NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 341 of 2898

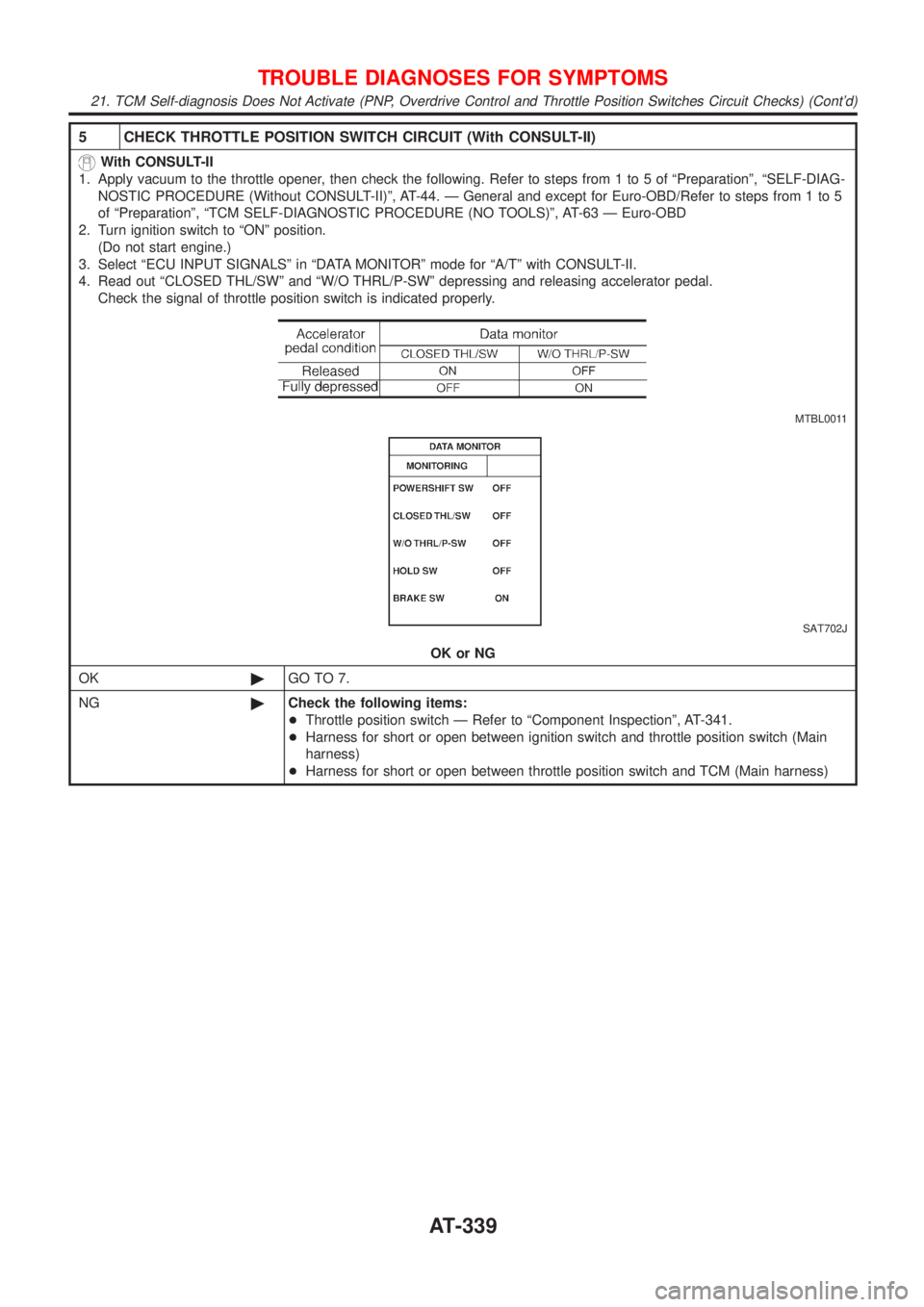

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps from 1 to 5 of ªPreparationº, ªSELF-DIAG-

NOSTIC PROCEDURE (Without CONSULT-II)º, AT-44. Ð General and except for Euro-OBD/Refer to steps from 1 to 5

of ªPreparationº, ªTCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)º, AT-63 Ð Euro-OBD

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

4. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

SAT702J

OK or NG

OK©GO TO 7.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponent Inspectionº, AT-341.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-339

Page 342 of 2898

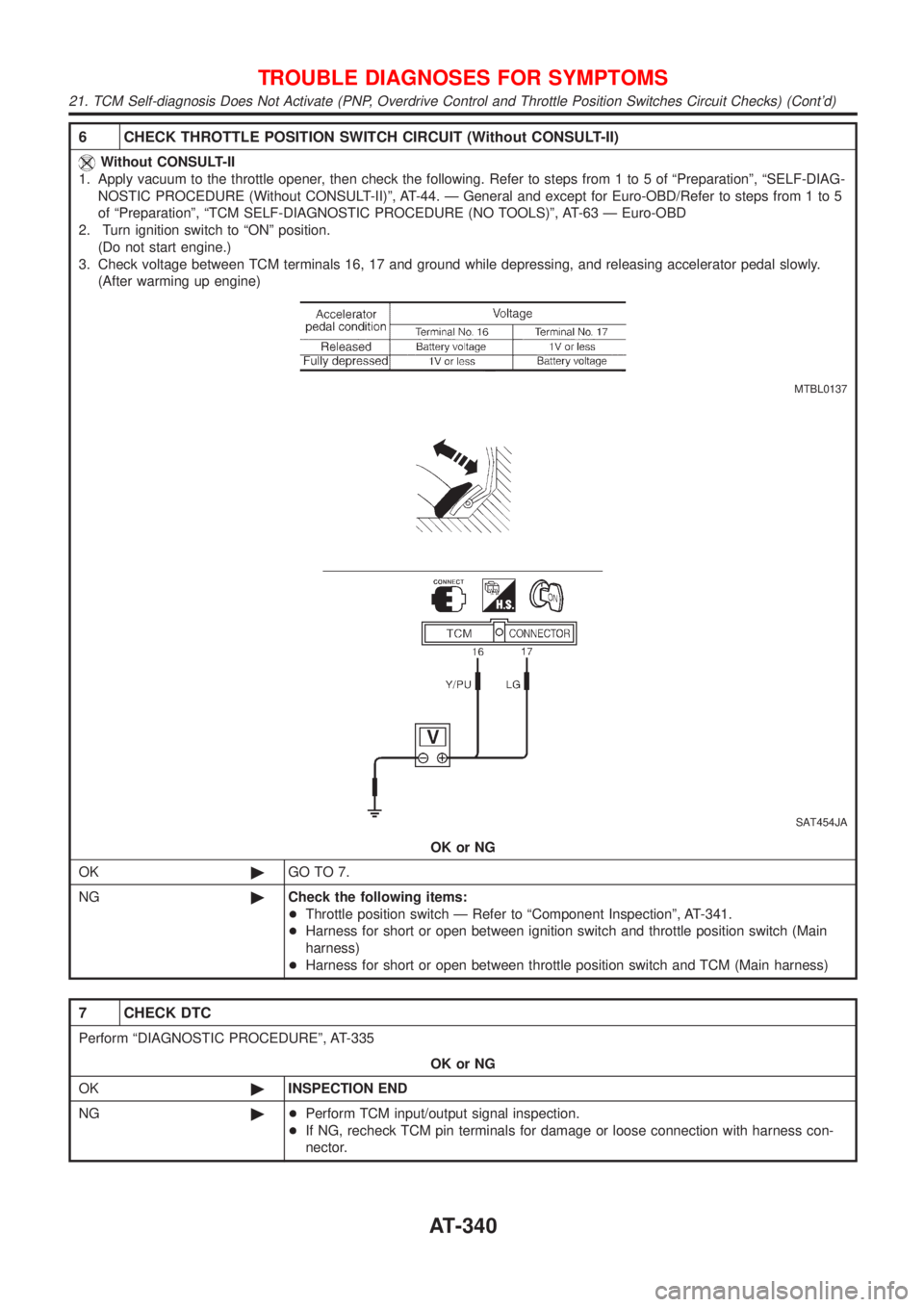

6 CHECK THROTTLE POSITION SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps from 1 to 5 of ªPreparationº, ªSELF-DIAG-

NOSTIC PROCEDURE (Without CONSULT-II)º, AT-44. Ð General and except for Euro-OBD/Refer to steps from 1 to 5

of ªPreparationº, ªTCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)º, AT-63 Ð Euro-OBD

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly.

(After warming up engine)

MTBL0137

SAT454JA

OK or NG

OK©GO TO 7.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponent Inspectionº, AT-341.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

7 CHECK DTC

Perform ªDIAGNOSTIC PROCEDUREº, AT-335

OK or NG

OK©INSPECTION END

NG©+Perform TCM input/output signal inspection.

+If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-340

Page 343 of 2898

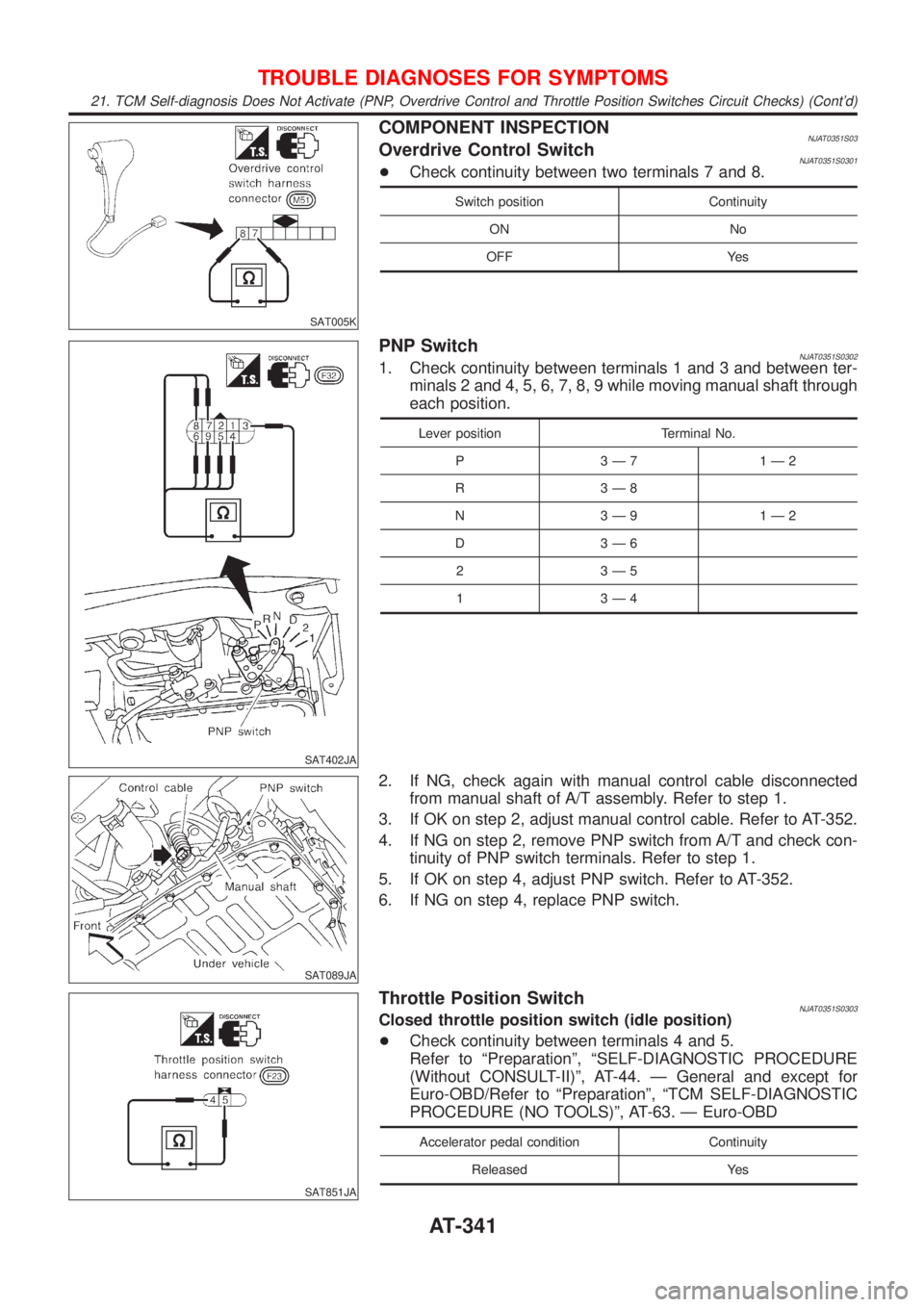

SAT005K

COMPONENT INSPECTIONNJAT0351S03Overdrive Control SwitchNJAT0351S0301+Check continuity between two terminals 7 and 8.

Switch position Continuity

ON No

OFF Yes

SAT402JA

PNP SwitchNJAT0351S03021. Check continuity between terminals 1 and 3 and between ter-

minals 2 and 4, 5, 6, 7, 8, 9 while moving manual shaft through

each position.

Lever position Terminal No.

P 3Ð7 1Ð2

R 3Ð8

N 3Ð9 1Ð2

D 3Ð6

2 3Ð5

1 3Ð4

SAT089JA

2. If NG, check again with manual control cable disconnected

from manual shaft of A/T assembly. Refer to step 1.

3. If OK on step 2, adjust manual control cable. Refer to AT-352.

4. If NG on step 2, remove PNP switch from A/T and check con-

tinuity of PNP switch terminals. Refer to step 1.

5. If OK on step 4, adjust PNP switch. Refer to AT-352.

6. If NG on step 4, replace PNP switch.

SAT851JA

Throttle Position SwitchNJAT0351S0303Closed throttle position switch (idle position)

+Check continuity between terminals 4 and 5.

Refer to ªPreparationº, ªSELF-DIAGNOSTIC PROCEDURE

(Without CONSULT-II)º, AT-44. Ð General and except for

Euro-OBD/Refer to ªPreparationº, ªTCM SELF-DIAGNOSTIC

PROCEDURE (NO TOOLS)º, AT-63. Ð Euro-OBD

Accelerator pedal condition Continuity

Released Yes

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-341

Page 344 of 2898

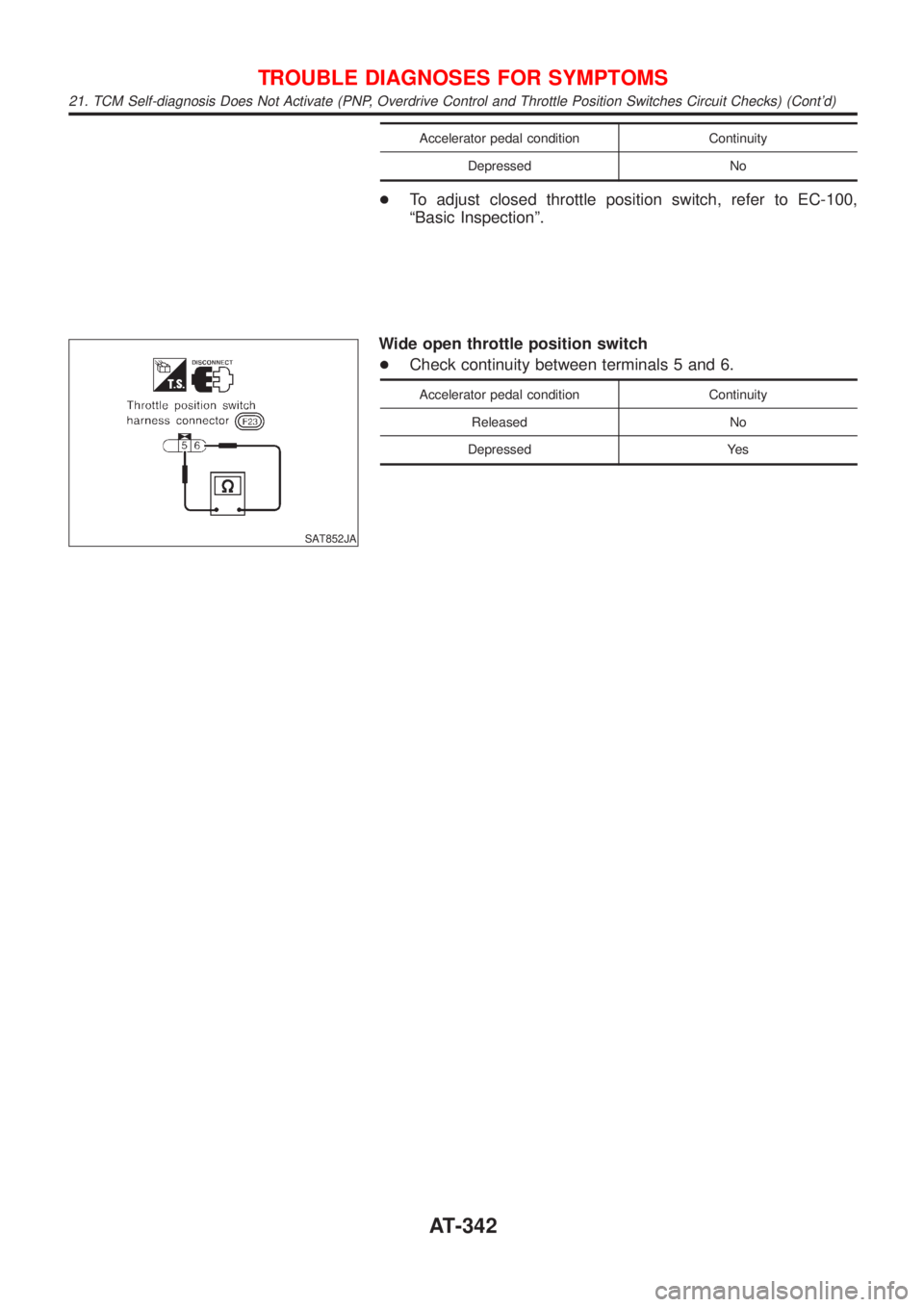

Accelerator pedal condition Continuity

Depressed No

+To adjust closed throttle position switch, refer to EC-100,

ªBasic Inspectionº.

SAT852JA

Wide open throttle position switch

+Check continuity between terminals 5 and 6.

Accelerator pedal condition Continuity

Released No

Depressed Yes

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-342

Page 345 of 2898

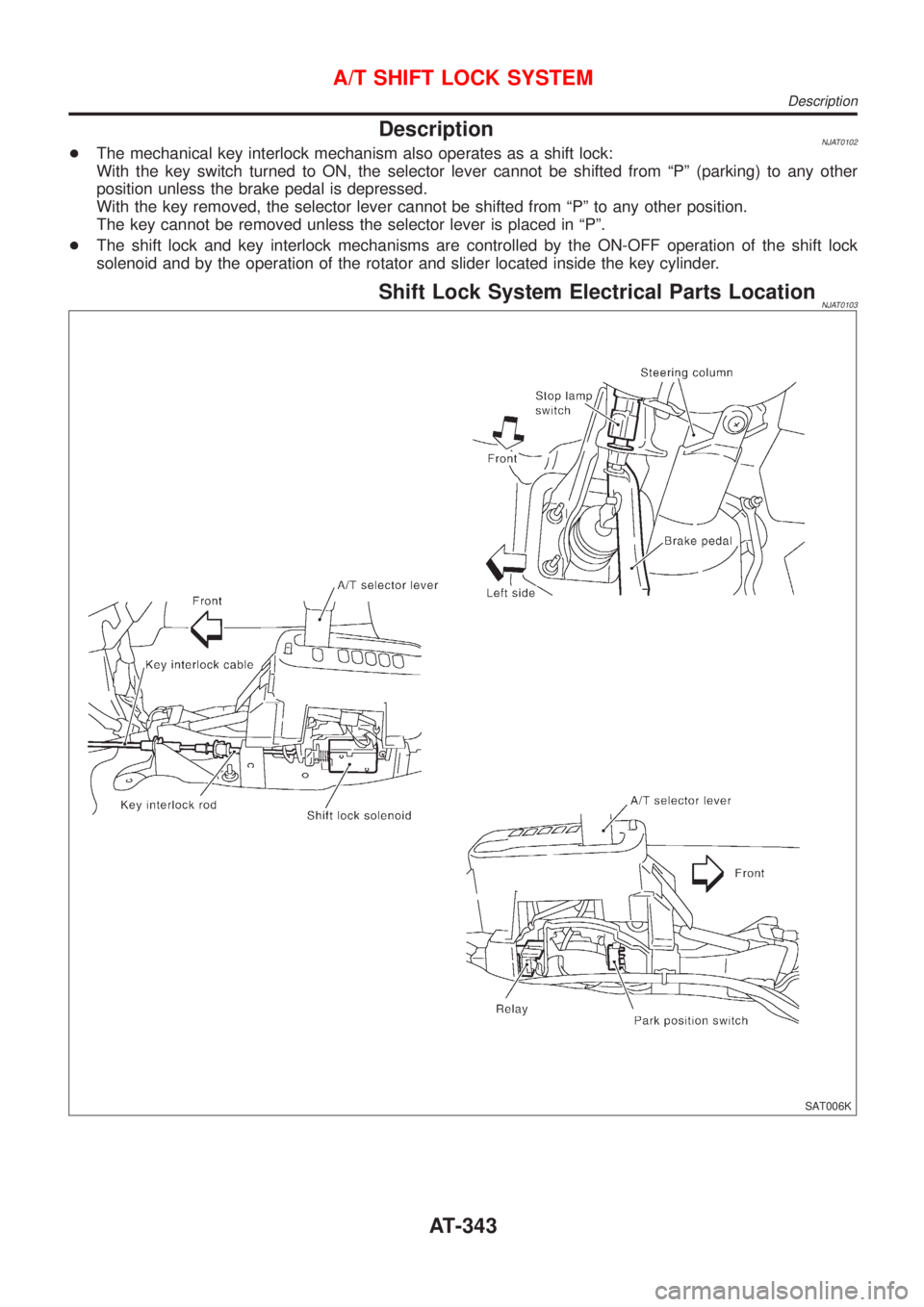

DescriptionNJAT0102+The mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the selector lever cannot be shifted from ªPº (parking) to any other

position unless the brake pedal is depressed.

With the key removed, the selector lever cannot be shifted from ªPº to any other position.

The key cannot be removed unless the selector lever is placed in ªPº.

+The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock

solenoid and by the operation of the rotator and slider located inside the key cylinder.

Shift Lock System Electrical Parts LocationNJAT0103

SAT006K

A/T SHIFT LOCK SYSTEM

Description

AT-343

Page 346 of 2898

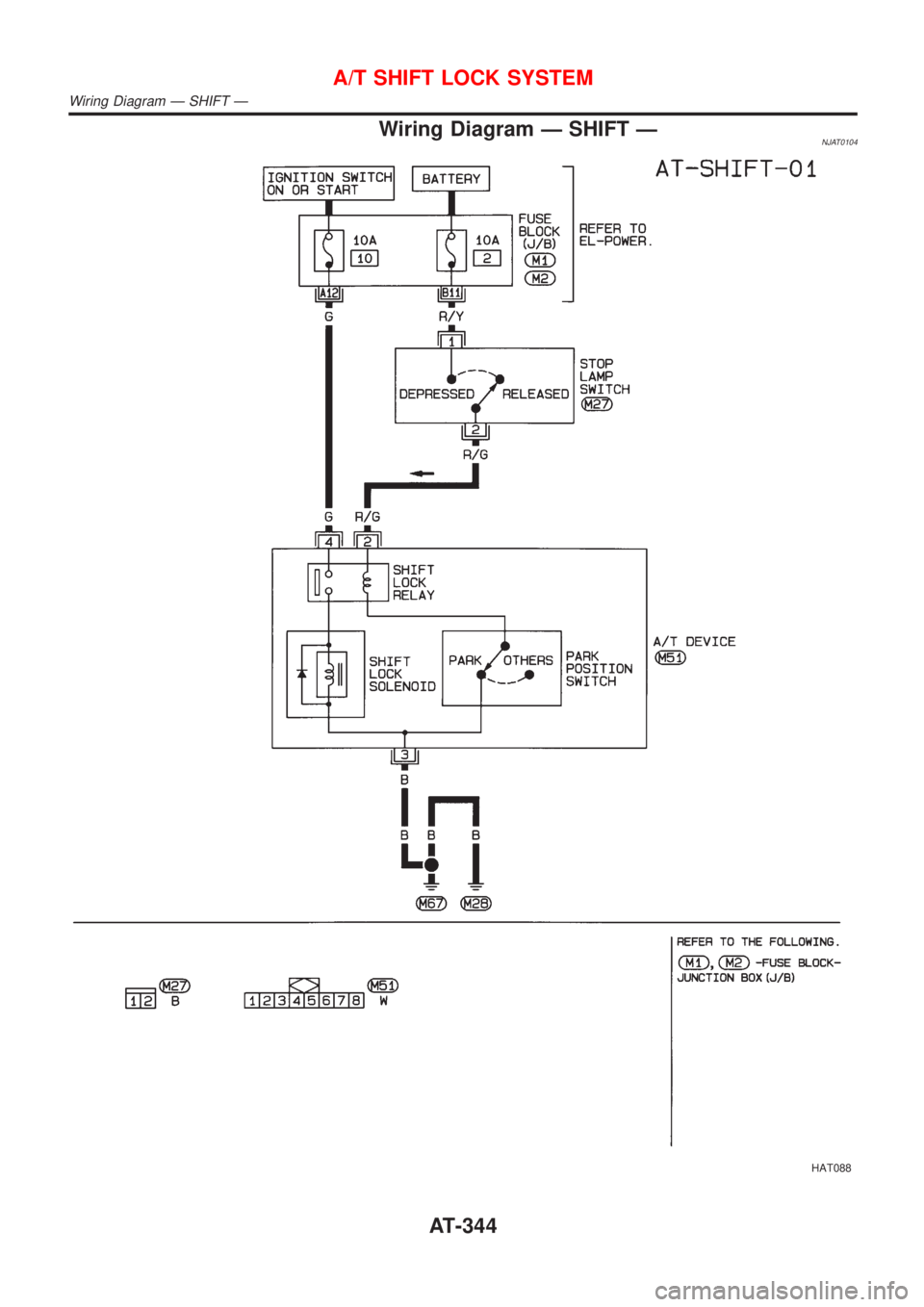

Wiring Diagram Ð SHIFT ÐNJAT0104

HAT088

A/T SHIFT LOCK SYSTEM

Wiring Diagram Ð SHIFT Ð

AT-344

Page 347 of 2898

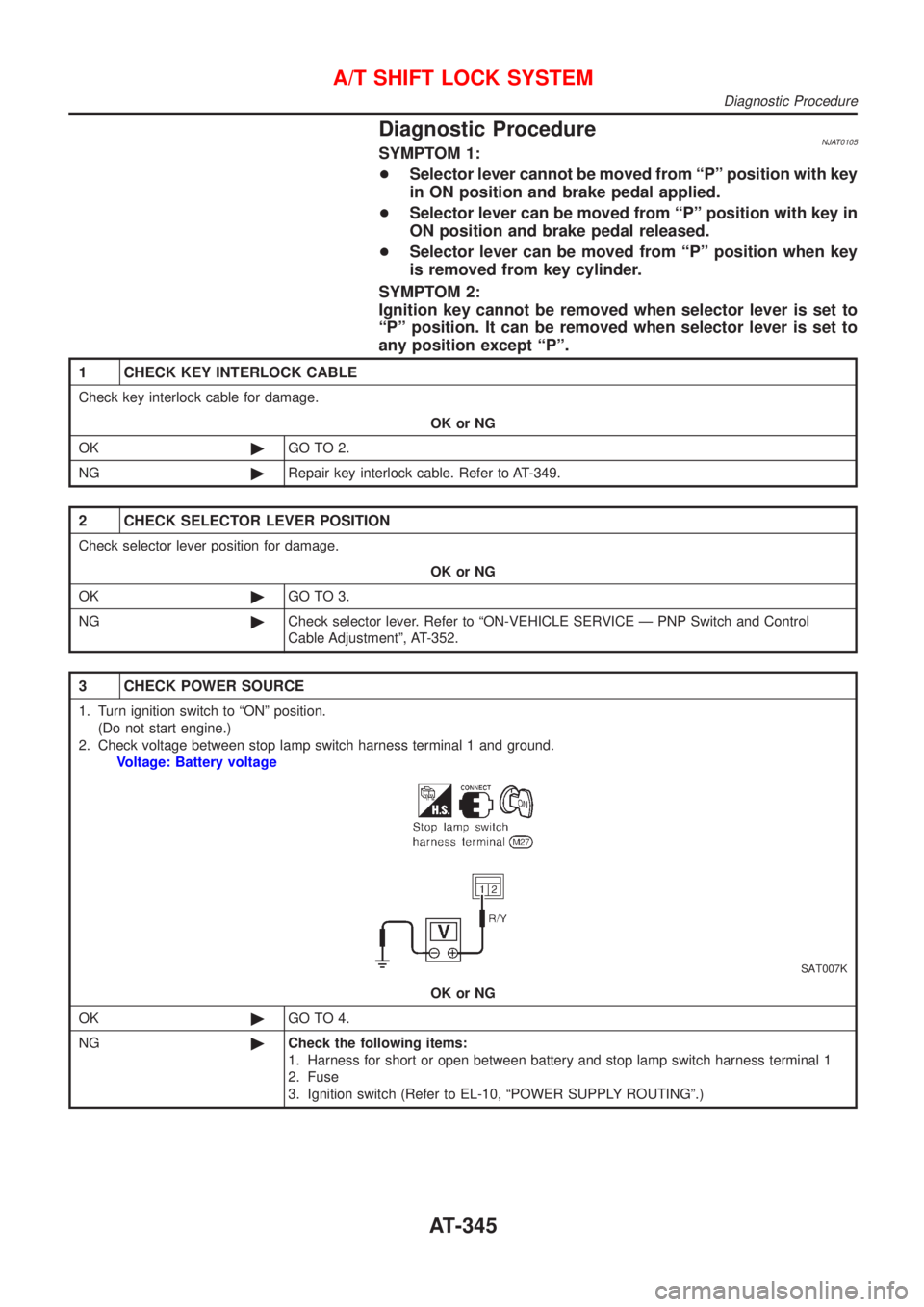

Diagnostic ProcedureNJAT0105SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with key

in ON position and brake pedal applied.

+Selector lever can be moved from ªPº position with key in

ON position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to AT-349.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Control

Cable Adjustmentº, AT-352.

3 CHECK POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

Voltage: Battery voltage

SAT007K

OK or NG

OK©GO TO 4.

NG©Check the following items:

1. Harness for short or open between battery and stop lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer to EL-10, ªPOWER SUPPLY ROUTINGº.)

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-345

Page 348 of 2898

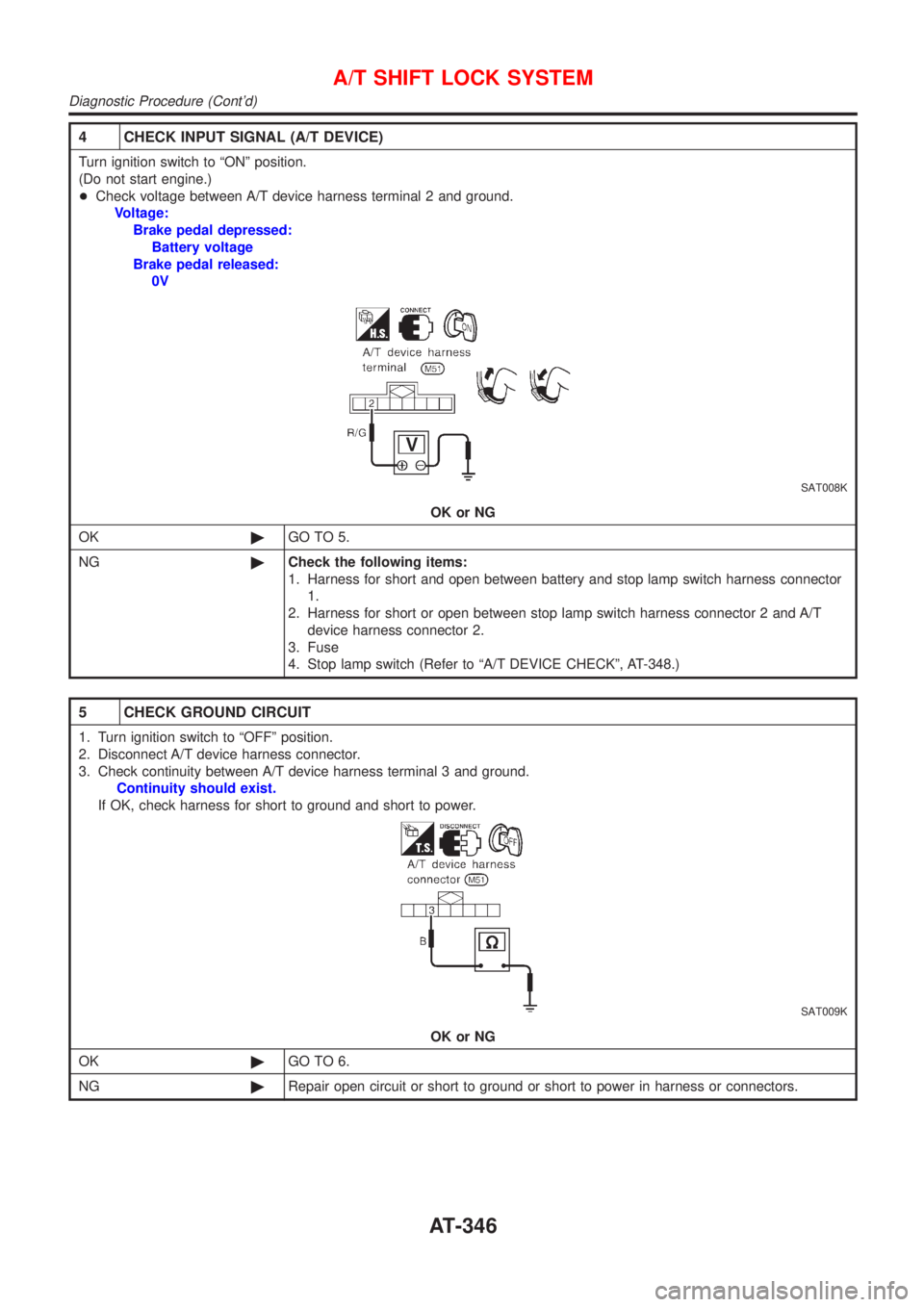

4 CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device harness terminal 2 and ground.

Voltage:

Brake pedal depressed:

Battery voltage

Brake pedal released:

0V

SAT008K

OK or NG

OK©GO TO 5.

NG©Check the following items:

1. Harness for short and open between battery and stop lamp switch harness connector

1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T

device harness connector 2.

3. Fuse

4. Stop lamp switch (Refer to ªA/T DEVICE CHECKº, AT-348.)

5 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 3 and ground.

Continuity should exist.

If OK, check harness for short to ground and short to power.

SAT009K

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-346

Page 349 of 2898

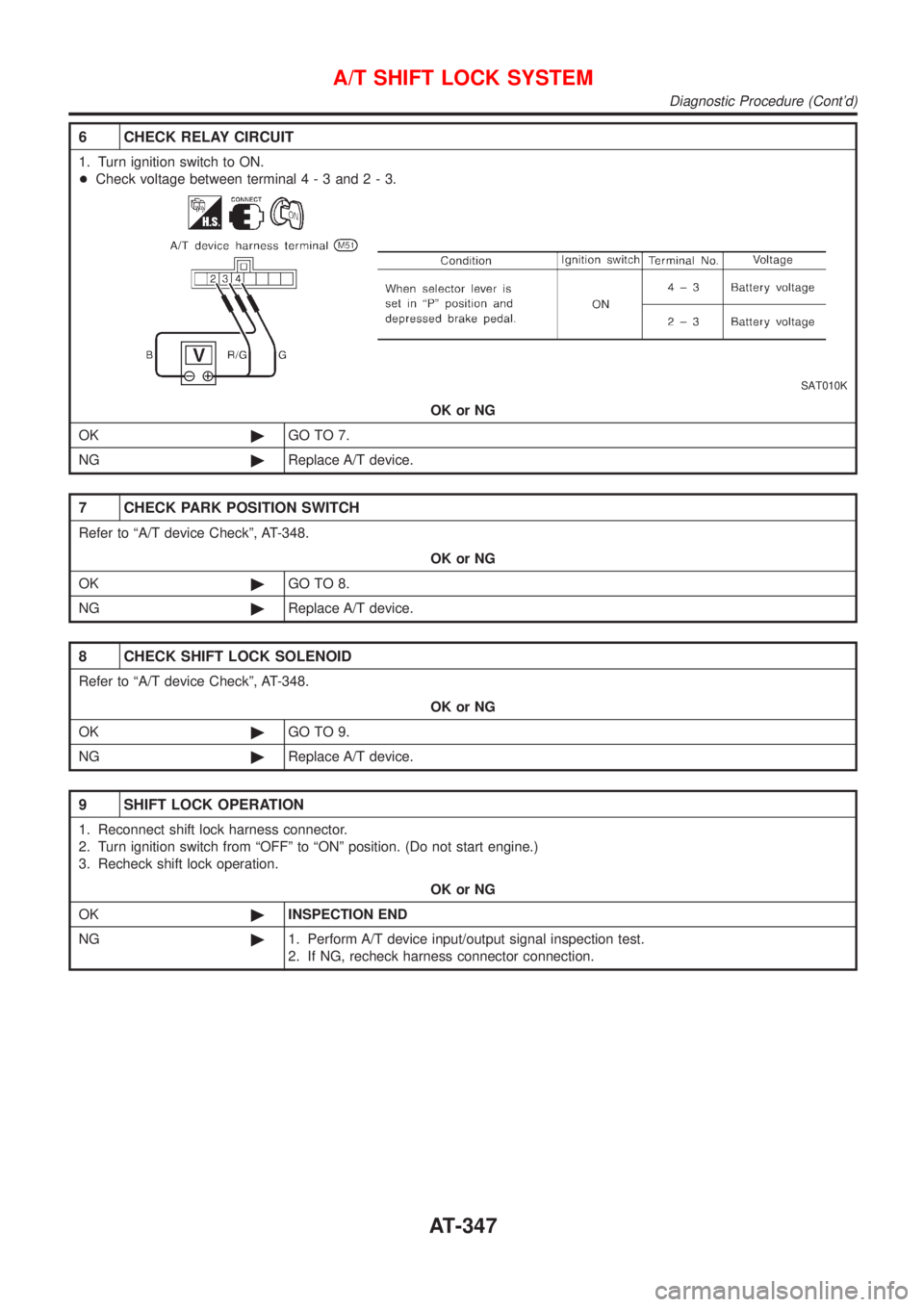

6 CHECK RELAY CIRCUIT

1. Turn ignition switch to ON.

+Check voltage between terminal4-3and2-3.

SAT010K

OK or NG

OK©GO TO 7.

NG©Replace A/T device.

7 CHECK PARK POSITION SWITCH

Refer to ªA/T device Checkº, AT-348.

OK or NG

OK©GO TO 8.

NG©Replace A/T device.

8 CHECK SHIFT LOCK SOLENOID

Refer to ªA/T device Checkº, AT-348.

OK or NG

OK©GO TO 9.

NG©Replace A/T device.

9 SHIFT LOCK OPERATION

1. Reconnect shift lock harness connector.

2. Turn ignition switch from ªOFFº to ªONº position. (Do not start engine.)

3. Recheck shift lock operation.

OK or NG

OK©INSPECTION END

NG©1. Perform A/T device input/output signal inspection test.

2. If NG, recheck harness connector connection.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-347

Page 350 of 2898

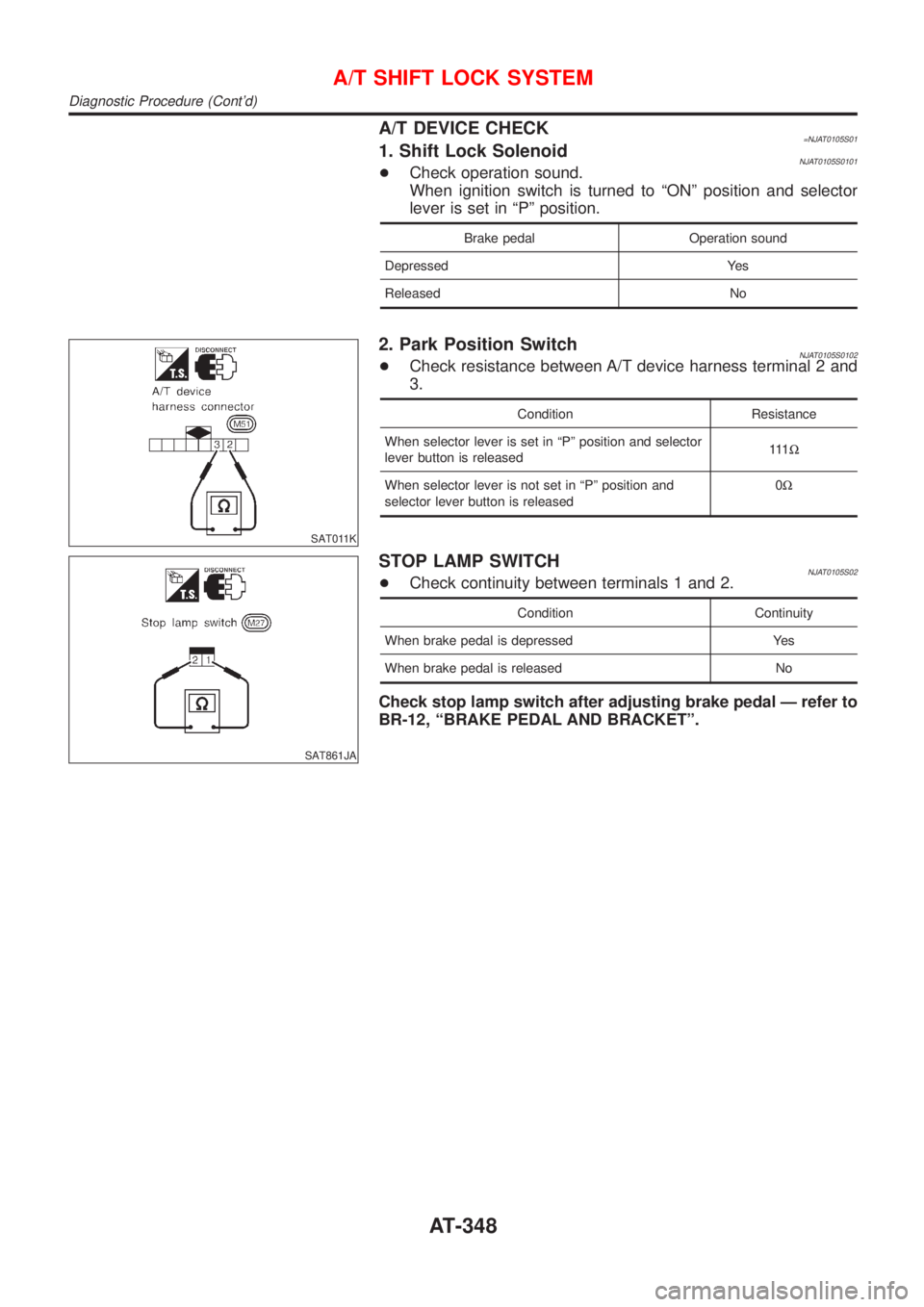

A/T DEVICE CHECK=NJAT0105S011. Shift Lock SolenoidNJAT0105S0101+Check operation sound.

When ignition switch is turned to ªONº position and selector

lever is set in ªPº position.

Brake pedal Operation sound

Depressed Yes

Released No

SAT011K

2. Park Position SwitchNJAT0105S0102+Check resistance between A/T device harness terminal 2 and

3.

Condition Resistance

When selector lever is set in ªPº position and selector

lever button is released111W

When selector lever is not set in ªPº position and

selector lever button is released0W

SAT861JA

STOP LAMP SWITCHNJAT0105S02+Check continuity between terminals 1 and 2.

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

Check stop lamp switch after adjusting brake pedal Ð refer to

BR-12, ªBRAKE PEDAL AND BRACKETº.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-348