NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1371 of 1701

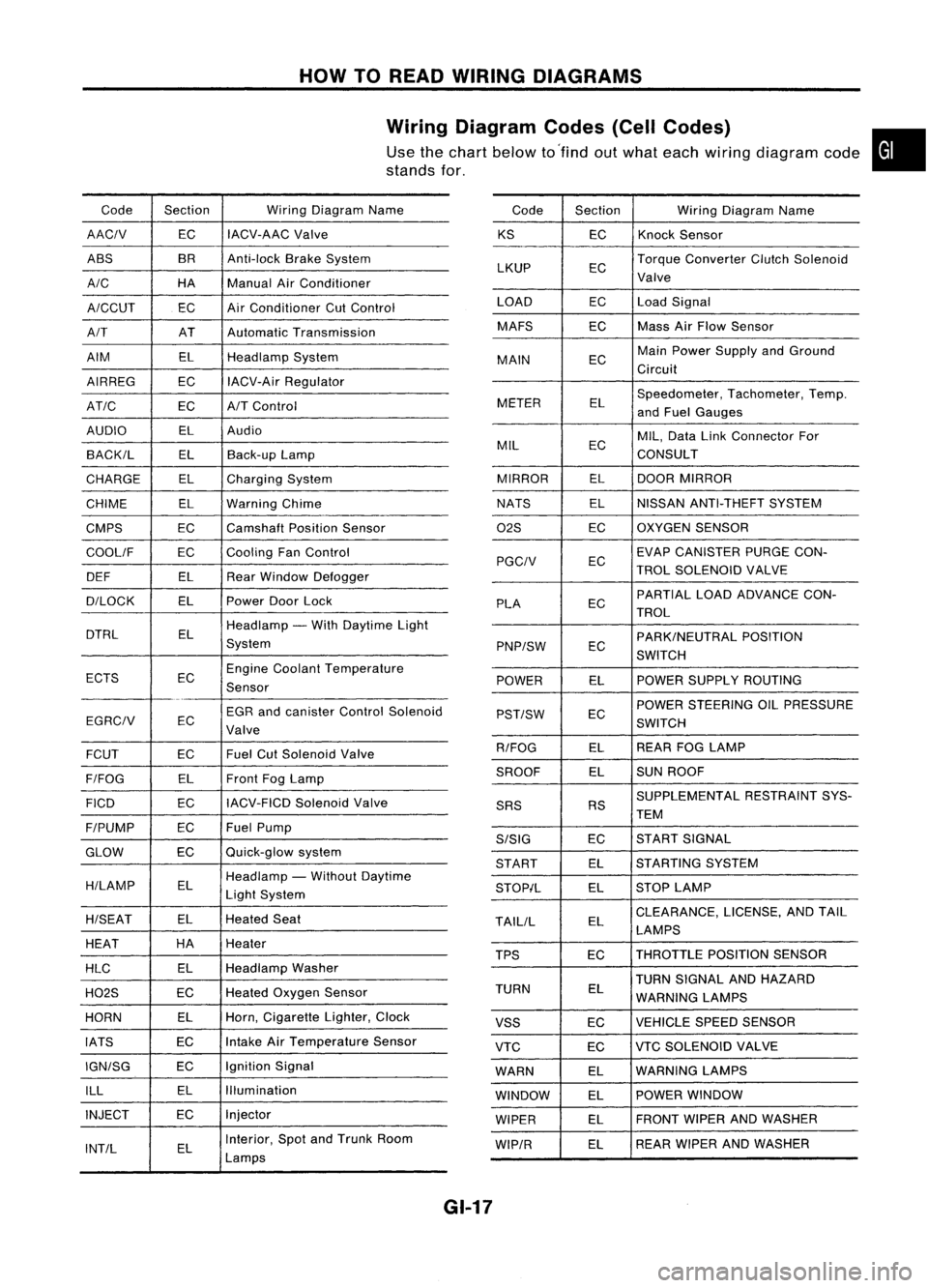

HOWTOREAD WIRING DIAGRAMS

Wiring Diagram Codes(CellCodes)

Use thechart below to'find outwhat each wiring diagram code•

stands for,

Code Section WiringDiagram Name

AACIV ECIACV-AAC

Valve

ABS BR

Anti-lock BrakeSystem

A/C HAManualAirConditioner

A/CCUT ECAir

Conditioner CutControl

A/T ATAutomatic Transmission

AIM ELHeadlamp System

AIRREG ECIACV-Air Regulator

AT/C ECA/TControl

AUDIO ELAudio

BACK/L ELBack-up Lamp

CHARGE ELCharging System

CHIME ELWarning Chime

CMPS EC

Camshaft PositionSensor

COOllF ECCooling

FanControl

DEF ELRearWindow Defogger

D/LOCK ELPowerDoorLock

DTRL ELHeadlamp

-With Daytime Light

System

ECTS ECEngine

Coolant Temperature

Sensor

EGR andcanister ControlSolenoid

EGRCIV EC

Valve

FCUT ECFuel

CutSolenoid Valve

F/FOG ELFront

FogLamp

FICO ECIACV-FICD

SolenoidValve

F/PUMP ECFuel

Pump

GLOW ECQuick-glow

system

H/LAMP ELHeadlamp

-Without Daytime

Light System

H/SEAT ELHeated

Seat

HEAT HA

Heater

HLC ELHeadlamp

Washer

H02S ECHeated

Oxygen Sensor

HORN ELHorn,

Cigarette Lighter,Clock

IATS ECIntake

AirTemperature Sensor

IGN/SG ECIgnition

Signal

ILL ELIllumination

INJECT ECInjector

INT/L ELInterior,

SpotandTrunk Room

Lamps Code

Section WiringDiagram Name

KS ECKnock

Sensor

LKUP ECTorque

Converter ClutchSolenoid

Valve

LOAD ECLoadSignal

MAFS ECMass

AirFlow Sensor

MAIN ECMain

Power Supply andGround

Circuit

METER ELSpeedometer,

Tachometer,Temp.

and Fuel Gauges

MIL ECMIL,

Data LinkConnector For

CONSULT

MIRROR ELDOOR

MIRROR

NATS ELNISSAN

ANTI-THEFT SYSTEM

02S ECOXYGEN

SENSOR

EC EVAP

CANISTER PURGECON-

PGCIV TROLSOLENOID VALVE

PLA ECPARTIAL

LOADADVANCE CON-

TROL

EC PARK/NEUTRAL

POSITION

PNP/SW SWITCH

POWER ELPOWER

SUPPLY ROUTING

POWER STEERING OILPRESSURE

PST/SW EC

SWITCH

R/FOG ELREAR

FOGLAMP

SROOF ELSUN

ROOF

SUPPLEMENTAL RESTRAINTSYS-

SRS RS

TEM

S/SIG ECST

ART SIGNAL

START ELSTARTING

SYSTEM

STOP/L ELSTOP

LAMP

TAllIL ELCLEARANCE,

LICENSE,ANDTAIL

LAMPS

TPS ECTHROTTLE

POSITIONSENSOR

TURN SIGNAL ANDHAZARD

TURN EL

WARNING LAMPS

VSS ECVEHICLE

SPEEDSENSOR

VTC ECVTC

SOLENOID VALVE

WARN ELWARNING

LAMPS

WINDOW ELPOWER

WINDOW

WIPER ELFRONT

WIPERANDWASHER

WIP/R ELREAR

WIPER ANDWASHER

GI-17

Page 1372 of 1701

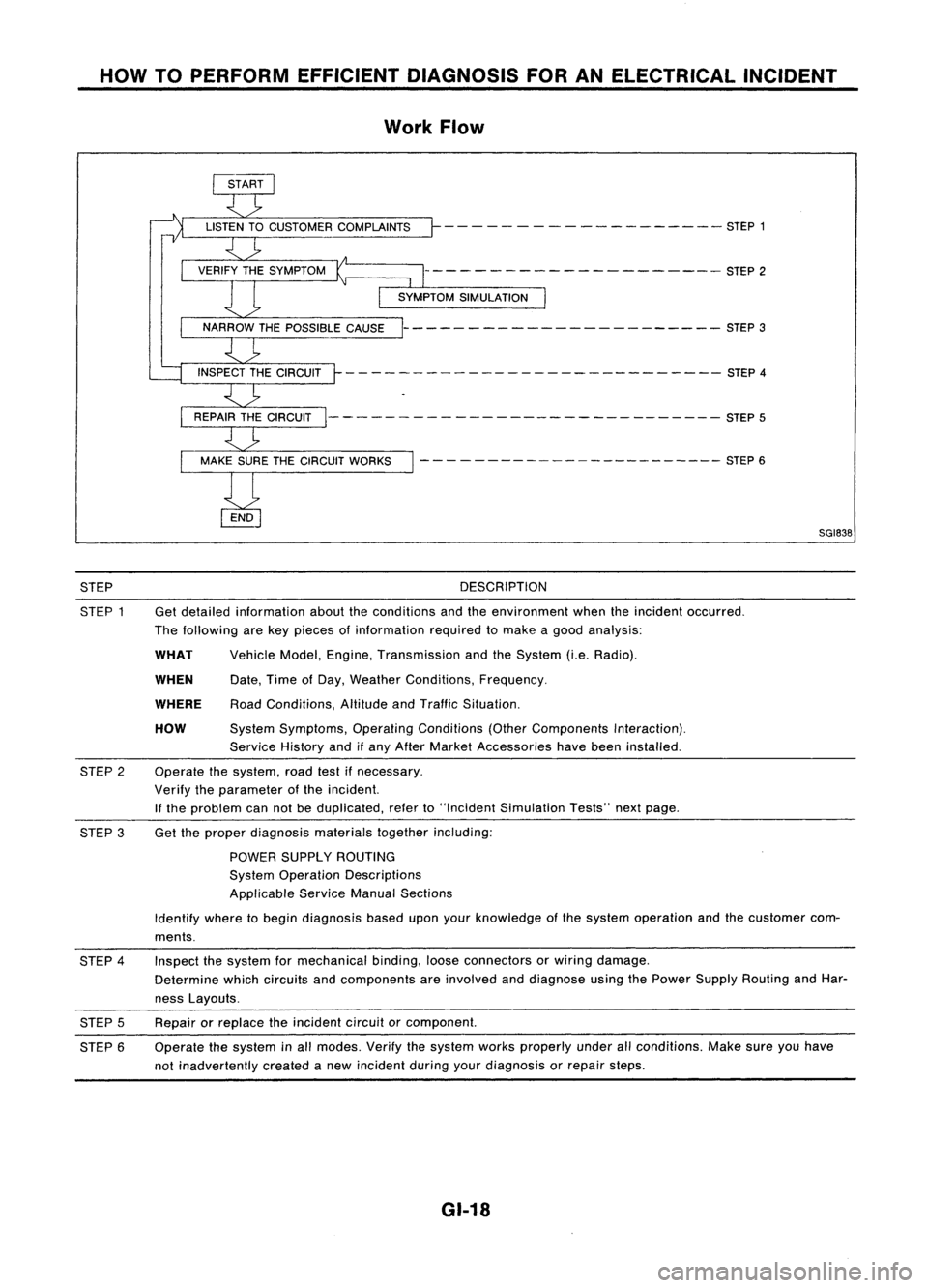

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Work Flow

- - - -- - -- ------ -- - -- STEP 1

--------------------- STEP2

----------------------- STEP3

- - -- ---- - --- - -- --- --- - - --- -- STEP 4

--------- -------------------- STEP5

- - - - ---- -- -- -- -- -- --- --- STEP 6

SGI838

STEP

STEP 1 DESCRIPTION

Get detailed information abouttheconditions andtheenvironment whentheincident occurred.

The following arekey pieces ofinformation requiredtomake agood analysis:

HOW

WHEN

WHAT

WHERE

Vehicle

Model,Engine, Transmission andtheSystem (i.e.Radio).

Date, TimeofDay, Weather Conditions, Frequency.

Road Conditions, AltitudeandTraffic Situation.

System Symptoms, OperatingConditions (OtherComponents Interaction).

Service Historyandifany After Market Accessories havebeen installed.

Operate thesystem, roadtestifnecessary.

Verify theparameter ofthe incident.

If the problem cannotbeduplicated, referto"Incident Simulation Tests"nextpage.

STEP

2

STEP 3Get

theproper diagnosis materialstogetherincluding:

POWER SUPPLY ROUTING

System Operation Descriptions

Applicable ServiceManualSections

Identify wheretobegin diagnosis baseduponyourknowledge ofthe system operation andthecustomer com-

ments.

STEP 4

STEP 5

STEP 6 Inspect

thesystem formechanical binding,looseconnectors orwiring damage.

Determine whichcircuits andcomponents areinvolved anddiagnose usingthePower Supply Routing andHar-

ness Layouts.

Repair orreplace theincident circuitorcomponent.

Operate thesystem inall modes. Verifythesystem worksproperly underallconditions. Makesureyouhave

not inadvertently createdanew incident duringyourdiagnosis orrepair steps.

GI-18

Page 1373 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Incident Simulation Tests

INTRODUCTION

Sometimes thesymptom isnot present whenthevehicle isbrought infor service.

If

possible, re-create

the conditions presentatthe time ofthe incident. Doingsomay help avoid aNo Trouble FoundDiag-

nosis. Thefollowing sectionillustrates waystosimulate theconditionslenvironment underwhich the

owner experiences anelectrical incident.

The section isbroken intothesixfollowing topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold orhot start up

Get athorough description ofthe incident fromthecustomer. Itis important forsimulating thecondi-

tions ofthe problem.

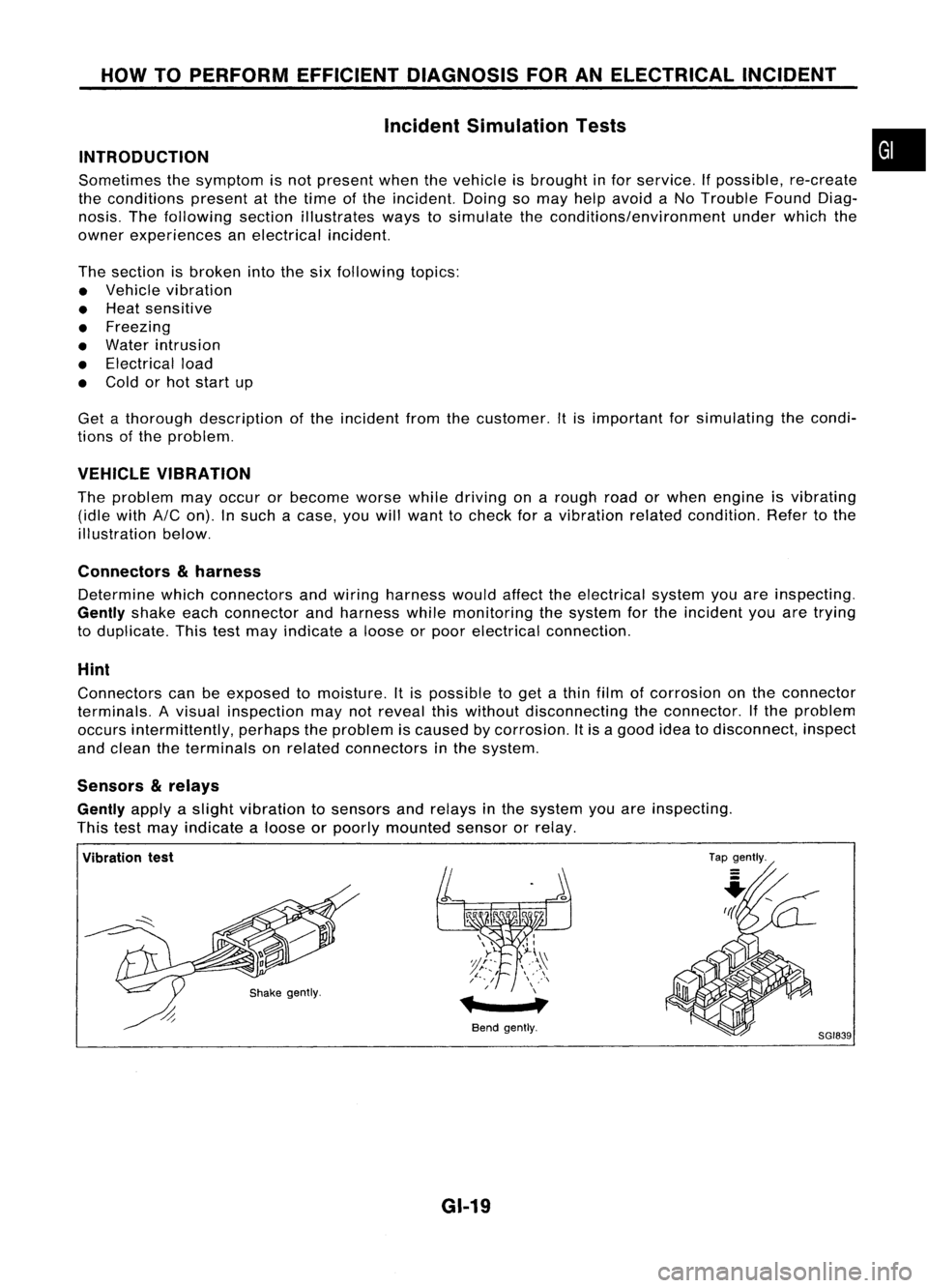

VEHICLE VIBRATION

The problem mayoccur orbecome worsewhiledriving onarough roadorwhen engine isvibrating

(idle with

AIC

on). Insuch acase, youwillwant tocheck foravibration relatedcondition. Refertothe

illustration below.

Connectors

&

harness

Determine whichconnectors andwiring harness wouldaffecttheelectrical systemyouareinspecting.

Gently

shakeeachconnector andharness whilemonitoring thesystem forthe incident youaretrying

to duplicate. Thistestmay indicate aloose orpoor electrical connection.

Hint

Connectors canbeexposed tomoisture. Itis possible toget athin film ofcorrosion onthe connector

terminals. Avisual inspection maynotreveal thiswithout disconnecting theconnector. Ifthe problem

occurs intermittently, perhapstheproblem iscaused bycorrosion. Itis agood ideatodisconnect, inspect

and clean theterminals onrelated connectors inthe system.

Sensors

&

relays

Gently

applyaslight vibration tosensors andrelays inthe system youareinspecting.

This testmay indicate aloose orpoorly mounted sensororrelay.

•

Vibration test

Bendgently.

GI-19

Tap

gently.

8GI839

Page 1374 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

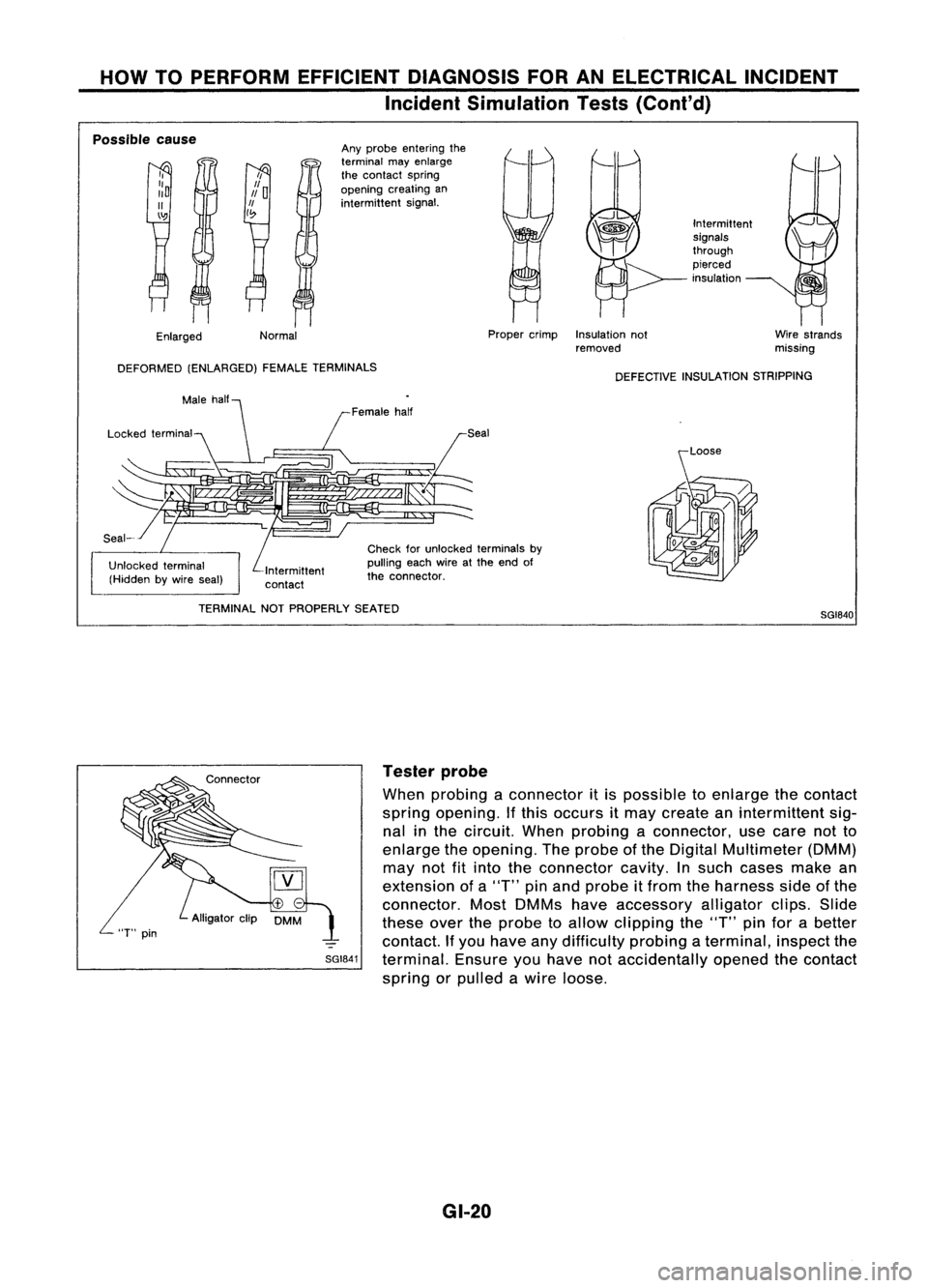

Incident Simulation Tests(Cont'd)

Wirestrands

missing

Intermittent

signals

through

pierced

insulation

Proper crimp Insulation not

removed

Any

probe entering the

terminal mayenlarge

the contact spring

opening creatingan

intermittent signal.

Normal

II

Po

1/

I~

I,

::0

II

\':!J

Enlarged

Possible

cause

DEFORMED (ENLARGED) FEMALETERMINALS

DEFECTIVEINSULATION STRIPPING

Seal

Intermittent

contact Female

half

Check forunlocked terminals by

pulling eachwireatthe end of

the connector.

/

[1/

TERMINAL NOTPROPERLY SEATED

SGI840

SGI841 Tester

probe

When probing aconnector itis possible toenlarge thecontact

spring opening. Ifthis occurs itmay create anintermittent sig-

nal inthe circuit. Whenprobing aconnector, usecare notto

enlarge theopening. Theprobe ofthe Digital Multimeter (DMM)

may notfitinto theconnector cavity.

In

such cases makean

extension ofa"T" pinand probe itfrom theharness sideofthe

connector. MostDMMs haveaccessory alligatorclips.Slide

these overtheprobe toallow clipping the"T" pinforabetter

contact. Ifyou have anydifficulty probingaterminal, inspectthe

terminal. Ensureyouhave notaccidentally openedthecontact

spring orpulled awire loose.

GI-20

Page 1375 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Incident Simulation Tests(Cont'd)

Engine compartment

There areseveral reasons avehicle orengine vibration could•

cause anelectrical complaint. Someofthe things tocheck for

are:

• Connectors notfully seated.

• Wiring harness notlong enough andisbeing stressed due

to engine vibrations orrocking.

• Wires laying across brackets ormoving components.

• Loose, dirtyorcorroded groundwires.

• Wires routed tooclose tohot components.

To inspect components underthehood, startbyverifying the

integrity ofground connections. (RefertoGROUND INSPEC-

TION described later.)Firstcheck thatthesystem isproperly

grounded. Thencheck forloose connection by

gently shaking

the wiring orcomponents aspreviously explained. Usingthe

wiring diagrams inspectthewiring forcontinuity.

Behind theinstrument panel

An improperly routedorimproperly clampedharnesscan

become pinchedduringaccessory installation. Vehiclevibra-

tion canaggravate aharness whichisrouted alongabracket

or near ascrew.

Under seating areas

An unclamped orloose harness cancause wiring tobe pinched

by seat components (suchasslide guides) duringvehicle vibra-

tion. Ifthe wiring runsunder seating areas,inspect wirerout-

ing forpossible damageorpinching.

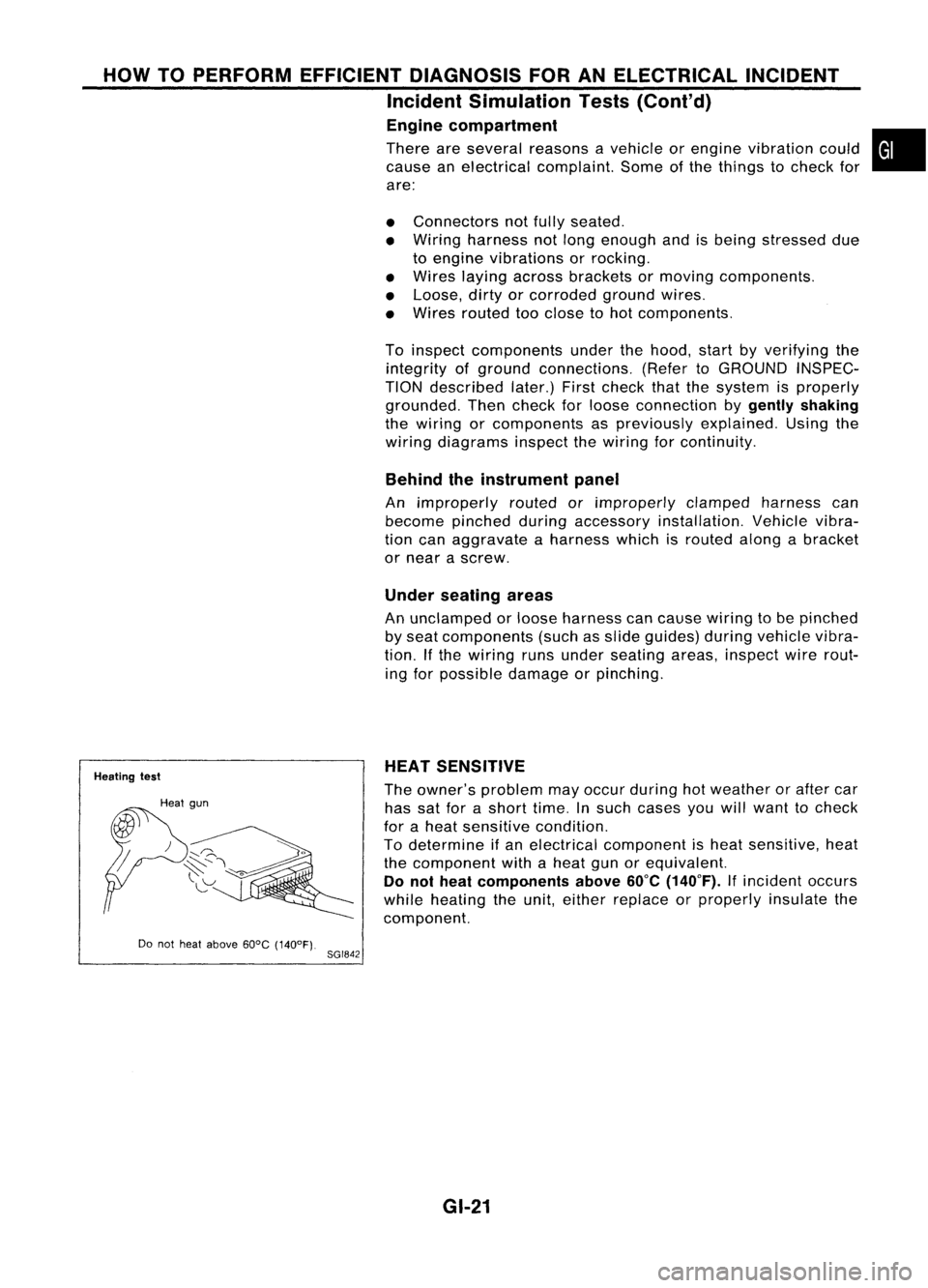

Heating test

Do not heat above 60°C(140°F).

8GI842 HEAT

SENSITIVE

The owner's problem mayoccur during hotweather orafter car

has satforashort time.Insuch cases youwillwant tocheck

for aheat sensitive condition.

To determine ifan electrical component isheat sensitive, heat

the component withaheat gunorequivalent.

Do not heat components above

60°C

(140°F).

Ifincident occurs

while heating theunit, either replace orproperly insulatethe

component.

GI-21

Page 1376 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Incident Simulation Tests(Cont'd)

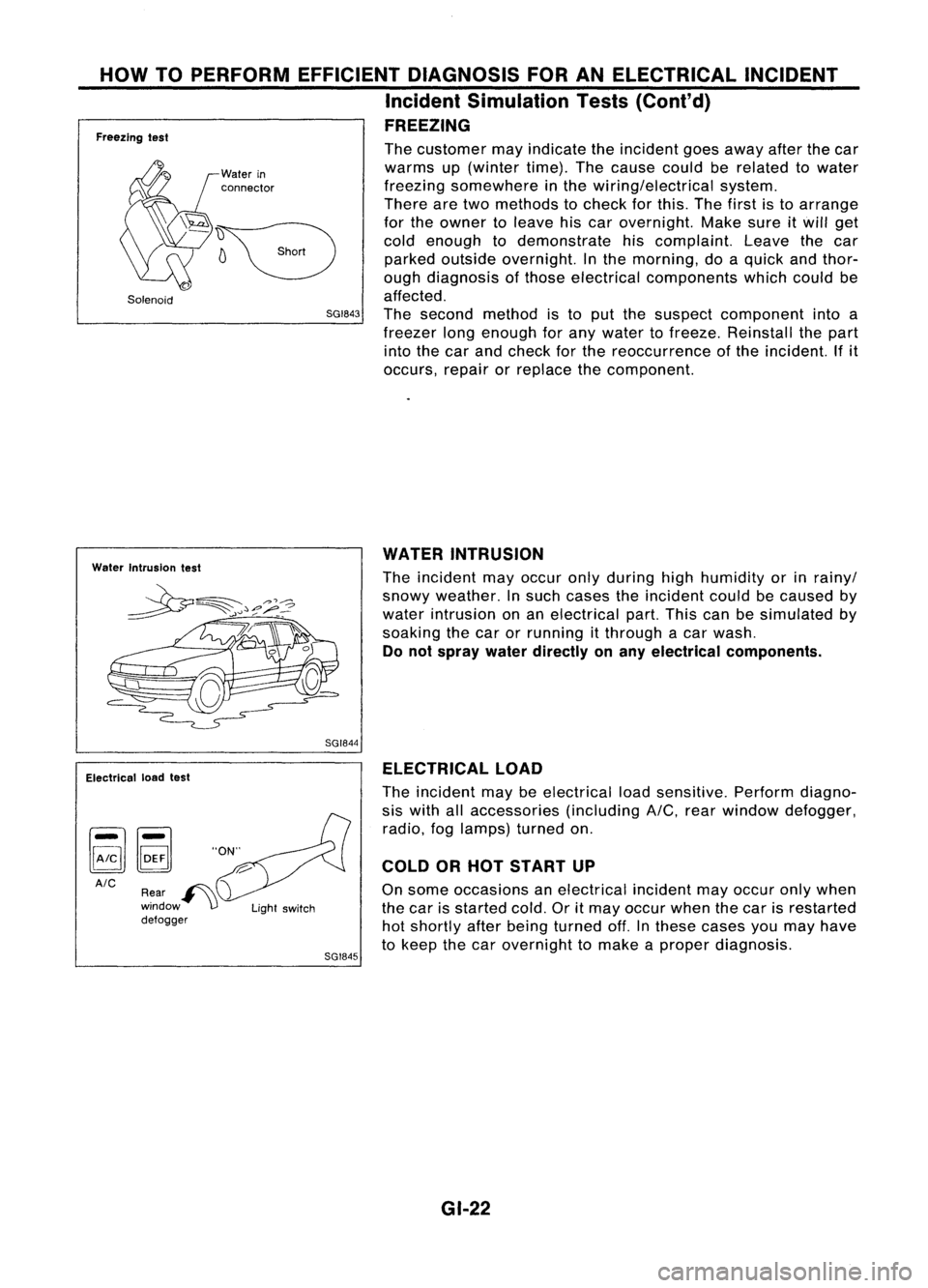

FREEZING

Freezing test

Solenoid

Water

in

connector

The

customer mayindicate theincident goesaway afterthecar

warms up(winter time).Thecause couldberelated towater

freezing somewhere inthe wiring/electrical system.

There aretwo methods tocheck forthis. Thefirst isto arrange

for the owner toleave hiscar overnight. Makesureitwill get

cold enough todemonstrate hiscomplaint. Leavethecar

parked outside overnight. Inthe morning, doaquick andthor-

ough diagnosis ofthose electrical components whichcouldbe

affected.

SGI843

Thesecond method isto put the suspect component intoa

freezer longenough forany water tofreeze. Reinstall thepart

into thecar and check forthe reoccurrence ofthe incident. Ifit

occurs, repairorreplace thecomponent.

Water Intrusion test

WATER

INTRUSION

The incident mayoccur onlyduring highhumidity orinrainy/

snowy weather. Insuch cases theincident couldbecaused by

water intrusion onan electrical part.Thiscanbesimulated by

soaking thecar orrunning itthrough acar wash.

Do not spray waterdirectly onany electrical components.

SGI844

Electrical loadtest

AIC SGI845ELECTRICAL

LOAD

The incident maybeelectrical loadsensitive. Performdiagno-

sis with allaccessories (includingA/C,rearwindow defogger,

radio, foglamps) turnedon.

COLD ORHOT START UP

On some occasions anelectrical incidentmayoccur onlywhen

the car isstarted cold.Oritmay occur whenthecar isrestarted

hot shortly afterbeing turned off.Inthese cases youmay have

to keep thecar overnight tomake aproper diagnosis.

GI-22

Page 1377 of 1701

•SHORT CIRCUIT

• SHORT TOGROUND

HOW

TOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Circuit Inspection

•

A circuit isopen when thereisno continuity throughasection ofthe circuit.

There aretwo types ofshorts.

Whenacircuit contacts anothercircuitandcauses the

normal resistance tochange.

When acircuit contacts aground sourceandgrounds the

circuit.

INTRODUCTION

In general, testingelectrical circuitsisan easy taskifitis approached inalogical andorganized method.

Before beginning itis important tohave allavailable information onthe system tobe tested. Also,get

a thorough understanding ofsystem operation. Thenyouwillbeable touse theappropriate equipment

and follow thecorrect testprocedure.

You may have tosimulate vehiclevibrations whiletesting electrical components.

Gentlyshake

thewir-

ing harness orelectrical component todo this.

OPEN

SHORT

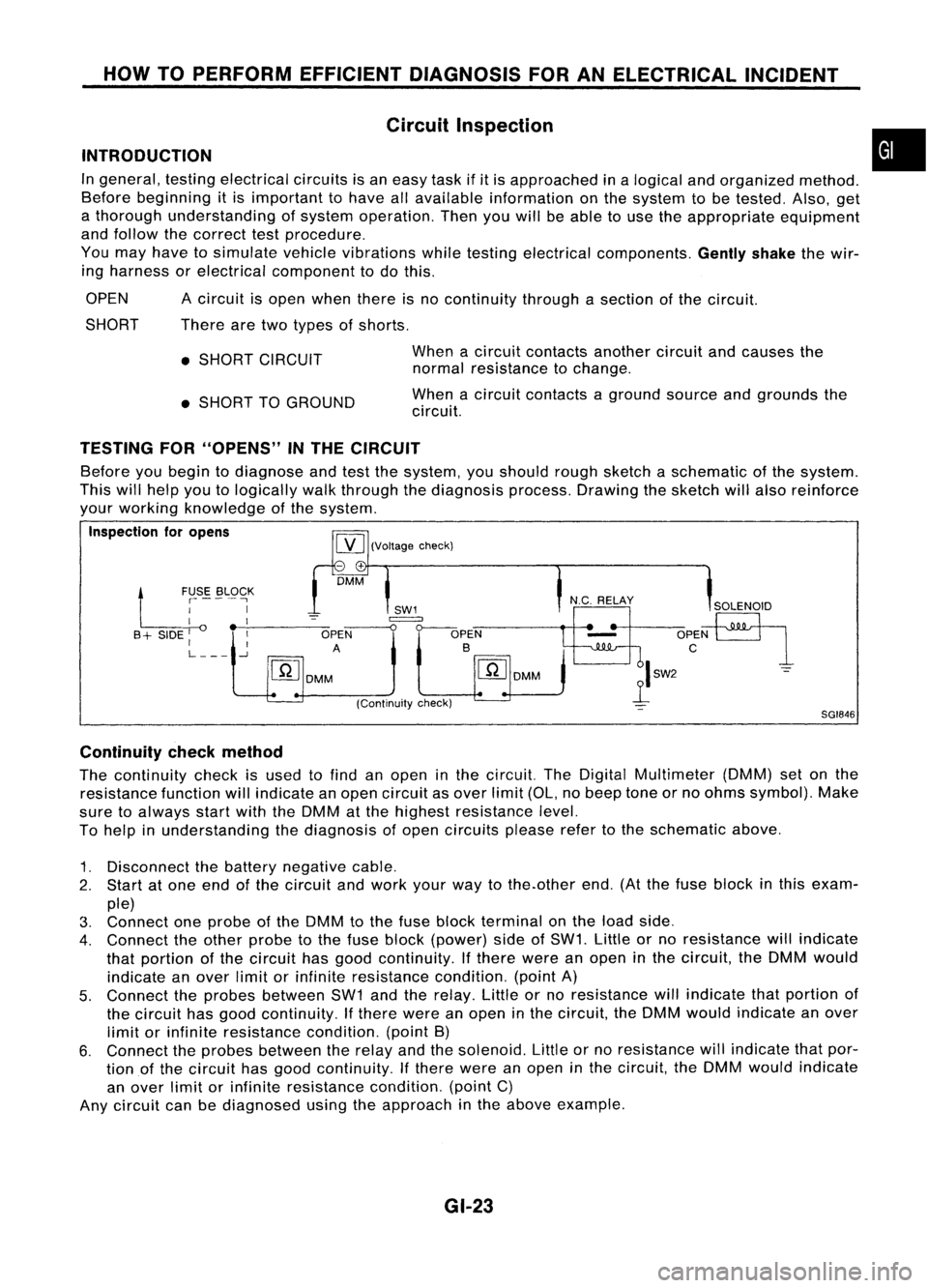

TESTING FOR"OPENS" INTHE CIRCUIT

[YJ

(Voltage check)

Before

youbegin todiagnose andtestthesystem, youshould roughsketch aschematic ofthe system.

This willhelp youtologically walkthrough thediagnosis process.Drawingthesketch willalso reinforce

your working knowledge ofthe system.

Inspection foropens

-+

DMM

Ll

~SE. ~L9~K

I

I

I __-,----

B + SIDE

I

OPEN

I I

A

L

-.J

[ill

DMM

SGI846

Continuity checkmethod

The continuity checkisused tofind anopen inthe circuit. TheDigital Multimeter (DMM)setonthe

resistance functionwillindicate anopen circuit asover limit(OL,nobeep toneorno ohms symbol). Make

sure toalways startwiththeDMM atthe highest resistance level.

To help inunderstanding thediagnosis ofopen circuits pleaserefertothe schematic above.

1. Disconnect thebattery negative cable.

2. Start atone end ofthe circuit andwork yourwaytothe.other end.(Atthe fuse block inthis exam-

ple)

3. Connect oneprobe ofthe DMM tothe fuse block terminal onthe load side.

4. Connect theother probe tothe fuse block (power) sideofSW1. Littleorno resistance willindicate

that portion ofthe circuit hasgood continuity. Ifthere wereanopen inthe circuit, theDMM would

indicate anover limitorinfinite resistance condition.(pointA)

5. Connect theprobes between SW1andtherelay. Littleorno resistance willindicate thatportion of

the circuit hasgood continuity. Ifthere wereanopen inthe circuit, theDMM would indicate anover

limit orinfinite resistance condition.(pointB)

6. Connect theprobes between therelay andthesolenoid. Littleorno resistance willindicate thatpor-

tion ofthe circuit hasgood continuity. Ifthere wereanopen inthe circuit, theDMM would indicate

an over limitorinfinite resistance condition.(pointC)

Any circuit canbediagnosed usingtheapproach inthe above example.

GI-23

Page 1378 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

Voltage checkmethod

To help inunderstanding thediagnosis ofopen circuits pleaserefertothe previous schematic.

In any powered circuit,anopen canbefound bymethodically checkingthesystem forthe presence of

voltage. Thisisdone byswitching theDMM tothe voltage function.

1. Connect oneprobe ofthe DMM toaknown goodground.

2. Begin probing atone endofthe circuit andwork yourwaytothe other end.

3. With SW1open, probe atSW1 tocheck forvoltage.

voltage; openisfurther downthecircuit thanSW1.

no voltage; openisbetween fuseblock andSW1 (point A).

4. Close SW1andprobe atrelay.

voltage; openisfurther downthecircuit thantherelay.

no voltage; openisbetween SW1andrelay (point B).

5. Close therelay andprobe atthe solenoid.

voltage; openisfurther downthecircuit thanthesolenoid.

no voltage; openisbetween relayandsolenoid (pointC).

Any powered circuitcanbediagnosed usingtheapproach inthe above example.

SGI847

RELAY

~I SH~

SW2

c

1

(Resistance

check)

IGN "ON"

t

OR "S~:R.T~ '::~SEBLOCK

I I '-

SWl

I I

-=

B+SIOEl~~-:-~

~r-o~

SHORT SHORT

[YJ

DMMA B

+ -

(Voltage check)

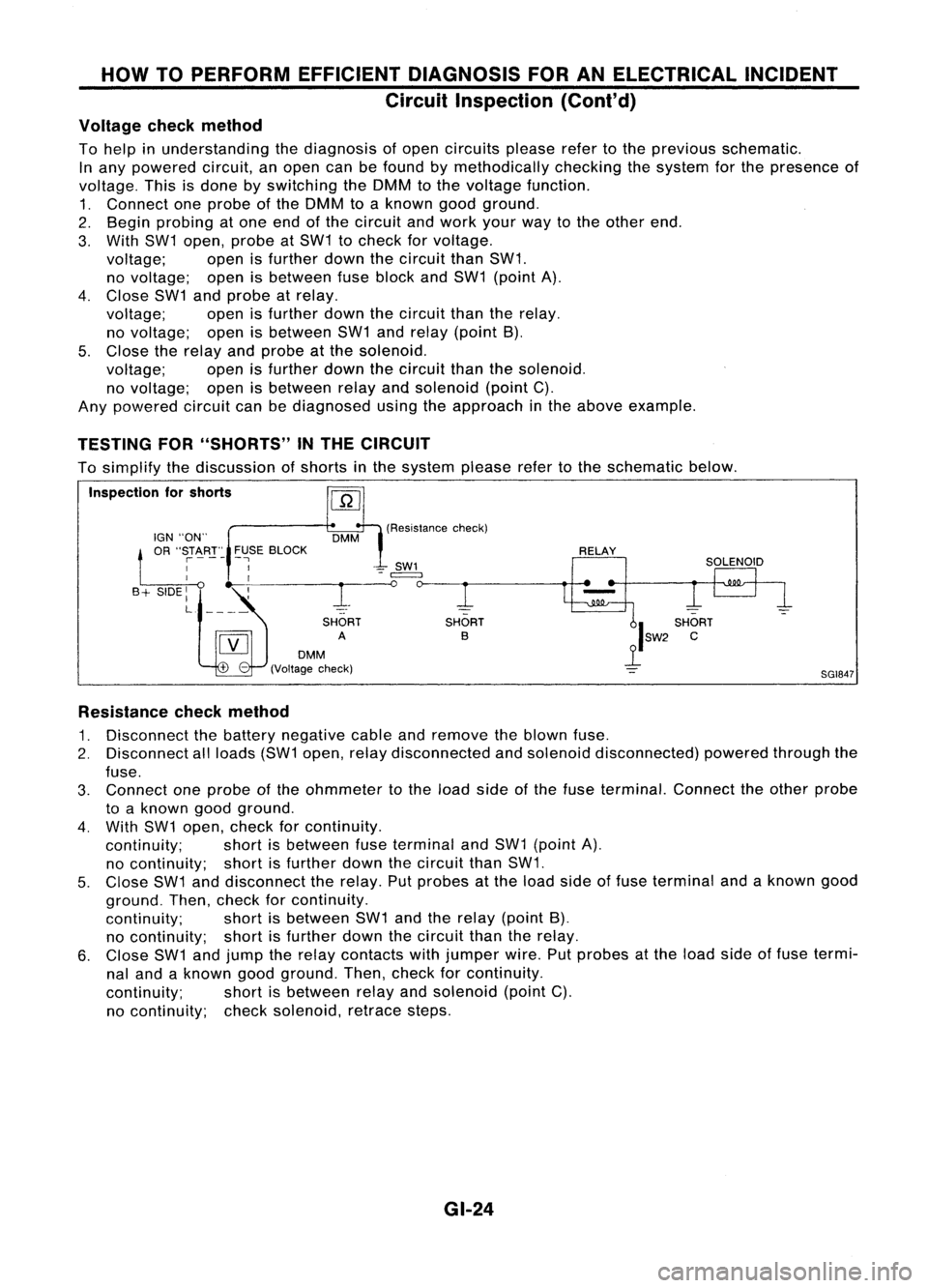

TESTING

FOR"SHORTS" INTHE CIRCUIT

To simplify thediscussion ofshorts inthe system pleaserefertothe schematic below.

Inspection forshorts

Resistance checkmethod

1. Disconnect thebattery negative cableandremove theblown fuse.

2. Disconnect allloads (SW1open, relaydisconnected andsolenoid disconnected) poweredthroughthe

fuse.

3. Connect oneprobe ofthe ohmmeter tothe load sideofthe fuse terminal. Connecttheother probe

to aknown goodground.

4. With SW1open, check forcontinuity.

continuity; shortisbetween fuseterminal andSW1 (point A).

no continuity; shortisfurther downthecircuit thanSW1.

5. Close SW1anddisconnect therelay. Putprobes atthe load side offuse terminal andaknown good

ground. Then,check forcontinuity.

continuity; shortisbetween SW1andtherelay (point B),

no continuity; shortisfurther downthecircuit thantherelay.

6. Close SW1andjump therelay contacts withjumper wire.Putprobes atthe load sideoffuse termi-

nal and aknown goodground. Then,check forcontinuity.

continuity; shortisbetween relayandsolenoid (pointC).

no continuity; checksolenoid, retracesteps.

GI-24

Page 1379 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

Voltage checkmethod

1. Remove theblown fuseanddisconnect allloads (i.e.SW1 open, relaydisconnected andsolenoid •

disconnected) poweredthroughthefuse.

2. Turn theignition keytothe ONorSTART position. Verifybattery voltage atthe B

+

side ofthe fuse

terminal (oneleadonthe B

+

terminal sideofthe fuse block andone lead onaknown goodground).

3. With SW1 open andtheDMM leads across bothfuseterminals, checkforvoltage.

voltage; shortisbetween fuseblock andSW1 (point A).

no voltage; shortisfurther downthecircuit thanSW1.

4. With SW1 closed, relayandsolenoid disconnected andtheDMM leadsacross bothfuseterminals,

check forvoltage.

voltage; shortisbetween SW1andtherelay (point B).

no voltage; shortisfurther downthecircuit thantherelay.

5. With SW1 closed, relaycontacts jumpedwithfused jumper wirecheck forvoltage.

voltage; shortisdown thecircuit ofthe relay orbetween therelay andthedisconnected sole-

noid (point C).

no voltage; retracestepsandcheck power tofuse block.

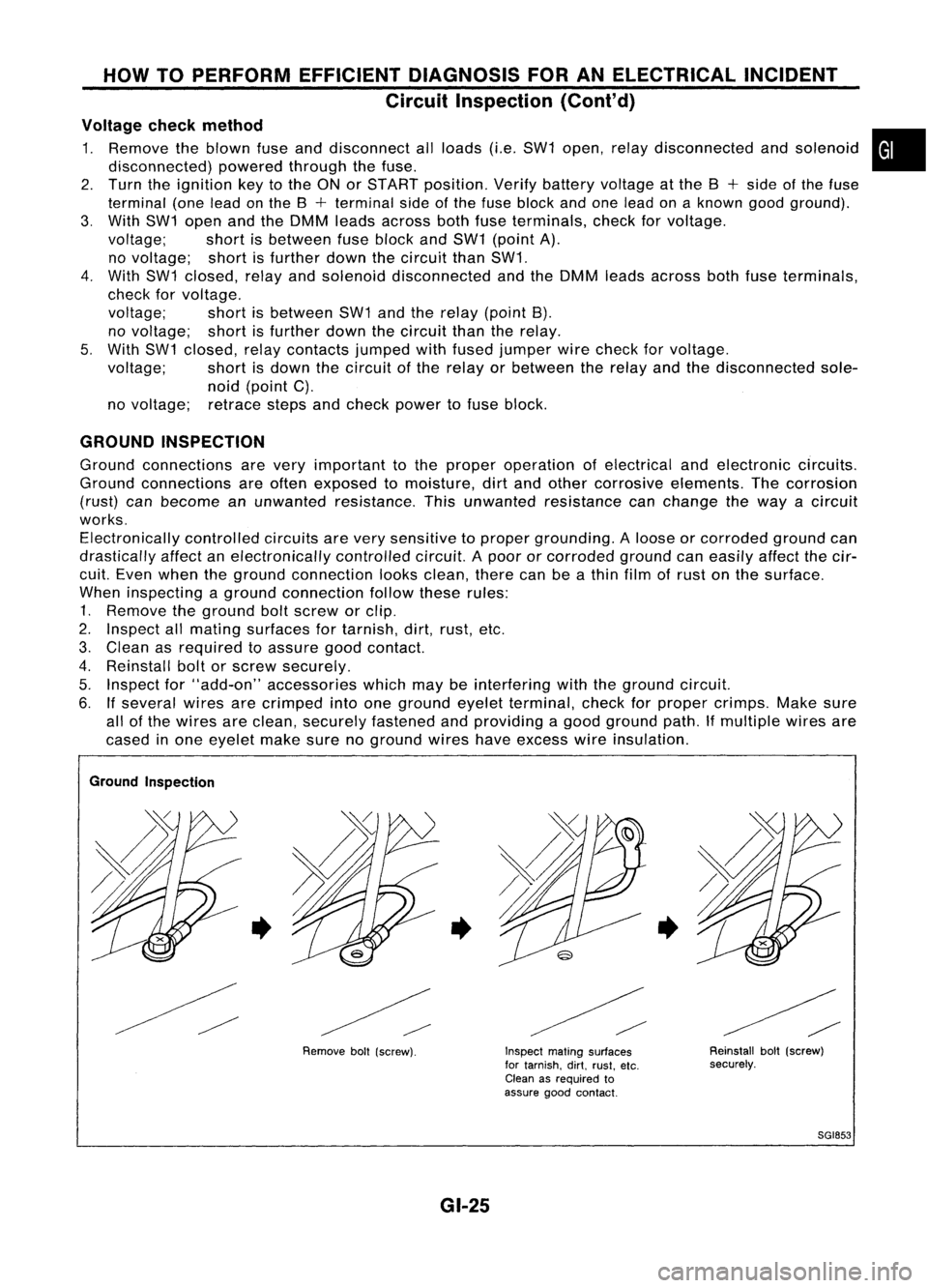

GROUND INSPECTION

Ground connections arevery important tothe proper operation ofelectrical andelectronic circuits.

Ground connections areoften exposed tomoisture, dirtand other corrosive elements. Thecorrosion

(rust) canbecome anunwanted resistance. Thisunwanted resistance canchange theway acircuit

works. Electronically controlledcircuitsarevery sensitive toproper grounding. Aloose orcorroded groundcan

drastically affectanelectronically controlledcircuit.Apoor orcorroded groundcaneasily affectthecir-

cuit. Even when theground connection looksclean, therecanbeathin film ofrust onthe surface.

When inspecting aground connection followtheserules:

1. Remove theground boltscrew orclip.

2. Inspect allmating surfaces fortarnish, dirt,rust, etc.

3. Clean asrequired toassure goodcontact.

4. Reinstall boltorscrew securely.

5. Inspect for"add-on" accessories whichmaybeinterfering withtheground circuit.

6. Ifseveral wiresarecrimped intoone ground eyeletterminal, checkforproper crimps. Makesure

all ofthe wires areclean, securely fastened andproviding agood ground path.Ifmultiple wiresare

cased inone eyelet makesurenoground wireshaveexcess wireinsulation.

Ground Inspection

•

Removeboll(screw).

•

GI-25

Inspect

matingsurfaces

for tarnish. dirt.rust. etc.

Clean asrequired to

assure goodcontact.

•

Reinstallbolt(screw)

securely.

SGI853

Page 1380 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

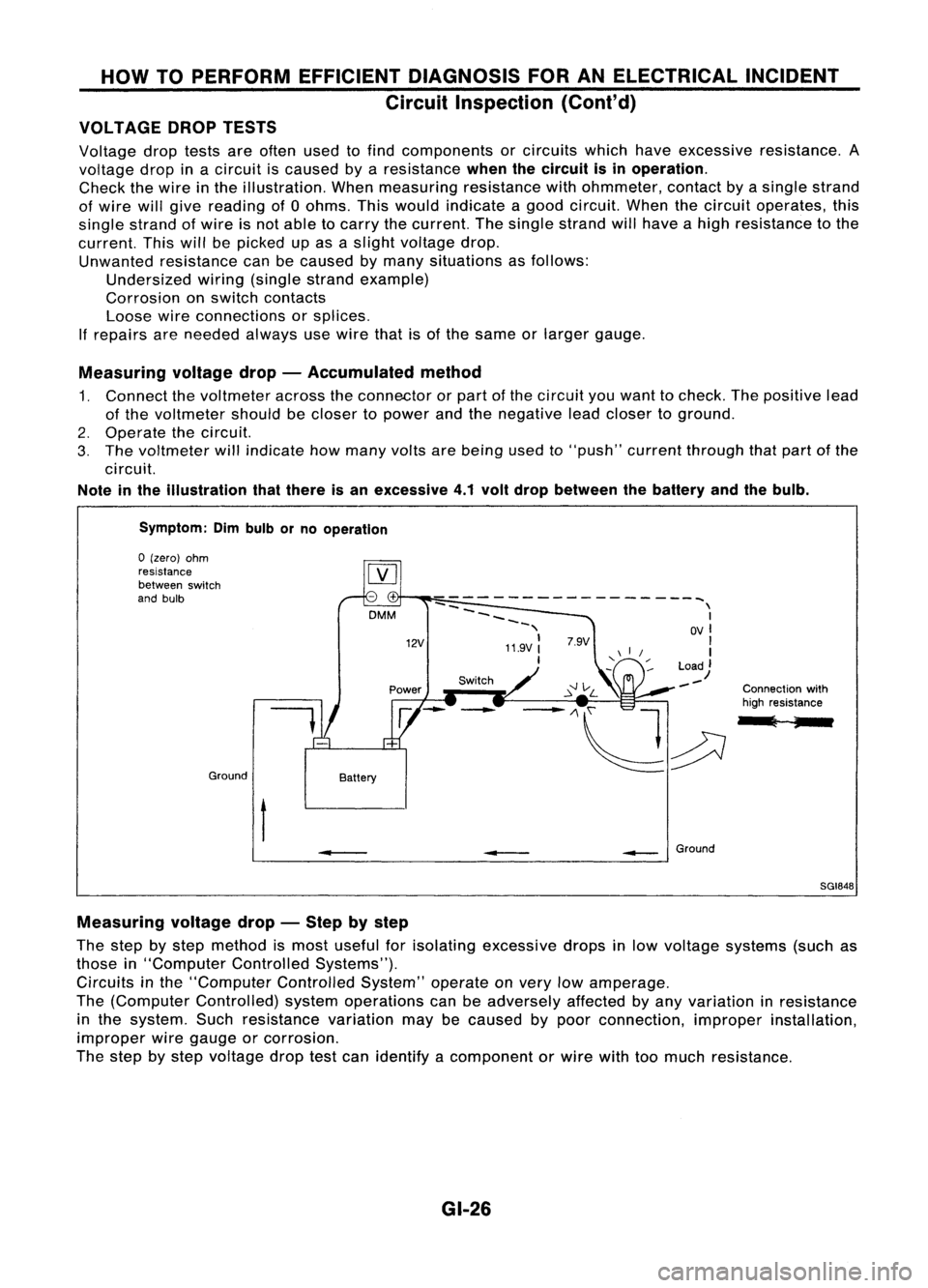

VOLTAGE DROPTESTS

Voltage droptests areoften usedtofind components orcircuits whichhaveexcessive resistance. A

voltage dropinacircuit iscaused byaresistance

whenthecircuit isin operation.

Check thewire inthe illustration. Whenmeasuring resistancewithohmmeter, contactbyasingle strand

of wire willgive reading of0ohms. Thiswould indicate agood circuit. Whenthecircuit operates, this

single strand ofwire isnot able tocarry thecurrent. Thesingle strand willhave ahigh resistance tothe

current. Thiswillbepicked upasaslight voltage drop.

Unwanted resistance canbecaused bymany situations asfollows:

Undersized wiring(single strandexample)

Corrosion onswitch contacts

Loose wireconnections orsplices.

If

repairs areneeded alwaysusewire thatisof the same orlarger gauge.

Measuring voltagedrop-Accumulated method

1. Connect thevoltmeter acrosstheconnector orpart ofthe circuit youwant tocheck. Thepositive lead

of the voltmeter shouldbecloser topower andthenegative leadcloser toground.

2. Operate thecircuit.

3. The voltmeter willindicate howmany voltsarebeing usedto"push" current through thatpart ofthe

circuit.

Note inthe illustration thatthere isan excessive 4.1volt drop between thebattery andthebulb.

Symptom: Dimbulb orno operation

Switch Connectionwith

high resistance

l ;

--

------------------~

--

\

~~~~ I

-, OVI

11.9V:

'I

I

Load)

--

12V

DMM

Battery

Ground

o

(zero) ohm

resistance

between switch

and bulb

t

•

__

Ground

SGI848

Measuring voltagedrop-Step bystep

The step bystep method ismost useful forisolating excessive dropsinlow voltage systems (suchas

those in"Computer ControlledSystems").

Circuits inthe "Computer ControlledSystem"operateonvery lowamperage.

The (Computer Controlled) systemoperations canbeadversely affectedbyany variation inresistance

in the system. Suchresistance variationmaybecaused bypoor connection, improperinstallation,

improper wiregauge orcorrosion.

The step bystep voltage droptestcan identify acomponent orwire withtoomuch resistance.

GI-26