NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1191 of 1701

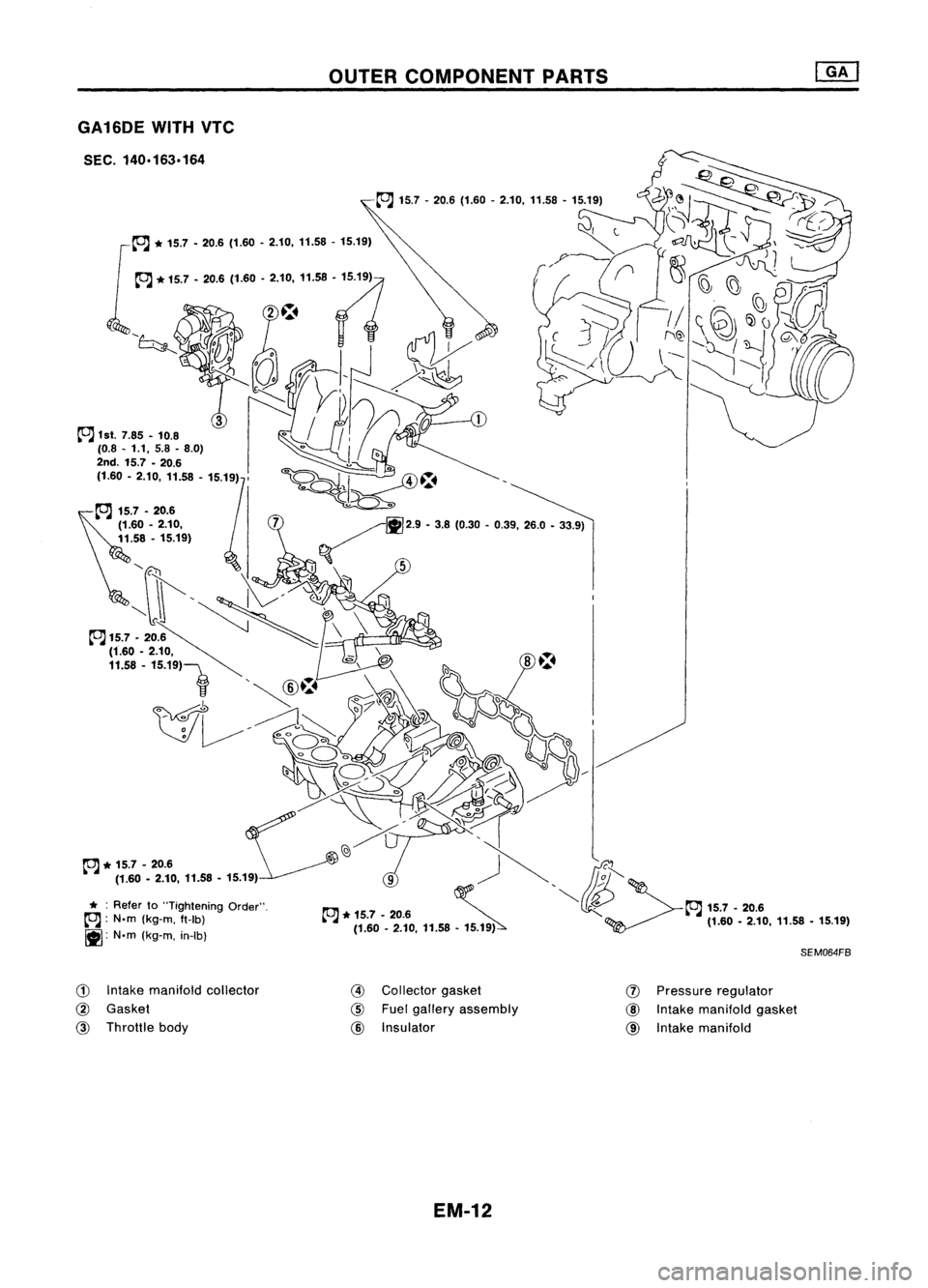

GA16DEWITHVTC

SEC. 140.163.164

~ 1st.

7.85 •10.8

(0.8. 1.1,5.8.8.0)

G)

Intake manifold collector

@

Gasket

@

Throttle body

OUTER

COMPONENT PARTS

@

Collector gasket

@

Fuelgallery assembly

@

Insulator

EM-12

(J)

Pressure regulator

@

Intake manifold gasket

@

Intake manifold

SEM064FB

Page 1192 of 1701

OUTERCOMPONENT PARTS

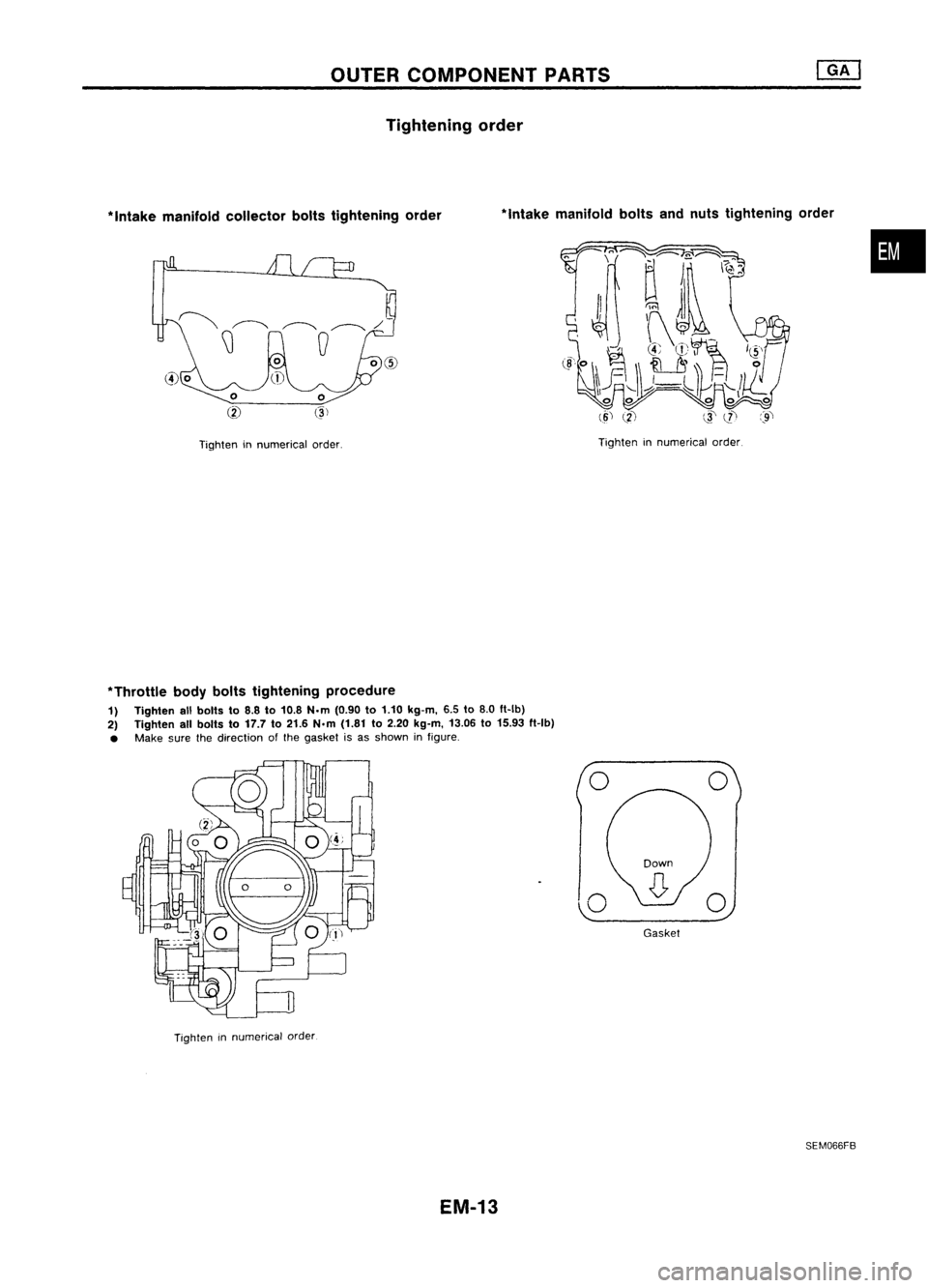

Tightening order

*

Intake manifold collector boltstightening order

Tighten innumerical order.

*Intake

manifold boltsandnuts tightening order

Tighten innumerical order.

•

*Throttle bodybolts tightening procedure

1) Tighten allbolts to8.8 to10.8 N.m (0.90 to1.10 kg-m, 6.5to8.0 ft-Ib)

2) Tighten allbolts to17.7 to21.6 N.m (1.81 to2.20 kg-m, 13.06to15.93 ft-Ib)

• Make surethedirection ofthe gasket isas shown infigure.

Tighten innumerical order

EM-13

o

,,-0

Gasket

o

SEM066FB

Page 1193 of 1701

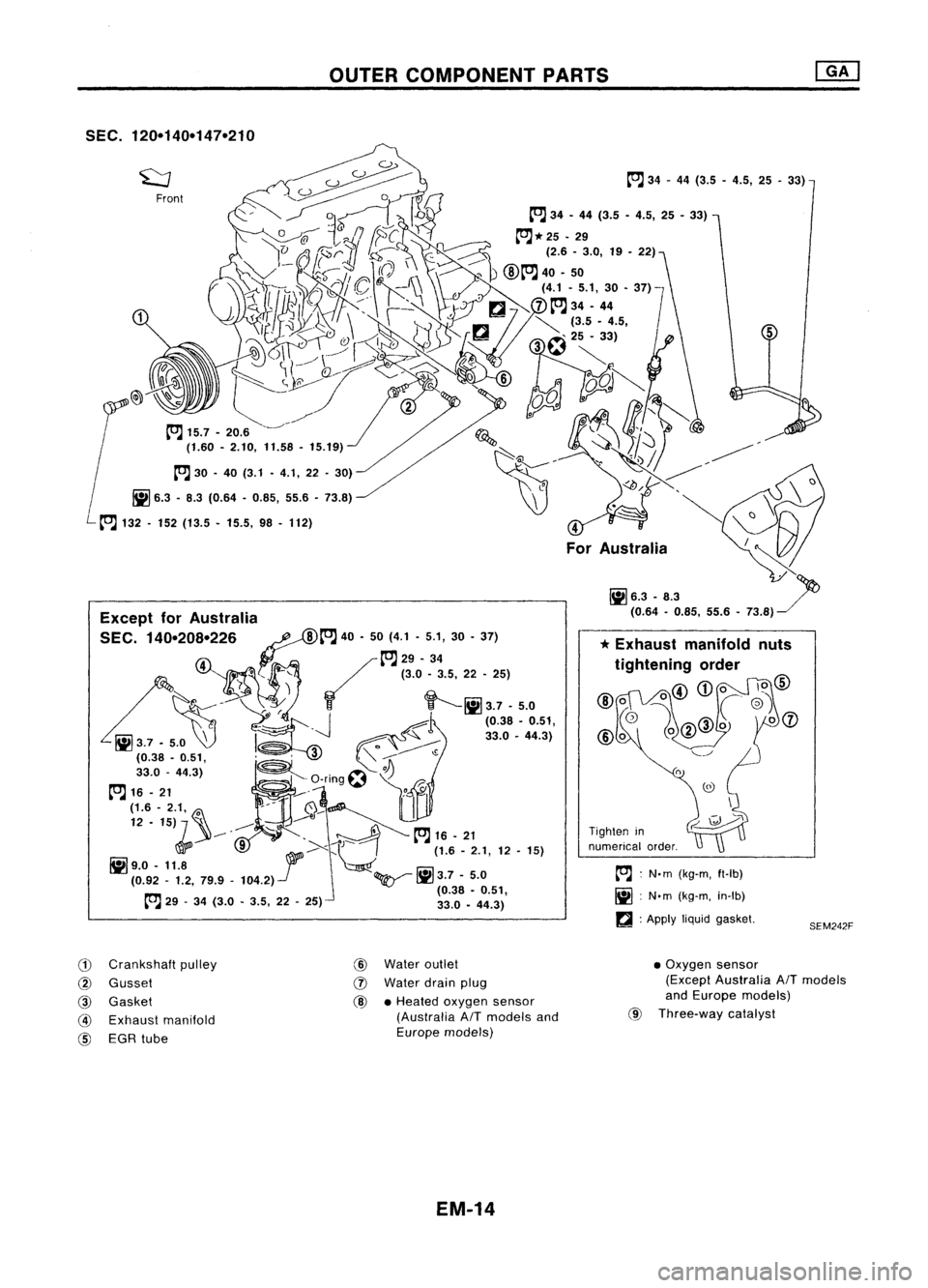

OUTERCOMPONENT PARTS

SEC. 120-140-147-210

Front

Except forAustralia

SEC. 140-208-226

P::~

40•50 (4.1 •5.1, 30•37)

~ ~~29-34

L

'r•,

t::~

(3.0-3.5, 22-25)

I'! - ~

r.e.t

r r

tf------- ~

3.7 -5.0

c -____

J

~l

(0.38•0.51,

~37'~

f'~~~

330-4431

(0.38 -0.51, ~

~Q;f;~

330 -443)

Ji

O'

L"'}.

J)

~ -rlng~

r

[O;J

16-21 _

y-' "

(1.6 -2.1, ~ ---

~~~I

12 •15) '\ ,-"

-- - .•to.]

16-21

!il',0 _

,,+ ·<1J1'>:t;)

(1.• -

2.1,

12-15)

(0.92 -1.2, 79.9_104.2).../ ~1iI3.7-5.0

rrTl

(0.38•0.51,

~-~ 29-34 (3.0 •3.5, 22•25) 33.0•44.3)

4

For Australia

Tighten in

numerical order.

~ :N.m (kg-m, ft-Ib)

1iI :N'm (kg-m, in-Ib)

a :

Apply

liquidgasket.

5

SEM242F

G)

Crankshaft pulley

@

Gusset

@

Gasket

@

Exhaust manifold

@

EGR tube

@

Water outlet

IJ)

Water drainplug

@ •

Heated oxygen sensor

(Australia

AIT

models and

Europe models)

EM-14

•

Oxygen sensor

(Except Australia

AIT

models

and Europe models)

@

Three-way catalyst

Page 1194 of 1701

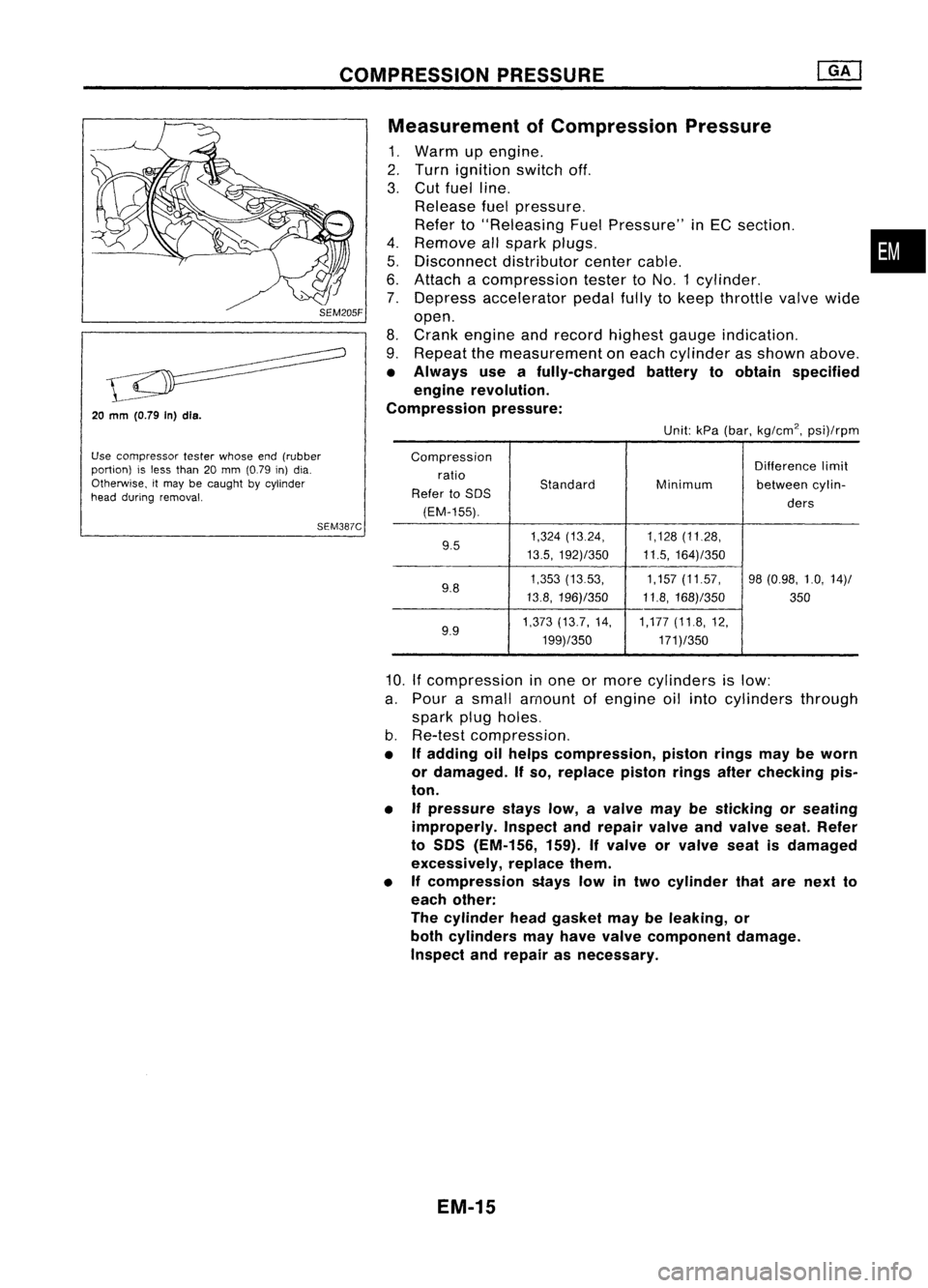

COMPRESSIONPRESSURE

20

mm

(O.79 In)dls.

Use compressor testerwhose end(rubber

portion) isless than 20mm (0.79 in)dia.

Otherwise, itmay becaught bycylinder

head during removal.

SEM387CMeasurement

ofCompression Pressure

1. Warm upengine.

2. Turn ignition switchoff.

3. Cut fuel line.

Release fuelpressure.

Refer to"Releasing FuelPressure" inEC section. •

4. Remove allspark plugs.

5. Disconnect distributorcentercable.

6. Attach acompression testertoNO.1 cylinder.

7. Depress accelerator pedalfullytokeep throttle valvewide

open.

8. Crank engine andrecord highest gaugeindication.

9. Repeat themeasurement oneach cylinder asshown above.

• Always useafully-charged batterytoobtain specified

engine revolution.

Compression pressure:

Unit:kPa(bar, kg/cm

2,

psi)/rpm

Compression Differencelimit

ratio

Standard

Refer toSOS Minimum

betweencylin-

(EM-155). ders

9.5 1,324

(13.24, 1,128(11.28,

13.5, 192)/350 11.5,164)/350

9.8 1,353

(1353, 1,157(11.57, 98(0.98, 1.0,14)/

13.8, 196)/350 11.8,168)/350

350

9.9 1,373

(13.7, 14, 1,177(11.8,12,

199)/350 171)/350

10.

If

compression inone ormore cylinders islow:

a. Pour asmall amount ofengine oilinto cylinders through

spark plugholes.

b. Re-test compression,

• Ifadding oilhelps compression, pistonringsmaybeworn

or damaged. Ifso, replace pistonringsafterchecking pis-

ton.

• Ifpressure stayslow,avalve maybesticking orseating

improperly. Inspectandrepair valveandvalve seat.Refer

to SOS (EM-156, 159).Ifvalve orvalve seatisdamaged

excessively, replacethem.

• Ifcompression stayslowintwo cylinder thatarenext to

each other:

The cylinder headgasket maybeleaking, or

both cylinders mayhave valve component damage.

Inspect andrepair asnecessary.

EM-15

Page 1195 of 1701

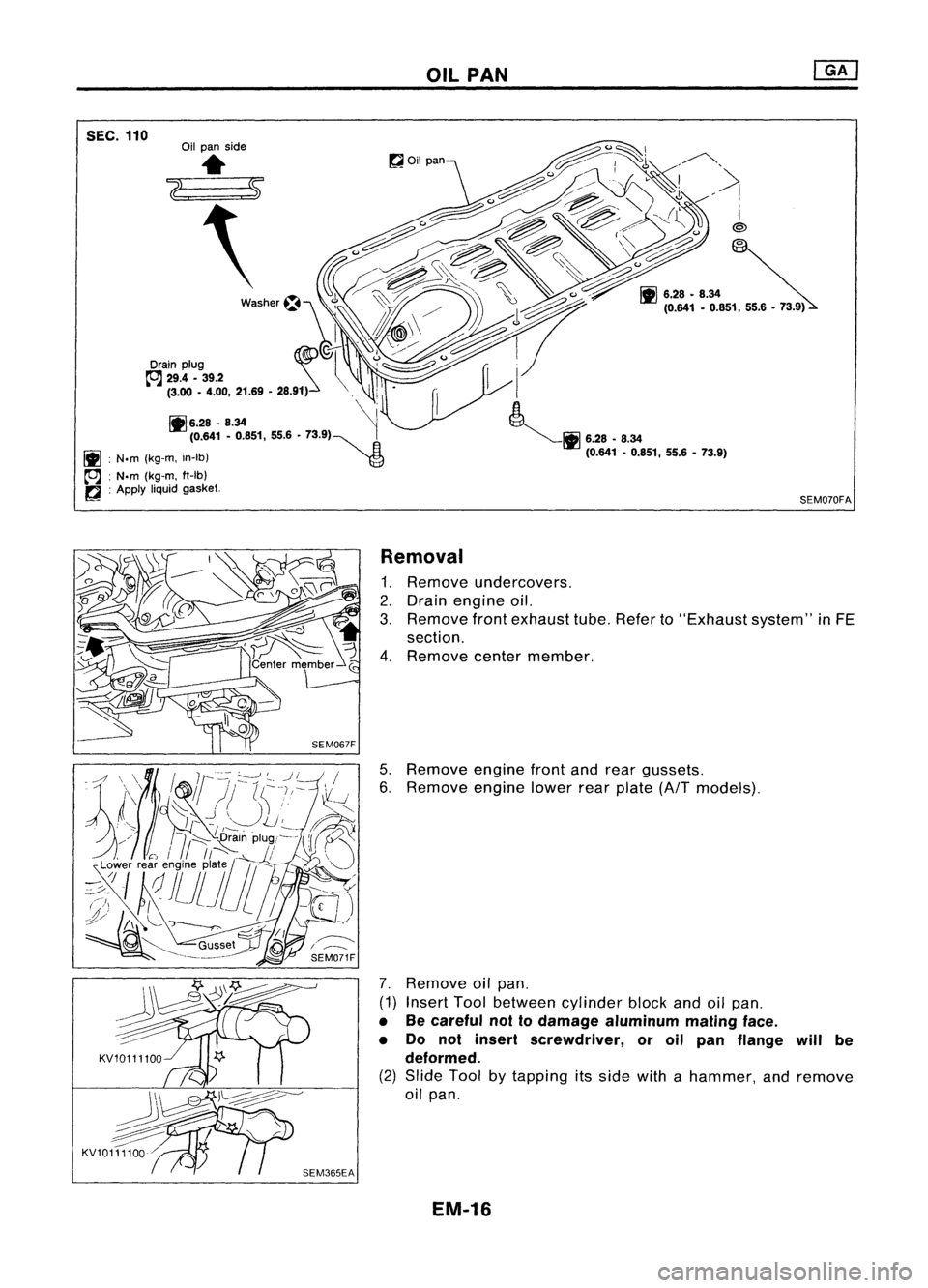

SEC.110

OIL

PAN

SEM070FA

Removal

1. Remove undercovers.

2. Drain engine oil.

3. Remove frontexhaust tube.Refer to"Exhaust system"inFE

section.

4. Remove centermember.

5. Remove enginefrontandrear gussets.

6. Remove enginelowerrearplate (AfTmodels).

7. Remove oilpan.

(1) Insert Toolbetween cylinderblockandoilpan.

• Becareful nottodamage aluminum matingface.

• Do not insert screwdriver, oroil pan flange willbe

deformed.

(2) Slide Toolbytapping itsside withahammer, andremove

oil pan.

EM-16

Page 1196 of 1701

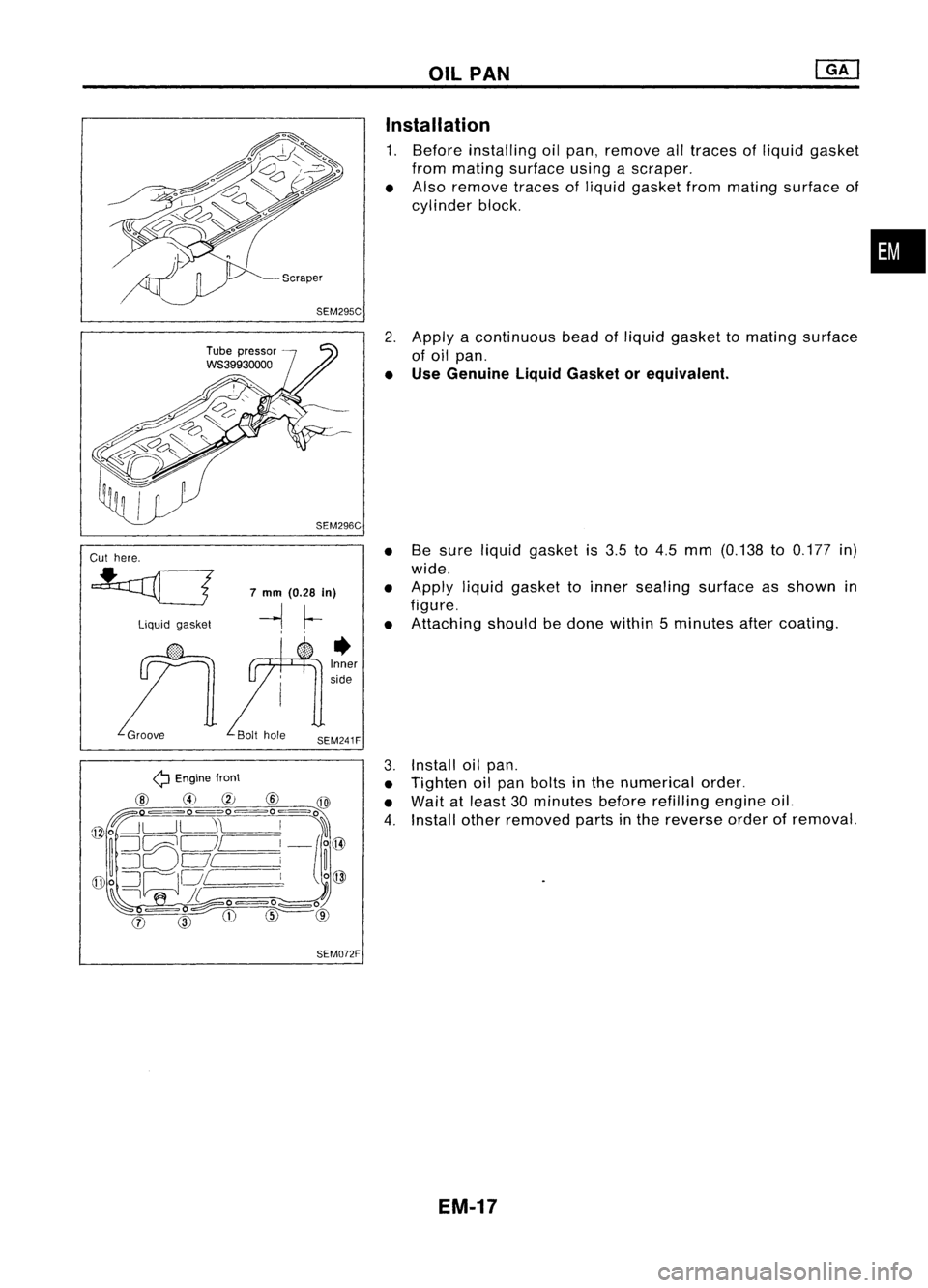

OilPAN

SEM295C Installation

1. Before installing oilpan,

remove

alltraces ofliquid gasket

from mating surface usingascraper.

• Also

remove

tracesofliquid gasket frommating surface of

cylinder block.

•

Cut here.

liquid gasket

7

mm

(0.28

in)

-1 ~

•

Inner

side

2.

Apply acontinuous beadofliquid gasket tomating surface

of oil pan.

• Use Genuine LiquidGasket orequivalent.

• Besure liquid gasket is3.5 to4.5 mm (0.138 to0.177 in)

wide.

• Apply liquidgasket toinner sealing surface asshown in

figure.

• Attaching shouldbedone within 5minutes aftercoating.

Q

Engine front

@

@

CV

@

@

~ ==O=O=O~o

@o~L-J~\

I

%

~ ~C:;;;}Oc=J/

I

_/o@

~ =:J

Of

i~

([Do

:=JODI

I

o@

~\I

JL.-=o=o

0

~ =

0~---

<:::::==

(j)

CIDCDW

@

SEM072F

3.

Install oilpan.

• Tighten oilpan bolts inthe numerical order.

• Wait atleast 30minutes beforerefilling engineoil.

4. Install other

removed

partsinthe reverse orderof

removal.

EM-17

Page 1197 of 1701

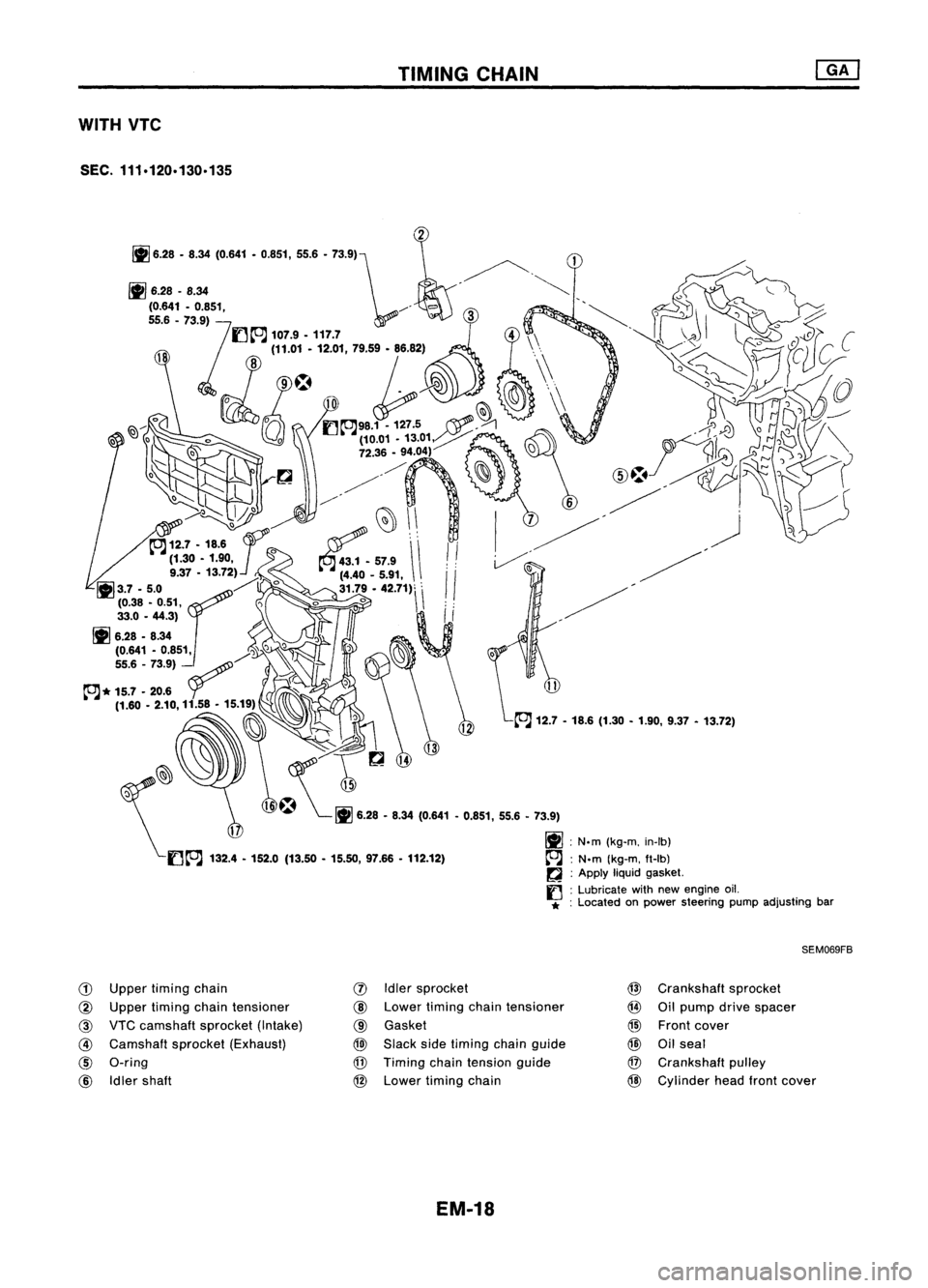

TIMINGCHAIN

WITH VTC

SEC. 111.120.130.135

~~

\£It''J

132.'.152.•(13 .... 15.... 97.&6 .112.12)

SEM069FB

CD

Upper timing chain

@

Upper timing chaintensioner

@

VTCcamshaft sprocket(Intake)

@

Camshaft sprocket(Exhaust)

@

O-ring

@

Idler shaft

(J)

Idlersprocket

@

Lower timing chaintensioner

@

Gasket

@)

Slack sidetiming chainguide

@

Timing chaintension guide

@

Lower timing chain

EM-18 @

Crankshaft sprocket

@

Oilpump drivespacer

@

Front cover

@

Oilseal

@

Crankshaft pulley

@

Cylinder headfrontcover

Page 1198 of 1701

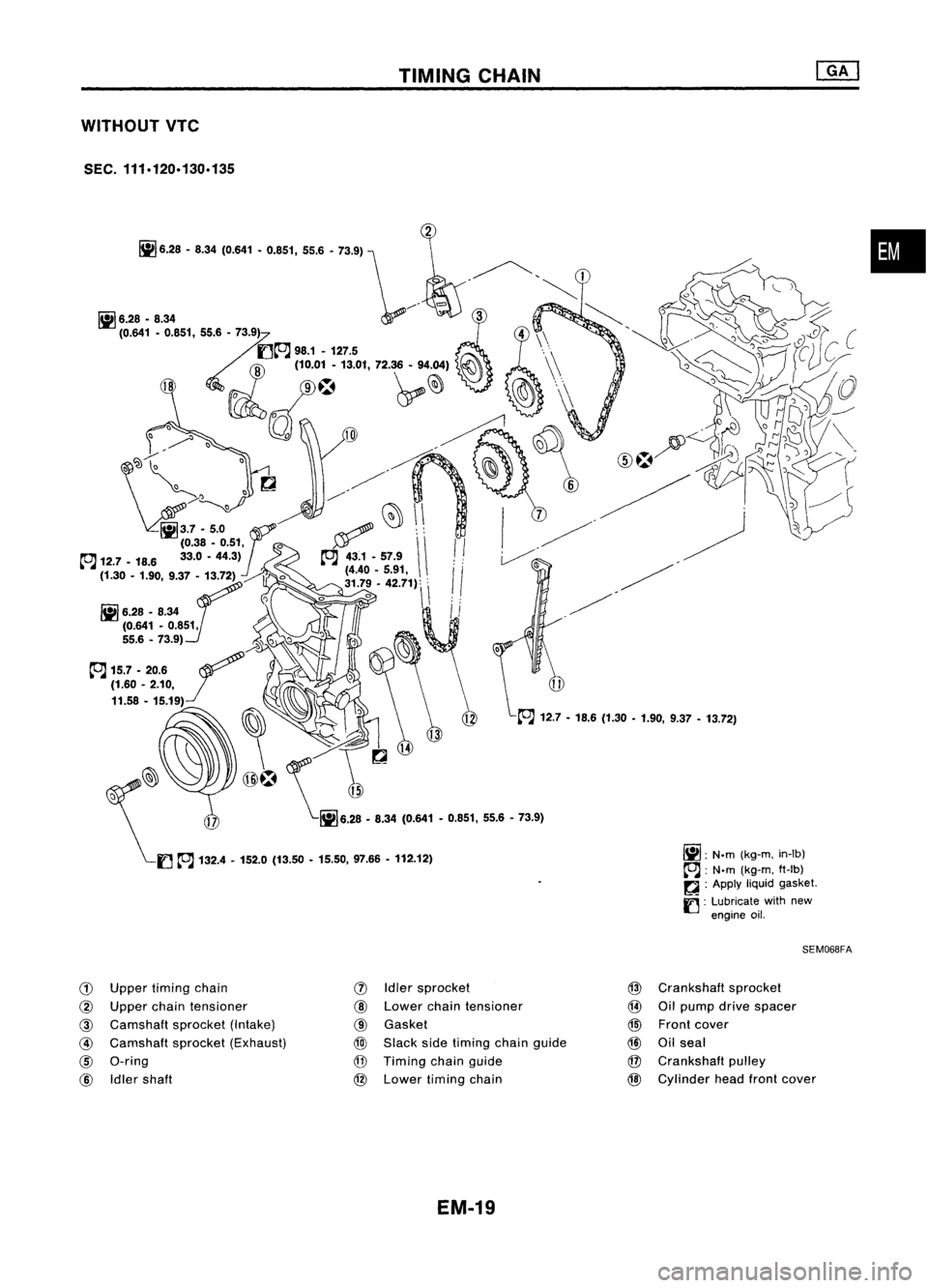

WITHOUT VTC

SEC. 111.120.130.135

G)

Upper timing chain

@

Upper chaintensioner

@

Camshaft sprocket(Intake)

@

Camshaft sprocket(Exhaust)

@)

a-ring

@

Idler shaft

TIMING

CHAIN

(j)

Idler sprocket

@

Lower chaintensioner

@

Gasket

@

Slack sidetiming chaingUide

@

Timing chainguide

@

Lower timing chain

EM-19

~:

N.m

(kg-m,

in-lb)

~ :N'm

(kg-m, ft-Ib)

~ :Apply

liquidgasket.

fJ :

Lubricate withnew

engine oil.

SEM068FA

@

Crankshaft sprocket

@

Oilpump drivespacer

@)

Front cover

@

Oilseal

@

Crankshaft pulley

@

Cylinder headfrontcover

•

Page 1199 of 1701

TIMINGCHAIN

Without

VTC

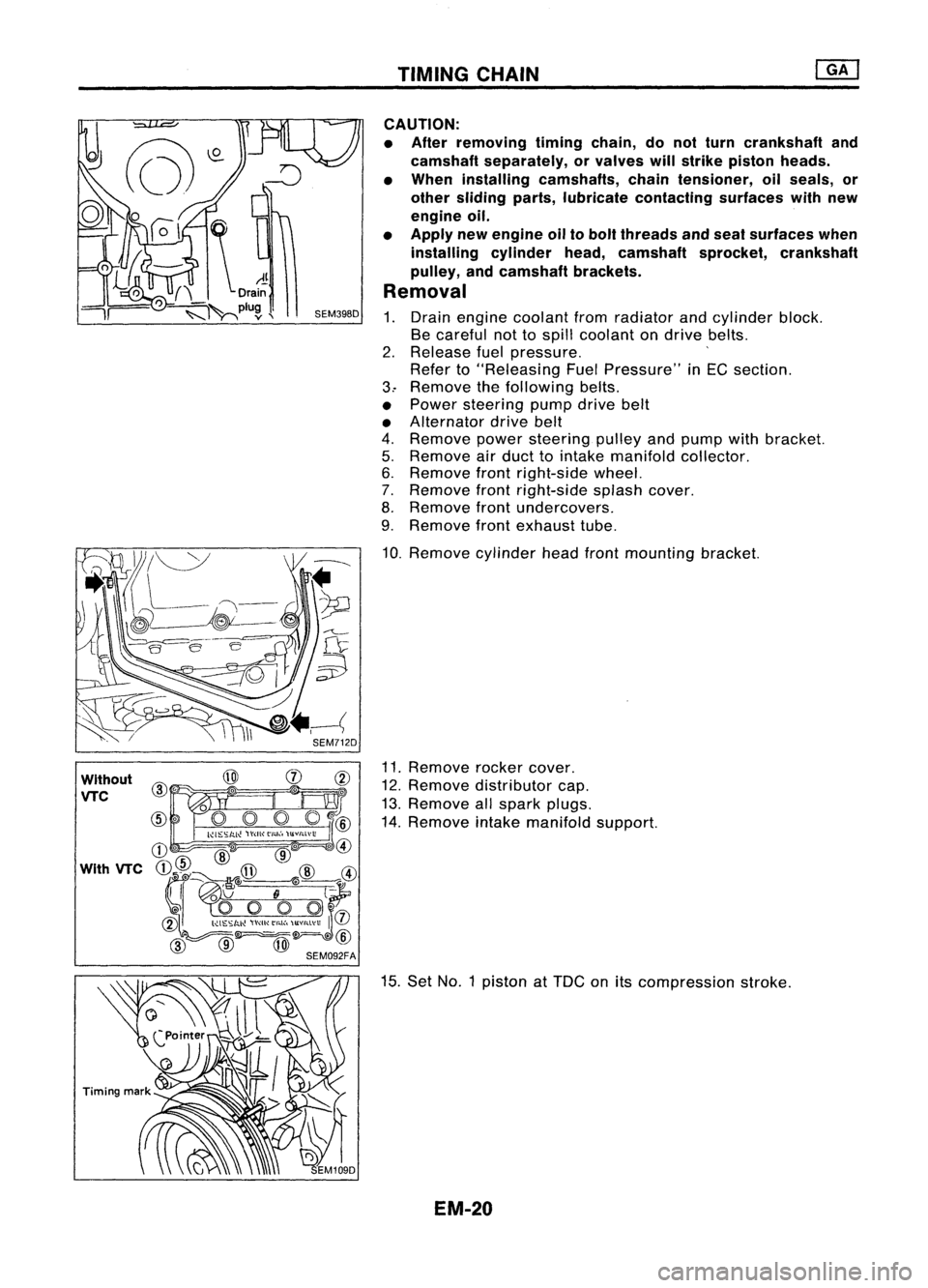

CAUTION:

• After removing timingchain,donot turn crankshaft and

camshaft separately, orvalves willstrike piston heads.

• When installing camshafts, chaintensioner, oilseals, or

other sliding parts,lubricate contacting surfaceswithnew

engine oil.

• Apply newengine oiltobolt threads andseat surfaces when

installing cylinderhead,camshaft sprocket,crankshaft

pulley, andcamshaft brackets.

Removal

1. Drain engine coolant fromradiator andcylinder block.

Be careful nottospill coolant ondrive belts.

2. Release fuelpressure. '

Refer to"Releasing FuelPressure" inEG section.

3.. Remove thefollowing belts.

• Power steering pumpdrivebelt

• Alternator drivebelt

4. Remove powersteering pulleyandpump withbracket.

5. Remove airduct tointake manifold collector.

6. Remove frontright-side wheel.

7. Remove frontright-side splashcover.

8. Remove frontundercovers.

9. Remove frontexhaust tube.

10. Remove cylinderheadfrontmounting bracket.

11. Remove rockercover.

12. Remove distributor cap.

13. Remove allspark plugs.

14. Remove intakemanifold support.

15. Set NO.1 piston at

TOG

onitscompression stroke.

EM-20

Page 1200 of 1701

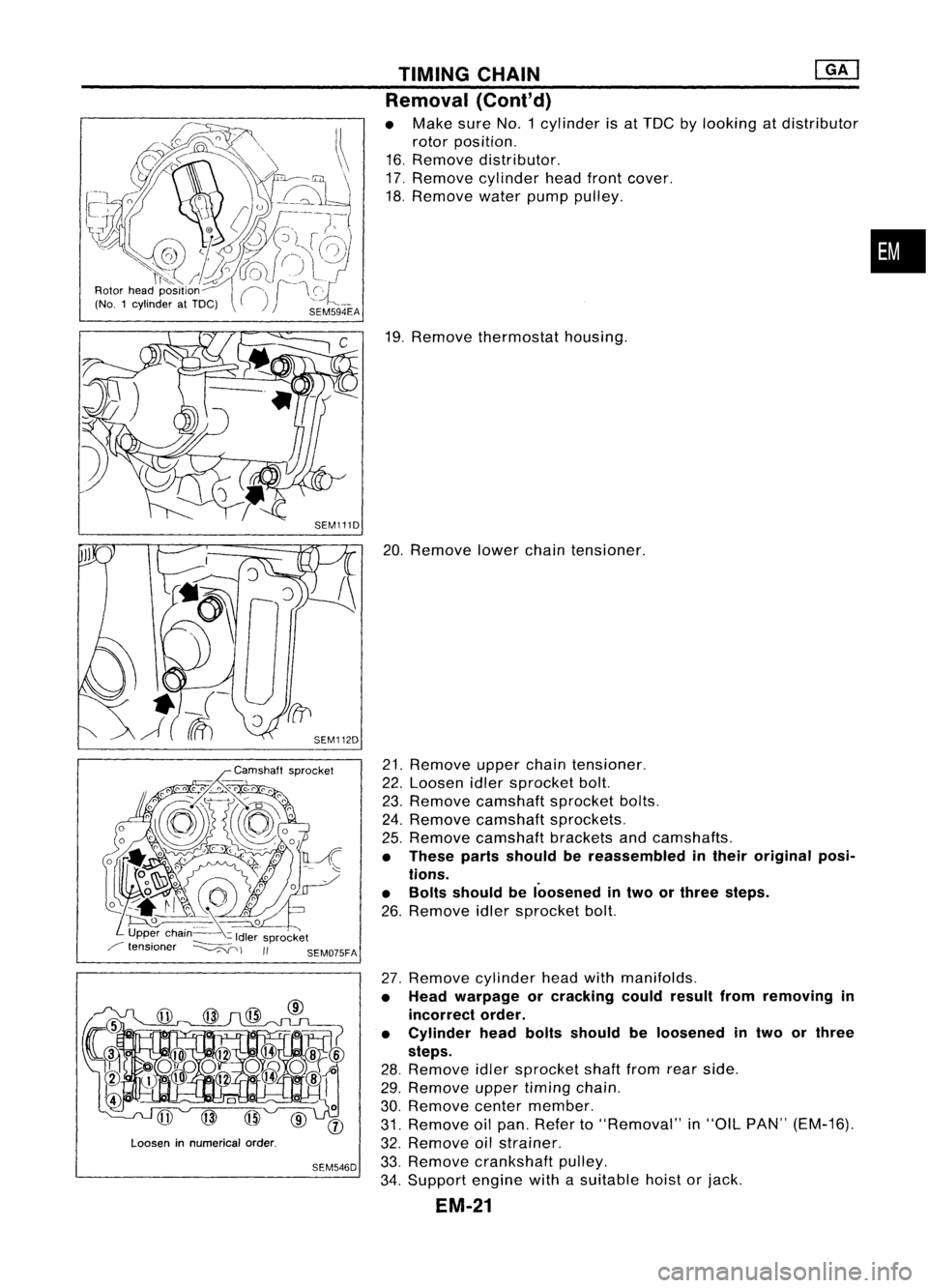

Looseninnumerical order.

SEM546D TIMING

CHAIN @KJ

Removal (Cont'd)

• Make sureNo.1 cylinder isat TDC bylooking atdistributor

rotor position.

16. Remove distributor.

17. Remove cylinder headfrontcover.

18. Remove waterpumppulley.

19. Remove thermostat housing.

20. Remove lowerchaintensioner.

21. Remove upperchaintensioner.

22. Loosen idlersprocket bolt.

23. Remove camshaft sprocketbolts.

24. Remove camshaft sprockets.

25. Remove camshaft bracketsandcamshafts.

• These partsshould bereassembled intheir original posi-

tions.

• Bolts should beloosened intwo orthree steps.

26. Remove idlersprocket bolt.

27. Remove cylinderheadwithmanifolds.

• Head warpage orcracking couldresult fromremoving in

incorrect order.

• Cylinder headboltsshould beloosened intwo orthree

steps.

28. Remove idlersprocket shaftfromrearside.

29. Remove uppertiming chain.

30. Remove centermember.

31. Remove oilpan. Refer to"Removal" in"OIL PAN" (EM-16).

32. Remove oilstrainer.

33. Remove crankshaft pulley.

34. Support enginewithasuitable hoistorjack.

EM-21

•