lock NISSAN ALMERA 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 452 of 2898

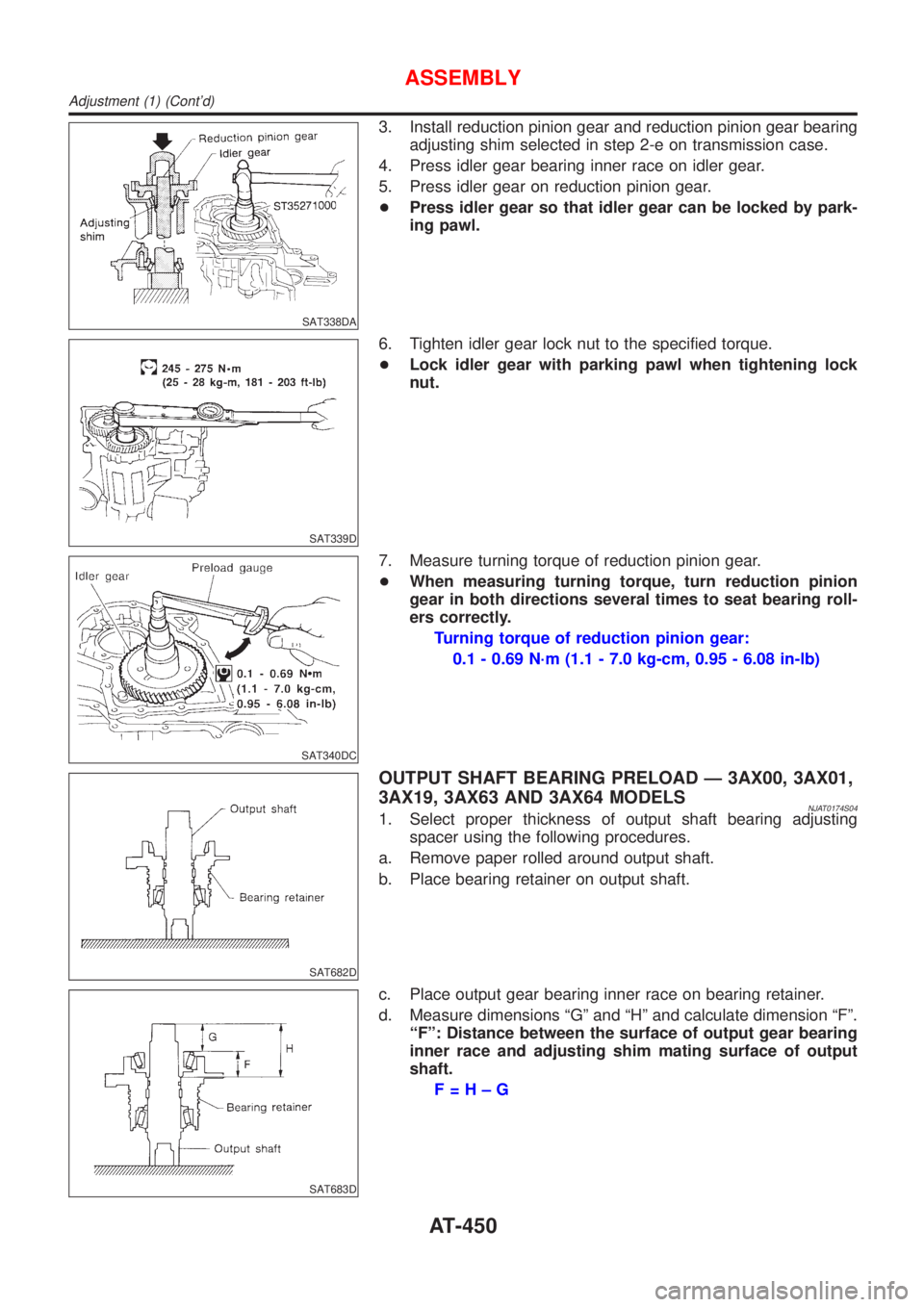

SAT338DA

3. Install reduction pinion gear and reduction pinion gear bearing

adjusting shim selected in step 2-e on transmission case.

4. Press idler gear bearing inner race on idler gear.

5. Press idler gear on reduction pinion gear.

+Press idler gear so that idler gear can be locked by park-

ing pawl.

SAT339D

6. Tighten idler gear lock nut to the specified torque.

+Lock idler gear with parking pawl when tightening lock

nut.

SAT340DC

7. Measure turning torque of reduction pinion gear.

+When measuring turning torque, turn reduction pinion

gear in both directions several times to seat bearing roll-

ers correctly.

Turning torque of reduction pinion gear:

0.1 - 0.69 N´m (1.1 - 7.0 kg-cm, 0.95 - 6.08 in-lb)

SAT682D

OUTPUT SHAFT BEARING PRELOAD Ð 3AX00, 3AX01,

3AX19, 3AX63 AND 3AX64 MODELS

NJAT0174S041. Select proper thickness of output shaft bearing adjusting

spacer using the following procedures.

a. Remove paper rolled around output shaft.

b. Place bearing retainer on output shaft.

SAT683D

c. Place output gear bearing inner race on bearing retainer.

d. Measure dimensions ªGº and ªHº and calculate dimension ªFº.

ªFº: Distance between the surface of output gear bearing

inner race and adjusting shim mating surface of output

shaft.

F=H±G

ASSEMBLY

Adjustment (1) (Cont'd)

AT-450

Page 454 of 2898

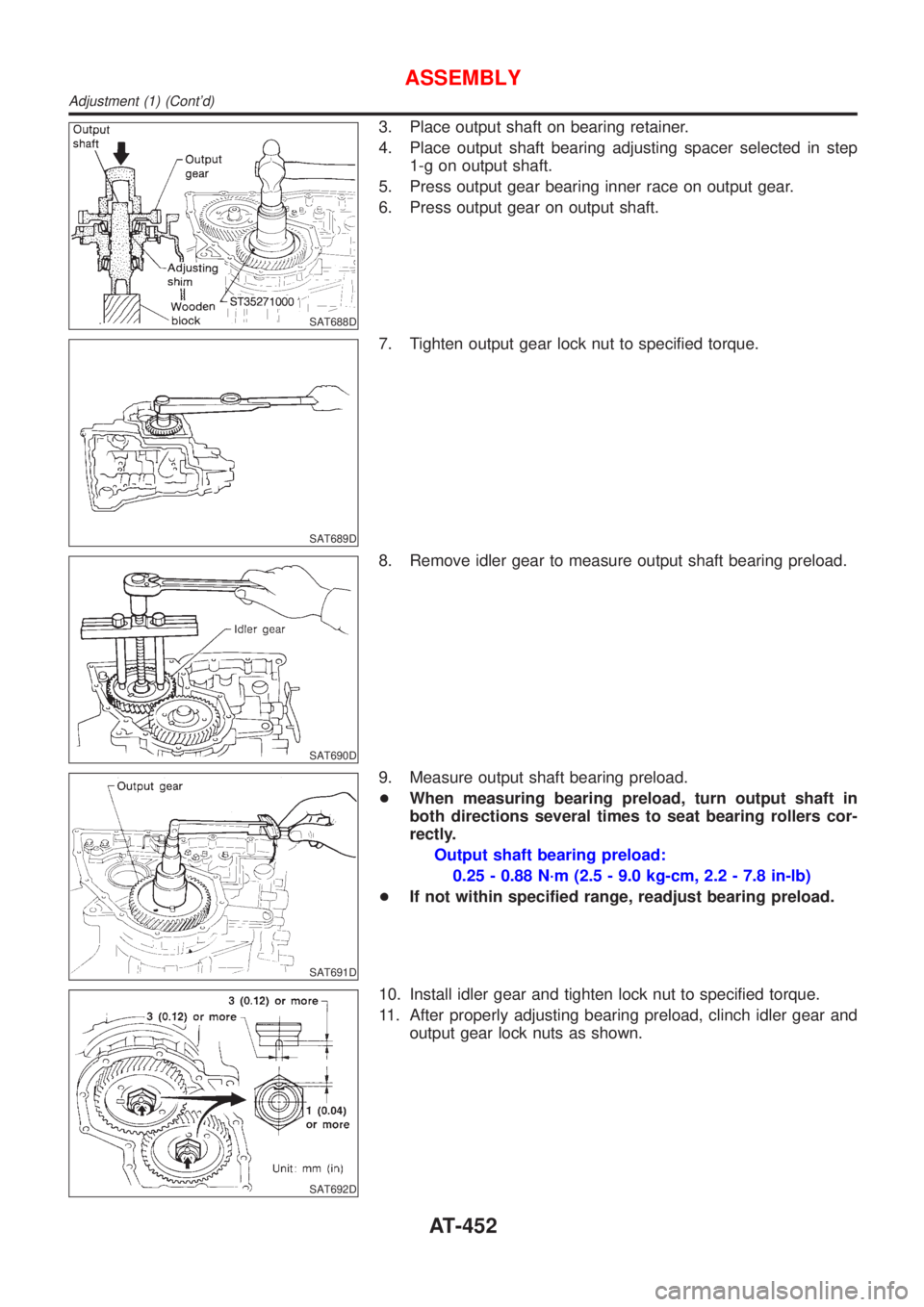

SAT688D

3. Place output shaft on bearing retainer.

4. Place output shaft bearing adjusting spacer selected in step

1-g on output shaft.

5. Press output gear bearing inner race on output gear.

6. Press output gear on output shaft.

SAT689D

7. Tighten output gear lock nut to specified torque.

SAT690D

8. Remove idler gear to measure output shaft bearing preload.

SAT691D

9. Measure output shaft bearing preload.

+When measuring bearing preload, turn output shaft in

both directions several times to seat bearing rollers cor-

rectly.

Output shaft bearing preload:

0.25 - 0.88 N´m (2.5 - 9.0 kg-cm, 2.2 - 7.8 in-lb)

+If not within specified range, readjust bearing preload.

SAT692D

10. Install idler gear and tighten lock nut to specified torque.

11. After properly adjusting bearing preload, clinch idler gear and

output gear lock nuts as shown.

ASSEMBLY

Adjustment (1) (Cont'd)

AT-452

Page 456 of 2898

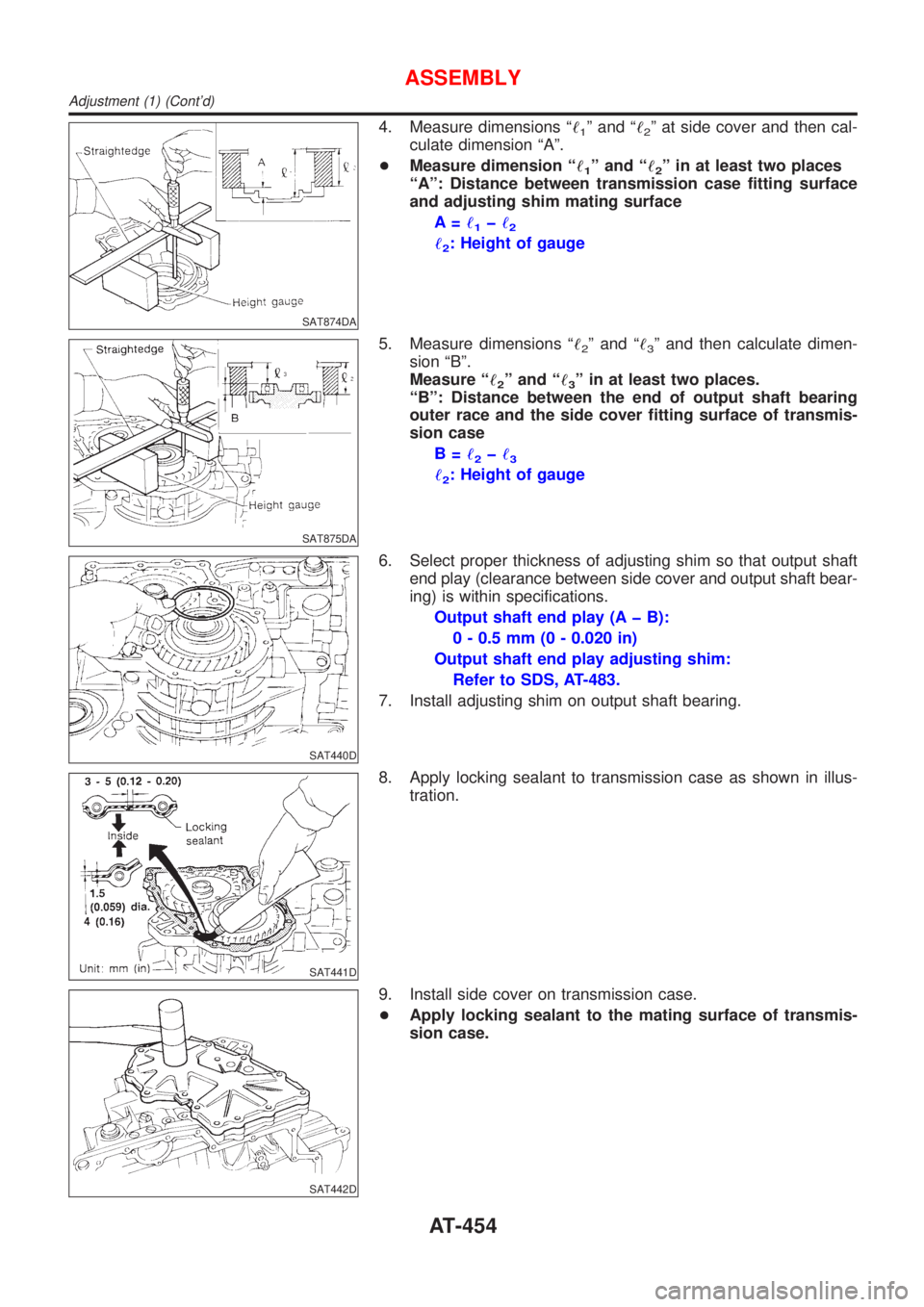

SAT874DA

4. Measure dimensions ª!1º and ª!2º at side cover and then cal-

culate dimension ªAº.

+Measure dimension ª!

1º and ª!2º in at least two places

ªAº: Distance between transmission case fitting surface

and adjusting shim mating surface

A=!

1þ!2

!2: Height of gauge

SAT875DA

5. Measure dimensions ª!2º and ª!3º and then calculate dimen-

sion ªBº.

Measure ª!

2º and ª!3º in at least two places.

ªBº: Distance between the end of output shaft bearing

outer race and the side cover fitting surface of transmis-

sion case

B=!

2þ!3

!2: Height of gauge

SAT440D

6. Select proper thickness of adjusting shim so that output shaft

end play (clearance between side cover and output shaft bear-

ing) is within specifications.

Output shaft end play (A þ B):

0 - 0.5 mm (0 - 0.020 in)

Output shaft end play adjusting shim:

Refer to SDS, AT-483.

7. Install adjusting shim on output shaft bearing.

SAT441D

8. Apply locking sealant to transmission case as shown in illus-

tration.

SAT442D

9. Install side cover on transmission case.

+Apply locking sealant to the mating surface of transmis-

sion case.

ASSEMBLY

Adjustment (1) (Cont'd)

AT-454

Page 458 of 2898

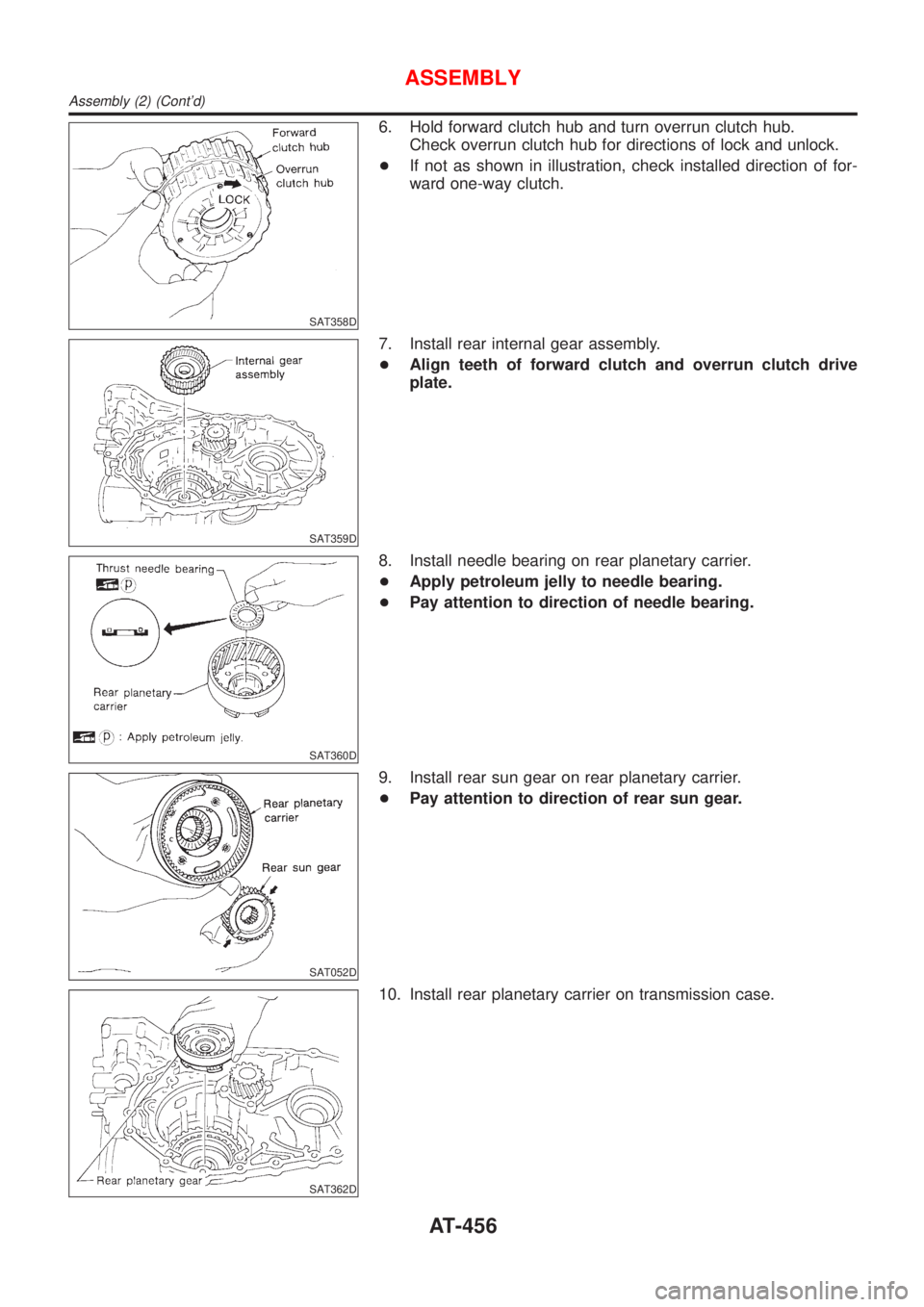

SAT358D

6. Hold forward clutch hub and turn overrun clutch hub.

Check overrun clutch hub for directions of lock and unlock.

+If not as shown in illustration, check installed direction of for-

ward one-way clutch.

SAT359D

7. Install rear internal gear assembly.

+Align teeth of forward clutch and overrun clutch drive

plate.

SAT360D

8. Install needle bearing on rear planetary carrier.

+Apply petroleum jelly to needle bearing.

+Pay attention to direction of needle bearing.

SAT052D

9. Install rear sun gear on rear planetary carrier.

+Pay attention to direction of rear sun gear.

SAT362D

10. Install rear planetary carrier on transmission case.

ASSEMBLY

Assembly (2) (Cont'd)

AT-456

Page 459 of 2898

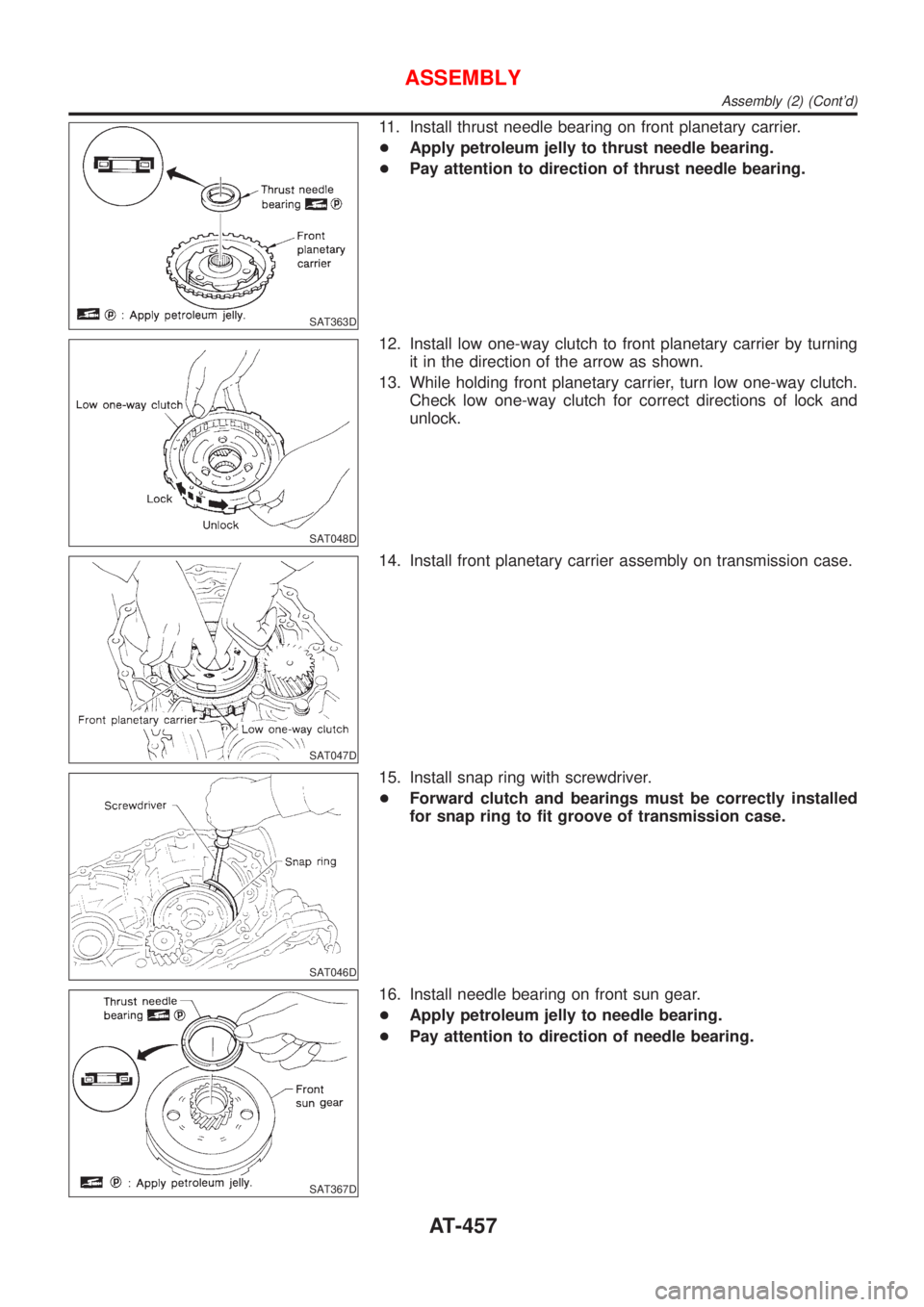

SAT363D

11. Install thrust needle bearing on front planetary carrier.

+Apply petroleum jelly to thrust needle bearing.

+Pay attention to direction of thrust needle bearing.

SAT048D

12. Install low one-way clutch to front planetary carrier by turning

it in the direction of the arrow as shown.

13. While holding front planetary carrier, turn low one-way clutch.

Check low one-way clutch for correct directions of lock and

unlock.

SAT047D

14. Install front planetary carrier assembly on transmission case.

SAT046D

15. Install snap ring with screwdriver.

+Forward clutch and bearings must be correctly installed

for snap ring to fit groove of transmission case.

SAT367D

16. Install needle bearing on front sun gear.

+Apply petroleum jelly to needle bearing.

+Pay attention to direction of needle bearing.

ASSEMBLY

Assembly (2) (Cont'd)

AT-457

Page 465 of 2898

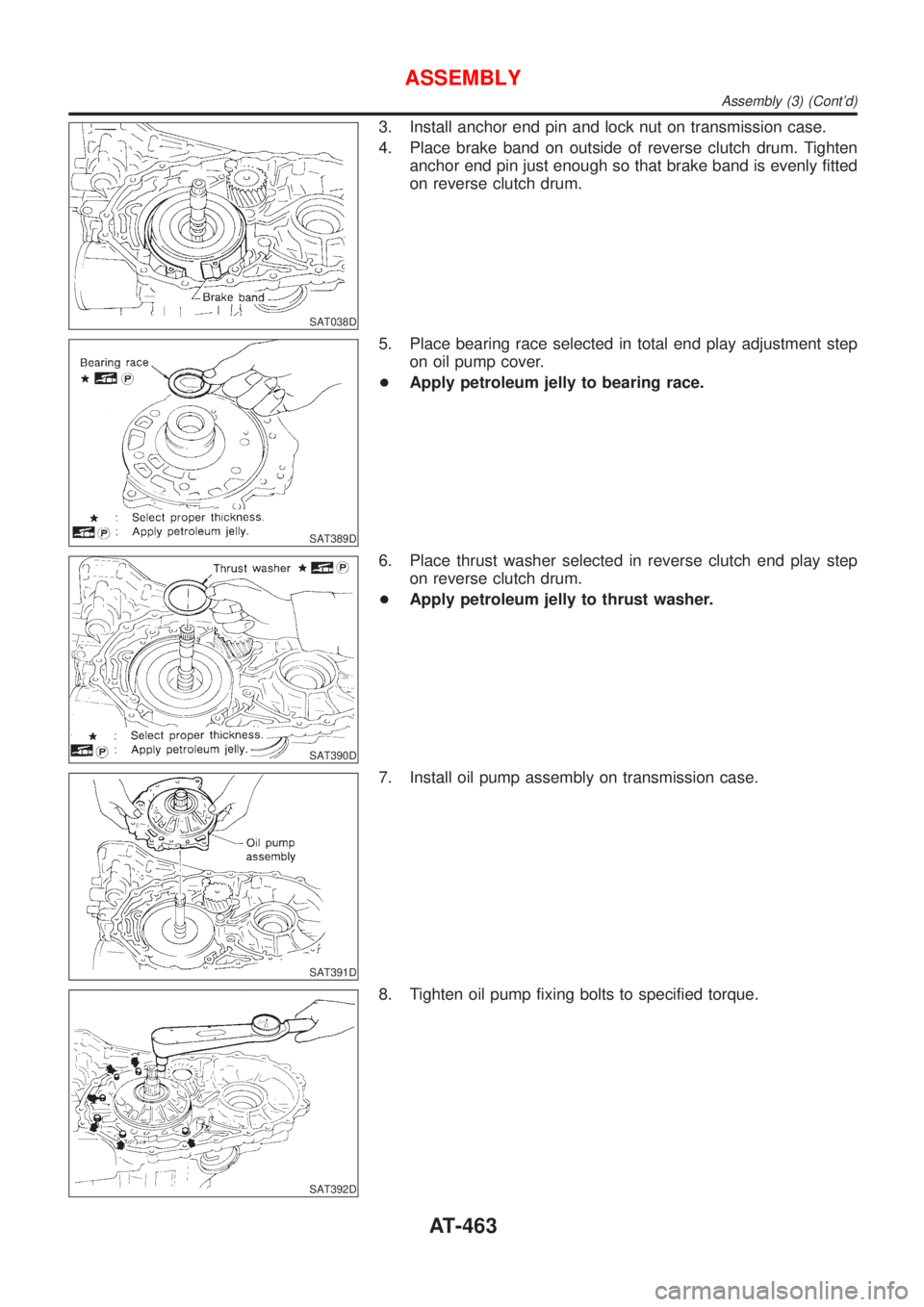

SAT038D

3. Install anchor end pin and lock nut on transmission case.

4. Place brake band on outside of reverse clutch drum. Tighten

anchor end pin just enough so that brake band is evenly fitted

on reverse clutch drum.

SAT389D

5. Place bearing race selected in total end play adjustment step

on oil pump cover.

+Apply petroleum jelly to bearing race.

SAT390D

6. Place thrust washer selected in reverse clutch end play step

on reverse clutch drum.

+Apply petroleum jelly to thrust washer.

SAT391D

7. Install oil pump assembly on transmission case.

SAT392D

8. Tighten oil pump fixing bolts to specified torque.

ASSEMBLY

Assembly (3) (Cont'd)

AT-463

Page 466 of 2898

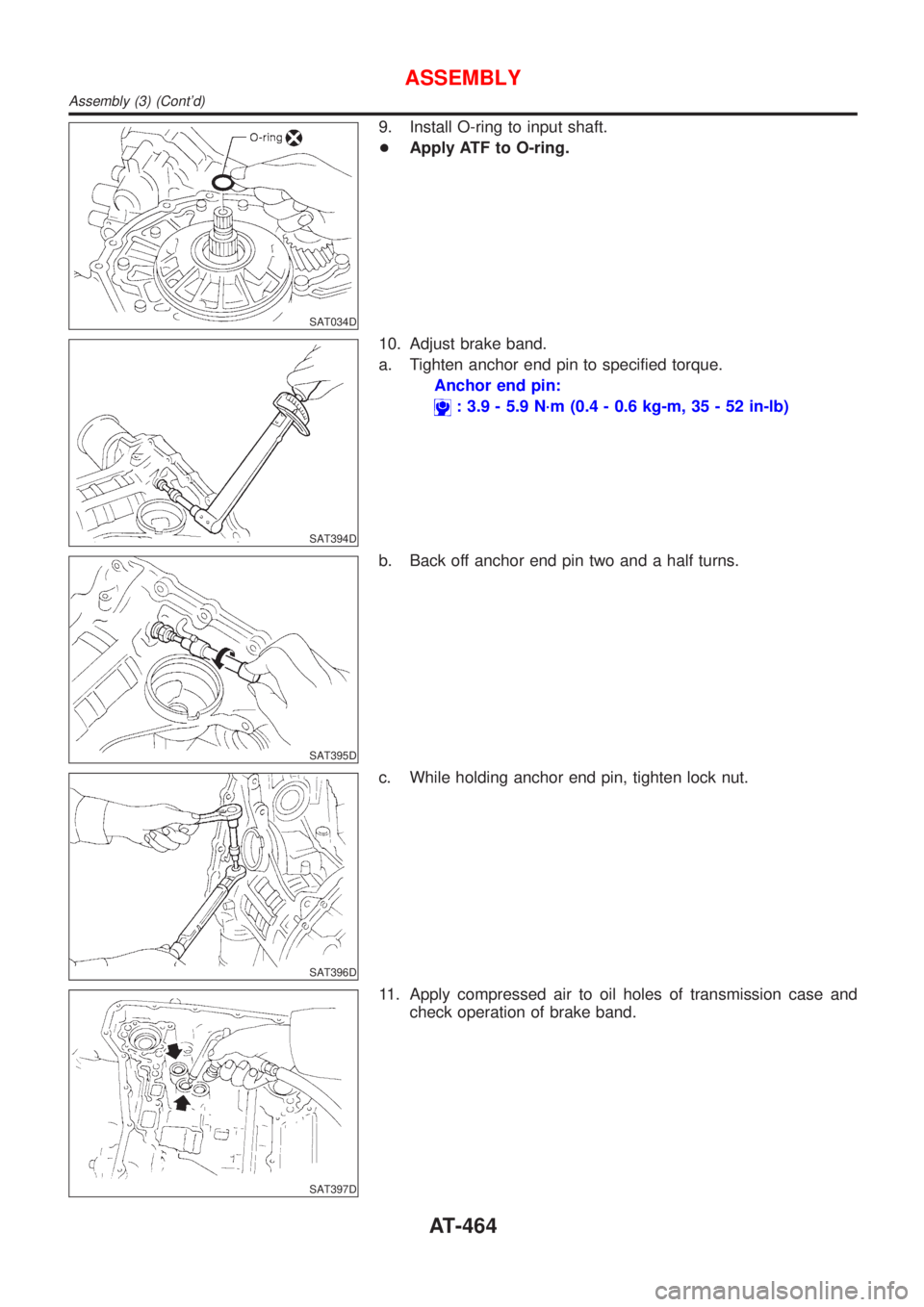

SAT034D

9. Install O-ring to input shaft.

+Apply ATF to O-ring.

SAT394D

10. Adjust brake band.

a. Tighten anchor end pin to specified torque.

Anchor end pin:

: 3.9 - 5.9 N´m (0.4 - 0.6 kg-m, 35 - 52 in-lb)

SAT395D

b. Back off anchor end pin two and a half turns.

SAT396D

c. While holding anchor end pin, tighten lock nut.

SAT397D

11. Apply compressed air to oil holes of transmission case and

check operation of brake band.

ASSEMBLY

Assembly (3) (Cont'd)

AT-464

Page 467 of 2898

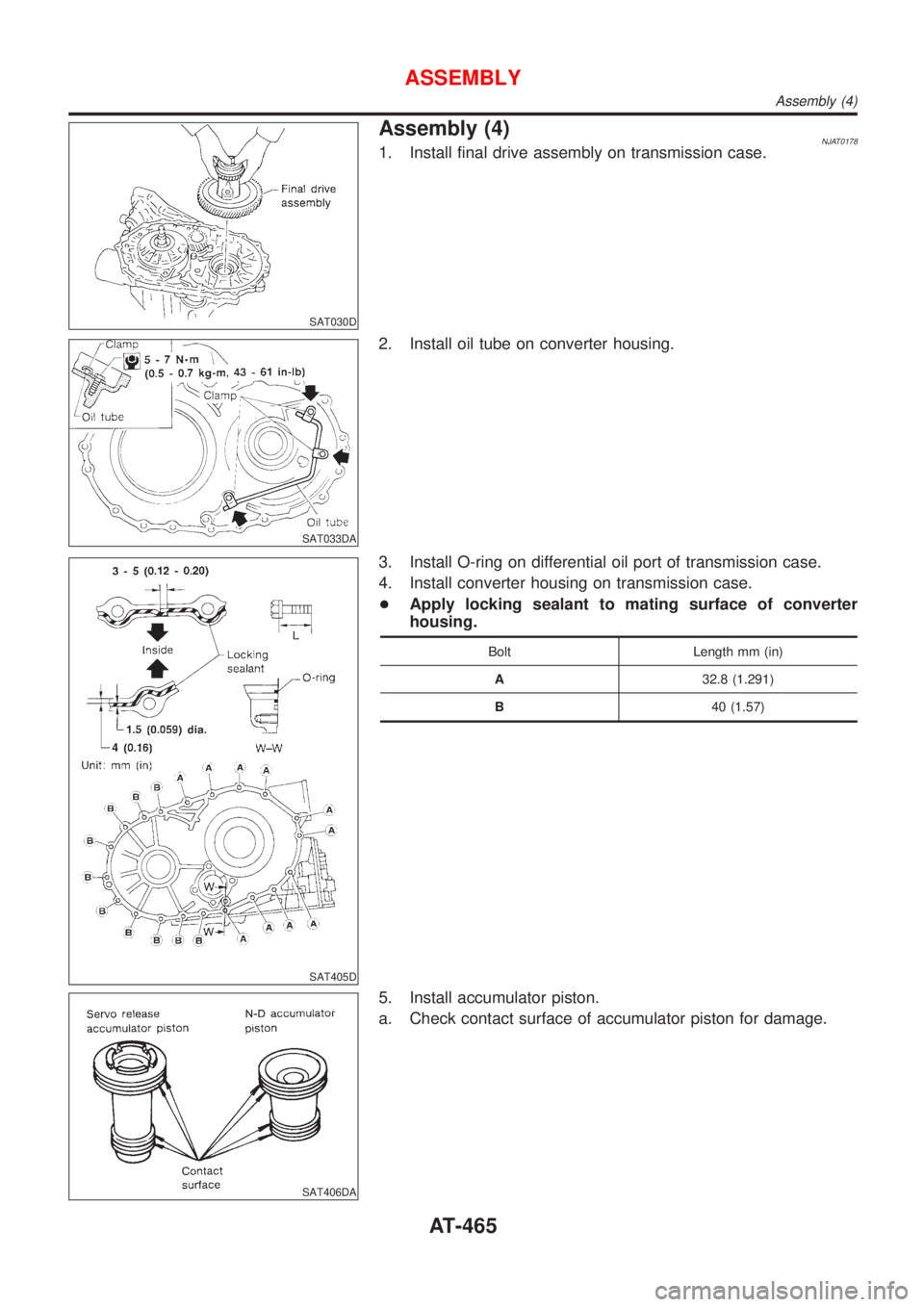

SAT030D

Assembly (4)NJAT01781. Install final drive assembly on transmission case.

SAT033DA

2. Install oil tube on converter housing.

SAT405D

3. Install O-ring on differential oil port of transmission case.

4. Install converter housing on transmission case.

+Apply locking sealant to mating surface of converter

housing.

Bolt Length mm (in)

A32.8 (1.291)

B40 (1.57)

SAT406DA

5. Install accumulator piston.

a. Check contact surface of accumulator piston for damage.

ASSEMBLY

Assembly (4)

AT-465

Page 475 of 2898

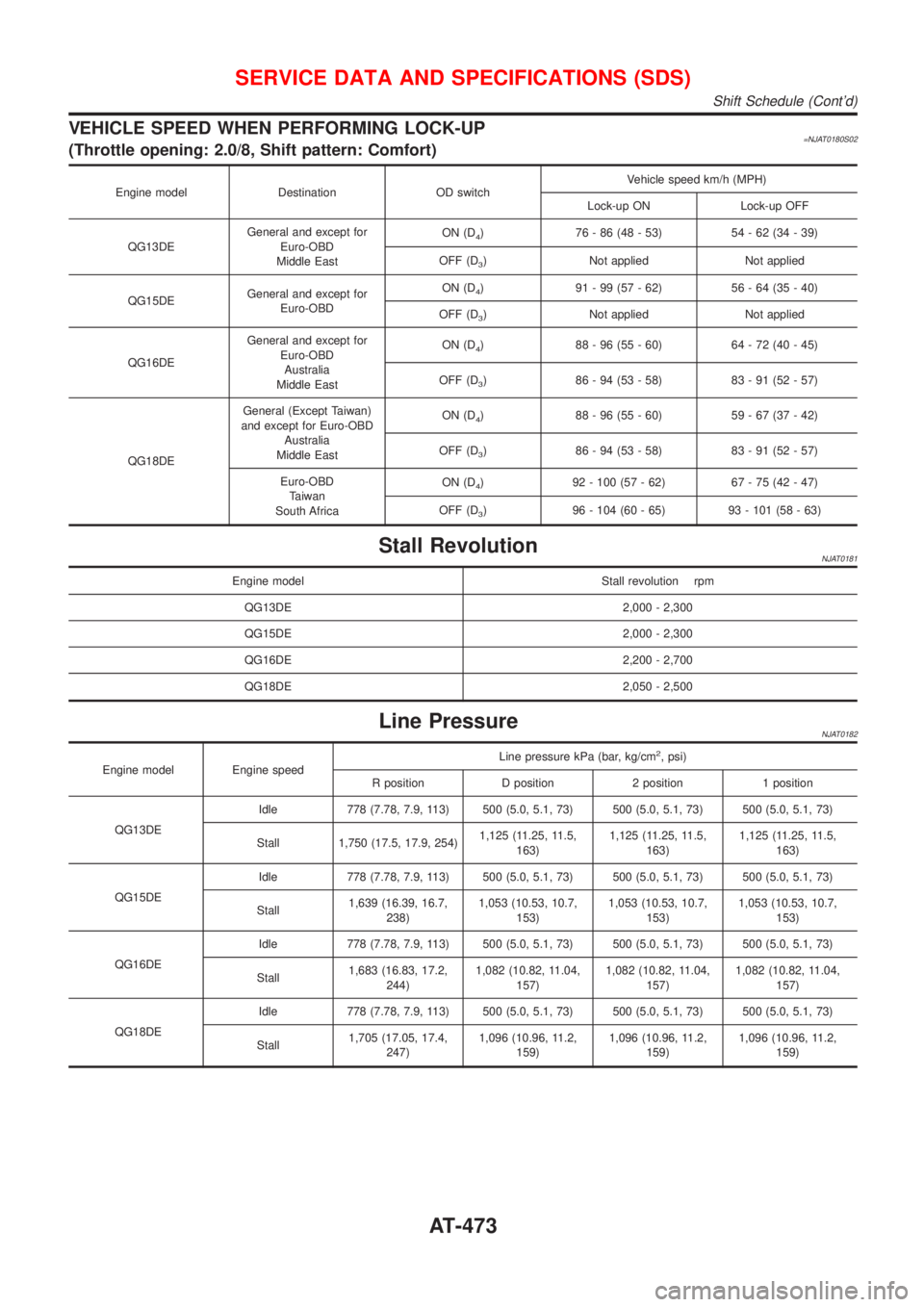

VEHICLE SPEED WHEN PERFORMING LOCK-UP=NJAT0180S02(Throttle opening: 2.0/8, Shift pattern: Comfort)

Engine model Destination OD switchVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

QG13DEGeneral and except for

Euro-OBD

Middle EastON (D

4) 76-86(48-53) 54-62(34-39)

OFF (D

3) Not applied Not applied

QG15DEGeneral and except for

Euro-OBDON (D

4) 91-99(57-62) 56-64(35-40)

OFF (D

3) Not applied Not applied

QG16DEGeneral and except for

Euro-OBD

Australia

Middle EastON (D

4) 88-96(55-60) 64-72(40-45)

OFF (D

3) 86-94(53-58) 83-91(52-57)

QG18DEGeneral (Except Taiwan)

and except for Euro-OBD

Australia

Middle EastON (D

4) 88-96(55-60) 59-67(37-42)

OFF (D

3) 86-94(53-58) 83-91(52-57)

Euro-OBD

Taiwan

South AfricaON (D

4) 92 - 100 (57 - 62) 67 - 75 (42 - 47)

OFF (D

3) 96 - 104 (60 - 65) 93 - 101 (58 - 63)

Stall RevolutionNJAT0181

Engine model Stall revolution rpm

QG13DE 2,000 - 2,300

QG15DE 2,000 - 2,300

QG16DE 2,200 - 2,700

QG18DE 2,050 - 2,500

Line PressureNJAT0182

Engine model Engine speedLine pressure kPa (bar, kg/cm

2, psi)

R position D position 2 position 1 position

QG13DEIdle 778 (7.78, 7.9, 113) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73)

Stall 1,750 (17.5, 17.9, 254)1,125 (11.25, 11.5,

163)1,125 (11.25, 11.5,

163)1,125 (11.25, 11.5,

163)

QG15DEIdle 778 (7.78, 7.9, 113) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73)

Stall1,639 (16.39, 16.7,

238)1,053 (10.53, 10.7,

153)1,053 (10.53, 10.7,

153)1,053 (10.53, 10.7,

153)

QG16DEIdle 778 (7.78, 7.9, 113) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73)

Stall1,683 (16.83, 17.2,

244)1,082 (10.82, 11.04,

157)1,082 (10.82, 11.04,

157)1,082 (10.82, 11.04,

157)

QG18DEIdle 778 (7.78, 7.9, 113) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73)

Stall1,705 (17.05, 17.4,

247)1,096 (10.96, 11.2,

159)1,096 (10.96, 11.2,

159)1,096 (10.96, 11.2,

159)

SERVICE DATA AND SPECIFICATIONS (SDS)

Shift Schedule (Cont'd)

AT-473

Page 479 of 2898

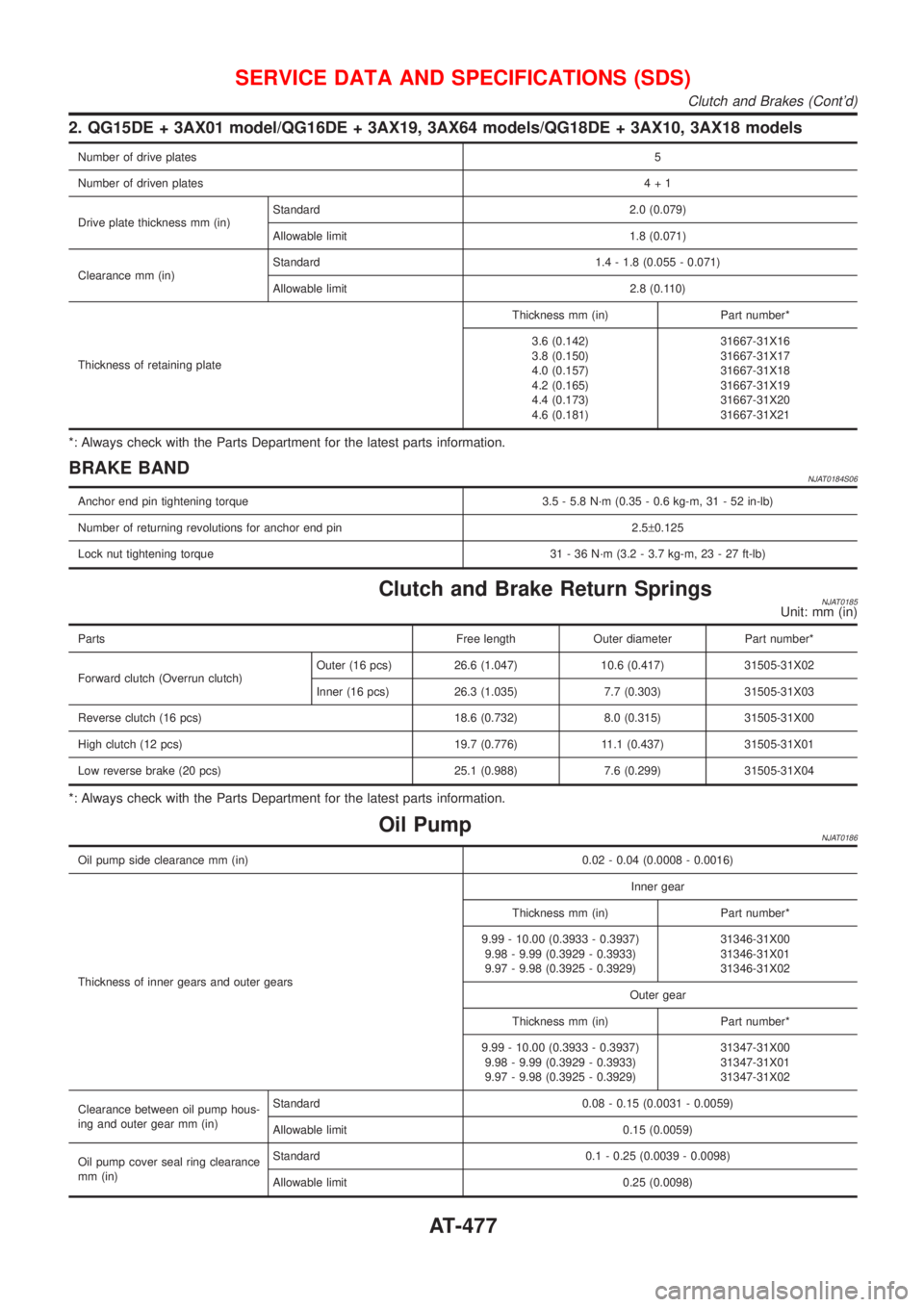

2. QG15DE + 3AX01 model/QG16DE + 3AX19, 3AX64 models/QG18DE + 3AX10, 3AX18 models

Number of drive plates5

Number of driven plates4+1

Drive plate thickness mm (in)Standard 2.0 (0.079)

Allowable limit 1.8 (0.071)

Clearance mm (in)Standard 1.4 - 1.8 (0.055 - 0.071)

Allowable limit 2.8 (0.110)

Thickness of retaining plateThickness mm (in) Part number*

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)31667-31X16

31667-31X17

31667-31X18

31667-31X19

31667-31X20

31667-31X21

*: Always check with the Parts Department for the latest parts information.

BRAKE BANDNJAT0184S06

Anchor end pin tightening torque 3.5 - 5.8 N´m (0.35 - 0.6 kg-m, 31 - 52 in-lb)

Number of returning revolutions for anchor end pin 2.5±0.125

Lock nut tightening torque 31 - 36 N´m (3.2 - 3.7 kg-m, 23 - 27 ft-lb)

Clutch and Brake Return SpringsNJAT0185Unit: mm (in)

Parts Free length Outer diameter Part number*

Forward clutch (Overrun clutch)Outer (16 pcs) 26.6 (1.047) 10.6 (0.417) 31505-31X02

Inner (16 pcs) 26.3 (1.035) 7.7 (0.303) 31505-31X03

Reverse clutch (16 pcs) 18.6 (0.732) 8.0 (0.315) 31505-31X00

High clutch (12 pcs) 19.7 (0.776) 11.1 (0.437) 31505-31X01

Low reverse brake (20 pcs) 25.1 (0.988) 7.6 (0.299) 31505-31X04

*: Always check with the Parts Department for the latest parts information.

Oil PumpNJAT0186

Oil pump side clearance mm (in) 0.02 - 0.04 (0.0008 - 0.0016)

Thickness of inner gears and outer gearsInner gear

Thickness mm (in) Part number*

9.99 - 10.00 (0.3933 - 0.3937)

9.98 - 9.99 (0.3929 - 0.3933)

9.97 - 9.98 (0.3925 - 0.3929)31346-31X00

31346-31X01

31346-31X02

Outer gear

Thickness mm (in) Part number*

9.99 - 10.00 (0.3933 - 0.3937)

9.98 - 9.99 (0.3929 - 0.3933)

9.97 - 9.98 (0.3925 - 0.3929)31347-31X00

31347-31X01

31347-31X02

Clearance between oil pump hous-

ing and outer gear mm (in)Standard 0.08 - 0.15 (0.0031 - 0.0059)

Allowable limit 0.15 (0.0059)

Oil pump cover seal ring clearance

mm (in)Standard 0.1 - 0.25 (0.0039 - 0.0098)

Allowable limit 0.25 (0.0098)

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch and Brakes (Cont'd)

AT-477