torque NISSAN ALMERA 2001 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 544 of 2898

SBR976B

SBR932C

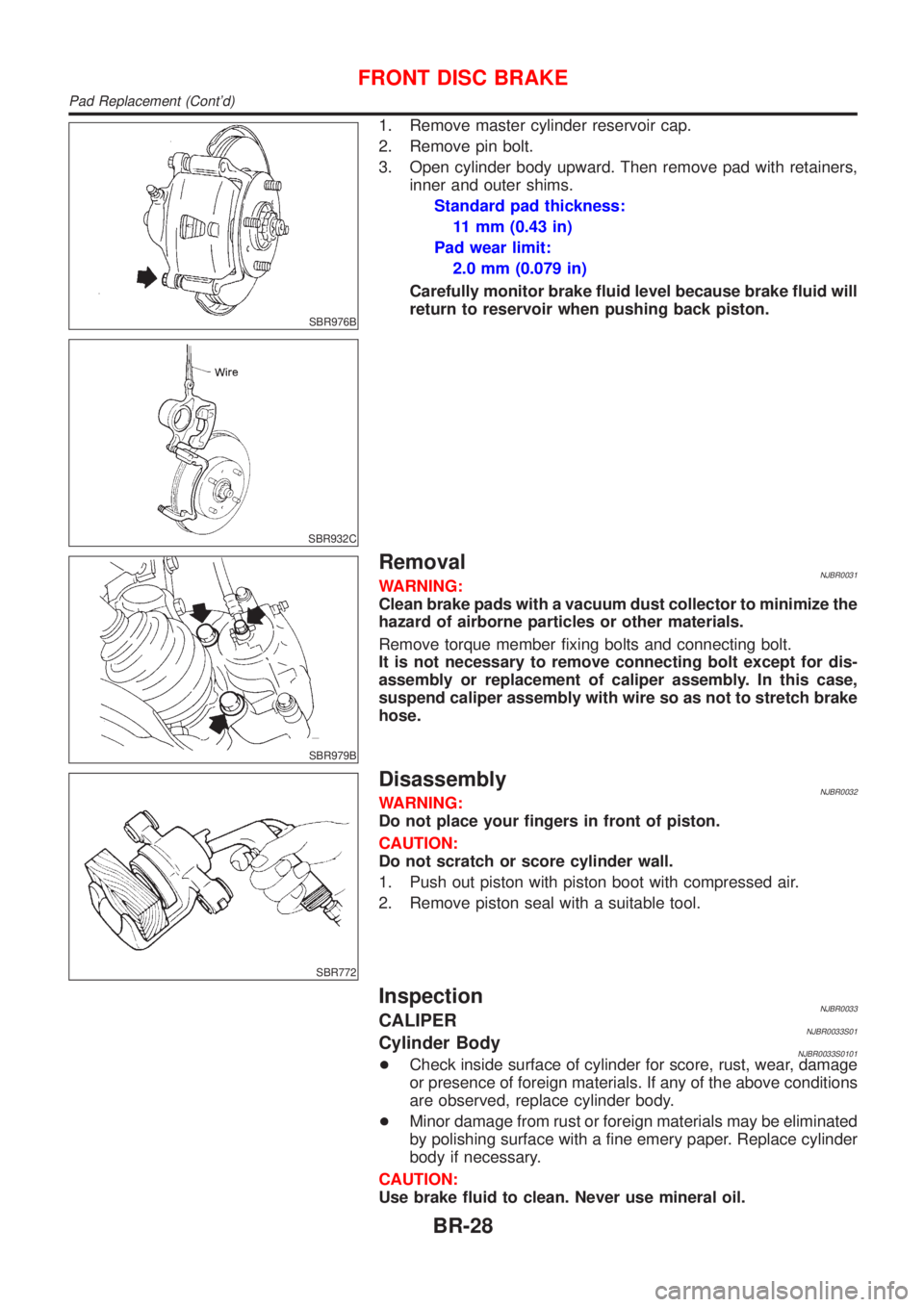

1. Remove master cylinder reservoir cap.

2. Remove pin bolt.

3. Open cylinder body upward. Then remove pad with retainers,

inner and outer shims.

Standard pad thickness:

11 mm (0.43 in)

Pad wear limit:

2.0 mm (0.079 in)

Carefully monitor brake fluid level because brake fluid will

return to reservoir when pushing back piston.

SBR979B

RemovalNJBR0031WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

Remove torque member fixing bolts and connecting bolt.

It is not necessary to remove connecting bolt except for dis-

assembly or replacement of caliper assembly. In this case,

suspend caliper assembly with wire so as not to stretch brake

hose.

SBR772

DisassemblyNJBR0032WARNING:

Do not place your fingers in front of piston.

CAUTION:

Do not scratch or score cylinder wall.

1. Push out piston with piston boot with compressed air.

2. Remove piston seal with a suitable tool.

InspectionNJBR0033CALIPERNJBR0033S01Cylinder BodyNJBR0033S0101+Check inside surface of cylinder for score, rust, wear, damage

or presence of foreign materials. If any of the above conditions

are observed, replace cylinder body.

+Minor damage from rust or foreign materials may be eliminated

by polishing surface with a fine emery paper. Replace cylinder

body if necessary.

CAUTION:

Use brake fluid to clean. Never use mineral oil.

FRONT DISC BRAKE

Pad Replacement (Cont'd)

BR-28

Page 551 of 2898

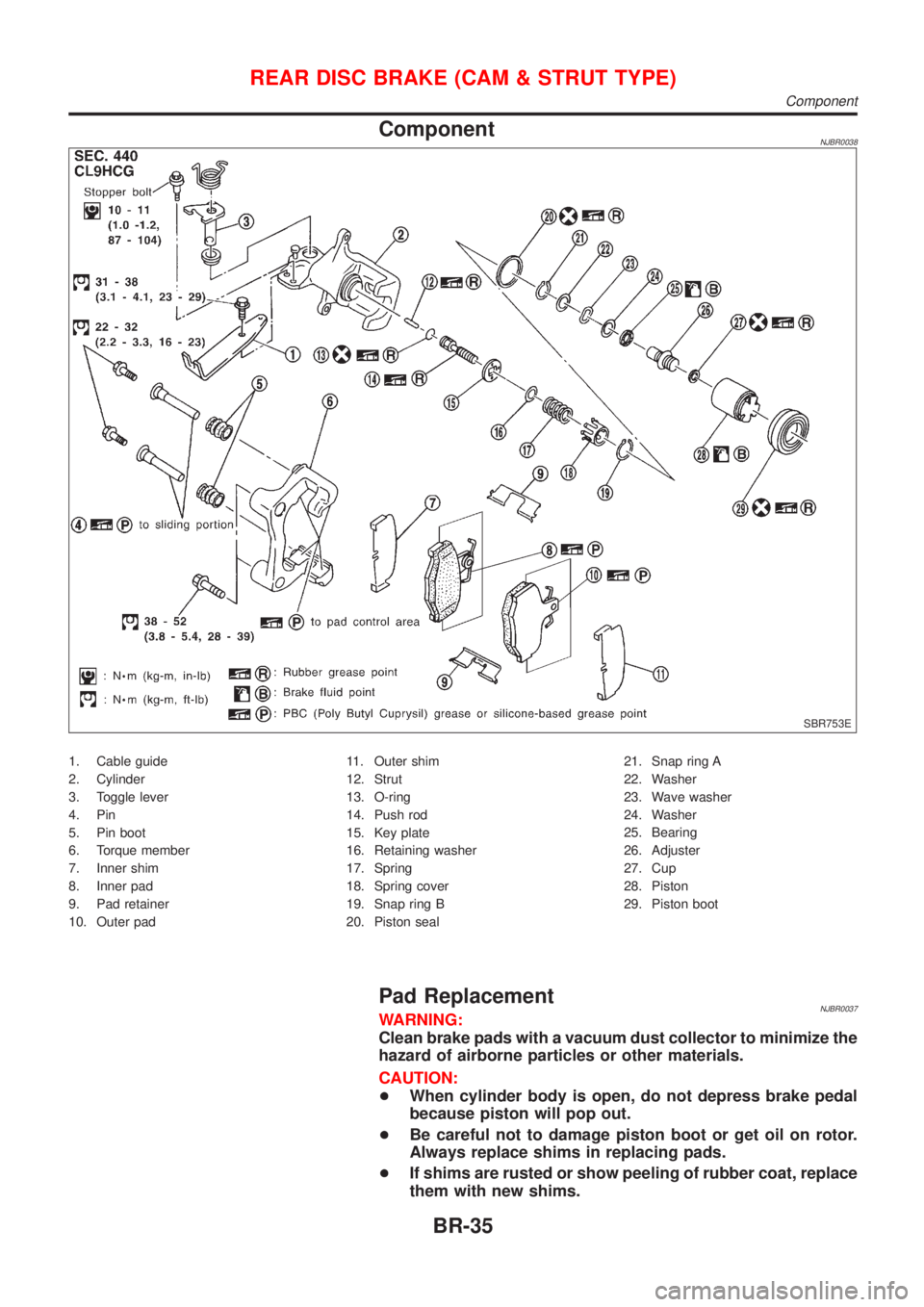

ComponentNJBR0038

SBR753E

1. Cable guide

2. Cylinder

3. Toggle lever

4. Pin

5. Pin boot

6. Torque member

7. Inner shim

8. Inner pad

9. Pad retainer

10. Outer pad11. Outer shim

12. Strut

13. O-ring

14. Push rod

15. Key plate

16. Retaining washer

17. Spring

18. Spring cover

19. Snap ring B

20. Piston seal21. Snap ring A

22. Washer

23. Wave washer

24. Washer

25. Bearing

26. Adjuster

27. Cup

28. Piston

29. Piston boot

Pad ReplacementNJBR0037WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

+When cylinder body is open, do not depress brake pedal

because piston will pop out.

+Be careful not to damage piston boot or get oil on rotor.

Always replace shims in replacing pads.

+If shims are rusted or show peeling of rubber coat, replace

them with new shims.

REAR DISC BRAKE (CAM & STRUT TYPE)

Component

BR-35

Page 553 of 2898

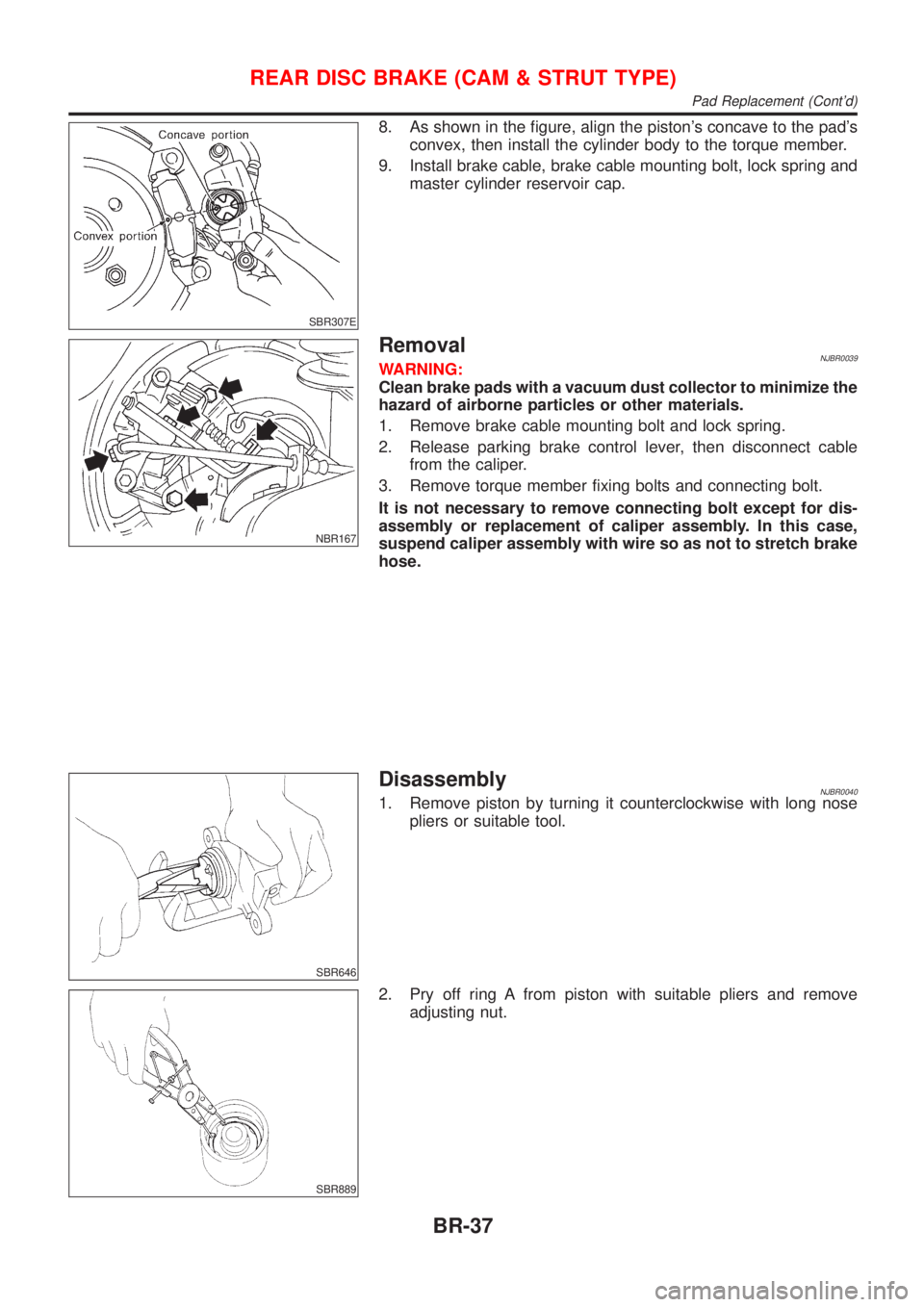

SBR307E

8. As shown in the figure, align the piston's concave to the pad's

convex, then install the cylinder body to the torque member.

9. Install brake cable, brake cable mounting bolt, lock spring and

master cylinder reservoir cap.

NBR167

RemovalNJBR0039WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

1. Remove brake cable mounting bolt and lock spring.

2. Release parking brake control lever, then disconnect cable

from the caliper.

3. Remove torque member fixing bolts and connecting bolt.

It is not necessary to remove connecting bolt except for dis-

assembly or replacement of caliper assembly. In this case,

suspend caliper assembly with wire so as not to stretch brake

hose.

SBR646

DisassemblyNJBR00401. Remove piston by turning it counterclockwise with long nose

pliers or suitable tool.

SBR889

2. Pry off ring A from piston with suitable pliers and remove

adjusting nut.

REAR DISC BRAKE (CAM & STRUT TYPE)

Pad Replacement (Cont'd)

BR-37

Page 554 of 2898

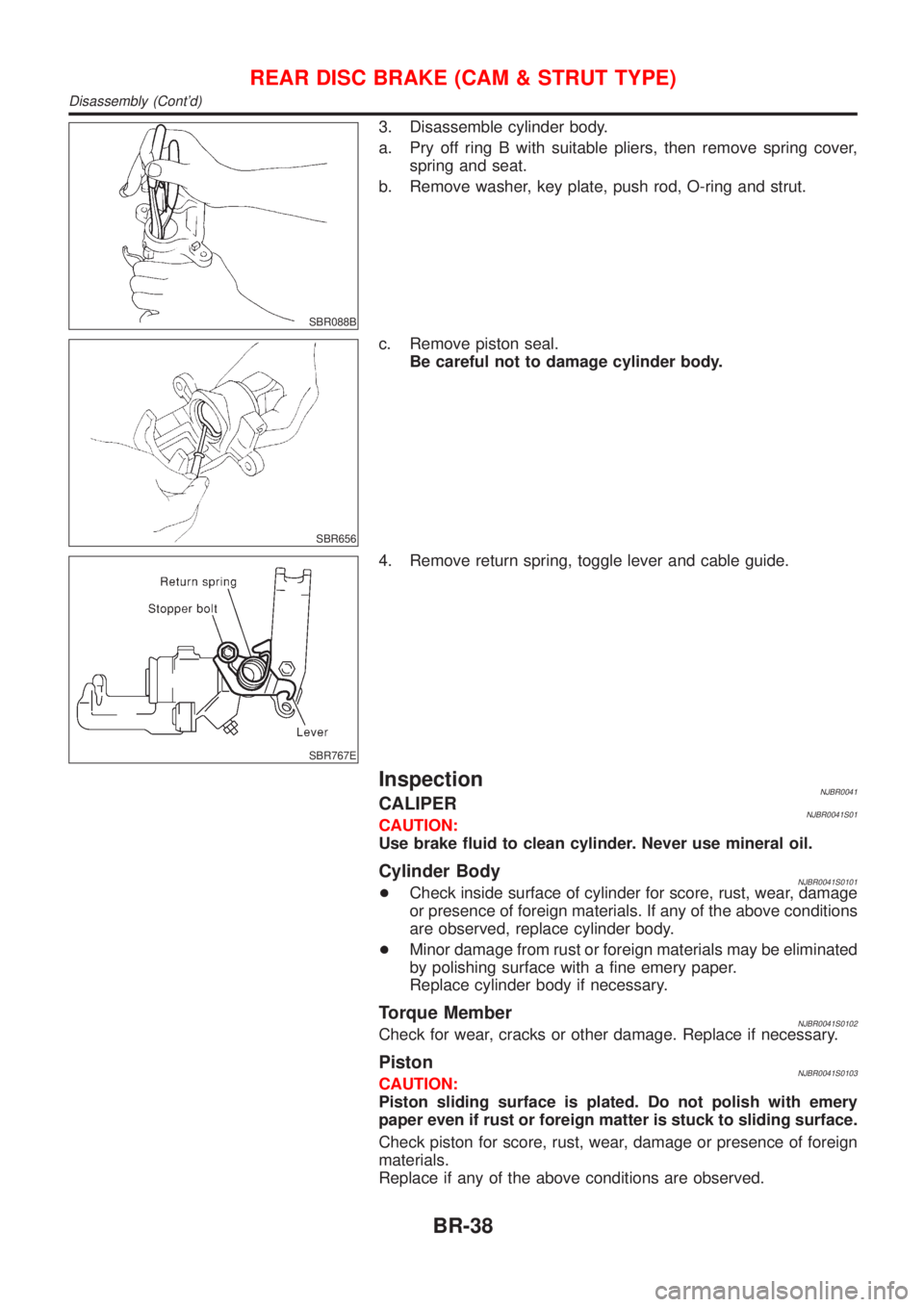

SBR088B

3. Disassemble cylinder body.

a. Pry off ring B with suitable pliers, then remove spring cover,

spring and seat.

b. Remove washer, key plate, push rod, O-ring and strut.

SBR656

c. Remove piston seal.

Be careful not to damage cylinder body.

SBR767E

4. Remove return spring, toggle lever and cable guide.

InspectionNJBR0041CALIPERNJBR0041S01CAUTION:

Use brake fluid to clean cylinder. Never use mineral oil.

Cylinder BodyNJBR0041S0101+Check inside surface of cylinder for score, rust, wear, damage

or presence of foreign materials. If any of the above conditions

are observed, replace cylinder body.

+Minor damage from rust or foreign materials may be eliminated

by polishing surface with a fine emery paper.

Replace cylinder body if necessary.

Torque MemberNJBR0041S0102Check for wear, cracks or other damage. Replace if necessary.

PistonNJBR0041S0103CAUTION:

Piston sliding surface is plated. Do not polish with emery

paper even if rust or foreign matter is stuck to sliding surface.

Check piston for score, rust, wear, damage or presence of foreign

materials.

Replace if any of the above conditions are observed.

REAR DISC BRAKE (CAM & STRUT TYPE)

Disassembly (Cont'd)

BR-38

Page 558 of 2898

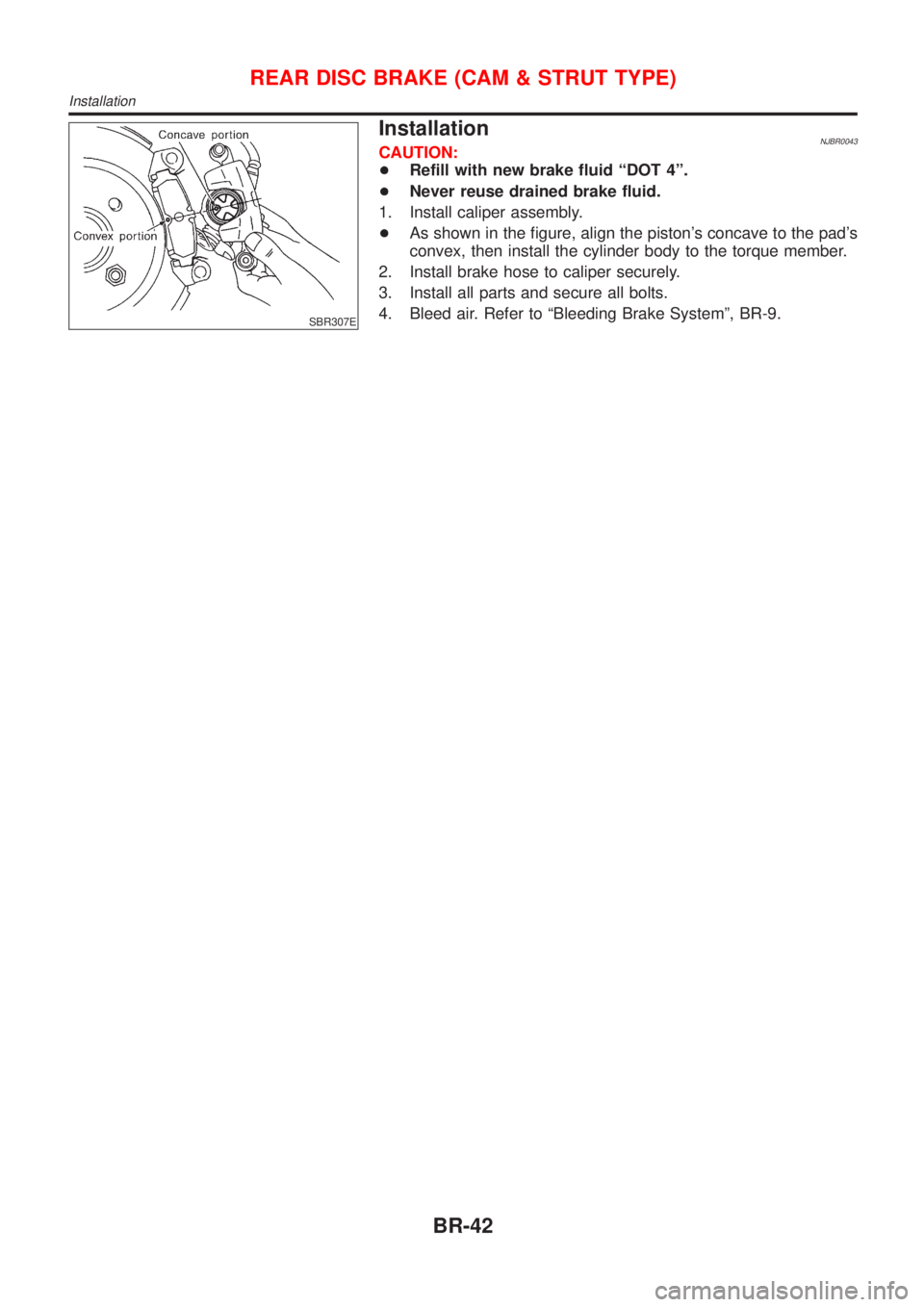

SBR307E

InstallationNJBR0043CAUTION:

+Refill with new brake fluid ªDOT 4º.

+Never reuse drained brake fluid.

1. Install caliper assembly.

+As shown in the figure, align the piston's concave to the pad's

convex, then install the cylinder body to the torque member.

2. Install brake hose to caliper securely.

3. Install all parts and secure all bolts.

4. Bleed air. Refer to ªBleeding Brake Systemº, BR-9.

REAR DISC BRAKE (CAM & STRUT TYPE)

Installation

BR-42

Page 559 of 2898

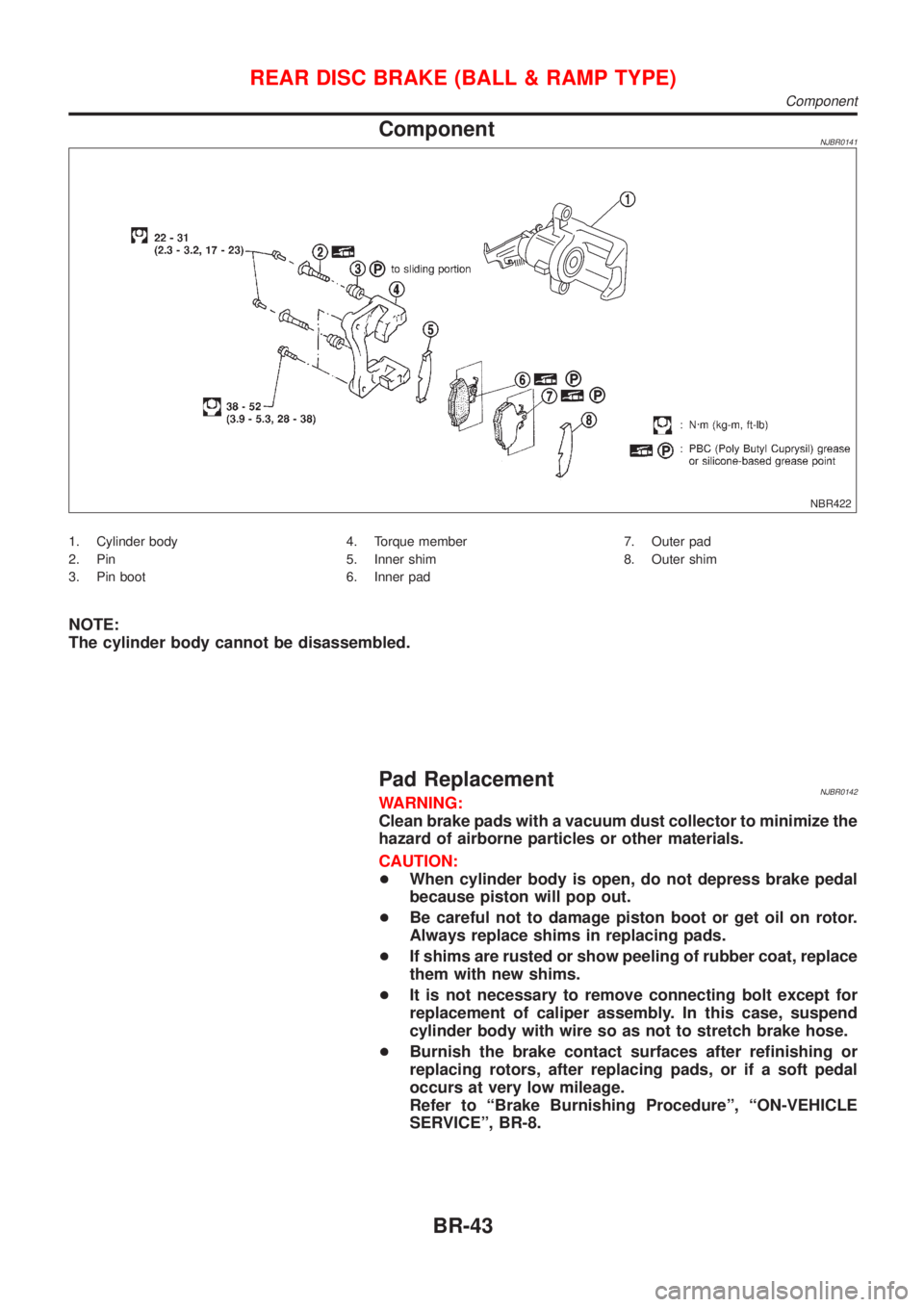

ComponentNJBR0141

NBR422

1. Cylinder body

2. Pin

3. Pin boot4. Torque member

5. Inner shim

6. Inner pad7. Outer pad

8. Outer shim

NOTE:

The cylinder body cannot be disassembled.

Pad ReplacementNJBR0142WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

+When cylinder body is open, do not depress brake pedal

because piston will pop out.

+Be careful not to damage piston boot or get oil on rotor.

Always replace shims in replacing pads.

+If shims are rusted or show peeling of rubber coat, replace

them with new shims.

+It is not necessary to remove connecting bolt except for

replacement of caliper assembly. In this case, suspend

cylinder body with wire so as not to stretch brake hose.

+Burnish the brake contact surfaces after refinishing or

replacing rotors, after replacing pads, or if a soft pedal

occurs at very low mileage.

Refer to ªBrake Burnishing Procedureº, ªON-VEHICLE

SERVICEº, BR-8.

REAR DISC BRAKE (BALL & RAMP TYPE)

Component

BR-43

Page 560 of 2898

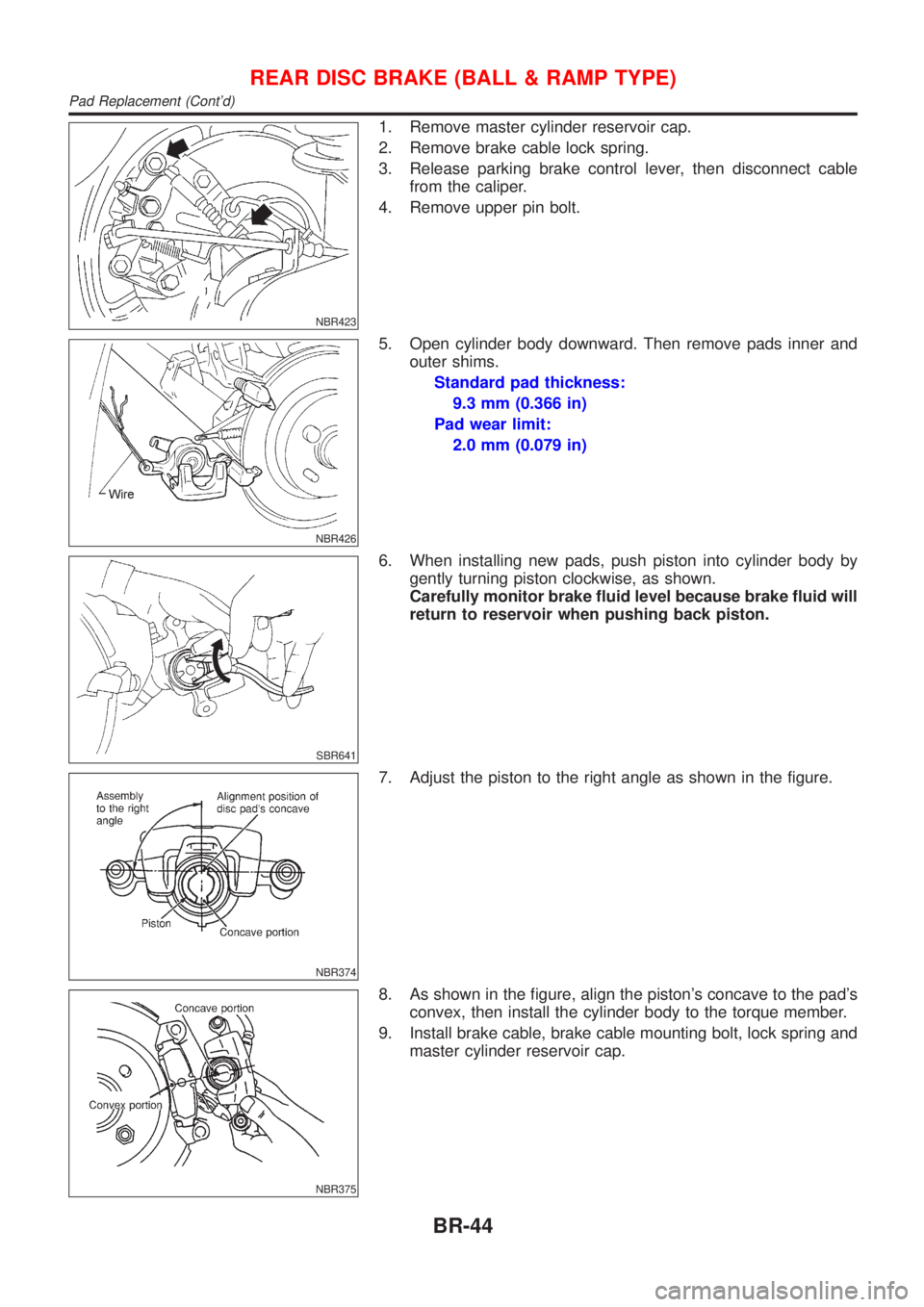

NBR423

1. Remove master cylinder reservoir cap.

2. Remove brake cable lock spring.

3. Release parking brake control lever, then disconnect cable

from the caliper.

4. Remove upper pin bolt.

NBR426

5. Open cylinder body downward. Then remove pads inner and

outer shims.

Standard pad thickness:

9.3 mm (0.366 in)

Pad wear limit:

2.0 mm (0.079 in)

SBR641

6. When installing new pads, push piston into cylinder body by

gently turning piston clockwise, as shown.

Carefully monitor brake fluid level because brake fluid will

return to reservoir when pushing back piston.

NBR374

7. Adjust the piston to the right angle as shown in the figure.

NBR375

8. As shown in the figure, align the piston's concave to the pad's

convex, then install the cylinder body to the torque member.

9. Install brake cable, brake cable mounting bolt, lock spring and

master cylinder reservoir cap.

REAR DISC BRAKE (BALL & RAMP TYPE)

Pad Replacement (Cont'd)

BR-44

Page 561 of 2898

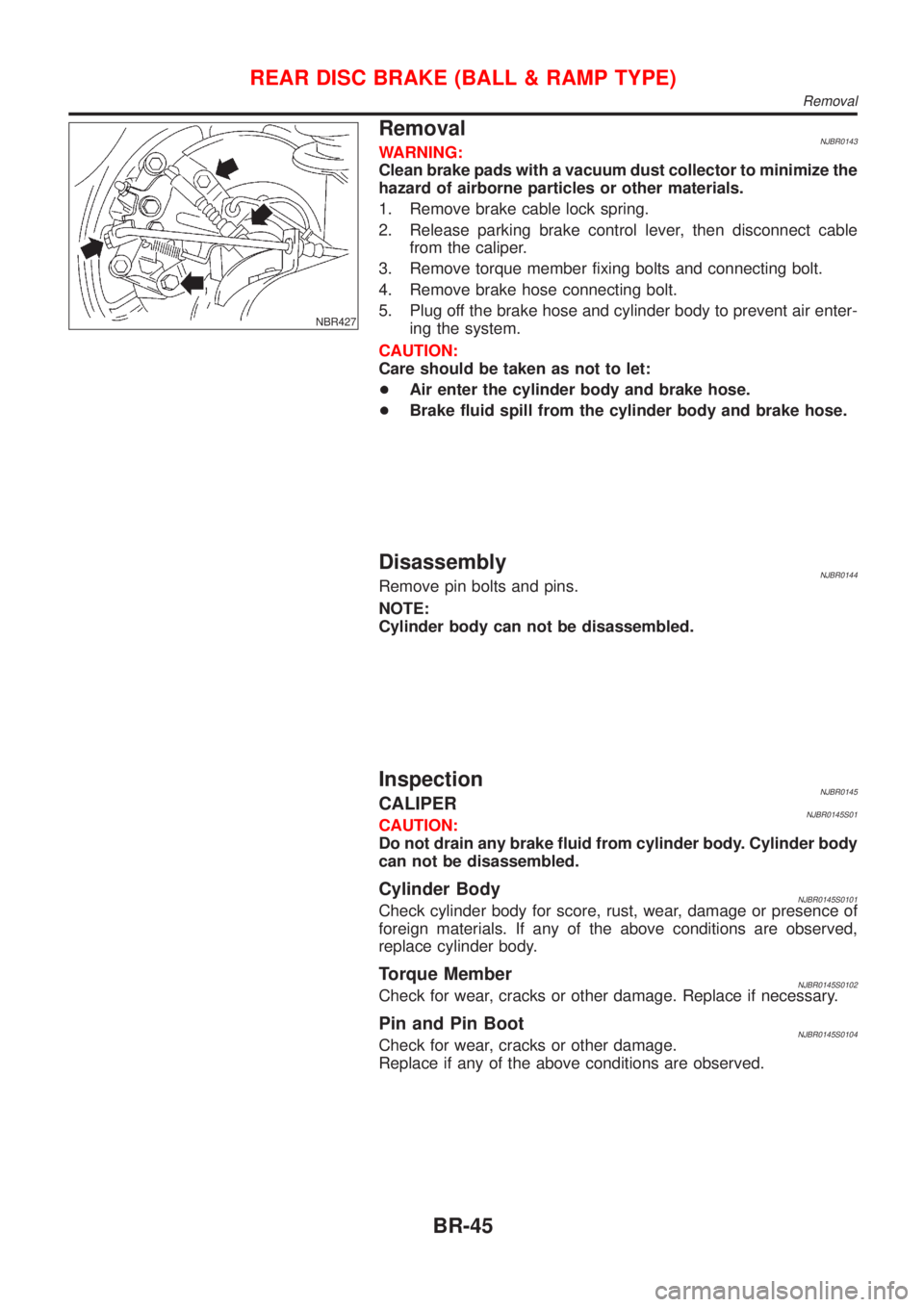

NBR427

RemovalNJBR0143WARNING:

Clean brake pads with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

1. Remove brake cable lock spring.

2. Release parking brake control lever, then disconnect cable

from the caliper.

3. Remove torque member fixing bolts and connecting bolt.

4. Remove brake hose connecting bolt.

5. Plug off the brake hose and cylinder body to prevent air enter-

ing the system.

CAUTION:

Care should be taken as not to let:

+Air enter the cylinder body and brake hose.

+Brake fluid spill from the cylinder body and brake hose.

DisassemblyNJBR0144Remove pin bolts and pins.

NOTE:

Cylinder body can not be disassembled.

InspectionNJBR0145CALIPERNJBR0145S01CAUTION:

Do not drain any brake fluid from cylinder body. Cylinder body

can not be disassembled.

Cylinder BodyNJBR0145S0101Check cylinder body for score, rust, wear, damage or presence of

foreign materials. If any of the above conditions are observed,

replace cylinder body.

Torque MemberNJBR0145S0102Check for wear, cracks or other damage. Replace if necessary.

Pin and Pin BootNJBR0145S0104Check for wear, cracks or other damage.

Replace if any of the above conditions are observed.

REAR DISC BRAKE (BALL & RAMP TYPE)

Removal

BR-45

Page 562 of 2898

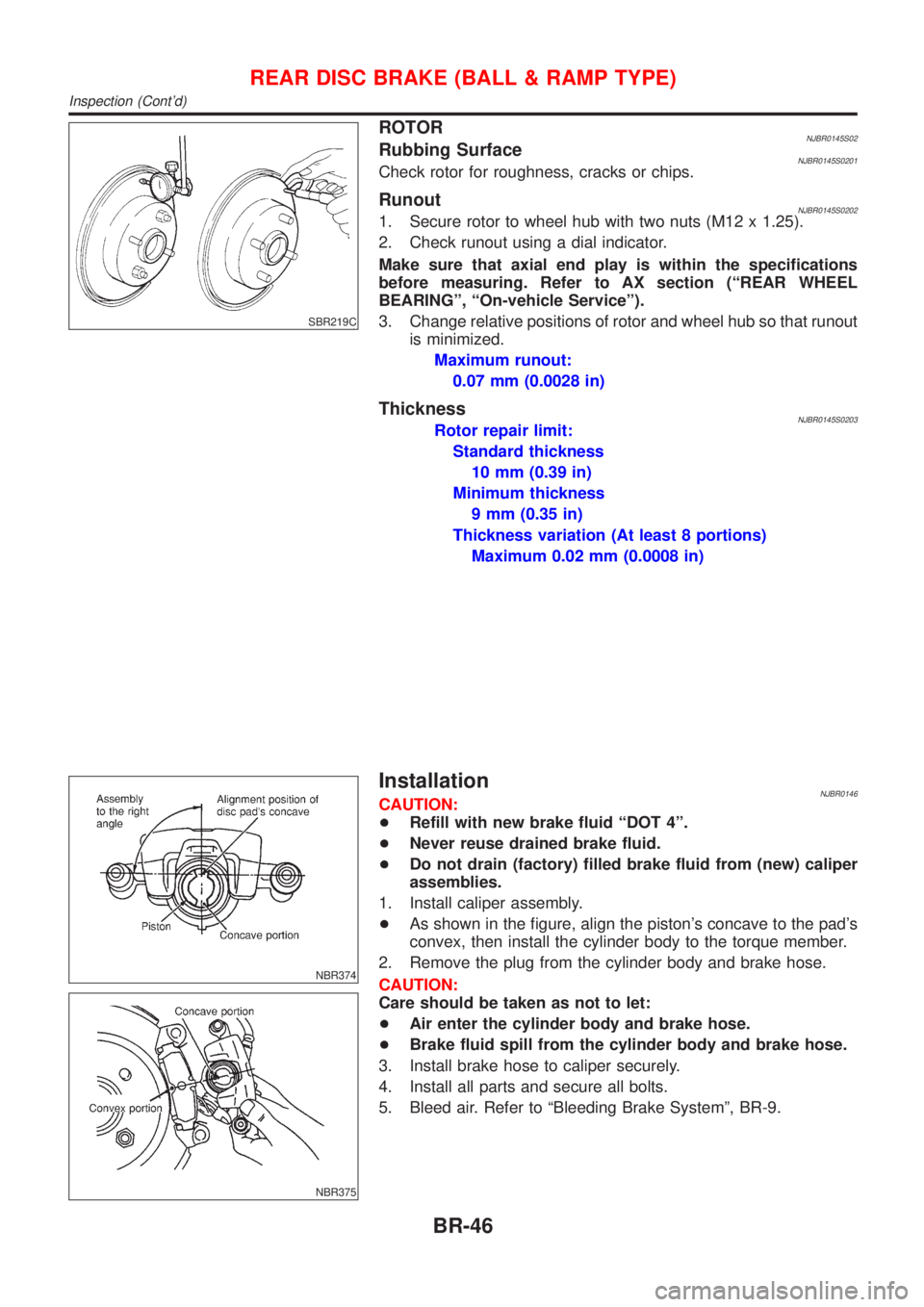

SBR219C

ROTORNJBR0145S02Rubbing SurfaceNJBR0145S0201Check rotor for roughness, cracks or chips.

RunoutNJBR0145S02021. Secure rotor to wheel hub with two nuts (M12 x 1.25).

2. Check runout using a dial indicator.

Make sure that axial end play is within the specifications

before measuring. Refer to AX section (ªREAR WHEEL

BEARINGº, ªOn-vehicle Serviceº).

3. Change relative positions of rotor and wheel hub so that runout

is minimized.

Maximum runout:

0.07 mm (0.0028 in)

ThicknessNJBR0145S0203Rotor repair limit:

Standard thickness

10 mm (0.39 in)

Minimum thickness

9 mm (0.35 in)

Thickness variation (At least 8 portions)

Maximum 0.02 mm (0.0008 in)

NBR374

NBR375

InstallationNJBR0146CAUTION:

+Refill with new brake fluid ªDOT 4º.

+Never reuse drained brake fluid.

+Do not drain (factory) filled brake fluid from (new) caliper

assemblies.

1. Install caliper assembly.

+As shown in the figure, align the piston's concave to the pad's

convex, then install the cylinder body to the torque member.

2. Remove the plug from the cylinder body and brake hose.

CAUTION:

Care should be taken as not to let:

+Air enter the cylinder body and brake hose.

+Brake fluid spill from the cylinder body and brake hose.

3. Install brake hose to caliper securely.

4. Install all parts and secure all bolts.

5. Bleed air. Refer to ªBleeding Brake Systemº, BR-9.

REAR DISC BRAKE (BALL & RAMP TYPE)

Inspection (Cont'd)

BR-46

Page 703 of 2898

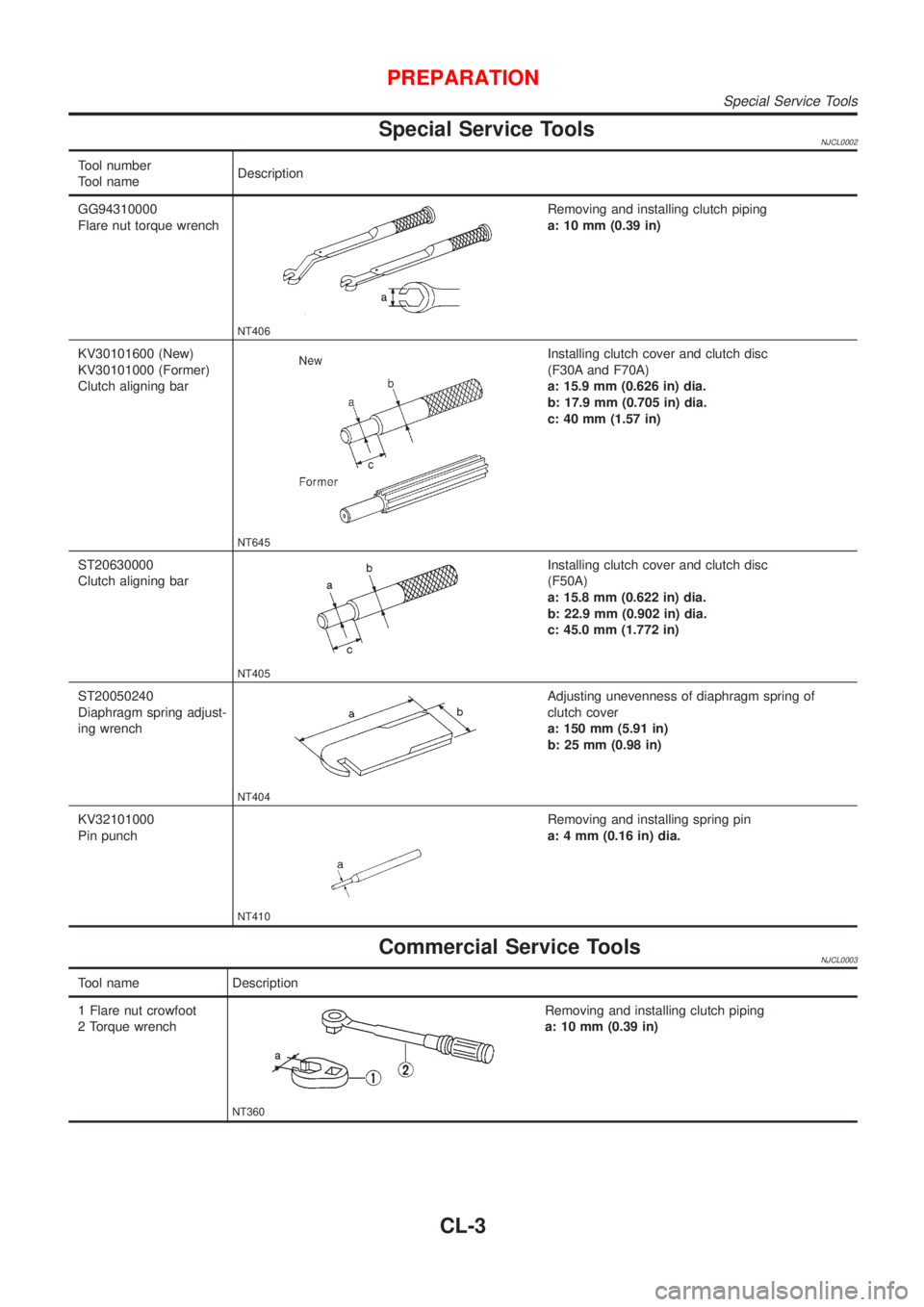

Special Service ToolsNJCL0002

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

NT406

Removing and installing clutch piping

a: 10 mm (0.39 in)

KV30101600 (New)

KV30101000 (Former)

Clutch aligning bar

NT645

Installing clutch cover and clutch disc

(F30A and F70A)

a: 15.9 mm (0.626 in) dia.

b: 17.9 mm (0.705 in) dia.

c: 40 mm (1.57 in)

ST20630000

Clutch aligning bar

NT405

Installing clutch cover and clutch disc

(F50A)

a: 15.8 mm (0.622 in) dia.

b: 22.9 mm (0.902 in) dia.

c: 45.0 mm (1.772 in)

ST20050240

Diaphragm spring adjust-

ing wrench

NT404

Adjusting unevenness of diaphragm spring of

clutch cover

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

KV32101000

Pin punch

NT410

Removing and installing spring pin

a: 4 mm (0.16 in) dia.

Commercial Service ToolsNJCL0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing clutch piping

a: 10 mm (0.39 in)

PREPARATION

Special Service Tools

CL-3