engine NISSAN ALMERA N15 1995 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 28 of 1701

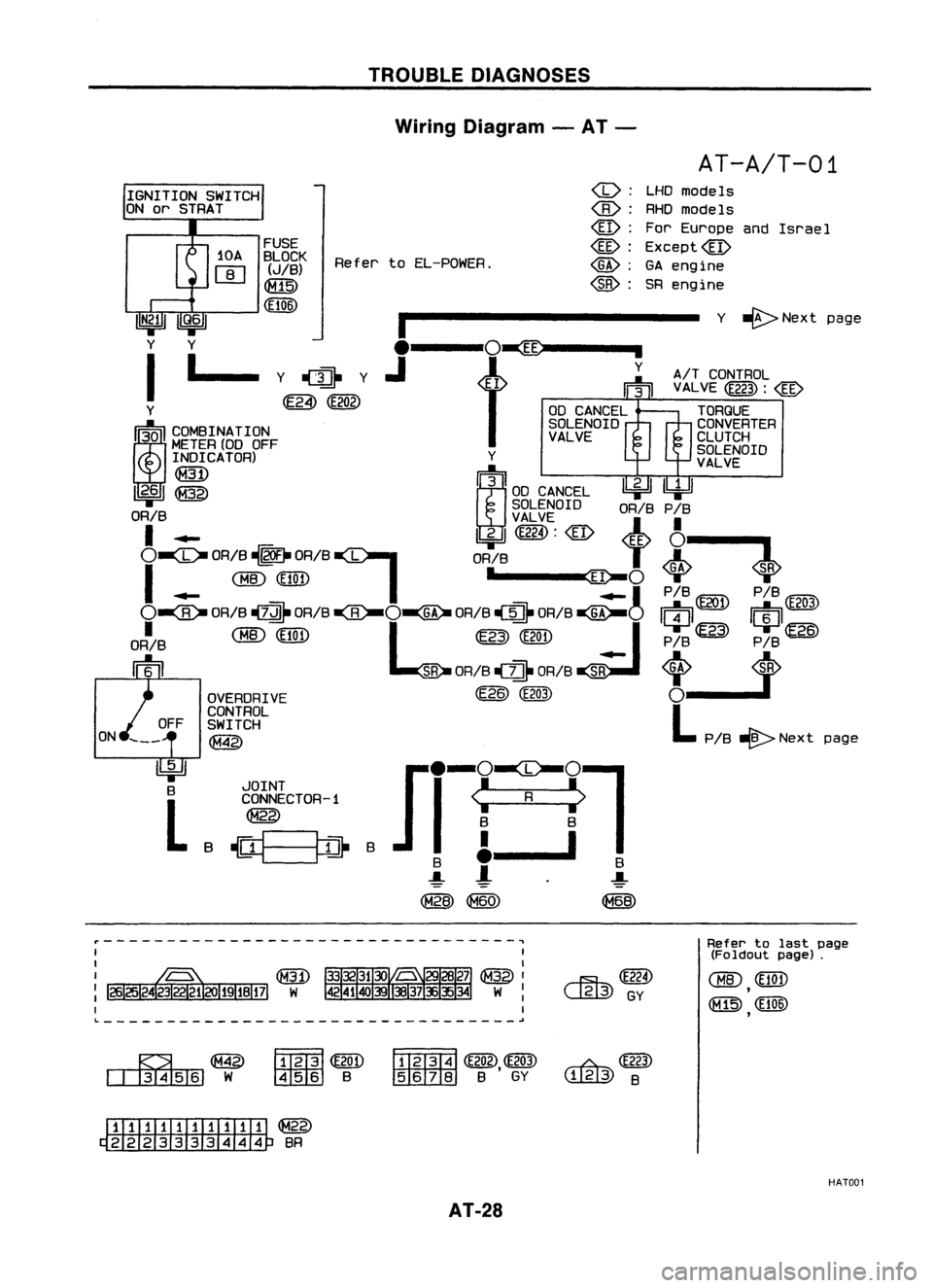

TROUBLEDIAGNOSES

Wiring Diagram -AT -

AT-A/T-01

page

Israel

Y ~Next page

A!T CONTROL

VAL VE

(E223) :

@

TORQUE

CONVERTER

CLUTCH

SOLENOID

VALVE

LHD

models

RHO models

For Europe and

Except@

GA engine

SR engine

(b):

:

@:

@:

@:

@:

Refer

toEL-POWER.

FUSE

BLOCK (J!B)

([@

(El06)

I

y ~.~ y

l---t~'~

Y ~(E202)

III

C~INATION

METER

(00OFF

INDICATOR) Y

~ t~)

11

2•6

1

@

300 CANCEL ~~

SOLENOID OR!BP!B

OR!B VALVE

I .-

I!::iJl

(E224) :

@

4~~

O~

OR!B

~1-

DRIB

I

OR!B

T

A

I

(BID

(Elan •

~o~

SR

.- .-1

P!B@l) P!B~

O~

OR!B~ DRIB

-ea-O~

OR!B~ OR!B

~O

/I;

II

E20l

II

i

II

E203

ORI!B

CBID

(El0n

L

@

(E20n

I

P!B~ P!B~

rm

SR

OR!B

-cz::n.

OR!B~

<0> ~

OVERDRIVE (E?6)

(E203)

0--1

CONTROL

L

OFF SWITCH

~ PIB-@>Next

ON

~

B

L

JOINT

CONNECTOR-1

~

B

~==~

B

r---------------------------------,

~(E224)

~GY

L ~

Refer

tolast page

(Foldout page).

CHID

(EtOn

,

([@

(El06)

,

~~

~W

~@D

~ B

~

(E202),~ ~

@J)

rn:rn:rz::rnJ

BGY

W@

B

ITIII:illIillIi ~

~ BR

HAT001

AT-28

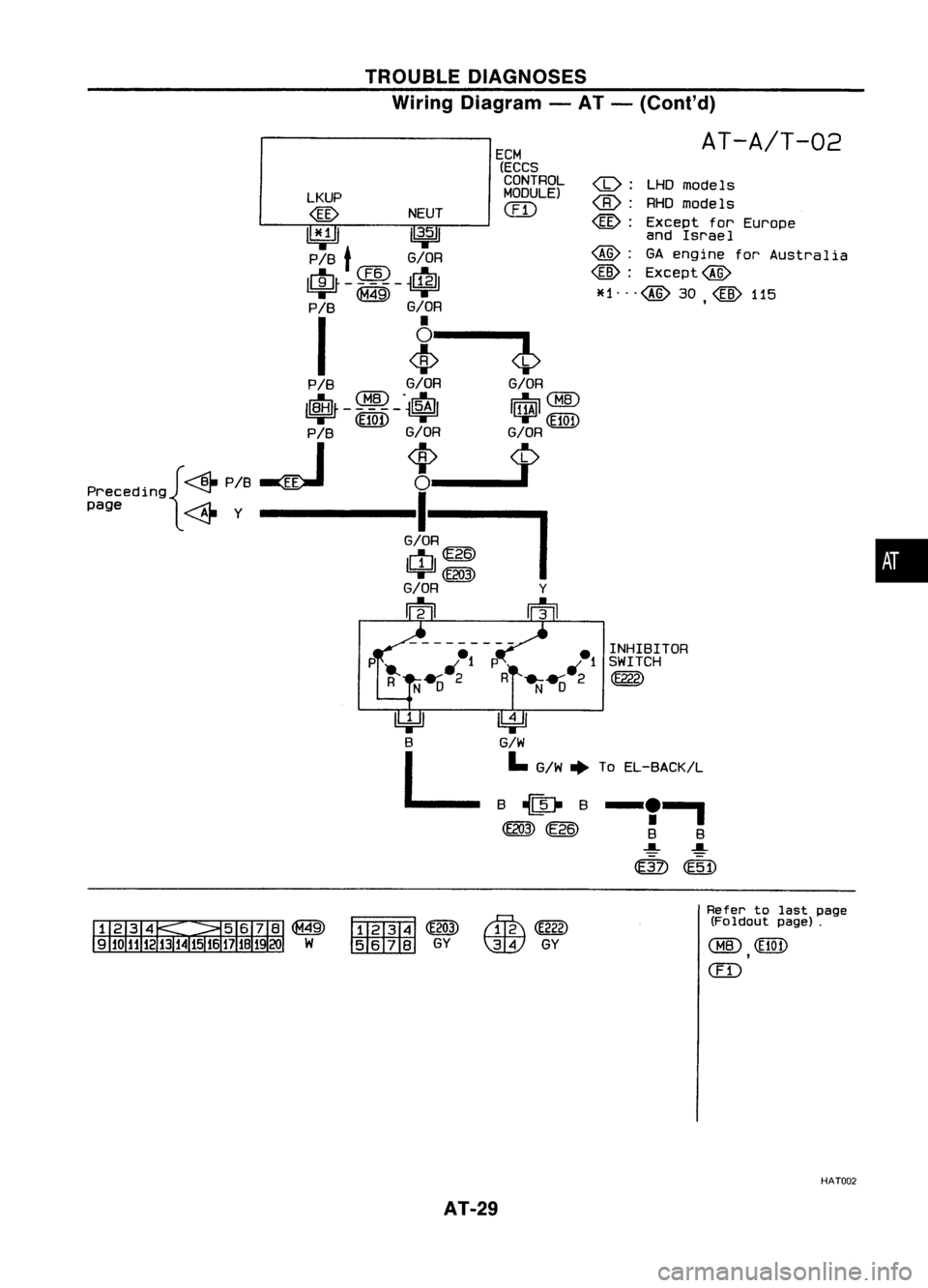

Page 29 of 1701

•

(b):

LHDmodels

:

RHOmodels

@:

Except forEurope

and Israel

~: GAengine forAustralia

@:

Except@

*1 ...

@

30

@

115

,

ECM

(ECCS

CONTROL

MODULE)

em

_ INHIBITOR

P .. ..1P ..

-1

SWITCH

R N-0 2 R

~-o

2

@g)

TROUBLE

DIAGNOSES

Wiring Diagram -AT -(Coni' d)

AT-A/T-02

LKUP

@

NEUT

I1¥Jl

11

3•5

1

P/B

t

G/OR

~CIID~

~-

I

i

P /B G/OR G/OR

~ CHID.

dI:-. ~

CHID

ll\tlJr -

$100 -~

I~I

P/B G/OR G/OR

. {~P/8~

*_1>

Precedlng ~

I

page ~Y-------G/O~

IUJI~

=w=

(E203)

G/OR Y

m rn

l!4='J

B

L

~

G/W

I.

G/W ~ToEL-BACK/L

-'I

B B

~ ~

@)

@j)

~

~ GY

~

(E222)

\IDY

GY Refer

tolast page

(Foldout page).

CHID

(EI0t)

,

(ill

HAT002

AT-29

Page 34 of 1701

(atP,)

p,

(Full throttle position)

~ThrOttle drum

Direction U

, ,-- p,

t

I ~.

(Idling

--r ~_ .)

position)

I

Direction T

Engine side"

bracket (at

P,)

~ Adjusting tube

Lock plate ON-VEHICLE

SERVICE

Throttle WireAdjustment (Cont'd)

1. Turn ignition switchtoOFF.

2. While pressing lockplate, moveadjusting tubeindirection

"T" (Transaxle side).

3. Return lockplate.

(Adjusting tubeislocked atthis time.)

4. Move throttle drumfrom

"P2"

to

"P

1"

quickly. Adjusting

tube moves indirection "U"(Engine side)while depressing

the lock plate. Ensure thatthrottle wirestroke "L"iswithin

the specified range,between fullthrottle andidle.

Throttle wirestroke "L":

40 -42

mm

(1.57 -1.65

in)

• Adjust throttle wirestroke afteraccelerator wireisinstalled

and adjusted.

• When connecting throttlewiretothrottle drum,donot use

tools. Manually hookit.

• Put mark onthrottle wiretofacilitate measuring wirestroke.

5. Clamp throttle wireatproper positions showninthe illus-

tration afteradjusting throttlewire.

6. After properly adjusting andclamping throttlewire,ensure

the parting lineisas straight aspossible.

SAT551D

4/4

Vehiclespeed

If

throttle wirestroke isimproperly adjustedthefollowing prob-

lems mayarise.

• "P

1"

isthe throttle drumfully-open position.When"P

1"

is

too farindirection

"T",

theshift schedule willbe

@

inthe

figure. Andthekickdown rangewillgreatly increase.

• When

"P1"

istoo farindirection "U",theshift schedule will

be

CD

inthe figure. Andthekickdown willnotoccur.

SAT669H

I

I

Normal :

,- .J

,/

/

,,~/~

/

---------1--

,/

'//

r-/

I

I

o

0>

c:

C

Q)

0-

o

~

2

£

I-

AT-34

Page 39 of 1701

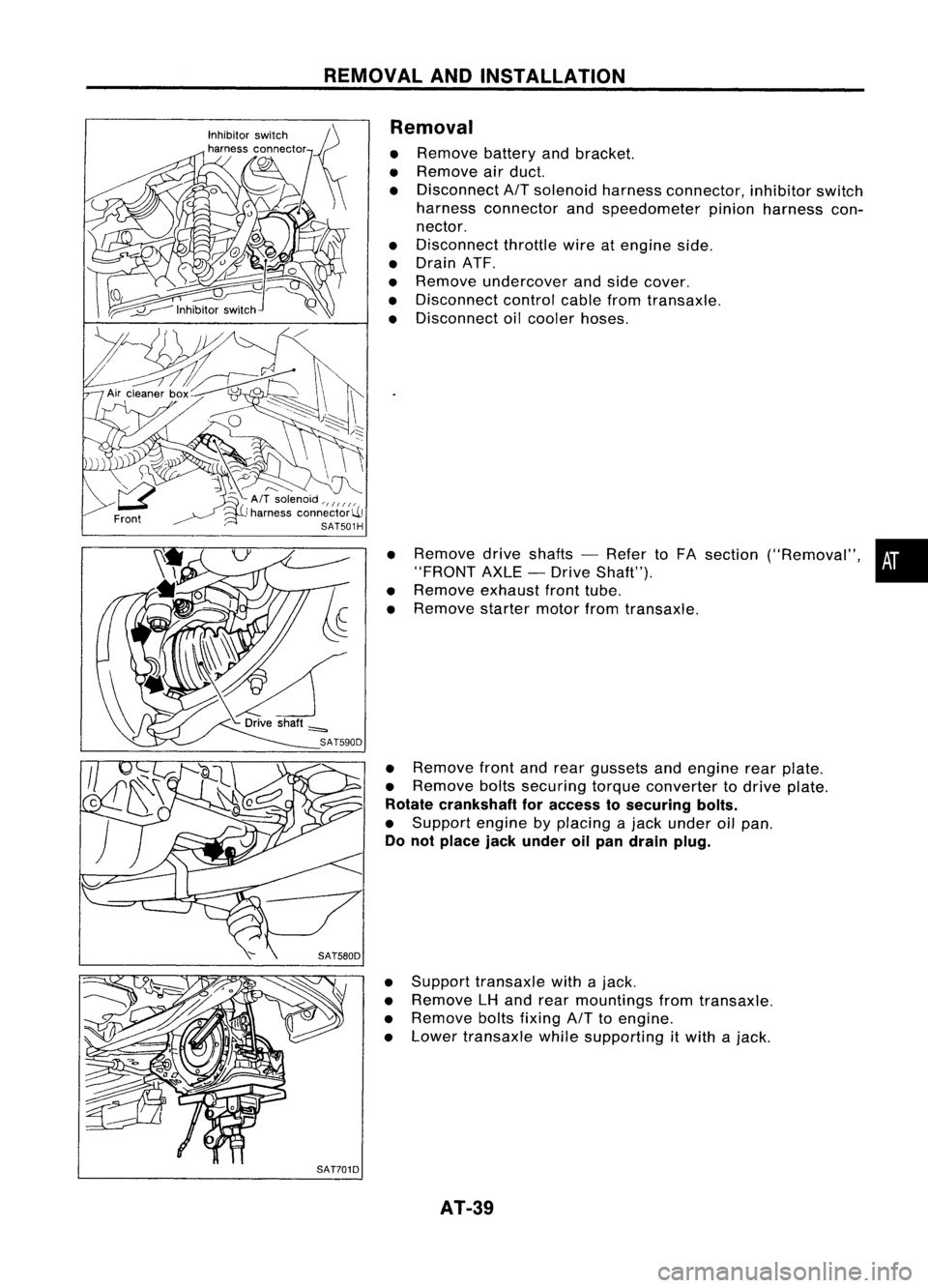

REMOVALANDINSTALLATION

Removal

• Remove batteryandbracket.

• Remove airduct.

• Disconnect

AIT

solenoid harnessconnector, inhibitorswitch

harness connector andspeedometer pinionharness con-

nector.

• Disconnect throttlewireatengine side.

• Drain ATF.

• Remove undercover andside cover.

• Disconnect controlcablefromtransaxle.

• Disconnect oilcooler hoses.

• Remove driveshafts -Refer toFA section ("Removal", •

"FRONT AXLE-Drive Shaft").

• Remove exhaustfronttube.

• Remove startermotorfromtransaxle.

• Remove frontandrear gussets andengine rearplate.

• Remove boltssecuring torqueconverter todrive plate.

Rotate crankshaft foraccess tosecuring bolts.

• Support enginebyplacing ajack under oilpan.

Do not place jackunder oilpan drain plug.

• Support transaxle withajack.

• Remove LHand rear mountings fromtransaxle.

• Remove boltsfixing

AIT

toengine.

• Lower transaxle whilesupporting

it

with ajack.

AT-39

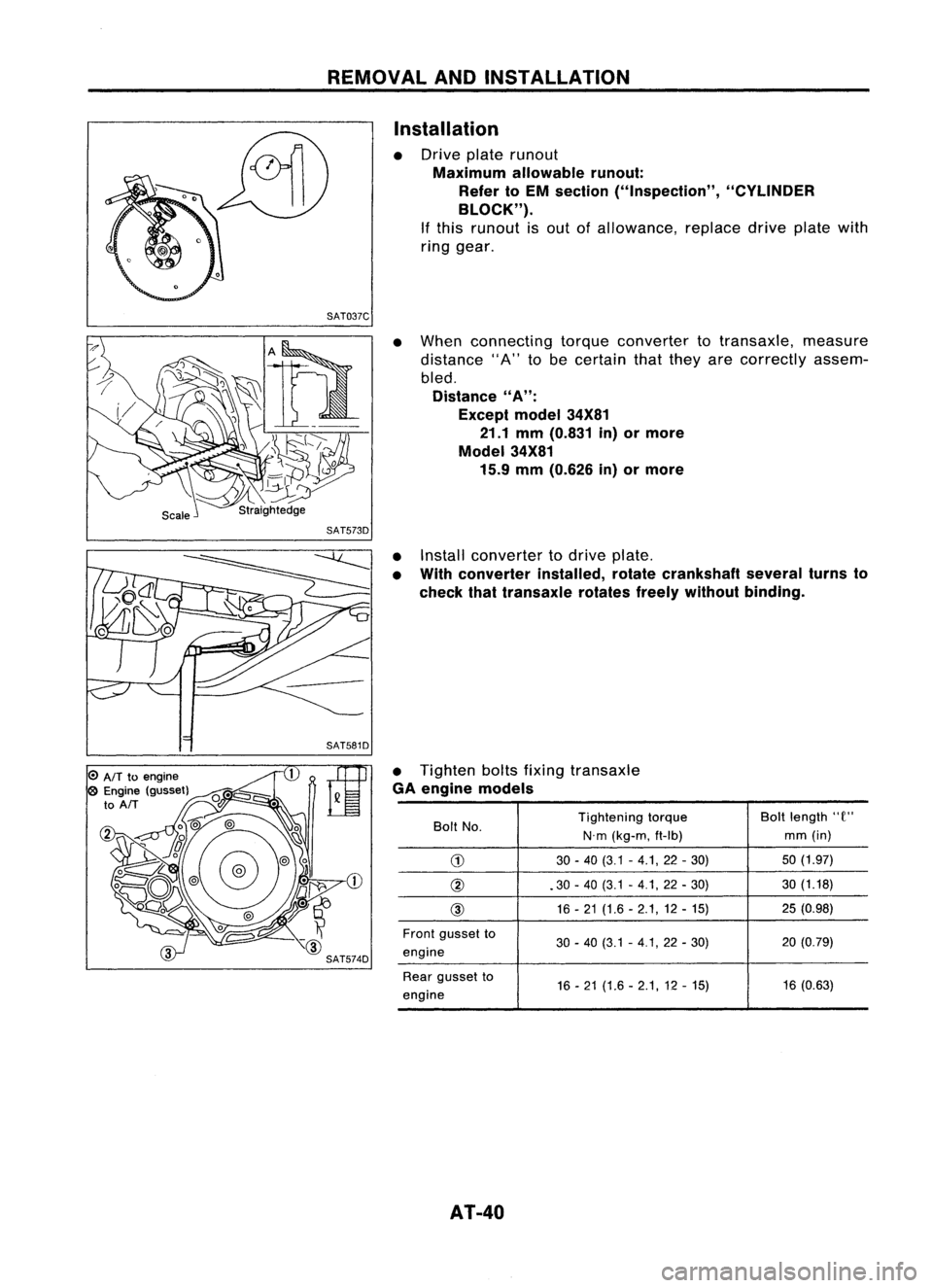

Page 40 of 1701

REMOVALANDINSTALLATION

Installation

• Drive platerunout

Maximum allowablerunout:

Refer toEM section ("Inspection", "CYLINDER

BLOCK").

If this runout isout ofallowance, replacedriveplatewith

ring gear.

SAT037C

•When connecting torqueconverter totransaxle, measure

distance "A"tobe certain thatthey arecorrectly assem-

bled.

Distance

"A":

Except model34X81

21.1 mm(0.831 in)ormore

Model 34X81

15.9 mm(0.626 in)ormore

o

AIT

toengine

o

Engine (gusset)

to

AIT

SAT573D

•Install converter todrive plate.

• With converter installed,rotatecrankshaft severalturnsto

check thattransaxle rotatesfreelywithout binding.

• Tighten boltsfixing transaxle

GA engine models

Bolt No. Tightening

torque Boltlength

"e"

N.m (kg-m, ft-Ib) mm

(in)

G)

30-40 (3.1 -4.1,22 -30) 50

(1.97)

@ .30-40 (3.1 -4.1, 22-30) 30

(1.18)

@ 16

-21 (1.6 -2.1,12 -15) 25

(0.98)

Front gusset to

30-40 (3.1 -4.1,22 -30) 20

(0.79)

engine

Rear gusset to

16-21 (1.6 -2.1,12 -15) 16

(0.63)

engine

AT-40

Page 41 of 1701

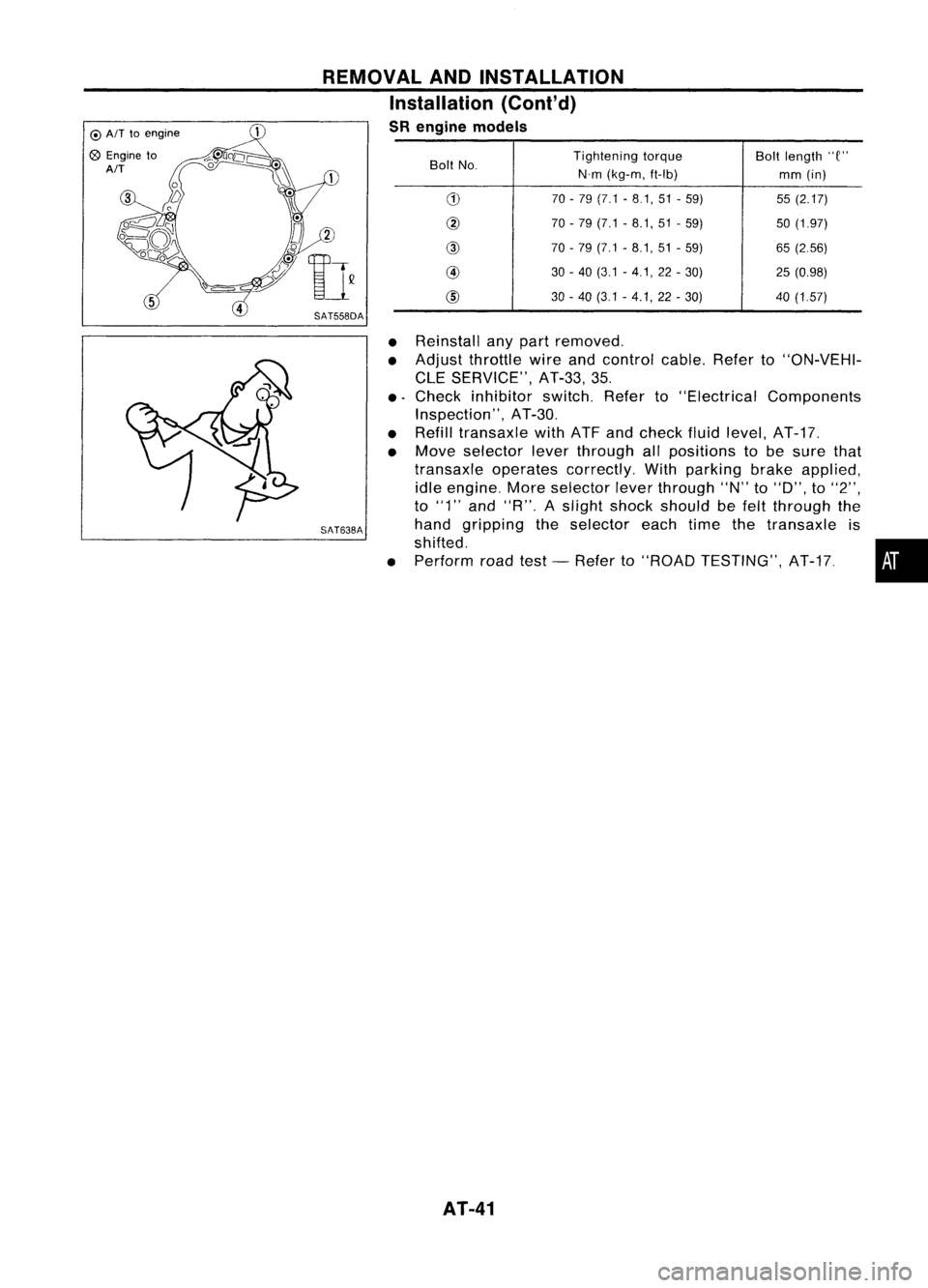

Boltlength

'T'

mm (in)

55 (2.17)

50 (1.97)

65 (2.56)

25 (0.98)

40 (1.57)

Tightening

torque

N'm (kg-m, ft-Ib)

70 -79 (7.1 -8.1,51 -59)

70 -79 (7.1 -8.1, 51-59)

70 -79 (7.1 -8.1,51 -59)

30 -40 (3.1 -4.1, 22-30)

30 -40 (3.1 -4.1, 22-30)

CD

@

@

@

@

Bolt

No.

• Reinstall anypart removed.

• Adjust throttle wireandcontrol cable.Referto"ON-VEHI-

CLE SERVICE", AT-33,35.

•. Check inhibitor switch.Referto"Electrical Components

Inspection", AT-3D.

• Refill transaxle withATFandcheck fluidlevel, AT-17.

• Move selector leverthrough allpositions tobe sure that

transaxle operatescorrectly. Withparking brakeapplied,

idle engine. Moreselector leverthrough "N"to"D", to"2",

to "1" and "R". Aslight shock should befelt through the

hand gripping theselector eachtimethetransaxle is

shifted. •

• Perform roadtest-Refer to"ROAD TESTING", AT-17.

i

REMOVAL

ANDINSTAllATION

Installation (Cont'd)

SR engine models

SAT638A

SAT558DA

AIT

toengine

@

Engine to

AIT

AT-41

Page 51 of 1701

SAT620EDISASSEMBL

Y

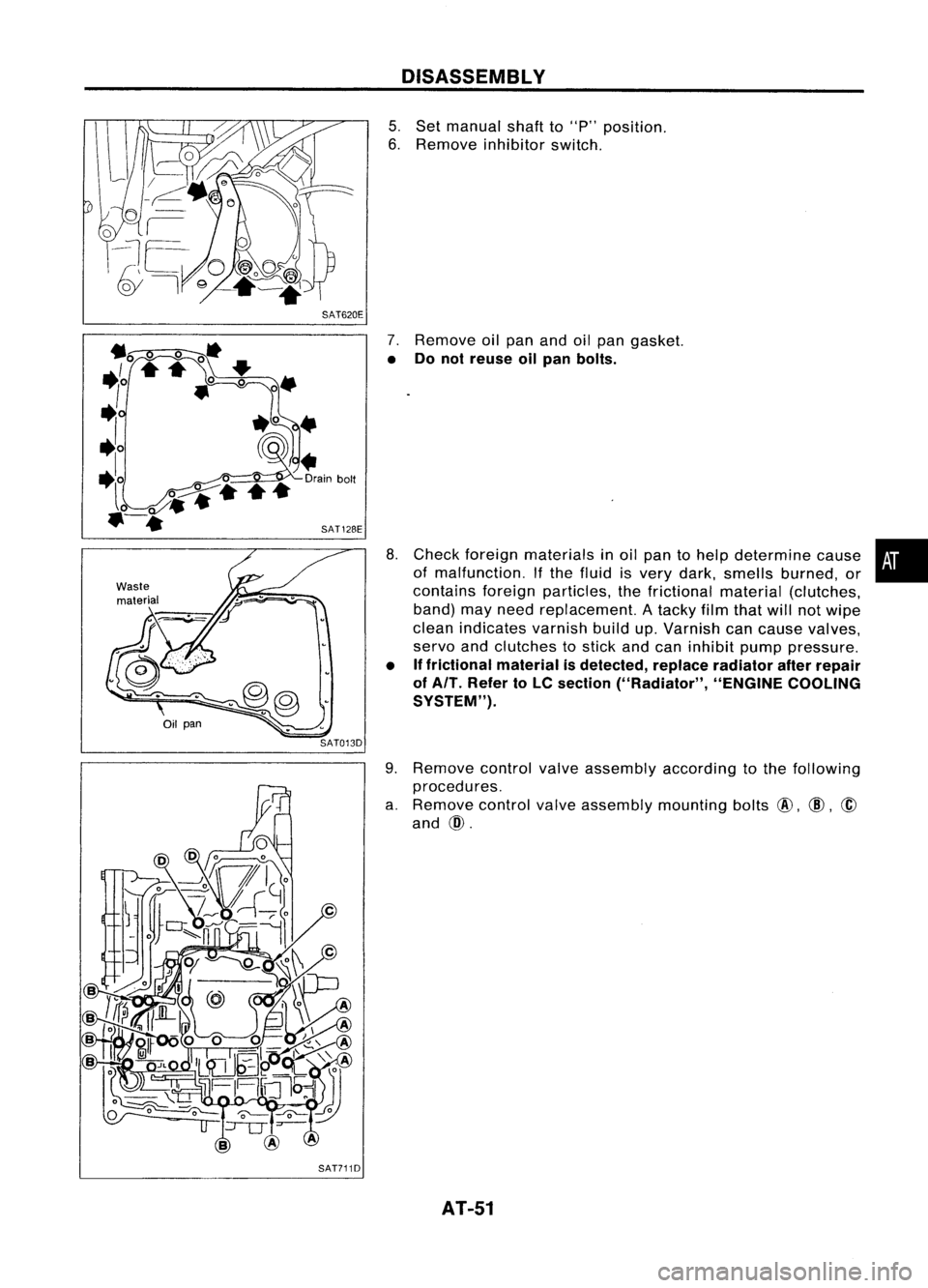

5. Set manual shaftto"P" position.

6. Remove inhibitorswitch.

Waste material

Oil

pan

SAT013D

7.

Remove oilpan andoilpan gasket.

• Donot reuse oilpan bolts.

8. Check foreign materials inoil pan tohelp determine cause•

of malfunction. Ifthe fluid isvery dark, smells burned, or

contains foreignparticles, thefrictional material(clutches,

band) mayneed replacement. Atacky filmthat willnotwipe

clean indicates varnishbuildup.Varnish cancause valves,

servo andclutches tostick andcaninhibit pumppressure.

• Iffrictional materialisdetected, replaceradiator afterrepair

of AlT. Refer toLC section ("Radiator", "ENGINECOOLING

SYSTEM").

SAT711D

9.

Remove controlvalveassembly according tothe following

procedures.

a. Remove controlvalveassembly mountingbolts@,

CID,

@

and @.

AT-51

Page 166 of 1701

Vehiclespeed

km/h (MPH)

Gear position

Throttle position

SERVICE

OATAAND SPECIFICATIONS (SOS)

Specifications andAdjustments (Cont'd)

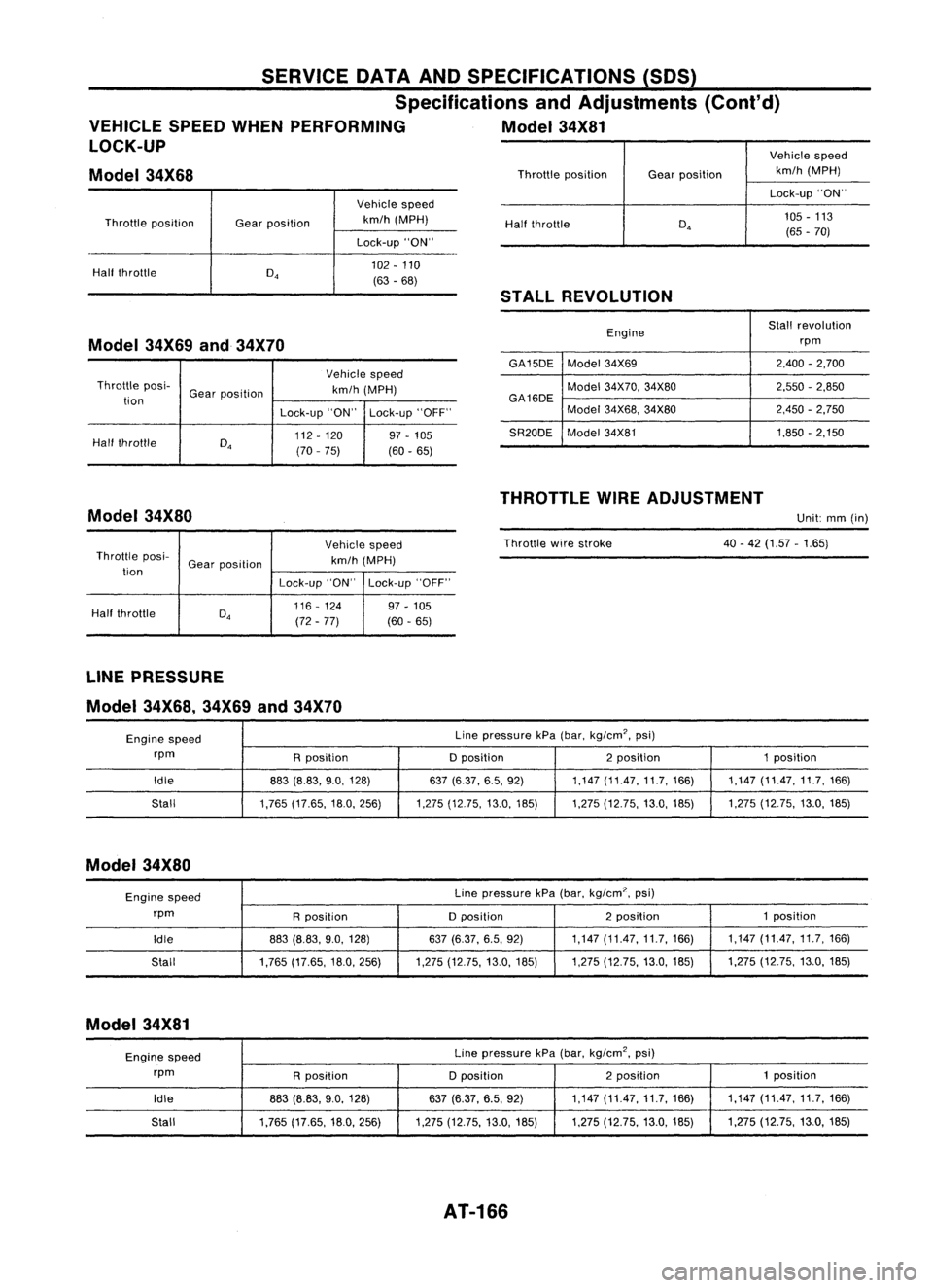

VEHICLE SPEEDWHENPERFORMING Model34X81

LOCK-UP

Model 34X68

Throttle position

Half throttle Gear

position Vehicle

speed

km/h (MPH)

Lock-up "ON"

102 -110

(63 -68)

Half

throttle

STALL REVOLUTION

Lock-up

"ON"

105 -113

(65 -70)

Model 34X69and34X70

Vehiclespeed

Throttle posi-

Gearposition km/h

(MPH)

tion

Lock-up"ON"Lock-up "OFF"

Half throttle

D

4

112

-120 97-105

(70 -75)

(60-65) Engine

Stall

revolution

rpm

GA15DE Model34X69 2,400

-2,700

Model 34X70, 34X80 2,550-2,850

GA16DE Model34X68, 34X80 2,450

-2,750

SR20DE Model

34X81 1,850-2,150

THROTTLE WIREADJUSTMENT

Model 34X80

Unit:mm(in)

Vehicle speed

Throttle posi-

Gearposition km/h

(MPH)

tion Lock-up"ON"Lock-up "OFF"

Half throttle

D

4

116

-124 97-105

(72 -77) (60

-65) Throttle

wirestroke 40-42 (1.57 -1.65)

LINE PRESSURE

Model 34X68, 34X69and34X70

Engine speed Line

pressure kPa(bar, kg/em', psi)

rpm Rposition Dposition 2position 1position

Idle 883(8.83, 9.0,128) 637

(6.37, 6.5,92) 1,147(11.47,11.7,166) 1,147(11.47,11.7,166)

Stall 1,765(17.65, 18.0,256) 1,275(12.75,13.0,185) 1,275(12.75, 13.0,185) 1,275

(12.75,13.0,185)

Model 34X80

Engine speed Line

pressure kPa(bar, kg/em?, psi)

rpm Rposition Dposition 2

position 1position

Idle 883(8.83, 9.0,128) 637(6.37, 6.5,92) 1,147

(11.47,11.7,166) 1,147

(11.47,11.7,166)

Stall 1,765

(17.65, 18.0,256) 1,275(12.75, 13.0,185) 1,275(12.75, 13.0,185) 1,275

(12.75, 13.0,185)

Model 34X81

Engine speed Line

pressure kPa(bar, kg/em', psi)

rpm Rposition Dposition 2position 1

position

Idle 883(8.83, 9.0,128) 637(6.37, 6.5,92) 1,147

(11.47,11.7,166) 1,147

(11.47,11.7,166)

Stall 1,765

(17.65, 18.0,256) 1,275(12.75, 13.0,185) 1,275(12.75, 13.0,185) 1,275

(12.75, 13.0,185)

AT-166

Page 175 of 1701

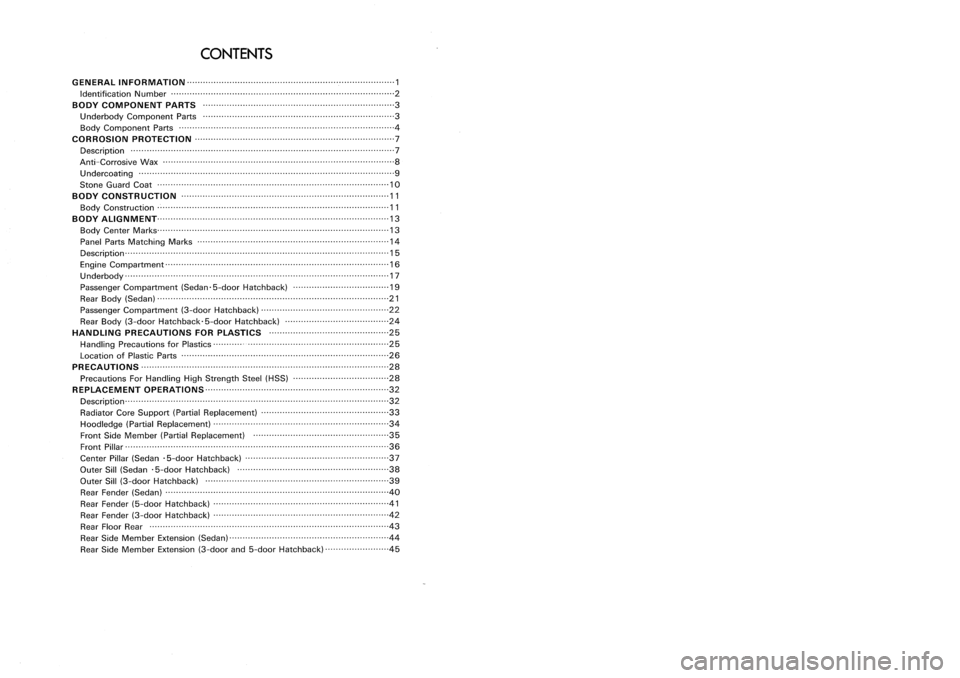

CONTENTS

G EN ERAL IN FORMATION 1

Identification Number 2

BODY COMPONENT PARTS 3

U nderbody Component Parts 3

Body Component Parts 4

CO RROSlO NPR OTECTI 0N 7

Description 7

Anti -Co rrosive Wax 8

Undercoating 9

Stone Guard Coat 10

BODY CONSTRUCTION 11

Body Construction .~ 11

BODY ALIGNM ENT 13

Body Center Marks 13

Panel PartsMatching Marks 14

Description 15

Engine Compartment 16

Underbody 17

Passenger Compartment (Sedan-5-door Hatchback) 19

Rear Body (Sedan) 21

Passenger Compartment (3-doorHatchback) 22

Rear Body (3-door Hatchback-5-door Hatchback) 24

HANDLING PRECAUTIONS FORPLASTICS 25

Handling Precautions forPlastics

>-•••••••••••••••••••••••••••••••••••••••••••••••••••••

25

Location ofPlastic Parts - 26

PR ECAUTIONS 28

Precautions ForHandling HighStrength Steel(HSS) 28

R EPLACEM ENTOPERATIONS 32

Description 32

Radiator CoreSupport (PartialReplacement) 33

Hoodledge (PartialReplacement) 34

Front SideMember (PartialReplacement) 35

Front Pillar..~ 36

Center Pillar(Sedan -5-door Hatchback) 37

Outer Sill(Sedan -5-door Hatchback) 38

Outer Sill(3-door Hatchback) 39

Rear Fender (Sedan) 40

Rear Fender (5-door Hatchback) 41

Rear Fender (3-door Hatchback) 42

Rear Floor Rear 43

Rear SideMember Extension (Sedan) 44

Rear SideMember Extension (3-doorand5-door Hatchback) 45

Page 176 of 1701

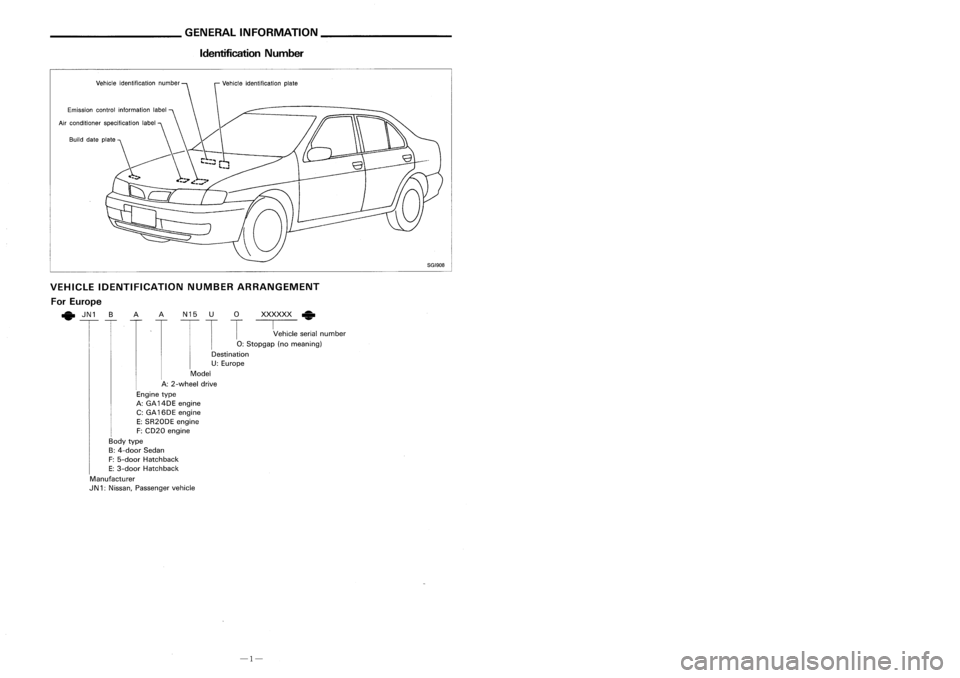

~~~~~~~~_GENERALJNFORM~ION~~~~~~~~_

IdentificationNumber _

REPLACEMENTOPERATIONS

Rear SideMember Extension

Sedan

-------

/

/\

---

/ \ -

'------- /~ ,,\I

c-

~ ~>~

111

114

Service

Joint

SGI908

Vehicle

identification plate

A

A

Vehicle

identification number

N15 U

0

xxxxxx.

T

T

---c::

serialnumber

0:

Stopgap (nomeaning)

Destination

U: Europe

Model

A: 2-wheel drive

Engine type

A: GA 14DE engine

C: GA 16DE engine

E: SR20DE engine

F: CD20 engine

Body type

B: 4-door Sedan

F: 5-door Hatchback

E: 3-door Hatchback

Manufacturer

J

N 1: Nissan, Passenger vehicle

Emission

controlinformation label

VEHICLE IDENTIFICATION NUMBERARRANGEMENT

For Europe

• JN1 B

2-spotwelds 3-spotwelds M.I.G plug weld

(For 3panels plugweld method )

d

r;==

dA~ dB~

GTJ ~

M.

I.G seam weld/

Point weld

-1-

-44-