NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1391 of 1701

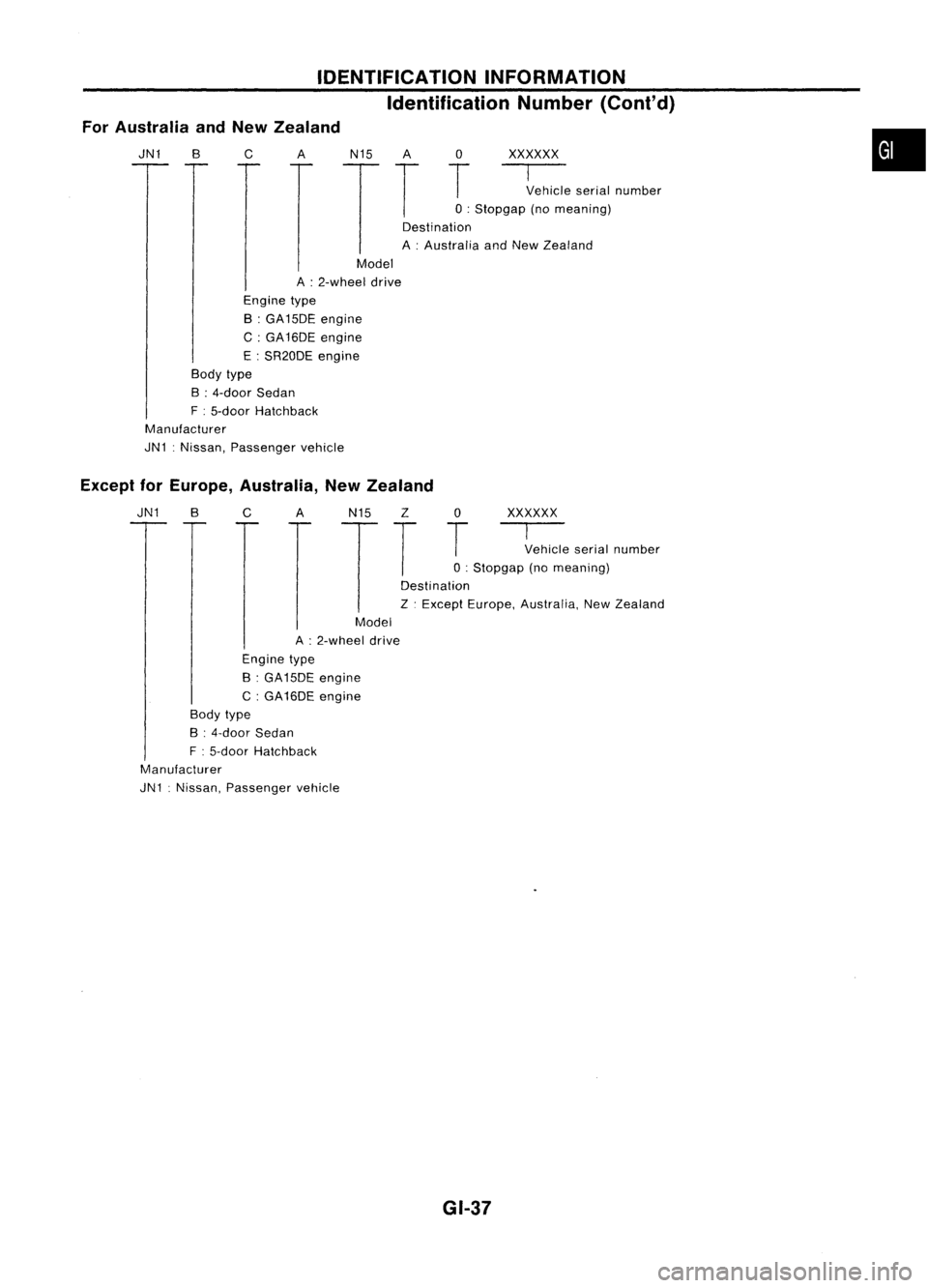

ForAustralia andNew Zealand IDENTIFICATION

INFORMATION

Identification Number(Cont'd)

JN1 B

c

A

N15A 0

xxxxxx

T

T

T

~ehicleserialnumber

o :

Stopgap (nomeaning)

Destination

A :Australia andNew Zealand

•

Model

A :2-wheel drive

Engine type

B :GA15DE engine

C: GA16DE engine

E :SR20DE engine

Body type

B :4-door Sedan

F :5-door Hatchback

Manufacturer

JN1 :Nissan, Passenger vehicle

Except forEurope, Australia, NewZealand

JN1 BC AN15Z 0

xxxxxx

T

T

T

~ehicleserialnumber

o :

Stopgap (nomeaning)

Destination

Z .Except Europe, Australia, NewZealand

Model

A :2-wheel drive

Engine type

B :GA 15DE engine

C :GA16DE engine

Body type

B :4-door Sedan

F :5-door Hatchback

Manufacturer

JN1 :Nissan, Passenger vehicle

GI.37

Page 1392 of 1701

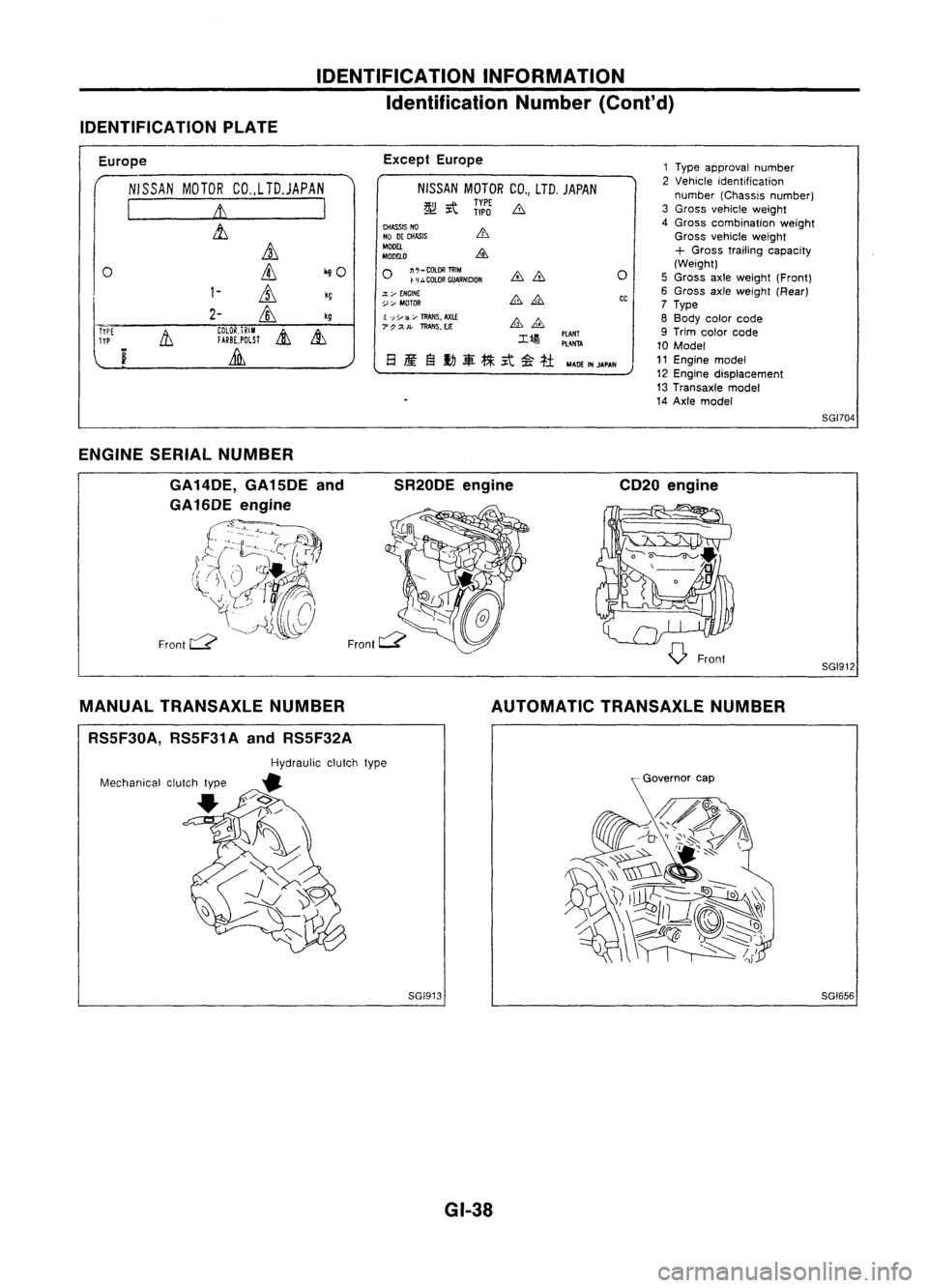

IDENTIFICATIONINFORMATION

Identification Number(Cont'd)

IDENTIFICATION PLATE

Europe

NISSAN MOTORCO.,LTD.JAPAN

I

It

I

&,

it

0

ill

iliO

1-

ill

kg

2-

&,

kg

Tri'[

11

COlOR.iRIM

&

&,

TYP

fARBE,POLSl

i

Lilli

Except

Europe

NISSAN MOTORCO.,LTD. JAPAN

~ it

ii:J

b

CHASS~ NO

NO DECHASIS

MODEL

MDDELO

o

~;::~:~~NlctDN

.:t;..-

ENGINE

~:,... MOTOR

~ ';;Y

3;..-

TRANS~

AXl.£

7P;;<'.

ll!AIIS.EJt:

M4DEINJAPAN

o

CC

1

Type approval number

2 Vehicle identification

number (Chassis number)

3 Gross vehicle weight

4 Gross combination weight

Gross vehicle weight

+

Gross trailing capacity

(Weight)

5 Gross axleweight (Front)

6 Gross axleweight (Rear)

7 Type

8 Body colorcode

9 Trim color code

10 Model

11 Engine model

12 Engine displacement

13 Transaxle model

14 Axle model

SGI704

ENGINE SERIALNUMBER

GA 14DE, GA15DE and

GA16DE engine

£~b-=~~rrf~)

(J~~~6

Front

c:::?

SR20DE

engine CD20engine

SGI912

MANUAL TRANSAXLE NUMBER

RS5F30A, RS5F31AandRS5F32A AUTOMATIC

TRANSAXLE NUMBER

SGI913 GI-38 SGI656

Page 1393 of 1701

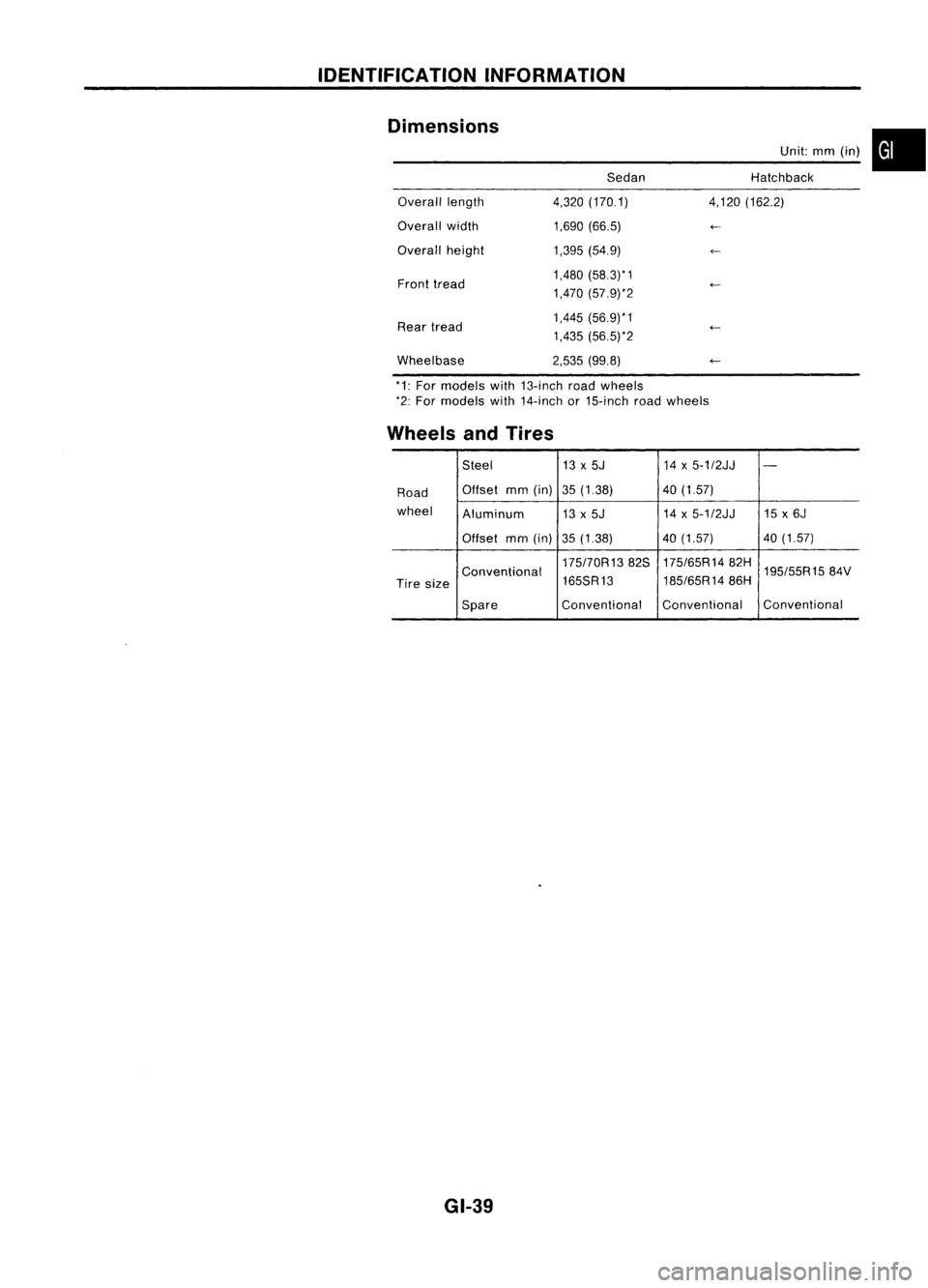

IDENTIFICATIONINFORMATION

Dimensions SedanUnit:

mm(in) •

Hatchback

Overall length

Overall width

Overall height

Front tread

Rear tread

Wheelbase 4,320

(170.1)

1,690 (66.5)

1,395 (54.9)

1,480 (58.3)* 1

1,470 (57.9)*2

1,445 (56.9)*1

1,435 (56.5)*2

2,535 (99.8) 4,120

(162.2)

*1: For models with13-inch roadwheels

*2: For models with14-inch or15-inch roadwheels

Wheels andTires

Steel 13x5J 14x5-1/2JJ

-

Road Offset

mm(in) 35(1.38) 40(1.57)

wheel Aluminum 13x5J 14

x5-1/2JJ 15x6J

Offset mm(in)

35(1.38) 40

(1.57) 40(1.57)

175170R1382S 175/65R1482H

195/55R1584V

Conventional

185/65R1486H

Tire size 165SR13

Spare Conventional

Conventional Conventional

GI-39

Page 1394 of 1701

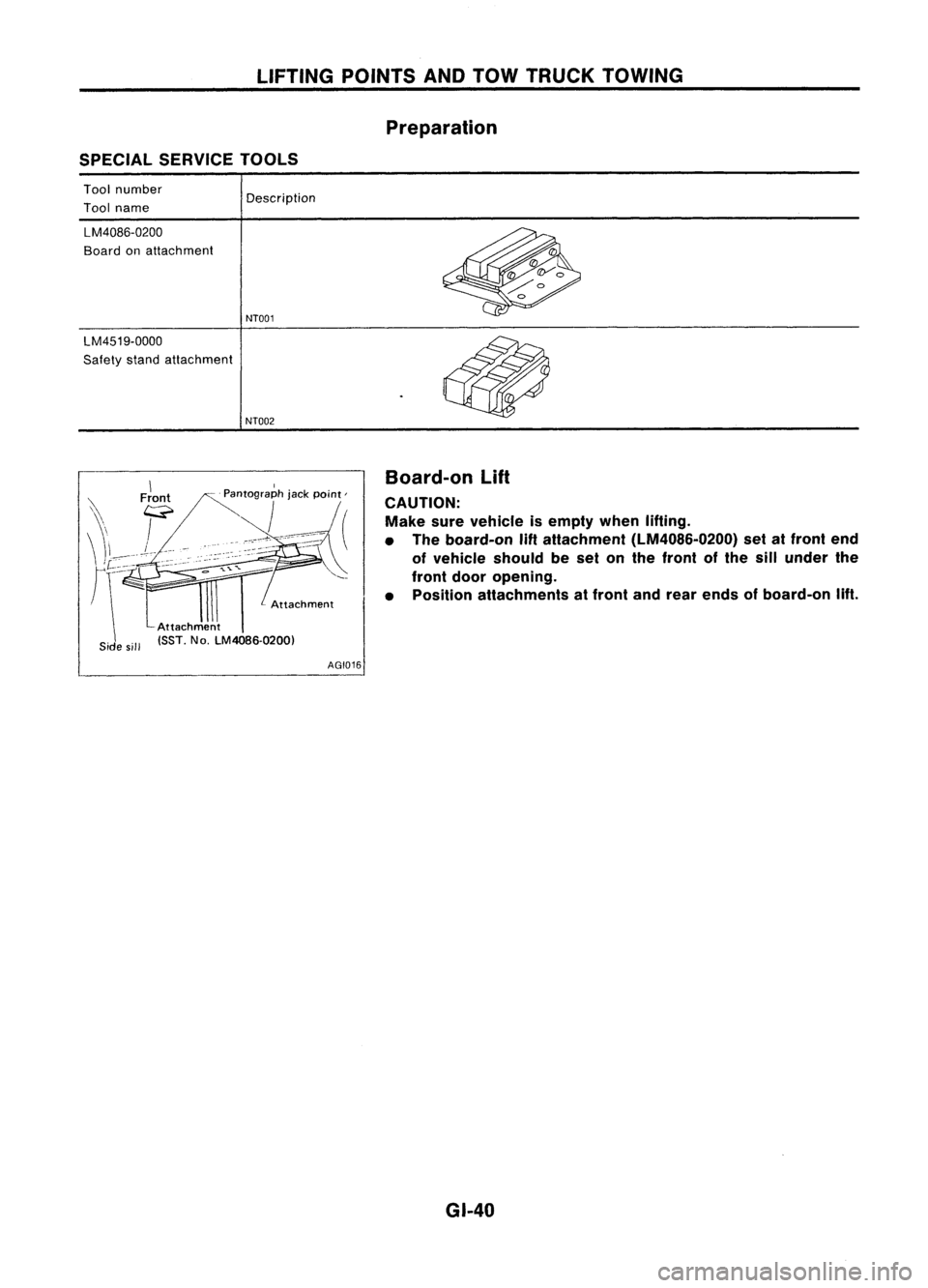

LIFTINGPOINTSANDTOW TRUCK TOWING

Preparation

SPECIAL SERVICE TOOLS

Tool number

Tool name

LM4086-0200

Board onattachment

LM4519-0000

Safety standattachment Description

NT001

NT002

\

'\ Front

\\ F

\\1_ L.--

<

'f- --

r\-=-

Attachment

Attachment

Side sill ISST. No.LM40B6.0200)

AGI016Board-on

Lift

CAUTION: Make surevehicle isempty whenlifting.

• The board-on

lift

attachment (LM4086-0200) setatfront end

of vehicle shouldbeset onthe front ofthe sillunder the

front dooropening.

• Position attachments atfront andrear ends ofboard-on lift.

GI-40

Page 1395 of 1701

LIFTINGPOINTSANDTOW TRUCK TOWING

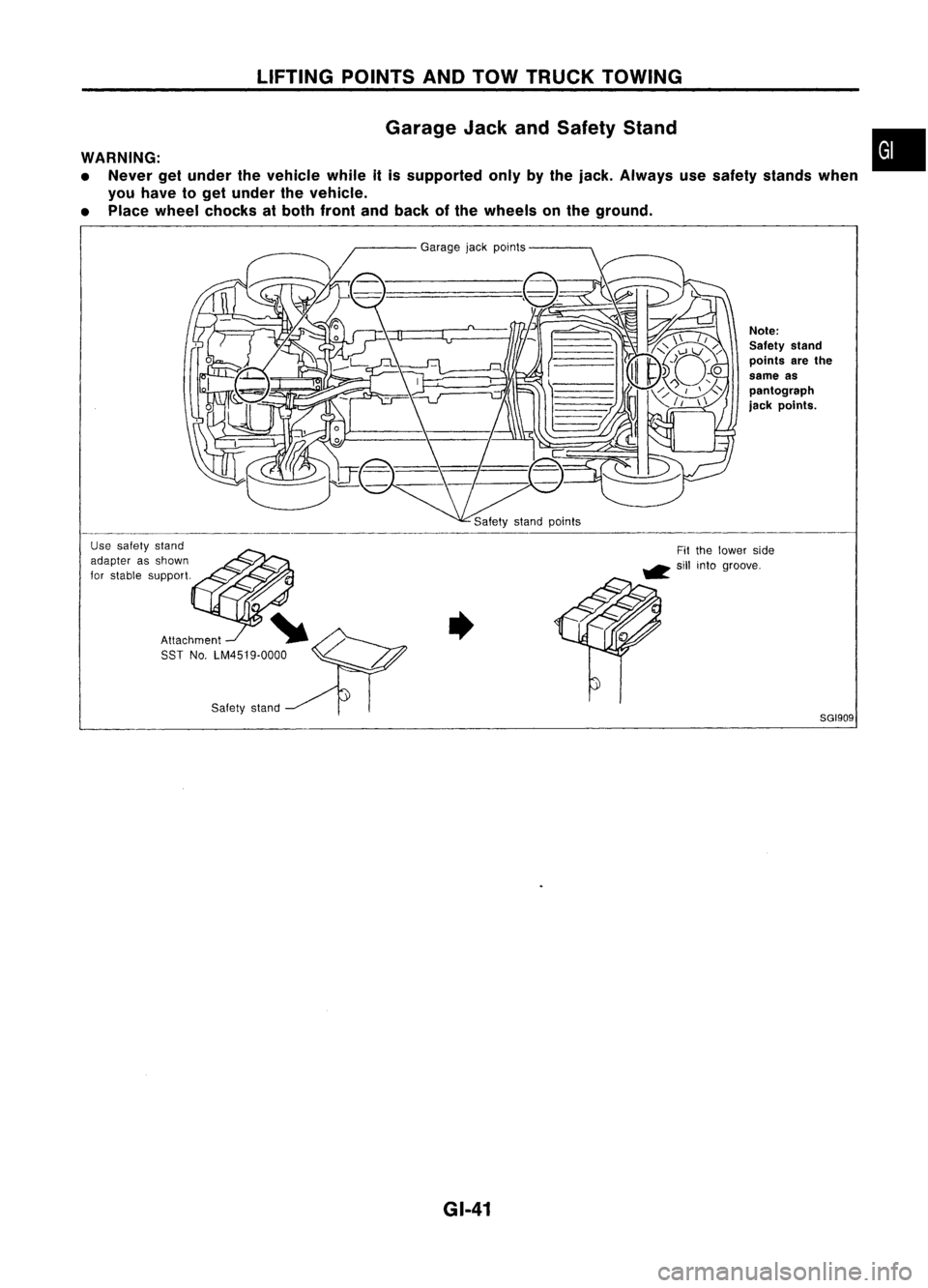

Garage JackandSafety Stand

WARNING:

• Never getunder thevehicle whileitis supported onlybythe jack. Always usesafety stands when

you have toget under thevehicle.

• Place wheel chocks atboth front andback ofthe wheels onthe ground.

•

Safety stand

8GI909

Note:

Safety stand

points arethe

same as

pantograph

jack points.

Garage

jackpoints

Attachment SST No.LM4519.0000

Use

safety stand

adapter asshown

for stable support.

GI-41

Page 1396 of 1701

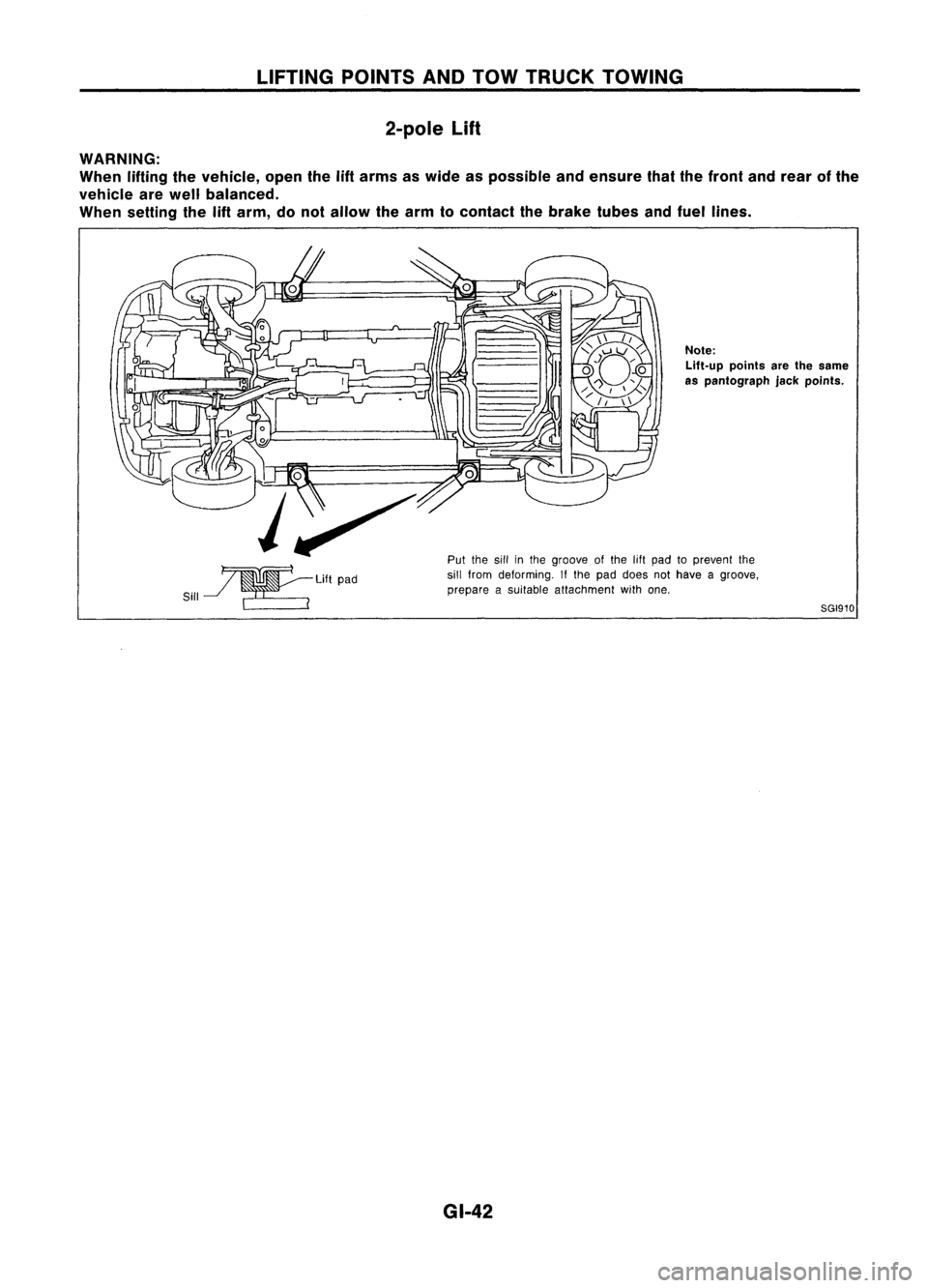

LIFTINGPOINTSANDTOW TRUCK TOWING

2-pole

Lift

WARNING:

When liftingthevehicle, openthe

lift

arms aswide aspossible andensure thatthefront andrear ofthe

vehicle arewell balanced.

When setting the

lift

arm, donot allow thearm tocontact thebrake tubesandfuel lines.

~LiftPad

Sill ~ ~__ ~ ~..

~---

Note:

Lift-up pointsarethesame

as pantograph jackpoints.

Put thesillinthe groove ofthe 11ftpad toprevent the

sill from deforming. Ifthe pad does nothave agroove,

prepare asuitable attachment withone.

8GI910

GI-42

Page 1397 of 1701

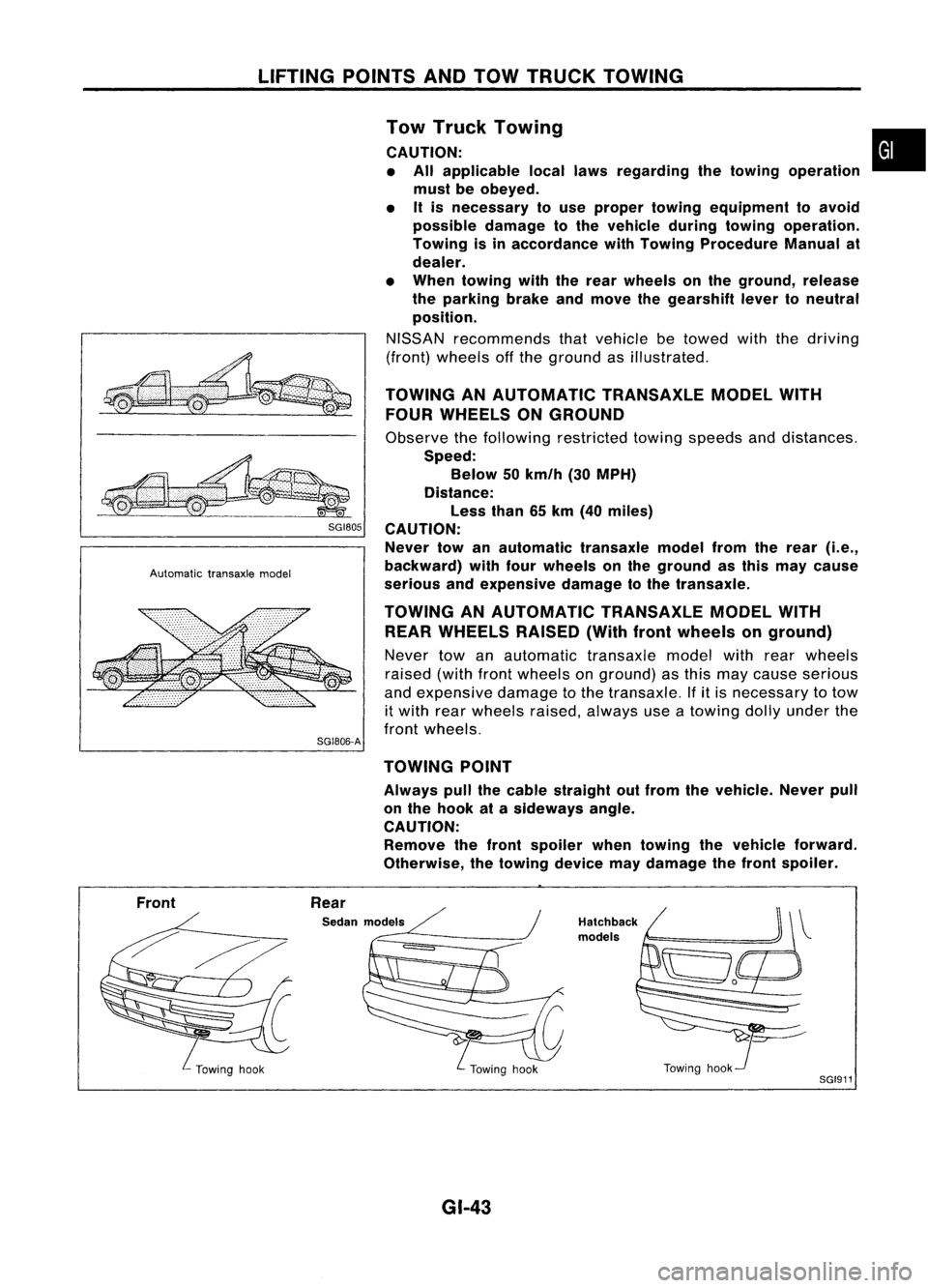

LIFTINGPOINTSANDTOW TRUCK TOWING

~ SGI80S

Automatic transaxlemodel

SG1806-A Tow

Truck Towing •

CAUTION: • All applicable locallawsregarding thetowing operation

must beobeyed.

• Itis necessary touse proper towing equipment toavoid

possible damagetothe vehicle duringtowing operation.

Towing isinaccordance withTowing Procedure Manualat

dealer.

• When towing withtherear wheels onthe ground, release

the parking brakeandmove thegearshift levertoneutral

position.

NISSAN recommends thatvehicle betowed withthedriving

(front) wheels offthe ground asillustrated.

TOWING ANAUTOMATIC TRANSAXLEMODELWITH

FOUR WHEELS ONGROUND

Observe thefollowing restricted towingspeeds anddistances.

Speed: Below 50km/h (30MPH)

Distance: Less than65km (40 miles)

CAUTION: Never towanautomatic transaxlemodelfromtherear

(i.e.,

backward) withfourwheels onthe ground asthis may cause

serious andexpensive damagetothe transaxle.

TOWING ANAUTOMATIC TRANSAXLEMODELWITH

REAR WHEELS RAISED(Withfrontwheels onground)

Never towanautomatic transaxlemodelwithrearwheels

raised (withfrontwheels onground) asthis may cause serious

and expensive damagetothe transaxle. Ifitis necessary totow

it with rearwheels raised,always useatowing dollyunder the

front wheels.

TOWING POINT

Always pullthecable straight outfrom thevehicle. Neverpull

on the hook atasideways angle.

CAUTION: Remove thefront spoiler whentowing thevehicle forward.

Otherwise, thetowing devicemaydamage thefront spoiler.

Front Rear

Sedan models

GI-43

Hatchback

models

Towinghook

SGI911

Page 1398 of 1701

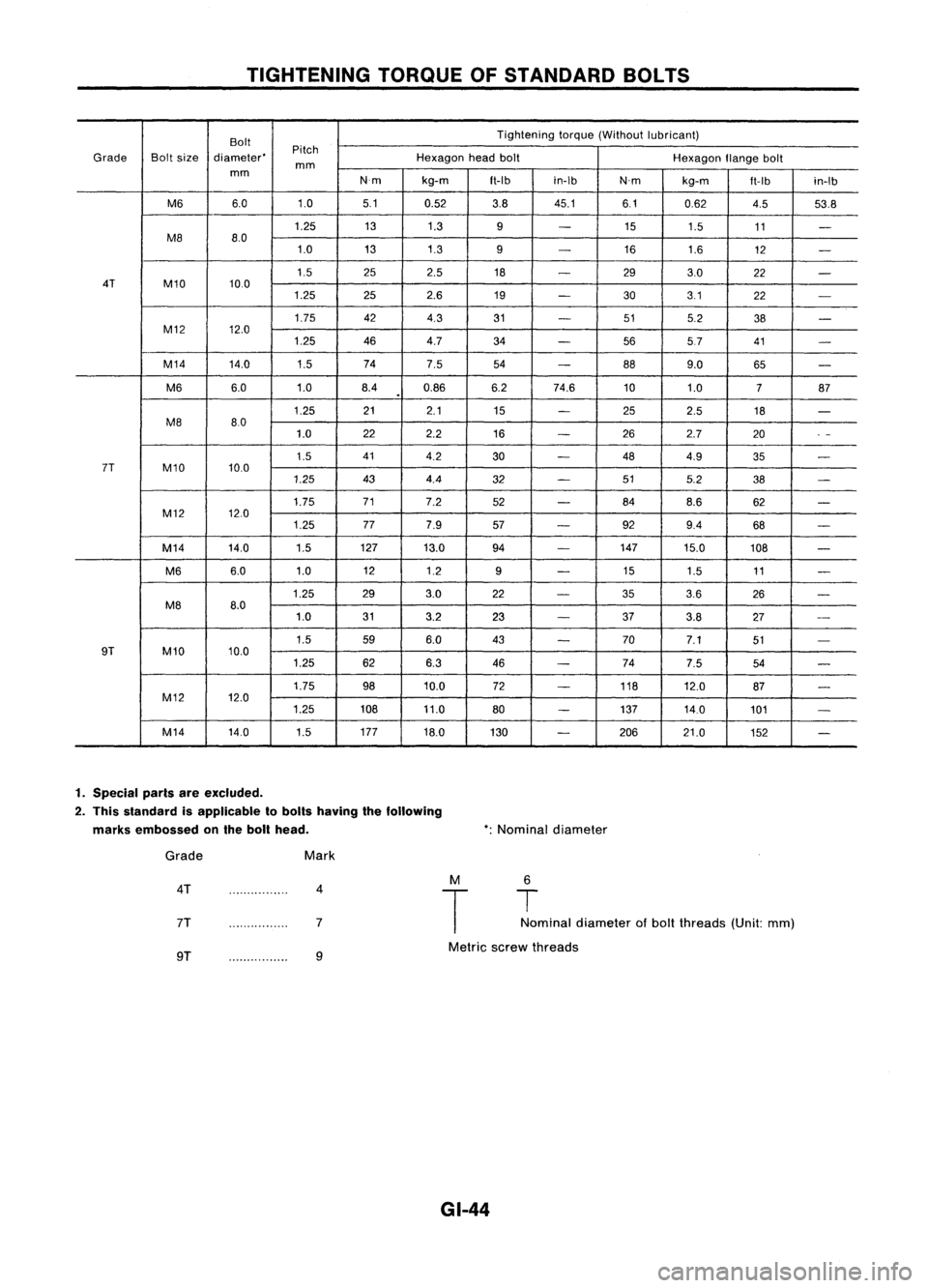

TIGHTENINGTORQUEOFSTANDARD BOLTS

Bolt Tightening

torque(Without lubricant)

Pitch

Grade Boltsize diameter' Hexagonheadbolt

Hexagonflangebolt

mm

mm

N'mkg-m

ft-Ibin-Ib

N'mkg-m

ft-Ib

in-Ib

M6 6.0 1.05.1

0.52 3.845.1 6.10.62

4.553.8

1.25 131.3

9

-

15

1.5 11

-

M8 8.0

1.0 131.3

9

-

16

1.6

12

-

1.5 252.5

18

-

293.0

22

-

4T M10 10.0

1.25 252.6

19

-

303.1

22

-

1.75 424.3

31

-

515.2

38

-

M12 12.0

1.25 464.7 34

-

5657 41

-

M14 14.0

1.574

7.5

54

-

889.0

65

-

M6 6.0

1.08.40.86 6.274.6 101.0

787

.

1.25 21

2.1 15

-

252.5 18

-

M8 80

1.0 22

2.2

16

-

262.7 20

.

-

1.5 41

4.2

30

-

484.9

35

-

7T M10 10.0

1.25 434.4

32

-

515.2

38

-

1.75 71

7.2

52

-

84

8.6 62

-

M12 12.0

1.25 777.9

57

-

929.4

68

-

M14 14.0 1.5127

13.0 94

-

147

15.0 108

-

M6 6.0

1.0 12

1.2

9

-

15

1.5 11

-

1.25 293.0

22

-

353.6

26

-

M8 8.0

1.0 313.2

23

-

37

3.8 27

--

1.5 596.0 43

-

70

7.1 51

-

9T M10 10.0

1.25 626.3

46

-

74

7.5 54

-

1.75 9810.0 72

-

118

12.0

87

-

M12 12.0

1.25 10811.0

80

-

137

14.0

101

-

M14 14.0

1.5177

18.0

130

-

206 21.0

152

-

1. Special parisareexcluded.

2. This slandard isapplicable 10bolls having thefollowing

marks embossed onthe boll head. *:

Nominal diameter

Grade

4T

7T

Mark

4

7 M

T

6

T

Nominal diameter ofbolt threads (Unit:mm)

9T 9

Metric

screwthreads

GI-44

Page 1399 of 1701

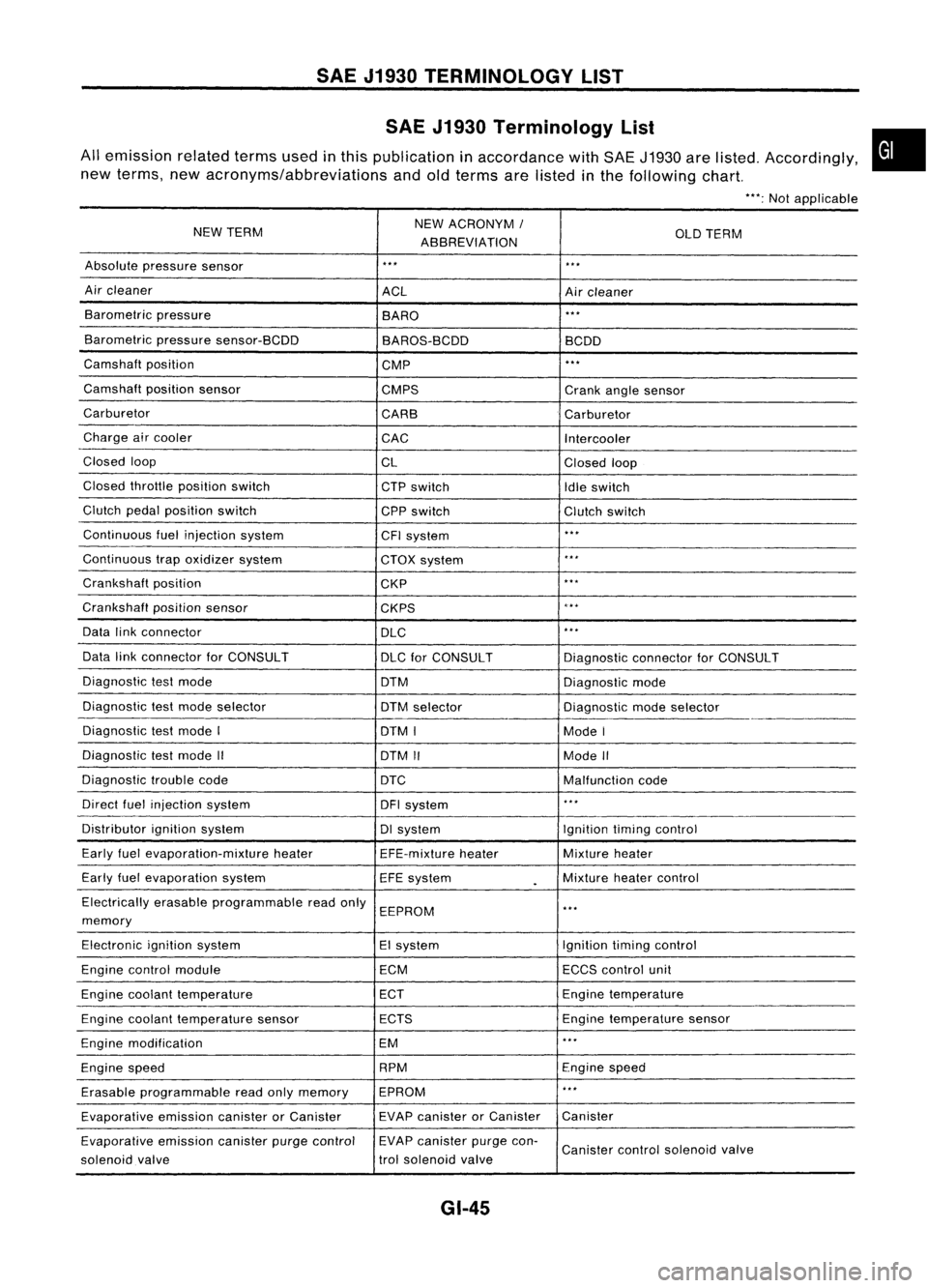

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List

All emission relatedtermsusedinthis publication inaccordance withSAE J1930 arelisted. Accordingly,

new terms, newacronyms/abbreviations andoldterms arelisted inthe following chart.

"':Not applicable

NEW TERM NEW

ACRONYM /

ABBREVIATION OLD

TERM

Absolute pressure sensor

'" '"

Air cleaner

ACLAircleaner

Barometric pressure

BARO

."

Barometric pressuresensor-BCDD

BAROS-BCDD BCDD

Camshaft position

CMP

'"

Camshaft positionsensor

CMPS Crankanglesensor

Carburetor CARBCarburetor

Charge aircooler

CACIntercooler

Closed loop

CLClosedloop

Closed throttle position switch

CTPswitch

Idleswitch

Clutch pedalposition switch

CPPswitch Clutchswitch

Continuous fuelinjection system

CFIsystem

'"

Continuous trapoxidizer system

CTOXsystem

...

Crankshaft position

CKP

'"

Crankshaft positionsensor

CKPS

~.**

Data linkconnector

DLC

,

..

Data linkconnector forCONSULT

DLCforCONSULT DiagnosticconnectorforCONSULT

Diagnostic testmode

DTMDiagnosticmode

Diagnostic testmode selector

DTMselector Diagnosticmodeselector

Diagnostic testmode I

DTMI ModeI

Diagnostic testmode II

DTMII ModeII

Diagnostic troublecode

DTC Malfunctioncode

Direct fuelinjection system

DFIsystem

..

,

Distributor ignitionsystem DIsystem Ignitiontimingcontrol

Early fuelevaporation-mixture heater

EFE-mixtureheater Mixture

heater

Early fuelevaporation system

EFEsystem

.

Mixture

heatercontrol

Electrically erasableprogrammable readonly

EEPROM

'"

memory

Electronic ignitionsystem EIsystem Ignitiontimingcontrol

Engine control module ECMECCScontrol unit

Engine coolant temperature ECTEngine

temperature

Engine coolant temperature sensor ECTS Engine

temperature sensor

Engine modification EM

'"

Engine speed RPM

Enginespeed

Erasable programmable readonlymemory EPROM

'"

Evaporative emissioncanisterorCanister EVAP

canister orCanister Canister

Evaporative emissioncanisterpurgecontrol EVAP

canister purgecon-

Canister controlsolenoid valve

solenoid valve trol

solenoid valve

GI-45

•

Page 1400 of 1701

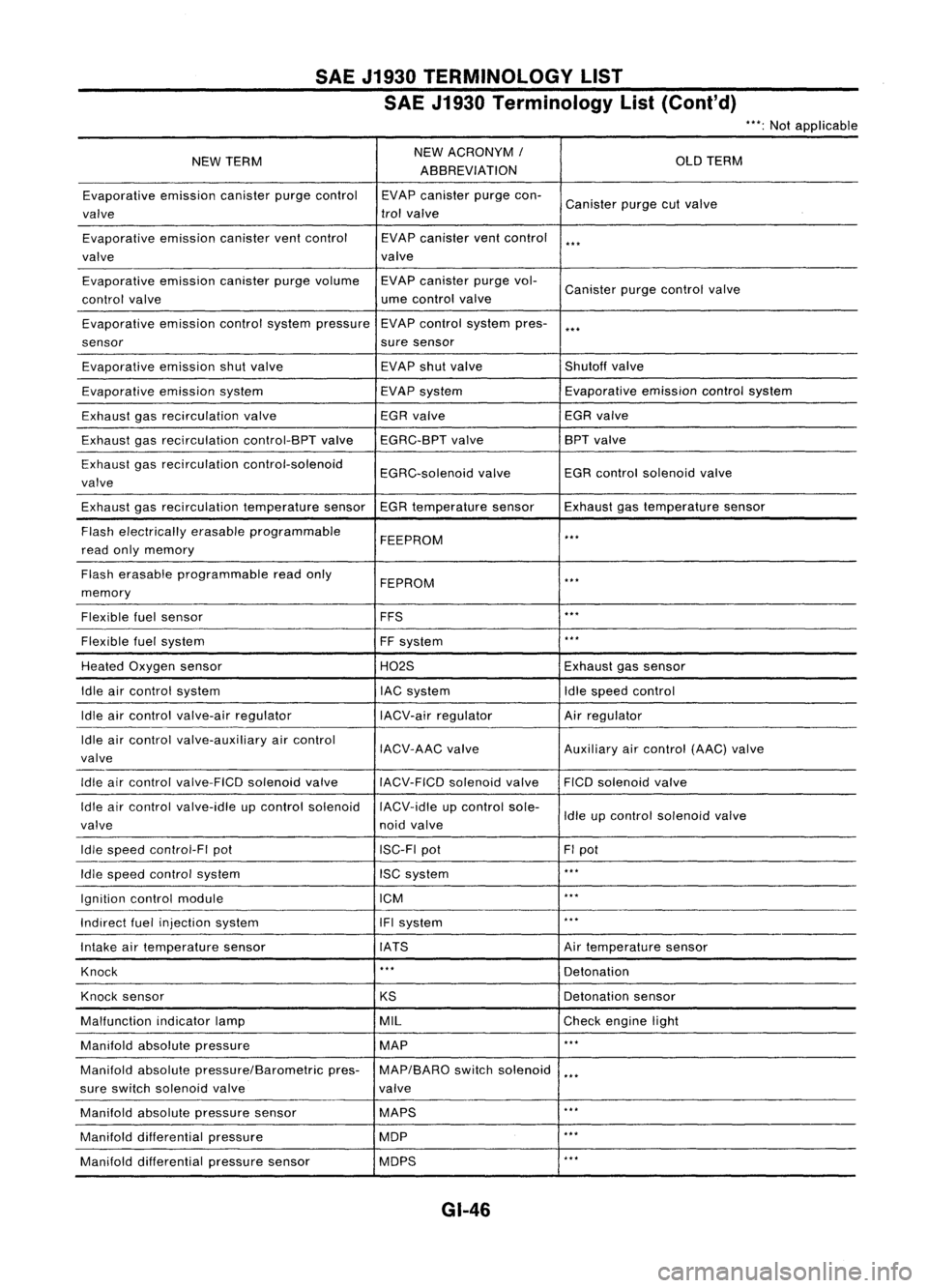

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List(Cont'd)

***:

Not applicable

NEW TERM NEW

ACRONYM /

OLDTERM

ABBREVIATION

Evaporative emissioncanisterpurgecontrol EVAPcanister purgecon-

Canister purgecutvalve

valve trol

valve

Evaporative emissioncanisterventcontrol EVAPcanister ventcontrol

***

valve valve

Evaporative emissioncanisterpurgevolume EVAPcanister purgevol-

Canister purgecontrol valve

control valve ume

control valve

Evaporative emissioncontrolsystem pressure EVAP

control system pres-

***

sensor suresensor

Evaporative emissionshutvalve EVAP

shutvalve Shutoffvalve

Evaporative emissionsystem EVAPsystem Evaporative

emissioncontrolsystem

Exhaust gasrecirculation valve EGR

valve EGRvalve

Exhaust gasrecirculation control-BPTvalveEGRC-BPT valve BPT

valve

Exhaust gasrecirculation control-solenoid

EGRC-solenoidvalveEGR

control solenoid valve

valve

Exhaust gasrecirculation temperaturesensorEGRtemperature sensorExhaustgastemperature sensor

Flash electrically erasableprogrammable

FEEPROM

***

read onlymemory

Flash erasable programmable readonly

FEPROM

**.

memory

Flexible fuelsensor FFS

***

Flexible fuelsystem

FFsystem

***

Heated Oxygen sensor H02SExhaustgassensor

Idle aircontrol system lACsystem Idlespeed control

Idle aircontrol valve-air regulator IACV-airregulator Airregulator

Idle aircontrol valve-auxiliary aircontrol

IACV-AACvalve Auxiliaryaircontrol (AAC)valve

valve

Idle aircontrol valve-FICO solenoidvalve

IACV-FICDsolenoidvalve FICOsolenoid valve

Idle aircontrol valve-idle upcontrol solenoid IACV-idleupcontrol sole-

Idleupcontrol solenoid valve

valve noidvalve

Idle speed control-FI pot ISC-FIpot FIpot

Idle speed control system ISCsystem

***

Ignition controlmodule ICM

***

Indirect fuelinjection system IFIsystem

***

Intake airtemperature sensor IATS Airtemperature sensor

Knock

***

Detonation

Knock sensor

KSDetonation

sensor

Malfunction indicatorlamp MIL

Checkengine light

Manifold absolutepressure MAP

***

Manifold absolutepressure/Barometric pres-MAP/BARO switchsolenoid

***

sure switch solenoid valve valve

Manifold absolutepressure sensor MAPS

**.

Manifold differential pressure MOP

***

Manifold differential pressuresensor MOPS

***

GI-46