NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: parking sensors, manual radio set, drain bolt, wheel, airbag, power steering, oil pressure

Page 1271 of 2898

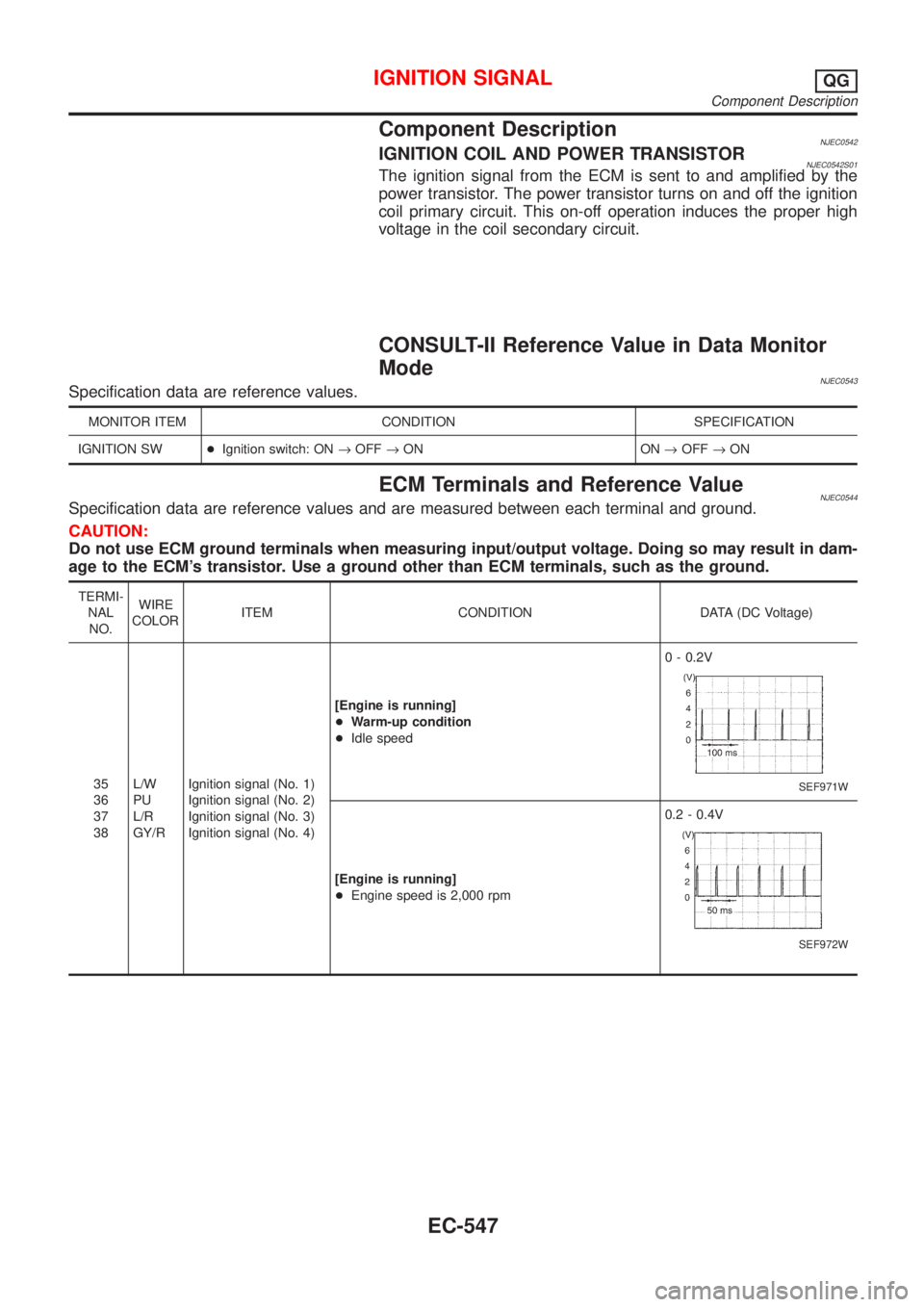

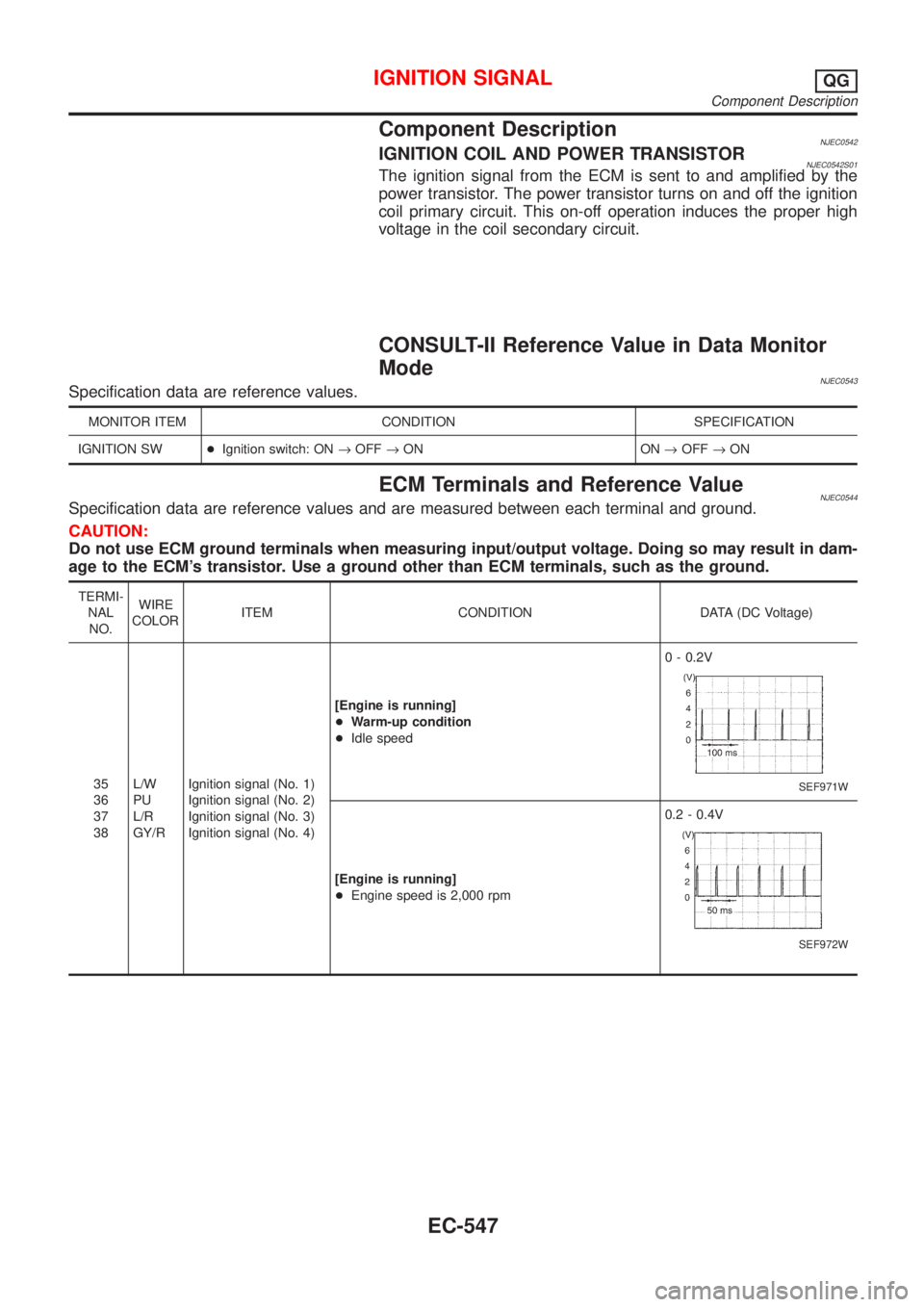

Component DescriptionNJEC0542IGNITION COIL AND POWER TRANSISTORNJEC0542S01The ignition signal from the ECM is sent to and amplified by the

power transistor. The power transistor turns on and off the ignition

coil primary circuit. This on-off operation induces the proper high

voltage in the coil secondary circuit.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0543Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

IGNITION SW+Ignition switch: ON®OFF®ON ON®OFF®ON

ECM Terminals and Reference ValueNJEC0544Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

35

36

37

38L/W

PU

L/R

GY/RIgnition signal (No. 1)

Ignition signal (No. 2)

Ignition signal (No. 3)

Ignition signal (No. 4)[Engine is running]

+Warm-up condition

+Idle speed0 - 0.2V

SEF971W

[Engine is running]

+Engine speed is 2,000 rpm0.2 - 0.4V

SEF972W

IGNITION SIGNALQG

Component Description

EC-547

Page 1272 of 2898

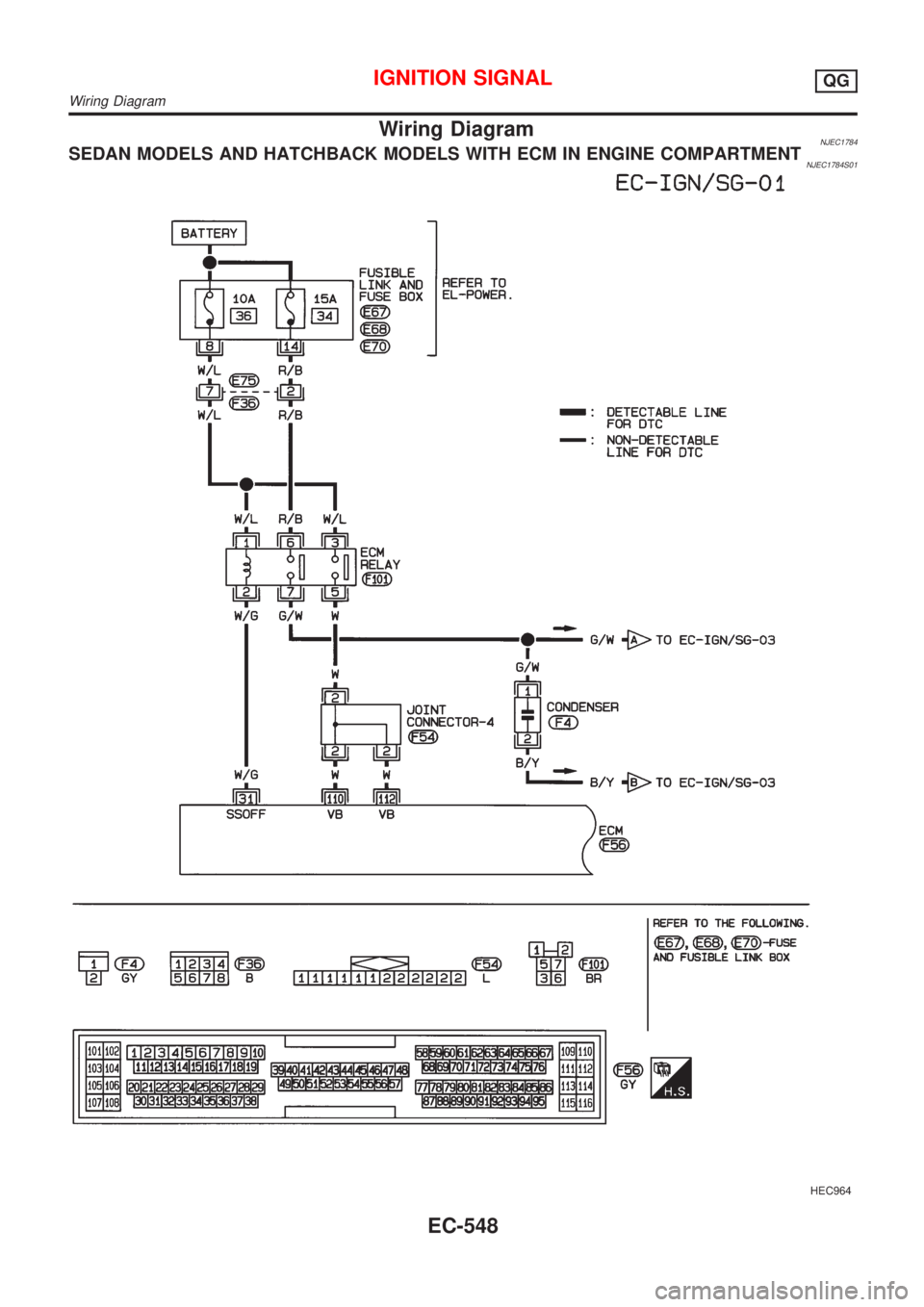

Wiring DiagramNJEC1784SEDAN MODELS AND HATCHBACK MODELS WITH ECM IN ENGINE COMPARTMENTNJEC1784S01

HEC964

IGNITION SIGNALQG

Wiring Diagram

EC-548

Page 1273 of 2898

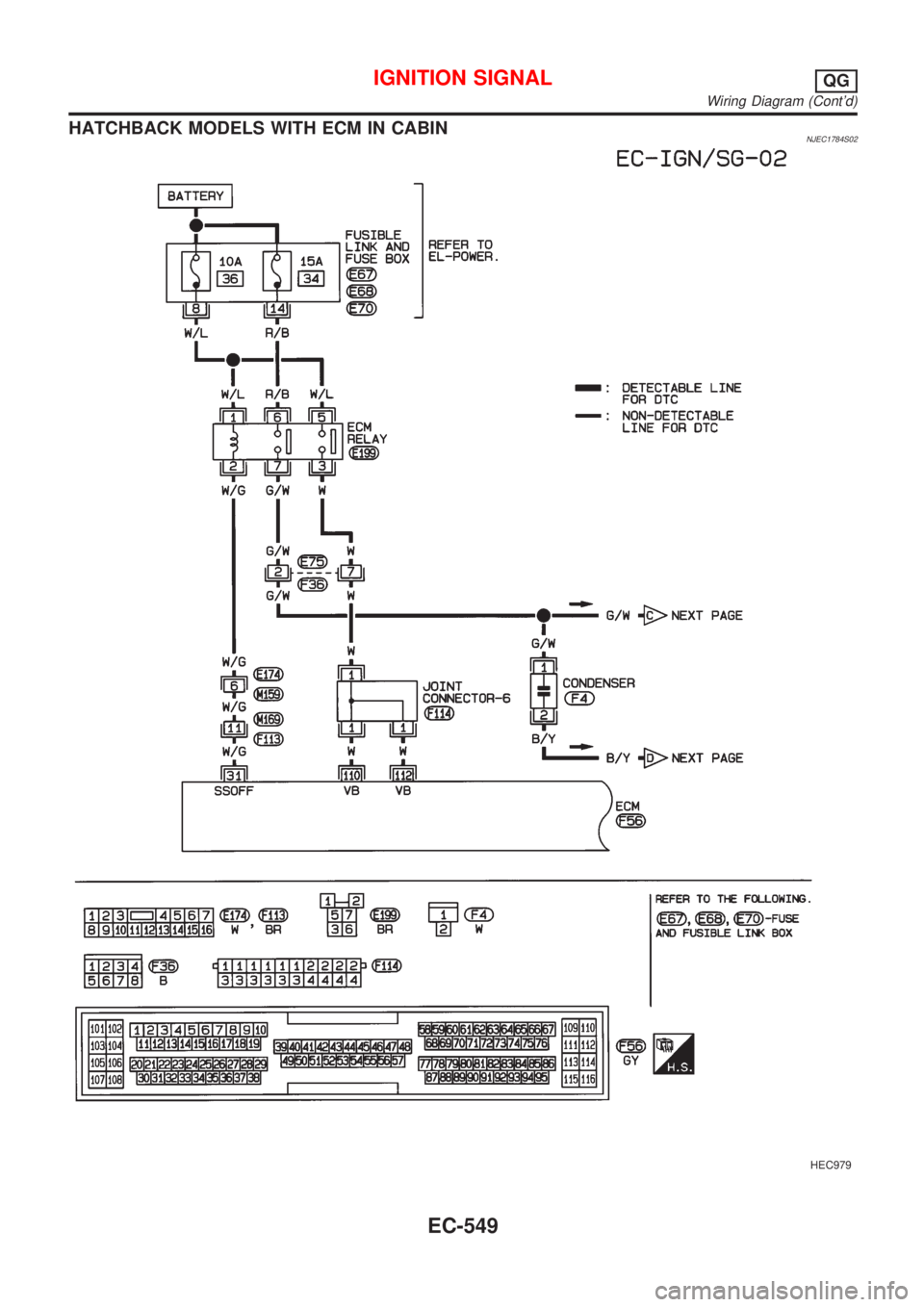

HATCHBACK MODELS WITH ECM IN CABINNJEC1784S02

HEC979

IGNITION SIGNALQG

Wiring Diagram (Cont'd)

EC-549

Page 1274 of 2898

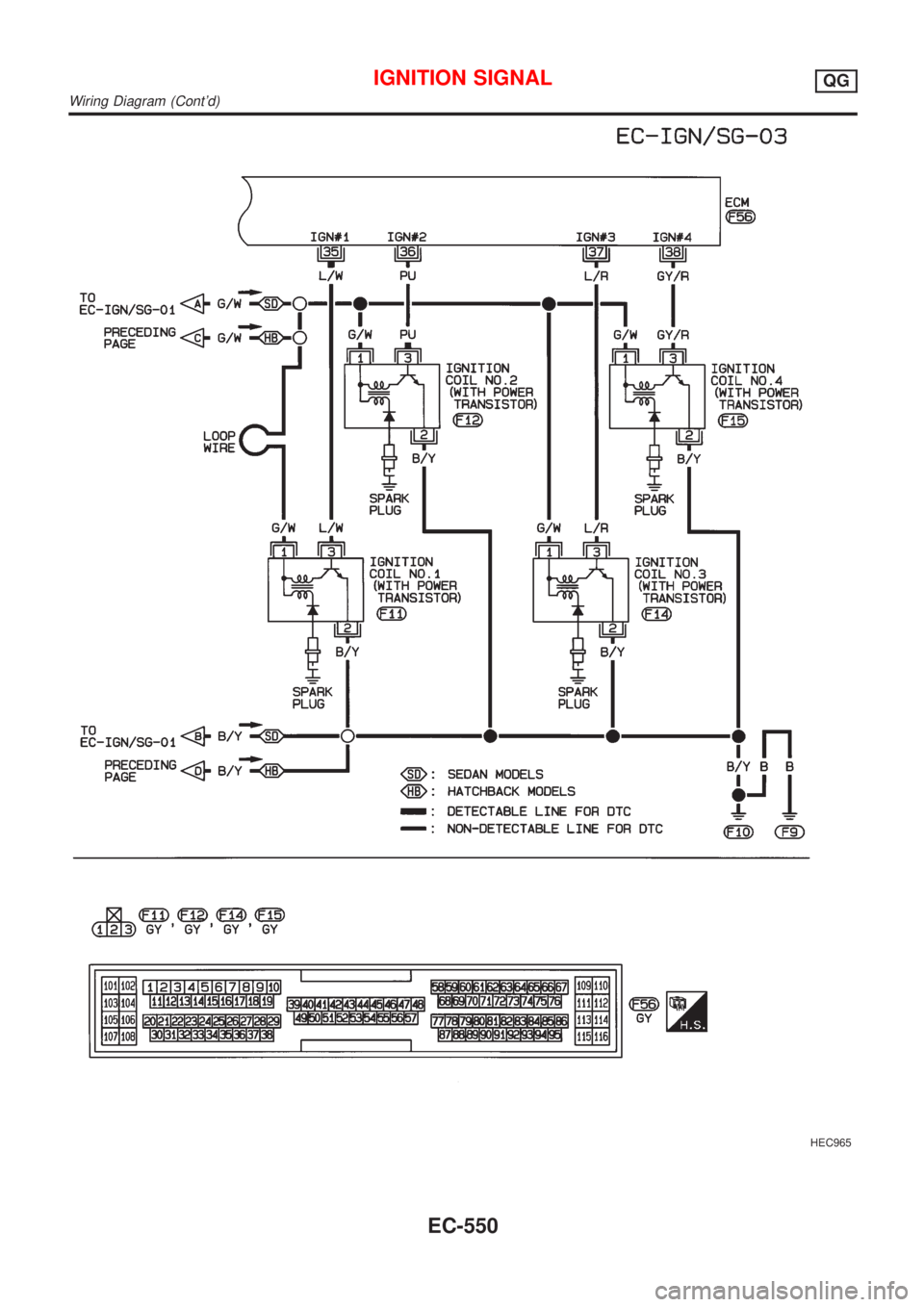

HEC965

IGNITION SIGNALQG

Wiring Diagram (Cont'd)

EC-550

Page 1275 of 2898

Diagnostic ProcedureNJEC0579

1 CHECK ENGINE START

Turn ignition switch ªOFFº, and restart engine.

Is engine running?

YesorNo

Yes (With CONSULT-II)©GO TO 2.

Yes (Without CONSULT-

II)©GO TO 12.

No©GO TO 3.

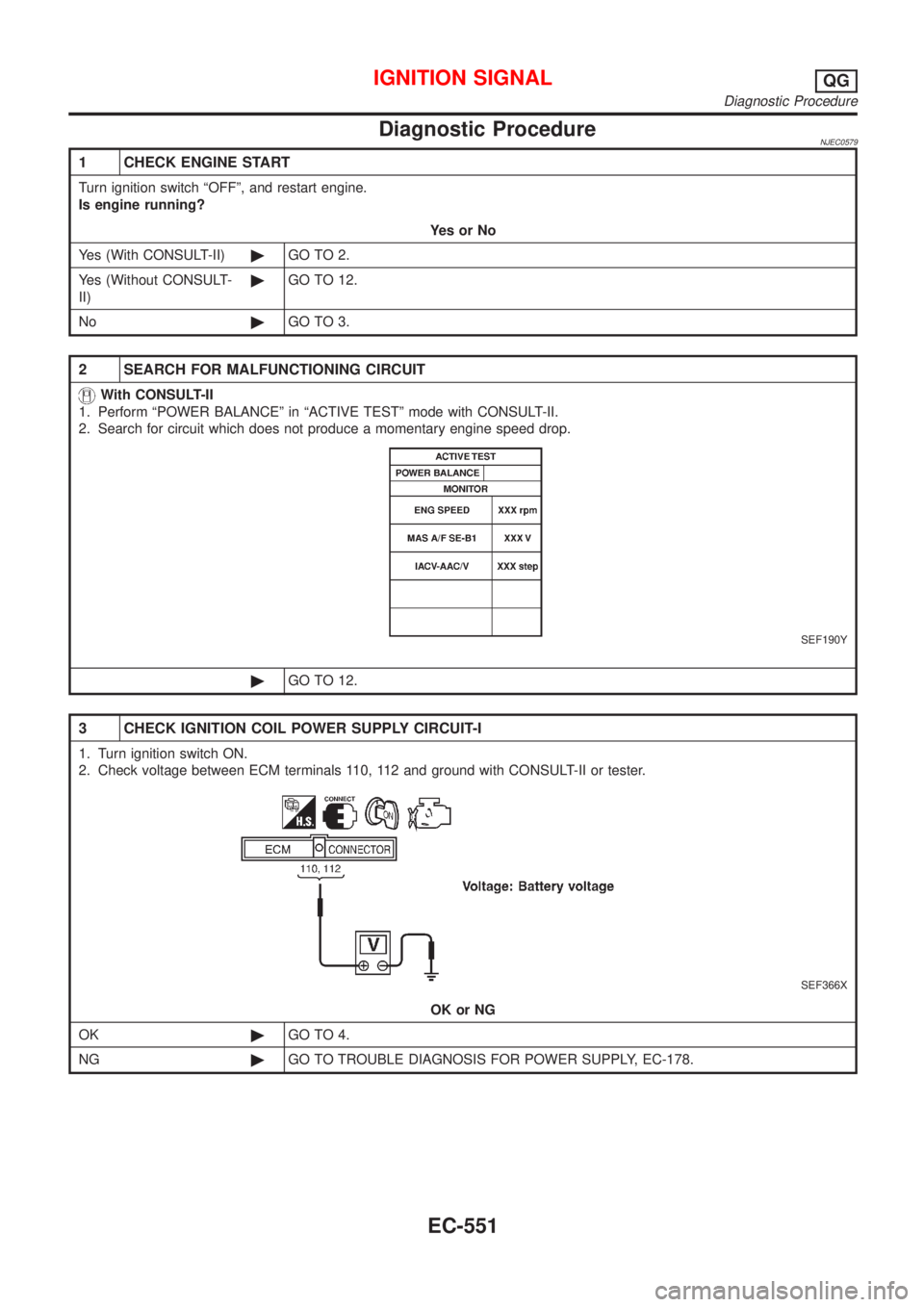

2 SEARCH FOR MALFUNCTIONING CIRCUIT

With CONSULT-II

1. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

2. Search for circuit which does not produce a momentary engine speed drop.

SEF190Y

©GO TO 12.

3 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check voltage between ECM terminals 110, 112 and ground with CONSULT-II or tester.

SEF366X

OK or NG

OK©GO TO 4.

NG©GO TO TROUBLE DIAGNOSIS FOR POWER SUPPLY, EC-178.

IGNITION SIGNALQG

Diagnostic Procedure

EC-551

Page 1276 of 2898

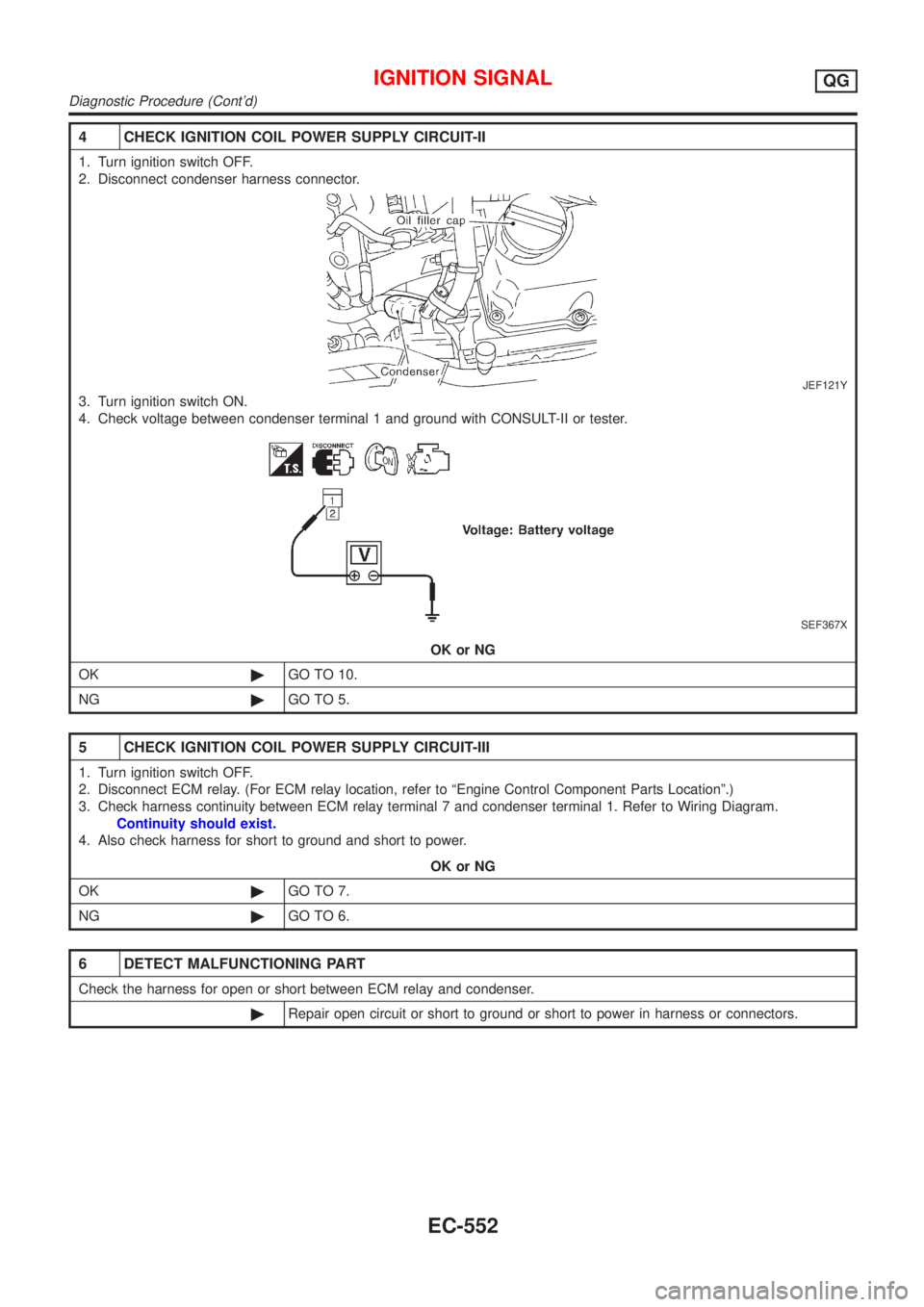

4 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect condenser harness connector.

JEF121Y

3. Turn ignition switch ON.

4. Check voltage between condenser terminal 1 and ground with CONSULT-II or tester.

SEF367X

OK or NG

OK©GO TO 10.

NG©GO TO 5.

5 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

2. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Component Parts Locationº.)

3. Check harness continuity between ECM relay terminal 7 and condenser terminal 1. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM relay and condenser.

©Repair open circuit or short to ground or short to power in harness or connectors.

IGNITION SIGNALQG

Diagnostic Procedure (Cont'd)

EC-552

Page 1277 of 2898

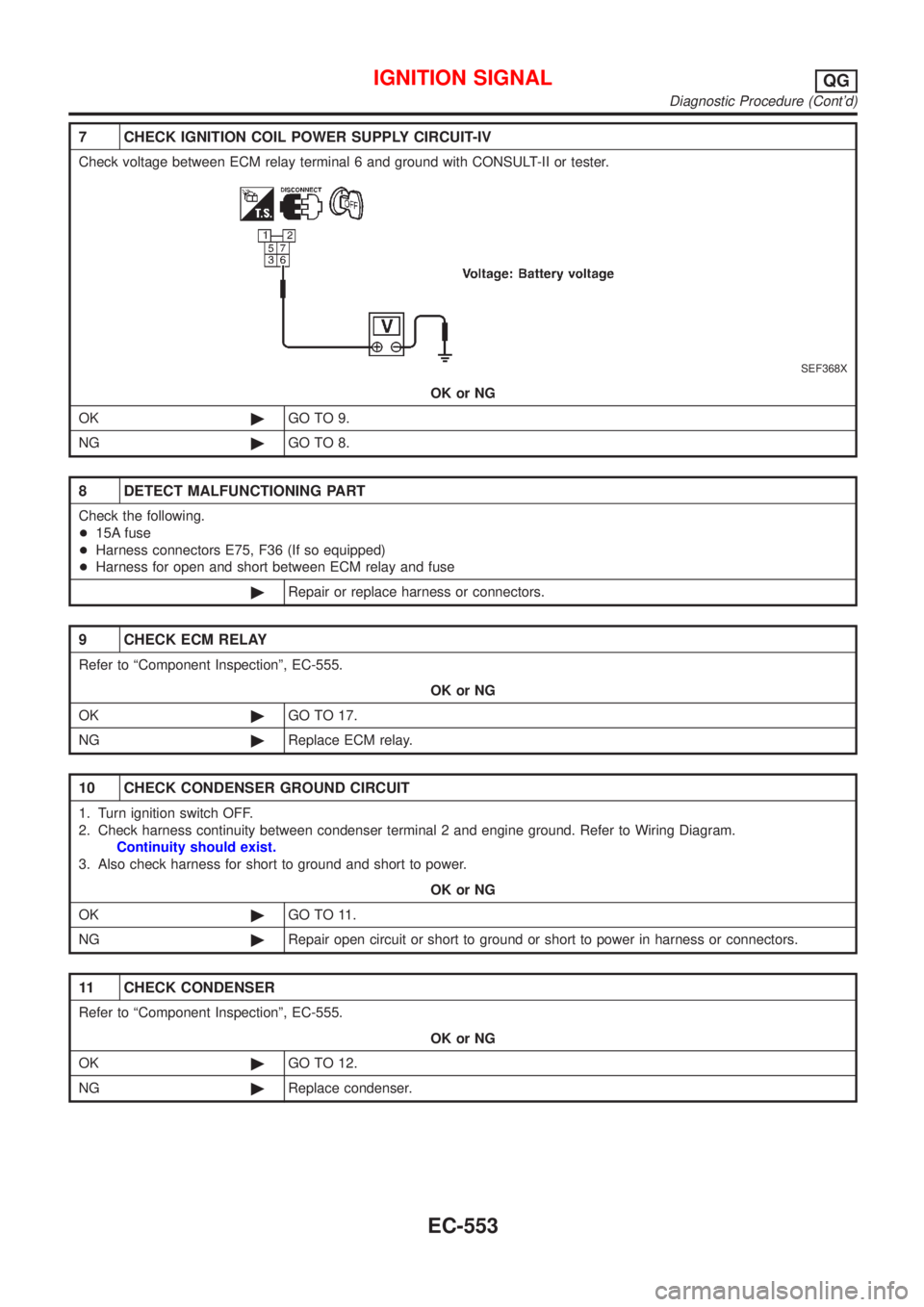

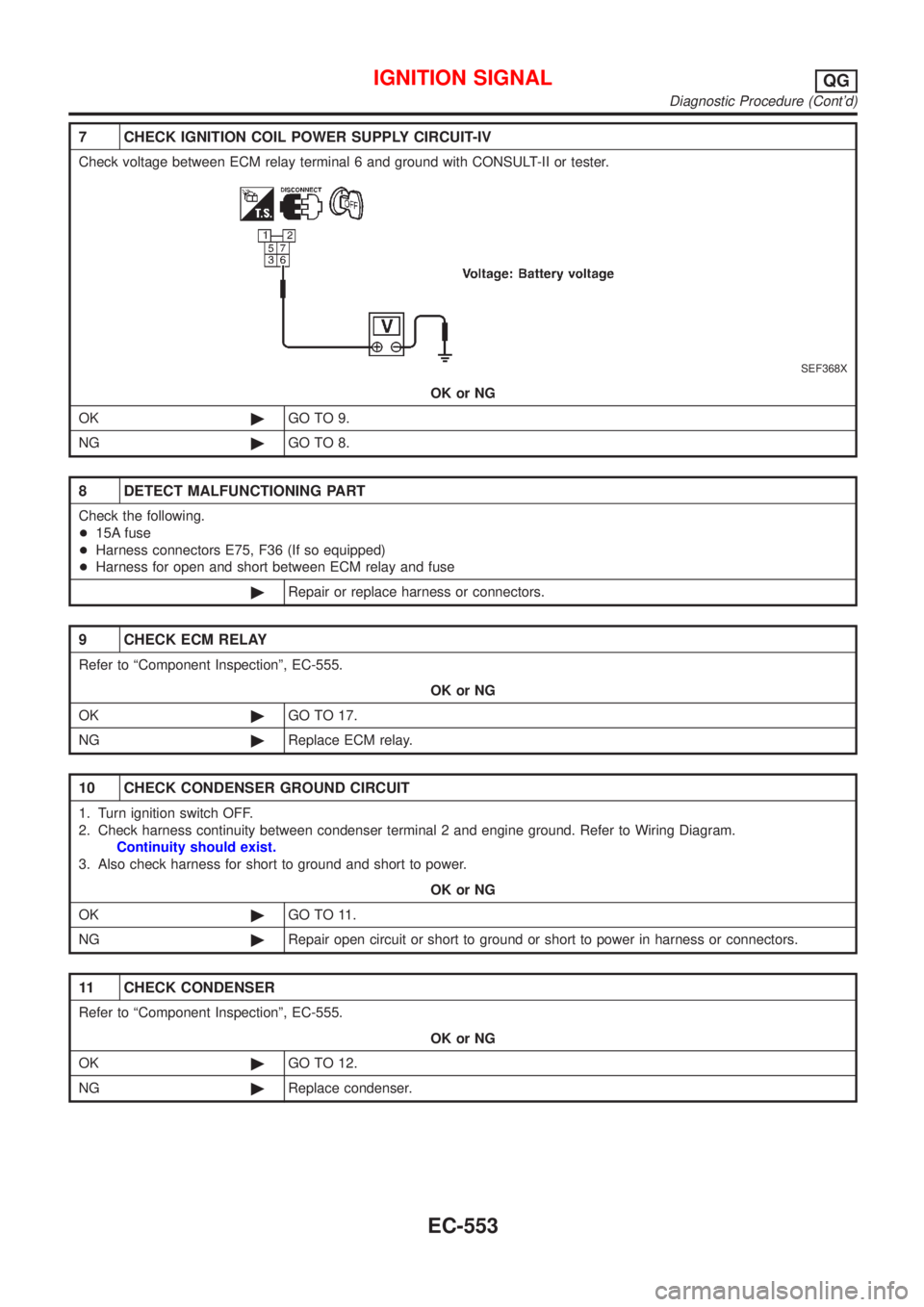

7 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-IV

Check voltage between ECM relay terminal 6 and ground with CONSULT-II or tester.

SEF368X

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+15A fuse

+Harness connectors E75, F36 (If so equipped)

+Harness for open and short between ECM relay and fuse

©Repair or replace harness or connectors.

9 CHECK ECM RELAY

Refer to ªComponent Inspectionº, EC-555.

OK or NG

OK©GO TO 17.

NG©Replace ECM relay.

10 CHECK CONDENSER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check harness continuity between condenser terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 11.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

11 CHECK CONDENSER

Refer to ªComponent Inspectionº, EC-555.

OK or NG

OK©GO TO 12.

NG©Replace condenser.

IGNITION SIGNALQG

Diagnostic Procedure (Cont'd)

EC-553

Page 1278 of 2898

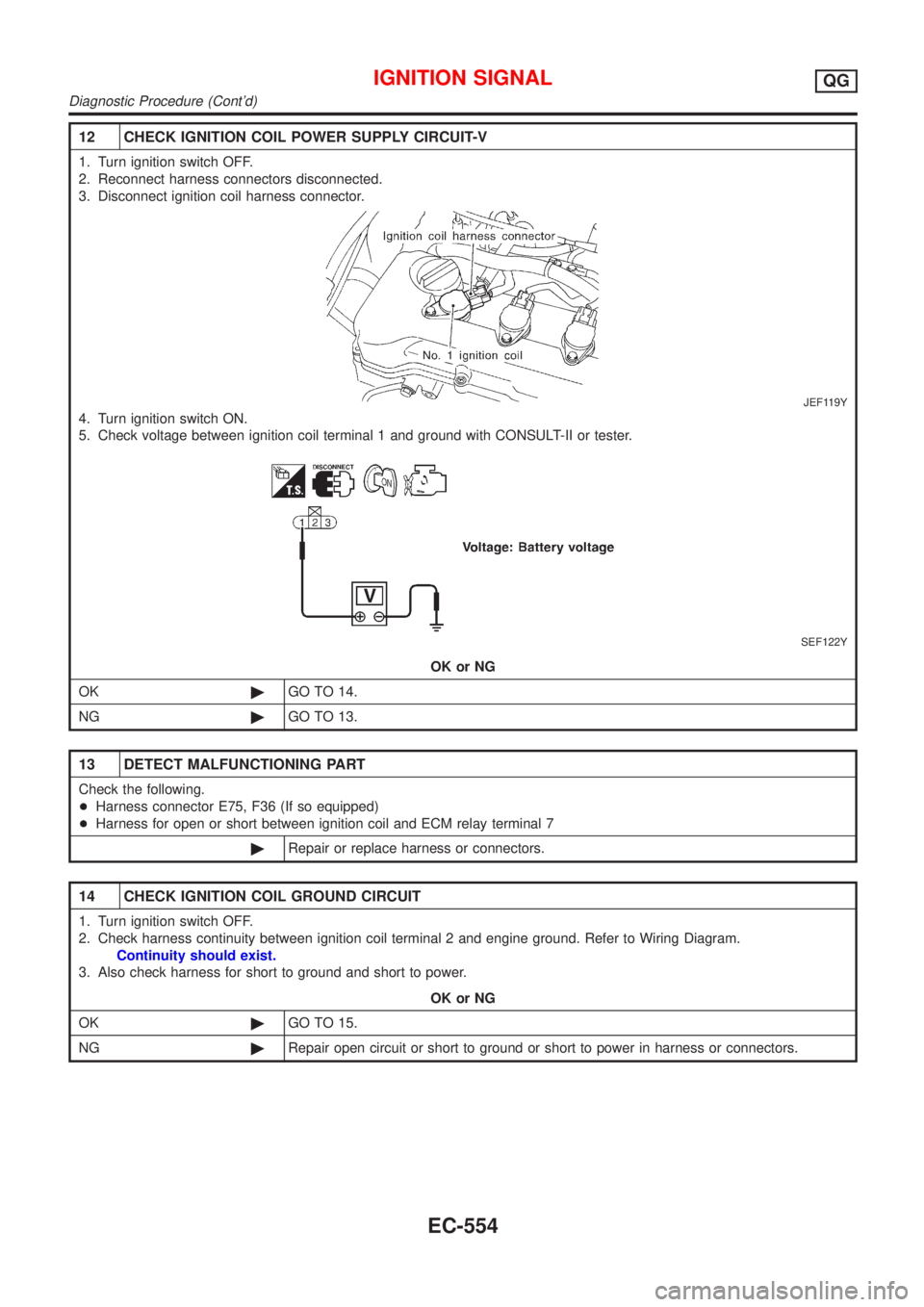

12 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-V

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect ignition coil harness connector.

JEF119Y

4. Turn ignition switch ON.

5. Check voltage between ignition coil terminal 1 and ground with CONSULT-II or tester.

SEF122Y

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 DETECT MALFUNCTIONING PART

Check the following.

+Harness connector E75, F36 (If so equipped)

+Harness for open or short between ignition coil and ECM relay terminal 7

©Repair or replace harness or connectors.

14 CHECK IGNITION COIL GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check harness continuity between ignition coil terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 15.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

IGNITION SIGNALQG

Diagnostic Procedure (Cont'd)

EC-554

Page 1279 of 2898

15 CHECK IGNITION COIL OUTPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 35, 36, 37, 38 and ignition coil terminal 3. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

16 CHECK IGNITION COIL WITH POWER TRANSISTOR

Refer to ªComponent Inspectionº, EC-555.

OK or NG

OK©GO TO 17.

NG©Replace ignition coil with power transistor.

17 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

SEF371Q

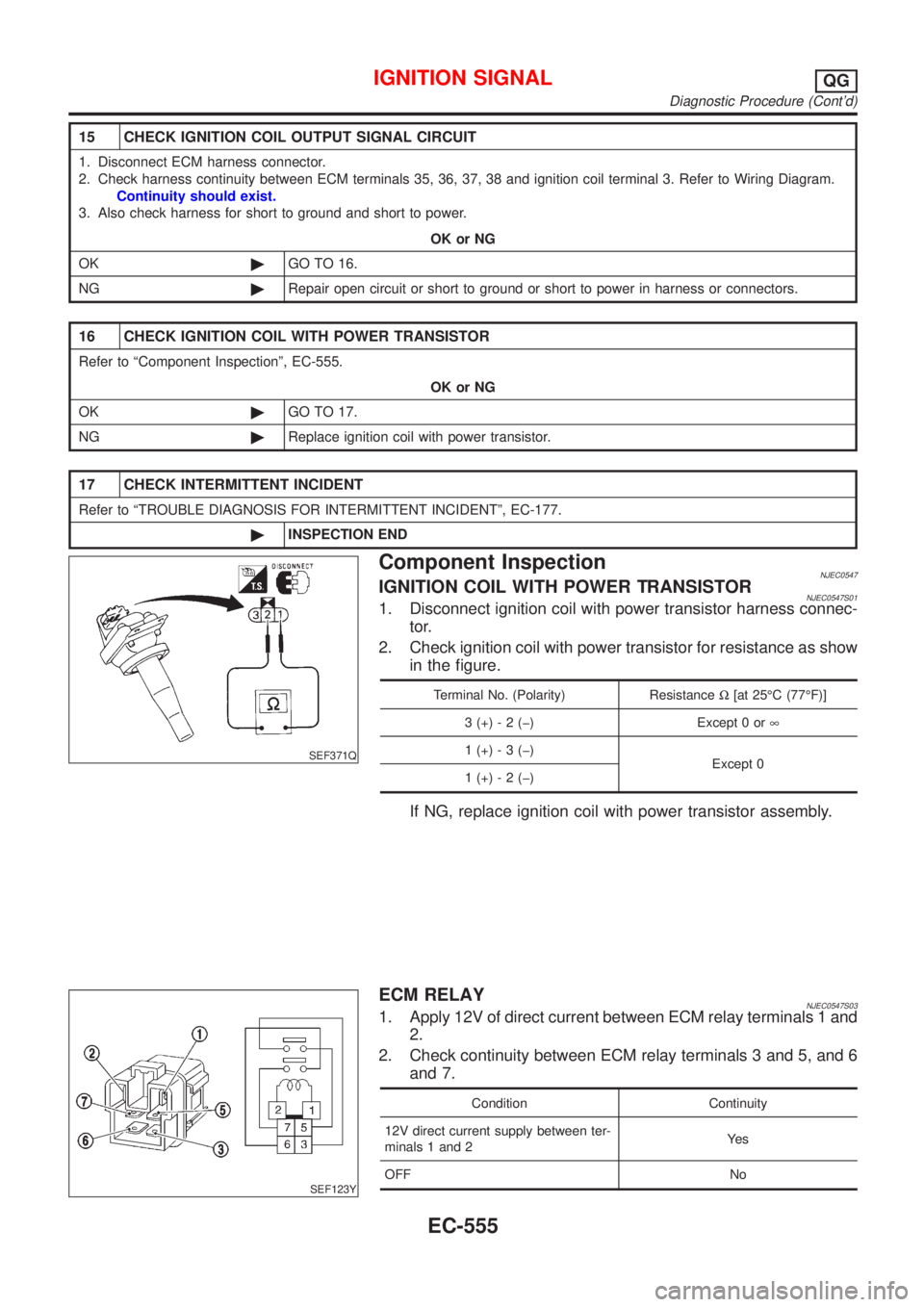

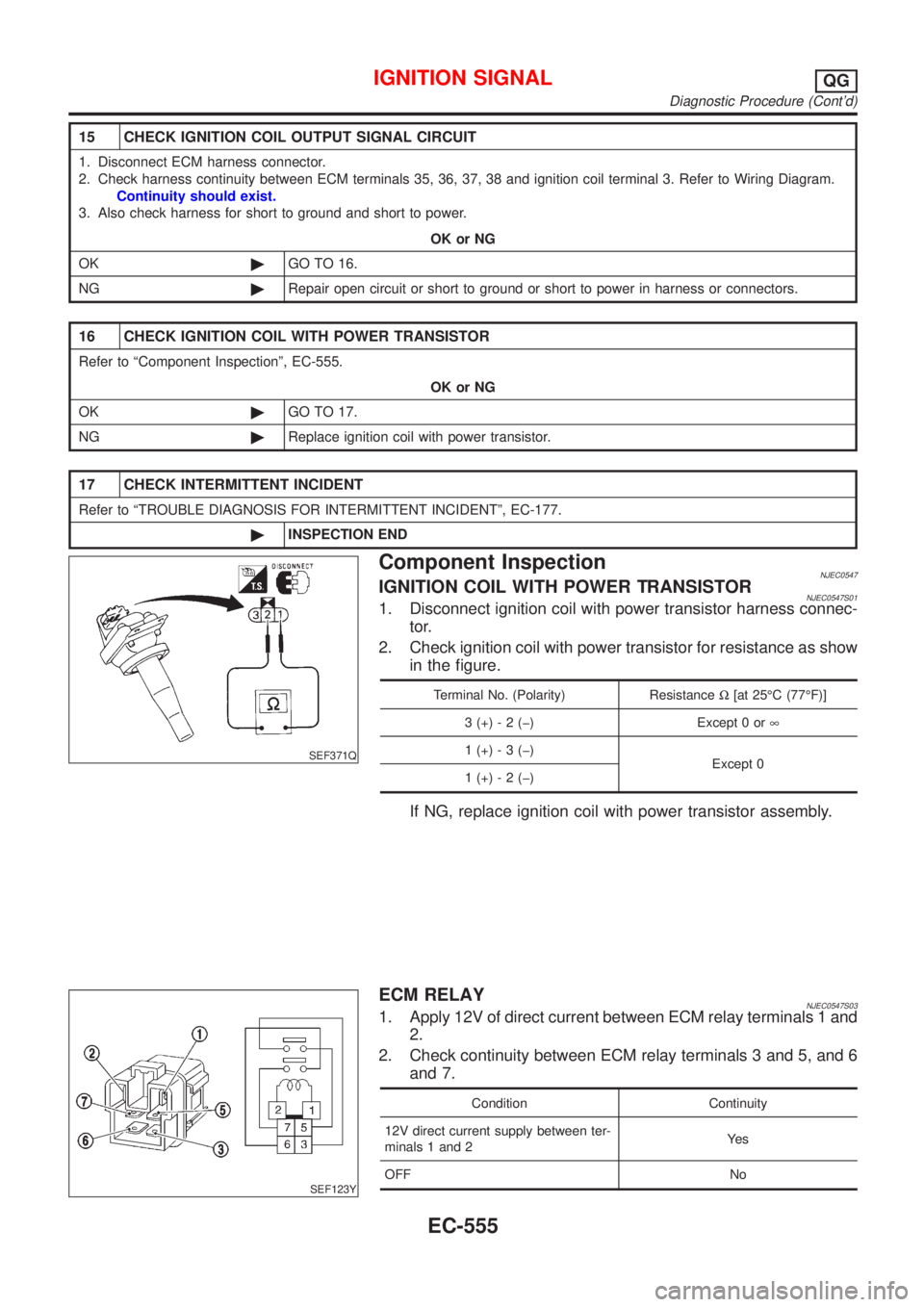

Component InspectionNJEC0547IGNITION COIL WITH POWER TRANSISTORNJEC0547S011. Disconnect ignition coil with power transistor harness connec-

tor.

2. Check ignition coil with power transistor for resistance as show

in the figure.

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 2 (þ) Except 0 or¥

1 (+) - 3 (þ)

Except 0

1 (+) - 2 (þ)

If NG, replace ignition coil with power transistor assembly.

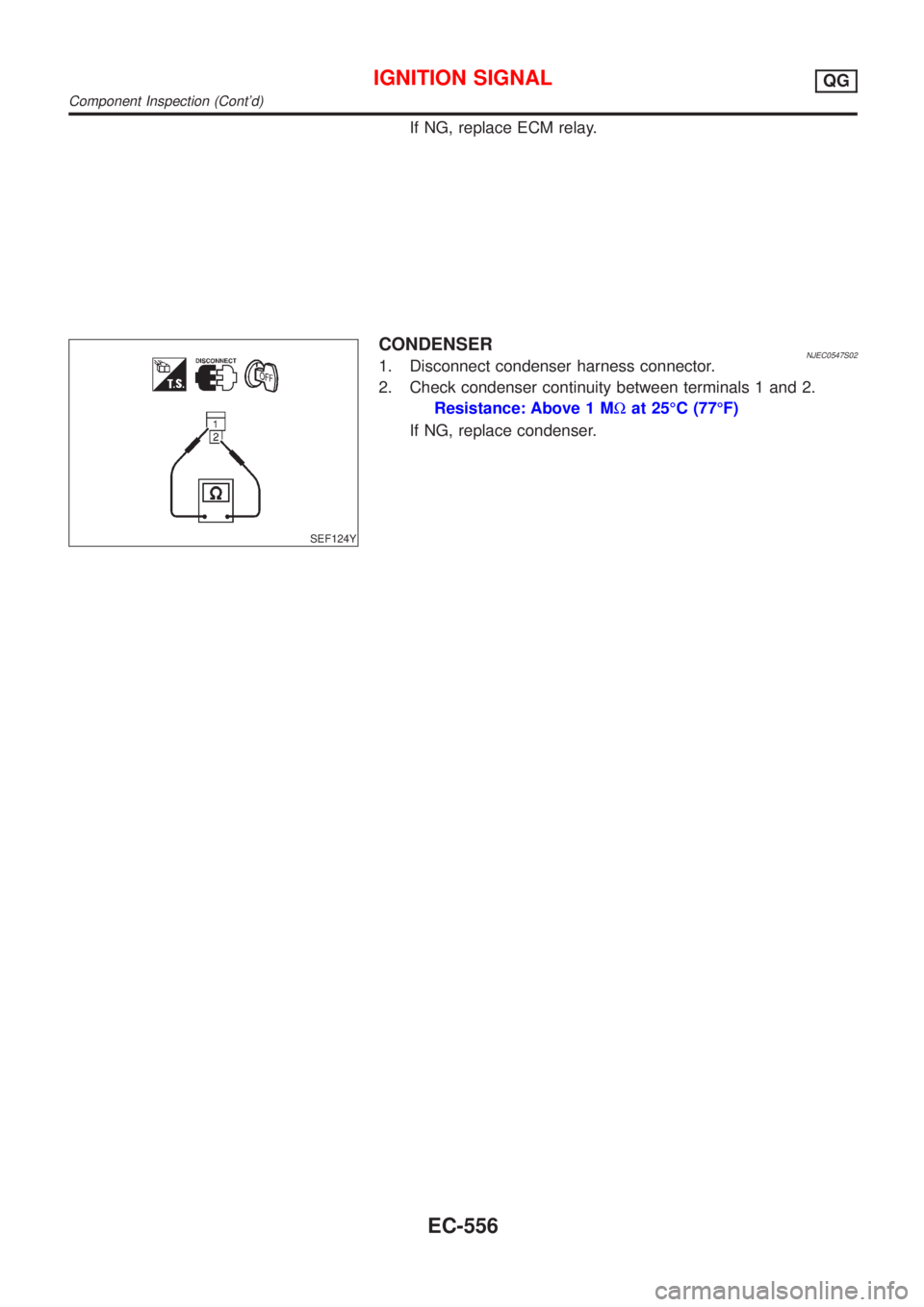

SEF123Y

ECM RELAYNJEC0547S031. Apply 12V of direct current between ECM relay terminals 1 and

2.

2. Check continuity between ECM relay terminals 3 and 5, and 6

and 7.

Condition Continuity

12V direct current supply between ter-

minals 1 and 2Ye s

OFF No

IGNITION SIGNALQG

Diagnostic Procedure (Cont'd)

EC-555

Page 1280 of 2898

If NG, replace ECM relay.

SEF124Y

CONDENSERNJEC0547S021. Disconnect condenser harness connector.

2. Check condenser continuity between terminals 1 and 2.

Resistance: Above 1 MWat 25ÉC (77ÉF)

If NG, replace condenser.

IGNITION SIGNALQG

Component Inspection (Cont'd)

EC-556

Trending: phone, jacking, heating, sensor, navigation system, inflation pressure, fuel consumption