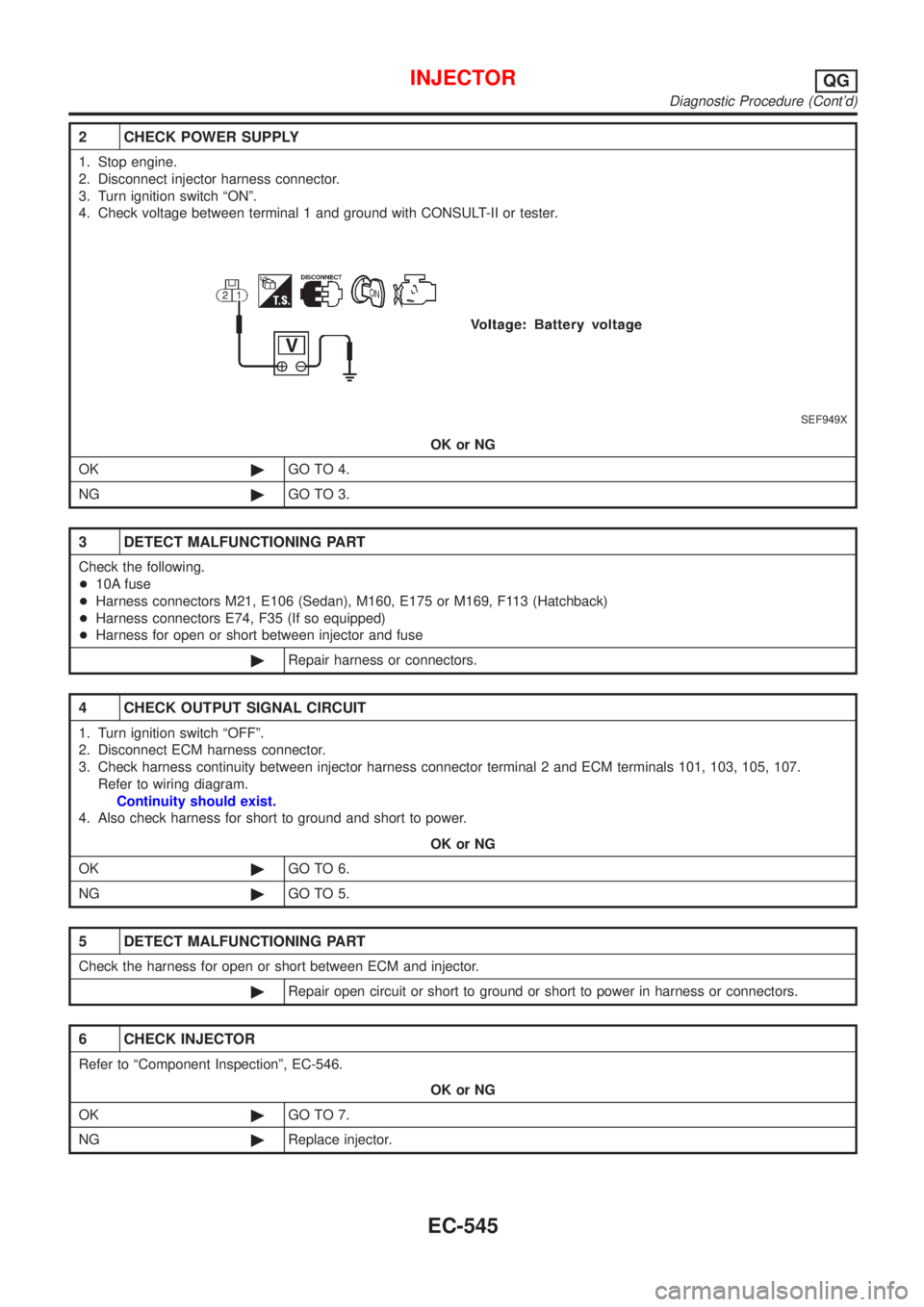

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect PNP switch harness connector.

SEF740W

3. Check harness continuity between PNP switch harness connector terminal 2 and body ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between PNP switch and body ground.

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 42 and PNP switch harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and PNP switch.

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK PNP SWITCH

Refer to MT-21, ªPOSITION SWITCH CHECKº or AT-183, ªPARK/NEUTRAL POSITION (PNP) SWITCHº.

OK or NG

OK©GO TO 9.

NG©Replace PNP switch.

PARK/NEUTRAL POSITION (PNP) SWITCHQG

Diagnostic Procedure (Cont'd)

EC-539

Page 1264 of 2898

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

PARK/NEUTRAL POSITION (PNP) SWITCHQG

Diagnostic Procedure (Cont'd)

EC-540

Page 1265 of 2898

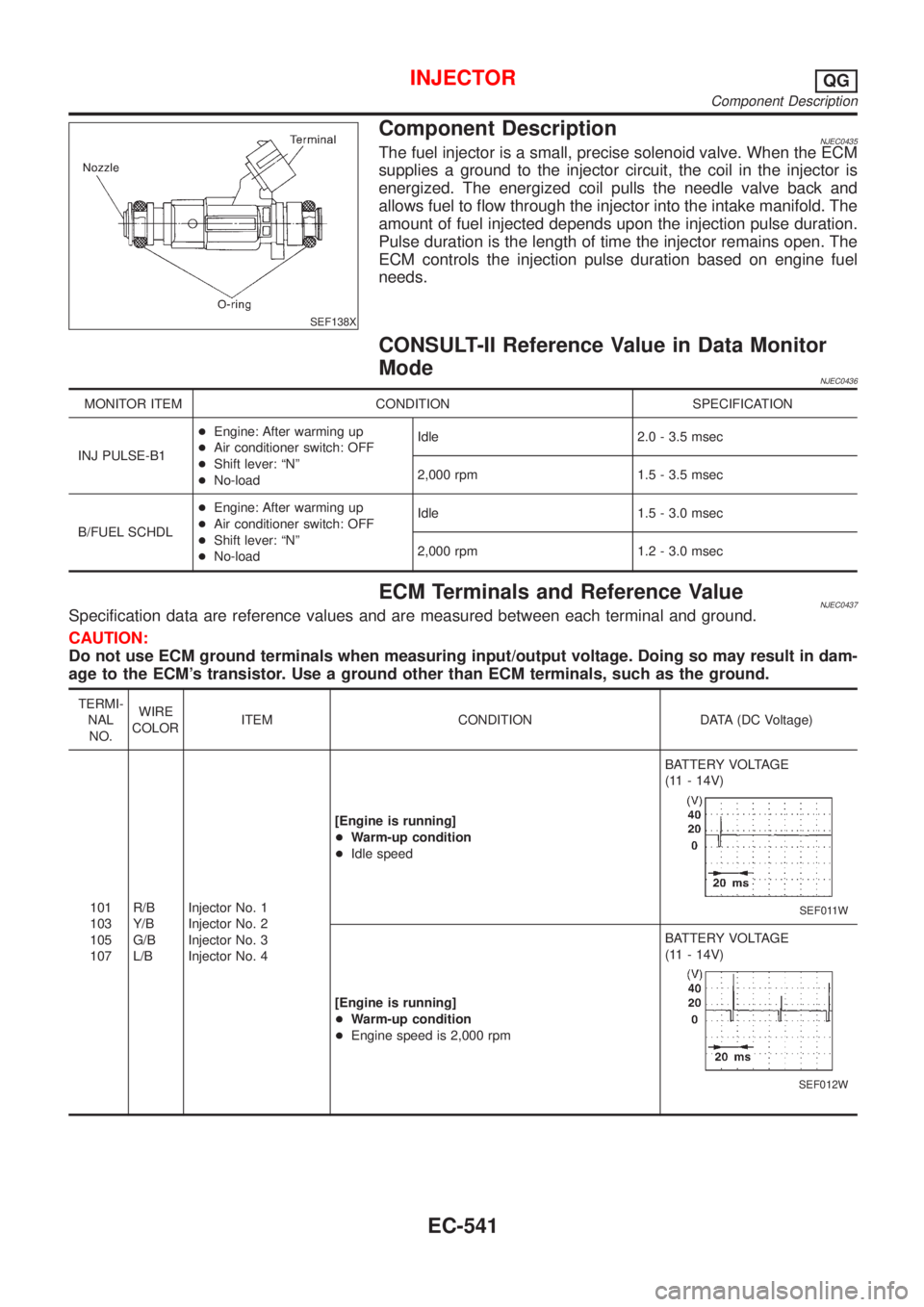

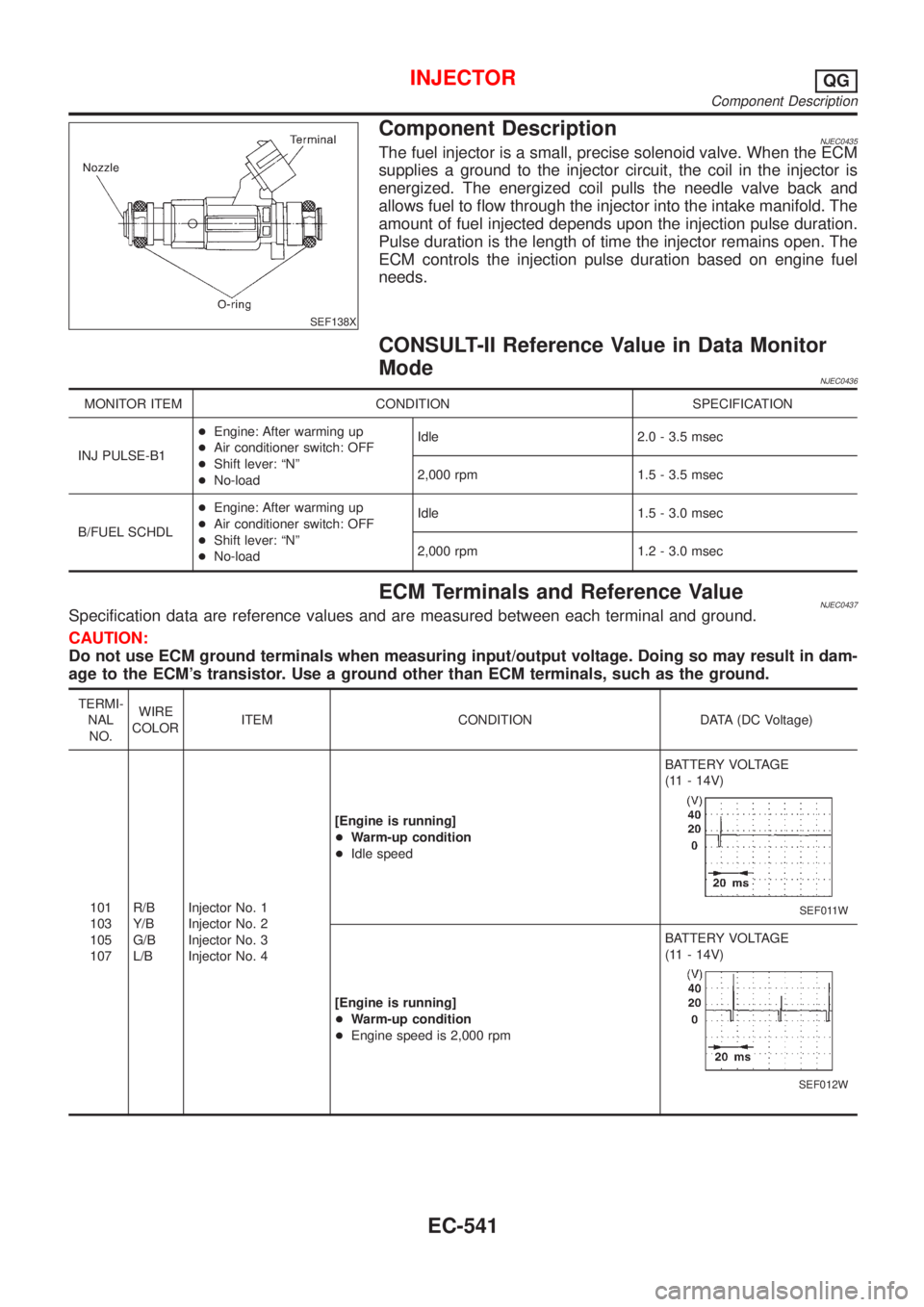

SEF138X

Component DescriptionNJEC0435The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the injector circuit, the coil in the injector is

energized. The energized coil pulls the needle valve back and

allows fuel to flow through the injector into the intake manifold. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the injector remains open. The

ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0436

MONITOR ITEM CONDITION SPECIFICATION

INJ PULSE-B1+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle 2.0 - 3.5 msec

2,000 rpm 1.5 - 3.5 msec

B/FUEL SCHDL+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ªNº

+No-loadIdle 1.5 - 3.0 msec

2,000 rpm 1.2 - 3.0 msec

ECM Terminals and Reference ValueNJEC0437Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

101

103

105

107R/B

Y/B

G/B

L/BInjector No. 1

Injector No. 2

Injector No. 3

Injector No. 4[Engine is running]

+Warm-up condition

+Idle speedBATTERY VOLTAGE

(11 - 14V)

SEF011W

[Engine is running]

+Warm-up condition

+Engine speed is 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

SEF012W

INJECTORQG

Component Description

EC-541

Page 1266 of 2898

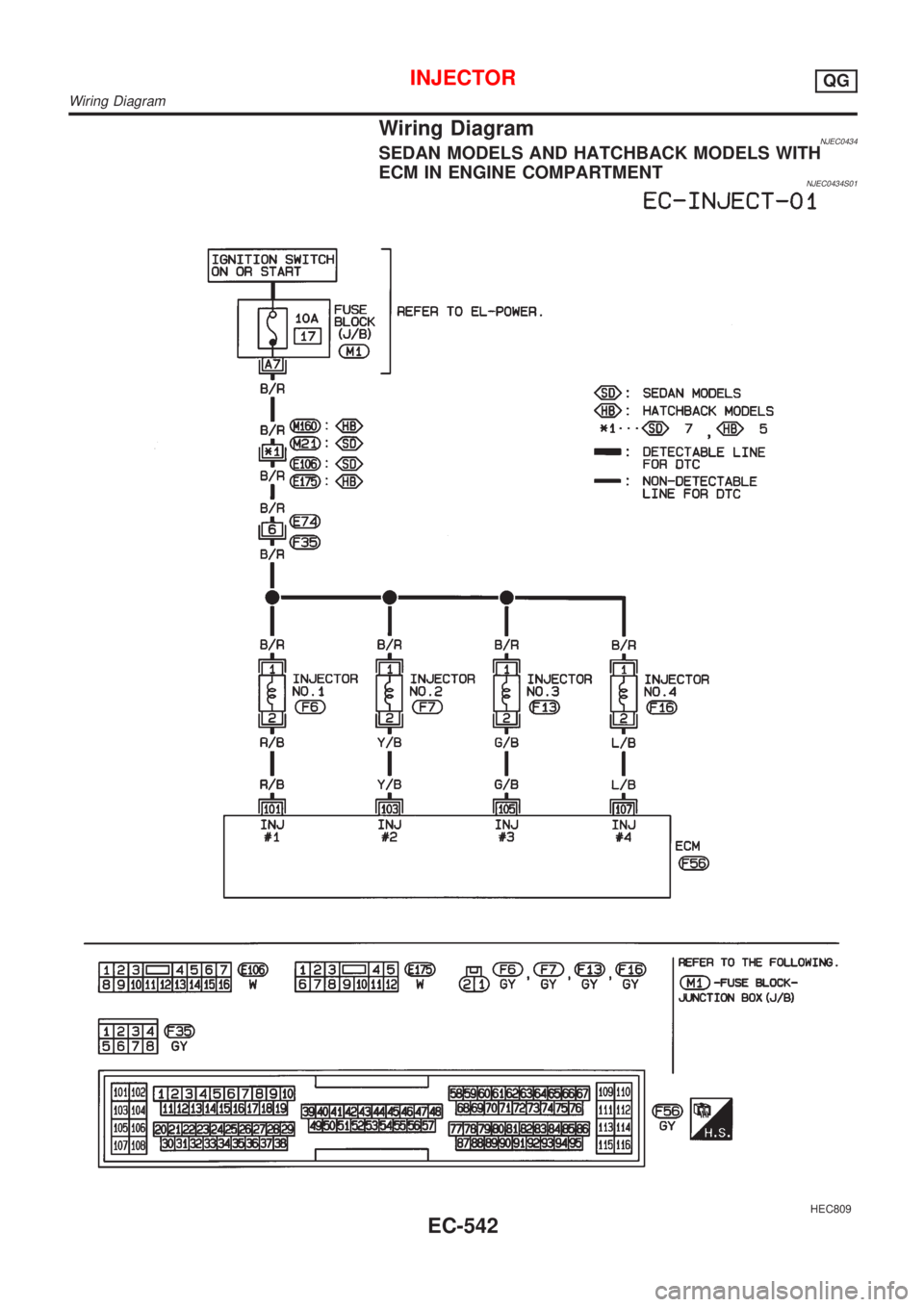

Wiring DiagramNJEC0434SEDAN MODELS AND HATCHBACK MODELS WITH

ECM IN ENGINE COMPARTMENT

NJEC0434S01

HEC809

INJECTORQG

Wiring Diagram

EC-542

Page 1267 of 2898

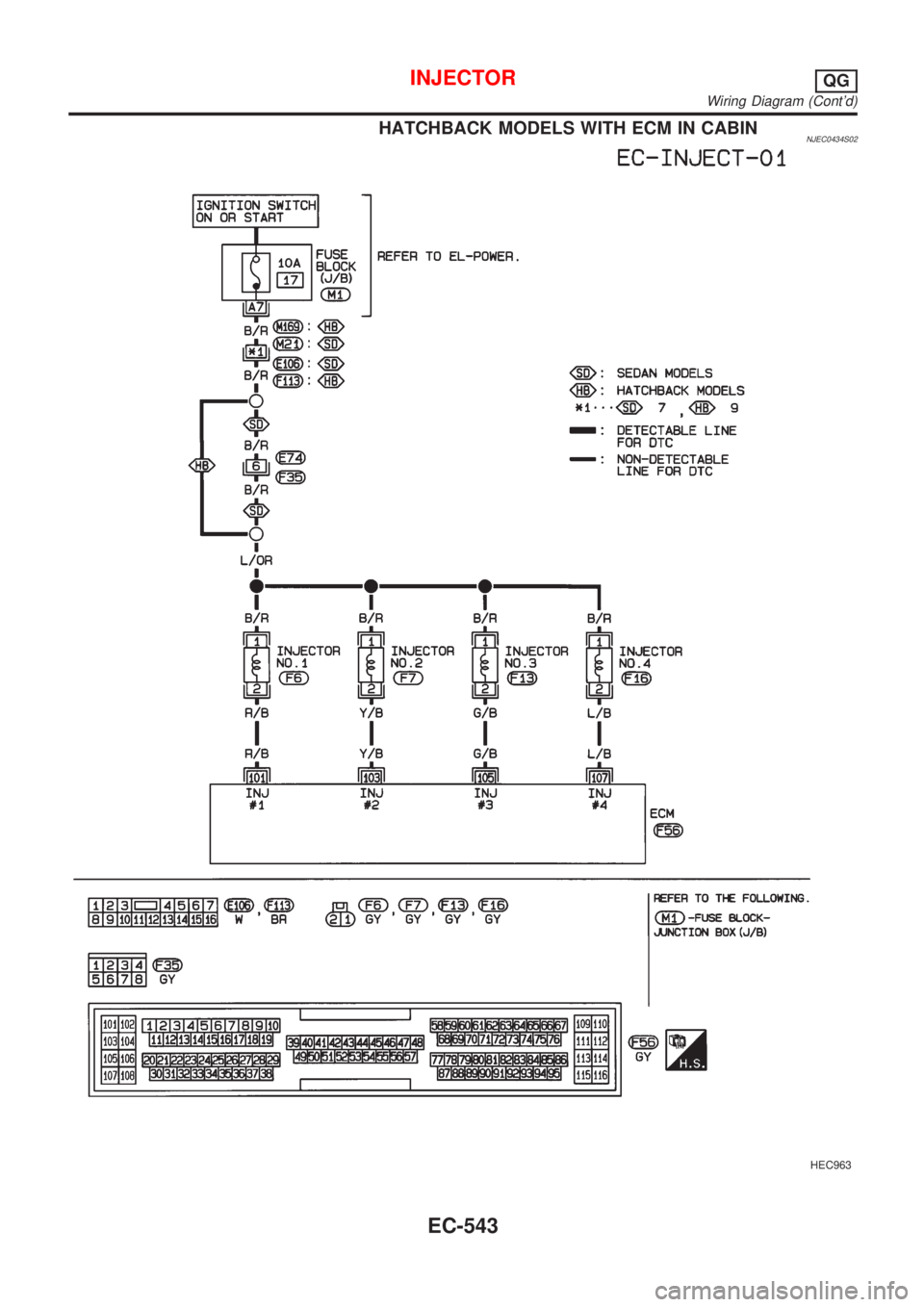

HATCHBACK MODELS WITH ECM IN CABINNJEC0434S02

HEC963

INJECTORQG

Wiring Diagram (Cont'd)

EC-543

Page 1268 of 2898

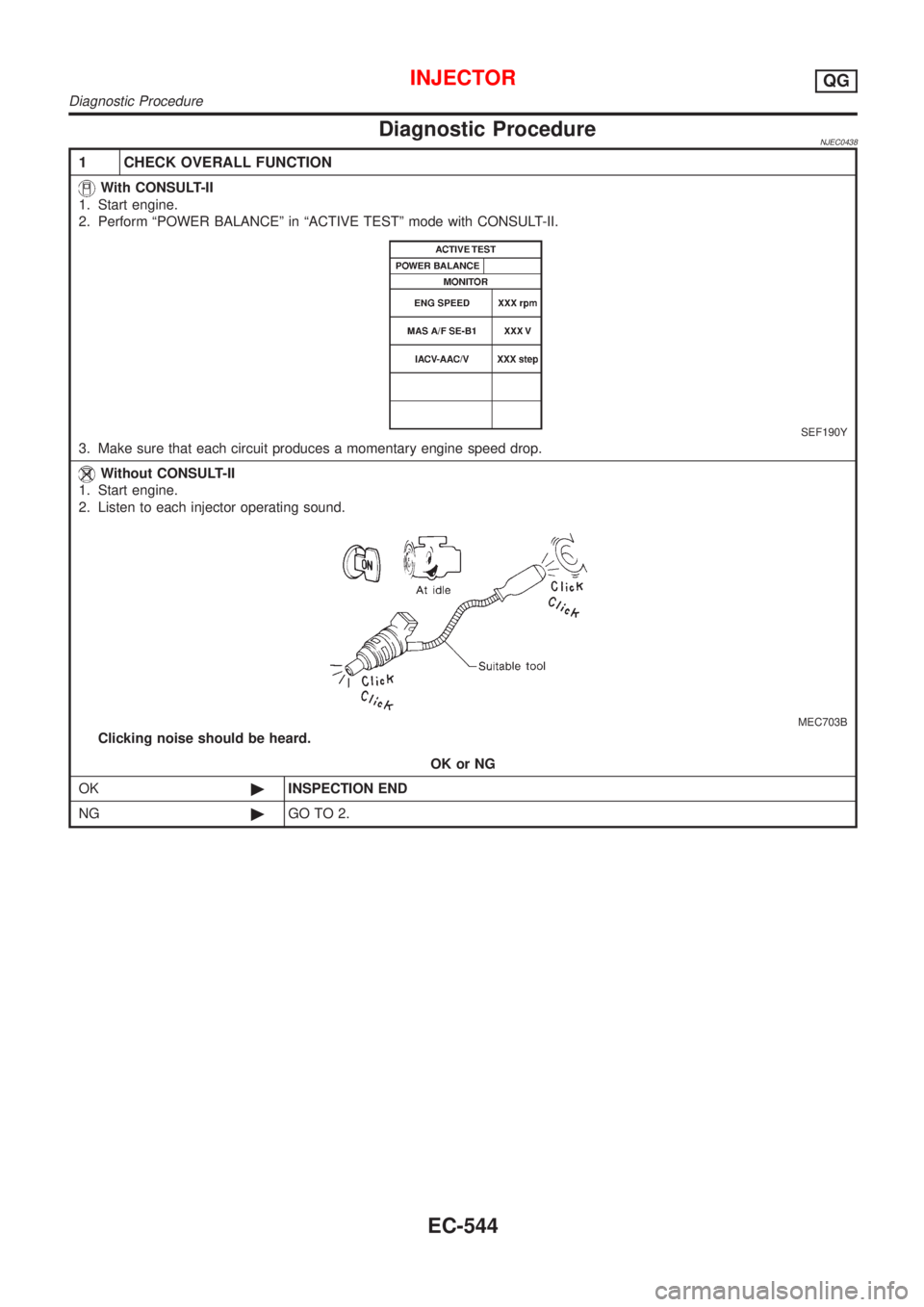

Diagnostic ProcedureNJEC0438

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

SEF190Y

3. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-II

1. Start engine.

2. Listen to each injector operating sound.

MEC703B

Clicking noise should be heard.

OK or NG

OK©INSPECTION END

NG©GO TO 2.

INJECTORQG

Diagnostic Procedure

EC-544

Page 1269 of 2898

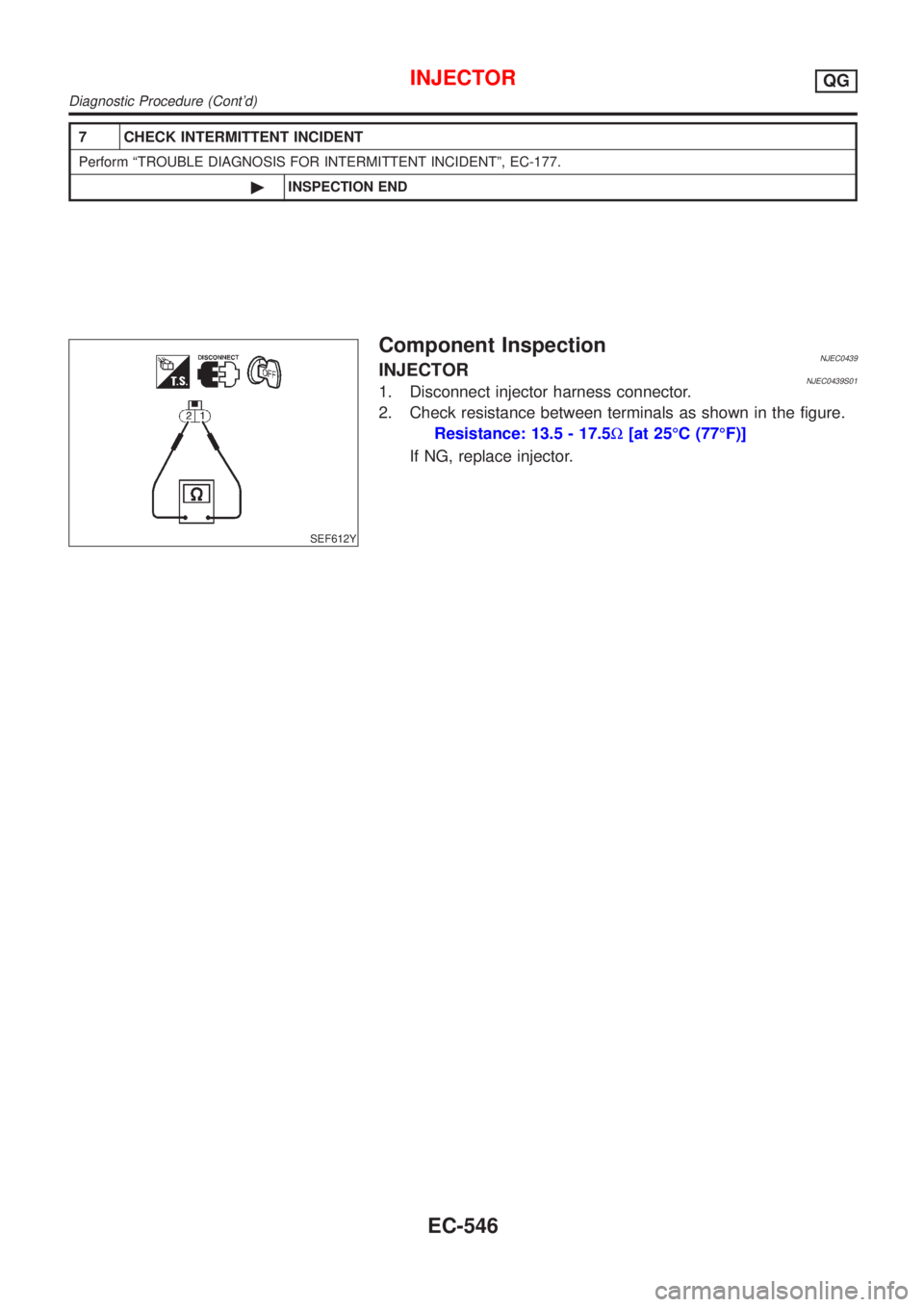

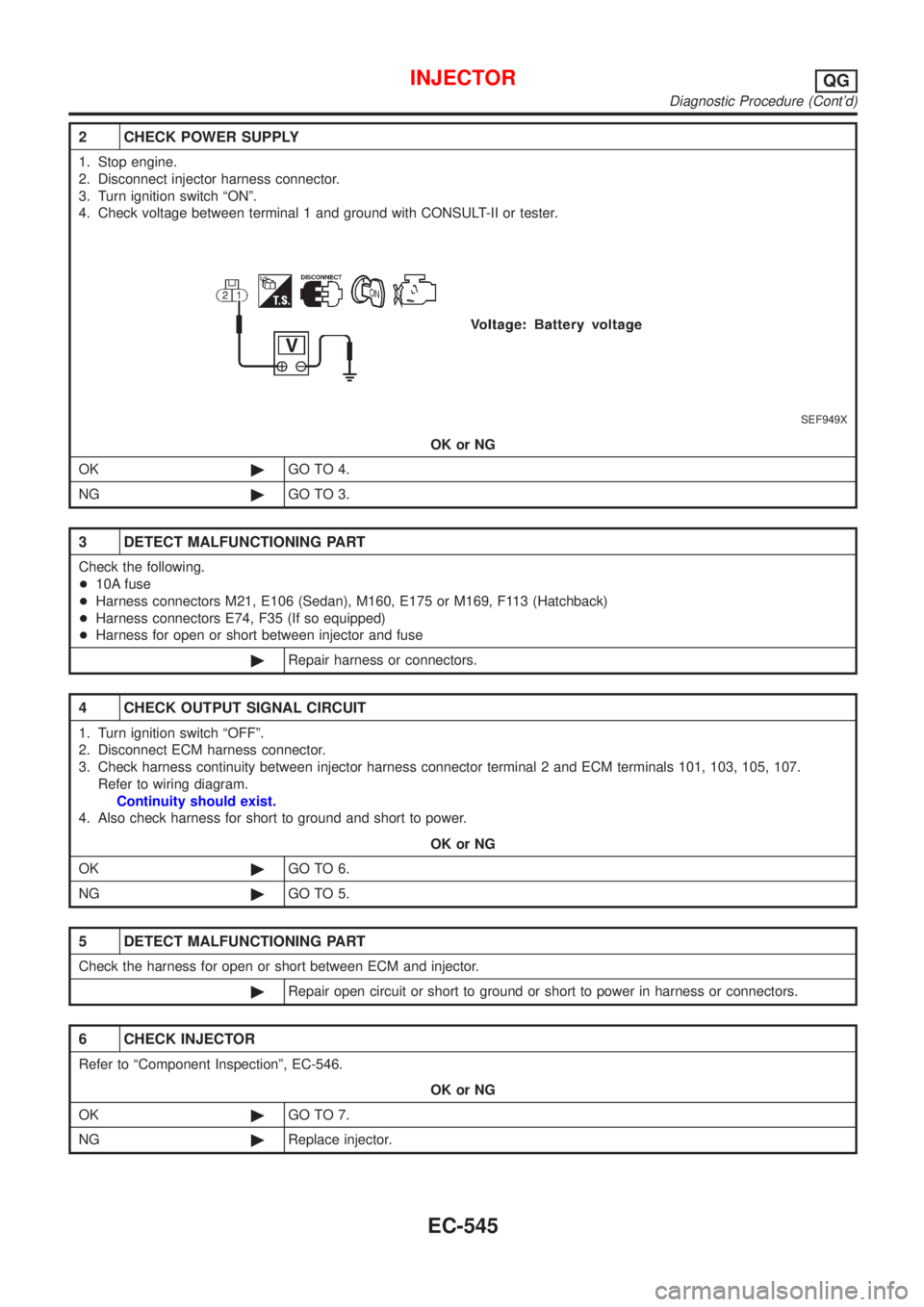

2 CHECK POWER SUPPLY

1. Stop engine.

2. Disconnect injector harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEF949X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+10A fuse

+Harness connectors M21, E106 (Sedan), M160, E175 or M169, F113 (Hatchback)

+Harness connectors E74, F35 (If so equipped)

+Harness for open or short between injector and fuse

©Repair harness or connectors.

4 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between injector harness connector terminal 2 and ECM terminals 101, 103, 105, 107.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and injector.

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK INJECTOR

Refer to ªComponent Inspectionº, EC-546.

OK or NG

OK©GO TO 7.

NG©Replace injector.

INJECTORQG

Diagnostic Procedure (Cont'd)

EC-545

Page 1270 of 2898

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

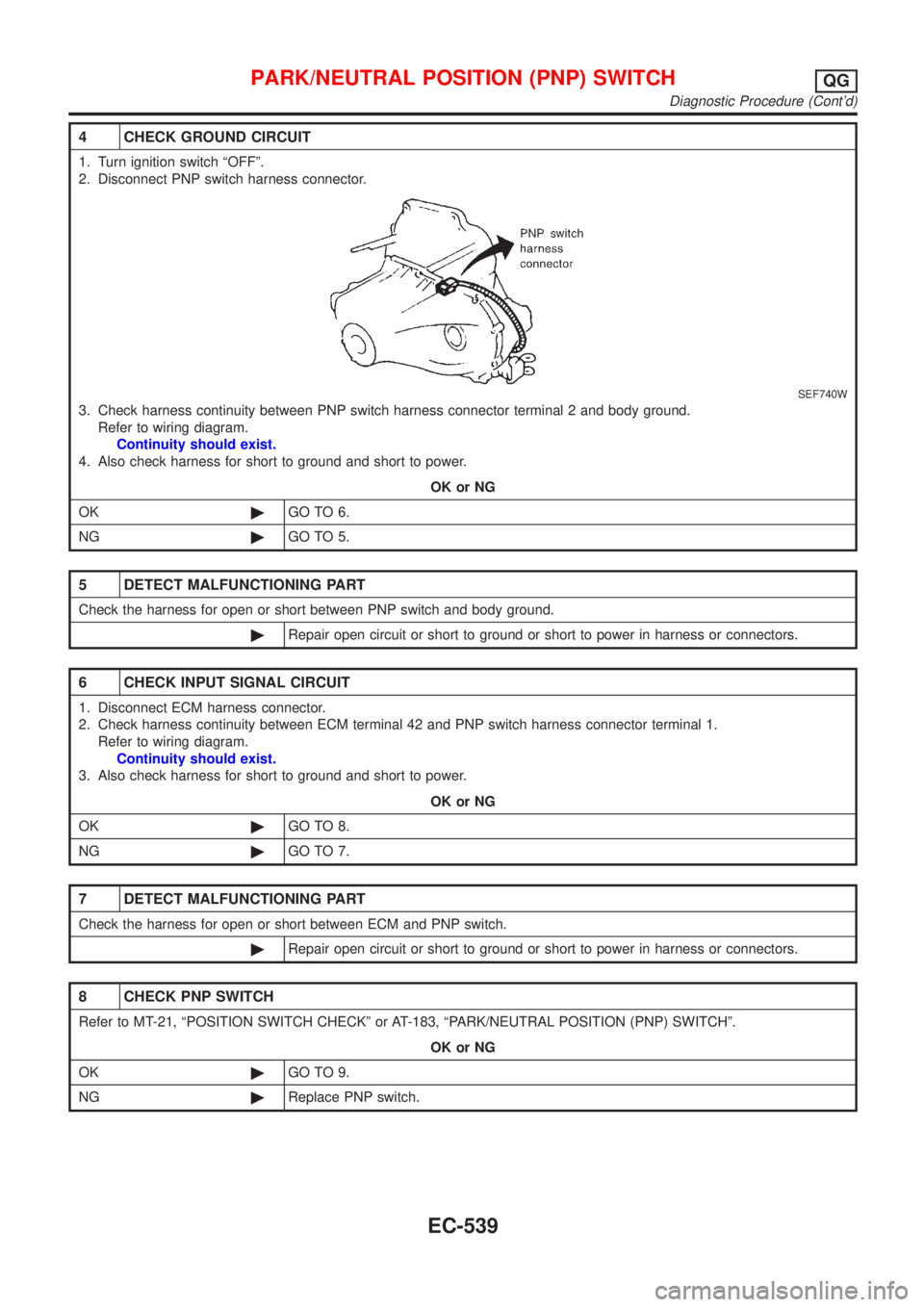

SEF612Y

Component InspectionNJEC0439INJECTORNJEC0439S011. Disconnect injector harness connector.

2. Check resistance between terminals as shown in the figure.

Resistance: 13.5 - 17.5W[at 25ÉC (77ÉF)]

If NG, replace injector.

INJECTORQG

Diagnostic Procedure (Cont'd)

EC-546

Trending: load capacity, airbag, battery capacity, oil level, boot, timing belt, headlamp