NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1091 of 1701

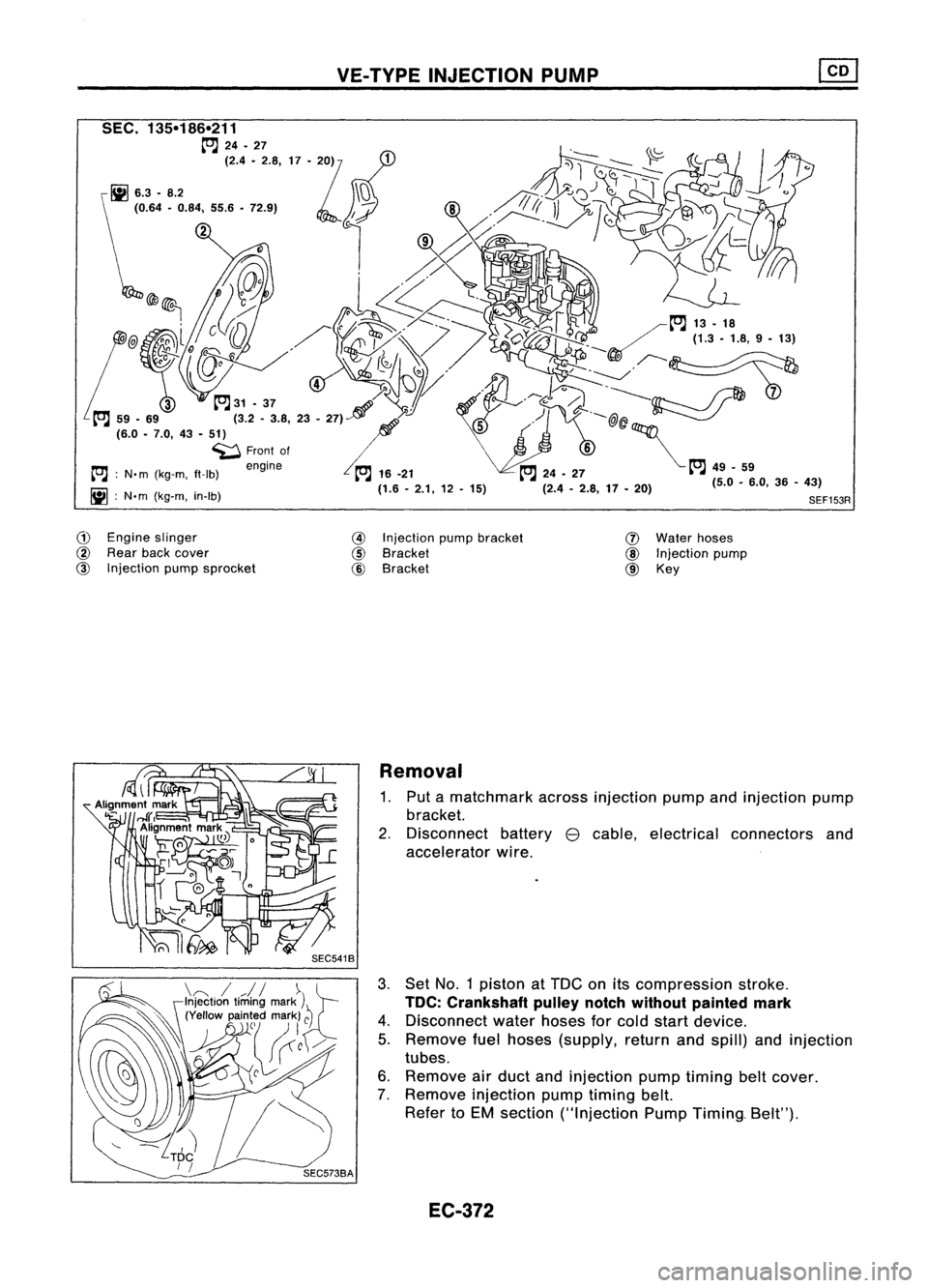

VE-TVPEINJECTION PUMP

G)

Engine slinger

@

Rear backcover

@

Injection pumpsprocket

@

Injection pumpbracket

@

Bracket

@

Bracket

(J)

Water hoses

@

Injection pump

@ Key

Removal

1. Put amatchmark acrossinjection pumpandinjection pump

bracket.

2. Disconnect battery

e

cable, electrical connectors and

accelerator wire.

3. Set No.1 piston atTDe onitscompression stroke.

TOC: Crankshaft pulleynotchwithout painted mark

4. Disconnect waterhoses forcold start device.

5. Remove fuelhoses (supply, returnandspill) andinjection

tubes.

6. Remove airduct andinjection pumptiming beltcover.

7. Remove injection pumptiming belt.

Refer toEM section ("Injection PumpTiming. Belt").

EC-372

Page 1092 of 1701

VE-TVPEINJECTION PUMP ~

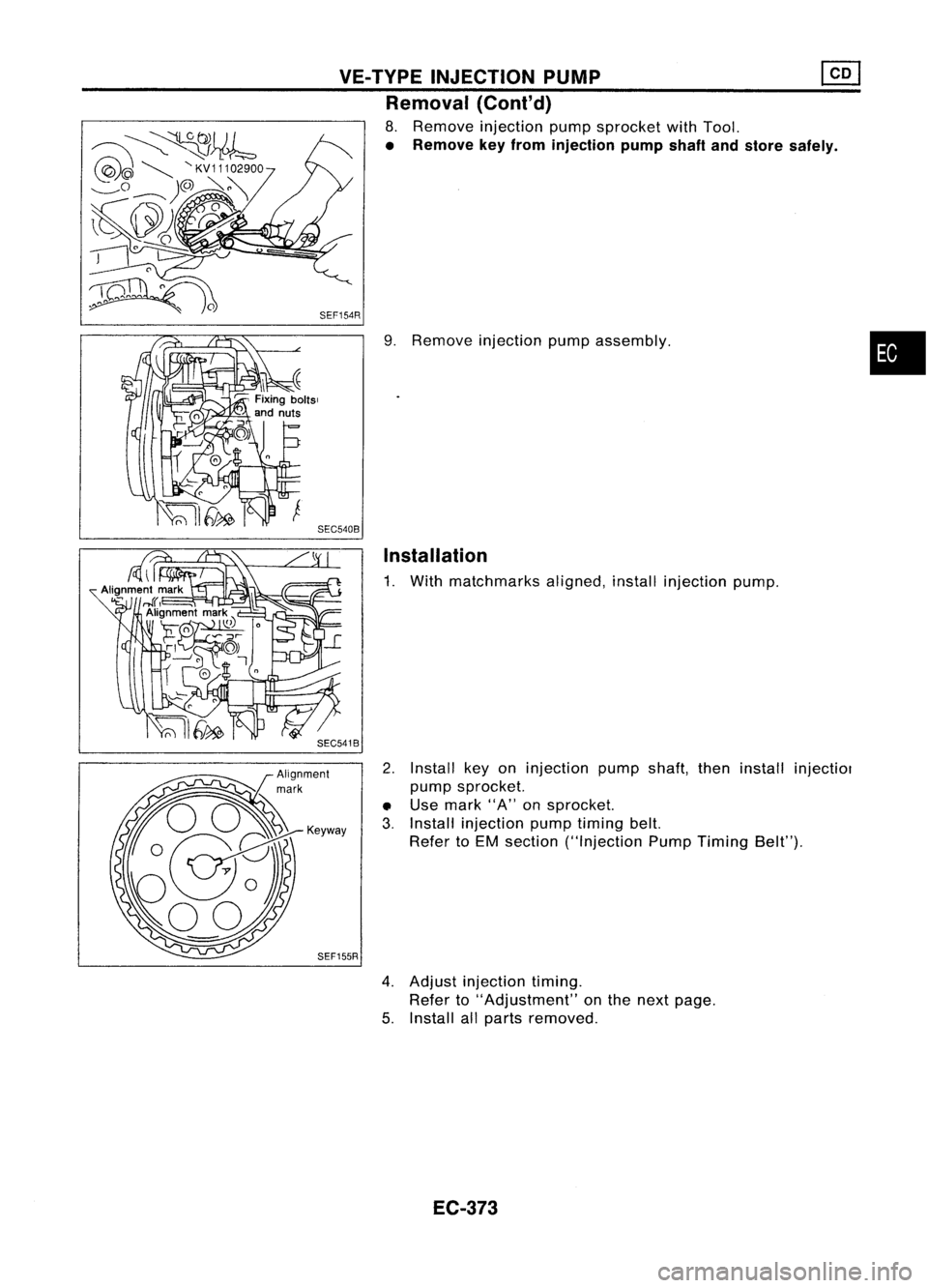

Removal (Cont'd)

8. Remove injection pumpsprocket withTool.

• Remove keyfrom injection pumpshaftandstore safely .

9. Remove injection pumpassembly.

Installation

1. With matchmarks aligned,installinjection pump.

2. Install keyoninjection pumpshaft,theninstall injectiol

pump sprocket.

• Use mark "A"onsprocket.

3. Install injection pumptiming belt.

Refer toEM section ("Injection PumpTiming Belt").

SEF155R

4.Adjust injection timing.

Refer to"Adjustment" onthe next page.

5. Install allparts removed.

EC-373

•

Page 1093 of 1701

VE-TYPE INJECTION PUMP

SEF779A

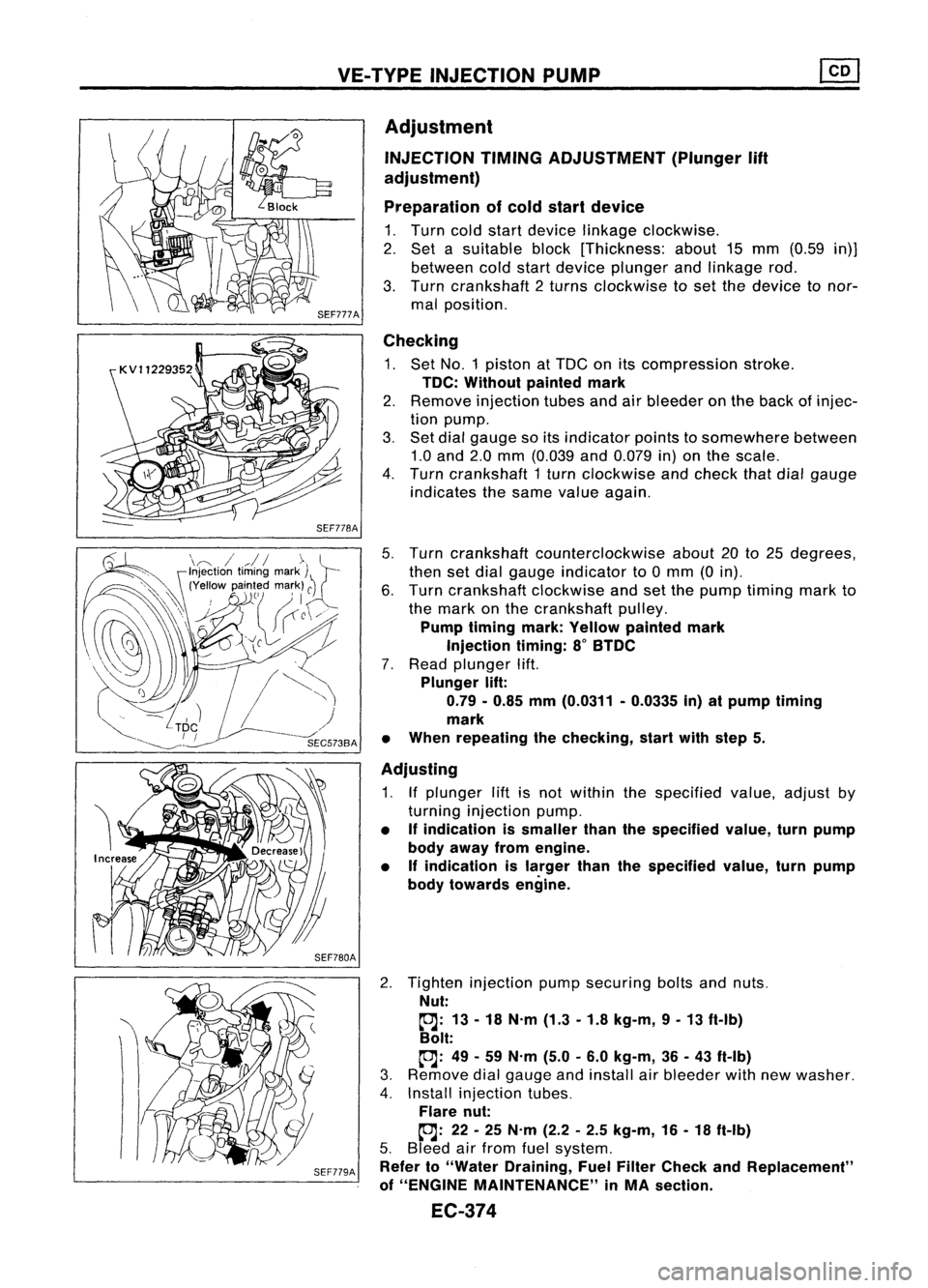

Adjustment

INJECTION TIMINGADJUSTMENT (Plunger

lift

adjustment)

Preparation ofcold start device

1. Turn coldstart device linkage clockwise.

2. Set asuitable block[Thickness: about15mm (0.59 in)]

between coldstart device plunger andlinkage rod.

3. Turn crankshaft 2turns clockwise toset the device tonor-

mal position.

Checking

1. Set NO.1 piston atTDC onitscompression stroke.

TDC: Without paintedmark

2. Remove injection tubesandairbleeder onthe back ofinjec-

tion pump.

3. Set dial gauge soitsindicator pointstosomewhere between

1.0 and 2.0mm (0.039 and0.079 in)onthe scale.

4. Turn crankshaft 1turn clockwise andcheck thatdialgauge

indicates thesame value again.

5. Turn crankshaft counterclockwise about20to25 degrees,

then setdial gauge indicator to0mm (0in).

6. Turn crankshaft clockwiseandsetthe pump timing markto

the mark onthe crankshaft pulley.

Pump timing mark:Yellow painted mark

Injection timing:8

0

BTDC

7. Read plunger lift.

Plunger lift:

0.79 -0.85 mm(0.0311 -0.0335 in)atpump timing

mark

• When repeating thechecking, startwithstep 5.

Adjusting

1. Ifplunger liftisnot within thespecified value,adjust by

turning injection pump.

• Ifindication issmaller thanthespecified value,turnpump

body away fromengine.

• Ifindication islarger thanthespecified value,turnpump

body towards engine.

2. Tighten injection pumpsecuring boltsandnuts.

Nut:

~: 13-18 N.m (1.3-1.8 kg-m, 9-13 ft-Ib)

Bolt:

~: 49-59 N.m (5.0-6.0 kg-m, 36-43 ft-Ib)

3. Remove dialgauge andinstall airbleeder withnewwasher.

4. Install injection tubes.

Flare nut:

~: 22-25 N.m (2.2-2.5 kg-m, 16-18 ft-Ib)

5. Bleed airfrom fuelsystem.

Refer to"Water Draining, FuelFilter Check andReplacement"

of "ENGINE MAINTENANCE" inMA section.

EC-374

Page 1094 of 1701

VE-TVPEINJECTION PUMP ~

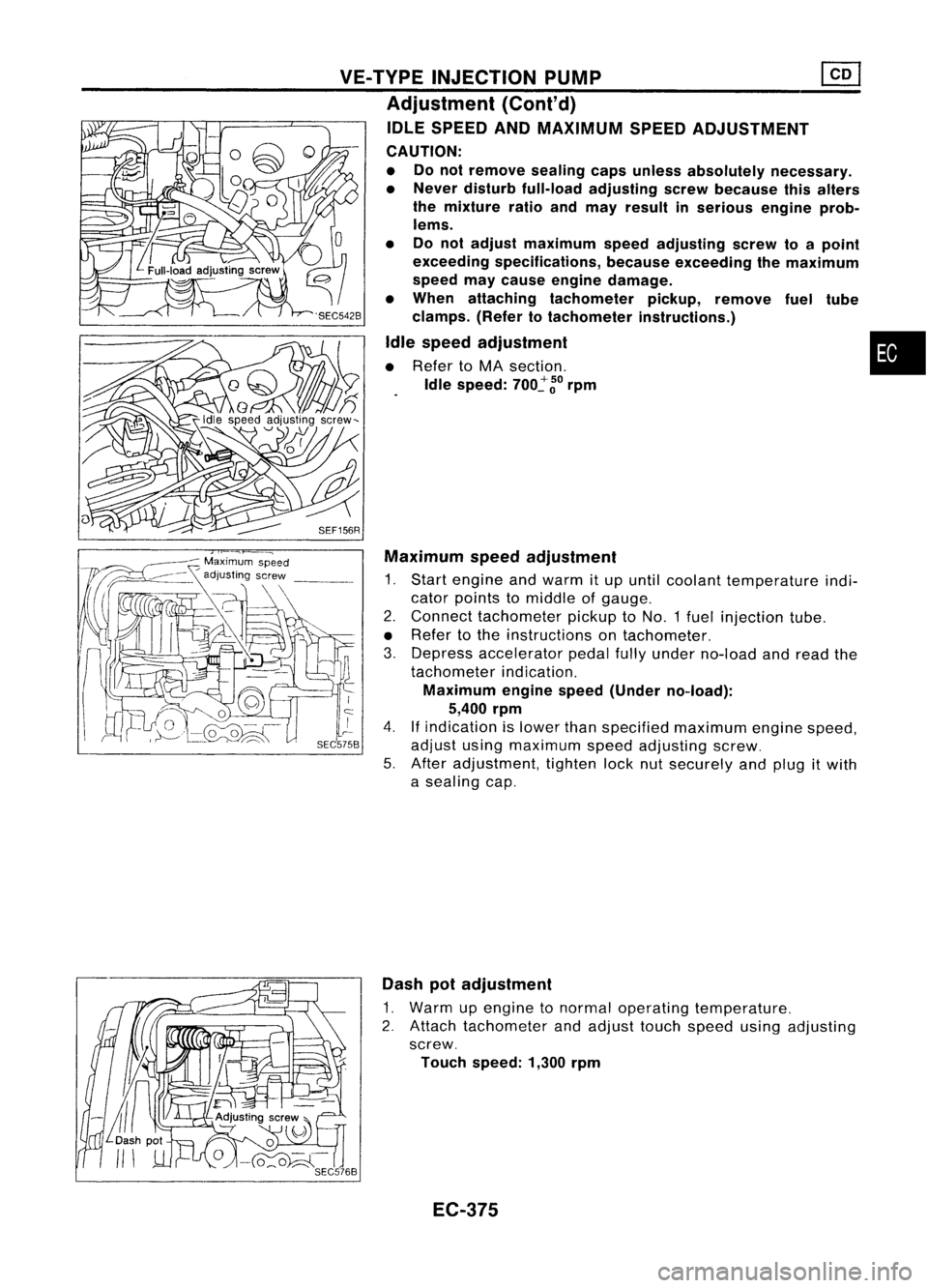

Adjustment (Cont'd)

IDLE SPEED ANDMAXIMUM SPEEDADJUSTMENT

CAUTION:

• Donot remove sealingcapsunless absolutely necessary.

• Never disturb full-load adjusting screwbecause thisalters

the mixture ratioandmay result inserious engineprob-

lems.

• Donot adjust maximum speedadjusting screwtoapoint

exceeding specifications, becauseexceeding themaximum

speed maycause engine damage.

• When attaching tachometer pickup,remove fueltUbe

clamps. (Refertotachometer instructions.)

Idle speed adjustment •

• Refer toMA section.

Idle speed:

700~

~o

rpm

SEF156R Maximum speedadjustment

1. Start engine andwarm itup until coolant temperature indi-

cator points tomiddle ofgauge.

2. Connect tachometer pickuptoNO.1 fuelinjection tube.

• Refer tothe instructions ontachometer.

3. Depress accelerator pedalfullyunder no-load andread the

tachometer indication.

Maximum enginespeed(Under no-load):

5,400 rpm

4.

If

indication islower thanspecified maximum enginespeed,

adjust usingmaximum speedadjusting screw.

5. After adjustment, tightenlocknutsecurely andplug itwith

a sealing cap.

Dash potadjustment

1. Warm upengine tonormal operating temperature.

2. Attach tachometer andadjust touchspeed usingadjusting

screw.

Touch speed: 1,300rpm

EC-375

Page 1095 of 1701

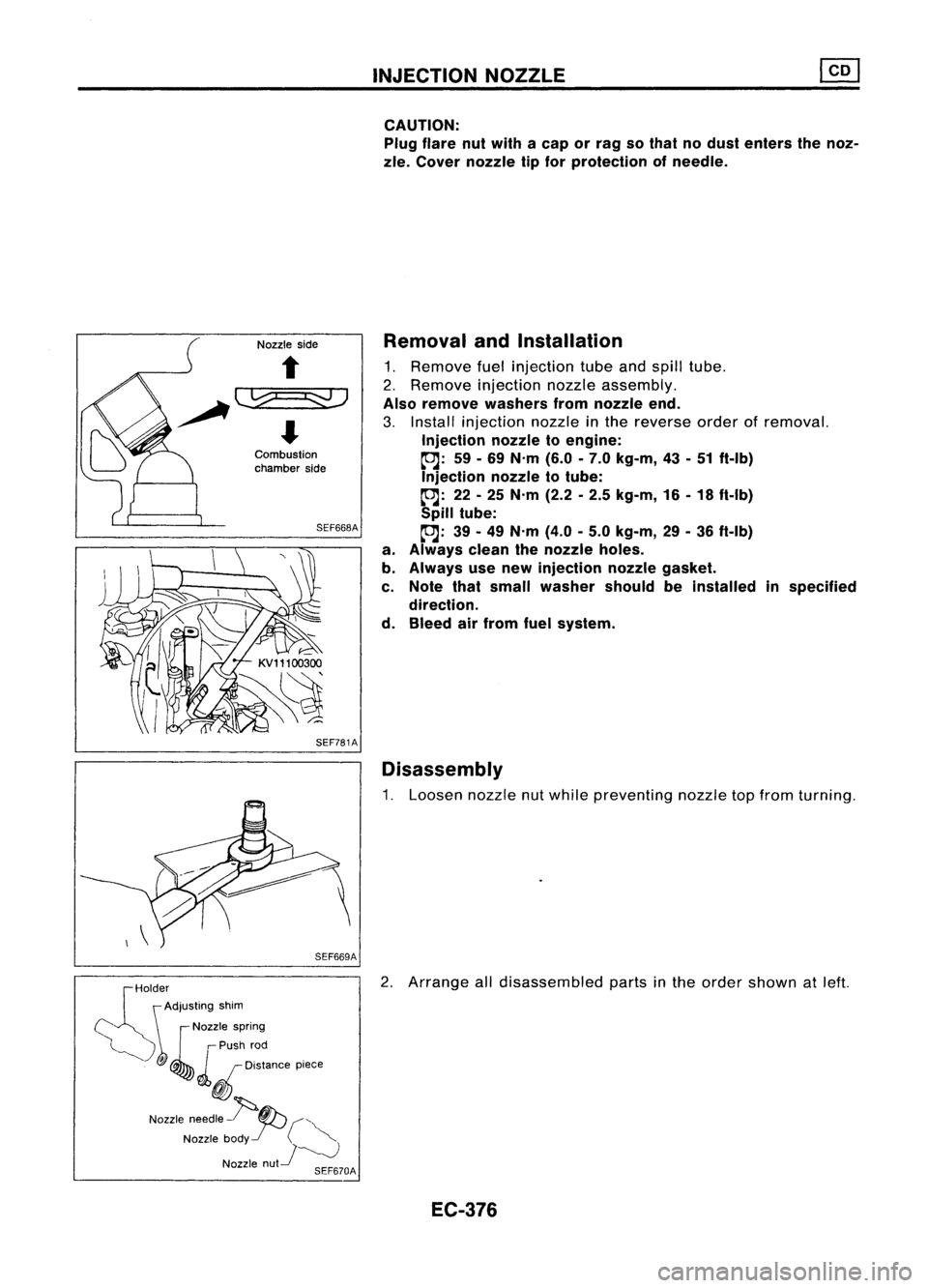

Nozzleside

Combustion

chamber side

SEF668A

SEF781A

SEF669A

:S

older ~Adiusting shim

c:,

Nozzlespring

~ '~[;{~I:,""'

pi,",

Nozzle needle~~(''''-

Nozzle bOdyr ~

Nozzle nut)

SEF670A INJECTION

NOZZLE

CAUTION: Plug flare nutwith acap orrag sothat nodust enters thenoz-

zle. Cover nozzle tipfor protection ofneedle.

Removal andInstallation

1. Remove fuelinjection tubeandspill tube.

2. Remove injection nozzleassembly.

Also remove washers fromnozzle end.

3. Install injection nozzleinthe reverse orderofremoval.

Injection nozzletoengine:

~: 59-69 N'm (6.0-7.0 kg-m, 43-51 ft-Ib)

Injection nozzletotube:

~: 22-25 N'm (2.2-2.5 kg-m, 16-18 ft-Ib)

Spill tube:

~: 39-49 N'm (4.0-5.0 kg-m, 29-36 ft-Ib)

a. Always cleanthenozzle holes.

b. Always usenew injection nozzlegasket.

c. Note thatsmall washer shouldbeinstalled inspecified

direction.

d. Bleed airfrom fuelsystem.

Disassembly

1. Loosen nozzlenutwhile preventing nozzletopfrom turning.

2. Arrange alldisassembled partsinthe order shown atleft.

EC-376

Page 1096 of 1701

SEF830INJECTION

NOZZLE

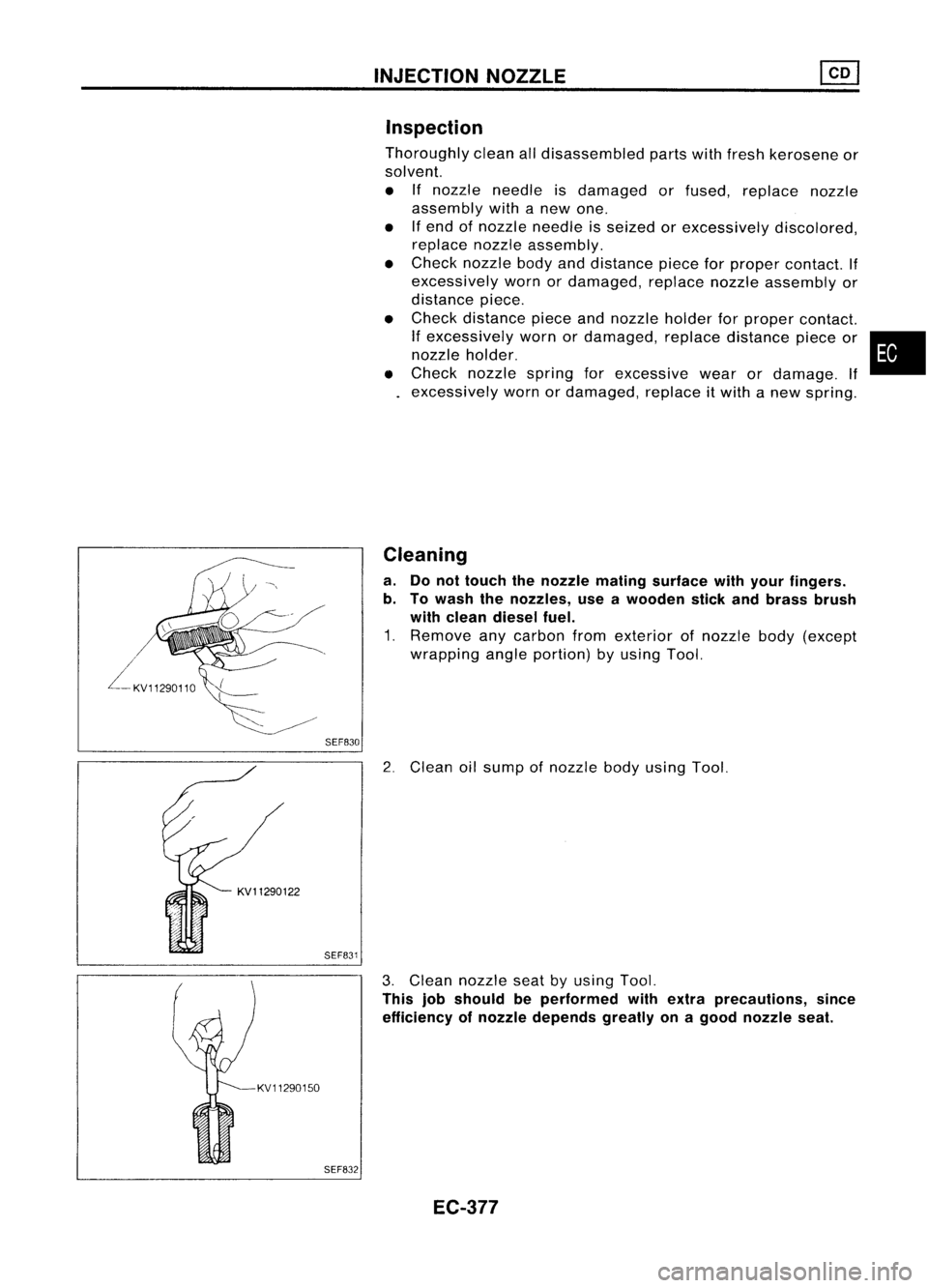

Inspection

Thoroughly cleanalldisassembled partswithfresh kerosene or

solvent.

• Ifnozzle needle isdamaged orfused, replace nozzle

assembly withanew one.

• Ifend ofnozzle needle isseized orexcessively discolored,

replace nozzleassembly.

• Check nozzle bodyanddistance pieceforproper contact. If

excessively wornordamaged, replacenozzleassembly or

distance piece.

• Check distance pieceandnozzle holderforproper contact.

If

excessively wornordamaged, replacedistance pieceor•

nozzle holder.

• Check nozzle springforexcessive wearordamage. If

excessively wornordamaged, replaceitwith anew spring.

Cleaning

a. Donot touch thenozzle mating surface withyour fingers.

b. Towash thenozzles, useawooden stickandbrass brush

with clean diesel fuel.

1. Remove anycarbon fromexterior ofnozzle body(except

wrapping angleportion) byusing Tool.

2. Clean oilsump ofnozzle bodyusing Tool.

KV11290150 SEF831

SEF832

3.

Clean nozzle seatbyusing Tool.

This jobshould beperformed withextra precautions, since

efficiency ofnozzle depends greatlyonagood nozzle seat.

EC-377

Page 1097 of 1701

KV11290220SEF833

SEF834

SEF835 INJECTION

NOZZLE ~

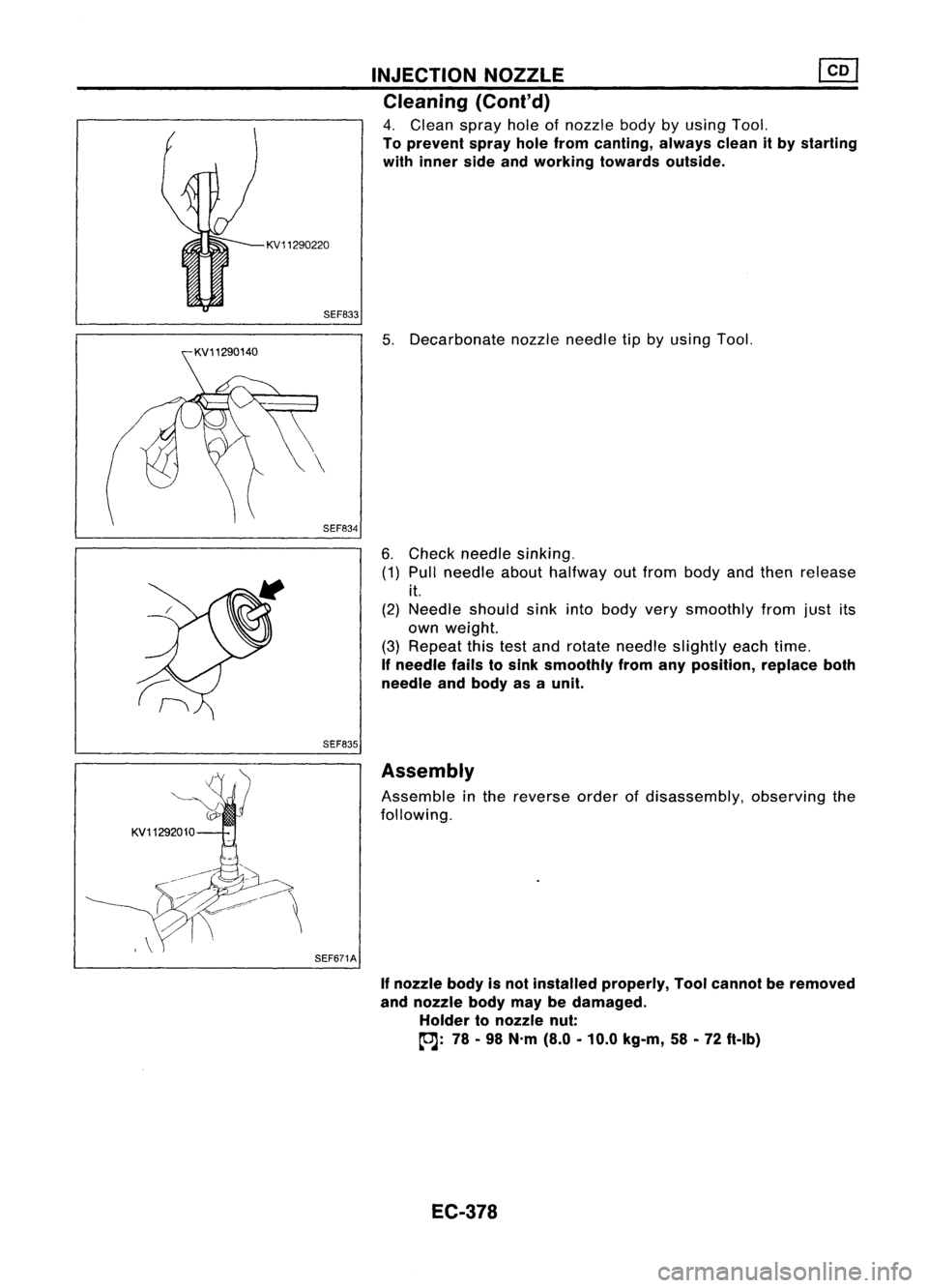

Cleaning (Coni'd)

4. Clean sprayholeofnozzle bodybyusing Tool.

To prevent sprayholefrom canting, alwayscleanitby starting

with inner sideandworking towardsoutside.

5. Decarbonate nozzleneedle tipbyusing Tool.

6. Check needle sinking.

(1) Pull needle abouthalfway outfrom body andthen release

it.

(2) Needle shouldsinkintobody verysmoothly fromjustits

own weight.

(3) Repeat thistestand rotate needle slightly eachtime.

If

needle failstosink smoothly fromanyposition, replaceboth

needle andbody asaunit.

KV11292010 SEF671AAssembly

Assemble inthe reverse orderofdisassembly, observingthe

following.

If

nozzle bodyisnot installed properly, Toolcannot beremoved

and nozzle bodymaybedamaged.

Holder tonozzle nut:

(OJ:

78-98 N'm (8.0-10.0 kg-m, 58-72 ft-Ib)

EC-378

Page 1098 of 1701

EF791AINJECTION

NOZZLE

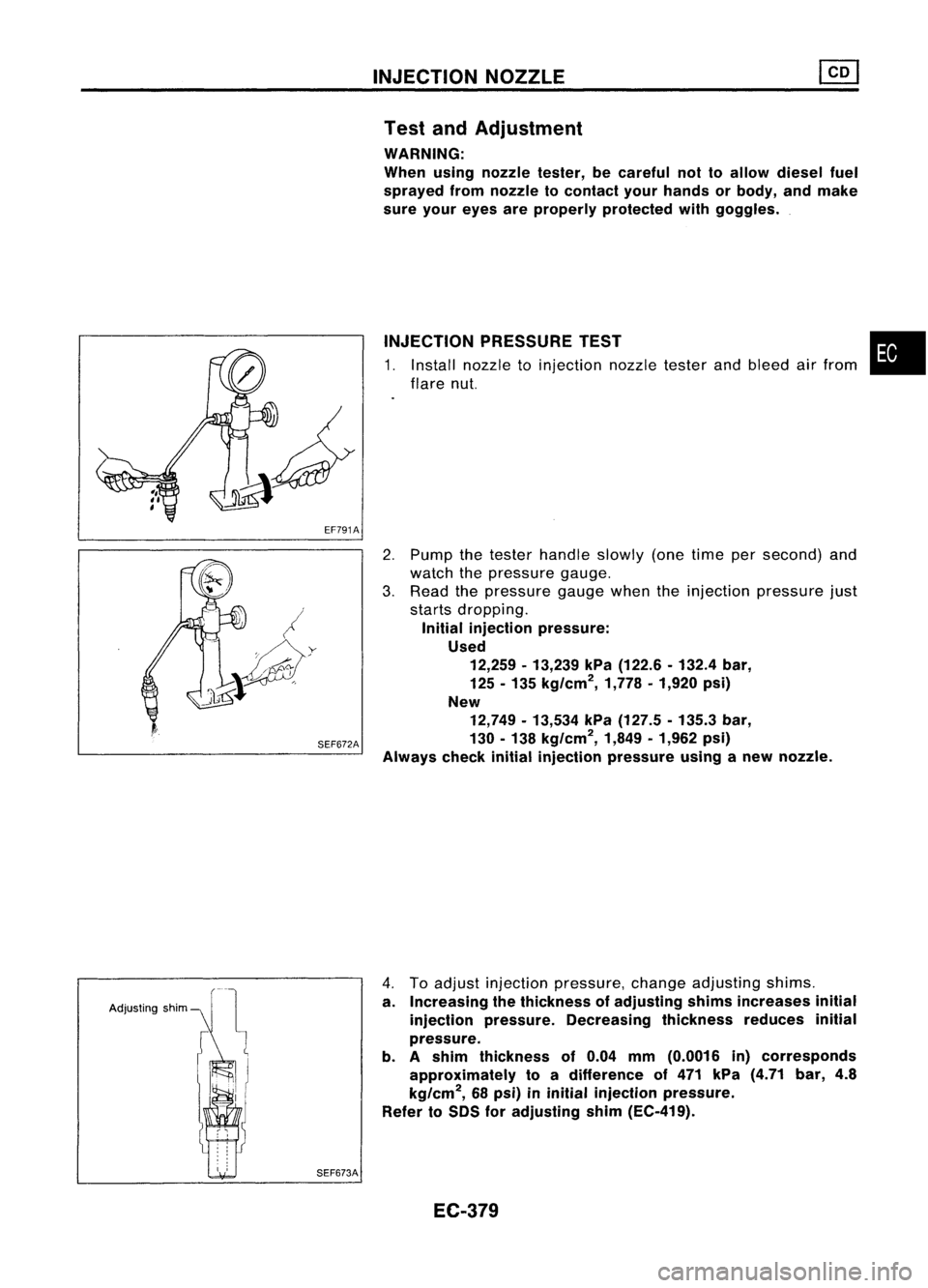

Test andAdjustment

WARNING:

When usingnozzle tester,becareful nottoallow diesel fuel

sprayed fromnozzle tocontact yourhands orbody, andmake

sure your eyes areproperly protected withgoggles .

INJECTION PRESSURE TEST

1. Install nozzle toinjection nozzletesterandbleed airfrom

flare nut.

•

SEF672A

2.

Pump thetester handle slowly(onetime persecond) and

watch thepressure gauge.

3. Read thepressure gaugewhentheinjection pressure just

starts dropping.

Initial injection pressure:

Used 12,259 -13,239 kPa(122.6 -132.4 bar,

125 -135 kg/cm

2,

1,778•1,920 psi)

New 12,749 -13,534 kPa(127.5 -135.3 bar,

130 -138 kg/cm

2,

1,849•1,962 psi)

Always checkinitialinjection pressure usinganew nozzle.

Adjusting shim

SEF673A

4.

Toadjust injection pressure, changeadjusting shims.

a. Increasing thethickness ofadjusting shimsincreases initial

injection pressure. Decreasing thicknessreducesinitial

pressure.

b. Ashim thickness of0.04 mm(0.0016 in)corresponds

approximately toadifference of471 kPa (4.71 bar,4.8

kg/cm

2,

68psi) ininitial injection pressure.

Refer toSDS foradjusting shim(EC-419).

EC-379

Page 1099 of 1701

INJECTIONNOZZLE ~

Test andAdjustment (Cont'd)

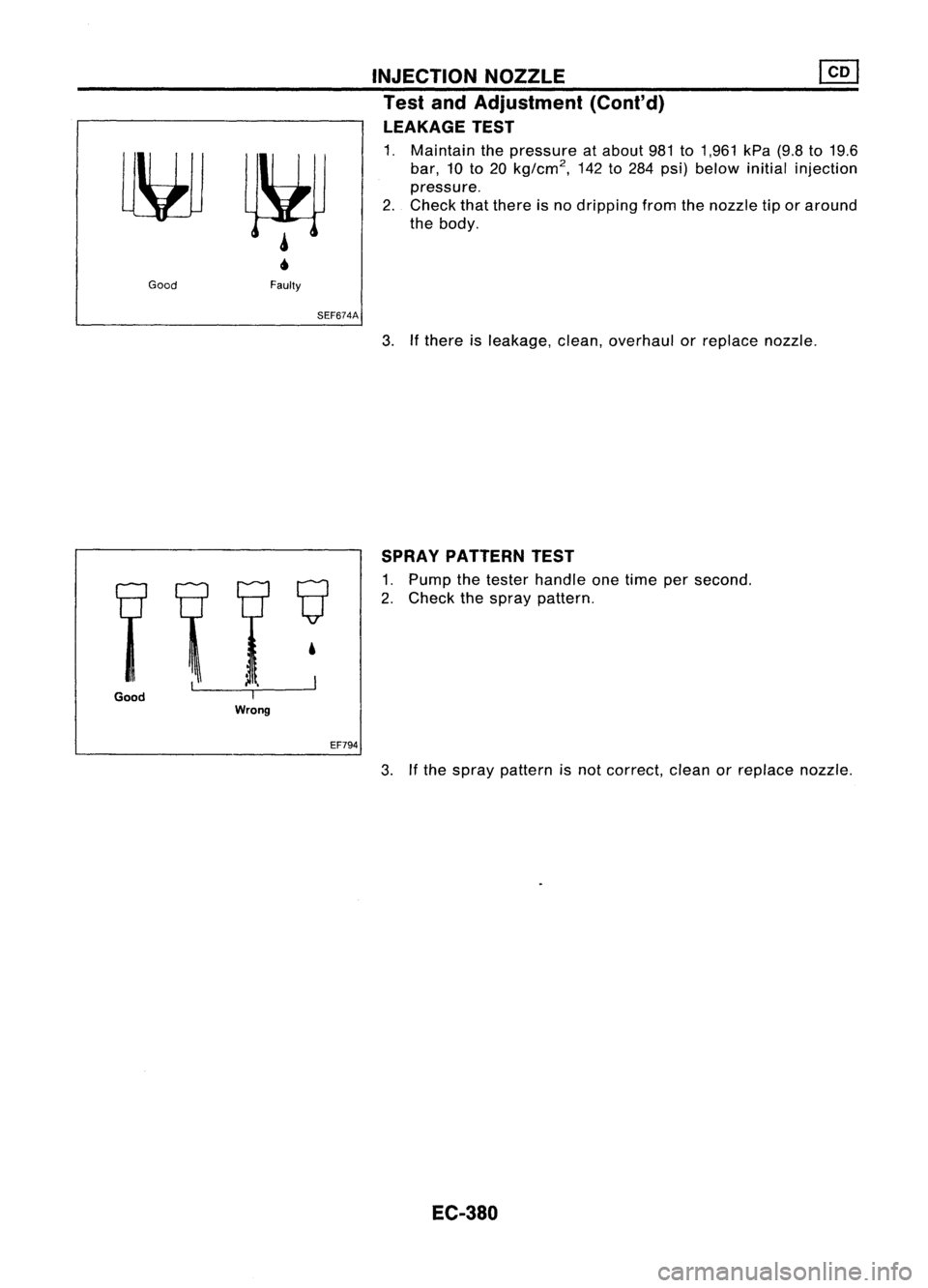

LEAKAGE TEST

1. Maintain thepressure atabout 981to1,961 kPa(9.8to19.6

bar, 10to20 kg/cm

2,

142to284 psi) below initialinjection

pressure.

2. Check thatthere isno dripping fromthenozzle tiporaround

the body.

Good

Faulty

SEF674A

3.Ifthere isleakage, clean,overhaul orreplace nozzle.

Good

I

Wrong

•

EF794 SPRAY

PATTERN TEST

1. Pump thetester handle onetime persecond.

2. Check thespray pattern .

3. Ifthe spray pattern isnot correct, cleanorreplace nozzle.

EC-380

Page 1100 of 1701

FUELSYSTEM CHECK

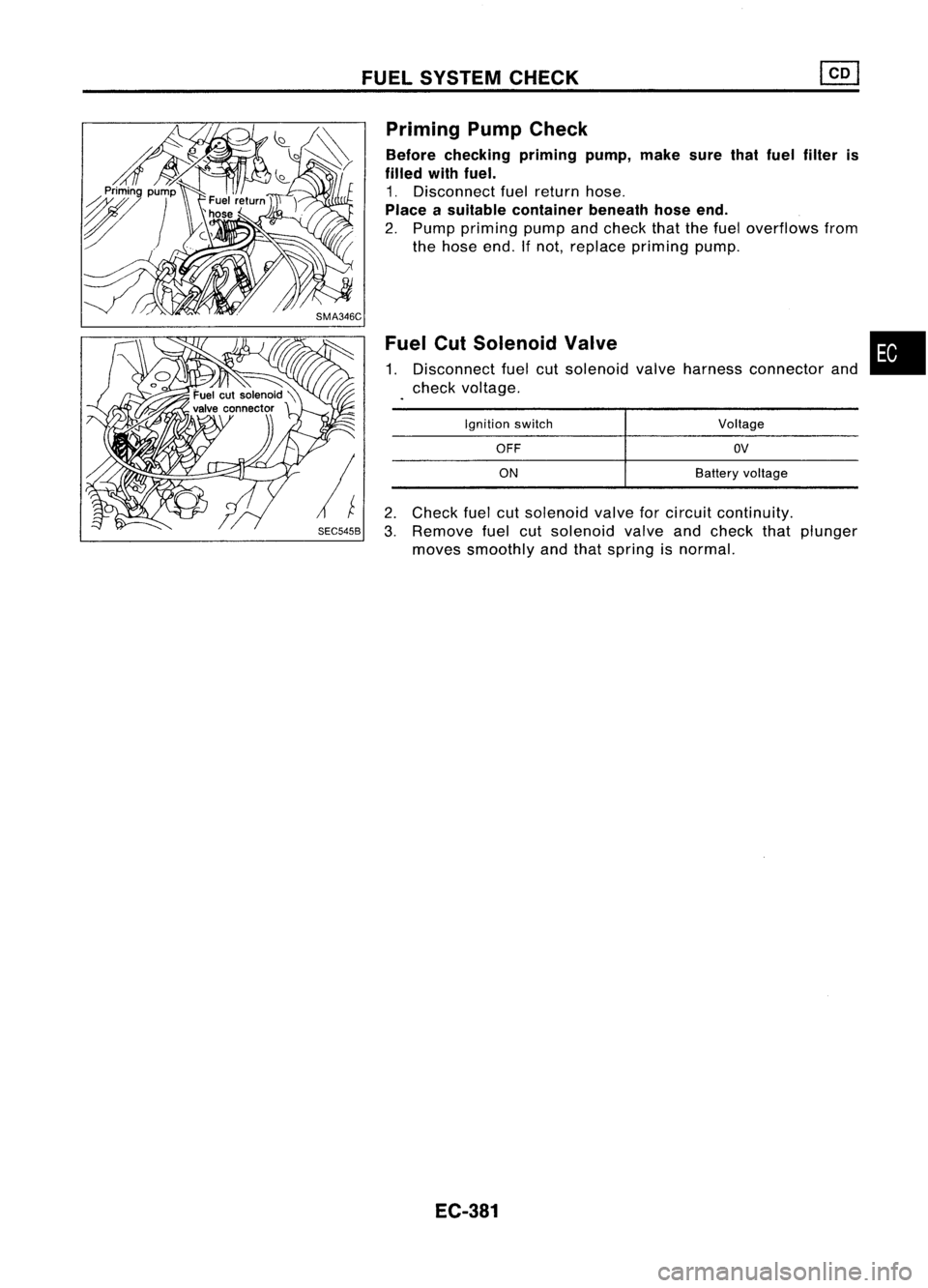

2. Check fuelcutsolenoid valveforcircuit continuity.

3. Remove fuelcutsolenoid valveandcheck thatplunger

moves smoothly andthat spring isnormal.

Fuel

CutSolenoid Valve

1. Disconnect fuelcutsolenoid valveharness connector and

check voltage.

Priming

PumpCheck

Before checking primingpump,makesurethatfuel filter is

filled withfuel.

1. Disconnect fuelreturn hose.

Place asuitable container beneathhoseend.

2. Pump priming pumpandcheck thatthefuel overflows from

the hose end.Ifnot, replace priming pump.

•

Voltage

OV

Battery voltage

OFF

ON

Ignition

switch

EC-381