NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1411 of 1701

Open

Close

AIC

service valve

Counterclockwise

Clockwise

Shut

offvalve rotation

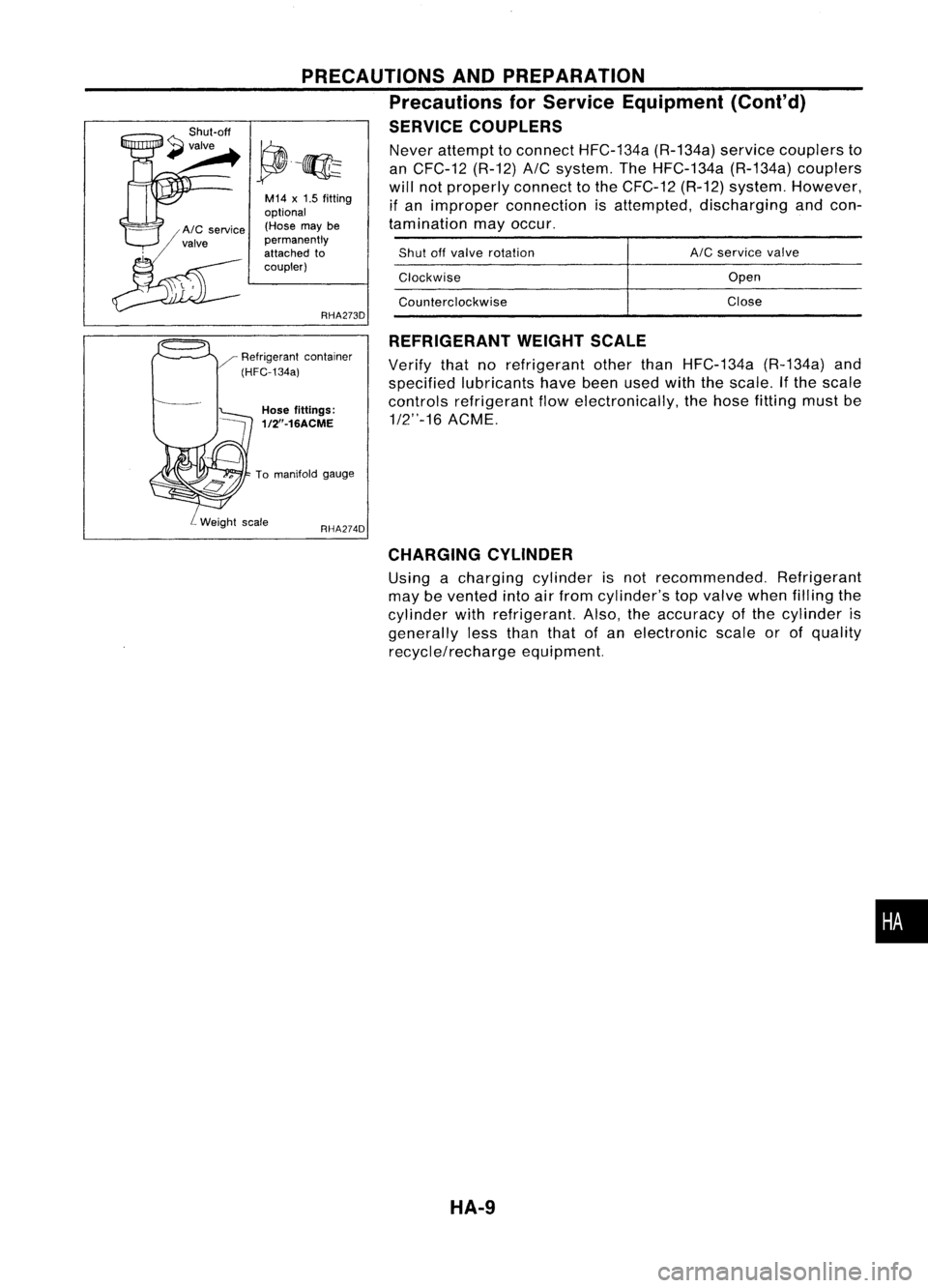

Never

attempt toconnect HFC-134a (R-134a)servicecouplers to

an CFC-12 (R-12)

A/C

system. TheHFC-134a (R-134a)couplers

will notproperly connecttothe CFC-12 (R-12)system. However,

if an improper connection isattempted, discharging andcon-

tamination mayoccur.

REFRIGERANT WEIGHTSCALE

Verify thatnorefrigerant otherthanHFC-134a (R-134a)and

specified lubricants havebeenusedwiththescale. Ifthe scale

controls refrigerant flowelectronically, thehose fitting mustbe

1/2"-16 ACME.

RHA274D

PRECAUTIONS

ANDPREPARATION

Precautions forService Equipment (Cont'd)

SERVICE COUPLERS

RHA273D

M14

x

1.5 fitting

optional (Hose maybe

permanently

attached to

coupler)

Hose fittings:

1/2"-16ACME

To manifold gauge

CHARGING CYLINDER

Using acharging cylinderisnot recommended. Refrigerant

may bevented intoairfrom cylinder's topvalve whenfilling the

cylinder withrefrigerant. Also,theaccuracy ofthe cylinder is

generally lessthan thatofan electronic scaleorofquality

recycle/recharge equipment.

•

HA-9

Page 1412 of 1701

DESCRIPTION

Refrigeration Cycle

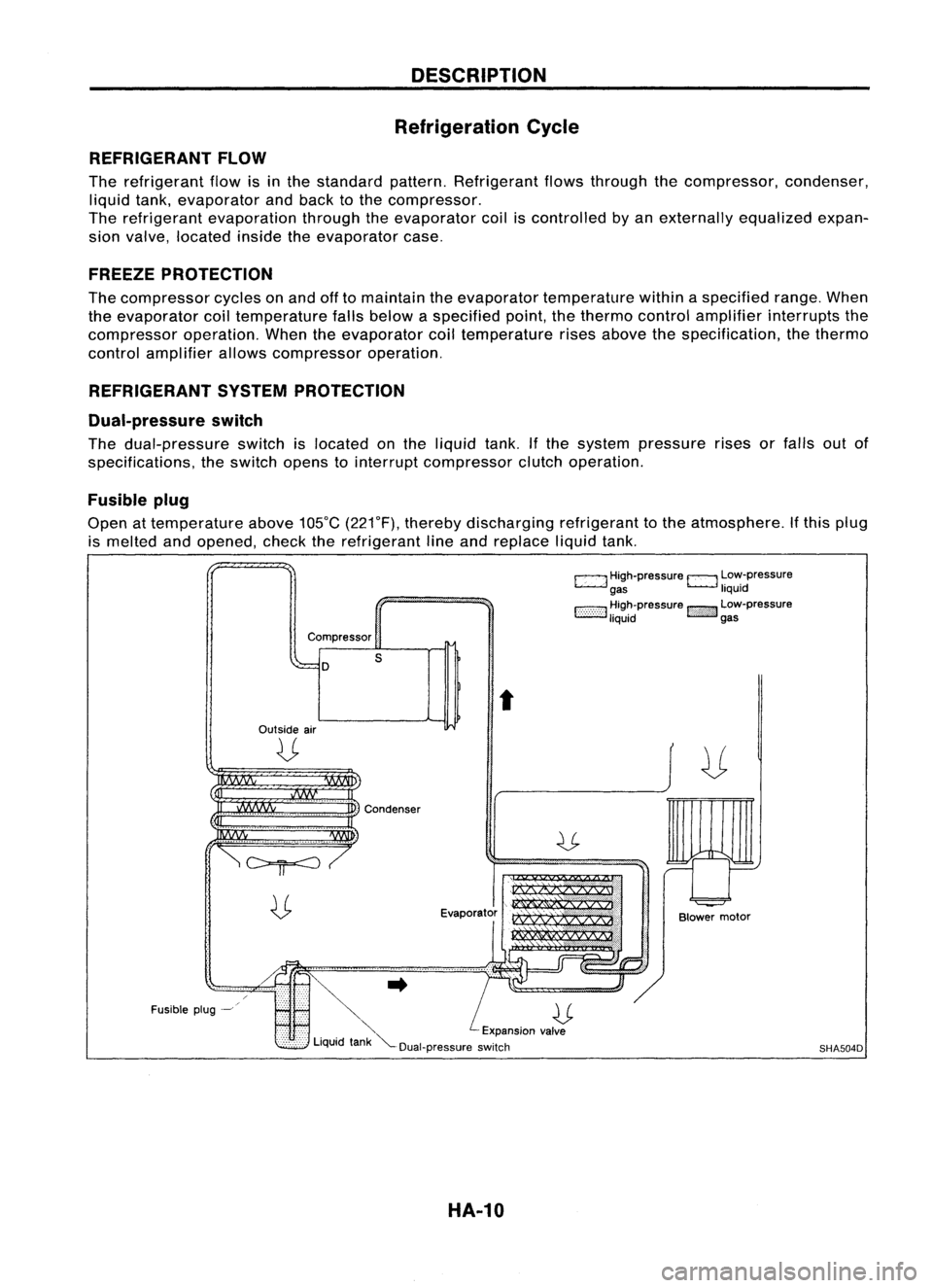

REFRIGERANT FLOW

The refrigerant flowisinthe standard pattern.Refrigerant flowsthrough thecompressor, condenser,

liquid tank,evaporator andback tothe compressor.

The refrigerant evaporation throughtheevaporator coiliscontrolled byan externally equalizedexpan-

sion valve, located insidetheevaporator case.

FREEZE PROTECTION

The compressor cyclesonand offtomaintain theevaporator temperature withinaspecified range.When

the evaporator coiltemperature fallsbelow aspecified point,thethermo controlamplifier interrupts the

compressor operation.Whentheevaporator coiltemperature risesabove thespecification, thethermo

control amplifier allowscompressor operation.

REFRIGERANT SYSTEMPROTECTION

Dual-pressure switch

The dual-pressure switchislocated onthe liquid tank.Ifthe system pressure risesorfalls outof

specifications, theswitch openstointerrupt compressor clutchoperation.

Fusible plug

Open attemperature above105°C(221°F), thereby discharging refrigeranttothe atmosphere. Ifthis plug

is melted andopened, checktherefrigerant lineand replace liquidtank.

c:::::.J

High-pressure

EJ

Low-pressure

gas liquid

1:-:-:-:-::-:-::-:-:1

~~~~pressure

!::i'i'i':}':J

~~:-pressure

Compressor

D

Outside air

U

s

t

Fusible plug-~

~..

U

'" Expansionvalve

Liquid tank"'--Dual-pressure switch

HA-10

Blower

motor

SHA504D

Page 1413 of 1701

270-271-272-273

SEC.

tnozzle

Side defros er

__________

~==D=ES=C~R~I~P~TI~O~N~~---------

Component Layout

Defroster nozzle

Sidedefroster nozzle

.1 tor duct

Side venlia Center

ventilator duct

Control assembly Side

ventilator duct

Cooling unit

•

D models. ositetothis layout.

.

.11 stration isfor

LH .

symmetrically opp

This

I

u RHOmodels

IS

The layout for

RHA312F

HA-11

Page 1414 of 1701

DESCRIPTION

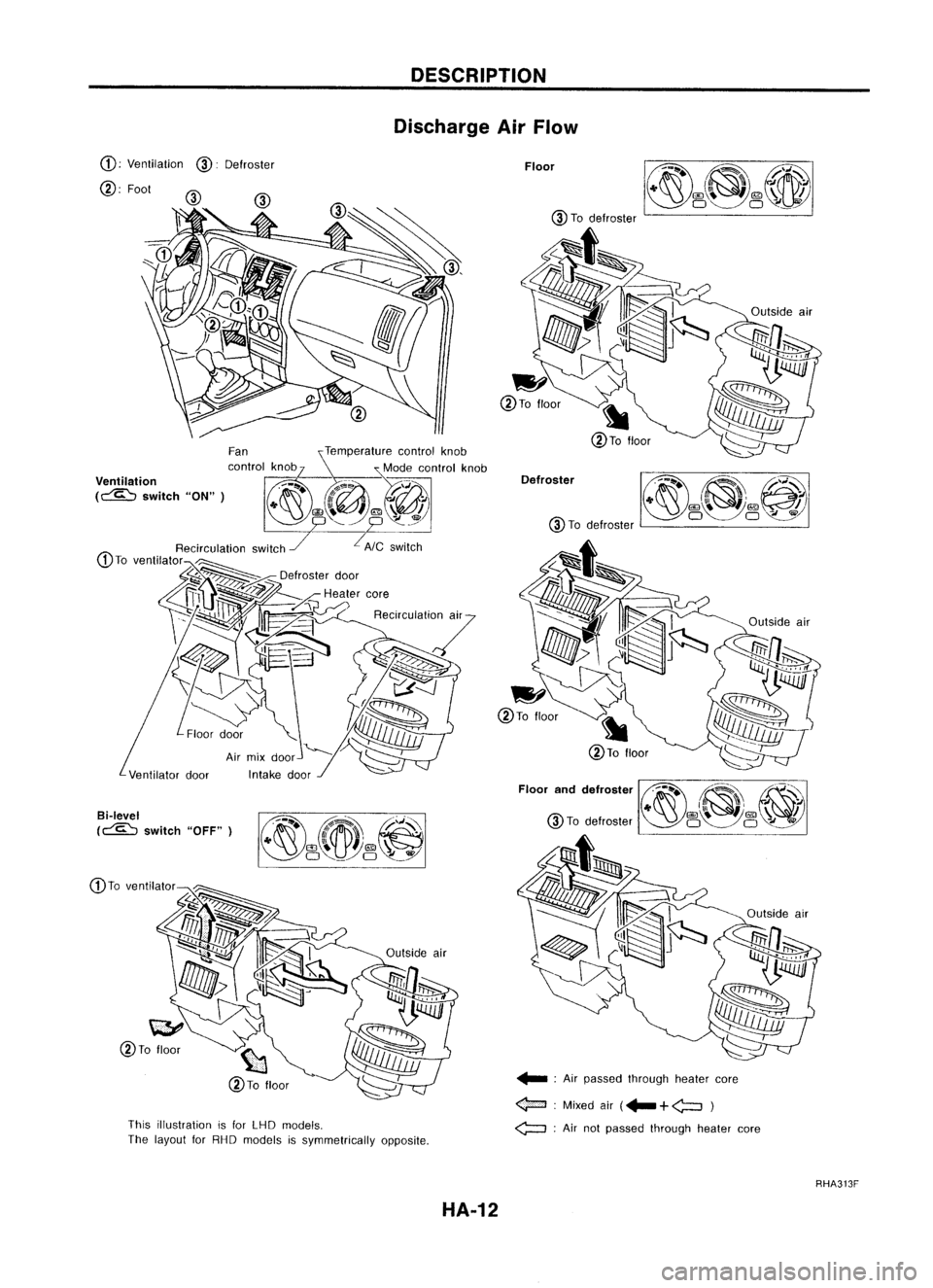

Discharge AirFlow

@ Todefroster

Floor

Defroster

.... ;Air passed through heatercore

<$=::I :

Mixed air(...

+

<;::::J )

<:;:::::J ;

Air not passed through heatercore

This

illustration isfor LHD models.

The layout forRHD models issymmetrically opposite.

Ventilator

door

CD;

Ventilation

@:

Defroster

@; Fool

Bi-Ievel

(~ switch"OFF")

RHA313F

HA-12

Page 1415 of 1701

DESCRIPTION

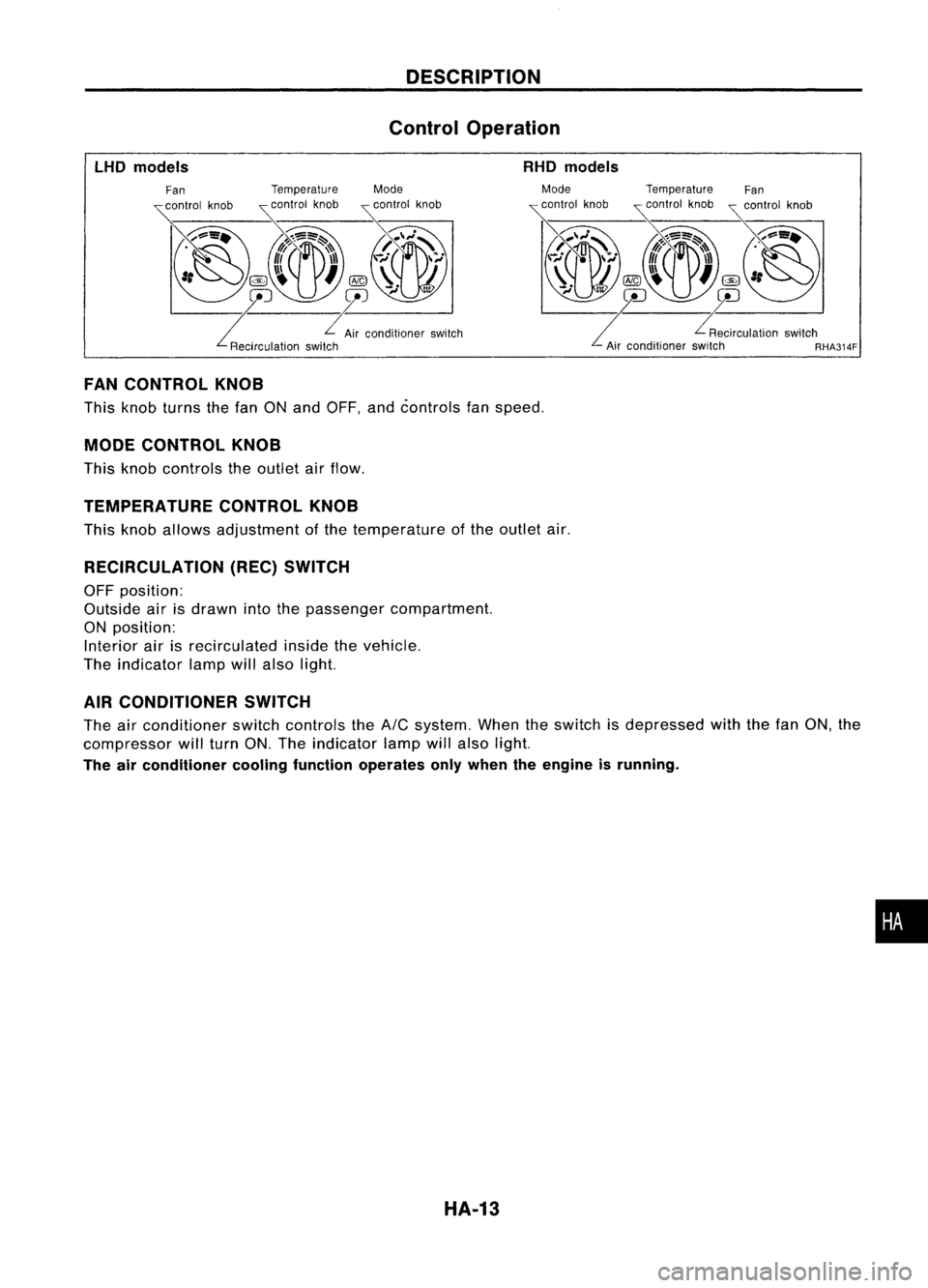

Control Operation

LHO models RHO

models

FAN CONTROL KNOB

This knob turns thefan ONand OFF, andcontrols fanspeed.

MODE CONTROL KNOB

This knob controls theoutlet airflow.

TEMPERATURE CONTROLKNOB

This knob allows adjustment ofthe temperature ofthe outlet air.

RECIRCULATION (REC)SWITCH

OFF position:

Outside airisdrawn intothepassenger compartment.

ON position:

Interior airisrecirculated insidethevehicle.

The indicator lampwillalso light.

AIR CONDITIONER SWITCH

The airconditioner switchcontrols the

Ale

system. Whentheswitch isdepressed withthefan ON, the

compressor willturn ON.The indicator lampwillalso light.

The airconditioner coolingfunction operates onlywhen theengine isrunning.

HA-13

•

Page 1416 of 1701

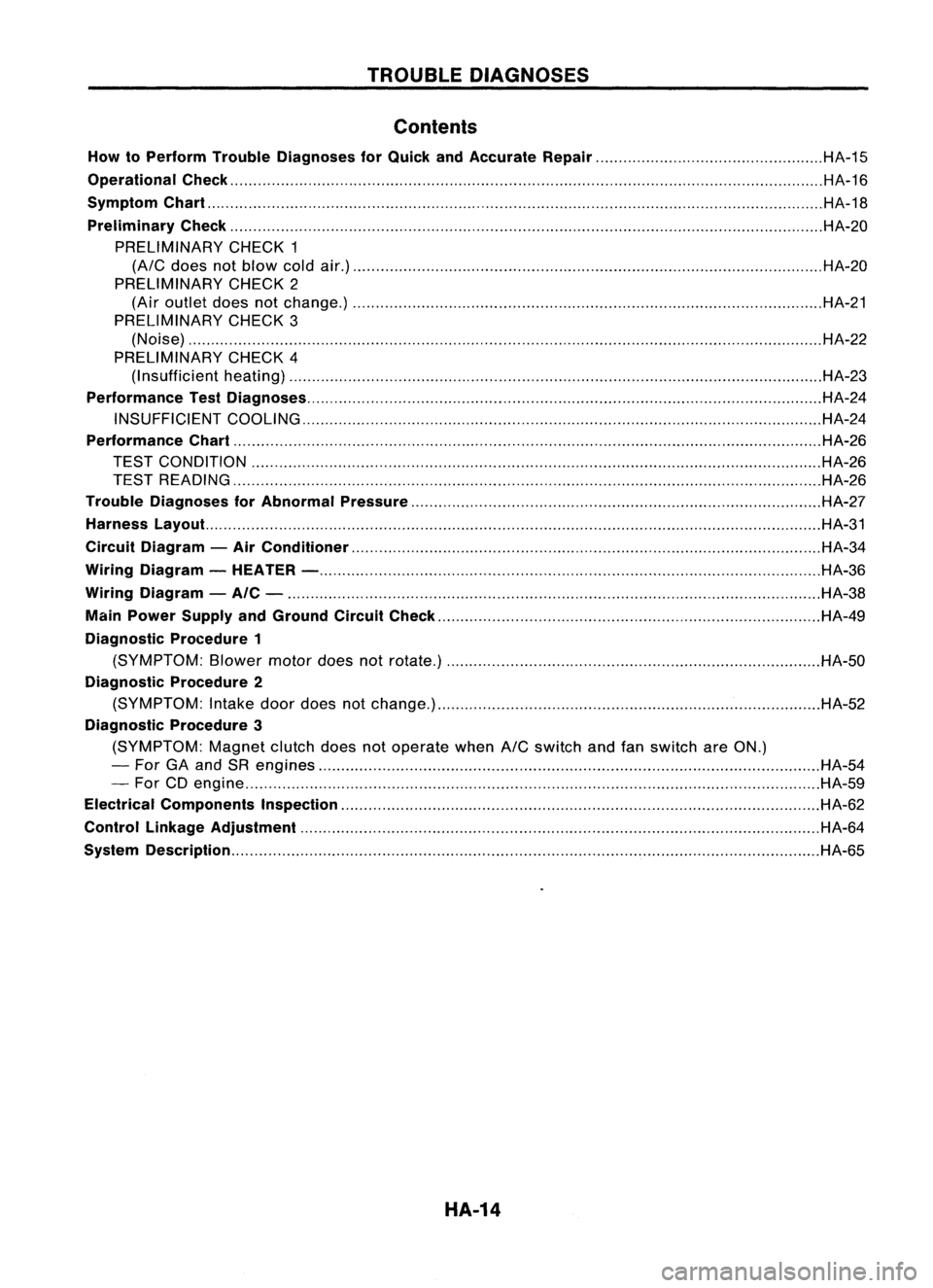

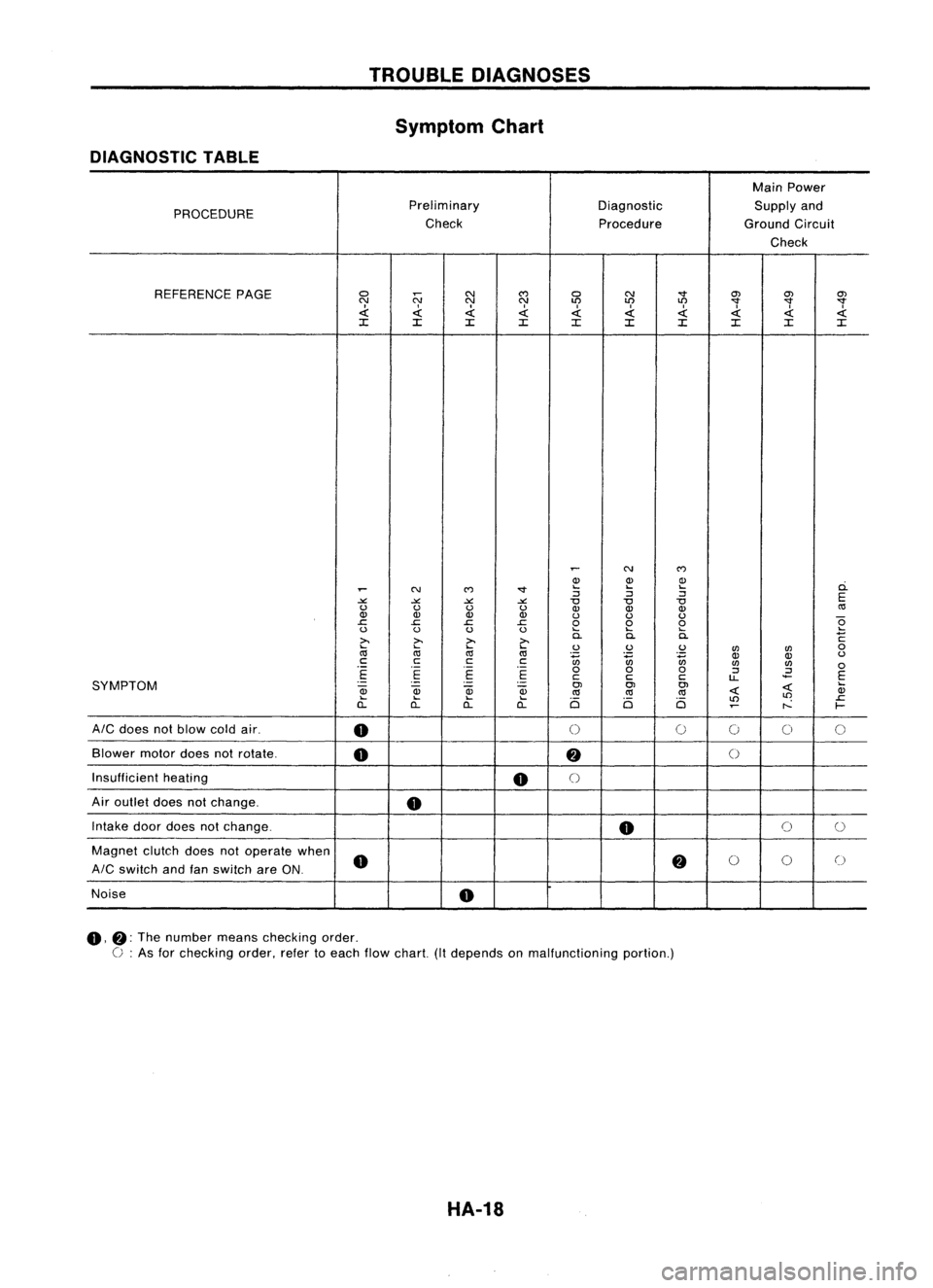

TROUBLEDIAGNOSES

Contents

How toPerform TroubleDiagnoses forQuick andAccurate Repair HA-15

Operational Check HA-16

Symptom Chart HA-18

Preliminary Check HA-20

PRELIMINARY CHECK1

(A/C

does notblow coldair.) HA-20

PRELIMINARY CHECK2

(Air outlet doesnotchange.) HA-21

PRELIMINARY CHECK3

(Noise) HA-22

PRELIMINARY CHECK4

(I nsufficient heating) HA-23

Performance TestDiagnoses HA-24

INSUFFICIENT COOLING HA-24

Performance Chart HA-26

TEST CONDITION HA-26

TEST READING HA-26

Trouble Diagnoses forAbnormal Pressure HA-27

Harness Layout. HA-31

Circuit Diagram -Air Conditioner HA-34

Wiring Diagram -HEATER - HA-36

Wiring Diagram -AIC - HA-38

Main Power Supply andGround CircuitCheck HA-49

Diagnostic Procedure1

(SYMPTOM: Blowermotordoesnotrotate.) HA-50

Diagnostic Procedure2

(SYMPTOM: Intake doordoes notchange.) HA-52

Diagnostic Procedure3

(SYMPTOM: Magnetclutchdoesnotoperate when

A/C

switch andfanswitch areON.)

- For GAand SRengines HA-54

- For CDengine HA-59

Electrical Components Inspection HA-62

Control Linkage Adjustment HA-64

System Description HA-65

HA-14

Page 1417 of 1701

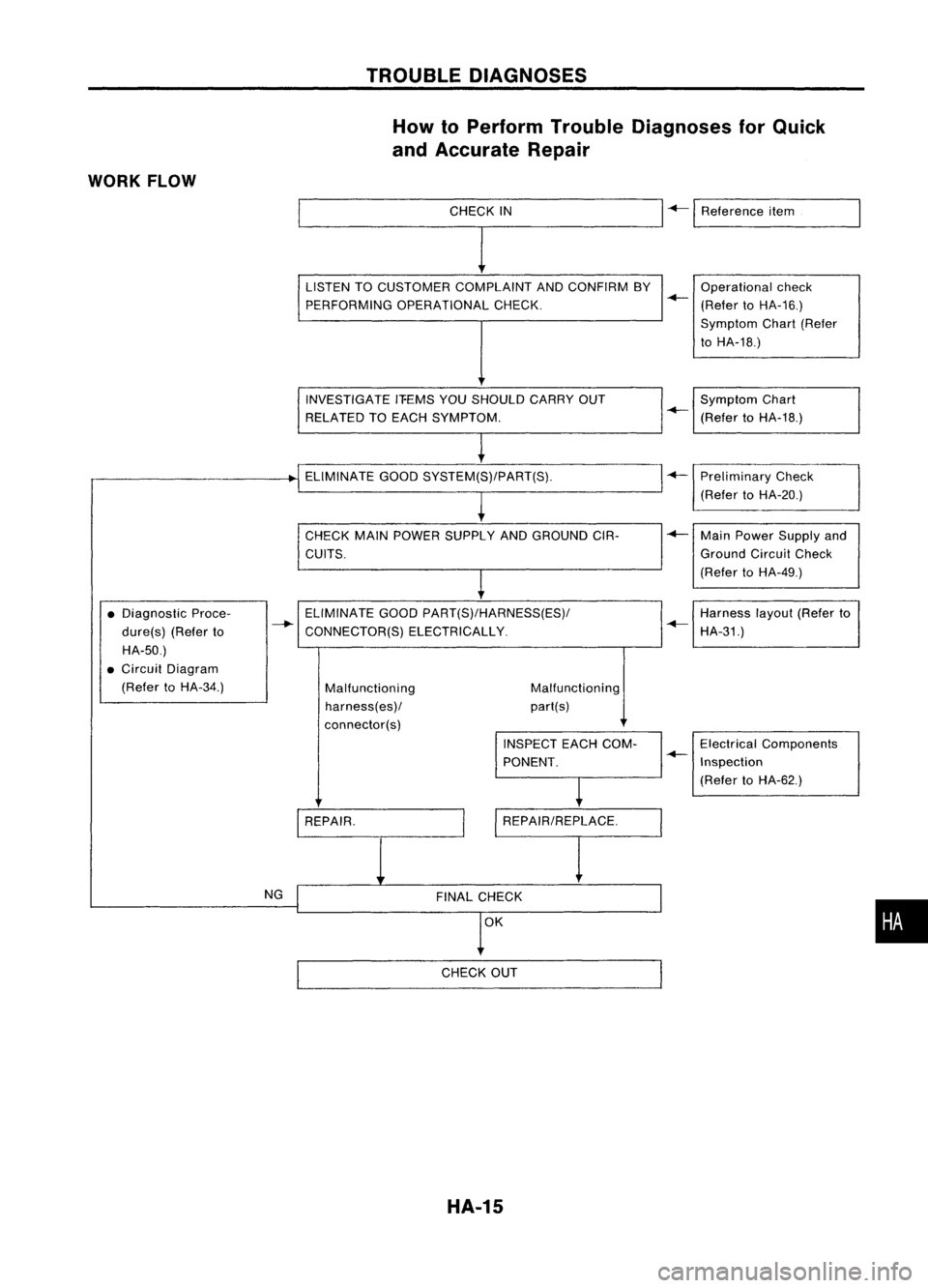

TROUBLEDIAGNOSES

How toPerform TroubleDiagnoses forQuick

and Accurate Repair

WORK FLOW

_________C_H_EI_K_I_N

I

+-1

Reference item

.--------------,

ELIMINATE GOODSYSTEM(S)/PART(S).

INVESTIGATE

IT-EMSYOUSHOULD CARRYOUT

RELATED TOEACH SYMPTOM.

CHECK MAINPOWER SUPPLY ANDGROUND CIR-

CUITS. LISTEN

TOCUSTOMER COMPLAINT ANDCONFIRM BY

PERFORMING OPERATIONAL CHECK. Operational

check

+-

(Refer toHA-16.)

Symptom Chart(Refer

to HA-18.)

Symptom Chart

+-

(Refer toHA-18.)

+-

Preliminary Check

(Refer toHA-20.)

+-

MainPower Supply and

Ground CircuitCheck

(Refer toHA-49.)

Harness layout(Referto

+-

HA-31.)

Malfunctioning

part(s)

Malfunctioning

harness( es)/

connector(s)

ELIMINATE

GOODPART(S)/HARNESS(ES)/

CONNECTOR(S) ELECTRICALLY.

•

Diagnostic Proce-

dure(s) (Referto

HA-50.)

• Circuit Diagram

(Refer toHA-34.)

NG

I

REPAIR. INSPECT

EACHCOM-

PONENT.

FINAL CHECK Electrical

Components

+-

Inspection

(Refer toHA-62.)

•

CHECK OUT

HA-15

Page 1418 of 1701

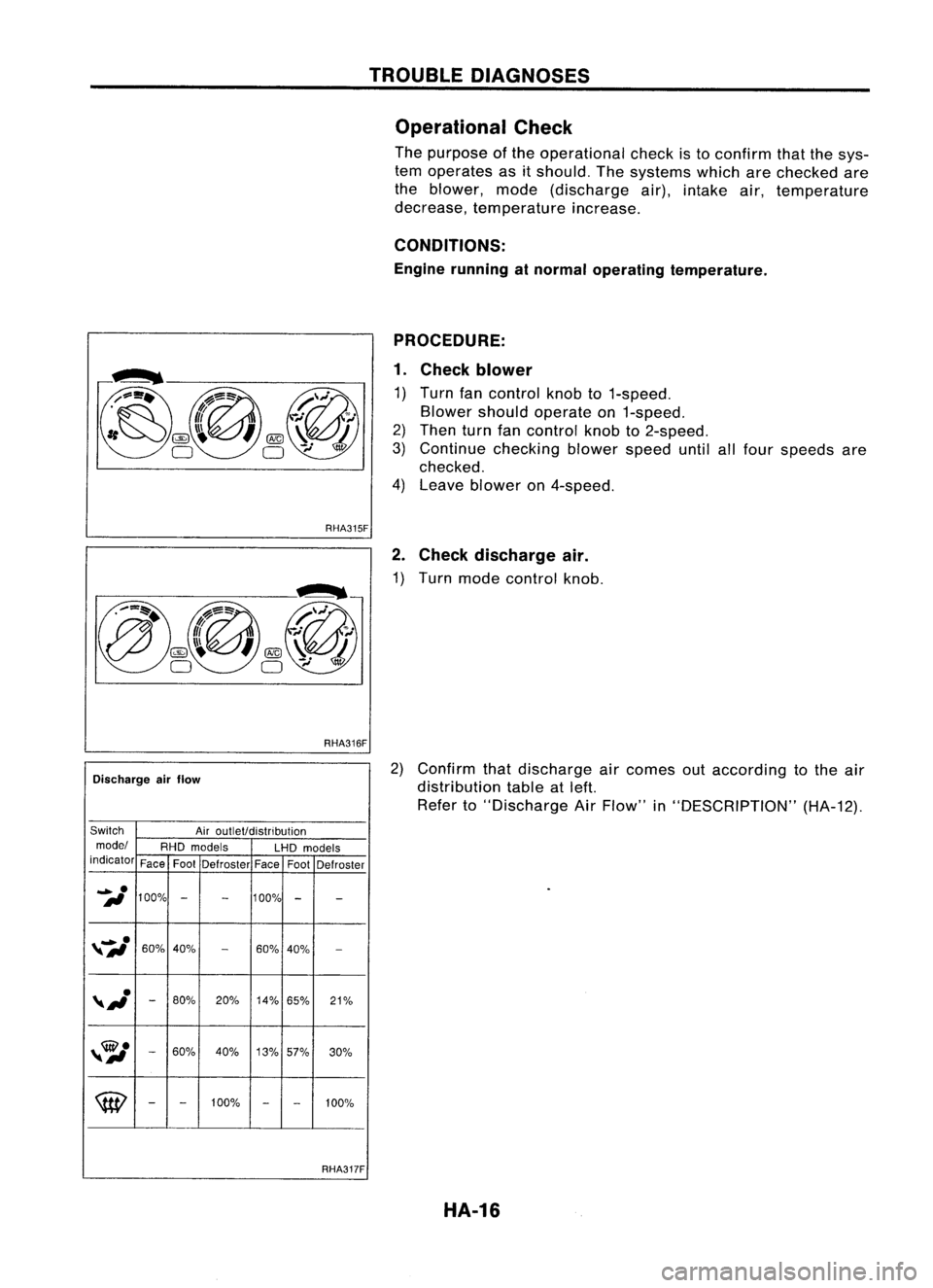

TROUBLEDIAGNOSES

Operational Check

The purpose ofthe operational checkisto confirm thatthesys-

tem operates asitshould. Thesystems whicharechecked are

the blower, mode(discharge air),intake air,temperature

decrease, temperature increase.

CONDITIONS:

Engine running atnormal operating temperature.

RHA315F

RHA316F

Discharge airflow

Switch Airoutlet/distribution

model RHDmodels

LHDmodels

indicator FaceFootDefroster FaceFoot

Defroster

_e

100% 100%

II

-

- -

-

"#Ie

60%

40%

-

60%

40%

-

"J

-

80%

20%14%

65% 21%

,,

60% 40%

13%57%

30%

W

-

-

100%

-

-

100%

RHA317F PROCEDURE:

1. Check blower

1) Turn fancontrol knobto1-speed.

Blower shouldoperate on1-speed.

2) Then turnfancontrol knobto2-speed.

3) Continue checking blowerspeeduntilallfour speeds are

checked.

4) Leave blower on4-speed.

2. Check discharge air.

1) Turn mode control knob.

2) Confirm thatdischarge aircomes outaccording tothe air

distribution tableatleft.

Refer to"Discharge AirFlow" in"DESCRIPTION" (HA-12).

HA-16

Page 1419 of 1701

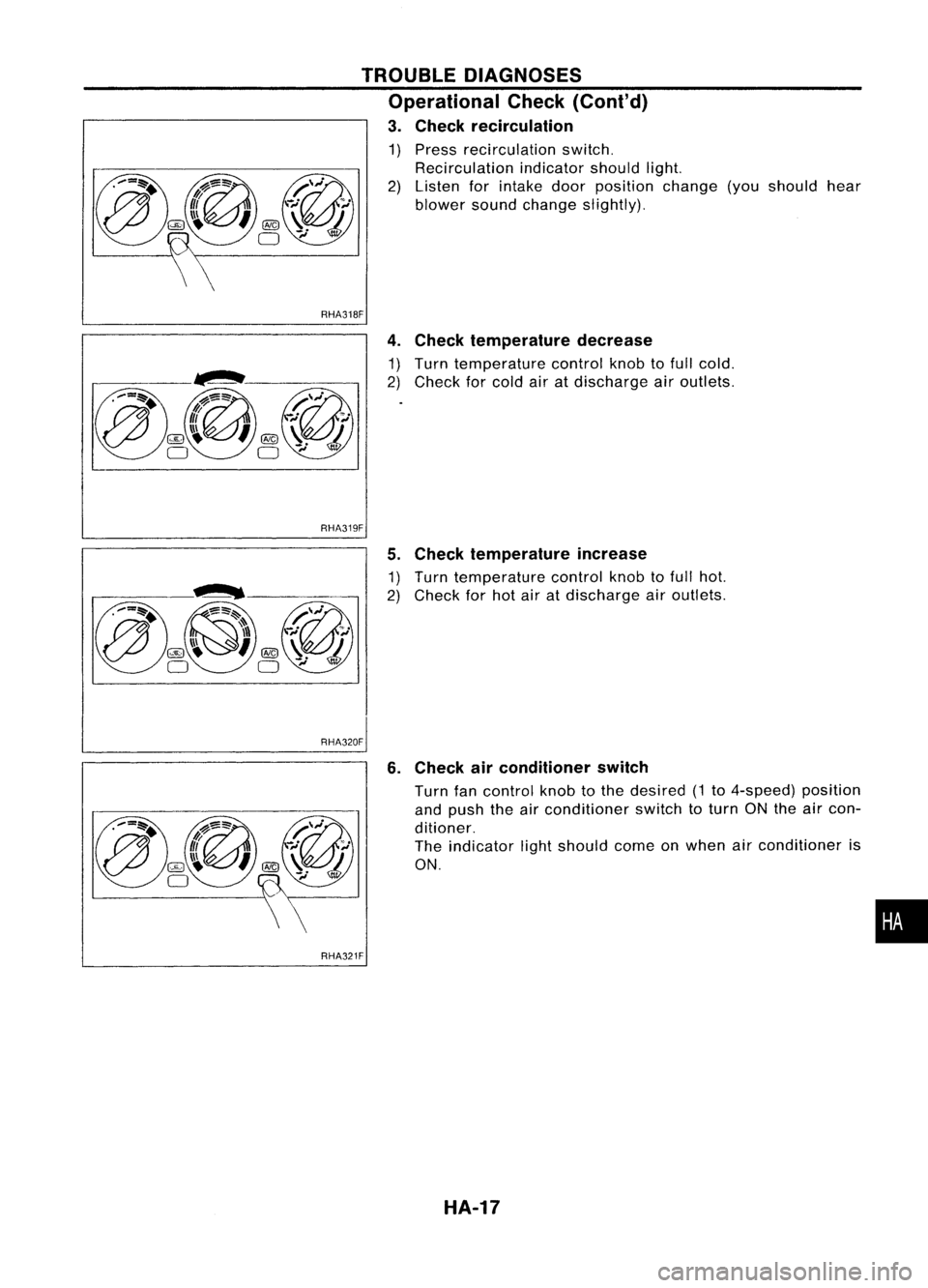

RHA318F

4.Check temperature decrease

~~ ~~~nC~ef~~~~~~ur~ cont:olknobtofull cold.

air atdischarge airoutlets.

TROUBLE

DIAGNOSES

Operational Check(Cont'd)

3. Check recirculation

1) Pre~s recirculation switch.

2) ~.eclrculati~n indicatorshouldlight

Isten forIntake doorposition ch'an

blower soundchange slightly). ge(you should hear

RHA319F

5.Check temperature increase

~~ ~~rn ~efmperatu:e controlknobtofull hot

ec orhot airatdischarge airoutlets:

RHA320F

6.Check airconditioner switch

Turn fancontrol knobtothe desired 1

a~? push theairconditioner 'th (to 4-speed) position

dltlOner.

SWI

ctoturn ONtheaircon-

The indicator lightshould com .

ON. eon when airconditioner is

•

RHA321F

HA-17

Page 1420 of 1701

TROUBLEDIAGNOSES

Symptom Chart

DIAGNOSTIC TABLE

MainPower

PROCEDURE Preliminary

DiagnosticSupplyand

Check ProcedureGroundCircuit

Check

REFERENCE PAGE

0

N

N

C')

0 N

"'"

O'J

O'JO'J

N NN

LO LO

LO

"'""'""'"

.d: .d:.d: .d:.d:

I

.d: .d:.d:

.d:

~

:c :c:c :c

:c :c:c :c:c:c

~

N

C')

Q) Q)Q)

ci.

~

N

C')

"'" ....

....

....

:J :J:J

E

-'" -'"-'" -'"

"0

"0"0

u uu u

Q)Q) Q)

«l

Q) Q)Q) Q)

uuu

e

.c

.c.c .c

000

u uu u

....

........

>.

~

>.

>.

0.

0.0.

C

~

....

....

uu u

UJ UJ

0

«l «l

«l

~ ~~

OJ

Q)

u

c cc

c

UJUJ

0

.-

.-

.-

000

:J

.2

E E

E E

ccc

u..

E

SYMPTOM

.-

-

.

-

OJOJOJ

~

....

~

OJ

Qj

Qj

«l«l

«l

~ Q)

.... .... ....

Ci Ci Ci

LO

LO

.c

a.. a..a..

a..

~

r--

f-

AIC

does notblow coldair.

0

0

0

0

00

Blower motordoesnotrotate.

0

fj

()

Insufficient heating

0

()

Air outlet doesnotchange.

0

Intake doordoes notchange.

0

0

0

Magnet clutchdoesnotoperate when

0

fj

0

0

0

AIC

switch andfanswitch areON.

Noise

0

0,

fj:

The number meanschecking order.

C :

As for checking order,refertoeach flowchart. (Itdepends onmalfunctioning portion.)

HA-18