NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2541 of 2898

Service Data and Specifications (SDS)

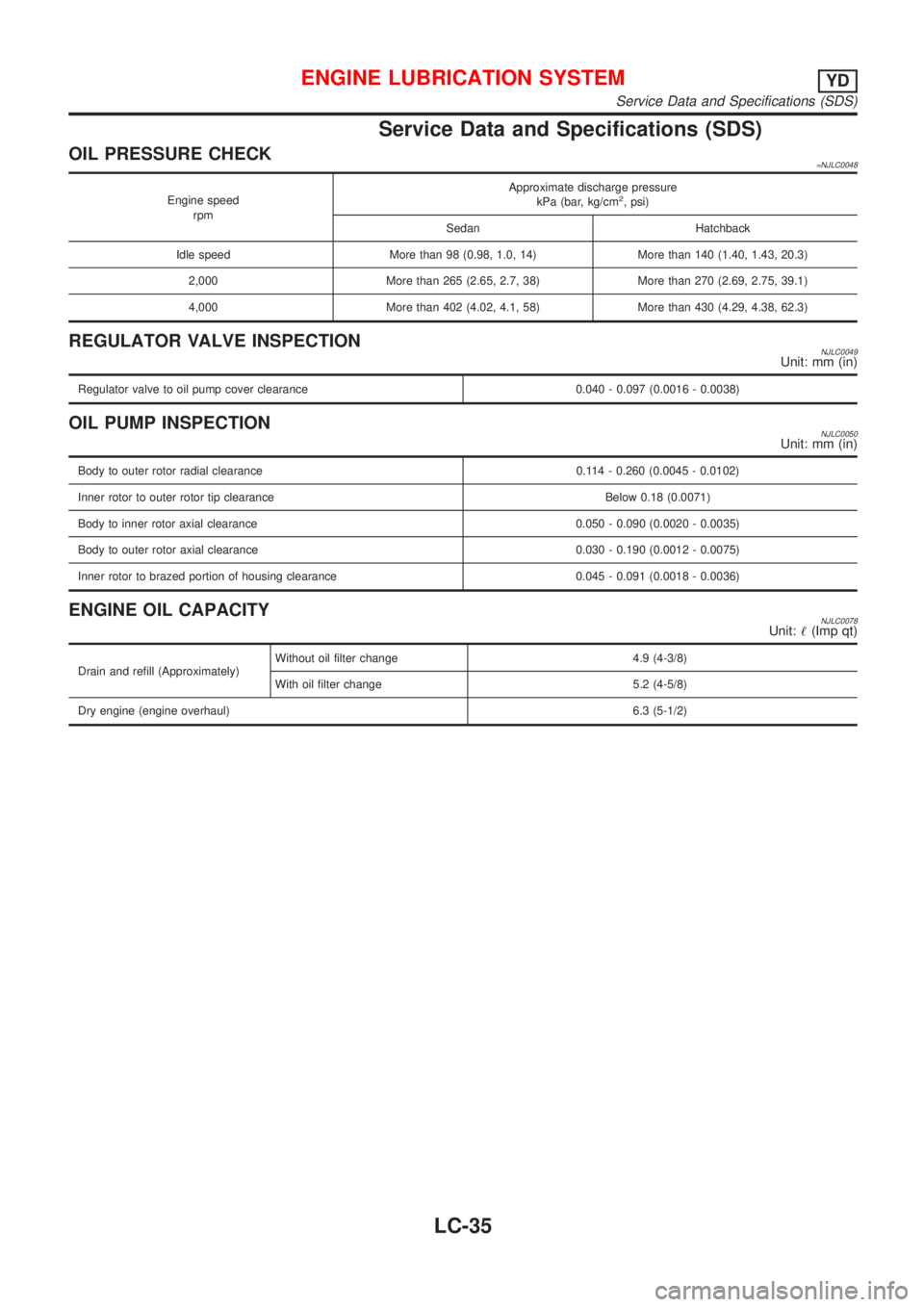

OIL PRESSURE CHECK=NJLC0048

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Sedan Hatchback

Idle speed More than 98 (0.98, 1.0, 14) More than 140 (1.40, 1.43, 20.3)

2,000 More than 265 (2.65, 2.7, 38) More than 270 (2.69, 2.75, 39.1)

4,000 More than 402 (4.02, 4.1, 58) More than 430 (4.29, 4.38, 62.3)

REGULATOR VALVE INSPECTIONNJLC0049Unit: mm (in)

Regulator valve to oil pump cover clearance 0.040 - 0.097 (0.0016 - 0.0038)

OIL PUMP INSPECTIONNJLC0050Unit: mm (in)

Body to outer rotor radial clearance 0.114 - 0.260 (0.0045 - 0.0102)

Inner rotor to outer rotor tip clearance Below 0.18 (0.0071)

Body to inner rotor axial clearance 0.050 - 0.090 (0.0020 - 0.0035)

Body to outer rotor axial clearance 0.030 - 0.190 (0.0012 - 0.0075)

Inner rotor to brazed portion of housing clearance 0.045 - 0.091 (0.0018 - 0.0036)

ENGINE OIL CAPACITYNJLC0078Unit:!(Imp qt)

Drain and refill (Approximately)Without oil filter change 4.9 (4-3/8)

With oil filter change 5.2 (4-5/8)

Dry engine (engine overhaul)6.3 (5-1/2)

ENGINE LUBRICATION SYSTEMYD

Service Data and Specifications (SDS)

LC-35

Page 2542 of 2898

SEM164F

AEM080

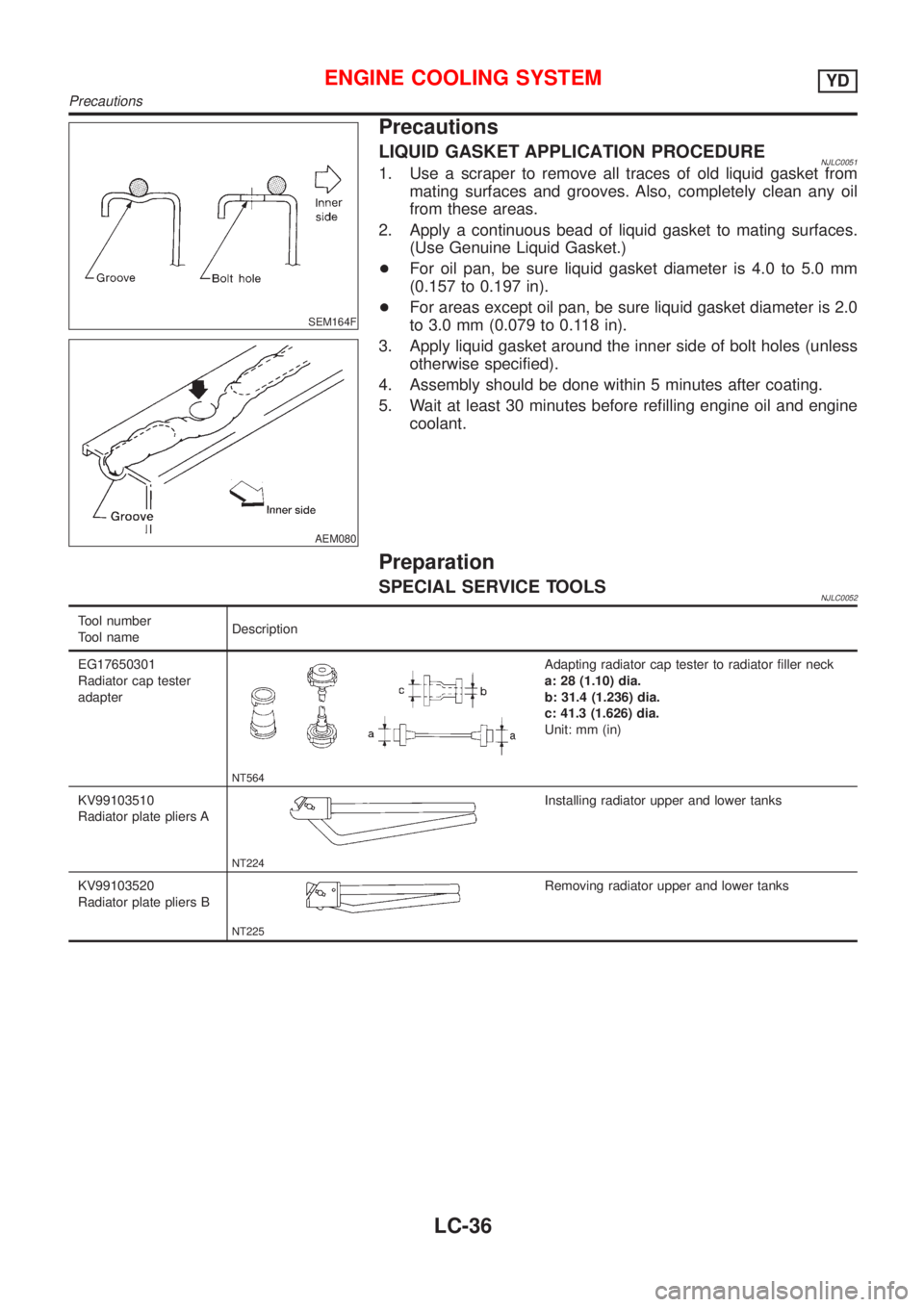

Precautions

LIQUID GASKET APPLICATION PROCEDURENJLC00511. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine Liquid Gasket.)

+For oil pan, be sure liquid gasket diameter is 4.0 to 5.0 mm

(0.157 to 0.197 in).

+For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

Preparation

SPECIAL SERVICE TOOLSNJLC0052

Tool number

Tool nameDescription

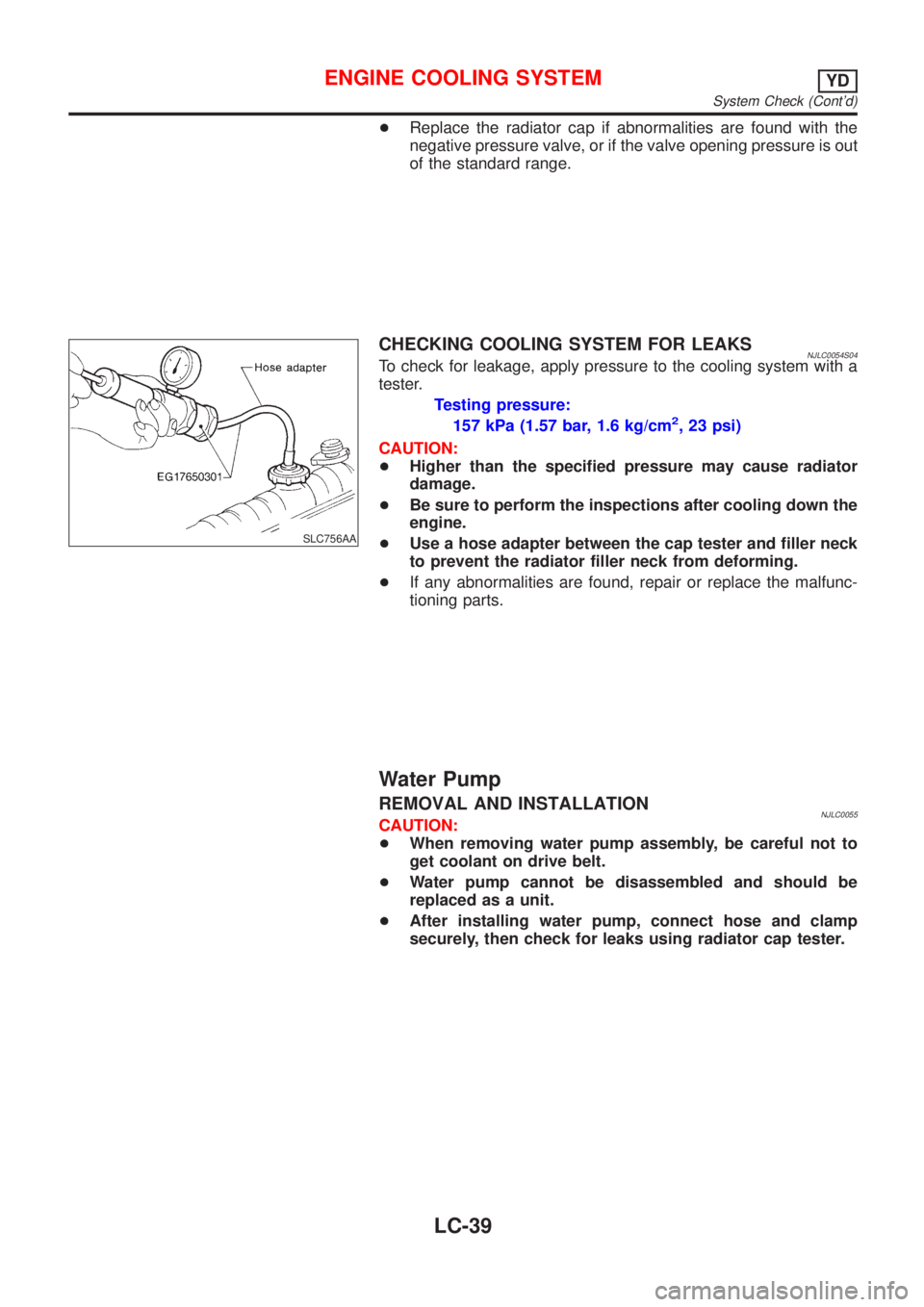

EG17650301

Radiator cap tester

adapter

NT564

Adapting radiator cap tester to radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV99103510

Radiator plate pliers A

NT224

Installing radiator upper and lower tanks

KV99103520

Radiator plate pliers B

NT225

Removing radiator upper and lower tanks

ENGINE COOLING SYSTEMYD

Precautions

LC-36

Page 2543 of 2898

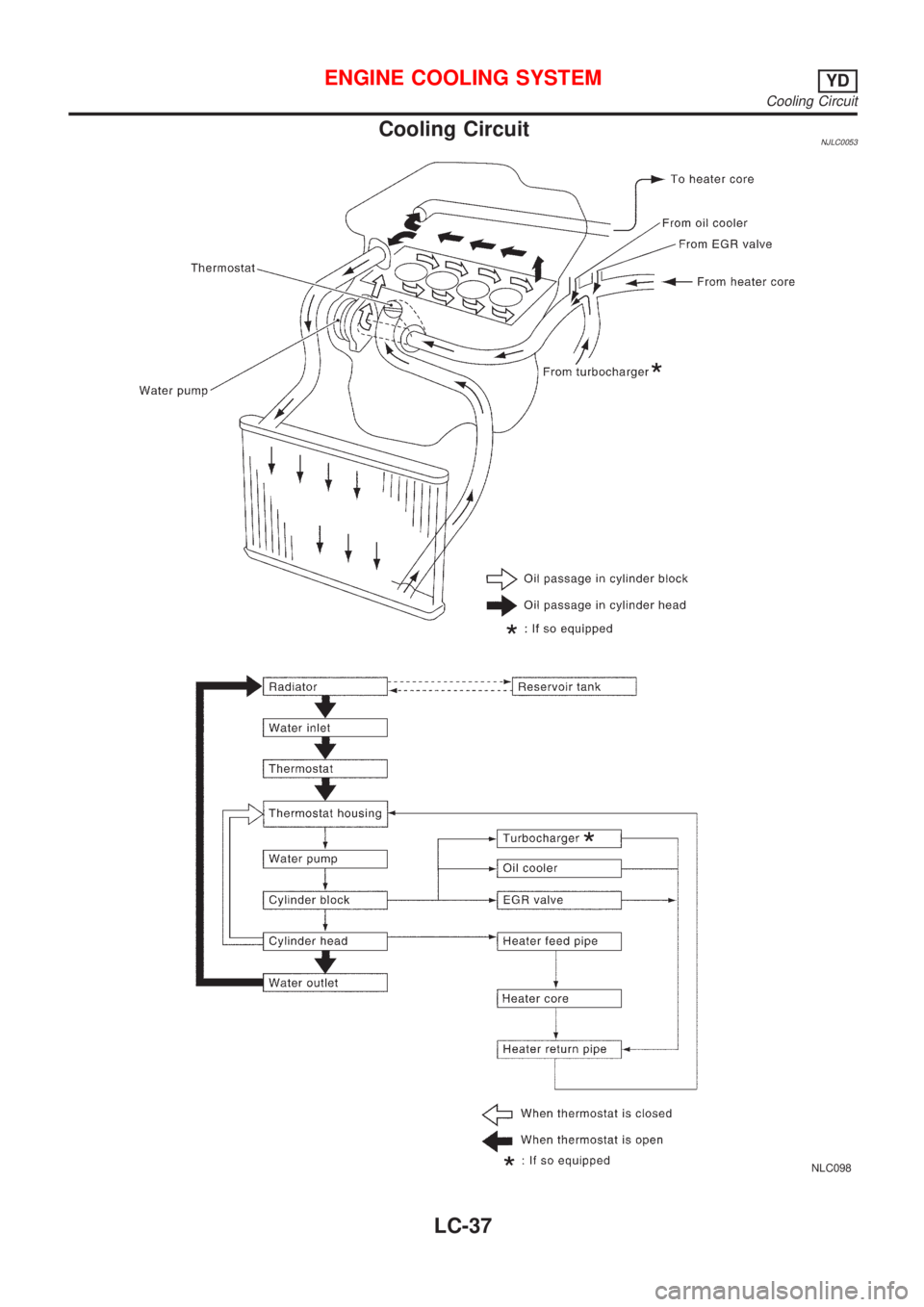

Cooling CircuitNJLC0053

NLC098

ENGINE COOLING SYSTEMYD

Cooling Circuit

LC-37

Page 2544 of 2898

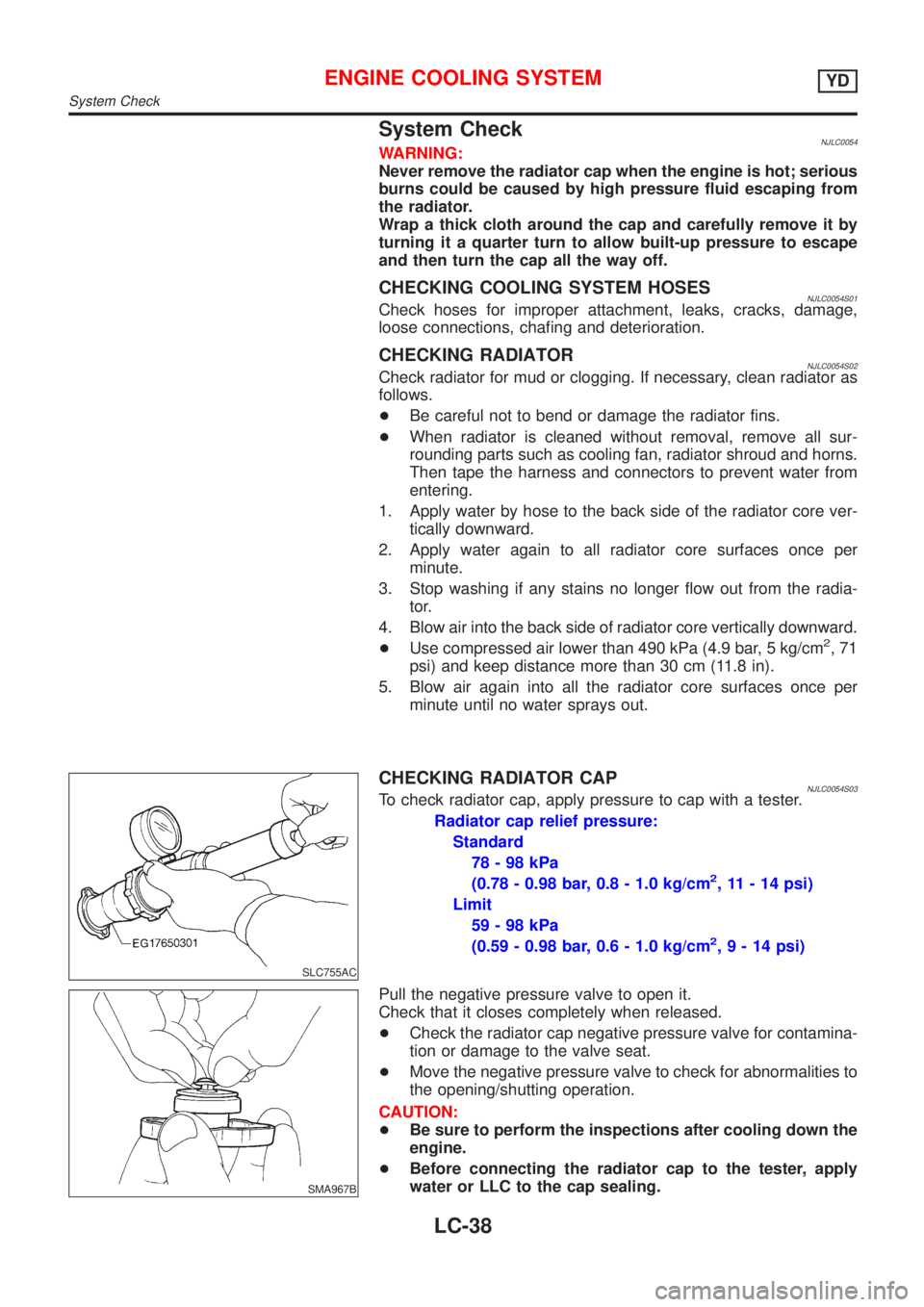

System CheckNJLC0054WARNING:

Never remove the radiator cap when the engine is hot; serious

burns could be caused by high pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap and carefully remove it by

turning it a quarter turn to allow built-up pressure to escape

and then turn the cap all the way off.

CHECKING COOLING SYSTEM HOSESNJLC0054S01Check hoses for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

CHECKING RADIATORNJLC0054S02Check radiator for mud or clogging. If necessary, clean radiator as

follows.

+Be careful not to bend or damage the radiator fins.

+When radiator is cleaned without removal, remove all sur-

rounding parts such as cooling fan, radiator shroud and horns.

Then tape the harness and connectors to prevent water from

entering.

1. Apply water by hose to the back side of the radiator core ver-

tically downward.

2. Apply water again to all radiator core surfaces once per

minute.

3. Stop washing if any stains no longer flow out from the radia-

tor.

4. Blow air into the back side of radiator core vertically downward.

+Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2,71

psi) and keep distance more than 30 cm (11.8 in).

5. Blow air again into all the radiator core surfaces once per

minute until no water sprays out.

SLC755AC

CHECKING RADIATOR CAPNJLC0054S03To check radiator cap, apply pressure to cap with a tester.

Radiator cap relief pressure:

Standard

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Limit

59-98kPa

(0.59 - 0.98 bar, 0.6 - 1.0 kg/cm

2,9-14psi)

SMA967B

Pull the negative pressure valve to open it.

Check that it closes completely when released.

+Check the radiator cap negative pressure valve for contamina-

tion or damage to the valve seat.

+Move the negative pressure valve to check for abnormalities to

the opening/shutting operation.

CAUTION:

+Be sure to perform the inspections after cooling down the

engine.

+Before connecting the radiator cap to the tester, apply

water or LLC to the cap sealing.

ENGINE COOLING SYSTEMYD

System Check

LC-38

Page 2545 of 2898

+Replace the radiator cap if abnormalities are found with the

negative pressure valve, or if the valve opening pressure is out

of the standard range.

SLC756AA

CHECKING COOLING SYSTEM FOR LEAKSNJLC0054S04To check for leakage, apply pressure to the cooling system with a

tester.

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2, 23 psi)

CAUTION:

+Higher than the specified pressure may cause radiator

damage.

+Be sure to perform the inspections after cooling down the

engine.

+Use a hose adapter between the cap tester and filler neck

to prevent the radiator filler neck from deforming.

+If any abnormalities are found, repair or replace the malfunc-

tioning parts.

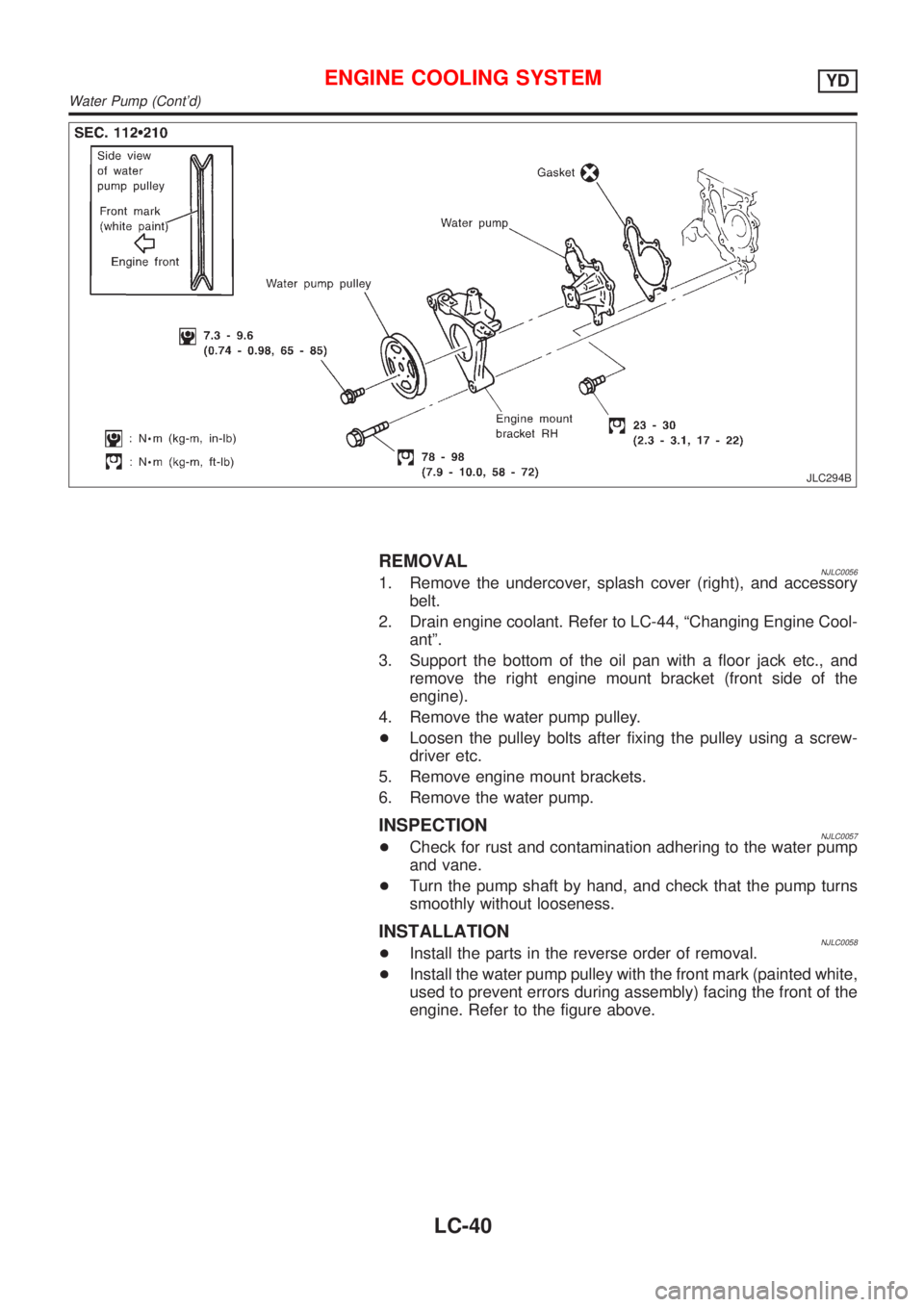

Water Pump

REMOVAL AND INSTALLATIONNJLC0055CAUTION:

+When removing water pump assembly, be careful not to

get coolant on drive belt.

+Water pump cannot be disassembled and should be

replaced as a unit.

+After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

ENGINE COOLING SYSTEMYD

System Check (Cont'd)

LC-39

Page 2546 of 2898

JLC294B

REMOVALNJLC00561. Remove the undercover, splash cover (right), and accessory

belt.

2. Drain engine coolant. Refer to LC-44, ªChanging Engine Cool-

antº.

3. Support the bottom of the oil pan with a floor jack etc., and

remove the right engine mount bracket (front side of the

engine).

4. Remove the water pump pulley.

+Loosen the pulley bolts after fixing the pulley using a screw-

driver etc.

5. Remove engine mount brackets.

6. Remove the water pump.

INSPECTIONNJLC0057+Check for rust and contamination adhering to the water pump

and vane.

+Turn the pump shaft by hand, and check that the pump turns

smoothly without looseness.

INSTALLATIONNJLC0058+Install the parts in the reverse order of removal.

+Install the water pump pulley with the front mark (painted white,

used to prevent errors during assembly) facing the front of the

engine. Refer to the figure above.

ENGINE COOLING SYSTEMYD

Water Pump (Cont'd)

LC-40

Page 2547 of 2898

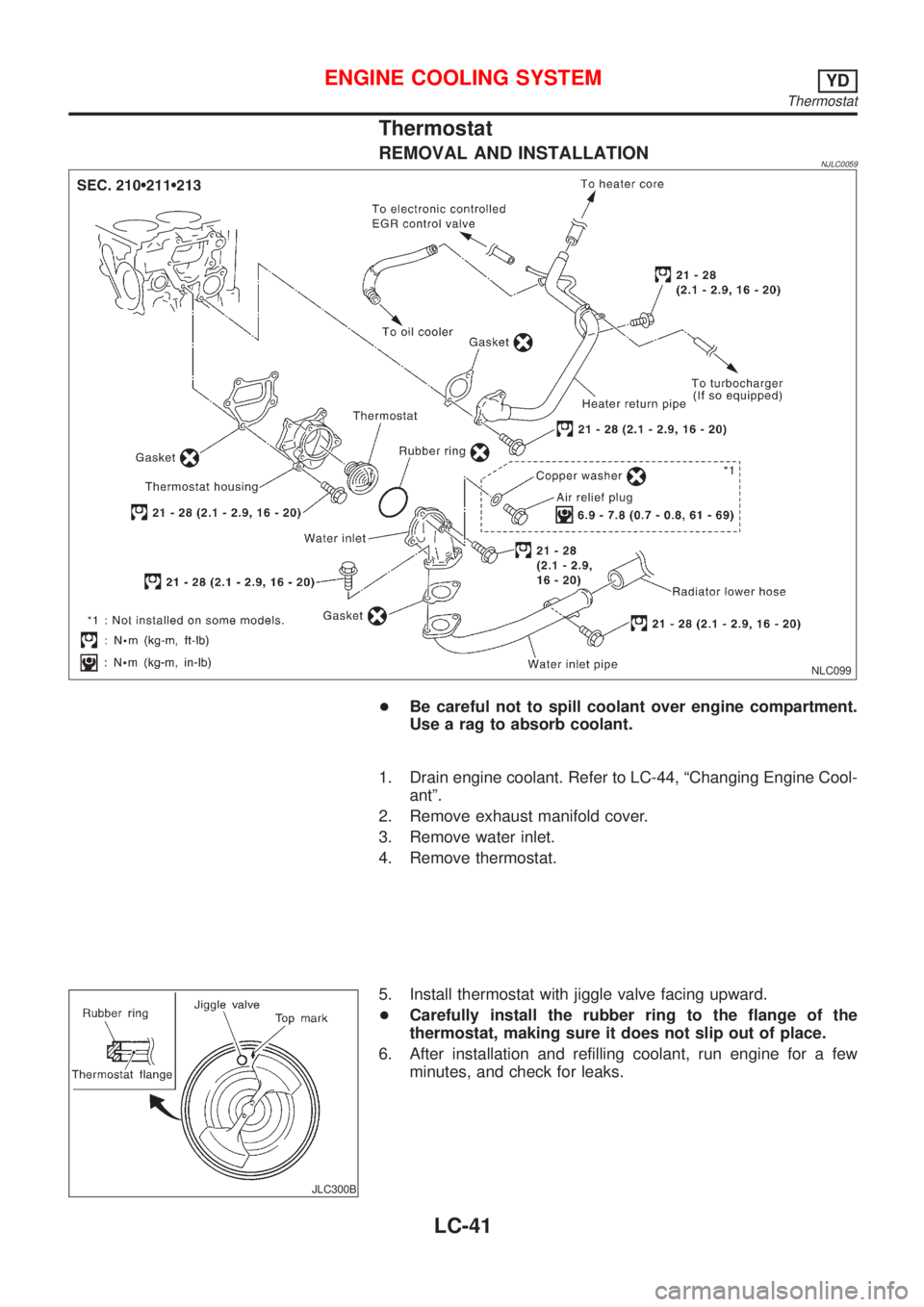

Thermostat

REMOVAL AND INSTALLATIONNJLC0059

NLC099

+Be careful not to spill coolant over engine compartment.

Use a rag to absorb coolant.

1. Drain engine coolant. Refer to LC-44, ªChanging Engine Cool-

antº.

2. Remove exhaust manifold cover.

3. Remove water inlet.

4. Remove thermostat.

JLC300B

5. Install thermostat with jiggle valve facing upward.

+Carefully install the rubber ring to the flange of the

thermostat, making sure it does not slip out of place.

6. After installation and refilling coolant, run engine for a few

minutes, and check for leaks.

ENGINE COOLING SYSTEMYD

Thermostat

LC-41

Page 2548 of 2898

SLC252B

INSPECTIONNJLC00601. Check valve seating condition at ordinary room temperatures.

It should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Standard

Valve opening temperature Above 80.5 - 83.5ÉC (177 - 182ÉF)

Valve lift More than 9 mm/95ÉC

(0.354 in/203ÉF)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

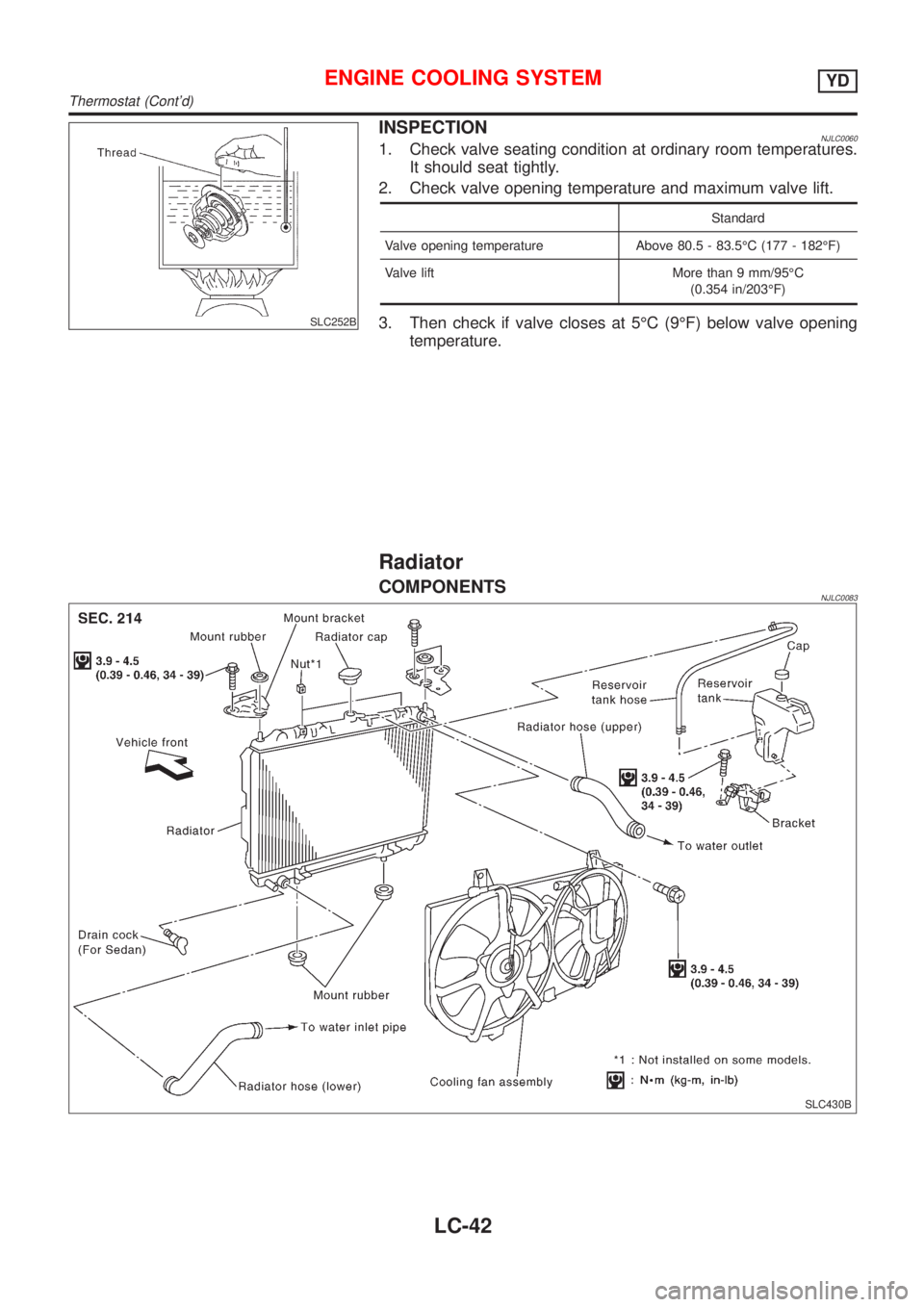

Radiator

COMPONENTSNJLC0083

SLC430B

ENGINE COOLING SYSTEMYD

Thermostat (Cont'd)

LC-42

Page 2549 of 2898

REMOVAL AND INSTALLATION=NJLC00631. Remove under cover.

2. For Sedan, drain coolant from radiator by drain cock, and for

Hatchback, drain coolant by removing lower radiator hose.

3. Disconnect radiator upper and lower hoses.

4. Remove radiator shroud.

5. Disconnect reservoir tank hose.

6. Remove radiator mounting bracket.

7. Remove radiator.

8. After repairing or replacing radiator, install any part removed in

reverse order of removal.

When filling radiator with coolant, refer to LC-44, ªChanging

Engine Coolantº.

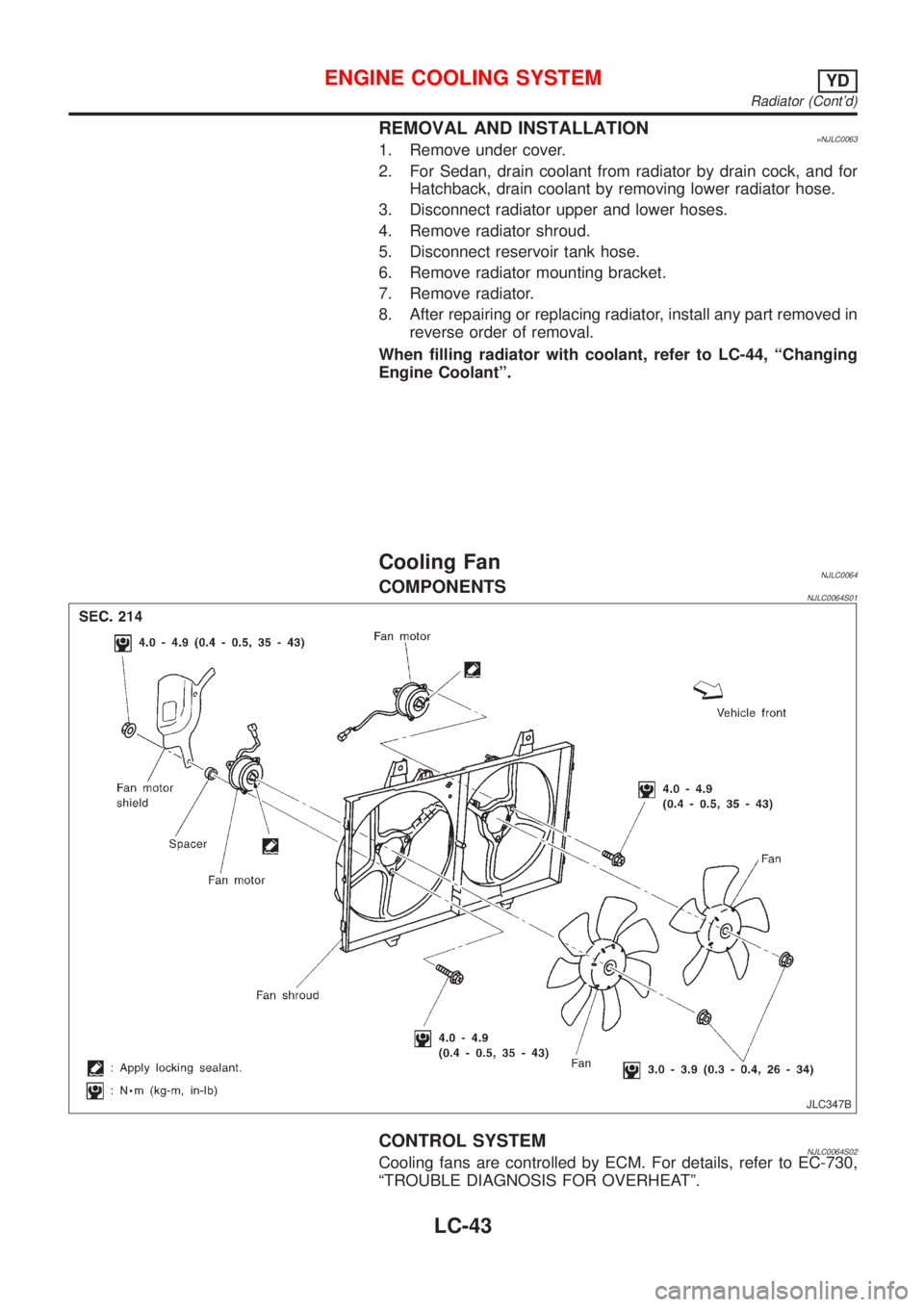

Cooling FanNJLC0064COMPONENTSNJLC0064S01

JLC347B

CONTROL SYSTEMNJLC0064S02Cooling fans are controlled by ECM. For details, refer to EC-730,

ªTROUBLE DIAGNOSIS FOR OVERHEATº.

ENGINE COOLING SYSTEMYD

Radiator (Cont'd)

LC-43

Page 2550 of 2898

SLC344B

JLC295B

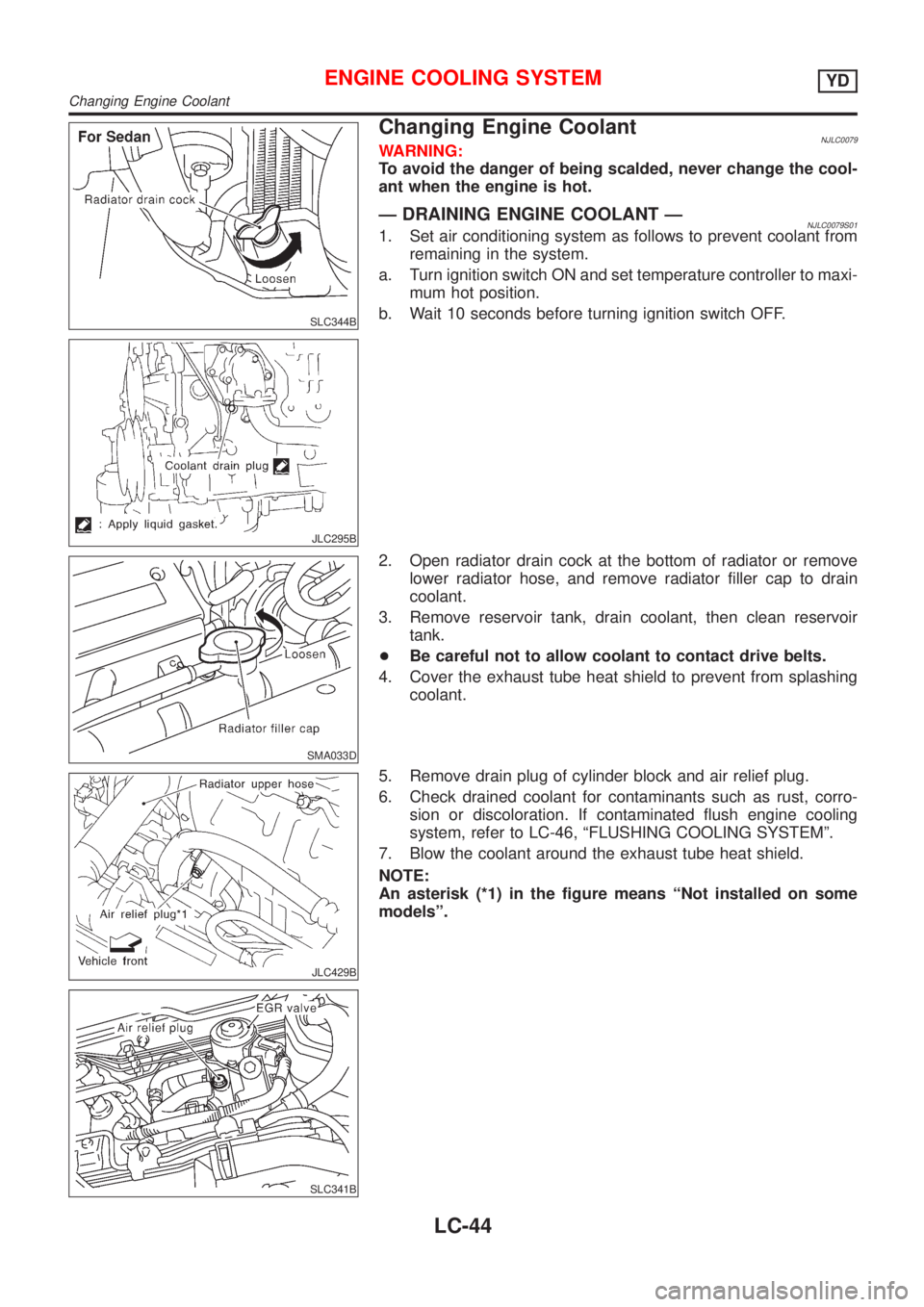

Changing Engine CoolantNJLC0079WARNING:

To avoid the danger of being scalded, never change the cool-

ant when the engine is hot.

Ð DRAINING ENGINE COOLANT ÐNJLC0079S011. Set air conditioning system as follows to prevent coolant from

remaining in the system.

a. Turn ignition switch ON and set temperature controller to maxi-

mum hot position.

b. Wait 10 seconds before turning ignition switch OFF.

SMA033D

2. Open radiator drain cock at the bottom of radiator or remove

lower radiator hose, and remove radiator filler cap to drain

coolant.

3. Remove reservoir tank, drain coolant, then clean reservoir

tank.

+Be careful not to allow coolant to contact drive belts.

4. Cover the exhaust tube heat shield to prevent from splashing

coolant.

JLC429B

SLC341B

5. Remove drain plug of cylinder block and air relief plug.

6. Check drained coolant for contaminants such as rust, corro-

sion or discoloration. If contaminated flush engine cooling

system, refer to LC-46, ªFLUSHING COOLING SYSTEMº.

7. Blow the coolant around the exhaust tube heat shield.

NOTE:

An asterisk (*1) in the figure means ªNot installed on some

modelsº.

ENGINE COOLING SYSTEMYD

Changing Engine Coolant

LC-44