engine NISSAN ALMERA N15 1995 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 177 of 1701

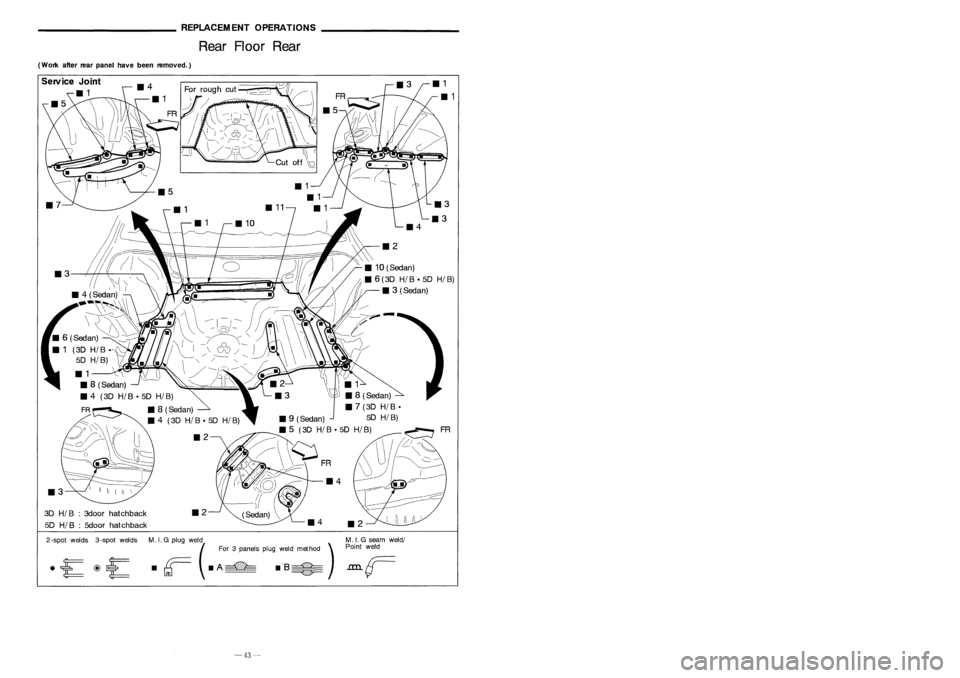

REPLACEMENTOPERATIONS

Rear Floor Rear ________

GENERALINFORMATION _

Identification Number(Cont'd)

(Work afterrearpanel havebeen removed.)

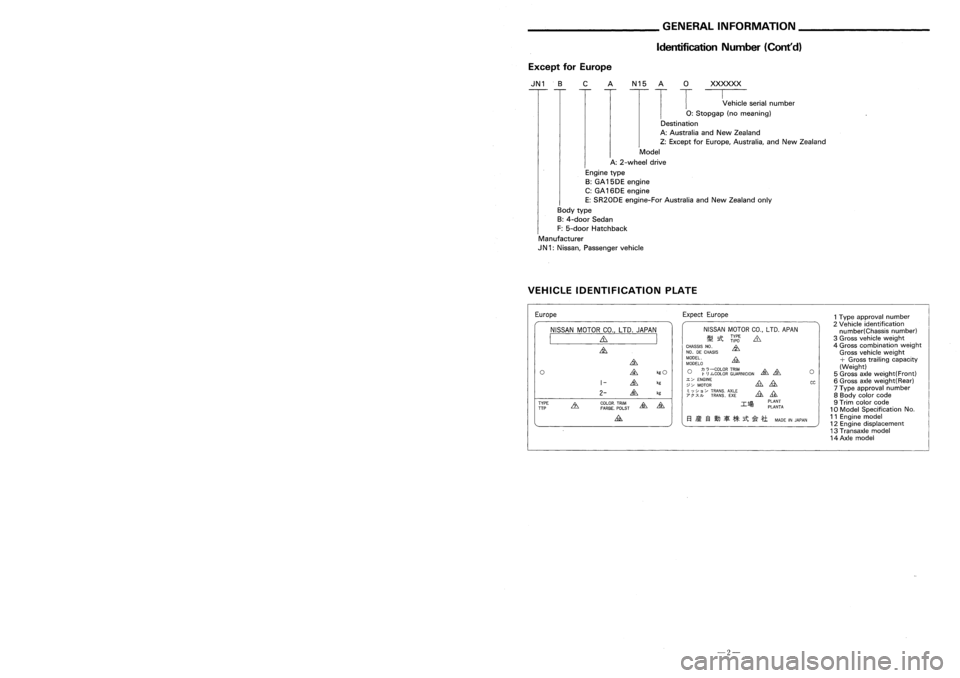

ExceptforEurope

IN 1 .B CAN 15A

0

XXXXXX

T

T

--c:::

serialnumber

0:

Stopgap (nomeaning)

Destination

A: Australia andNew Zealand

Z: Except forEurope, Australia, andNew Zealand

Model

A: 2-wheel drive

Engine type

B: GA 15DE engine

C: GA 16DE engine

E: SR20DE engine-For AustraliaandNew Zealand only

Body type

B: 4-door Sedan

F: 5-door Hatchback

Manufacturer

IN 1:Nissan, Passenger vehicle

VEHICLE IDENTIFICATION PLATE

1Type approval number

2 Vehicle identification

number(Chassis number)

3 Gross vehicle weight

4 Gross combination weight

Gross vehicle weight

+

Gross trailing capacity

(Weight)

5 Gross axleweight(Front)

6 Gross axleweight(Rear)

7 Type approval number

8 Body colorcode

9 Trim color code

10 Model Specification No.

11 Engine model

12 Engine displacement

13 Transaxle model

14 Axle model

cc

o

PLANT

PlANTA

El

ii:

13IJJ

if[

**

it~

*1

MADEINJAPAN

NISSAN

MOTORCO.,LTD. APAN

~ tt

~(:l

&

~~~sg~

CNHOA"SIS ~

~~~~~o

&

o ~

0

:ggtg~

~~~RNICION ~

&.

~~ ~~~~~ &

£

; ;~)~ /~~~~~'. AE~~

A1L11

Expect

Europe

~

&

kgO

1-

&

kg

2-

&

kg

COlOR. TRIM

~

&

FARBE. POlST

&

NISSAN

MOTORCO.,LTD. JAPAN

I ~ I

~

o

TYPE

TTP

Europe

FR

_2

3D

HI

B:3door hatchback

5D

HI

B:5door hatchback

Service

Joint

111

~

2-spot welds 3-spotwelds M.

I.

G plug weld .MIG seam weld/

(For 3panels plugweld method )P:

F

weld

• rr=- •

A

===-=

.'S~

.L.LLL

GTJ --- ~

-43-

-2-

Page 190 of 1701

__________ BODYALIGNMENT _

_ PRECAUTIONS _

Description PrecautionsForHandling HighStrength Steel

• Alldimensions indicatedinfigures areactual ones.

• When usingatracking gauge,adjustbothpointers toequal length. Thencheck thepointers andgauge

itself tomake surethere isno free play.

• When ameasuring tapeisused, check tobe sure there isno elongation, twistingorbending.

• Measurements shouldbetaken atthe center ofthe mounting holes.

• Anasterisk

(*)

following thevalue atthe measuring pointindicates thatthemeasuring pointonthe other

side issymmetrically thesame value.

• The coordinates ofthe measurement pointsarethe distances measured fromthestandard lineof"X", "V"

and "Z".

EngineCompartment

D=2T+3(mm)

D=2T+O.12 (in)

•

The electrode tipdiameter mustbereformed

properly according tothe panels thickness.

•

The spot ungget onHSS panel isharder than

that ofan ordinary steelpanel.

Therefore, forspot cutting HSSpanel, ahigh

torque drillofalow speed (1,000 to1,200

rpm) maybeused tomaintain itsdurability

and facilitate theoperation.

• HSS panels withatensile strength of785 to981 N/mm

2

(80to100 kg/mm

2,

114to142 klb/sq in),

used asreinforcement inthe door guard barand inthe bumper, istoo high intensile strength touse

for general repairs.Whenthesepanels aredamaged, theouter panels alsosustain consequential

damage; therefore, thesepanels arenever remedied withoutreplacing thedoor assembly orbumper

assembly.

2. Precautions inspot welding

This work should beperformed understandard workconditions. However,workcontrol mustbeexercised

as folloows:

SBF8?4GB

"Z":

Imaginary baseline

[200 mmbelow datum line

("OZ" atdesign plan)]

Front axlecenter

/

y (_)

(0)

Incorrect

Incorrect

Correct

D==Tip+diameter

T

,::=T====p=la::t_e=-=-_t_h=i_C=k=_n=_e_s=s= __,-- ~

• The panel surfaces mustbefitted toeach

other, leaving nogaps.

____

MEASURMENT _

SBT08?

-15- -30-

Page 191 of 1701

__________ PRECAUTIONS ___________

BODYALIGNMENT _

Precautions ForHandling HighStregth Steel Engine

Compartment

__ MEASURMENT POINTS__

Unit:mm

Front side

SBT088

Traction direction: ...

Not

recommended

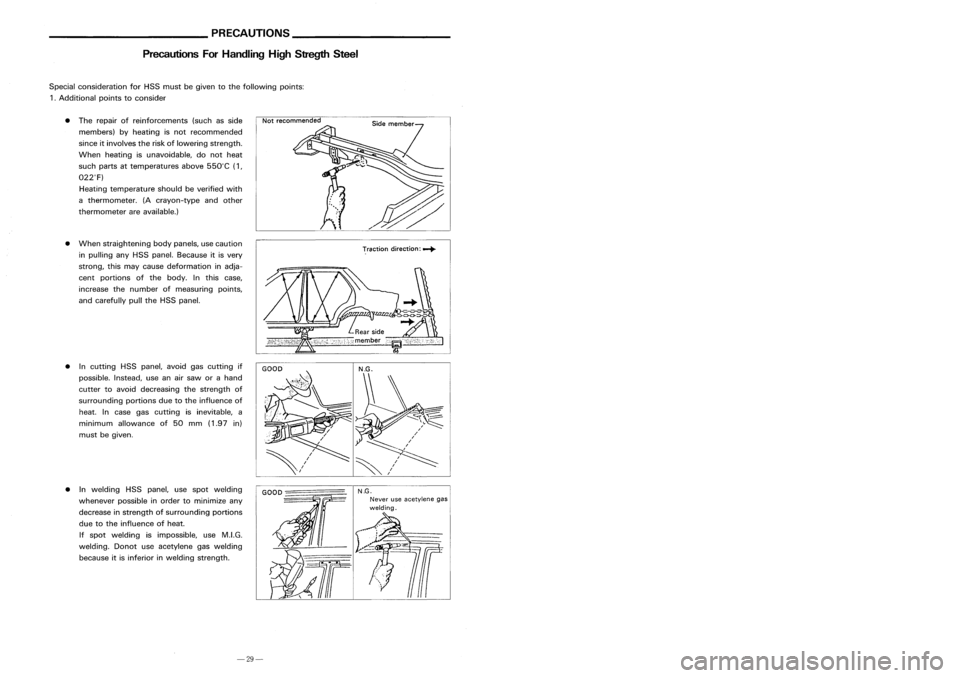

• The repair ofreinforcements (suchasside

members) byheating isnot recommended

since itinvolves theriskoflowering strength.

When heating isunavoidable, donot heat

such parts attemperatures above550°C (1,

022°F)

Heating temperature shouldbeverified with

a thermometer. (Acrayon-type andother

thermometer areavailable.)

• When straightening bodypanels, usecaution

in pulling anyHSS panel. Because itis very

strong, thismay cause deformation inadja-

cent portions ofthe body. Inthis case,

increase thenumber ofmeasuring points,

and carefully pulltheHSS panel.

Special

consideration forHSS must begiven tothe following points:

1 .Additional pointstoconsider

• Incutting HSSpanel, avoidgascutting if

possible. Instead,useanairsaw orahand

cutter toavoid decreasing thestrength of

surrounding portionsduetothe influence of

heat. Incase gascutting isinevitable, a

minimum allowance of50 mm (1.97 in)

must begiven.

SBT090

Radiator

coresupport lower

•

(b)

11

dia.

SBT094

• Inwelding HSSpanel, usespot welding

whenever possibleinorder tominimize any

decrease instrength ofsurrounding portions

due tothe influence ofheat.

If spot welding isimpossible, useM.LG.

welding. Donotuseacetylene gaswelding

because itis inferior inwelding strength.

GOOD

-================

N.G.

Never useacetylene .gas

welding.

Radiator

coresupport uppercenter

SBT091

-29-

-16-

Page 204 of 1701

__________ PRECAUTIONS ___________

BODYALIGNMENT _

Precautions ForHandling HighStregth Steel Engine

Compartment

__ MEASURMENT POINTS__

Unit:mm

Front side

SBT088

Traction direction: ...

Not

recommended

• The repair ofreinforcements (suchasside

members) byheating isnot recommended

since itinvolves theriskoflowering strength.

When heating isunavoidable, donot heat

such parts attemperatures above550°C (1,

022°F)

Heating temperature shouldbeverified with

a thermometer. (Acrayon-type andother

thermometer areavailable.)

• When straightening bodypanels, usecaution

in pulling anyHSS panel. Because itis very

strong, thismay cause deformation inadja-

cent portions ofthe body. Inthis case,

increase thenumber ofmeasuring points,

and carefully pulltheHSS panel.

Special

consideration forHSS must begiven tothe following points:

1 .Additional pointstoconsider

• Incutting HSSpanel, avoidgascutting if

possible. Instead,useanairsaw orahand

cutter toavoid decreasing thestrength of

surrounding portionsduetothe influence of

heat. Incase gascutting isinevitable, a

minimum allowance of50 mm (1.97 in)

must begiven.

SBT090

Radiator

coresupport lower

•

(b)

11

dia.

SBT094

• Inwelding HSSpanel, usespot welding

whenever possibleinorder tominimize any

decrease instrength ofsurrounding portions

due tothe influence ofheat.

If spot welding isimpossible, useM.LG.

welding. Donotuseacetylene gaswelding

because itis inferior inwelding strength.

GOOD

-================

N.G.

Never useacetylene .gas

welding.

Radiator

coresupport uppercenter

SBT091

-29-

-16-

Page 205 of 1701

__________ BODYALIGNMENT _

_ PRECAUTIONS _

Description PrecautionsForHandling HighStrength Steel

• Alldimensions indicatedinfigures areactual ones.

• When usingatracking gauge,adjustbothpointers toequal length. Thencheck thepointers andgauge

itself tomake surethere isno free play.

• When ameasuring tapeisused, check tobe sure there isno elongation, twistingorbending.

• Measurements shouldbetaken atthe center ofthe mounting holes.

• Anasterisk

(*)

following thevalue atthe measuring pointindicates thatthemeasuring pointonthe other

side issymmetrically thesame value.

• The coordinates ofthe measurement pointsarethe distances measured fromthestandard lineof"X", "V"

and "Z".

EngineCompartment

D=2T+3(mm)

D=2T+O.12 (in)

•

The electrode tipdiameter mustbereformed

properly according tothe panels thickness.

•

The spot ungget onHSS panel isharder than

that ofan ordinary steelpanel.

Therefore, forspot cutting HSSpanel, ahigh

torque drillofalow speed (1,000 to1,200

rpm) maybeused tomaintain itsdurability

and facilitate theoperation.

• HSS panels withatensile strength of785 to981 N/mm

2

(80to100 kg/mm

2,

114to142 klb/sq in),

used asreinforcement inthe door guard barand inthe bumper, istoo high intensile strength touse

for general repairs.Whenthesepanels aredamaged, theouter panels alsosustain consequential

damage; therefore, thesepanels arenever remedied withoutreplacing thedoor assembly orbumper

assembly.

2. Precautions inspot welding

This work should beperformed understandard workconditions. However,workcontrol mustbeexercised

as folloows:

SBF8?4GB

"Z":

Imaginary baseline

[200 mmbelow datum line

("OZ" atdesign plan)]

Front axlecenter

/

y (_)

(0)

Incorrect

Incorrect

Correct

D==Tip+diameter

T

,::=T====p=la::t_e=-=-_t_h=i_C=k=_n=_e_s=s= __,-- ~

• The panel surfaces mustbefitted toeach

other, leaving nogaps.

____

MEASURMENT _

SBT08?

-15- -30-

Page 218 of 1701

REPLACEMENTOPERATIONS

Rear Floor Rear ________

GENERALINFORMATION _

Identification Number(Cont'd)

(Work afterrearpanel havebeen removed.)

ExceptforEurope

IN 1 .B CAN 15A

0

XXXXXX

T

T

--c:::

serialnumber

0:

Stopgap (nomeaning)

Destination

A: Australia andNew Zealand

Z: Except forEurope, Australia, andNew Zealand

Model

A: 2-wheel drive

Engine type

B: GA 15DE engine

C: GA 16DE engine

E: SR20DE engine-For AustraliaandNew Zealand only

Body type

B: 4-door Sedan

F: 5-door Hatchback

Manufacturer

IN 1:Nissan, Passenger vehicle

VEHICLE IDENTIFICATION PLATE

1Type approval number

2 Vehicle identification

number(Chassis number)

3 Gross vehicle weight

4 Gross combination weight

Gross vehicle weight

+

Gross trailing capacity

(Weight)

5 Gross axleweight(Front)

6 Gross axleweight(Rear)

7 Type approval number

8 Body colorcode

9 Trim color code

10 Model Specification No.

11 Engine model

12 Engine displacement

13 Transaxle model

14 Axle model

cc

o

PLANT

PlANTA

El

ii:

13IJJ

if[

**

it~

*1

MADEINJAPAN

NISSAN

MOTORCO.,LTD. APAN

~ tt

~(:l

&

~~~sg~

CNHOA"SIS ~

~~~~~o

&

o ~

0

:ggtg~

~~~RNICION ~

&.

~~ ~~~~~ &

£

; ;~)~ /~~~~~'. AE~~

A1L11

Expect

Europe

~

&

kgO

1-

&

kg

2-

&

kg

COlOR. TRIM

~

&

FARBE. POlST

&

NISSAN

MOTORCO.,LTD. JAPAN

I ~ I

~

o

TYPE

TTP

Europe

FR

_2

3D

HI

B:3door hatchback

5D

HI

B:5door hatchback

Service

Joint

111

~

2-spot welds 3-spotwelds M.

I.

G plug weld .MIG seam weld/

(For 3panels plugweld method )P:

F

weld

• rr=- •

A

===-=

.'S~

.L.LLL

GTJ --- ~

-43-

-2-

Page 219 of 1701

~~~~~~~~_GENERALJNFORM~ION~~~~~~~~_

IdentificationNumber _

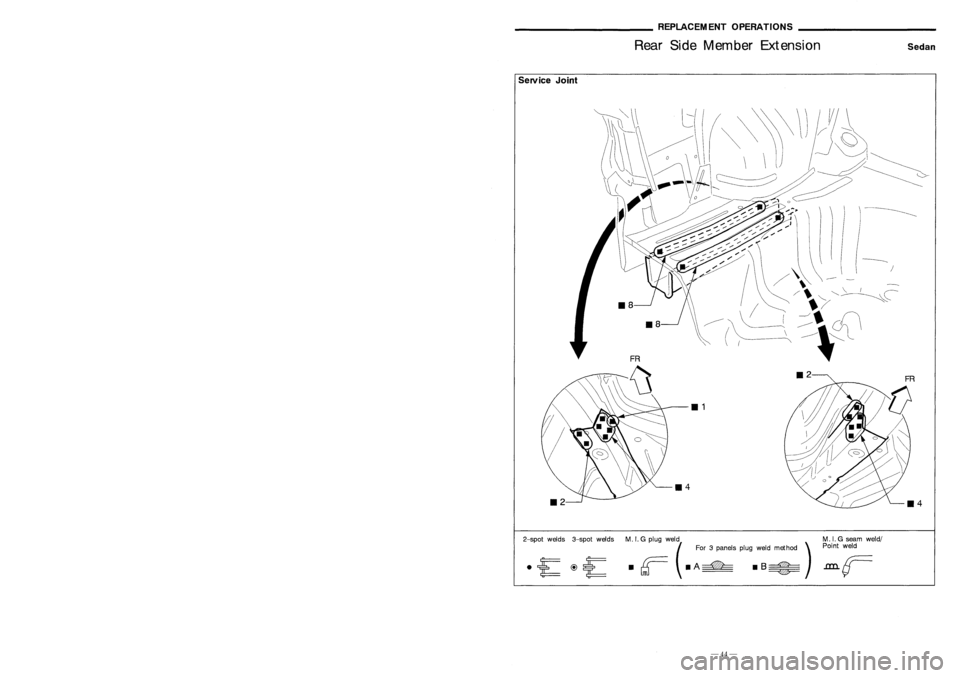

REPLACEMENTOPERATIONS

Rear SideMember Extension

Sedan

-------

/

/\

---

/ \ -

'------- /~ ,,\I

c-

~ ~>~

111

114

Service

Joint

SGI908

Vehicle

identification plate

A

A

Vehicle

identification number

N15 U

0

xxxxxx.

T

T

---c::

serialnumber

0:

Stopgap (nomeaning)

Destination

U: Europe

Model

A: 2-wheel drive

Engine type

A: GA 14DE engine

C: GA 16DE engine

E: SR20DE engine

F: CD20 engine

Body type

B: 4-door Sedan

F: 5-door Hatchback

E: 3-door Hatchback

Manufacturer

J

N 1: Nissan, Passenger vehicle

Emission

controlinformation label

VEHICLE IDENTIFICATION NUMBERARRANGEMENT

For Europe

• JN1 B

2-spotwelds 3-spotwelds M.I.G plug weld

(For 3panels plugweld method )

d

r;==

dA~ dB~

GTJ ~

M.

I.G seam weld/

Point weld

-1-

-44-

Page 221 of 1701

BODY

&

TRIM

SECTION

BT

CONTENTS

* For seat belt,refer toMA and RSsection.

* For wiring diagrams ofbody electrical systems,refertoEL section.

PRECAUTIONS

2

Service Notice 2

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 2

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 2

GENERAL SERViCiNG 3

Clip andFastener

3

BODY END

5

Body Front End

5

Body RearEndandOpener 7

DOOR 11

Front Door 11

Rear Door

12

INSTRUMENT PANEL

13

INTERIOR TRIM 16

Side andFloor Trim

16

Door Trim 22Roof

Trim 24

Trunk RoomTrim 26

Back DoorTrim 27

EXTERIOR 28

SEAT 35

Front Seat

35

Heated Seal... 36

Rear Seat 37

SUNROOF 39

WINDSHIELD ANDWINDOWS 43

Windshield andRear Window 43

Back DoorWindow 44

Rear SideWindow

.45

MIRROR 46

Door Mirror .46

BODY ALIGNMENT 47

Engine Compartment 47

Underbody .49

•

Page 225 of 1701

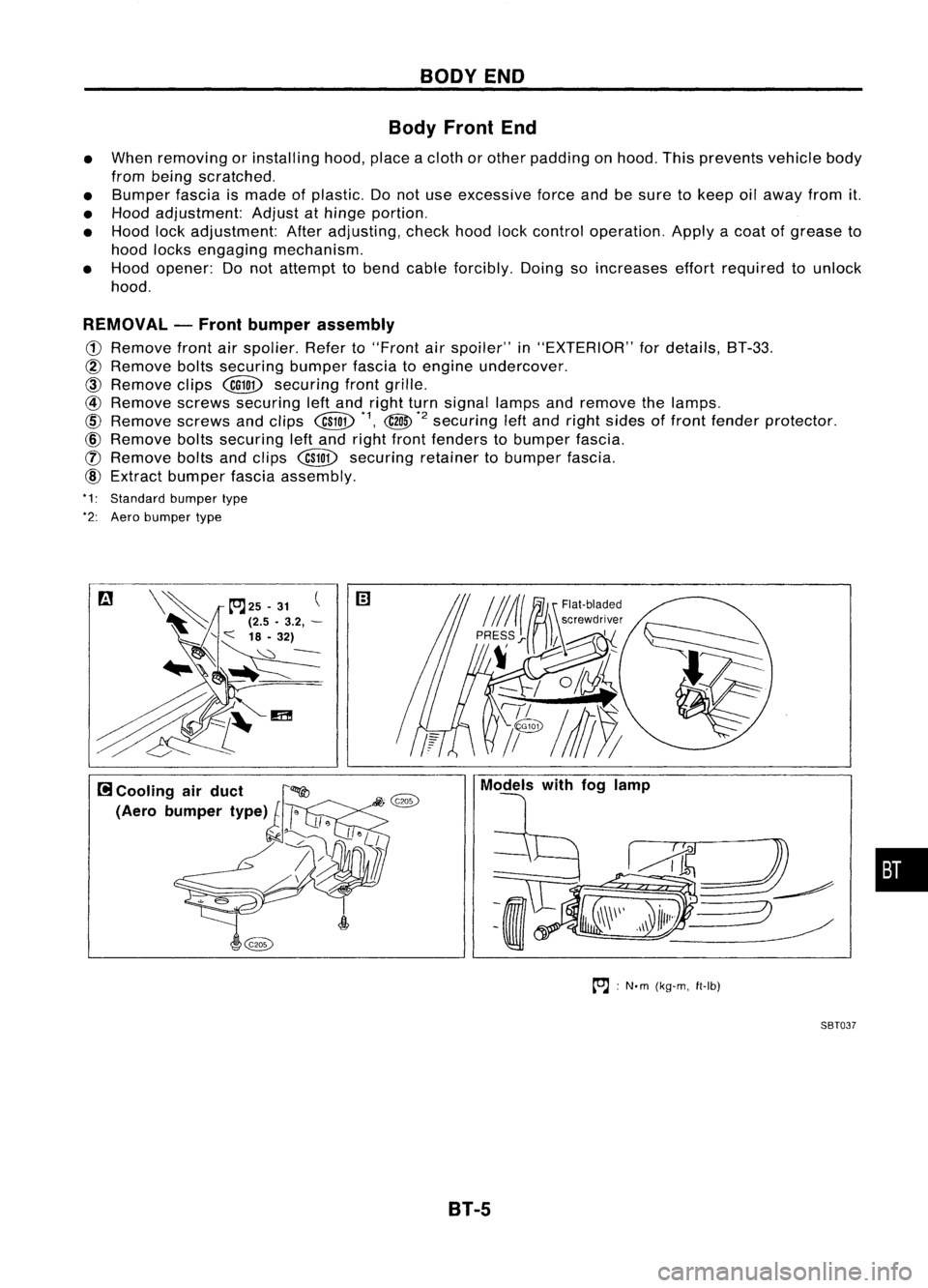

BODYEND

Body Front End

• When removing orinstalling hood,placeacloth orother padding onhood. Thisprevents vehiclebody

from being scratched.

• Bumper fasciaismade ofplastic. Donot use excessive forceandbesure tokeep oilaway fromit.

• Hood adjustment: Adjustathinge portion.

• Hood lockadjustment: Afteradjusting, checkhoodlockcontrol operation. Applyacoat ofgrease to

hood locks engaging mechanism.

• Hood opener: Donot attempt tobend cable forcibly. Doingsoincreases effortrequired tounlock

hood.

REMOVAL -Front bumper assembly

CD

Remove frontairspolier. Referto"Front

air

spoiler" in"EXTERIOR" fordetails, BT-33.

@

Remove boltssecuring bumperfasciatoengine undercover.

CID

Remove clips

@QD

securing frontgrille.

@

Remove screwssecuring leftand right turnsignal lampsandremove thelamps.

@

Remove screwsandclips

@W

*1,

@

*2

securing

leftand right sides offront fender protector.

@)

Remove boltssecuring leftand right front fenders tobumper fascia.

([) Remove boltsandclips

@W

securing retainertobumper fascia.

@)

Extract bumper fasciaassembly.

*1: Standard bumpertype

*2: Aero bumper type

to.J:

N'm (kg-m, ft-Ib)

SBT037

B1-5

•

Page 267 of 1701

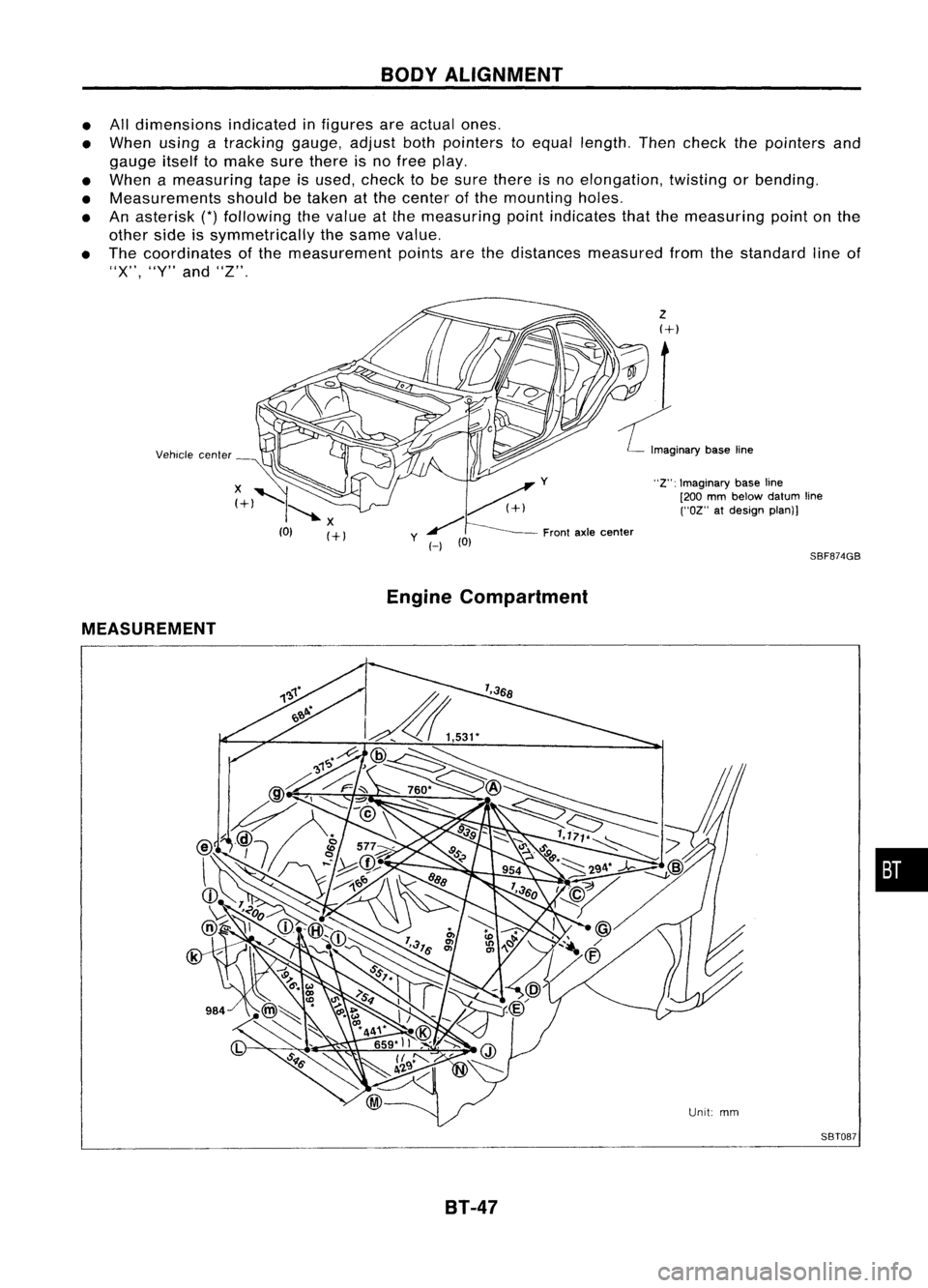

BODYALIGNMENT

• Alldimensions indicatedinfigures areactual ones.

• When usingatracking gauge,adjustbothpointers toequal length. Thencheck thepointers and

gauge itselftomake surethere isno free play.

• When ameasuring tapeisused, check tobe sure there isno elongation, twistingorbending.

• Measurements shouldbetaken atthe center ofthe mounting holes.

• Anasterisk

(*)

following thevalue atthe measuring pointindicates thatthemeasuring pointonthe

other sideissymmetrically thesame value.

• The coordinates ofthe measurement pointsarethedistances measured fromthestandard lineof

"X", "Y"andHZ".

Frontaxlecenter

I

v

~

/

y

H

(0)

2

(+)

~r

L"oo"

b.~

Ii"'

"2": Imaginary baseline

[200 mmbelow datum line

("02" atdesign plan)]

MEASUREMENT

SBF874GB

Engine Compartment

SBT087

8T-47

•