NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: engine oil capacity, coolant capacity, change time, bulb, remove seats, sat nav, tow

Page 2631 of 2898

SMT649D

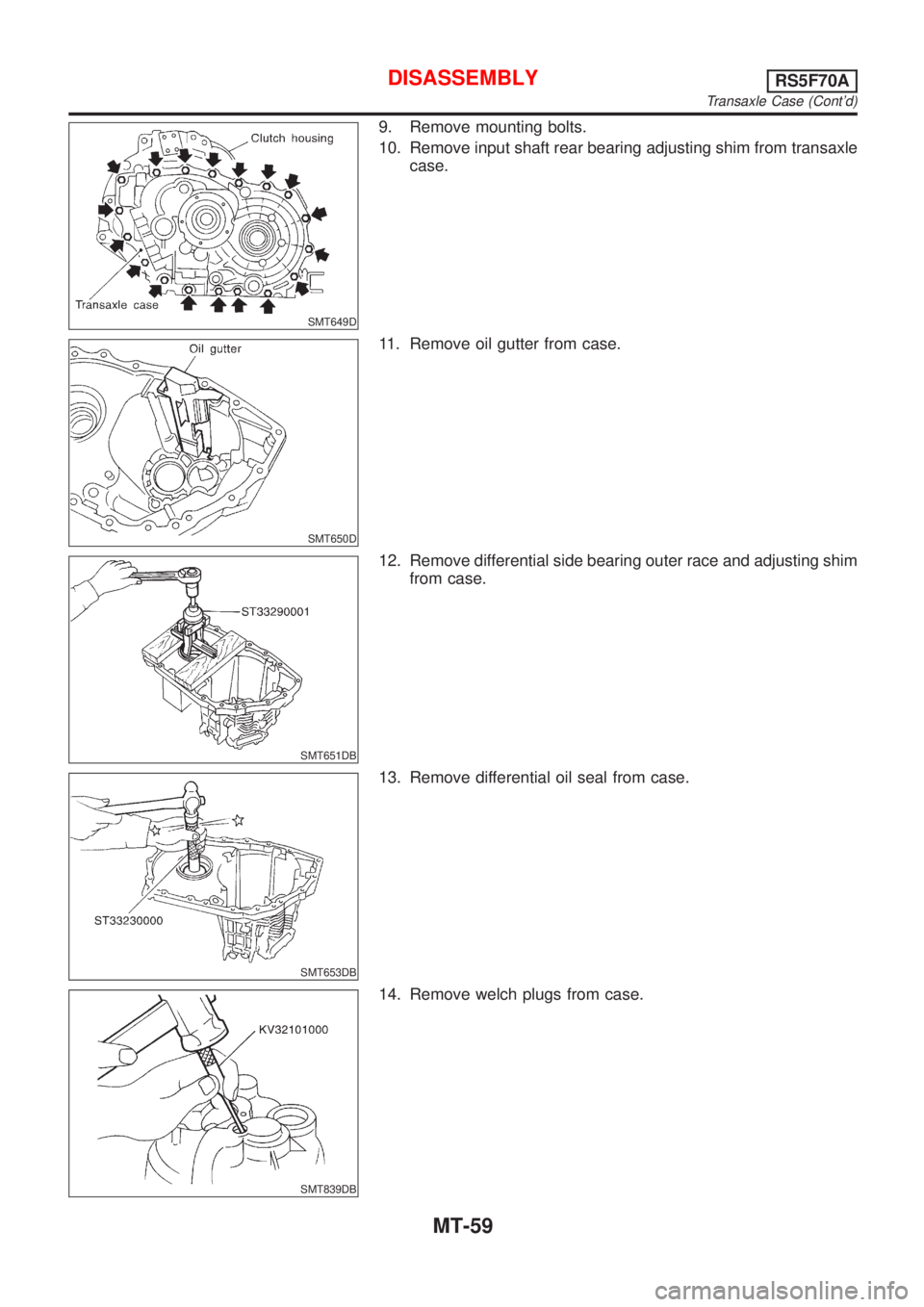

9. Remove mounting bolts.

10. Remove input shaft rear bearing adjusting shim from transaxle

case.

SMT650D

11. Remove oil gutter from case.

SMT651DB

12. Remove differential side bearing outer race and adjusting shim

from case.

SMT653DB

13. Remove differential oil seal from case.

SMT839DB

14. Remove welch plugs from case.

DISASSEMBLYRS5F70A

Transaxle Case (Cont'd)

MT-59

Page 2632 of 2898

SMT654D

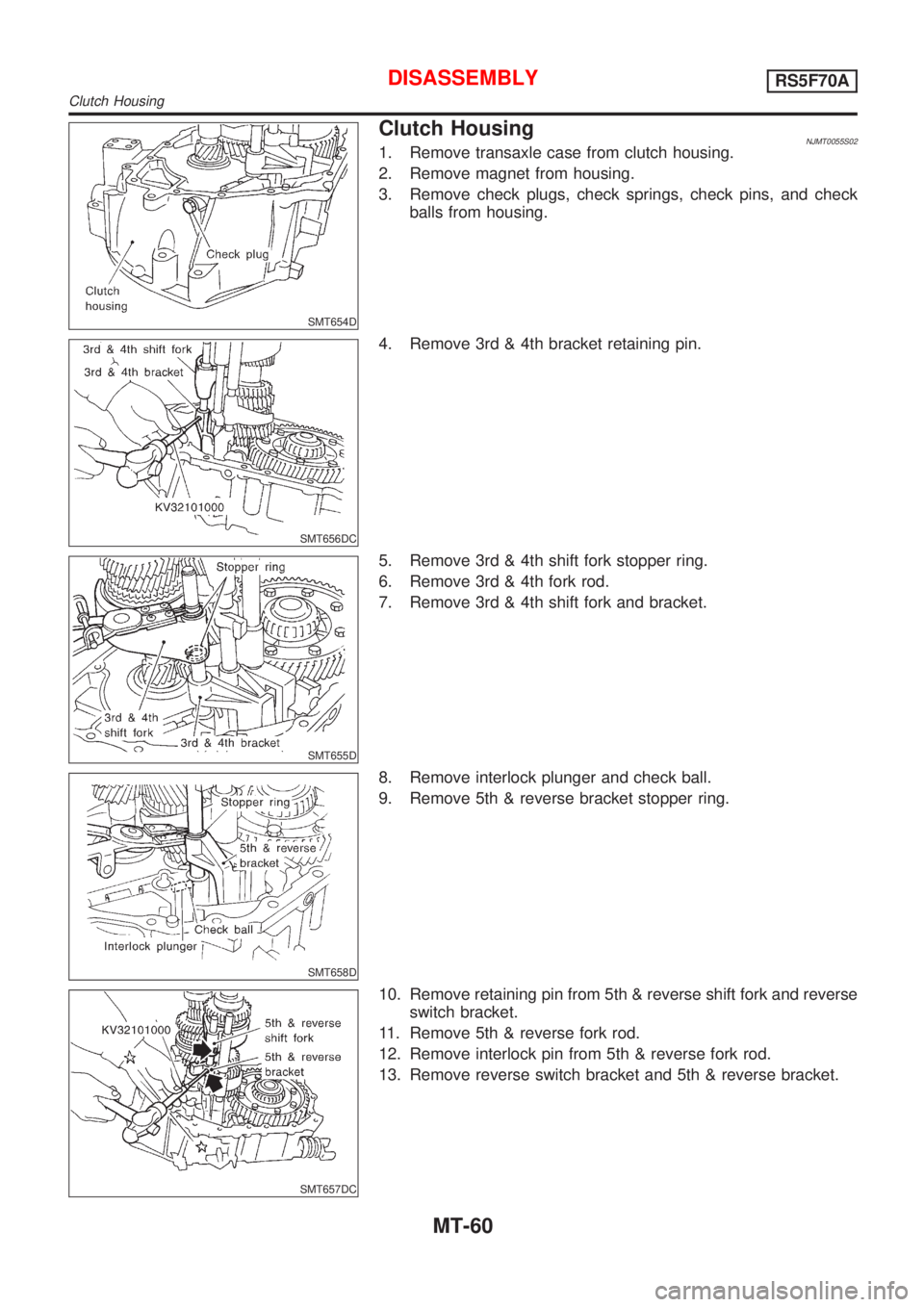

Clutch HousingNJMT0055S021. Remove transaxle case from clutch housing.

2. Remove magnet from housing.

3. Remove check plugs, check springs, check pins, and check

balls from housing.

SMT656DC

4. Remove 3rd & 4th bracket retaining pin.

SMT655D

5. Remove 3rd & 4th shift fork stopper ring.

6. Remove 3rd & 4th fork rod.

7. Remove 3rd & 4th shift fork and bracket.

SMT658D

8. Remove interlock plunger and check ball.

9. Remove 5th & reverse bracket stopper ring.

SMT657DC

10. Remove retaining pin from 5th & reverse shift fork and reverse

switch bracket.

11. Remove 5th & reverse fork rod.

12. Remove interlock pin from 5th & reverse fork rod.

13. Remove reverse switch bracket and 5th & reverse bracket.

DISASSEMBLYRS5F70A

Clutch Housing

MT-60

Page 2633 of 2898

SMT659DC

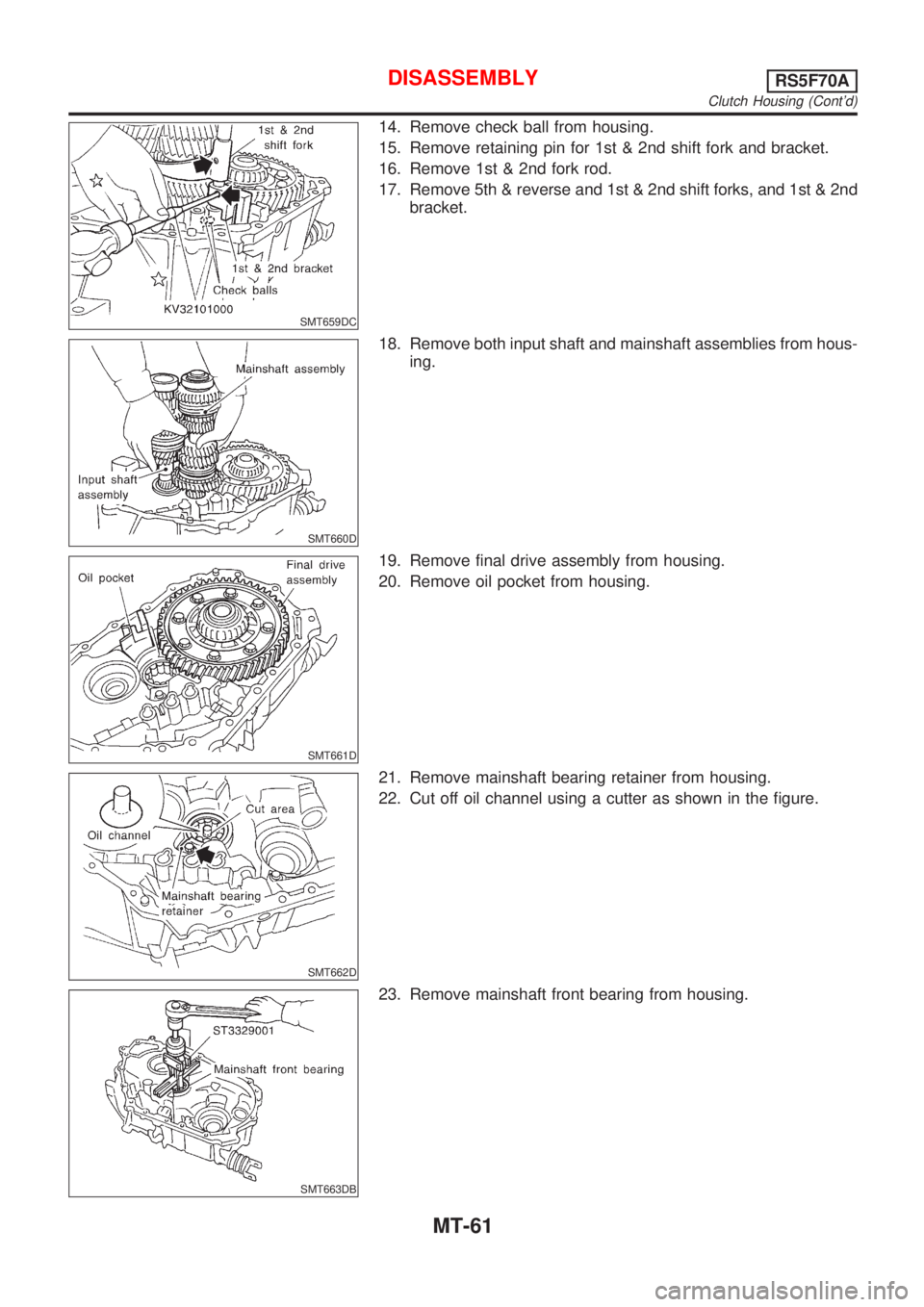

14. Remove check ball from housing.

15. Remove retaining pin for 1st & 2nd shift fork and bracket.

16. Remove 1st & 2nd fork rod.

17. Remove 5th & reverse and 1st & 2nd shift forks, and 1st & 2nd

bracket.

SMT660D

18. Remove both input shaft and mainshaft assemblies from hous-

ing.

SMT661D

19. Remove final drive assembly from housing.

20. Remove oil pocket from housing.

SMT662D

21. Remove mainshaft bearing retainer from housing.

22. Cut off oil channel using a cutter as shown in the figure.

SMT663DB

23. Remove mainshaft front bearing from housing.

DISASSEMBLYRS5F70A

Clutch Housing (Cont'd)

MT-61

Page 2634 of 2898

SMT664D

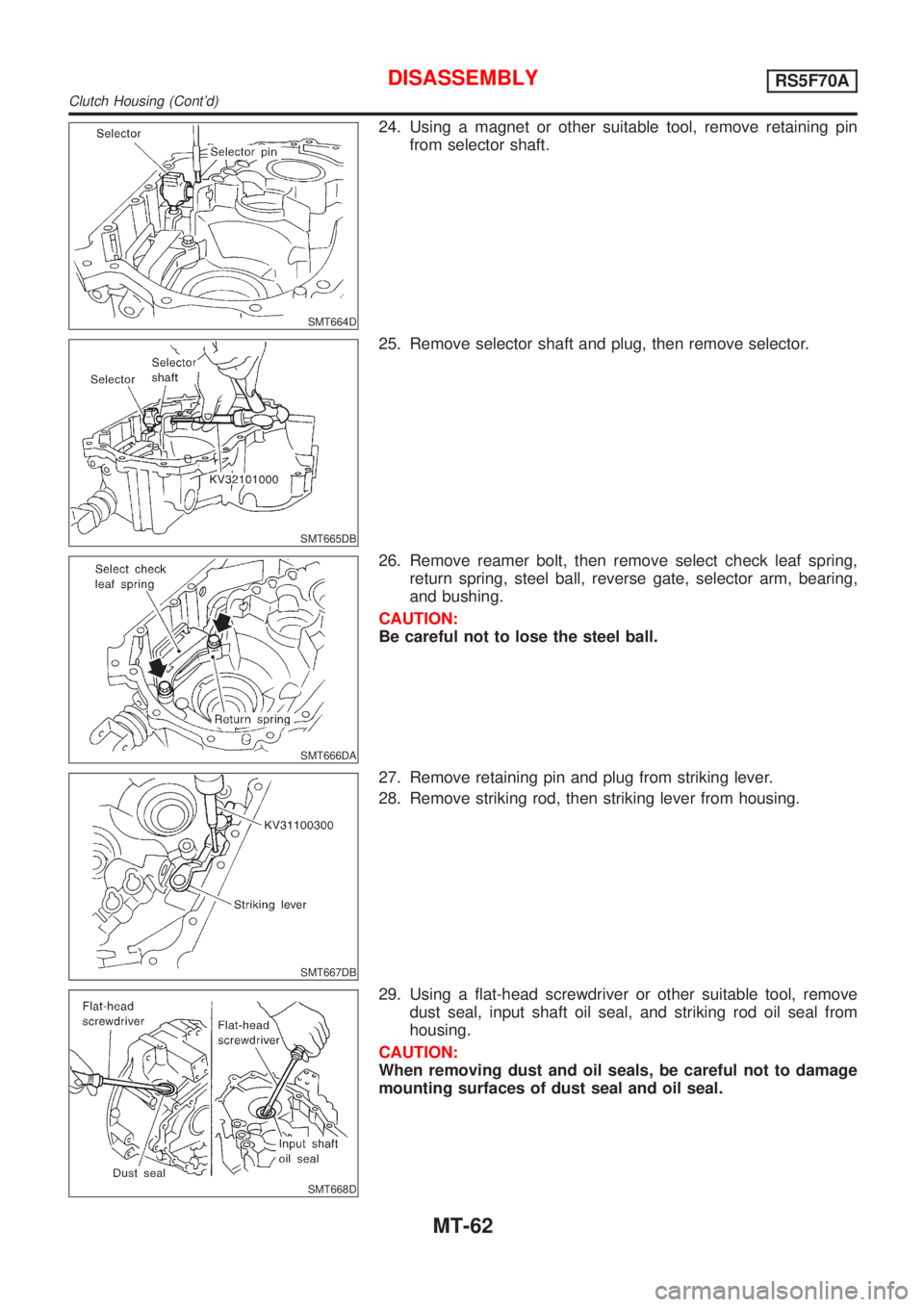

24. Using a magnet or other suitable tool, remove retaining pin

from selector shaft.

SMT665DB

25. Remove selector shaft and plug, then remove selector.

SMT666DA

26. Remove reamer bolt, then remove select check leaf spring,

return spring, steel ball, reverse gate, selector arm, bearing,

and bushing.

CAUTION:

Be careful not to lose the steel ball.

SMT667DB

27. Remove retaining pin and plug from striking lever.

28. Remove striking rod, then striking lever from housing.

SMT668D

29. Using a flat-head screwdriver or other suitable tool, remove

dust seal, input shaft oil seal, and striking rod oil seal from

housing.

CAUTION:

When removing dust and oil seals, be careful not to damage

mounting surfaces of dust seal and oil seal.

DISASSEMBLYRS5F70A

Clutch Housing (Cont'd)

MT-62

Page 2635 of 2898

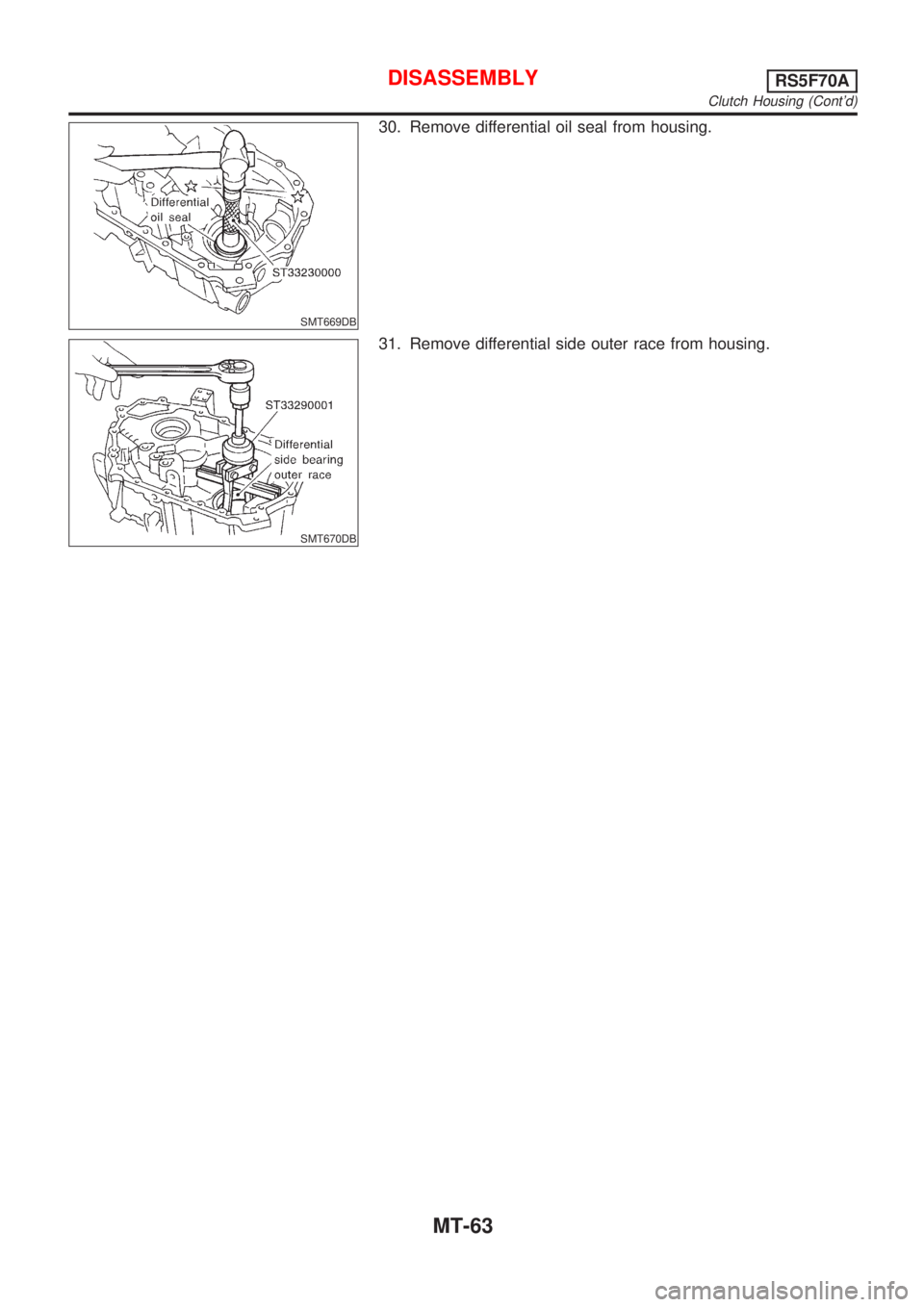

SMT669DB

30. Remove differential oil seal from housing.

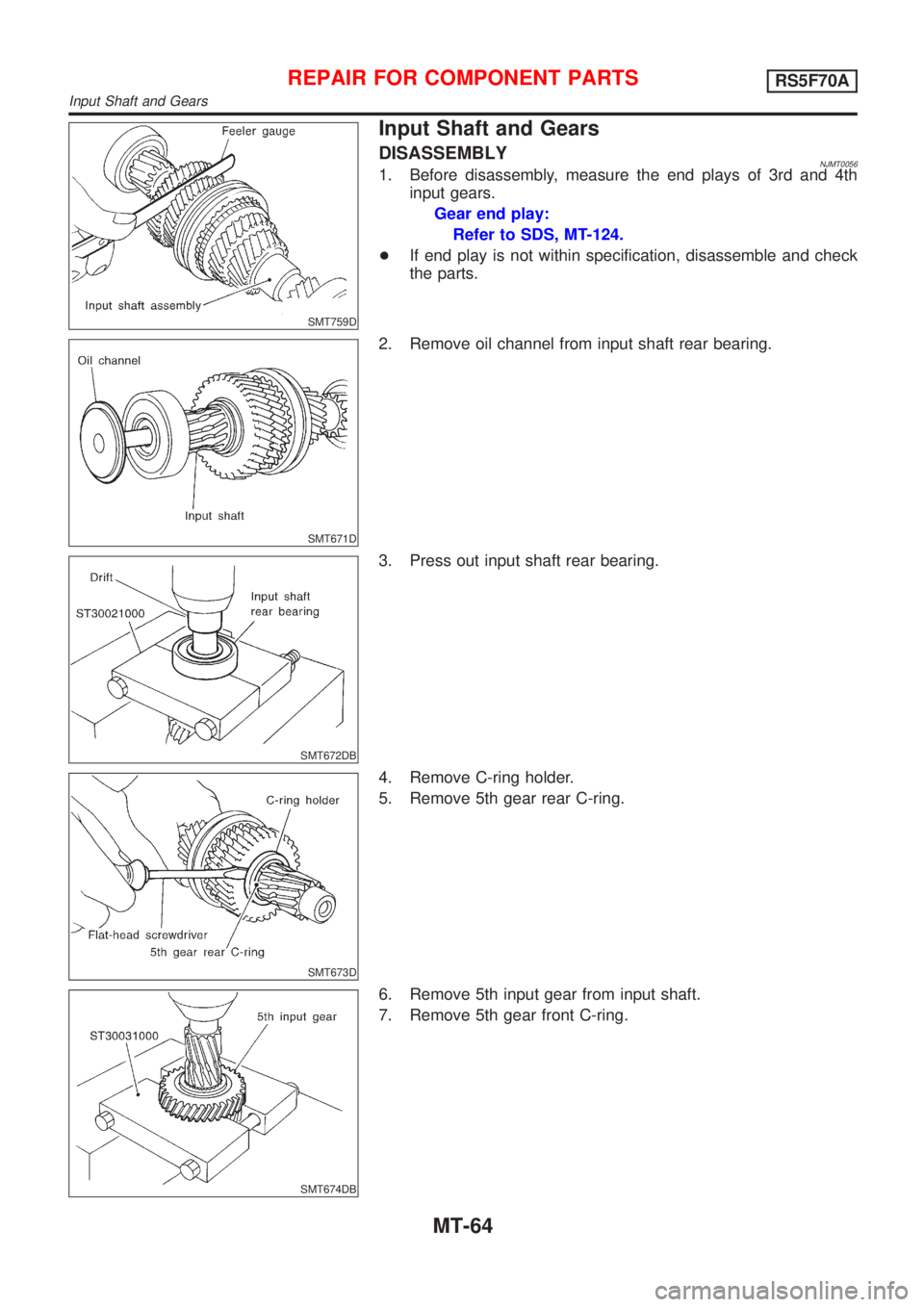

SMT670DB

31. Remove differential side outer race from housing.

DISASSEMBLYRS5F70A

Clutch Housing (Cont'd)

MT-63

Page 2636 of 2898

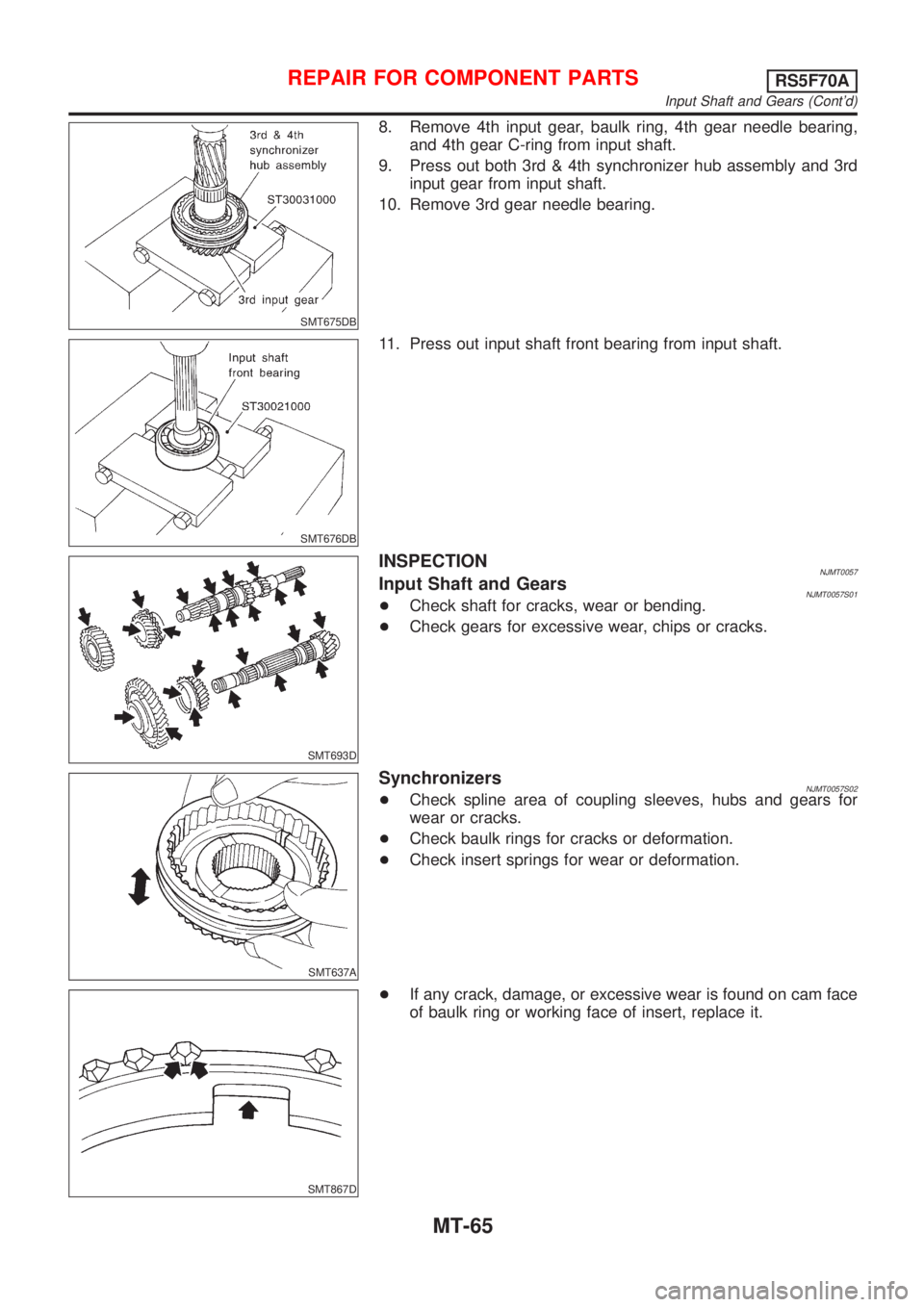

SMT759D

Input Shaft and Gears

DISASSEMBLYNJMT00561. Before disassembly, measure the end plays of 3rd and 4th

input gears.

Gear end play:

Refer to SDS, MT-124.

+If end play is not within specification, disassemble and check

the parts.

SMT671D

2. Remove oil channel from input shaft rear bearing.

SMT672DB

3. Press out input shaft rear bearing.

SMT673D

4. Remove C-ring holder.

5. Remove 5th gear rear C-ring.

SMT674DB

6. Remove 5th input gear from input shaft.

7. Remove 5th gear front C-ring.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears

MT-64

Page 2637 of 2898

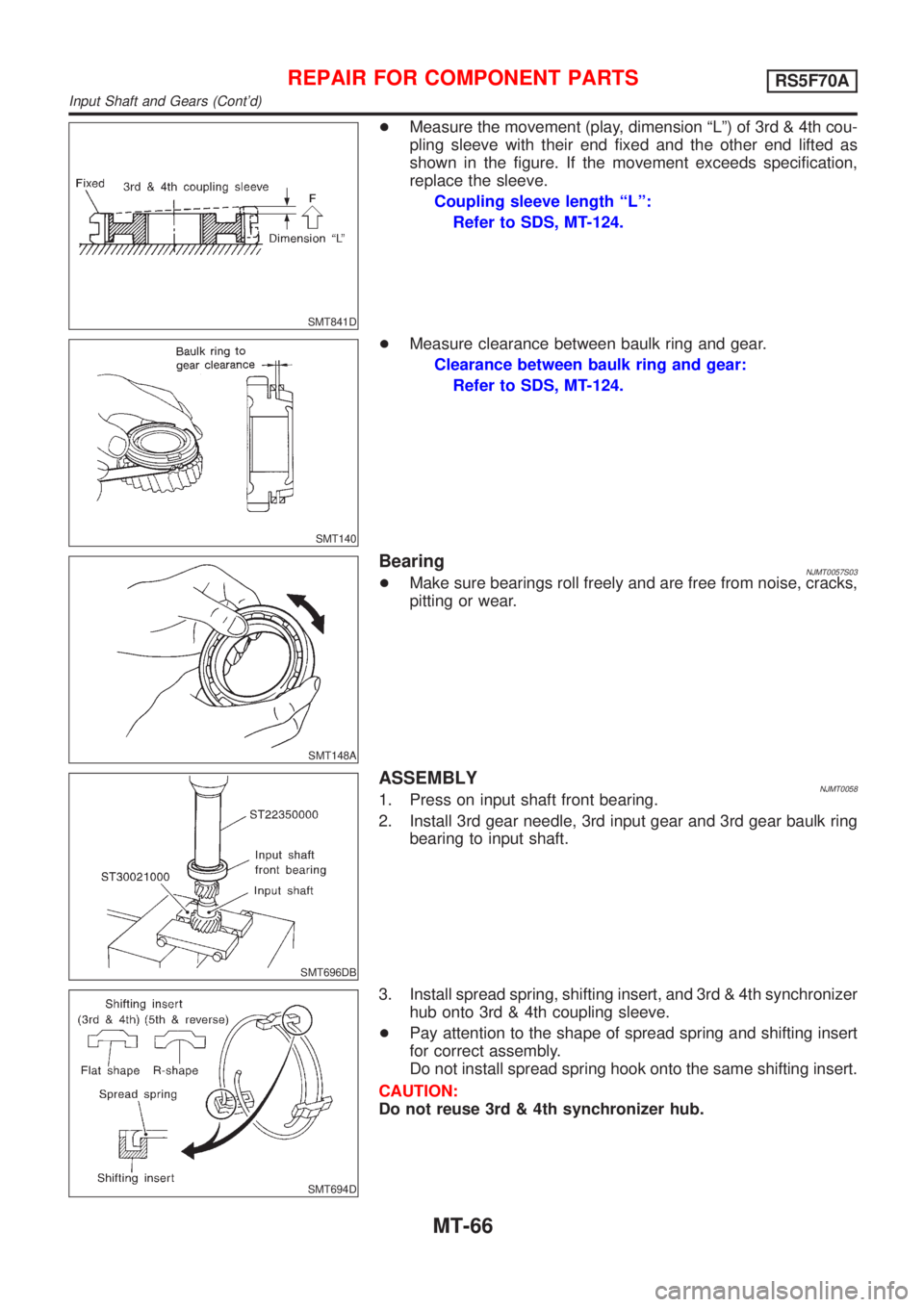

SMT675DB

8. Remove 4th input gear, baulk ring, 4th gear needle bearing,

and 4th gear C-ring from input shaft.

9. Press out both 3rd & 4th synchronizer hub assembly and 3rd

input gear from input shaft.

10. Remove 3rd gear needle bearing.

SMT676DB

11. Press out input shaft front bearing from input shaft.

SMT693D

INSPECTIONNJMT0057Input Shaft and GearsNJMT0057S01+Check shaft for cracks, wear or bending.

+Check gears for excessive wear, chips or cracks.

SMT637A

SynchronizersNJMT0057S02+Check spline area of coupling sleeves, hubs and gears for

wear or cracks.

+Check baulk rings for cracks or deformation.

+Check insert springs for wear or deformation.

SMT867D

+If any crack, damage, or excessive wear is found on cam face

of baulk ring or working face of insert, replace it.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears (Cont'd)

MT-65

Page 2638 of 2898

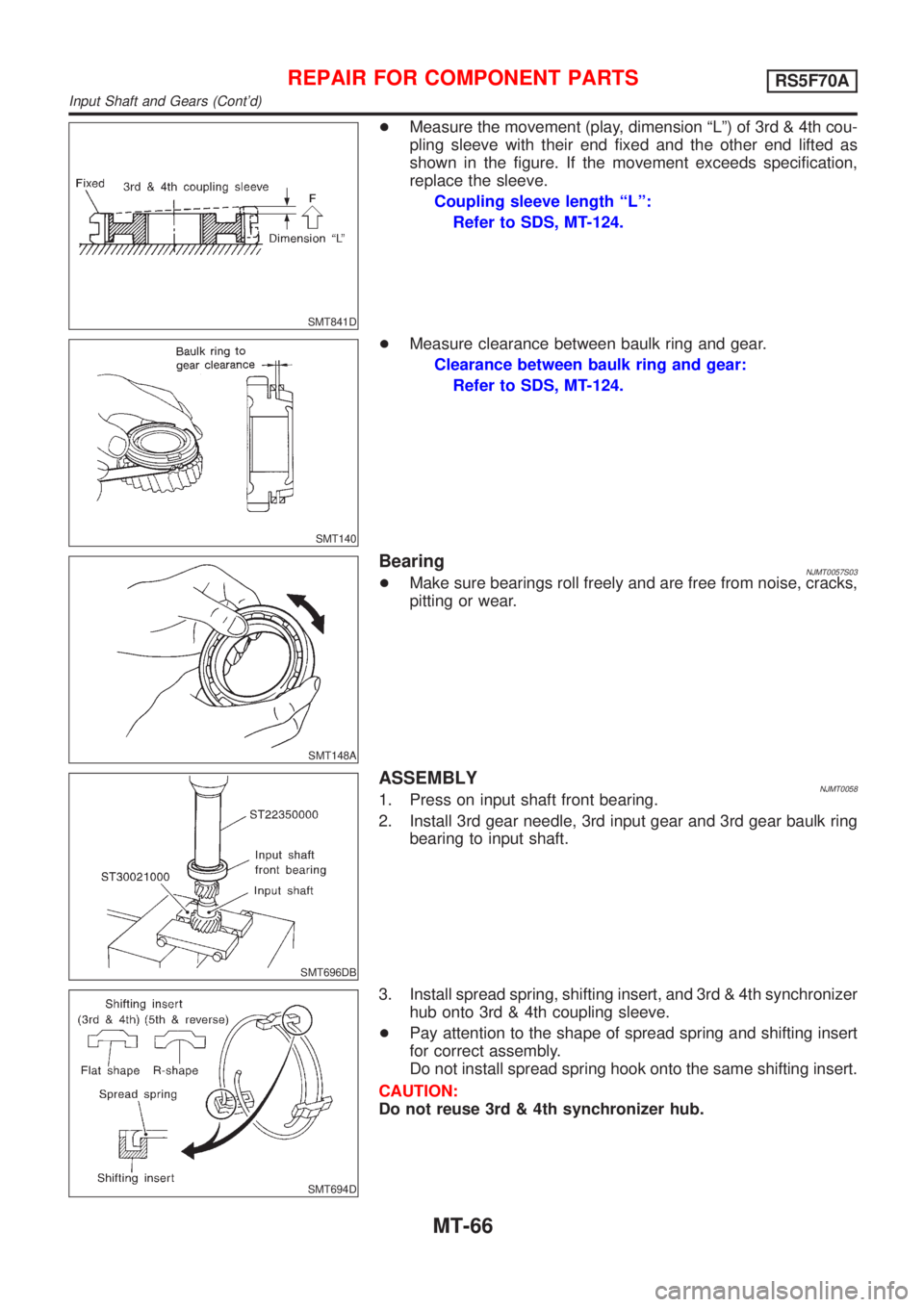

SMT841D

+Measure the movement (play, dimension ªLº) of 3rd & 4th cou-

pling sleeve with their end fixed and the other end lifted as

shown in the figure. If the movement exceeds specification,

replace the sleeve.

Coupling sleeve length ªLº:

Refer to SDS, MT-124.

SMT140

+Measure clearance between baulk ring and gear.

Clearance between baulk ring and gear:

Refer to SDS, MT-124.

SMT148A

BearingNJMT0057S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

SMT696DB

ASSEMBLYNJMT00581. Press on input shaft front bearing.

2. Install 3rd gear needle, 3rd input gear and 3rd gear baulk ring

bearing to input shaft.

SMT694D

3. Install spread spring, shifting insert, and 3rd & 4th synchronizer

hub onto 3rd & 4th coupling sleeve.

+Pay attention to the shape of spread spring and shifting insert

for correct assembly.

Do not install spread spring hook onto the same shifting insert.

CAUTION:

Do not reuse 3rd & 4th synchronizer hub.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears (Cont'd)

MT-66

Page 2639 of 2898

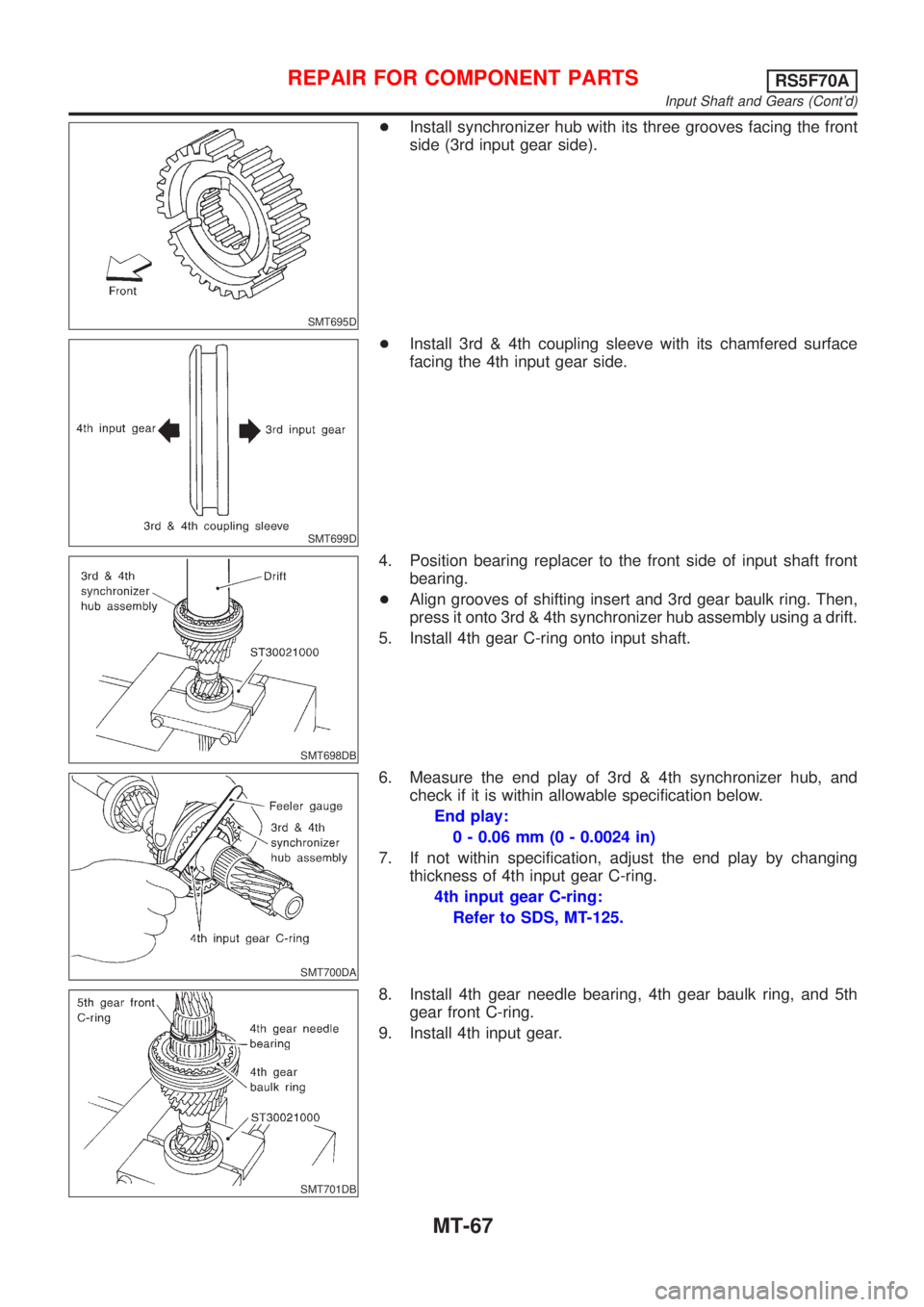

SMT695D

+Install synchronizer hub with its three grooves facing the front

side (3rd input gear side).

SMT699D

+Install 3rd & 4th coupling sleeve with its chamfered surface

facing the 4th input gear side.

SMT698DB

4. Position bearing replacer to the front side of input shaft front

bearing.

+Align grooves of shifting insert and 3rd gear baulk ring. Then,

press it onto 3rd & 4th synchronizer hub assembly using a drift.

5. Install 4th gear C-ring onto input shaft.

SMT700DA

6. Measure the end play of 3rd & 4th synchronizer hub, and

check if it is within allowable specification below.

End play:

0 - 0.06 mm (0 - 0.0024 in)

7. If not within specification, adjust the end play by changing

thickness of 4th input gear C-ring.

4th input gear C-ring:

Refer to SDS, MT-125.

SMT701DB

8. Install 4th gear needle bearing, 4th gear baulk ring, and 5th

gear front C-ring.

9. Install 4th input gear.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears (Cont'd)

MT-67

Page 2640 of 2898

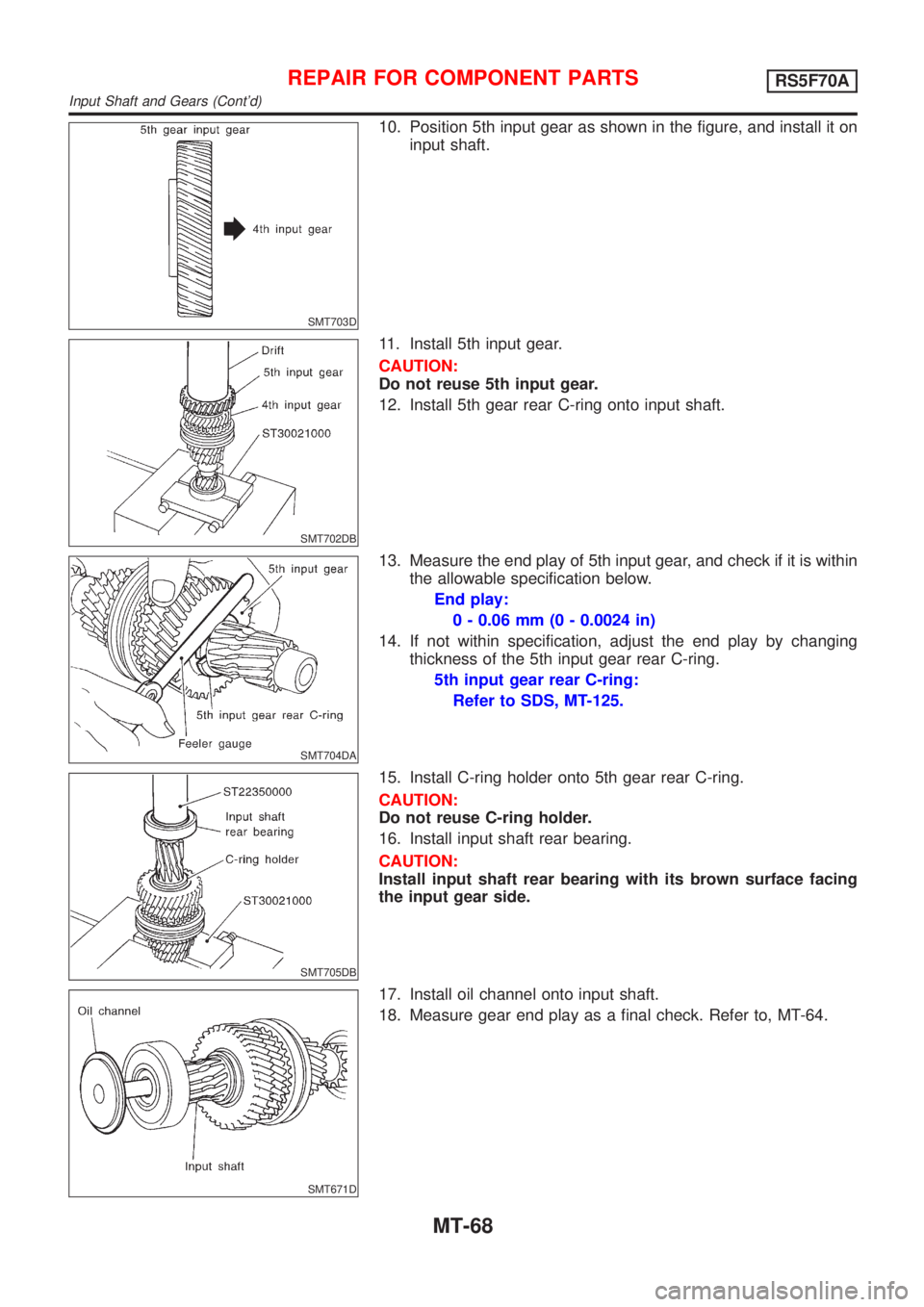

SMT703D

10. Position 5th input gear as shown in the figure, and install it on

input shaft.

SMT702DB

11. Install 5th input gear.

CAUTION:

Do not reuse 5th input gear.

12. Install 5th gear rear C-ring onto input shaft.

SMT704DA

13. Measure the end play of 5th input gear, and check if it is within

the allowable specification below.

End play:

0 - 0.06 mm (0 - 0.0024 in)

14. If not within specification, adjust the end play by changing

thickness of the 5th input gear rear C-ring.

5th input gear rear C-ring:

Refer to SDS, MT-125.

SMT705DB

15. Install C-ring holder onto 5th gear rear C-ring.

CAUTION:

Do not reuse C-ring holder.

16. Install input shaft rear bearing.

CAUTION:

Install input shaft rear bearing with its brown surface facing

the input gear side.

SMT671D

17. Install oil channel onto input shaft.

18. Measure gear end play as a final check. Refer to, MT-64.

REPAIR FOR COMPONENT PARTSRS5F70A

Input Shaft and Gears (Cont'd)

MT-68

Trending: fuel filter, automatic transmission, navigation system, flat tire, catalytic converter, high beam, fuse