NISSAN ALMERA 2001 Workshop Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Workshop Manual

Page 368 of 2898

NJAT0120

SAT049K

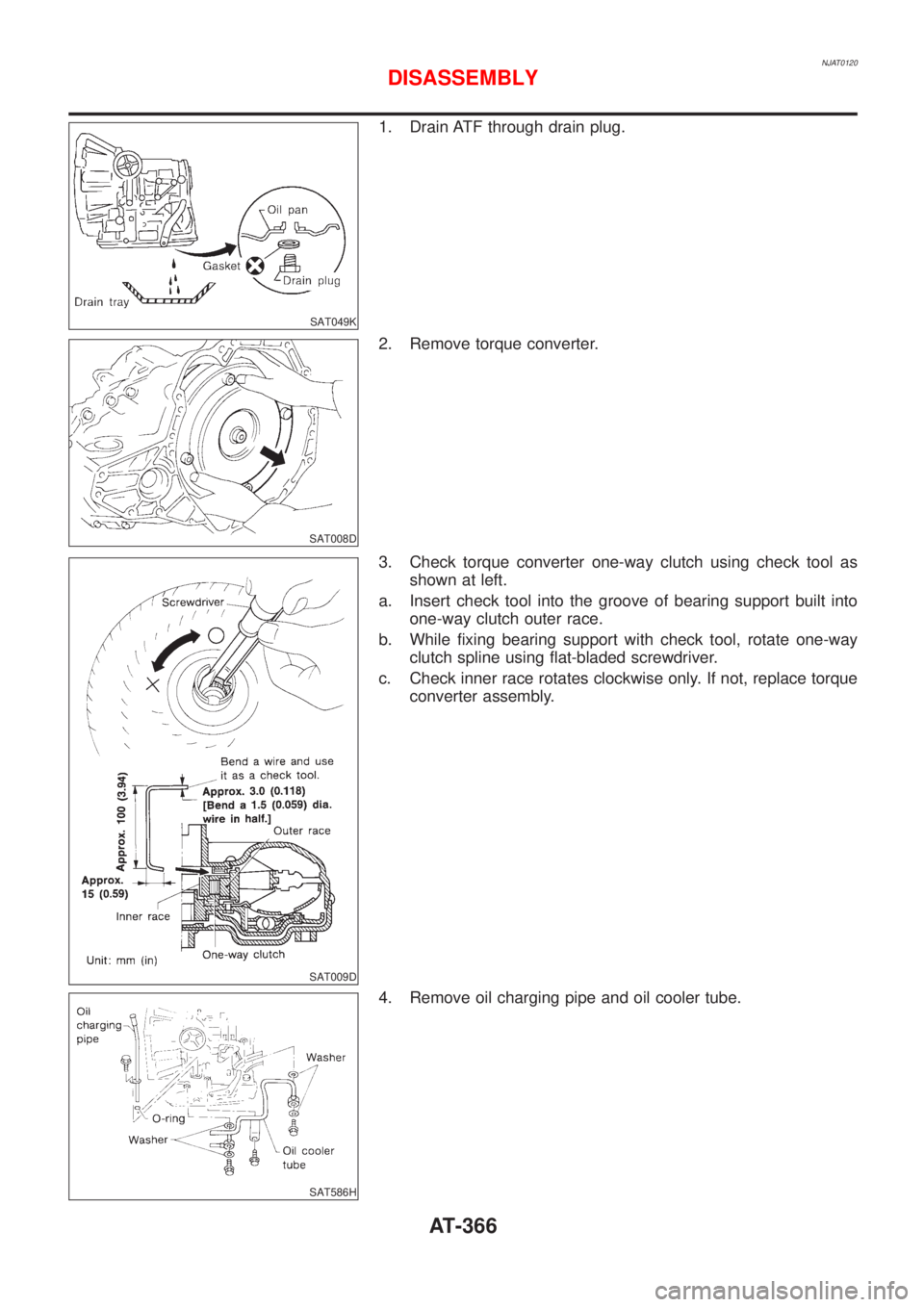

1. Drain ATF through drain plug.

SAT008D

2. Remove torque converter.

SAT009D

3. Check torque converter one-way clutch using check tool as

shown at left.

a. Insert check tool into the groove of bearing support built into

one-way clutch outer race.

b. While fixing bearing support with check tool, rotate one-way

clutch spline using flat-bladed screwdriver.

c. Check inner race rotates clockwise only. If not, replace torque

converter assembly.

SAT586H

4. Remove oil charging pipe and oil cooler tube.

DISASSEMBLY

AT-366

Page 374 of 2898

SAT037DA

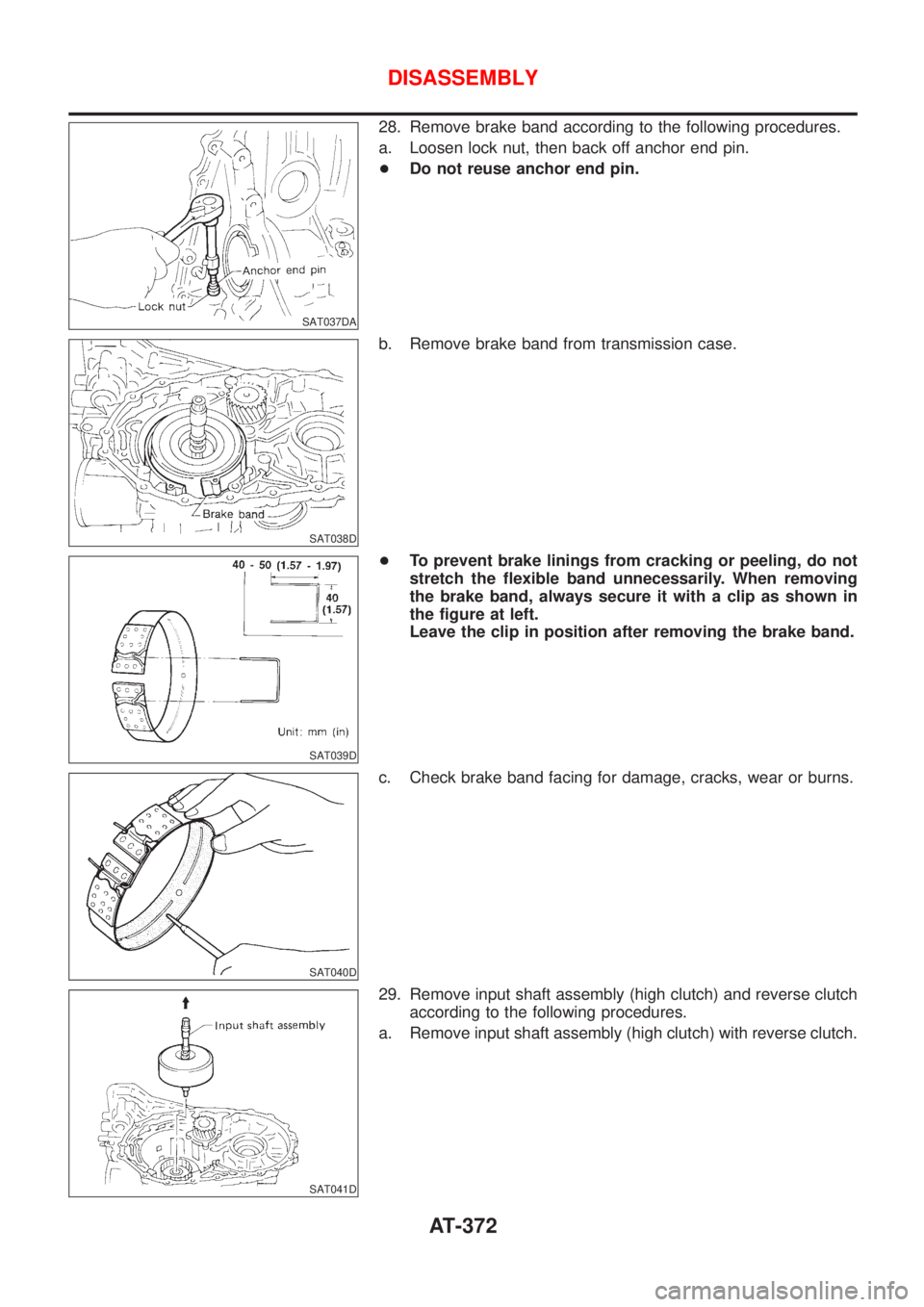

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pin.

+Do not reuse anchor end pin.

SAT038D

b. Remove brake band from transmission case.

SAT039D

+To prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown in

the figure at left.

Leave the clip in position after removing the brake band.

SAT040D

c. Check brake band facing for damage, cracks, wear or burns.

SAT041D

29. Remove input shaft assembly (high clutch) and reverse clutch

according to the following procedures.

a. Remove input shaft assembly (high clutch) with reverse clutch.

DISASSEMBLY

AT-372

Page 376 of 2898

SAT047D

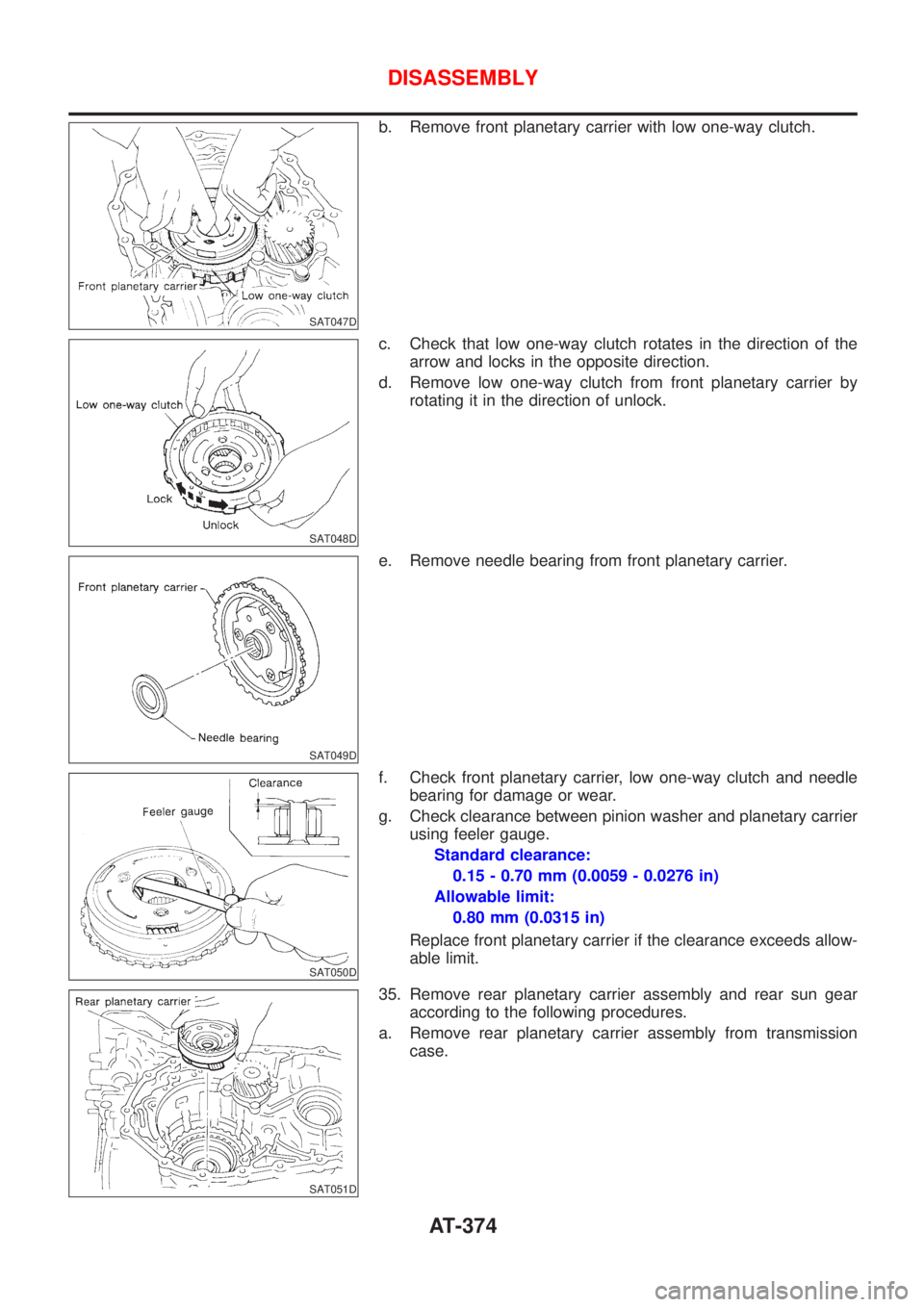

b. Remove front planetary carrier with low one-way clutch.

SAT048D

c. Check that low one-way clutch rotates in the direction of the

arrow and locks in the opposite direction.

d. Remove low one-way clutch from front planetary carrier by

rotating it in the direction of unlock.

SAT049D

e. Remove needle bearing from front planetary carrier.

SAT050D

f. Check front planetary carrier, low one-way clutch and needle

bearing for damage or wear.

g. Check clearance between pinion washer and planetary carrier

using feeler gauge.

Standard clearance:

0.15 - 0.70 mm (0.0059 - 0.0276 in)

Allowable limit:

0.80 mm (0.0315 in)

Replace front planetary carrier if the clearance exceeds allow-

able limit.

SAT051D

35. Remove rear planetary carrier assembly and rear sun gear

according to the following procedures.

a. Remove rear planetary carrier assembly from transmission

case.

DISASSEMBLY

AT-374

Page 378 of 2898

SAT272E

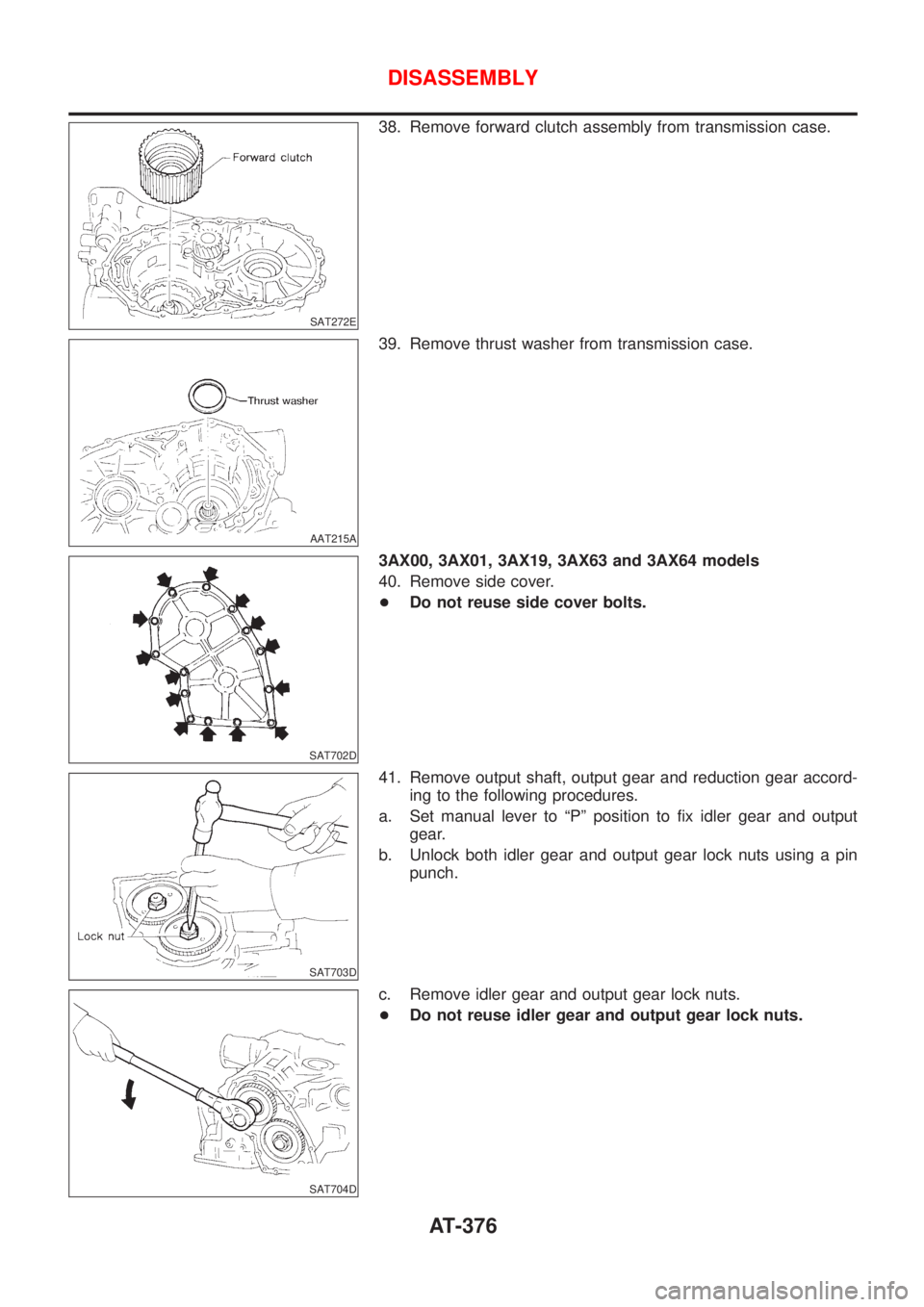

38. Remove forward clutch assembly from transmission case.

AAT215A

39. Remove thrust washer from transmission case.

SAT702D

3AX00, 3AX01, 3AX19, 3AX63 and 3AX64 models

40. Remove side cover.

+Do not reuse side cover bolts.

SAT703D

41. Remove output shaft, output gear and reduction gear accord-

ing to the following procedures.

a. Set manual lever to ªPº position to fix idler gear and output

gear.

b. Unlock both idler gear and output gear lock nuts using a pin

punch.

SAT704D

c. Remove idler gear and output gear lock nuts.

+Do not reuse idler gear and output gear lock nuts.

DISASSEMBLY

AT-376

Page 380 of 2898

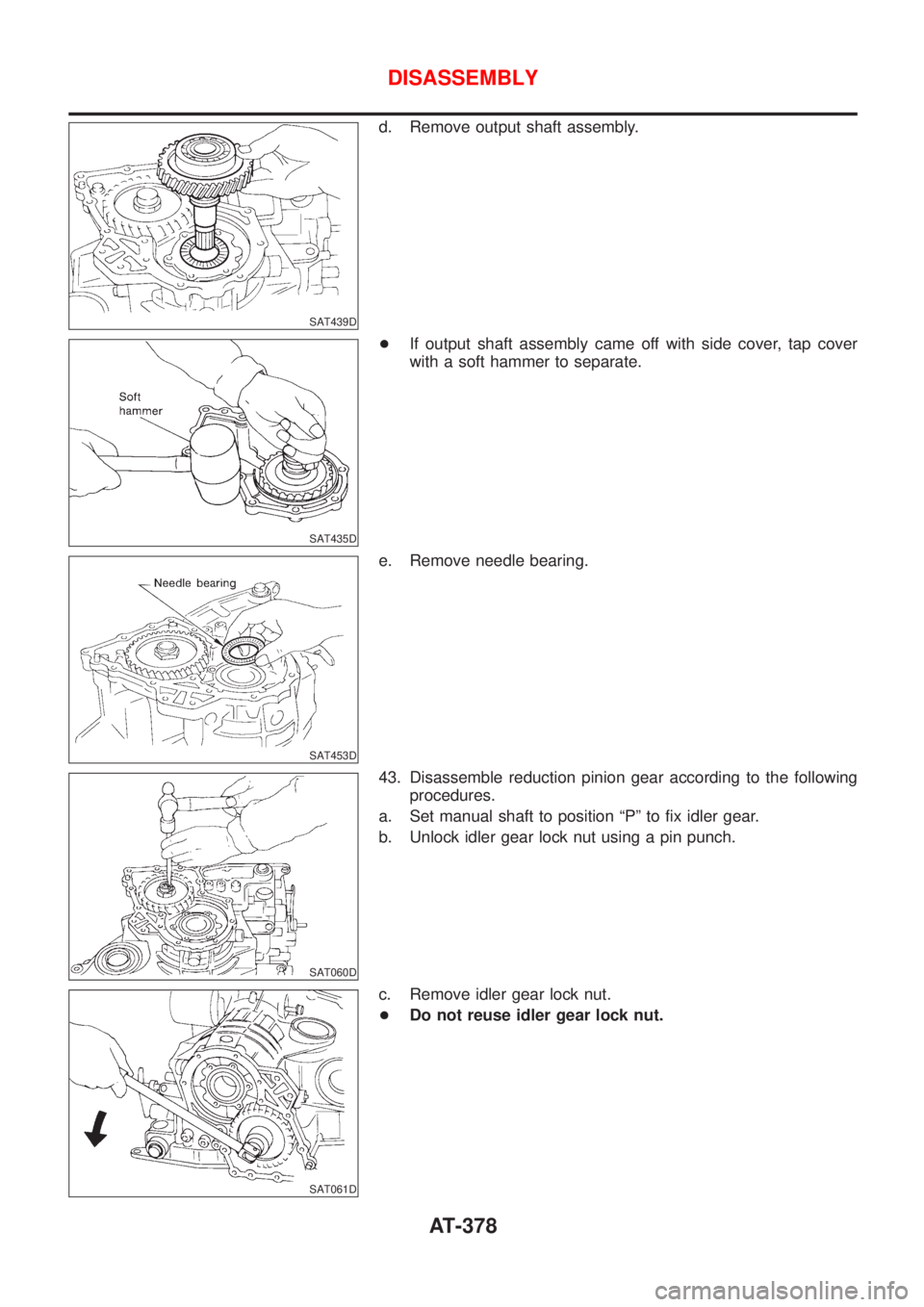

SAT439D

d. Remove output shaft assembly.

SAT435D

+If output shaft assembly came off with side cover, tap cover

with a soft hammer to separate.

SAT453D

e. Remove needle bearing.

SAT060D

43. Disassemble reduction pinion gear according to the following

procedures.

a. Set manual shaft to position ªPº to fix idler gear.

b. Unlock idler gear lock nut using a pin punch.

SAT061D

c. Remove idler gear lock nut.

+Do not reuse idler gear lock nut.

DISASSEMBLY

AT-378

Page 428 of 2898

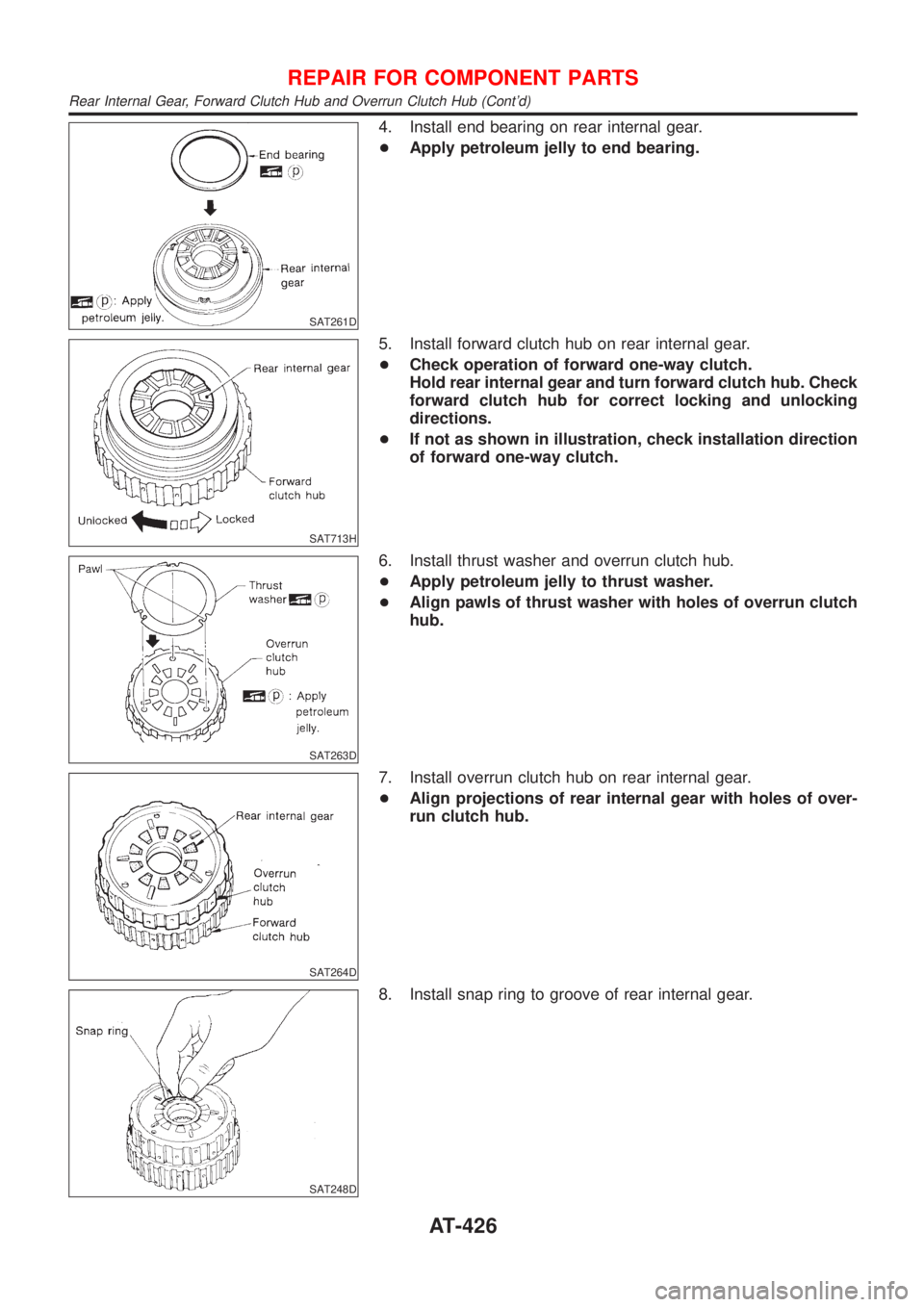

SAT261D

4. Install end bearing on rear internal gear.

+Apply petroleum jelly to end bearing.

SAT713H

5. Install forward clutch hub on rear internal gear.

+Check operation of forward one-way clutch.

Hold rear internal gear and turn forward clutch hub. Check

forward clutch hub for correct locking and unlocking

directions.

+If not as shown in illustration, check installation direction

of forward one-way clutch.

SAT263D

6. Install thrust washer and overrun clutch hub.

+Apply petroleum jelly to thrust washer.

+Align pawls of thrust washer with holes of overrun clutch

hub.

SAT264D

7. Install overrun clutch hub on rear internal gear.

+Align projections of rear internal gear with holes of over-

run clutch hub.

SAT248D

8. Install snap ring to groove of rear internal gear.

REPAIR FOR COMPONENT PARTS

Rear Internal Gear, Forward Clutch Hub and Overrun Clutch Hub (Cont'd)

AT-426

Page 440 of 2898

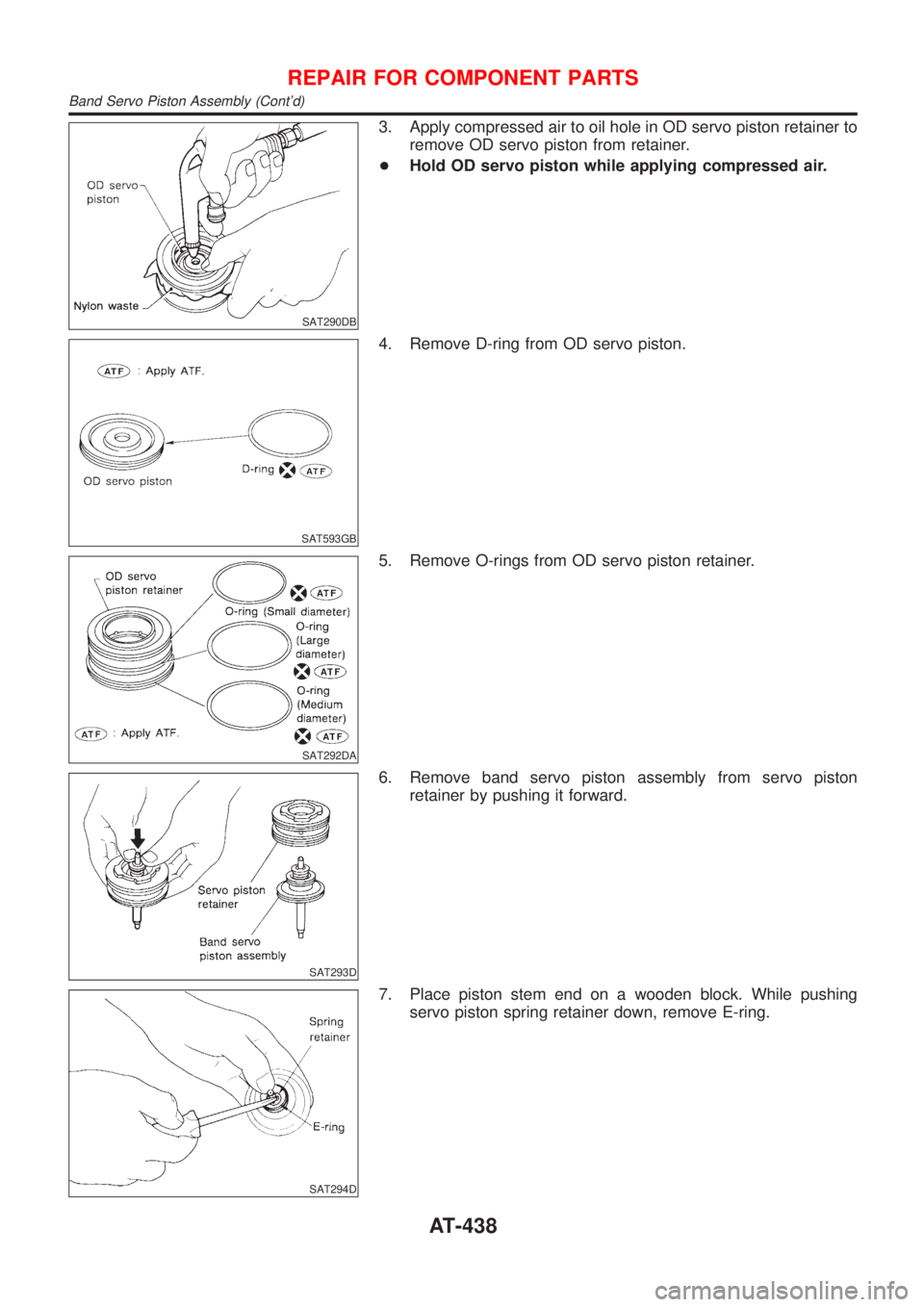

SAT290DB

3. Apply compressed air to oil hole in OD servo piston retainer to

remove OD servo piston from retainer.

+Hold OD servo piston while applying compressed air.

SAT593GB

4. Remove D-ring from OD servo piston.

SAT292DA

5. Remove O-rings from OD servo piston retainer.

SAT293D

6. Remove band servo piston assembly from servo piston

retainer by pushing it forward.

SAT294D

7. Place piston stem end on a wooden block. While pushing

servo piston spring retainer down, remove E-ring.

REPAIR FOR COMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

AT-438

Page 442 of 2898

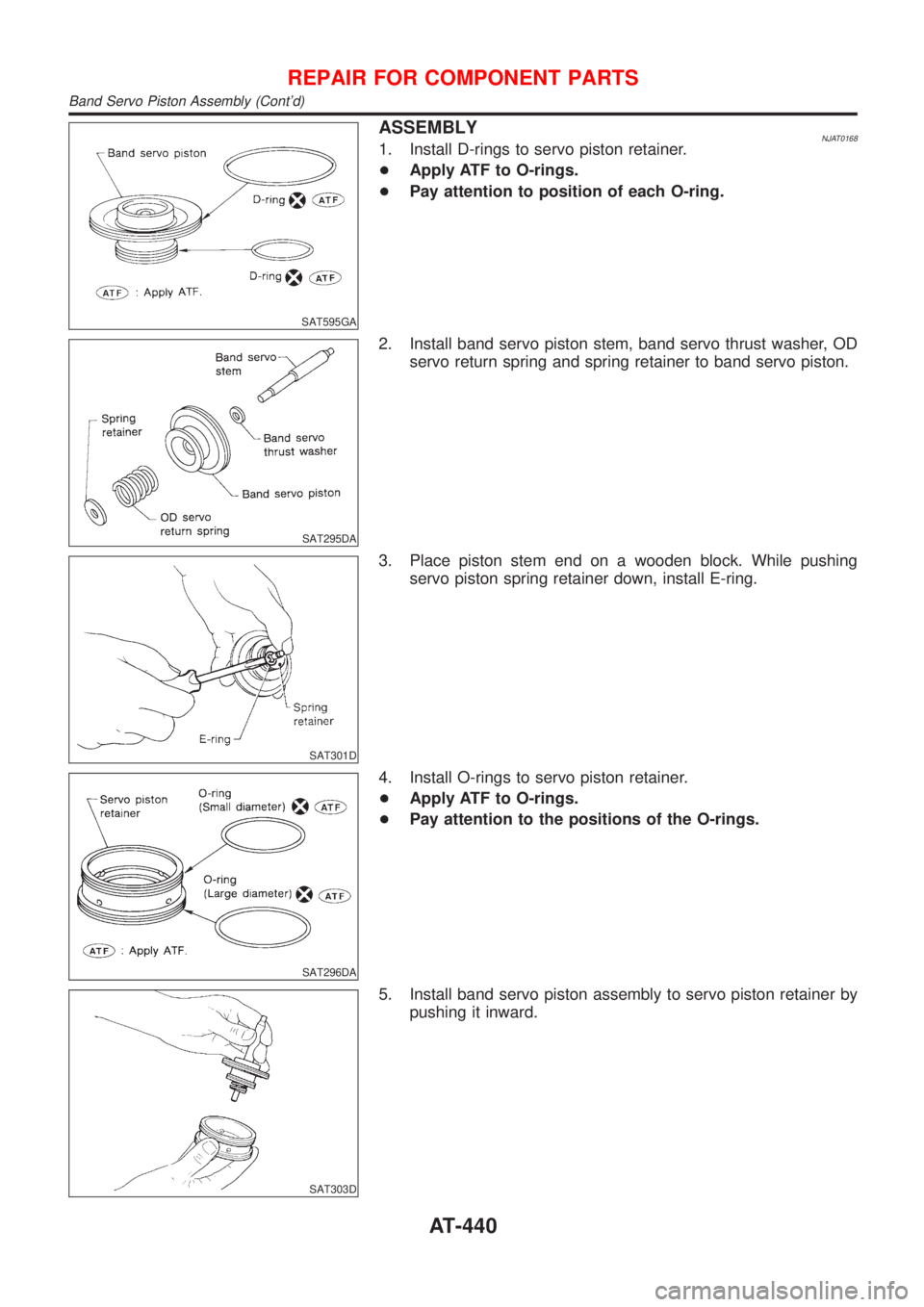

SAT595GA

ASSEMBLYNJAT01681. Install D-rings to servo piston retainer.

+Apply ATF to O-rings.

+Pay attention to position of each O-ring.

SAT295DA

2. Install band servo piston stem, band servo thrust washer, OD

servo return spring and spring retainer to band servo piston.

SAT301D

3. Place piston stem end on a wooden block. While pushing

servo piston spring retainer down, install E-ring.

SAT296DA

4. Install O-rings to servo piston retainer.

+Apply ATF to O-rings.

+Pay attention to the positions of the O-rings.

SAT303D

5. Install band servo piston assembly to servo piston retainer by

pushing it inward.

REPAIR FOR COMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

AT-440

Page 445 of 2898

SAT311D

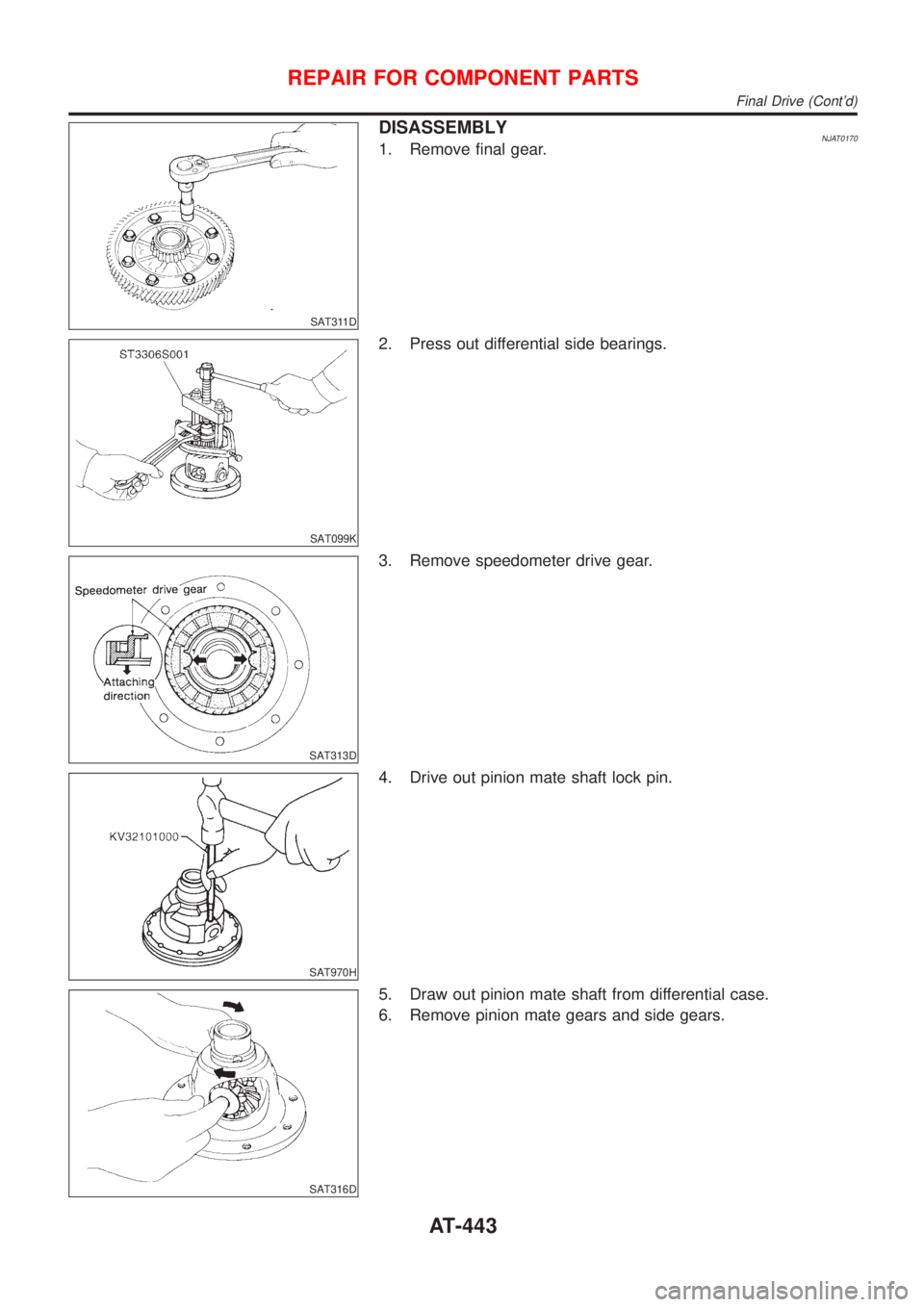

DISASSEMBLYNJAT01701. Remove final gear.

SAT099K

2. Press out differential side bearings.

SAT313D

3. Remove speedometer drive gear.

SAT970H

4. Drive out pinion mate shaft lock pin.

SAT316D

5. Draw out pinion mate shaft from differential case.

6. Remove pinion mate gears and side gears.

REPAIR FOR COMPONENT PARTS

Final Drive (Cont'd)

AT-443

Page 447 of 2898

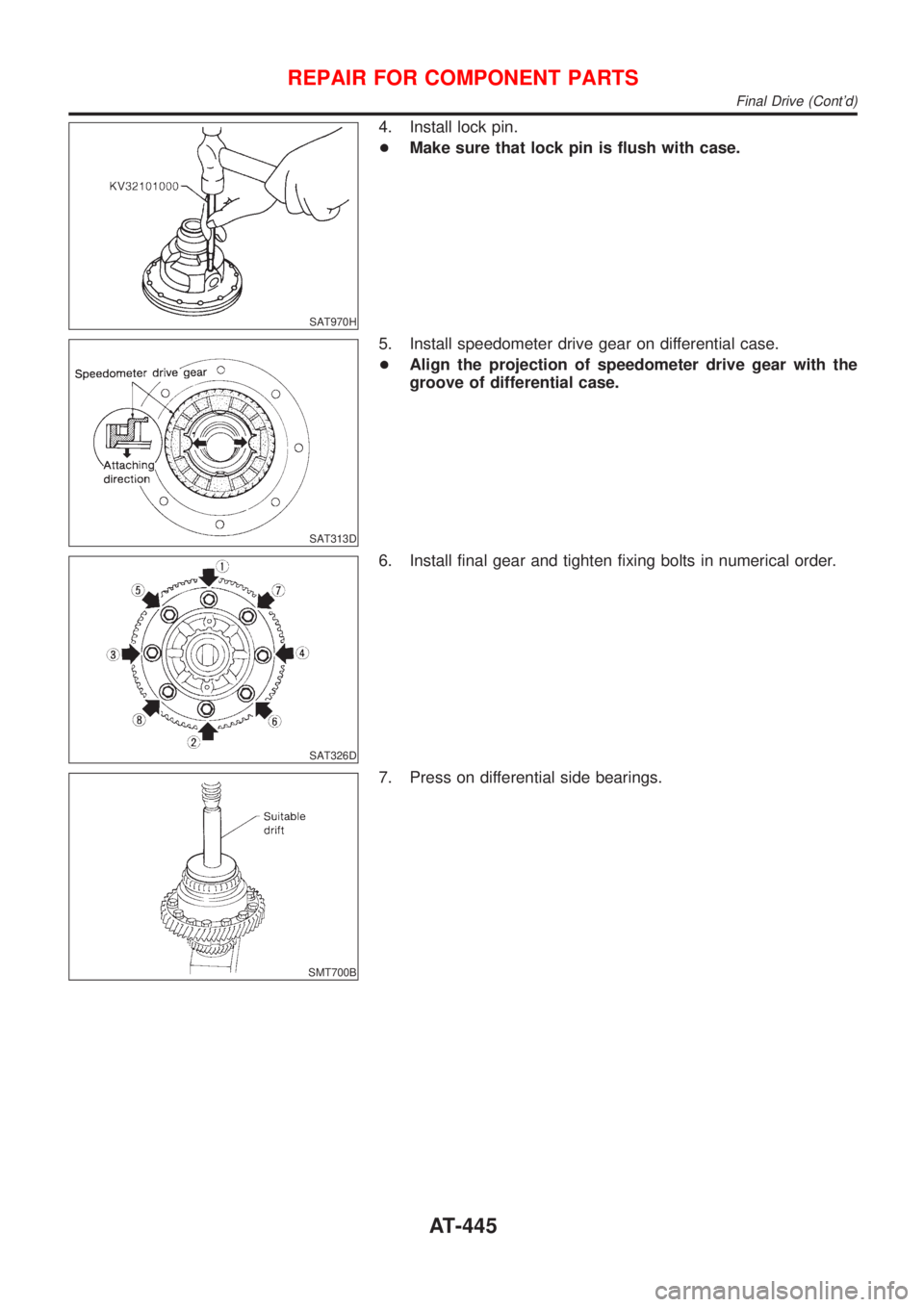

SAT970H

4. Install lock pin.

+Make sure that lock pin is flush with case.

SAT313D

5. Install speedometer drive gear on differential case.

+Align the projection of speedometer drive gear with the

groove of differential case.

SAT326D

6. Install final gear and tighten fixing bolts in numerical order.

SMT700B

7. Press on differential side bearings.

REPAIR FOR COMPONENT PARTS

Final Drive (Cont'd)

AT-445