NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2621 of 2898

NJMT0091

Differential Side Bearing PreloadNJMT0091S01If any of the following parts are replaced, adjust differential side

bearing preload.

+Differential case

+Differential side bearing

+Clutch housing

+Transmission case

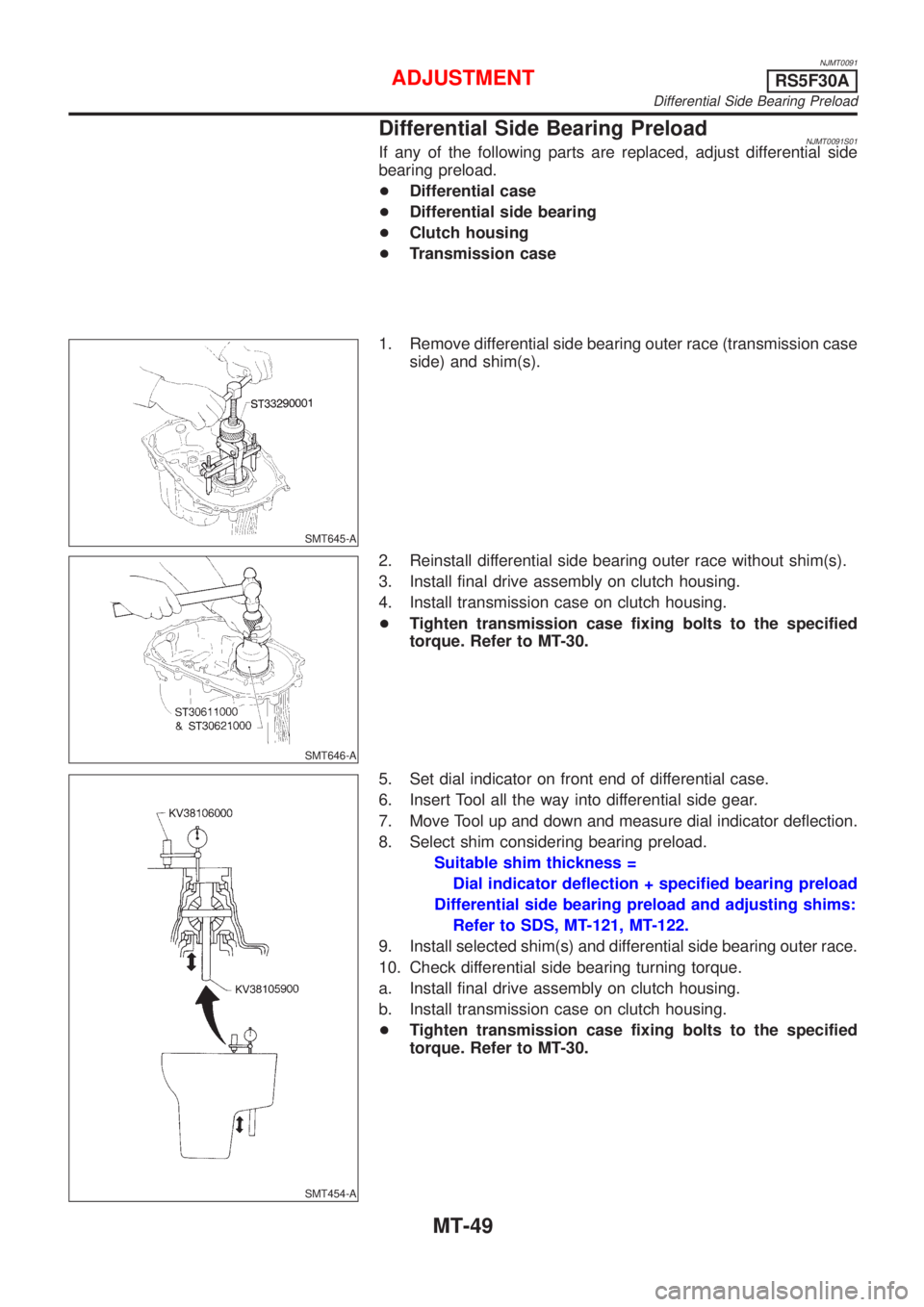

SMT645-A

1. Remove differential side bearing outer race (transmission case

side) and shim(s).

SMT646-A

2. Reinstall differential side bearing outer race without shim(s).

3. Install final drive assembly on clutch housing.

4. Install transmission case on clutch housing.

+Tighten transmission case fixing bolts to the specified

torque. Refer to MT-30.

SMT454-A

5. Set dial indicator on front end of differential case.

6. Insert Tool all the way into differential side gear.

7. Move Tool up and down and measure dial indicator deflection.

8. Select shim considering bearing preload.

Suitable shim thickness =

Dial indicator deflection + specified bearing preload

Differential side bearing preload and adjusting shims:

Refer to SDS, MT-121, MT-122.

9. Install selected shim(s) and differential side bearing outer race.

10. Check differential side bearing turning torque.

a. Install final drive assembly on clutch housing.

b. Install transmission case on clutch housing.

+Tighten transmission case fixing bolts to the specified

torque. Refer to MT-30.

ADJUSTMENTRS5F30A

Differential Side Bearing Preload

MT-49

Page 2622 of 2898

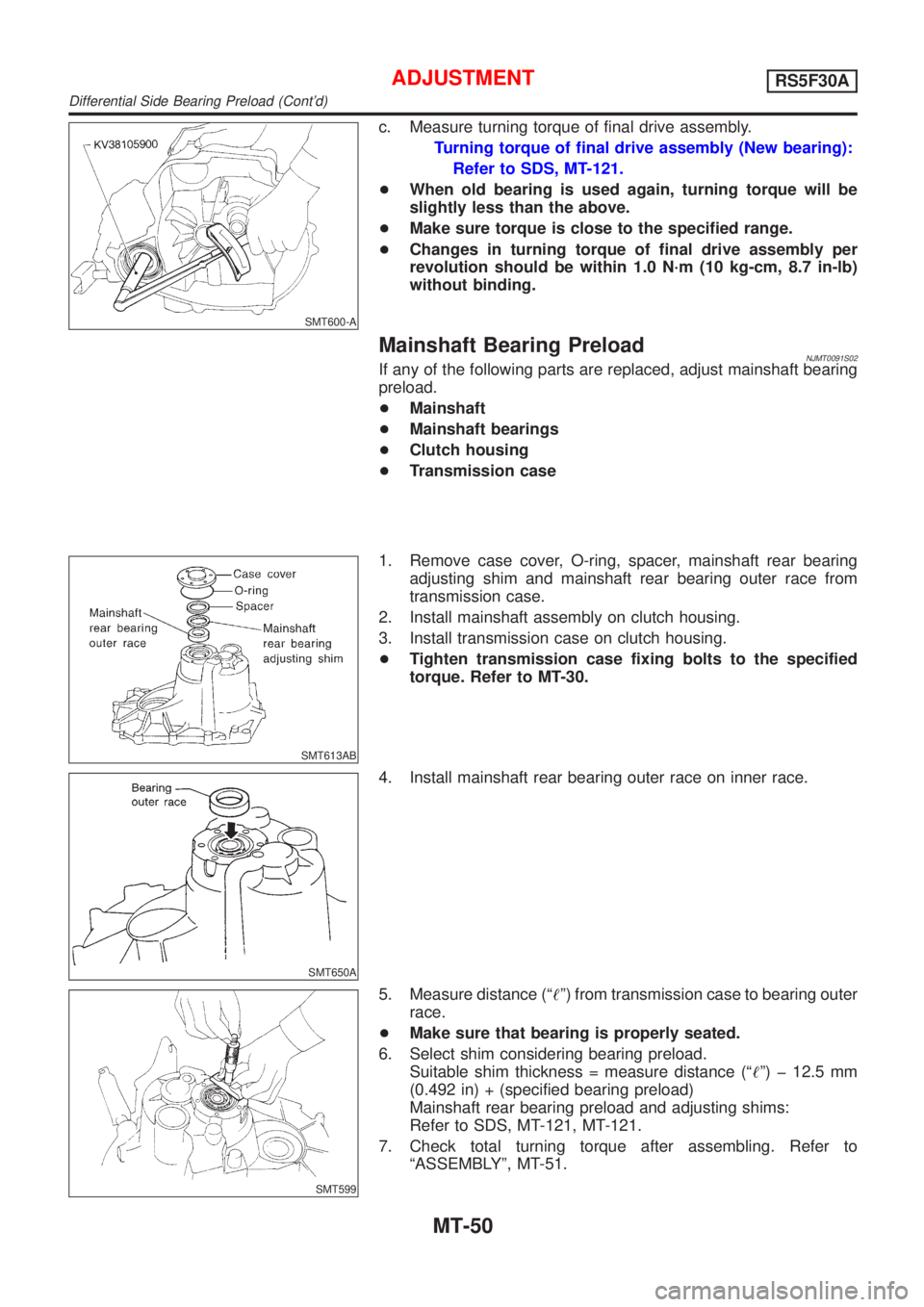

SMT600-A

c. Measure turning torque of final drive assembly.

Turning torque of final drive assembly (New bearing):

Refer to SDS, MT-121.

+When old bearing is used again, turning torque will be

slightly less than the above.

+Make sure torque is close to the specified range.

+Changes in turning torque of final drive assembly per

revolution should be within 1.0 N´m (10 kg-cm, 8.7 in-lb)

without binding.

Mainshaft Bearing PreloadNJMT0091S02If any of the following parts are replaced, adjust mainshaft bearing

preload.

+Mainshaft

+Mainshaft bearings

+Clutch housing

+Transmission case

SMT613AB

1. Remove case cover, O-ring, spacer, mainshaft rear bearing

adjusting shim and mainshaft rear bearing outer race from

transmission case.

2. Install mainshaft assembly on clutch housing.

3. Install transmission case on clutch housing.

+Tighten transmission case fixing bolts to the specified

torque. Refer to MT-30.

SMT650A

4. Install mainshaft rear bearing outer race on inner race.

SMT599

5. Measure distance (ª!º) from transmission case to bearing outer

race.

+Make sure that bearing is properly seated.

6. Select shim considering bearing preload.

Suitable shim thickness = measure distance (ª!º) þ 12.5 mm

(0.492 in) + (specified bearing preload)

Mainshaft rear bearing preload and adjusting shims:

Refer to SDS, MT-121, MT-121.

7. Check total turning torque after assembling. Refer to

ªASSEMBLYº, MT-51.

ADJUSTMENTRS5F30A

Differential Side Bearing Preload (Cont'd)

MT-50

Page 2623 of 2898

NJMT0092

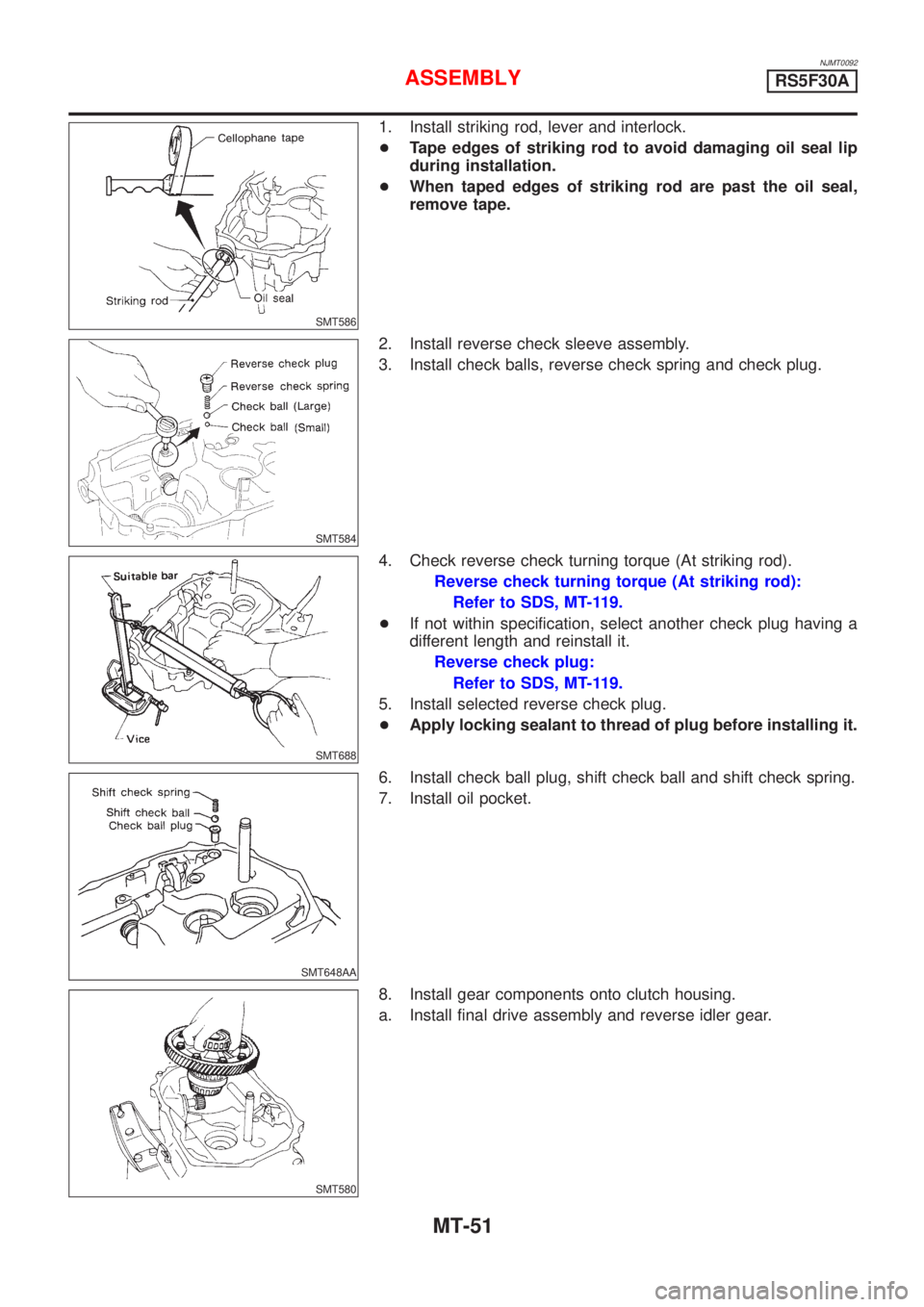

SMT586

1. Install striking rod, lever and interlock.

+Tape edges of striking rod to avoid damaging oil seal lip

during installation.

+When taped edges of striking rod are past the oil seal,

remove tape.

SMT584

2. Install reverse check sleeve assembly.

3. Install check balls, reverse check spring and check plug.

SMT688

4. Check reverse check turning torque (At striking rod).

Reverse check turning torque (At striking rod):

Refer to SDS, MT-119.

+If not within specification, select another check plug having a

different length and reinstall it.

Reverse check plug:

Refer to SDS, MT-119.

5. Install selected reverse check plug.

+Apply locking sealant to thread of plug before installing it.

SMT648AA

6. Install check ball plug, shift check ball and shift check spring.

7. Install oil pocket.

SMT580

8. Install gear components onto clutch housing.

a. Install final drive assembly and reverse idler gear.

ASSEMBLYRS5F30A

MT-51

Page 2624 of 2898

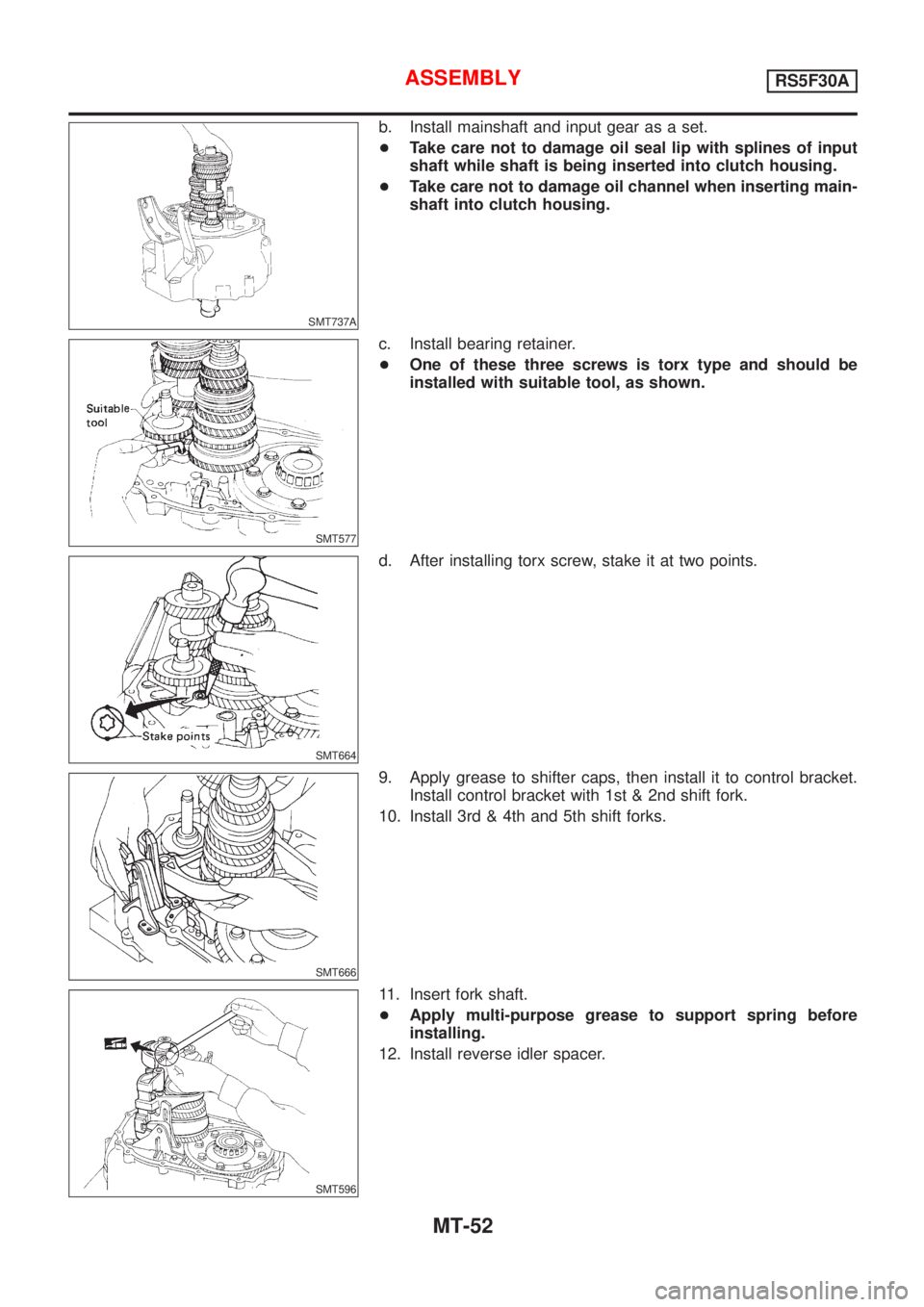

SMT737A

b. Install mainshaft and input gear as a set.

+Take care not to damage oil seal lip with splines of input

shaft while shaft is being inserted into clutch housing.

+Take care not to damage oil channel when inserting main-

shaft into clutch housing.

SMT577

c. Install bearing retainer.

+One of these three screws is torx type and should be

installed with suitable tool, as shown.

SMT664

d. After installing torx screw, stake it at two points.

SMT666

9. Apply grease to shifter caps, then install it to control bracket.

Install control bracket with 1st & 2nd shift fork.

10. Install 3rd & 4th and 5th shift forks.

SMT596

11. Insert fork shaft.

+Apply multi-purpose grease to support spring before

installing.

12. Install reverse idler spacer.

ASSEMBLYRS5F30A

MT-52

Page 2625 of 2898

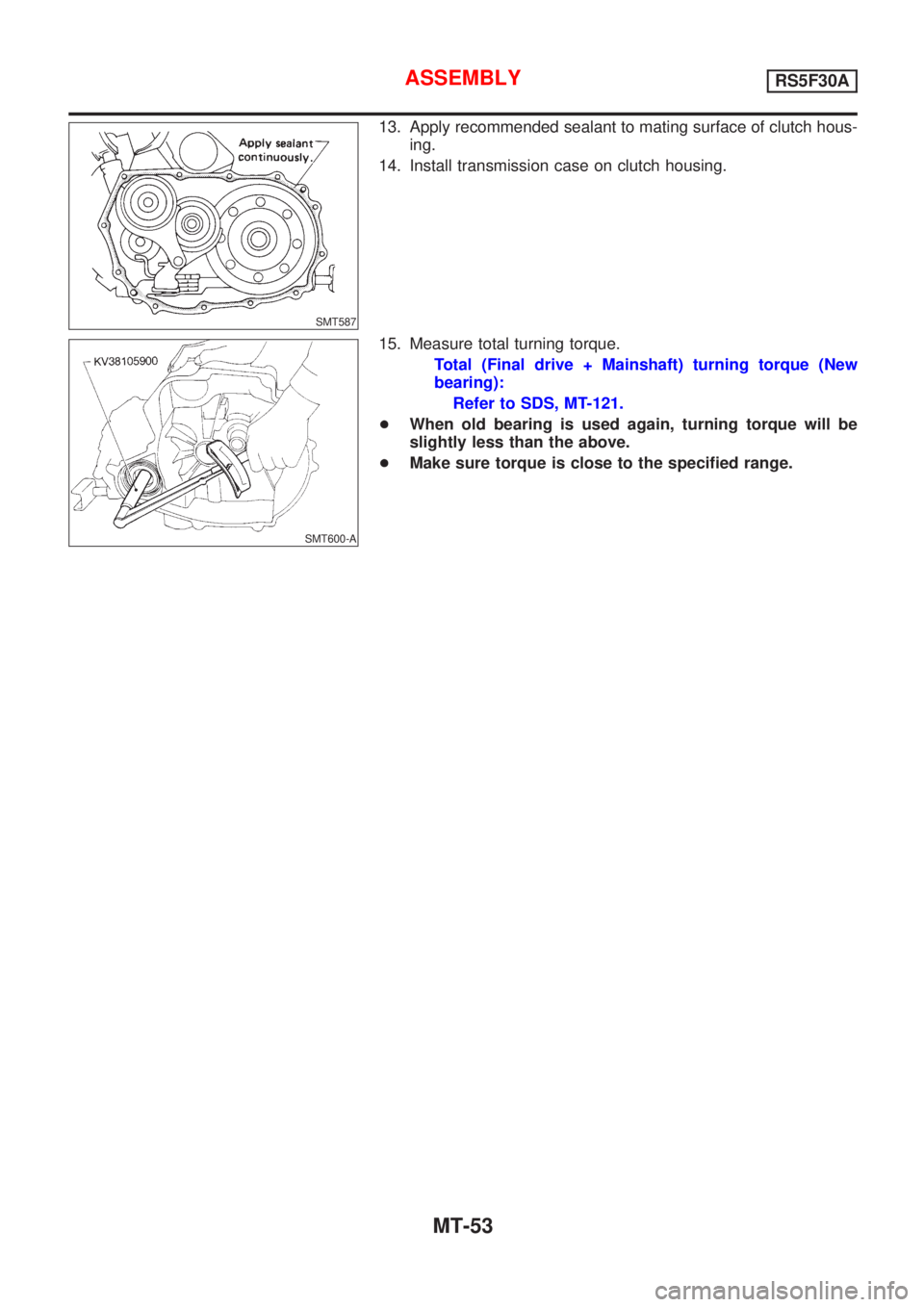

SMT587

13. Apply recommended sealant to mating surface of clutch hous-

ing.

14. Install transmission case on clutch housing.

SMT600-A

15. Measure total turning torque.

Total (Final drive + Mainshaft) turning torque (New

bearing):

Refer to SDS, MT-121.

+When old bearing is used again, turning torque will be

slightly less than the above.

+Make sure torque is close to the specified range.

ASSEMBLYRS5F30A

MT-53

Page 2626 of 2898

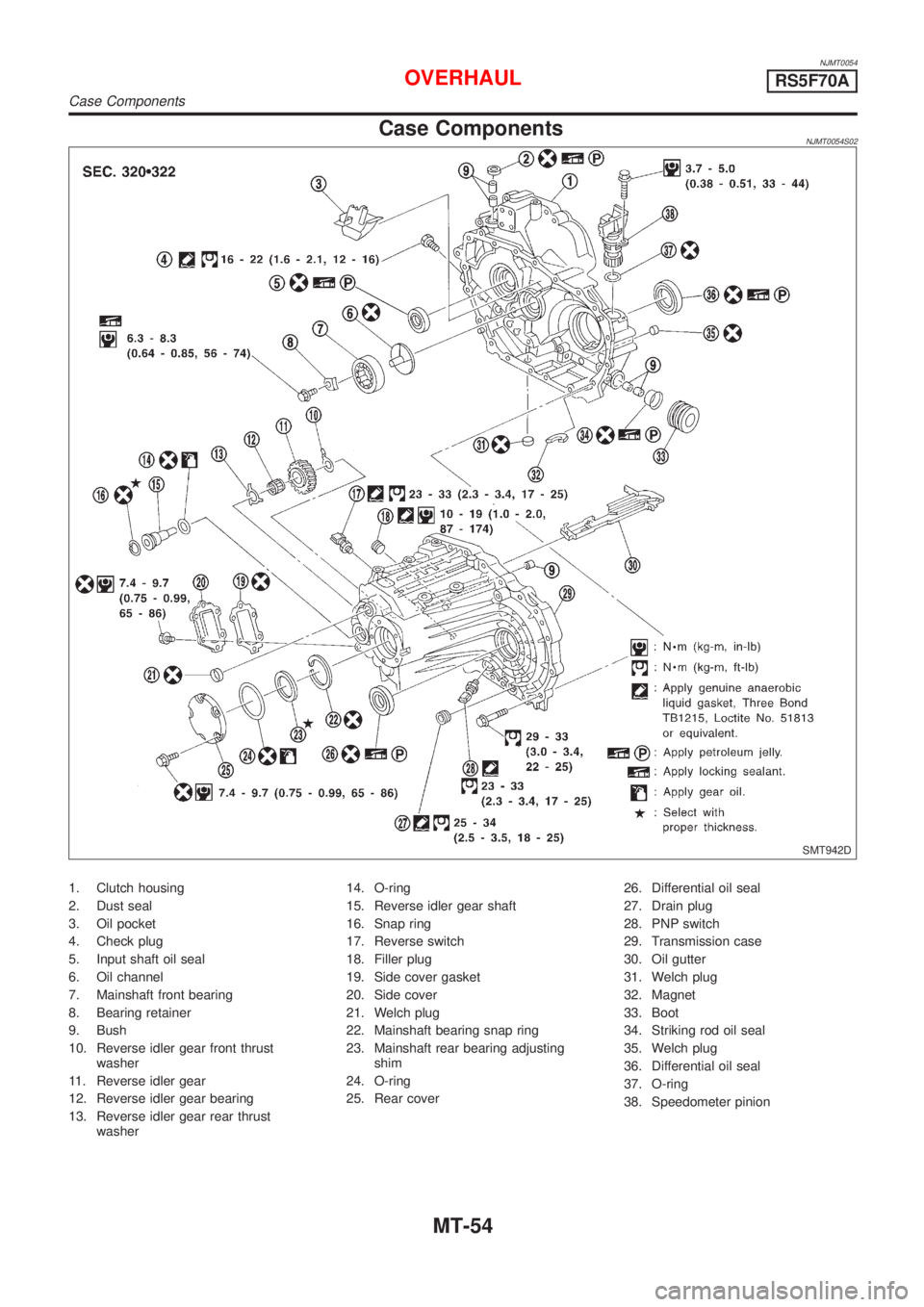

NJMT0054

Case ComponentsNJMT0054S02

SMT942D

1. Clutch housing

2. Dust seal

3. Oil pocket

4. Check plug

5. Input shaft oil seal

6. Oil channel

7. Mainshaft front bearing

8. Bearing retainer

9. Bush

10. Reverse idler gear front thrust

washer

11. Reverse idler gear

12. Reverse idler gear bearing

13. Reverse idler gear rear thrust

washer14. O-ring

15. Reverse idler gear shaft

16. Snap ring

17. Reverse switch

18. Filler plug

19. Side cover gasket

20. Side cover

21. Welch plug

22. Mainshaft bearing snap ring

23. Mainshaft rear bearing adjusting

shim

24. O-ring

25. Rear cover26. Differential oil seal

27. Drain plug

28. PNP switch

29. Transmission case

30. Oil gutter

31. Welch plug

32. Magnet

33. Boot

34. Striking rod oil seal

35. Welch plug

36. Differential oil seal

37. O-ring

38. Speedometer pinion

OVERHAULRS5F70A

Case Components

MT-54

Page 2627 of 2898

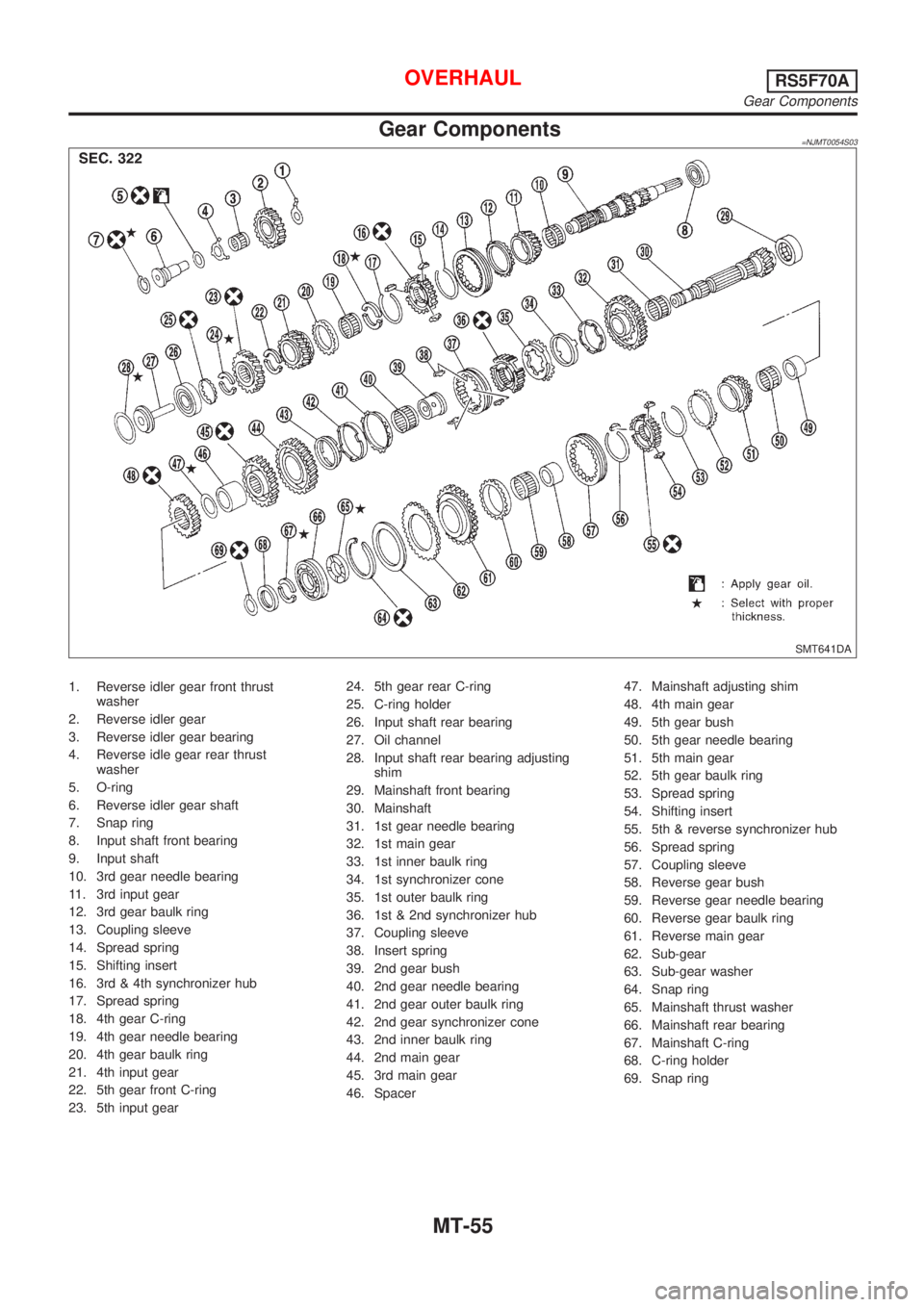

Gear Components=NJMT0054S03

SMT641DA

1. Reverse idler gear front thrust

washer

2. Reverse idler gear

3. Reverse idler gear bearing

4. Reverse idle gear rear thrust

washer

5. O-ring

6. Reverse idler gear shaft

7. Snap ring

8. Input shaft front bearing

9. Input shaft

10. 3rd gear needle bearing

11. 3rd input gear

12. 3rd gear baulk ring

13. Coupling sleeve

14. Spread spring

15. Shifting insert

16. 3rd & 4th synchronizer hub

17. Spread spring

18. 4th gear C-ring

19. 4th gear needle bearing

20. 4th gear baulk ring

21. 4th input gear

22. 5th gear front C-ring

23. 5th input gear24. 5th gear rear C-ring

25. C-ring holder

26. Input shaft rear bearing

27. Oil channel

28. Input shaft rear bearing adjusting

shim

29. Mainshaft front bearing

30. Mainshaft

31. 1st gear needle bearing

32. 1st main gear

33. 1st inner baulk ring

34. 1st synchronizer cone

35. 1st outer baulk ring

36. 1st & 2nd synchronizer hub

37. Coupling sleeve

38. Insert spring

39. 2nd gear bush

40. 2nd gear needle bearing

41. 2nd gear outer baulk ring

42. 2nd gear synchronizer cone

43. 2nd inner baulk ring

44. 2nd main gear

45. 3rd main gear

46. Spacer47. Mainshaft adjusting shim

48. 4th main gear

49. 5th gear bush

50. 5th gear needle bearing

51. 5th main gear

52. 5th gear baulk ring

53. Spread spring

54. Shifting insert

55. 5th & reverse synchronizer hub

56. Spread spring

57. Coupling sleeve

58. Reverse gear bush

59. Reverse gear needle bearing

60. Reverse gear baulk ring

61. Reverse main gear

62. Sub-gear

63. Sub-gear washer

64. Snap ring

65. Mainshaft thrust washer

66. Mainshaft rear bearing

67. Mainshaft C-ring

68. C-ring holder

69. Snap ring

OVERHAULRS5F70A

Gear Components

MT-55

Page 2628 of 2898

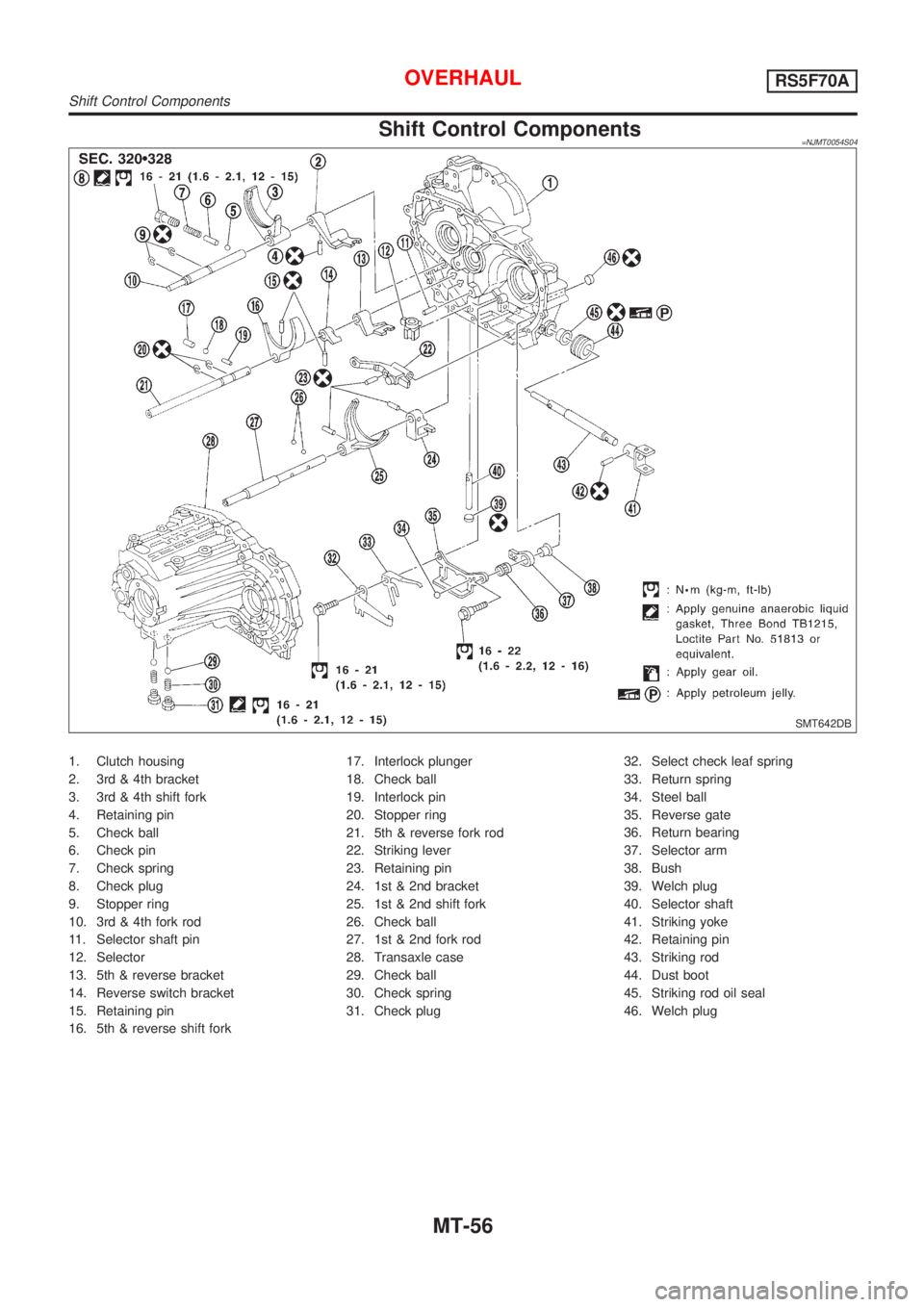

Shift Control Components=NJMT0054S04

SMT642DB

1. Clutch housing

2. 3rd & 4th bracket

3. 3rd & 4th shift fork

4. Retaining pin

5. Check ball

6. Check pin

7. Check spring

8. Check plug

9. Stopper ring

10. 3rd & 4th fork rod

11. Selector shaft pin

12. Selector

13. 5th & reverse bracket

14. Reverse switch bracket

15. Retaining pin

16. 5th & reverse shift fork17. Interlock plunger

18. Check ball

19. Interlock pin

20. Stopper ring

21. 5th & reverse fork rod

22. Striking lever

23. Retaining pin

24. 1st & 2nd bracket

25. 1st & 2nd shift fork

26. Check ball

27. 1st & 2nd fork rod

28. Transaxle case

29. Check ball

30. Check spring

31. Check plug32. Select check leaf spring

33. Return spring

34. Steel ball

35. Reverse gate

36. Return bearing

37. Selector arm

38. Bush

39. Welch plug

40. Selector shaft

41. Striking yoke

42. Retaining pin

43. Striking rod

44. Dust boot

45. Striking rod oil seal

46. Welch plug

OVERHAULRS5F70A

Shift Control Components

MT-56

Page 2629 of 2898

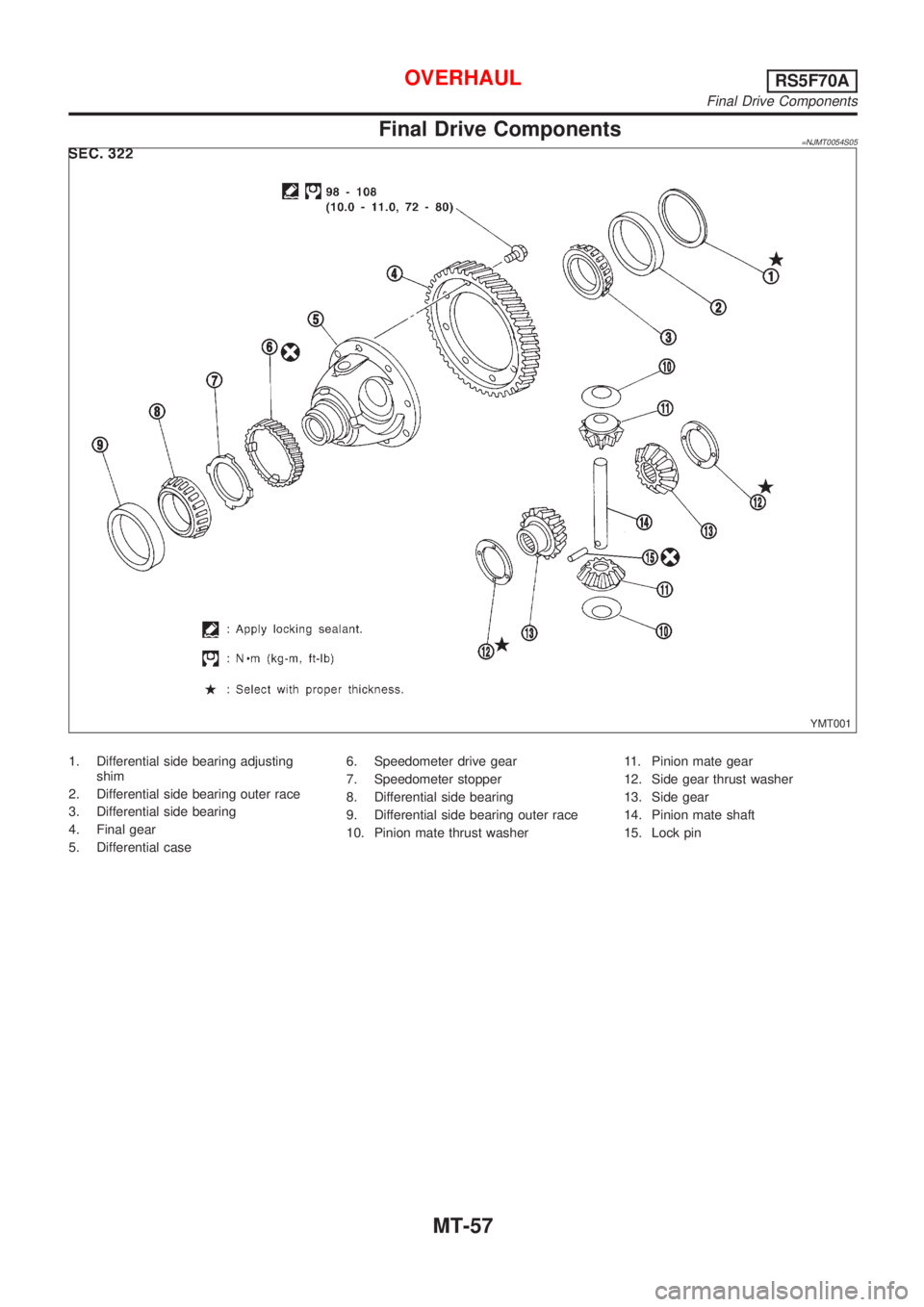

Final Drive Components=NJMT0054S05

YMT001

1. Differential side bearing adjusting

shim

2. Differential side bearing outer race

3. Differential side bearing

4. Final gear

5. Differential case6. Speedometer drive gear

7. Speedometer stopper

8. Differential side bearing

9. Differential side bearing outer race

10. Pinion mate thrust washer11. Pinion mate gear

12. Side gear thrust washer

13. Side gear

14. Pinion mate shaft

15. Lock pin

OVERHAULRS5F70A

Final Drive Components

MT-57

Page 2630 of 2898

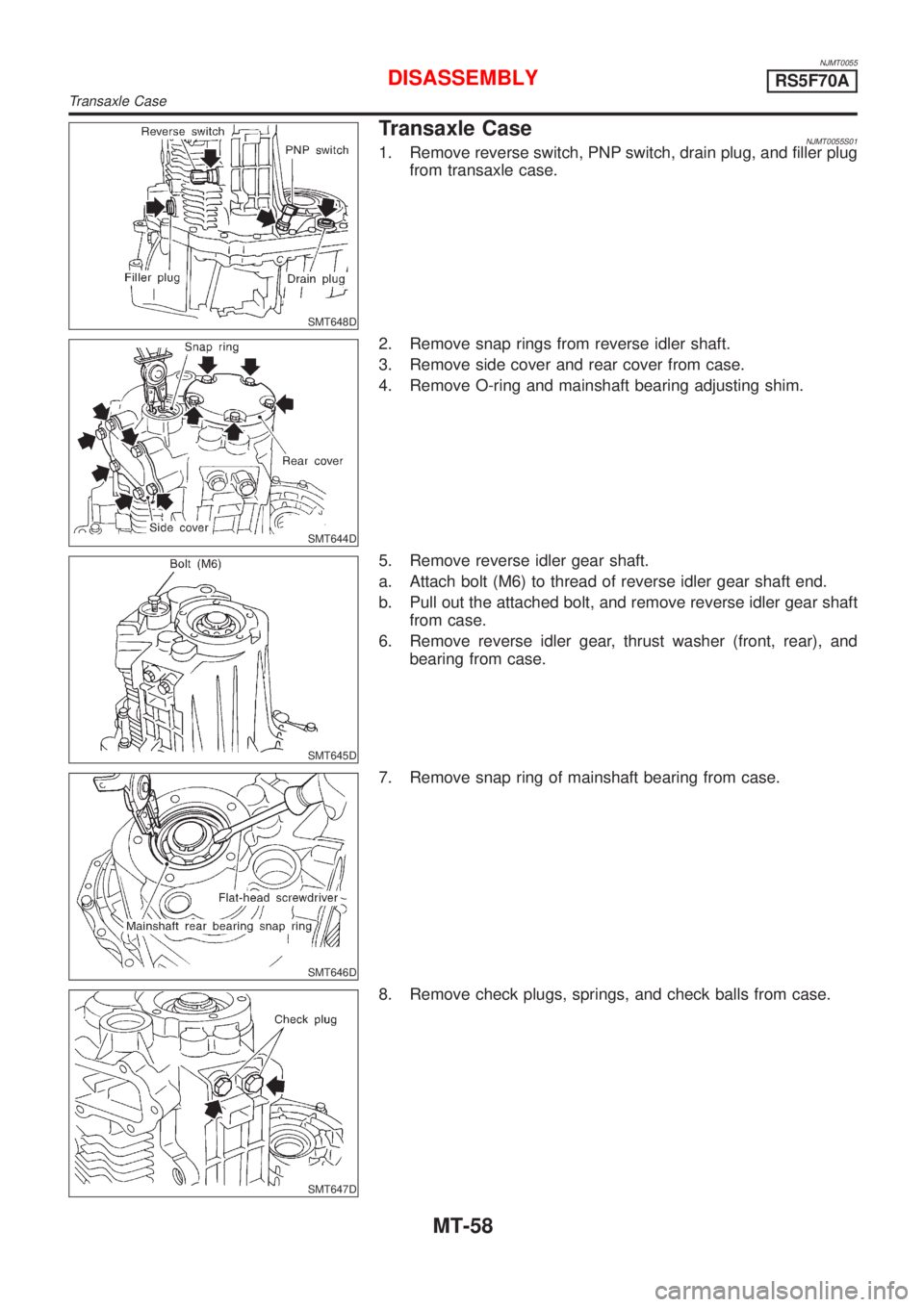

NJMT0055

SMT648D

Transaxle CaseNJMT0055S011. Remove reverse switch, PNP switch, drain plug, and filler plug

from transaxle case.

SMT644D

2. Remove snap rings from reverse idler shaft.

3. Remove side cover and rear cover from case.

4. Remove O-ring and mainshaft bearing adjusting shim.

SMT645D

5. Remove reverse idler gear shaft.

a. Attach bolt (M6) to thread of reverse idler gear shaft end.

b. Pull out the attached bolt, and remove reverse idler gear shaft

from case.

6. Remove reverse idler gear, thrust washer (front, rear), and

bearing from case.

SMT646D

7. Remove snap ring of mainshaft bearing from case.

SMT647D

8. Remove check plugs, springs, and check balls from case.

DISASSEMBLYRS5F70A

Transaxle Case

MT-58