NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1421 of 1701

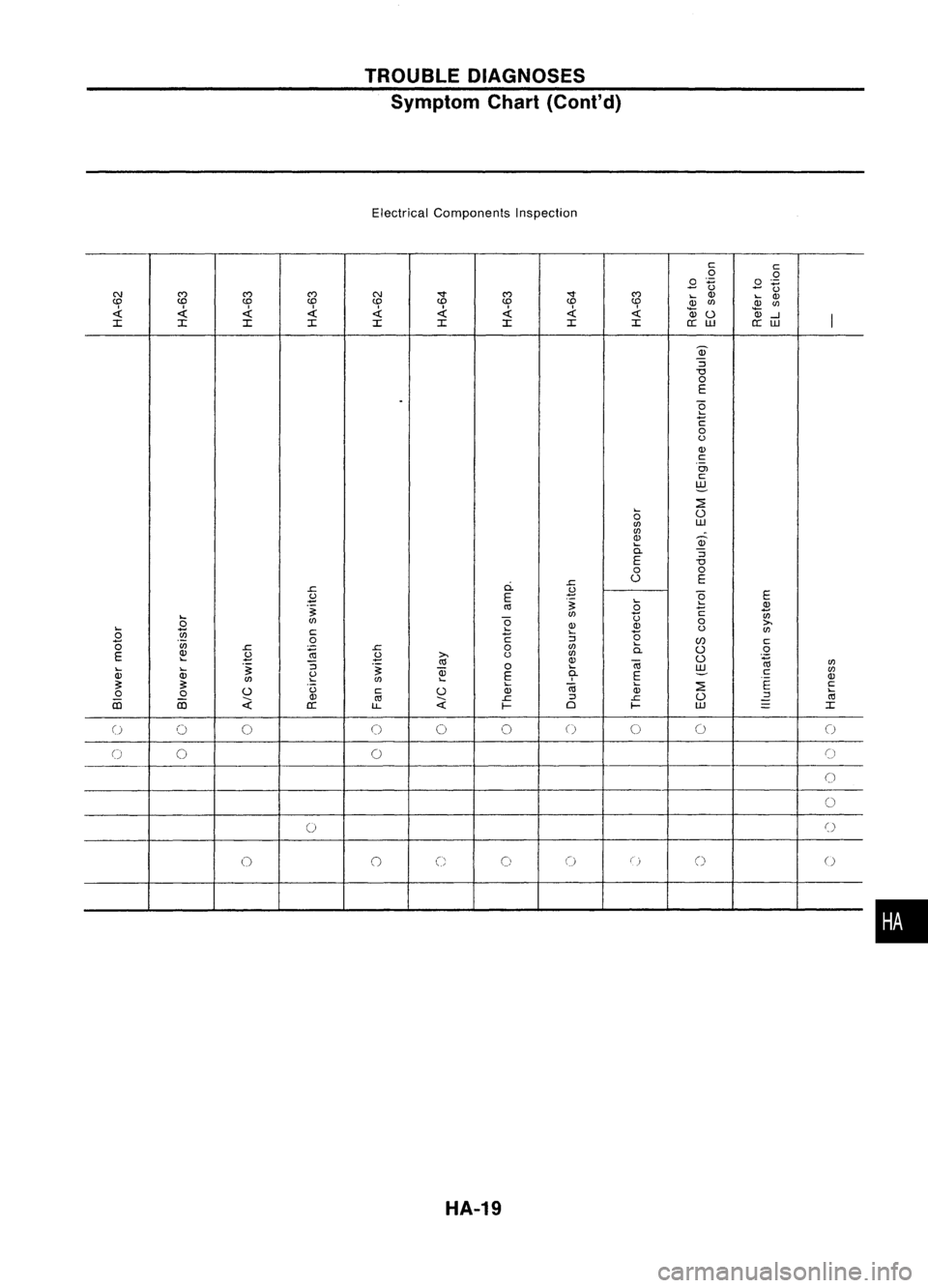

TROUBLEDIAGNOSES

Symptom Chart(Cont'd)

Electrical Components Inspection

cc

0

.Q

.8

on

.8

tl

C\J

C')

C')C')

C\J-.r

C')

-.r

C')

....

Q)

....

Q)

CD CD

CDCD

CDCD CDCD

CD

Q)

CfJ

Q)

CfJ

Qj

«

0-l

I

I

I IIII III

a::

w

a::

w

Q)

:J

"'0

0

E

.

~

c

0

(.)

Q)

c

Ol

c

~

....

~

0

0

CfJ

W

CfJ

Q) Q)

....

a.

:J

E

"'0

0

0

ci.

r.

0

E

r.

.B

E

.B

E

.~

....

~

.~

crl

0

C Q)

....

-

CfJ

tl

tl

0

CfJ

0

Q) Q)

0

>.

.... ....

(.)

CfJ

0

~

c

C

....

(5

(5

0

:J

....

(/J

c

CfJ

r.

:;

r.

0

CfJ

a.

0

0

E

Q)

.B .B

>.

(.)

CfJ

0

.~

....

crl

Q)

Ci3

CfJ

.... ....

.~

:J

.~

OJ

0

....

w

CfJ

Q) Q)

~

E

9-

E

c

Q)

CfJ CfJ

....

~ ~

....

Ci3

~

E

c

0

(.)

c

0

Q)

Q)

....

0

0

OJ

crl

r.

:J

r.

0

:J

crl

iii iii

;;:

;;:

-

a::

LL

I-

0

I-

W

-

I

-

()

0 0

0

0

0

()

00

0

0

0

0

()

0 0

()

0

0 0

(::

0

()

(0)

() ()

HA-19

•

Page 1422 of 1701

TROUBLEDIAGNOSES

Preliminary Check

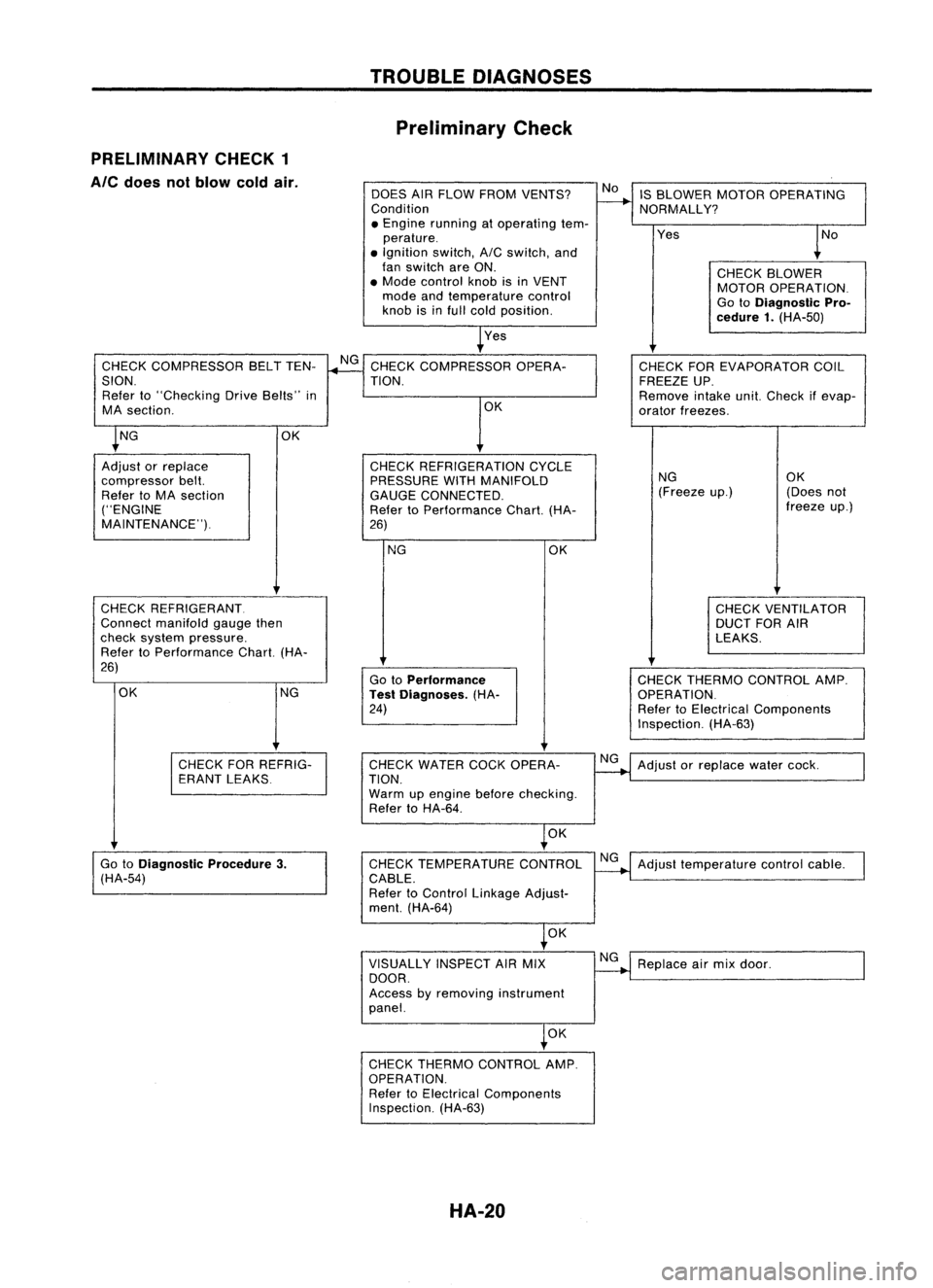

PRELIMINARY CHECK1

Ale

does notblow coldair.

DOESAIRFLOW FROM VENTS?

Condition

• Engine running atoperating tem-

perature .

• Ignition switch,AICswitch, and

fan switch areON.

• Mode control knobisin VENT

mode andtemperature control

knob isinfull cold position.

Yes IS

BLOWER MOTOROPERATING

NORMALLY?

Yes

CHECKBLOWER

MOTOR OPERATION.

Go toDiagnostic Pro-

cedure 1.(HA-50)

CHECK COMPRESSOR BELTTEN-

SION. Refer to"Checking DriveBelts" in

MA section.

CHECK REFRIGERANT.

Connect manifold gaugethen

check system pressure.

Refer toPerformance Chart.(HA-

26)

NG CHECK

THERMO CONTROL AMP.

OPERATION.

Refer toElectrical Components

Inspection. (HA-63)

CHECK

FOREVAPORATOR COIL

FREEZE UP.

Remove intakeunit.Check ifevap-

orator freezes.

NG OK

(Freeze up.) (Doesnot

freeze up.)

CHECK VENTILATOR

DUCT FORAIR

LEAKS.

OK

Go toPerformance

Test Diagnoses. (HA-

24)

NG

CHECK

REFRIGERATION CYCLE

PRESSURE WITHMANIFOLD

GAUGE CONNECTED.

Refer toPerformance Chart.(HA-

26) OK

CHECK

COMPRESSOR OPERA-

TION.

OK

OK NG

Adjust orreplace

compressor belt.

Refer toMA section

("ENGINE

MAINTENANCE").

CHECKFORREFRIG-

ERANT LEAKS CHECK

WATER COCKOPERA-

TION.

Warm upengine beforechecking.

Refer toHA-64.

NG

Adjust orreplace watercock.

OK

Go toDiagnostic Procedure3.

(HA-54) CHECK

TEMPERATURE CONTROL

CABLE.

Refer toControl Linkage Adjust-

ment. (HA-64) NG

Adjust temperature controlcable.

OK

VISUALLY INSPECTAIRMIX

DOOR.

Access byremoving instrument

panel. NG

Replace airmix door.

OK

CHECK THERMO CONTROL AMP.

OPERATION. Refer toElectrical Components

Inspection. (HA-63)

HA-20

Page 1423 of 1701

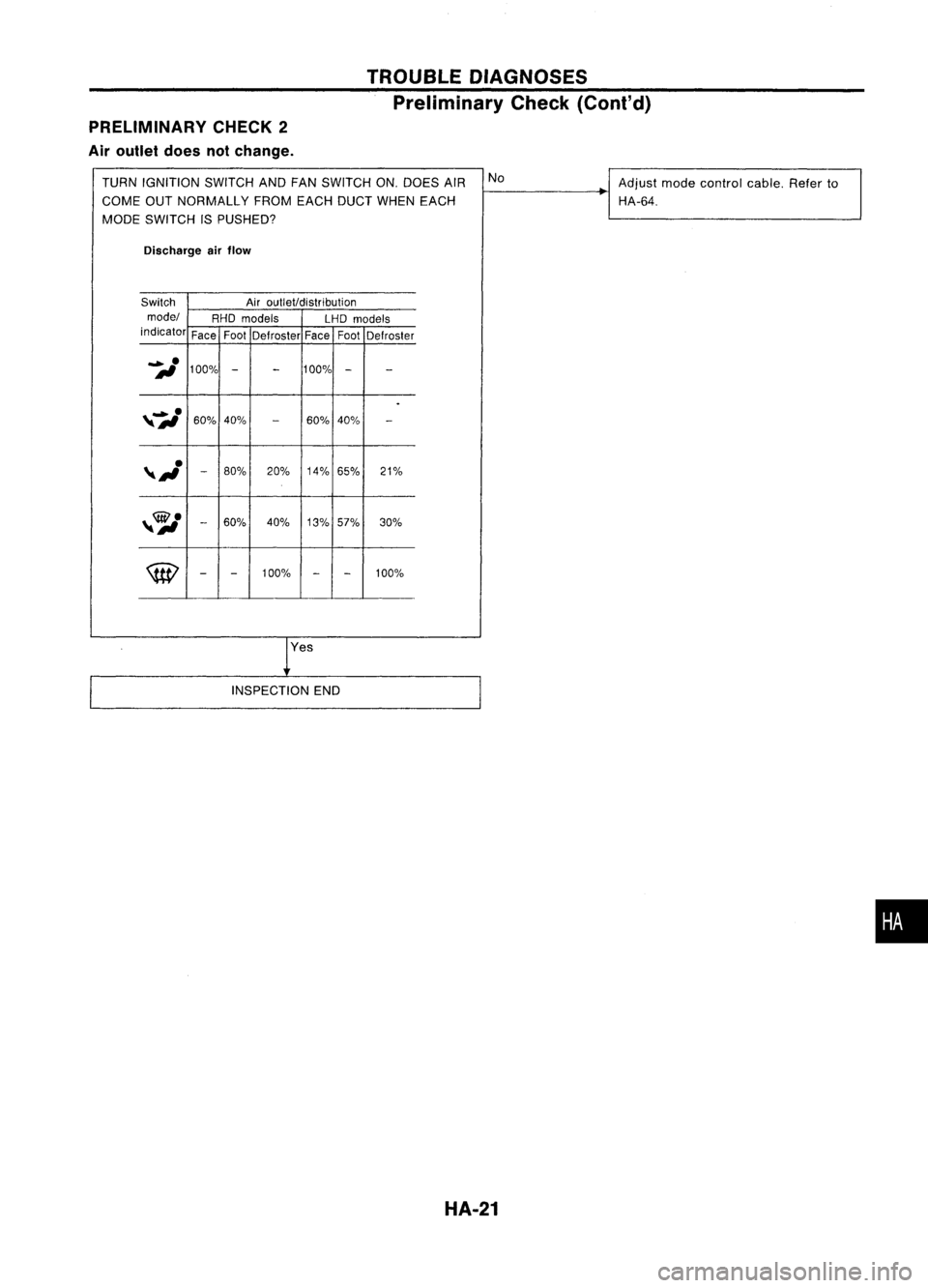

PRELIMINARY CHECK2

Air outlet doesnotchange. TROUBLE

DIAGNOSES

Preliminary Check(Cont'd)

TURN IGNITION SWITCHANDFANSWITCH ON.DOES AIR No

Adjustmodecontrol cable.Referto

COME OUTNORMALLY FROMEACHDUCTWHEN EACH HA-64.

MODE SWITCH ISPUSHED?

Discharge airflow

Switch Airoutlet/distribution

model RHOmodels

LHDmodels

indicator FaceFoot

Defroster FaceFoot

Defroster

iI

100%

-

-

100%

-

-

.

,7,./

60%40%

-

60%40%

-

,~

-

80%

20%14%65% 21%

,~

-

60% 40%

13%57% 30%

\tEl

-

-

100%

-

-

100%

res

INSPECTION END

HA-21

•

Page 1424 of 1701

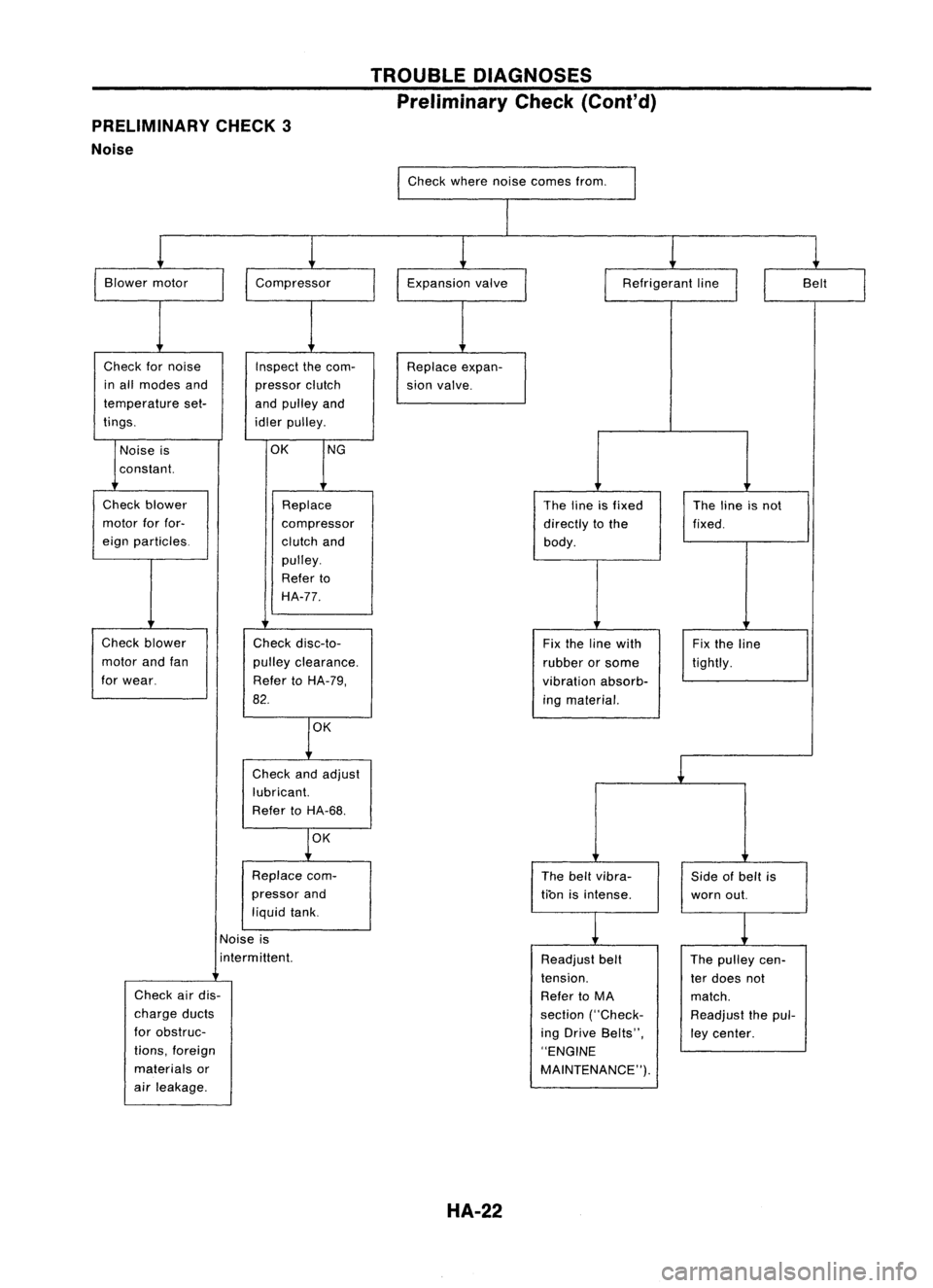

PRELIMINARY CHECK3

Noise TROUBLE

DIAGNOSES

Preliminary Check(Coni'd)

Check wherenoisecomes from.

I

I

Blower motor

Check fornoise

in all modes and

temperature set-

tings.

I

Compressor

Inspect thecom-

pressor clutch

and pulley and

idler pulley. Expansion

valve

Replace expan-

sion valve.

I

Refrigerant line

II

Belt

I

Noise is

constant.

OK

NG

Check blower

motor forfor-

eign particles.

Check blower

motor andfan

for wear. Replace

compressor

clutch and

pulley.

Refer to

HA-77.

Check disc-to-

pulley clearance.

Refer toHA-79,

82.

OK

Check andadjust

lubricant.

Refer toHA-68.

OK

Replace com-

pressor and

liquid tank. The

lineisfixed

directly tothe

body.

Fix the line with

rubber orsome

vibration absorb-

ing material.

The beltvibra-

tion isintense. The

lineisnot

fixed.

Fix the line

tightly.

Side ofbelt is

worn out.

Noise is

i nterm ittent.

Check airdis-

charge ducts

for obstruc-

tions, foreign

materials or

air leakage.

HA-22

Readjust

belt

tension.

Refer toMA

section ("Check-

ing Drive Belts",

"ENGINE

MAINTENANCE"). The

pulley cen-

ter does not

match.

Readjust thepul-

ley center.

Page 1425 of 1701

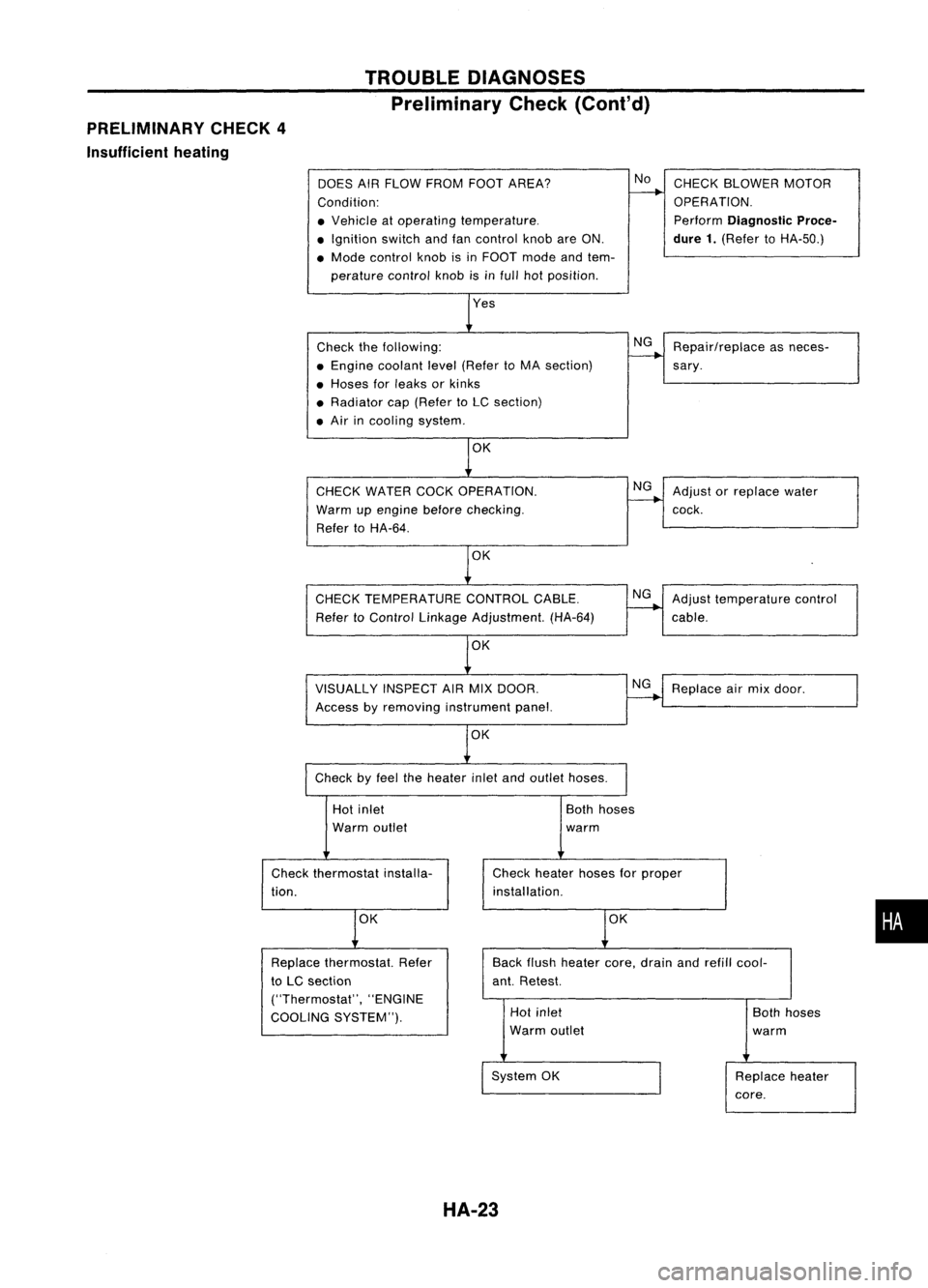

PRELIMINARY CHECK4

Insufficient heating TROUBLE

DIAGNOSES

Preliminary Check(Cont'd)

DOES AIRFLOW FROM FOOTAREA?

Condition:

• Vehicle atoperating temperature .

• Ignition switchandfancontrol knobareON.

• Mode control knobisin FOOT modeandtem-

perature controlknobisinfull hotposition.

Check thefollowing:

• Engine coolant level(Refer toMA section)

• Hoses forleaks orkinks

• Radiator cap(Refer toLC section)

• Air incooling system.

CHECK WATER COCKOPERATION.

Warm upengine before

checking.

Refer toHA-64.

OK

CHECK TEMPERATURE CONTROLCABLE.

Refer toControl Linkage Adjustment. (HA-64)

VISUALLY INSPECTAIRMIX DOOR.

Access byremoving instrument panel.

OK

Check byfeel theheater inletandoutlet hoses.

No

NG

NG

NG

NG

CHECK

BLOWER MOTOR

OPERATION.

Perform

Diagnostic Proce-

dure 1.

(Refer toHA-50.)

Repair/replace asneces-

sary .

Adjust orreplace water

cock.

Adjust temperature control

cable.

Replace airmix door.

Hot inlet

Warm outlet

Check thermostat installa-

tion.

OK

Both

hoses

warm

Check heater hosesforproper

installation.

OK

•

Back

flush heater core,drain andrefill cool-

ant. Retest.

Replace

thermostat. Refer

to LC section

("Thermostat", "ENGINE

COOLING SYSTEM"). Hot

inlet

Warm outlet

System OK

HA-23

Both

hoses

warm

Replace heater

core.

Page 1426 of 1701

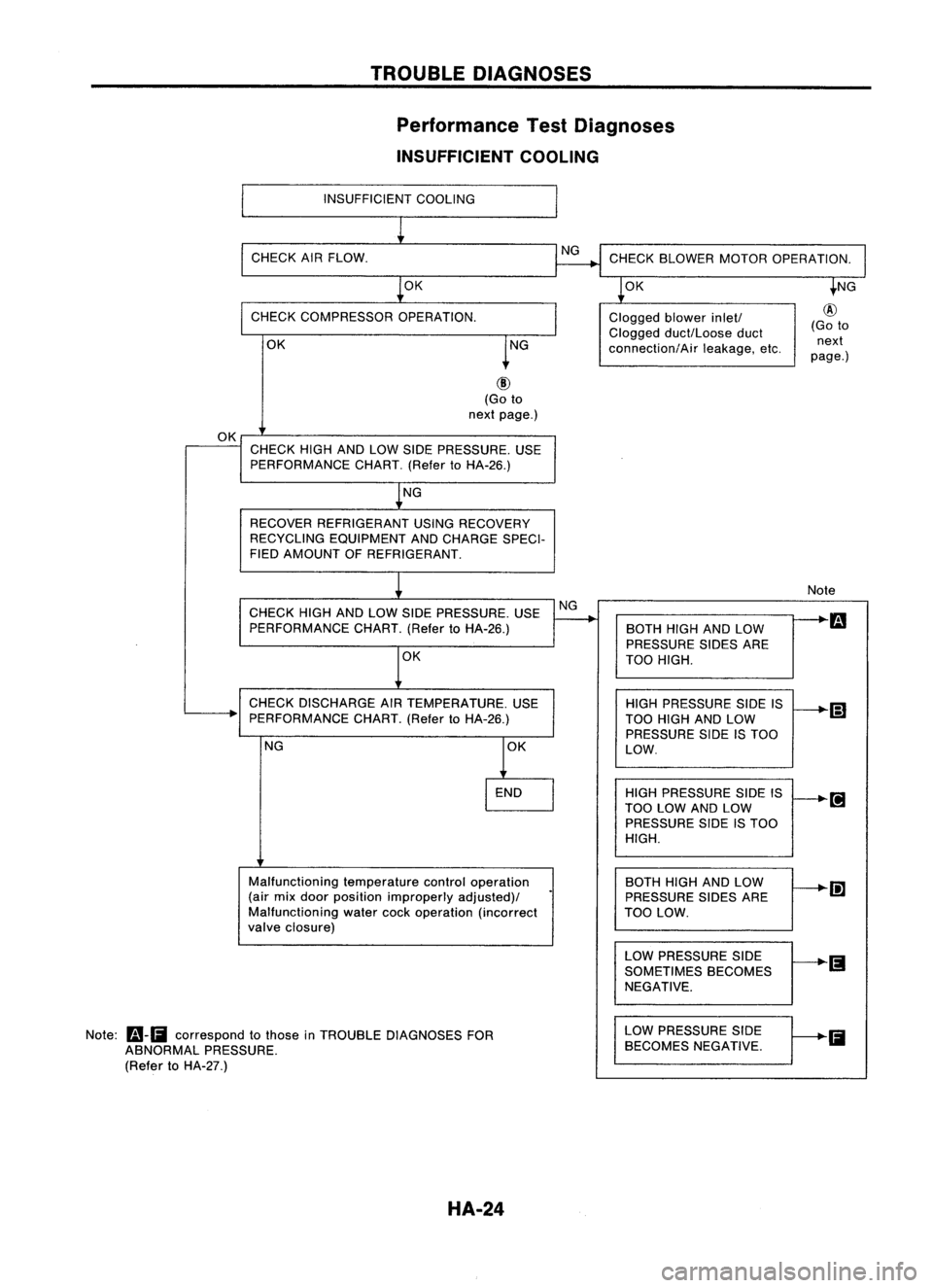

TROUBLEDIAGNOSES

Performance TestDiagnoses

INSUFFICIENT COOLING

INSUFFICIENT COOLING

CHECK AIRFLOW.

OK CHECK

BLOWER MOTOROPERATION.

OK

CHECK COMPRESSOR OPERATION.

OK Clogged

blowerinlet!

Clogged duct/Loose duct

connection/Air leakage,etc.

@

(Go to

next

page.)

(Go to

next page.)

OK CHECK HIGHANDLOW SIDE PRESSURE. USE

PERFORMANCE CHART.(RefertoHA-26.)

NG

RECOVER REFRIGERANT USINGRECOVERY

RECYCLING EQUIPMENT ANDCHARGE SPECI-

FIED AMOUNT OFREFRIGERANT.

CHECK HIGHANDLOW SIDE PRESSURE. USE

PERFORMANCE CHART.(RefertoHA-26.)

OK

CHECK DISCHARGE AIRTEMPERATURE. USE

PERFORMANCE CHART.(RefertoHA-26.)

NG

Malfunctioning temperaturecontroloperation

(air mix door position improperly adjusted)/

Malfunctioning watercockoperation (incorrect

valve closure)

Note:

Fa-Ii

correspond tothose inTROUBLE DIAGNOSES FOR

ABNORMAL PRESSURE.

(Refer toHA-27.)

HA-24NG

Note

BOTH HIGHANDLOW

m

PRESSURE SIDESARE

TOO HIGH.

HIGH PRESSURE SIDEIS

(;]

TOO HIGH ANDLOW

PRESSURE SIDEISTOO

LOW.

HIGH PRESSURE SIDEIS

TOO LOW ANDLOW

PRESSURE SIDEISTOO

HIGH.

BOTH HIGHANDLOW

Ii]

PRESSURE SIDESARE

TOO LOW.

LOW PRESSURE SIDE

SOMETIMES BECOMES

NEGATIVE.

LOW PRESSURE SIDE

Ii

BECOMES NEGATIVE.

Page 1427 of 1701

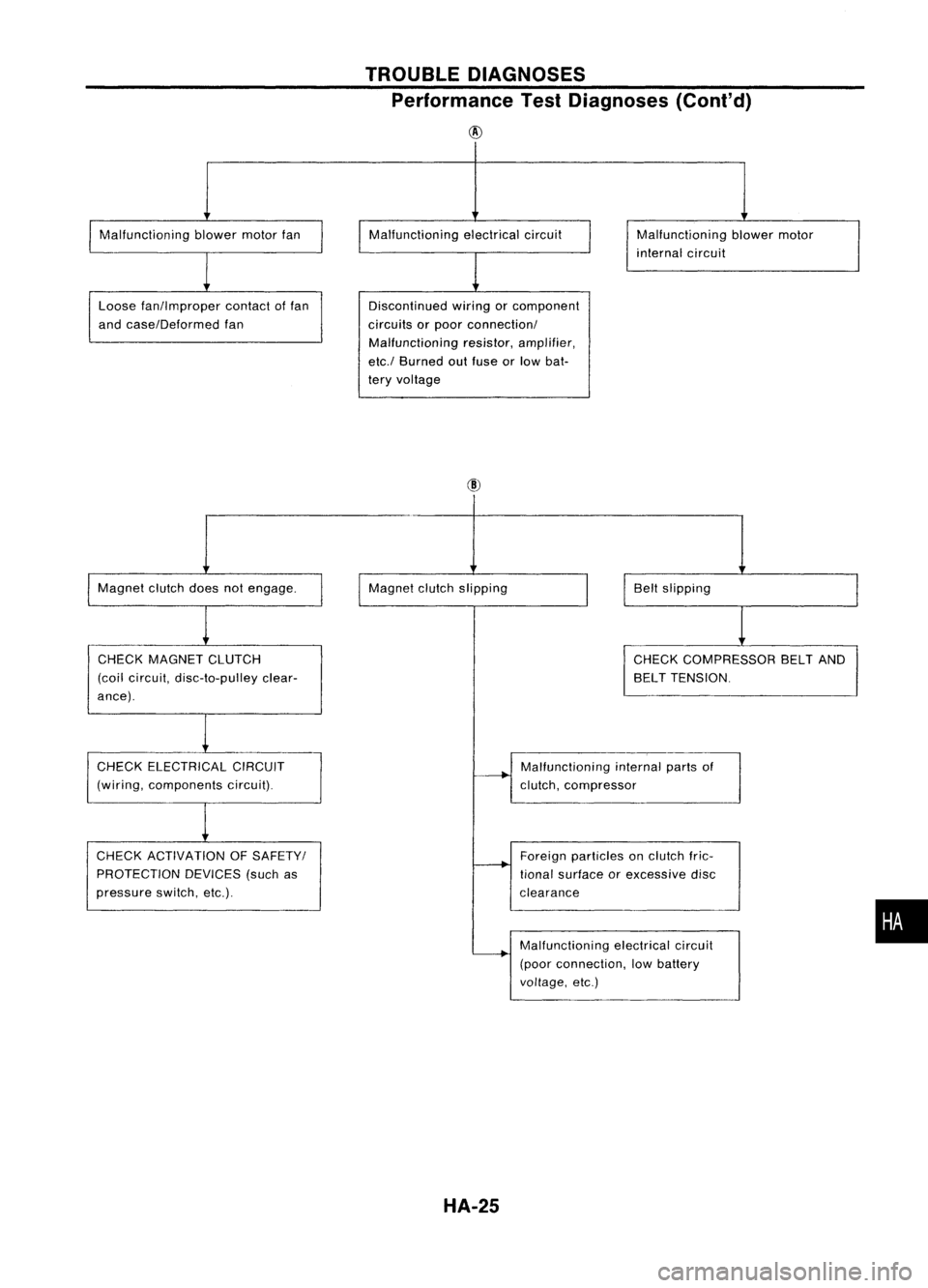

TROUBLEDIAGNOSES

Performance TestDiagnoses (Cont'd)

@

Malfunctioning blowermotorfan

Loose fan!lmproper contactoffan

and case!Deformed fan Malfunctioning

electricalcircuit

Discontinued wiringorcomponent

circuits orpoor connection!

Malfunctioning resistor,amplifier,

etc.! Burned outfuse orlow bat-

tery voltage Malfunctioning

blowermotor

internal circuit

Magnet clutchdoesnotengage.

CHECK MAGNET CLUTCH

(coil circuit, disc-to-pulley clear-

ance). Magnet

clutchslipping

Beltslipping

CHECK COMPRESSOR BELTAND

BELT TENSION.

CHECK ELECTRICAL CIRCUIT

(wiring, components circuit).

CHECK ACTIVATION OFSAFETY!

PROTECTION DEVICES(suchas

pressure switch,etc.). Malfunctioning

internalpartsof

clutch, compressor

Foreign particles onclutch fric-

tional surface orexcessive disc

clearance

Malfunctioning electricalcircuit

(poor connection, lowbattery

voltage, etc.)

HA-25

•

Page 1428 of 1701

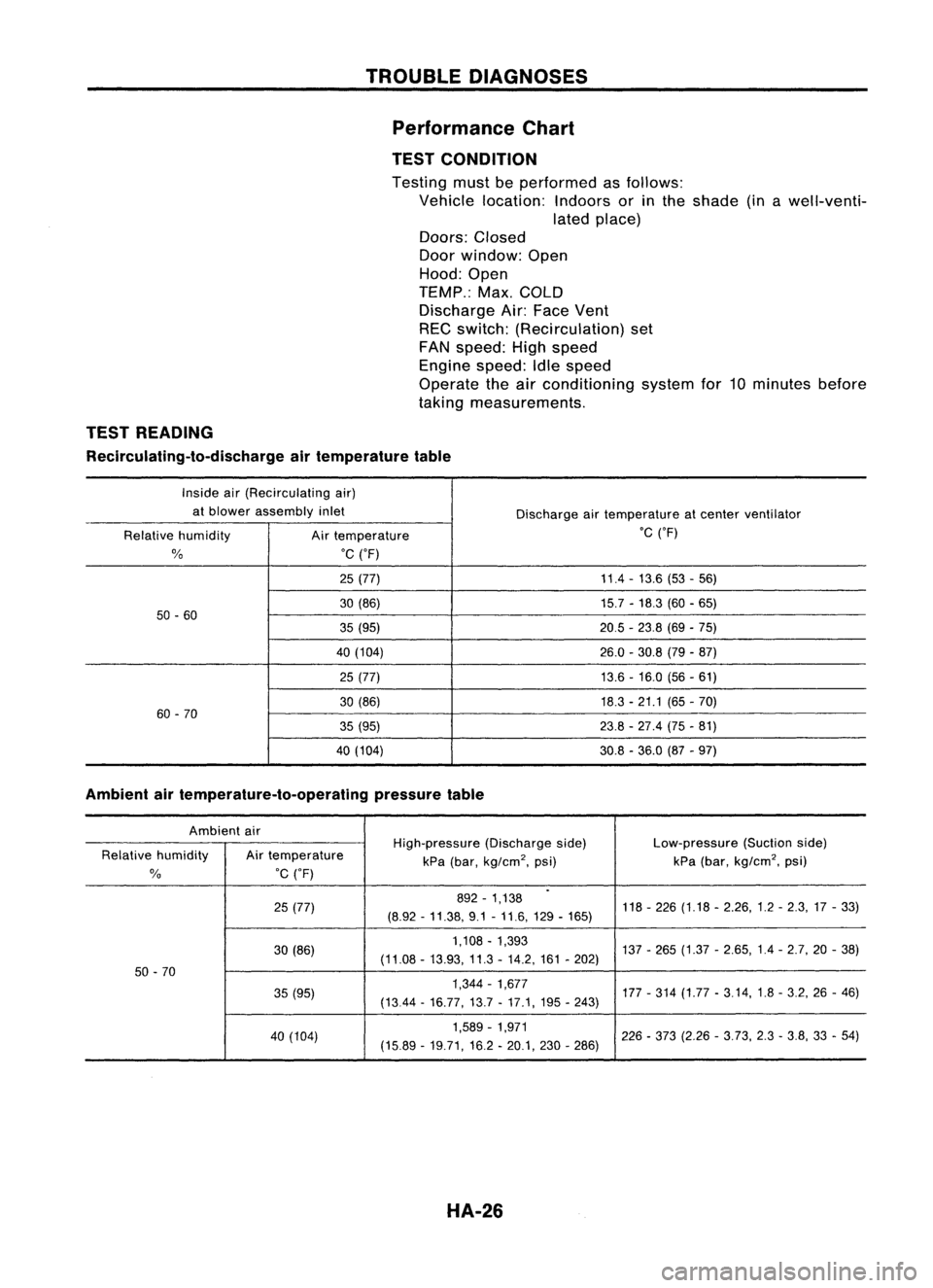

TROUBLEDIAGNOSES

Performance Chart

TEST CONDITION

Testing mustbeperformed asfollows:

Vehicle location: Indoorsorinthe shade (inawell-venti-

lated place)

Doors: Closed

Door window: Open

Hood: Open

TEMP.: Max.COLD

Discharge Air:Face Vent

REC switch: (Recirculation) set

FAN speed: Highspeed

Engine speed:Idlespeed

Operate theairconditioning systemfor10minutes before

taking measurements.

TEST READING

Recirculating-to-discharge airtemperature table

Inside air(Recirculating air)

at blower assembly inlet

Dischargeairtemperature atcenter ventilator

Relative humidity

Airtemperature .C

('F)

%

.C

('F)

25 (77) 11.4

-13.6 (53-56)

30 (86) 15.7-18.3 (60-65)

50 -60

35(95) 20.5-23.8 (69-75)

40 (104) 26.0-30.8 (79-87)

25 (77) 13.6-16.0 (56-61)

30 (86) 18.3-21.1 (65-70)

60 -70

35(95) 23.8-27.4 (75-81)

40 (104) 30.8-36.0 (87-97)

Ambient airtemperature-to-operating pressuretable

Ambient air

High-pressure(Dischargeside) Low-pressure

(Suctionside)

Relative humidity Airtemperature

kPa(bar,

kg/cm

2,

psi) kPa

(bar,

kg/cm

2,

psi)

%

.C

('F)

.

25 (77) 892

-1,138

118-226 (1.18 -2.26,1.2 -2.3,17 -33)

(8.92 -11.38, 9.1-11.6,129 -165)

30 (86) 1,108

-1,393

137-265 (1.37 -2.65,1.4 -2.7,20 -38)

(11.08 -13.93, 11.3-14.2, 161-202)

50 -70

35(95) 1,344

-1,677

177-314 (1.77 -3.14,1.8 -3.2, 26-46)

(1344 -16.77,13.7 -17.1, 195-243)

40 (104) 1,589

-1,971

226-373 (2.26 -3.73, 2.3-3.8, 33-54)

(15.89 -19.71,16.2 -20.1, 230-286)

HA-26

Page 1429 of 1701

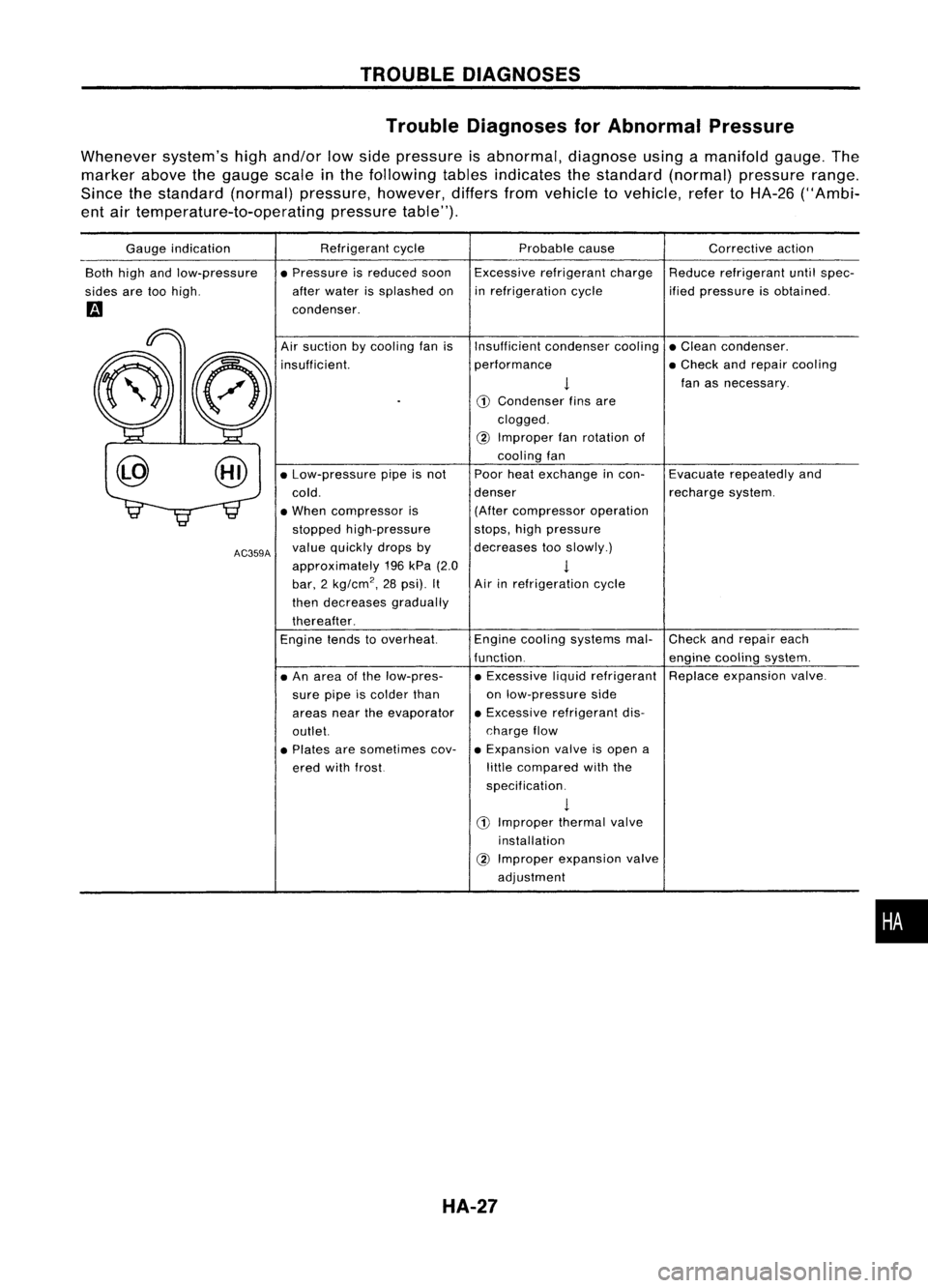

TROUBLEDIAGNOSES

Trouble Diagnoses forAbnormal Pressure

Whenever system'shighand/or lowside pressure isabnormal, diagnoseusingamanifold gauge.The

marker abovethegauge scale

in

the following tablesindicates thestandard (normal)pressure range.

Since thestandard (normal)pressure, however,differsfromvehicle tovehicle, refertoHA-26 ("Ambi-

ent airtemperature-to-operating pressuretable").

Gauge indication

Both highandlow-pressure

sides aretoohigh.

m

Refrigerant

cycle

• Pressure isreduced soon

after water issplashed on

condenser. Probable

cause

Excessive refrigerant charge

in refrigeration cycle Corrective

action

Reduce refrigerant untilspec-

ified pressure isobtained.

•

Check

andrepair each

engine cooling system.

Replace expansion valve.

Evacuate

repeatedly and

recharge system.

Insufficient

condensercooling•Clean condenser.

performance •Check andrepair cooling

!

fanasnecessary.

CD

Condenser finsare

clogged.

@

Improper fanrotation of

cooling fan

Poor heatexchange incon-

denser (After compressor operation

stops, highpressure

decreases tooslowly.)

1

Air inrefrigeration cycle

Engine cooling systems mal-

function. • Excessive liquidrefrigerant

on low-pressure side

• Excessive refrigerant dis-

charge flow

• Expansion valveisopen a

little compared withthe

specification.

1

CD

Improper thermalvalve

installation

@

Improper expansion valve

adjustment

Air

suction bycooling fanis

insufficient.

• An area ofthe low-pres-

sure pipeiscolder than

areas neartheevaporator

outlet.

• Plates aresometimes cov-

ered withfrost.

•

Low-pressure pipeisnot

cold.

• When compressor is

stopped high-pressure

value quickly dropsby

approximately 196kPa (2.0

bar, 2

kg/cm

2,

28psi). It

then decreases gradually

thereafter.

Engine tendstooverheat.

AC359A

HA-27

Page 1430 of 1701

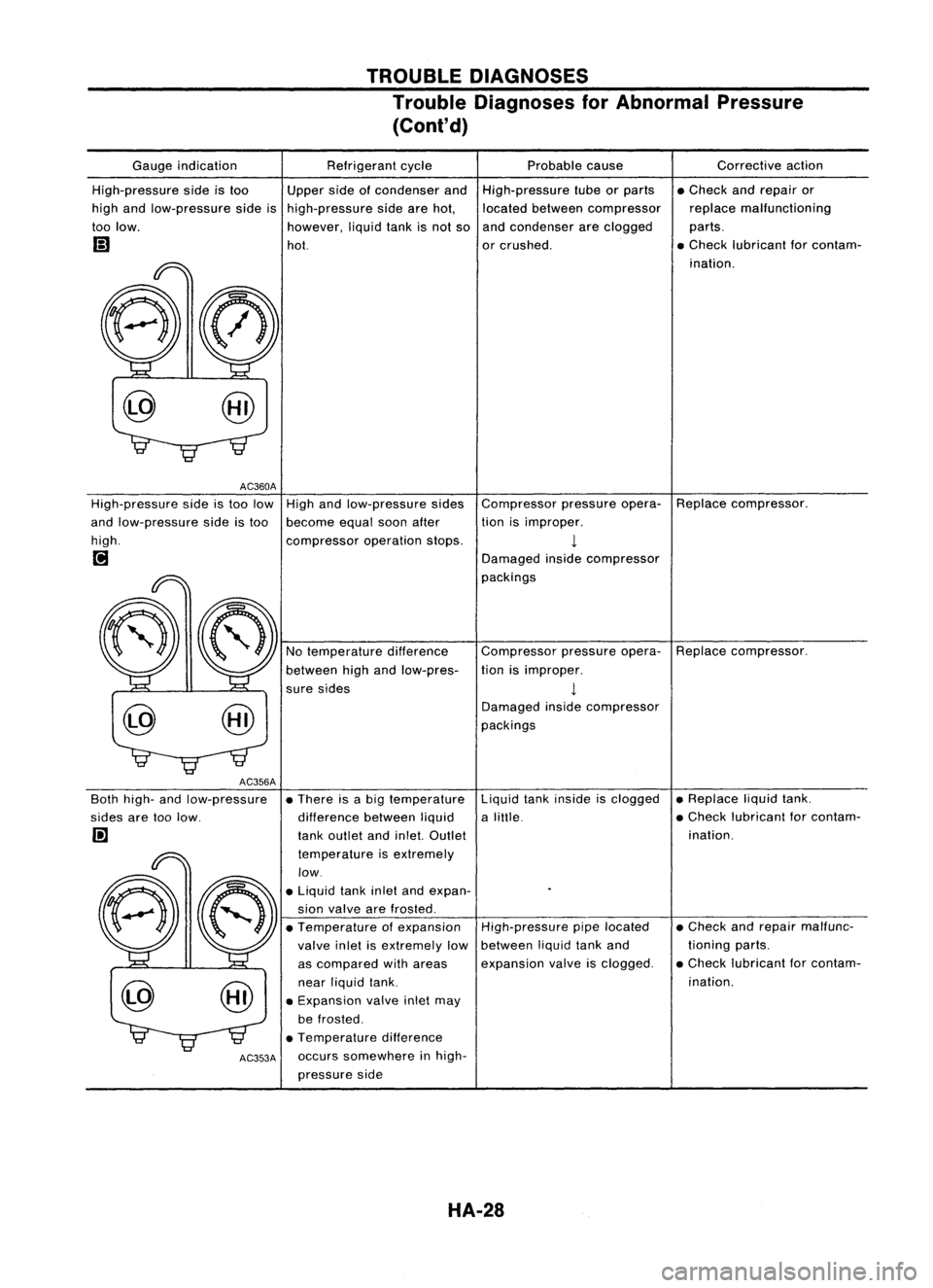

TROUBLEDIAGNOSES

Trouble Diagnoses forAbnormal Pressure

(Cont'd)

Compressorpressureopera-Replacecompressor.

tion isimproper.

1

Damaged insidecompressor

packings

Gauge

indication

High-pressure sideistoo

high andlow-pressure sideis

too low.

AC360A

High-pressure sideistoo low

and low-pressure sideistoo

high.

[;J

AC356A

80th high- andlow-pressure

sides aretoolow.

I!]

AC353A

Refrigerant

cycle

Upper sideofcondenser and

high-pressure sidearehot,

however, liquidtankisnot so

hot.

High andlow-pressure sides

become equalsoonafter

compressor operationstops.

No temperature difference

between highandlow-pres-

sure sides

• There isabig temperature

difference betweenliquid

tank outlet andinlel. Outlet

temperature isextremely

low .

• Liquid tankinletandexpan-

sion valve arefrosted.

• Temperature ofexpansion

valve inletisextremely low

as compared withareas

near liquid tank.

• Expansion valveinletmay

be frosted .

• Temperature difference

occurs somewhere inhigh-

pressure side Probable

cause

High-pressure tubeorparts

located between compressor

and condenser areclogged

or crushed.

Compressor pressureopera-

tion isimproper.

1

Damaged insidecompressor

packings

Liquid tankinside isclogged

a lillie.

High-pressure pipelocated

between liquidtankand

expansion valveisclogged. Corrective

action

• Check andrepair or

replace malfunctioning

parts .

• Check lubricant forcontam-

ination.

Replace compressor.

• Replace liquidtank.

• Check lubricant forcontam-

ination.

• Check andrepair malfunc-

tioning parts.

• Check lubricant forcontam-

ination.

HA-28