NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: oil change, wheel, BR -, trailer, dimensions, radiator cap, key

Page 2601 of 2898

NJMT0038

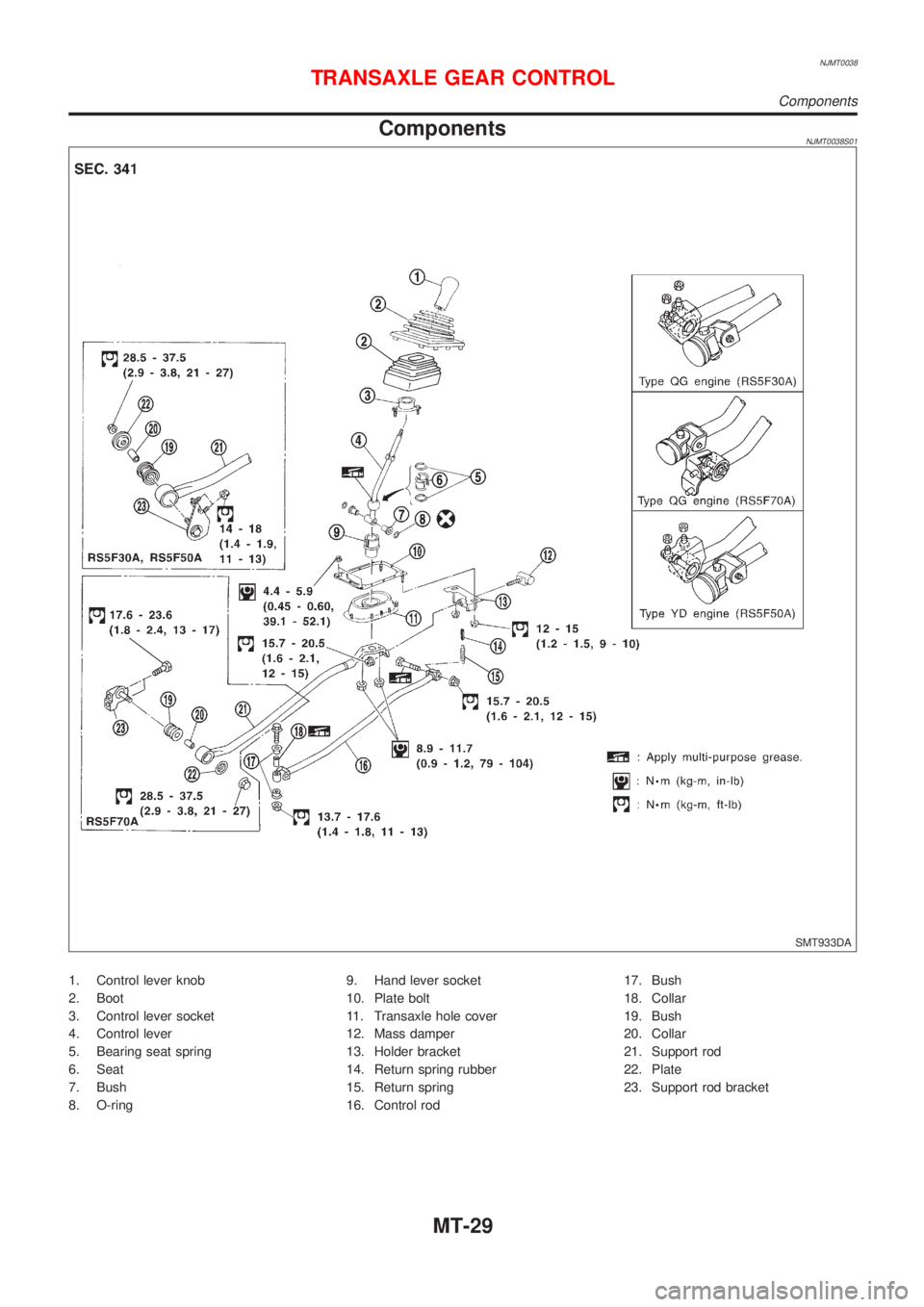

ComponentsNJMT0038S01

SMT933DA

1. Control lever knob

2. Boot

3. Control lever socket

4. Control lever

5. Bearing seat spring

6. Seat

7. Bush

8. O-ring9. Hand lever socket

10. Plate bolt

11. Transaxle hole cover

12. Mass damper

13. Holder bracket

14. Return spring rubber

15. Return spring

16. Control rod17. Bush

18. Collar

19. Bush

20. Collar

21. Support rod

22. Plate

23. Support rod bracket

TRANSAXLE GEAR CONTROL

Components

MT-29

Page 2602 of 2898

NJMT0039

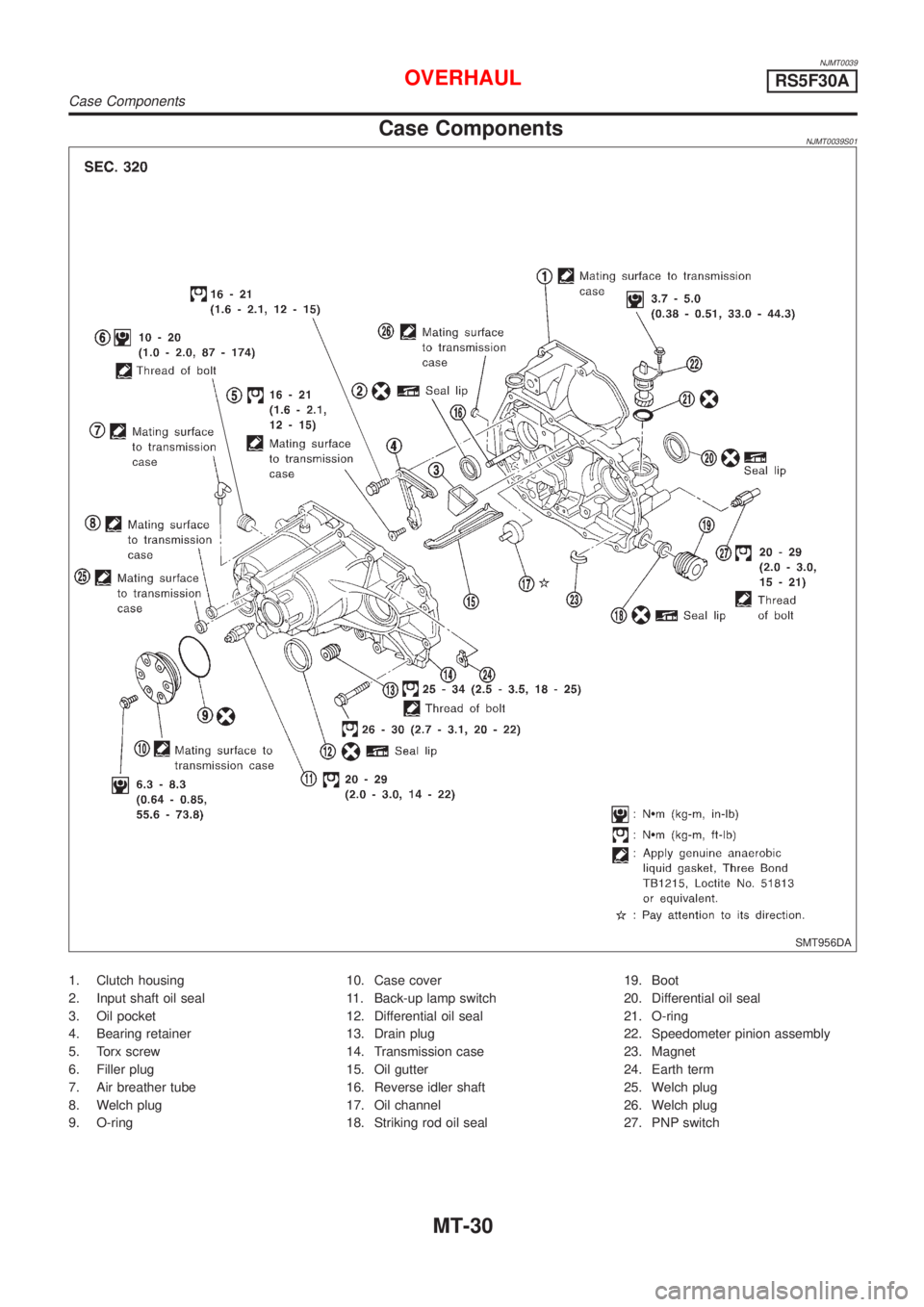

Case ComponentsNJMT0039S01

SMT956DA

1. Clutch housing

2. Input shaft oil seal

3. Oil pocket

4. Bearing retainer

5. Torx screw

6. Filler plug

7. Air breather tube

8. Welch plug

9. O-ring10. Case cover

11. Back-up lamp switch

12. Differential oil seal

13. Drain plug

14. Transmission case

15. Oil gutter

16. Reverse idler shaft

17. Oil channel

18. Striking rod oil seal19. Boot

20. Differential oil seal

21. O-ring

22. Speedometer pinion assembly

23. Magnet

24. Earth term

25. Welch plug

26. Welch plug

27. PNP switch

OVERHAULRS5F30A

Case Components

MT-30

Page 2603 of 2898

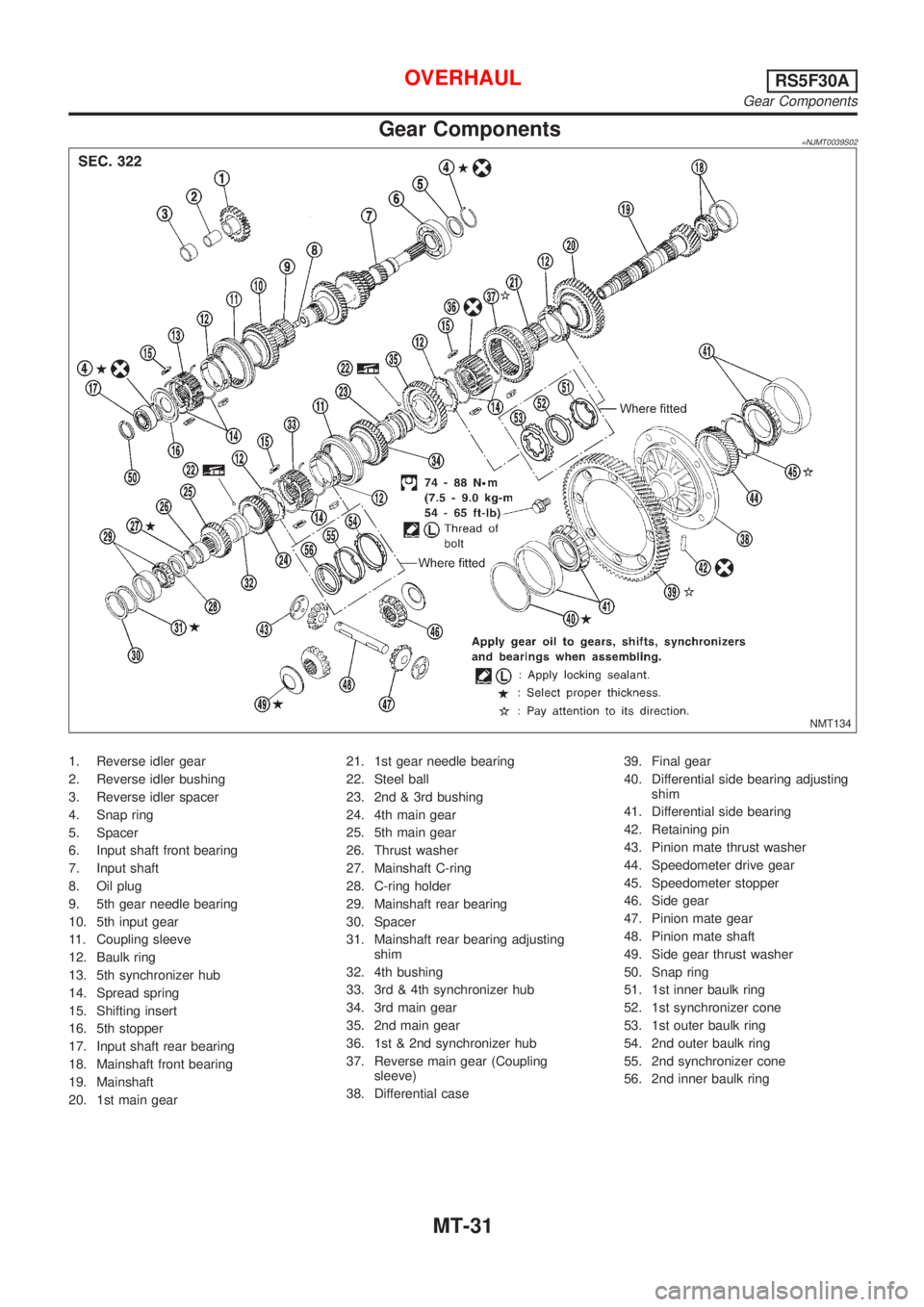

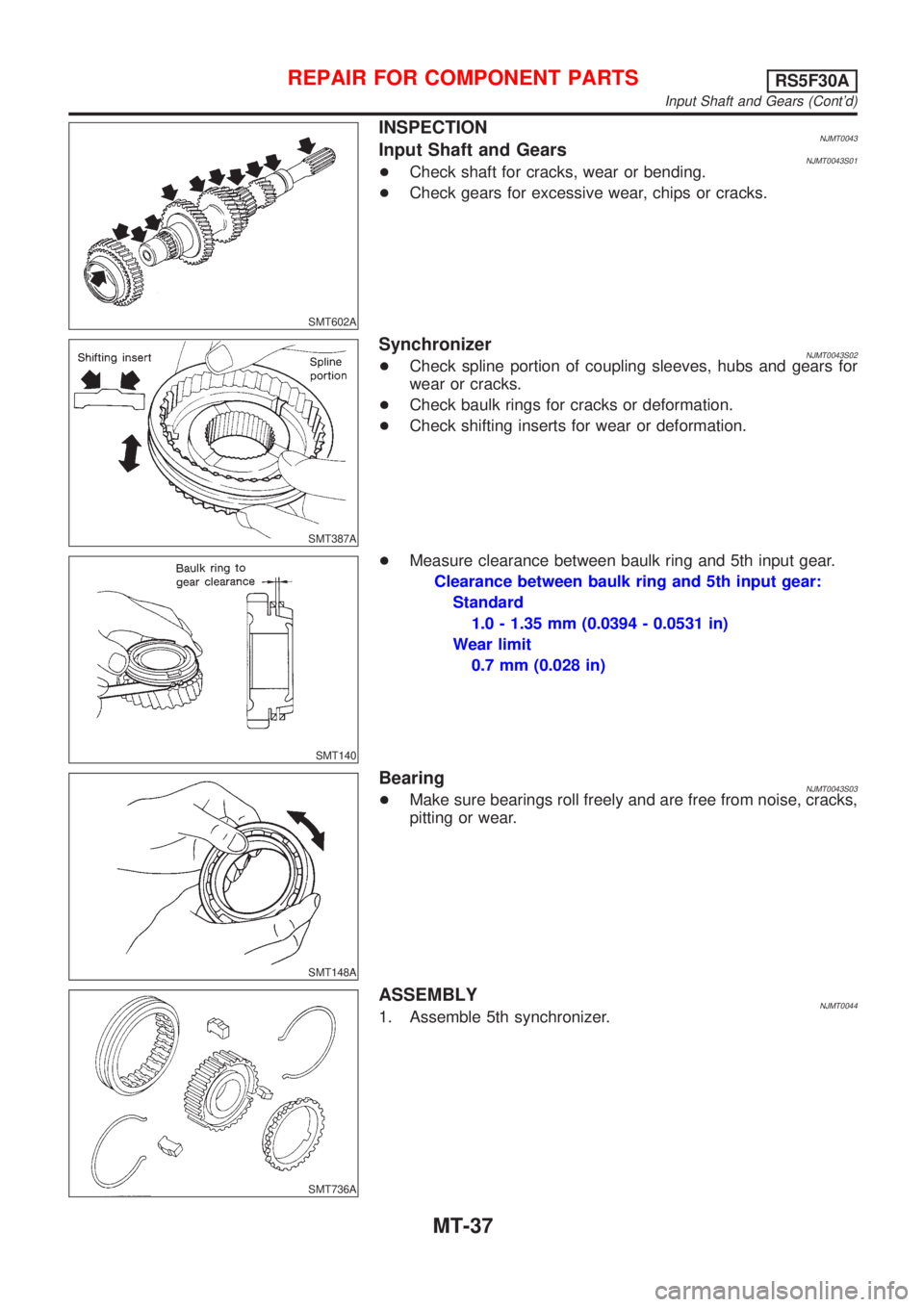

Gear Components=NJMT0039S02

NMT134

1. Reverse idler gear

2. Reverse idler bushing

3. Reverse idler spacer

4. Snap ring

5. Spacer

6. Input shaft front bearing

7. Input shaft

8. Oil plug

9. 5th gear needle bearing

10. 5th input gear

11. Coupling sleeve

12. Baulk ring

13. 5th synchronizer hub

14. Spread spring

15. Shifting insert

16. 5th stopper

17. Input shaft rear bearing

18. Mainshaft front bearing

19. Mainshaft

20. 1st main gear21. 1st gear needle bearing

22. Steel ball

23. 2nd & 3rd bushing

24. 4th main gear

25. 5th main gear

26. Thrust washer

27. Mainshaft C-ring

28. C-ring holder

29. Mainshaft rear bearing

30. Spacer

31. Mainshaft rear bearing adjusting

shim

32. 4th bushing

33. 3rd & 4th synchronizer hub

34. 3rd main gear

35. 2nd main gear

36. 1st & 2nd synchronizer hub

37. Reverse main gear (Coupling

sleeve)

38. Differential case39. Final gear

40. Differential side bearing adjusting

shim

41. Differential side bearing

42. Retaining pin

43. Pinion mate thrust washer

44. Speedometer drive gear

45. Speedometer stopper

46. Side gear

47. Pinion mate gear

48. Pinion mate shaft

49. Side gear thrust washer

50. Snap ring

51. 1st inner baulk ring

52. 1st synchronizer cone

53. 1st outer baulk ring

54. 2nd outer baulk ring

55. 2nd synchronizer cone

56. 2nd inner baulk ring

OVERHAULRS5F30A

Gear Components

MT-31

Page 2604 of 2898

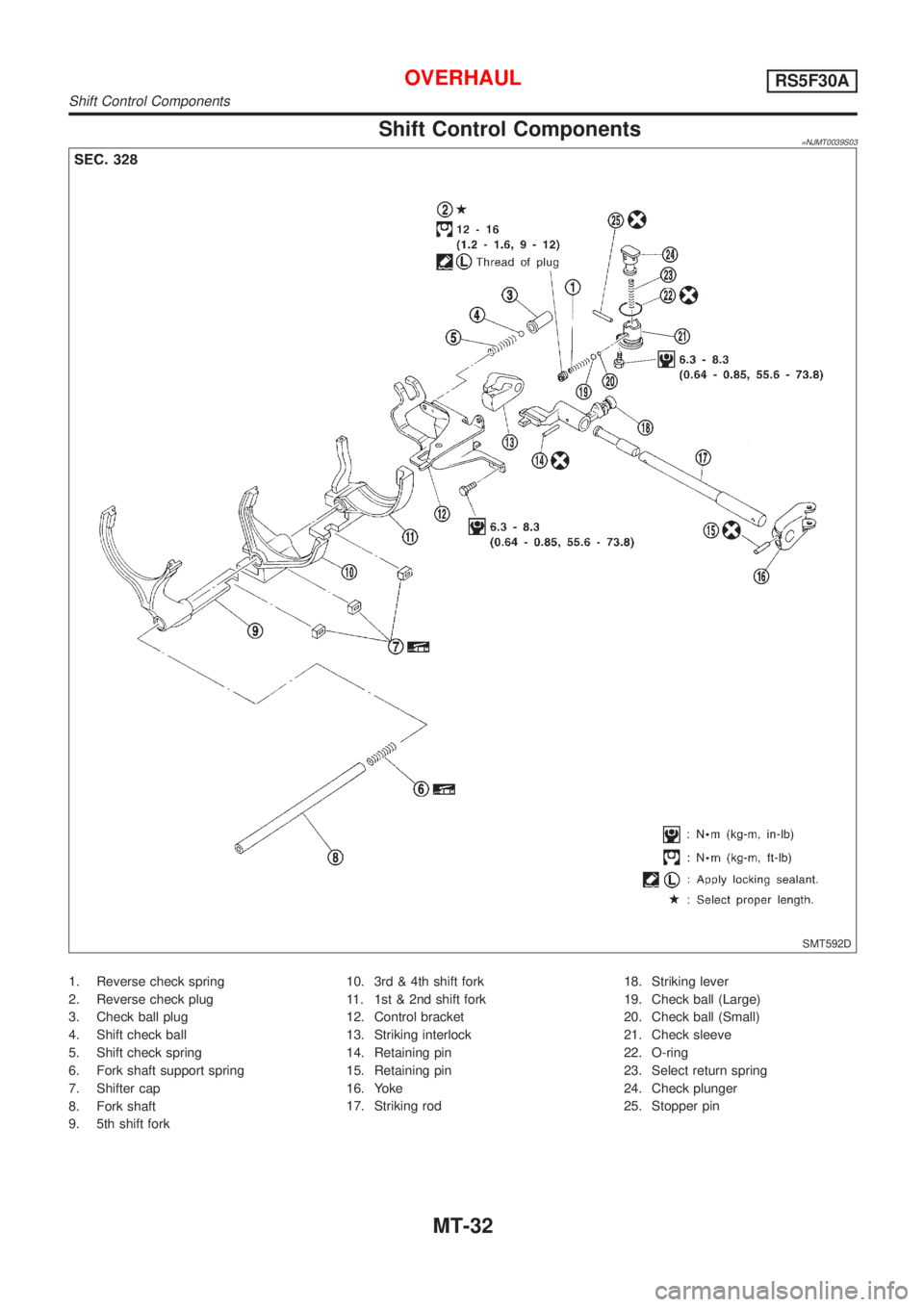

Shift Control Components=NJMT0039S03

SMT592D

1. Reverse check spring

2. Reverse check plug

3. Check ball plug

4. Shift check ball

5. Shift check spring

6. Fork shaft support spring

7. Shifter cap

8. Fork shaft

9. 5th shift fork10. 3rd & 4th shift fork

11. 1st & 2nd shift fork

12. Control bracket

13. Striking interlock

14. Retaining pin

15. Retaining pin

16. Yoke

17. Striking rod18. Striking lever

19. Check ball (Large)

20. Check ball (Small)

21. Check sleeve

22. O-ring

23. Select return spring

24. Check plunger

25. Stopper pin

OVERHAULRS5F30A

Shift Control Components

MT-32

Page 2605 of 2898

NJMT0040

SMT571

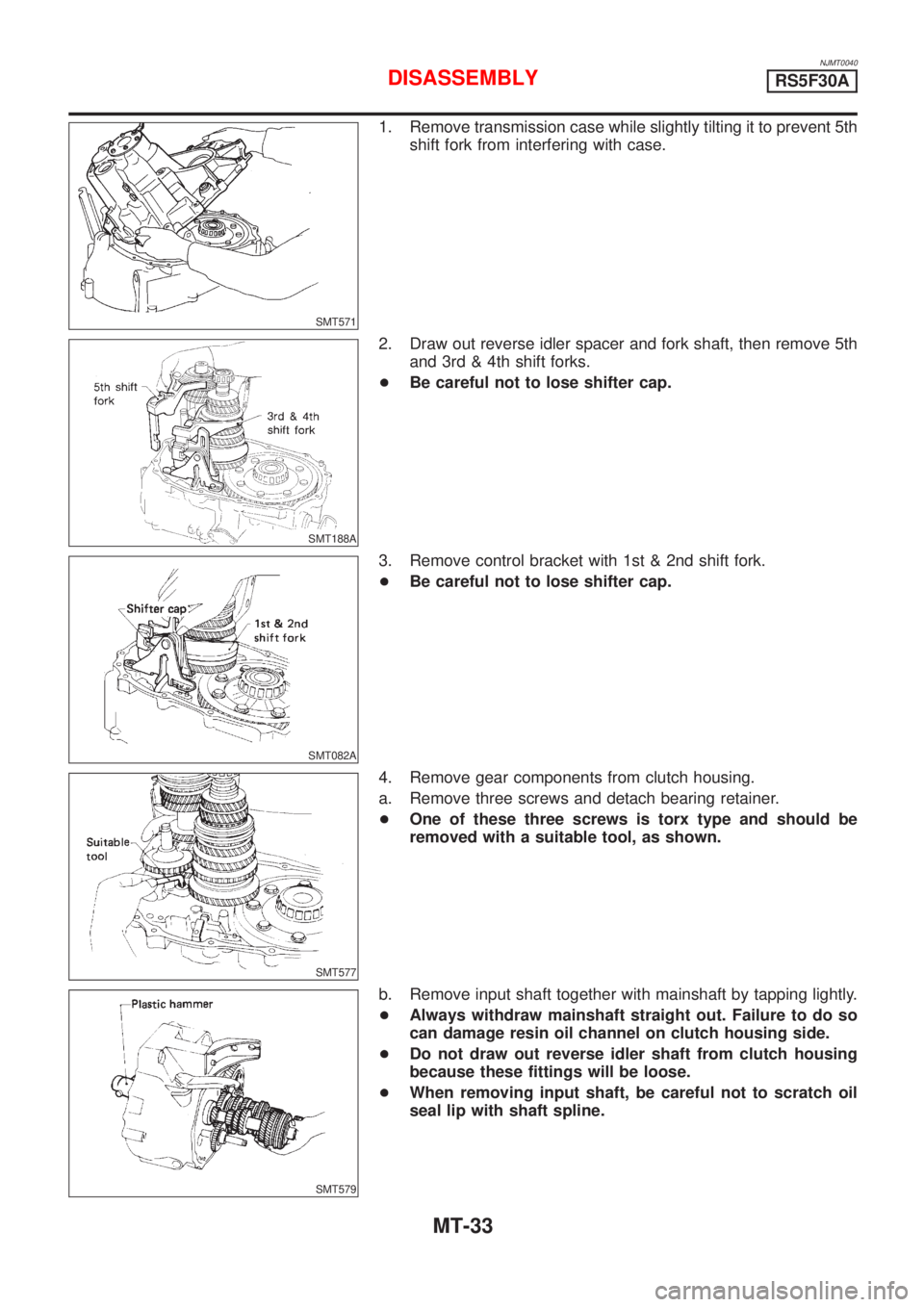

1. Remove transmission case while slightly tilting it to prevent 5th

shift fork from interfering with case.

SMT188A

2. Draw out reverse idler spacer and fork shaft, then remove 5th

and 3rd & 4th shift forks.

+Be careful not to lose shifter cap.

SMT082A

3. Remove control bracket with 1st & 2nd shift fork.

+Be careful not to lose shifter cap.

SMT577

4. Remove gear components from clutch housing.

a. Remove three screws and detach bearing retainer.

+One of these three screws is torx type and should be

removed with a suitable tool, as shown.

SMT579

b. Remove input shaft together with mainshaft by tapping lightly.

+Always withdraw mainshaft straight out. Failure to do so

can damage resin oil channel on clutch housing side.

+Do not draw out reverse idler shaft from clutch housing

because these fittings will be loose.

+When removing input shaft, be careful not to scratch oil

seal lip with shaft spline.

DISASSEMBLYRS5F30A

MT-33

Page 2606 of 2898

SMT580

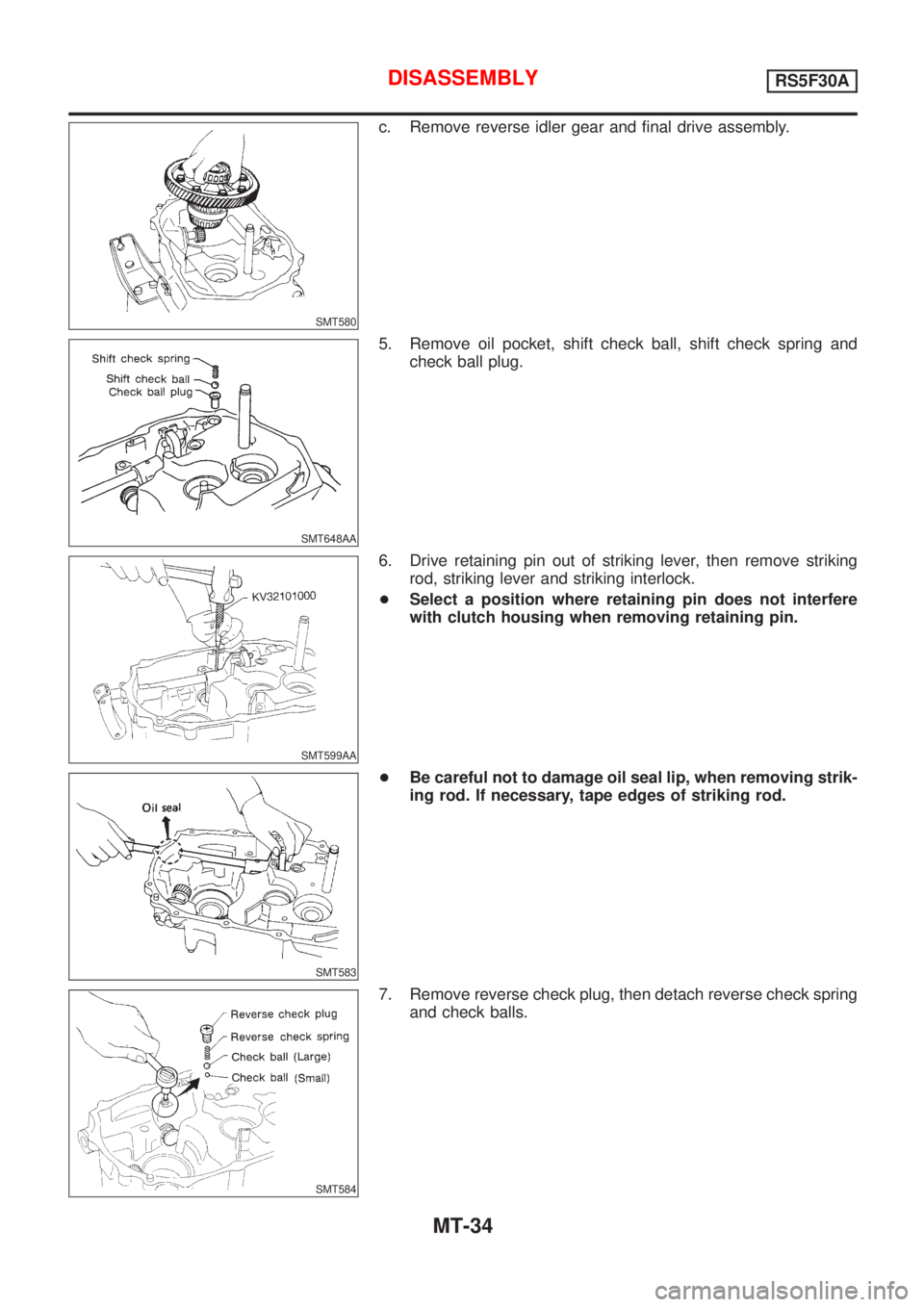

c. Remove reverse idler gear and final drive assembly.

SMT648AA

5. Remove oil pocket, shift check ball, shift check spring and

check ball plug.

SMT599AA

6. Drive retaining pin out of striking lever, then remove striking

rod, striking lever and striking interlock.

+Select a position where retaining pin does not interfere

with clutch housing when removing retaining pin.

SMT583

+Be careful not to damage oil seal lip, when removing strik-

ing rod. If necessary, tape edges of striking rod.

SMT584

7. Remove reverse check plug, then detach reverse check spring

and check balls.

DISASSEMBLYRS5F30A

MT-34

Page 2607 of 2898

SMT585

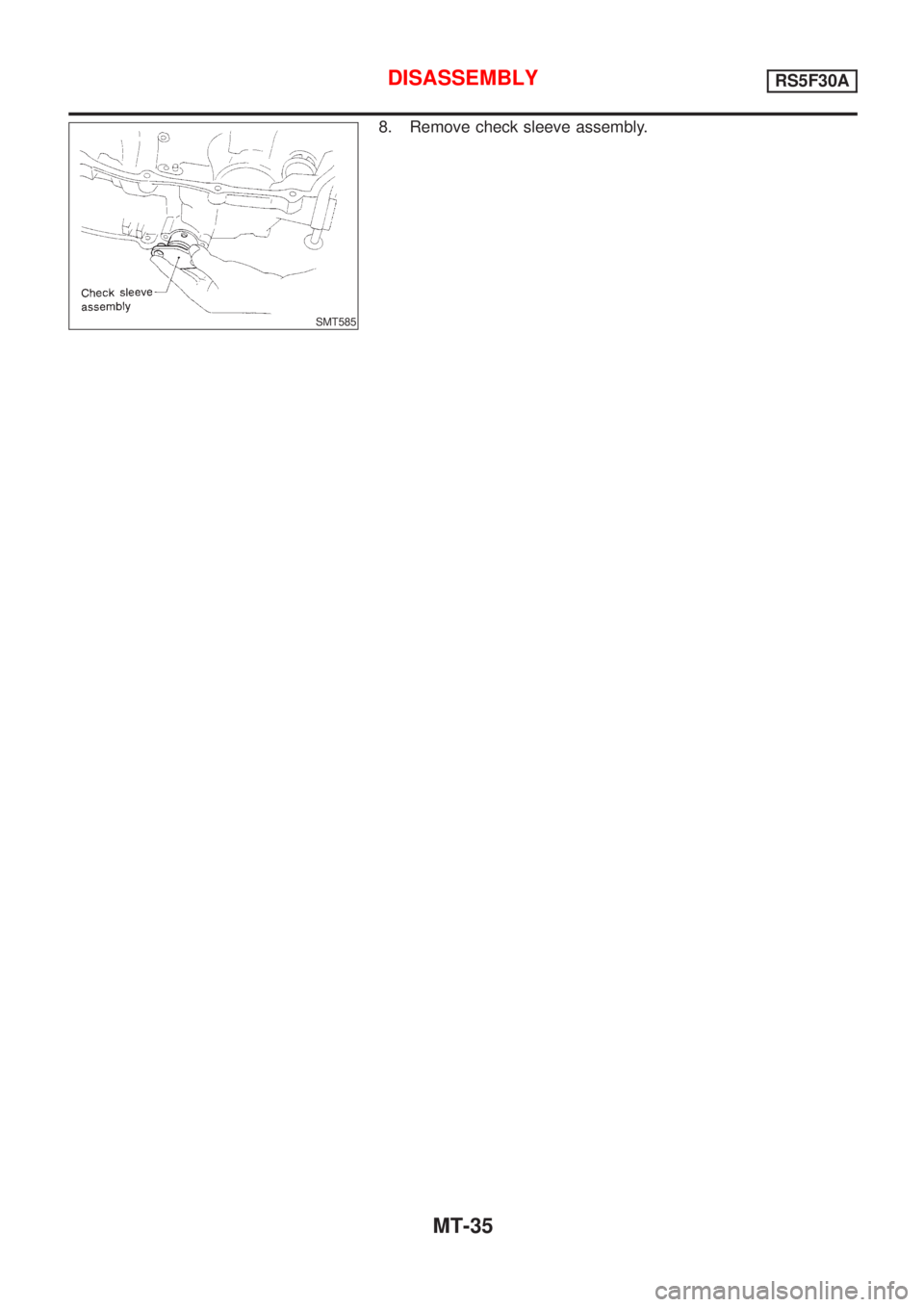

8. Remove check sleeve assembly.

DISASSEMBLYRS5F30A

MT-35

Page 2608 of 2898

SMT734A

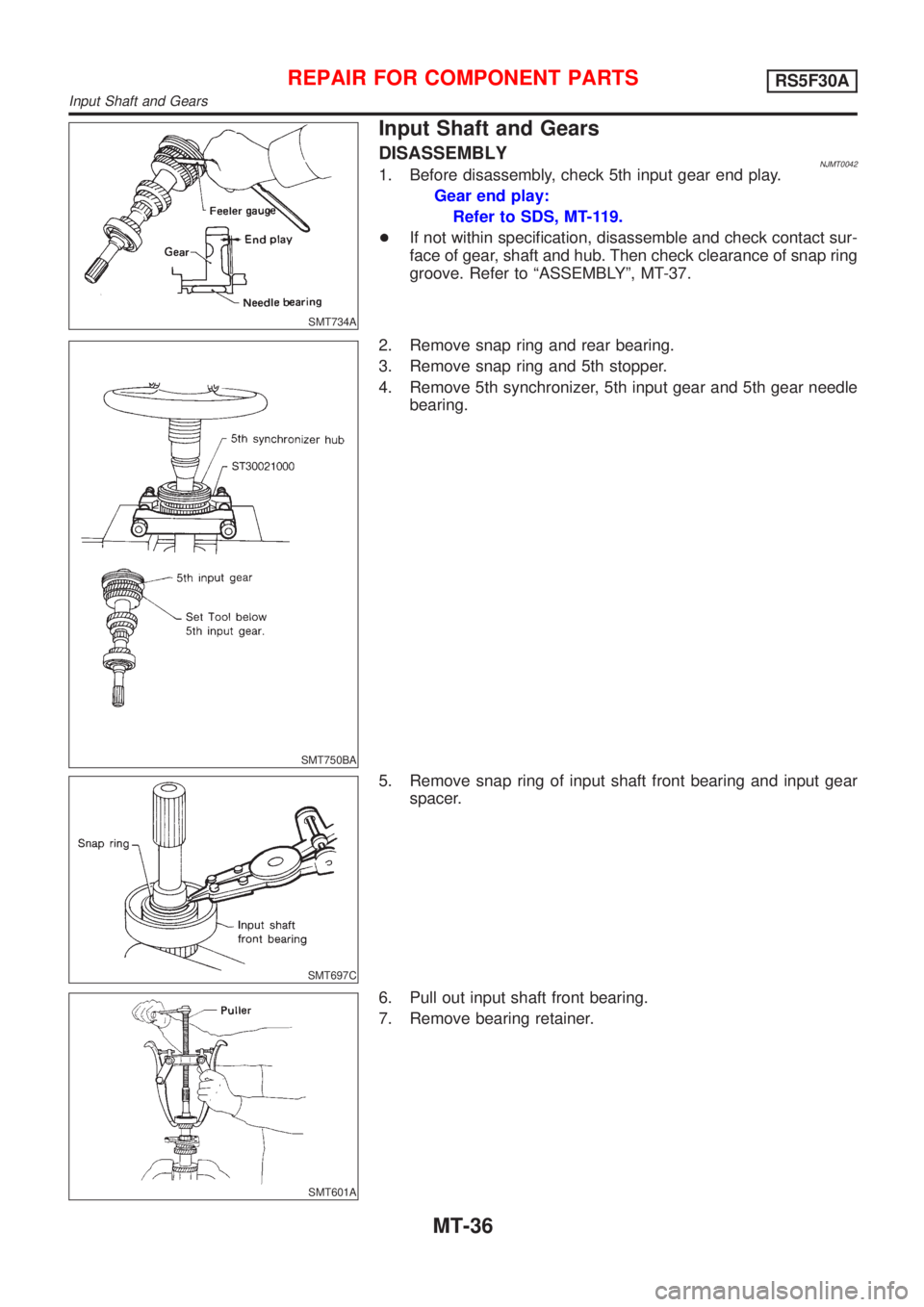

Input Shaft and Gears

DISASSEMBLYNJMT00421. Before disassembly, check 5th input gear end play.

Gear end play:

Refer to SDS, MT-119.

+If not within specification, disassemble and check contact sur-

face of gear, shaft and hub. Then check clearance of snap ring

groove. Refer to ªASSEMBLYº, MT-37.

SMT750BA

2. Remove snap ring and rear bearing.

3. Remove snap ring and 5th stopper.

4. Remove 5th synchronizer, 5th input gear and 5th gear needle

bearing.

SMT697C

5. Remove snap ring of input shaft front bearing and input gear

spacer.

SMT601A

6. Pull out input shaft front bearing.

7. Remove bearing retainer.

REPAIR FOR COMPONENT PARTSRS5F30A

Input Shaft and Gears

MT-36

Page 2609 of 2898

SMT602A

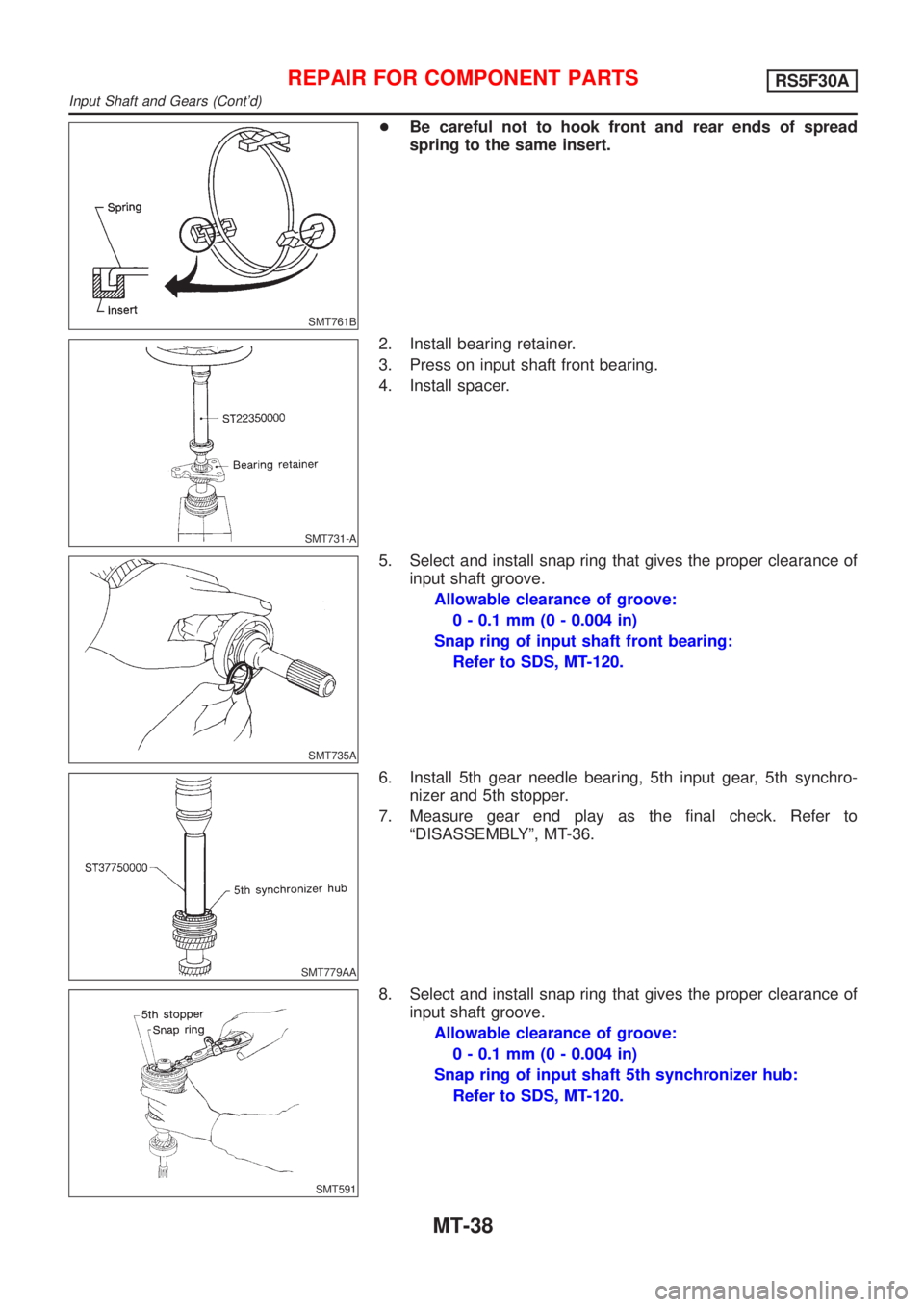

INSPECTIONNJMT0043Input Shaft and GearsNJMT0043S01+Check shaft for cracks, wear or bending.

+Check gears for excessive wear, chips or cracks.

SMT387A

SynchronizerNJMT0043S02+Check spline portion of coupling sleeves, hubs and gears for

wear or cracks.

+Check baulk rings for cracks or deformation.

+Check shifting inserts for wear or deformation.

SMT140

+Measure clearance between baulk ring and 5th input gear.

Clearance between baulk ring and 5th input gear:

Standard

1.0 - 1.35 mm (0.0394 - 0.0531 in)

Wear limit

0.7 mm (0.028 in)

SMT148A

BearingNJMT0043S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

SMT736A

ASSEMBLYNJMT00441. Assemble 5th synchronizer.

REPAIR FOR COMPONENT PARTSRS5F30A

Input Shaft and Gears (Cont'd)

MT-37

Page 2610 of 2898

SMT761B

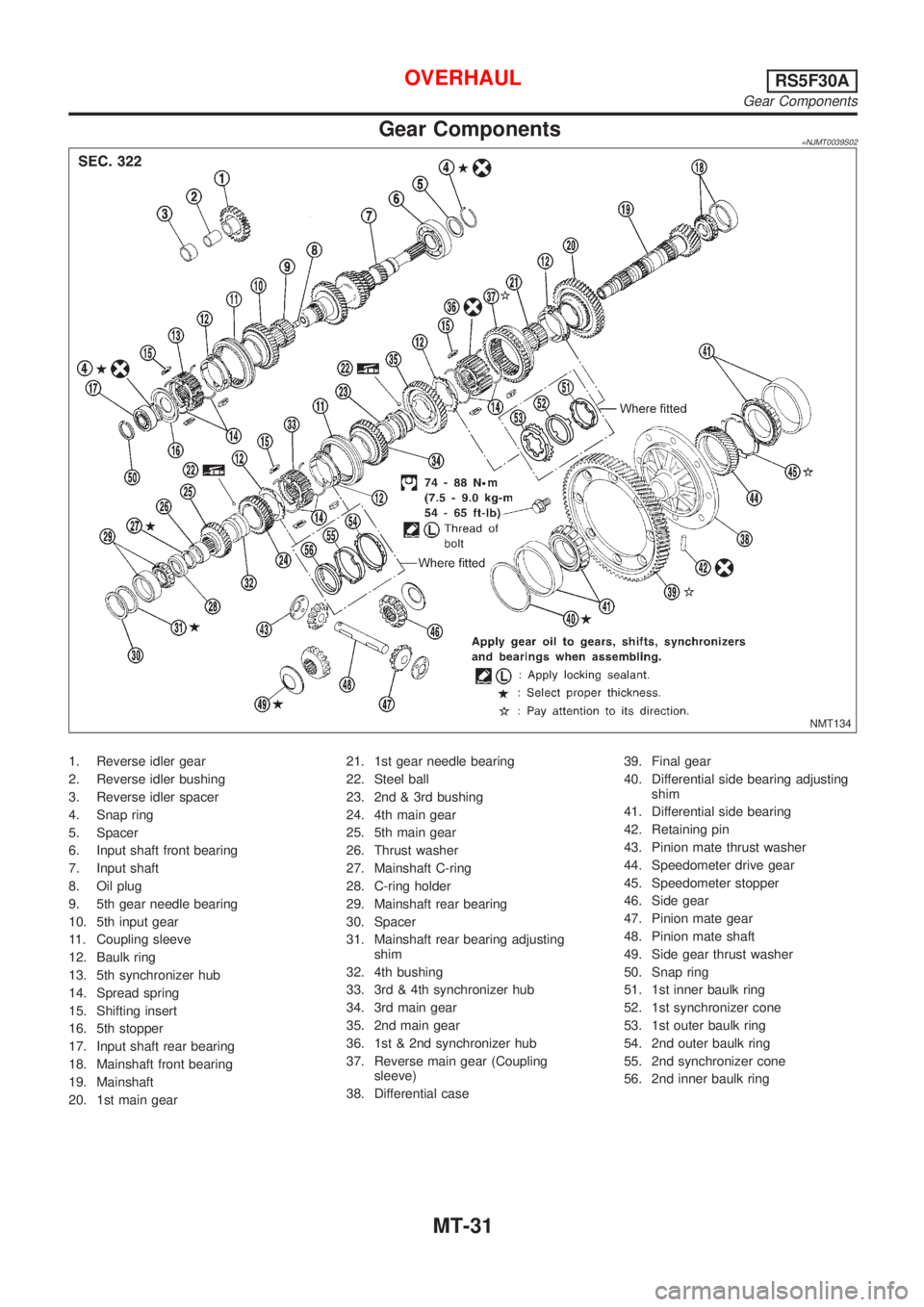

+Be careful not to hook front and rear ends of spread

spring to the same insert.

SMT731-A

2. Install bearing retainer.

3. Press on input shaft front bearing.

4. Install spacer.

SMT735A

5. Select and install snap ring that gives the proper clearance of

input shaft groove.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Snap ring of input shaft front bearing:

Refer to SDS, MT-120.

SMT779AA

6. Install 5th gear needle bearing, 5th input gear, 5th synchro-

nizer and 5th stopper.

7. Measure gear end play as the final check. Refer to

ªDISASSEMBLYº, MT-36.

SMT591

8. Select and install snap ring that gives the proper clearance of

input shaft groove.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Snap ring of input shaft 5th synchronizer hub:

Refer to SDS, MT-120.

REPAIR FOR COMPONENT PARTSRS5F30A

Input Shaft and Gears (Cont'd)

MT-38

Trending: o2 sensor, wiring diagram, horn, OBD port, jump cable, warning, Front brakes