engine NISSAN ALMERA N15 1995 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 332 of 1701

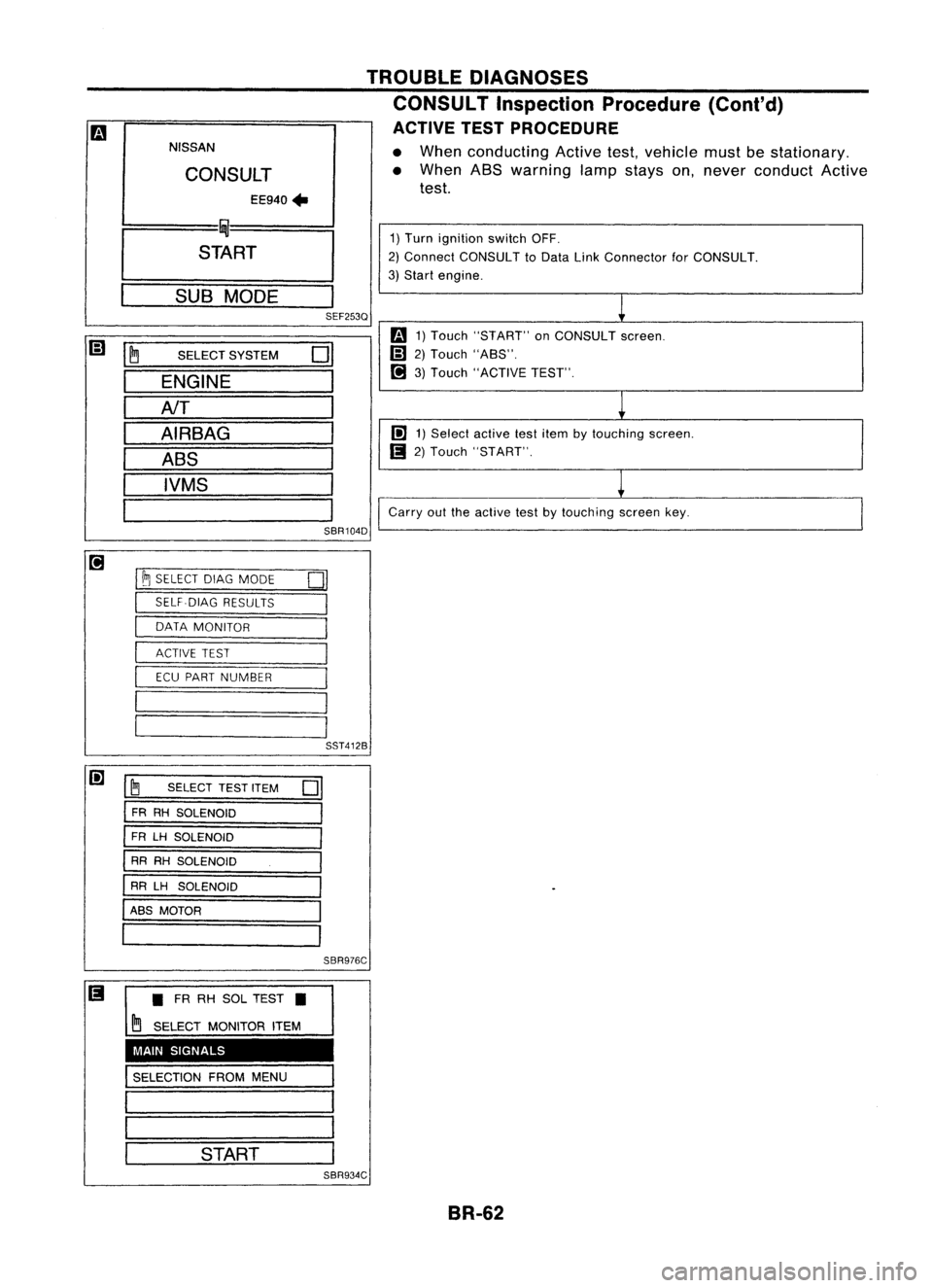

1)Turn ignition switchOFF.

2) Connect CONSULT toData LinkConnector forCONSULT.

3) Start engine.

l

Fa

1)Touch "START" onCONSULT screen.

m

2)Touch "ASS".

[!)

3)Touch "ACTIVE TEST".

~

£!1

1)Select activetestitem bytouching screen.

II

2)Touch "START".

~

I

Carry outtheactive testbytouching screenkey.

TROUBLE

DIAGNOSES

CONSULT Inspection Procedure (Coni'd)

ACTIVE TESTPROCEDURE

• When conducting Activetest,vehicle mustbestationary.

• When ASSwarning lampstays on,never conduct Active

test.

m

~ SELECT

SYSTEM

D

ENGINE

AlT

AIRBAG ASS IVMS

SBR104D

~ SELECT DIAGMODE

OJ

SELF.DIAG RESULTS

DATA MONITOR

ACTIVE TEST

ECU PART NUMBER

Fa

NISSAN

CONSULT EE940

+

I rBU

I

START

I

SUB

MODE

I

SEF253Q

SST412B

£!1

~SELECT

TESTITEM

0

FR RH SOLENOID

FR LHSOLENOID

RR RH SOLENOID

RR LH SOLENOID

I

ASS MOTOR

I

SBR976C

II

•FR RH SOL TEST •

~ SELECT

MONITOR ITEM

MAIN SIGNALS

SELECTION FROMMENU

START SBR934C

BR-62

Page 333 of 1701

DATAMONITOR MODE TROUBLE

DIAGNOSES

CONSULT Inspection Procedure(Cont'd)

MONITOR ITEM CONDITION

SPECIFICATION

FR RH SENSOR

FR LHSENSOR Drive

vehicle.

Almostthesame speed asspeedometer.

REAR RHSENSOR (Each

wheel isrotating.)

REAR LHSENSOR

STOP LAMP SW Brake

isdepressed. Depress

thepedal: ON

Release thepedal: OFF

FR RH INSOL

FR RH OUT SOL

FR LH INSOL

FR LH OUT SOL

Engineisrunning. Operating

conditions foreach solenoid valveareindicated.

RR RH INSOL ABS

isnot operating: OFF

RR RH OUT SOL

.

RR LHINSOL

RR LHOUT SOL

IgnitionswitchON(Engine stops):OFF

ACTUATOR RLY

Enginerunning: ON

MOTOR RELAY ABS

isnot operating: OFF

Ignition switchisON or

ABSisoperating: ON

engine isrunning.

WARNING LAMP Warning

lampisturned on:ON

Warning lampisturned off:OFF

BATTERY VOLT Power

supply voltage forcontrol unit

ACTIVE TESTMODE

TEST ITEM CONDITION JUDGEMENT

Brake fluidpressure controloperation

FR RH SOLENOID

INSOL OUTSOL

FR LH SOLENOID

RR RH SOLENOID UP

(Increase): OFF OFF

RR LHSOLENOID

Engineisrunning. KEEP

(Hold): ON OFF

DOWN (Decrease): ON ON

ABS actuator motor

ABS MOTOR ON:

Motor runs

OFF: Motor stops

Note: Active testwillautomatically stoptenseconds afterthe

test starts. (LIMIT SIGNAL monitorshowsON.)

BR-63

•

Page 352 of 1701

TROUBLEDIAGNOSES

Diagnostic Procedure8

CONTROL UNIT

(Malfunction codeNo.71)

Carry outself-diagnosis aftererasing

self-diagnostic results,BR-56.

Does warning lampindicate codeNo.

71 again?

No

Inspect thesystem according tothe

code No. Yes

Replace controlunit.

Brake pedal Diagnostic

Procedure9

SYMPTOM: Pedalvibration andnoise

No

Does thesymptom appearwhenelectri-

SAT797A

calequipment switches(suchashead-

lamp) areoperated?

1.

Apply brake.

2. Start engine.

3. Does thesymptom appearonlywhen

engine isstarted?

No

Yes

Check wheelsensor shieldgrou.nd

secured withcontrol unitmounting bolt.

Refer toBR-41. Yes

Carryoutself-diagnosis.

Refer toBR-53 (Europe)

or BR-56 (Except

Europe).

Go to

Ii1

inDiagnostic

Procedure 11,BR-83.

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

Note: ABSmayoperate andcause vibration underanyofthe

following conditions.

• Applying brakegradually whenshifting oroperating clutch.

• Low friction (slippery) road.

• High speed cornering.

• Driving overbumps andpotholes.

• Engine speedisover 5,000 rpmwith vehicle stopped.

BR-82

Page 358 of 1701

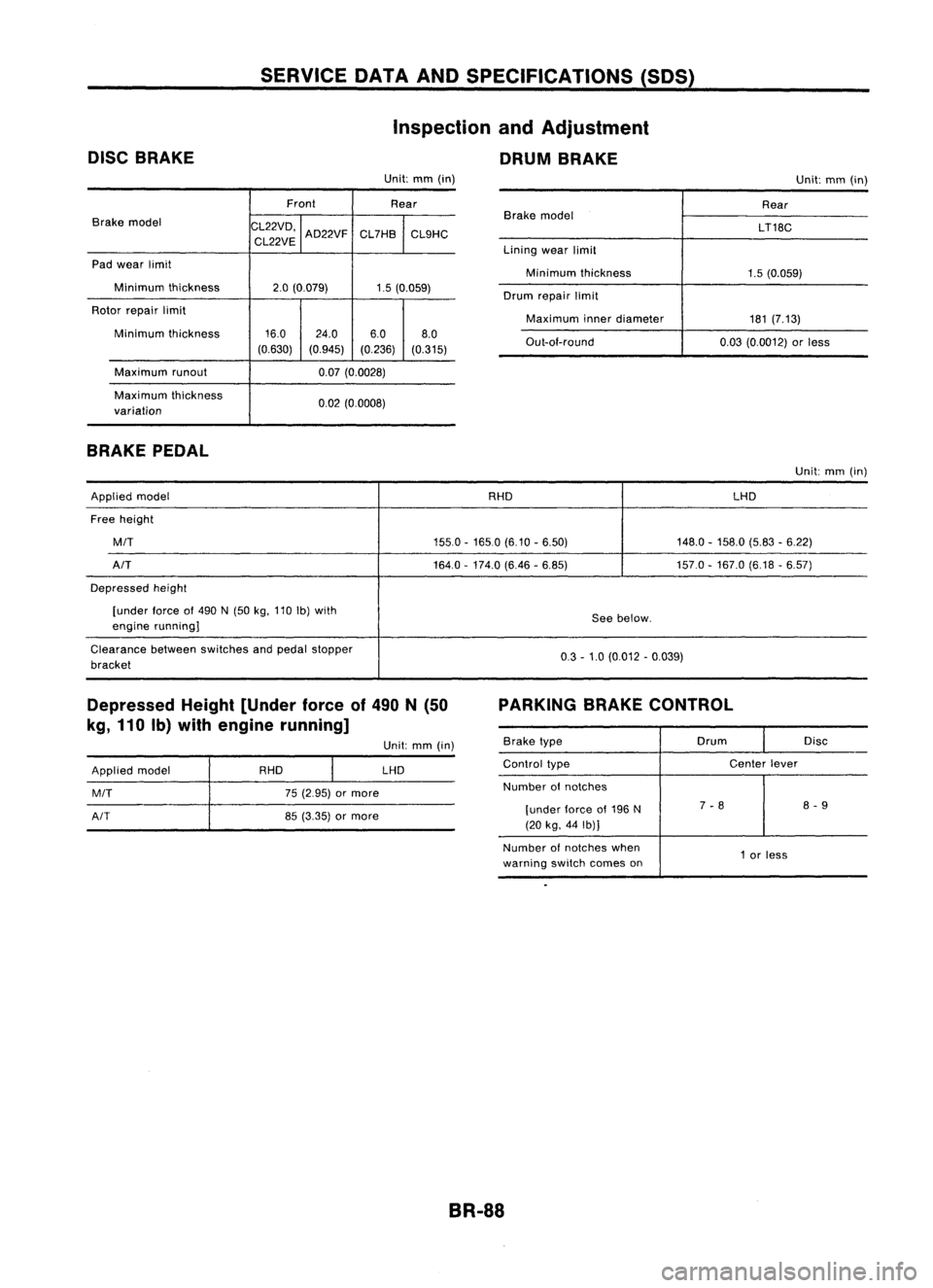

DISCBRAKE SERVICE

DATAANDSPECIFICATIONS (SDS)

Inspection andAdjustment

DRUM BRAKE

Unit: mm(in)

Unit:mm(in)

Front Rear

Brake model

CL22VD,

CL22VE AD22VF

CL7HB

CL9HC

Pad wear limit

Minimum thickness

2.0(0.079) 1.5(0.059)

Rotor repair limit

Minimum thickness 16.0

24.0 6.08.0

(0.630) (0.945) (0.236)(0.315)

Maximum runout 0.07(0.0028)

Maximum thickness

0.02(0.0008)

variation

BRAKE PEDAL

Brake

model

Lining wearlimit

Minimum thickness

Drum repair limit

Maximum innerdiameter

Out-ai-round Rear

LT18C

1.5 (0.059)

181 (7.13)

0.03 (0.0012) orless

Unit: mm(in)

Applied model RHDLHD

Free height

MIT

155.0-1650 (6.10-6.50) 148.0-158.0 (5.83-6.22)

AIT

164.0-174.0 (6.46-6.85) 157.0-167.0 (6.18-6.57)

Depressed height

[under force

01

490 N(50 kg,110 Ib)with

Seebelow.

engine running]

Clearance betweenswitches andpedal stopper

0.3-1.0 (0.012 -0.039)

bracket

Depressed Height[Under forceof490 N(50

kg, 110 Ib)with engine running] PARKING

BRAKECONTROL

Applied model

MIT

AIT

RHD

75(2.95) ormore

85 (3.35) ormore Unit:

mm(in)

LHD

Brake

type Drum

Disc

Control type Center

lever

Number

01

notches

[under lorceof196 N 7

-8 8

-9

(20 kg, 44Ib)]

Number ofnotches when

1or less

warning switchcomes on

BR-88

Page 363 of 1701

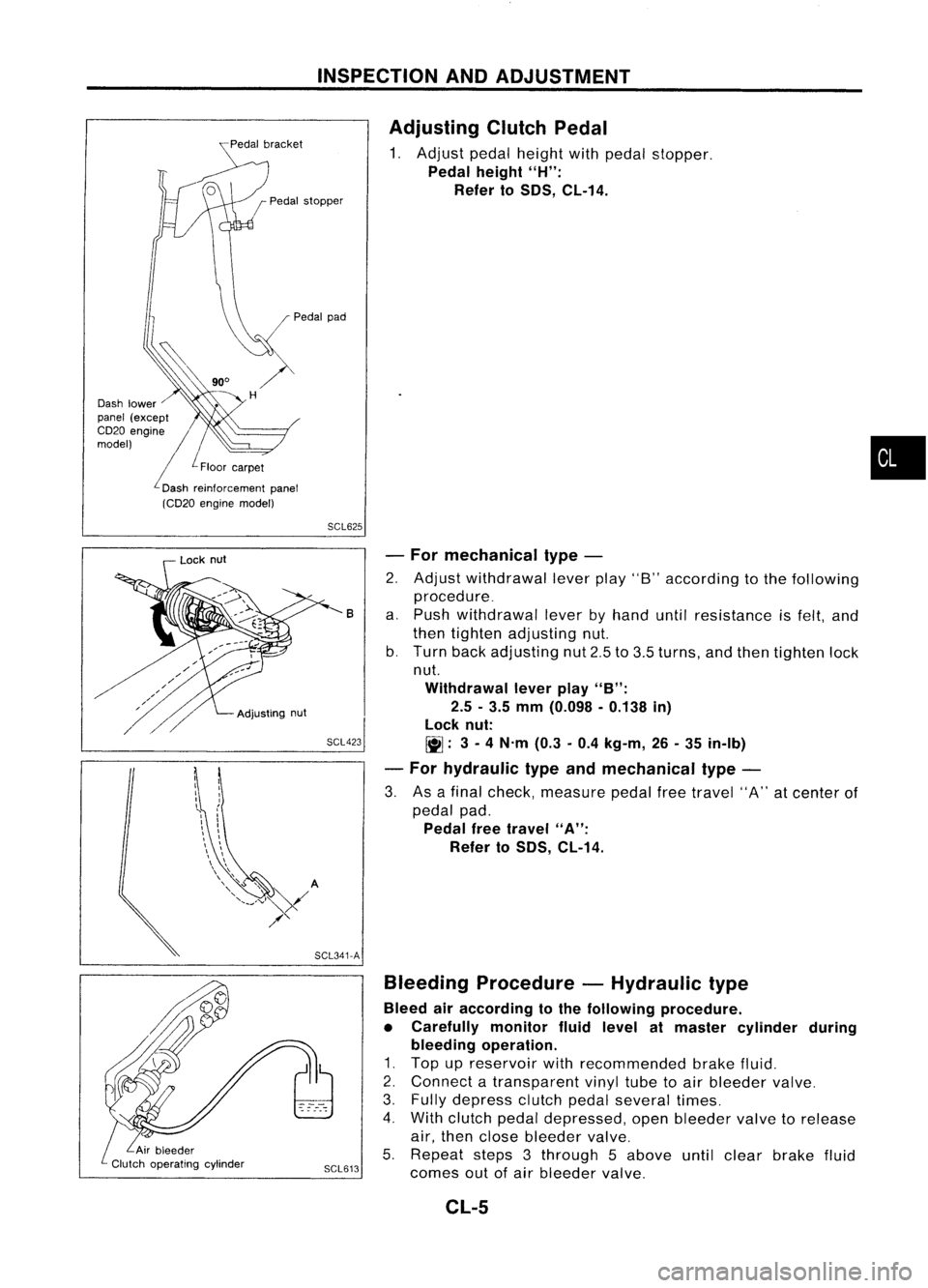

INSPECTIONANDADJUSTMENT

Pedal stopper

Dash lower

panel (except

CD20 engine //

model)

/L

Floor car-pet

L

Dash reinforcement panel

(CD20 engine model)

Adjusting

ClutchPedal

1. Adjust pedalheight withpedal stopper.

Pedal height

"H":

Refer to

50S,

CL-14.

•

SCL625

SCL423 -

For mechanical type-

2. Adjust withdrawal leverplay"8"according tothe following

procedure_

a. Push withdrawal leverbyhand untilresistance isfelt, and

then tighten adjusting nut.

b. Turn backadjusting nut2.5to3.5 turns, andthen tighten lock

nut.

Withdrawal leverplay

"B":

2.5 -3.5 mm (0.098 -0.138 in)

lock nut:

~: 3-

4 N'm (0.3-0.4 kg-m, 26-35 in-Ib)

- For hydraulic typeandmechanical type-

3. Asafinal check, measure pedalfreetravel "A"atcenter of

pedal pad.

Pedal freetravel

"A":

Refer to

50S,

CL-14.

B

Bleeding Procedure -Hydraulic type

Bleed airaccording tothe following procedure.

• Carefully monitorfluidlevel atmaster cylinder during

bleeding operation.

1. Top upreservoir withrecommended brakefluid.

2. Connect atransparent vinyltubetoair bleeder valve.

3. Fully depress clutchpedalseveral times.

4. With clutch pedaldepressed, openbleeder valvetorelease

air, then close bleeder valve.

5. Repeat steps3through 5above untilclear brake fluid

SCL613

comesoutofair bleeder valve.

SCL341-A

Adjusting

nut

Lock

nut

CL-5

Page 371 of 1701

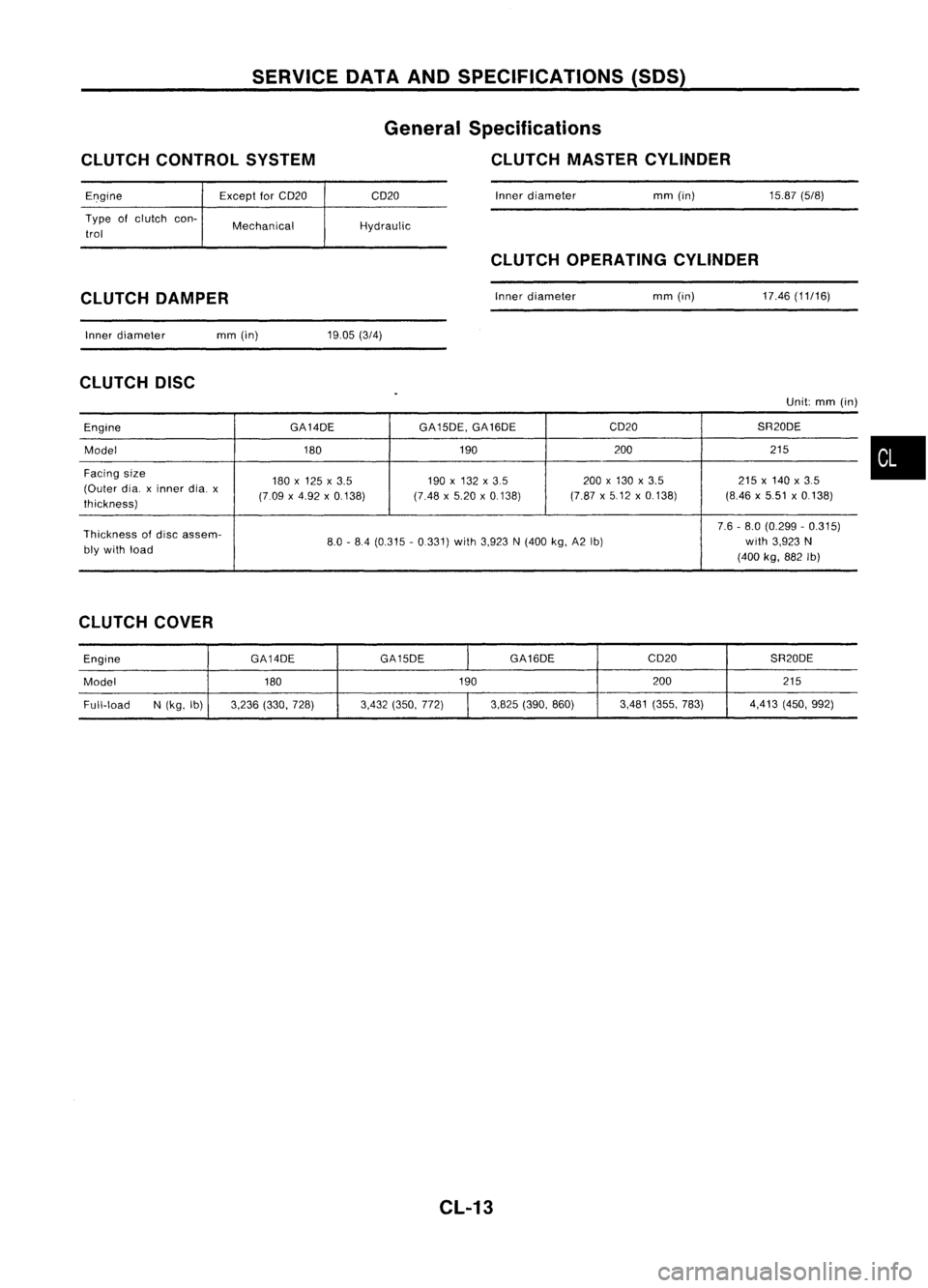

SERVICEDATAANDSPECIFICATIONS (SOS)

CLUTCH CONTROL SYSTEM General

Specifications

CLUTCH MASTER CYLINDER

Engine

Type ofclutch con-

trol Except

forCD20

Mechanical CD20

Hydraulic Inner

diameter

mm(in)

15.87(5/8)

CLUTCH OPERATING CYLINDER

CLUTCH DAMPER

Inner

diameter

mm(in)

17.46

(11/16)

Inner diameter

mm(in)

19.05

(3/4)

CLUTCH DISC

Unit:mm(in)

Engine GA14DEGA15DE,

GA16DE CD20

SR20DE

Model 180190

200 215

Facing size

180x125 x3.5 190

x132 x3.5 200

x130 x3.5 215x140 x3.5

(Outer dia.xinner dia.x

(7.09x4.92 x0.138) (7.48x5.20 x0.138) (7.87

x5.12 x0.138) (8.46x5.51 x0.138)

thickness)

Thickness ofdisc assem- 7.6

-8.0 (0.299 -0.315)

bly with load 8.0

-8.4 (0.315 -0331) with3,923 N(400 kg,A2Ib) with3,923 N

(400 kg,882 Ib)

CLUTCH COVER

Engine GA14DE

GA15DE

I

GA16DE

CD20

SR20DE

Model 180 190200

215

Full-load N

(kg, Ib) 3,236(330,728) 3,432(350,772)

I

3,825

(390,860) 3,481(355,783) 4,413

(450,992)

CL-13

•

Page 372 of 1701

SERVICEDATAANDSPECIFICATIONS (SOS)

Inspection andAdjustment

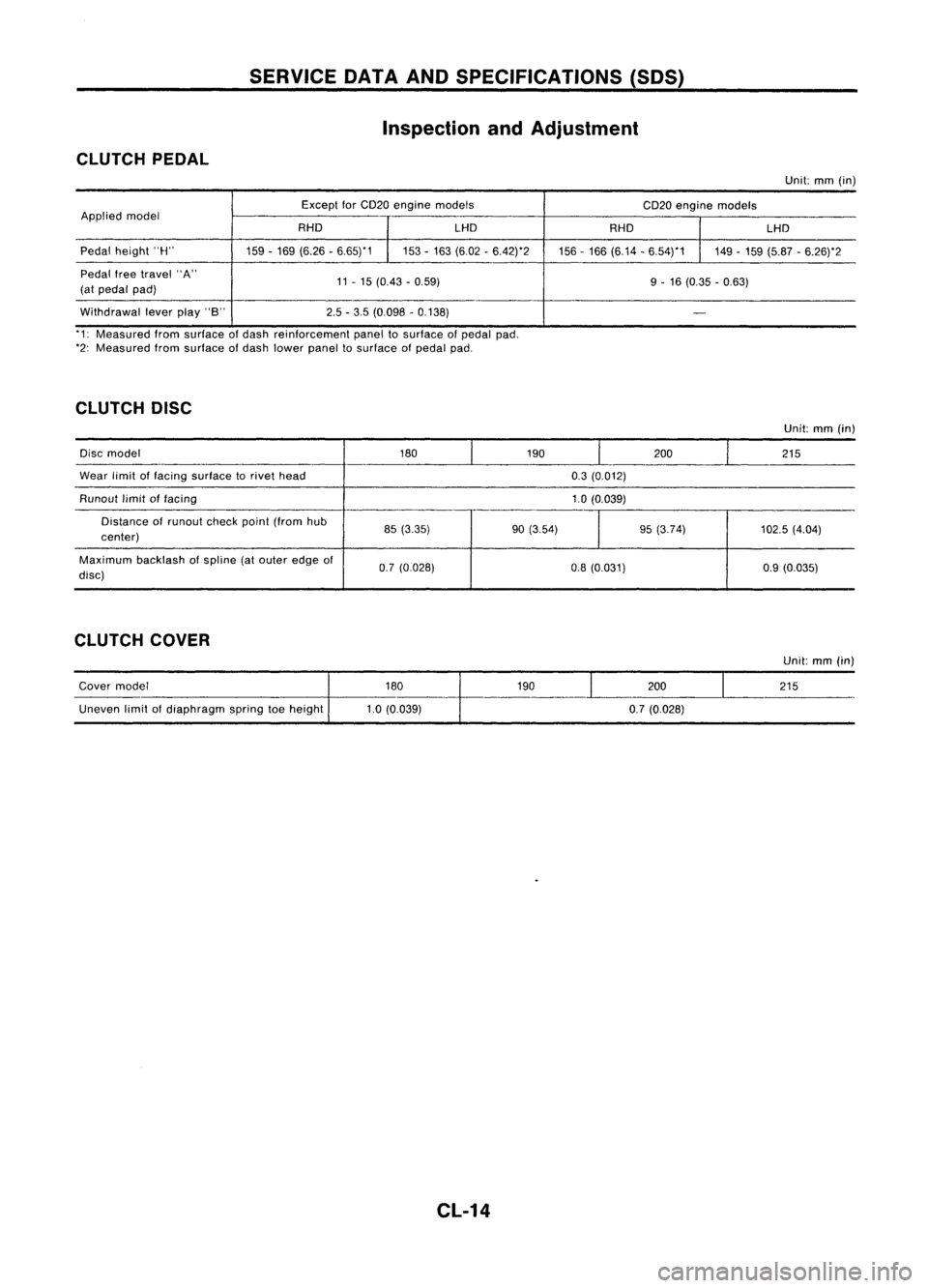

CLUTCH PEDAL

Unit:mm(in)

Except forCD20 engine models

CD20engine models

Applied model

RHOLHD

RHO LHD

Pedal height "H"

159-169 (6.26 -6.65)'1 153-163 (6.02 -6.42)*2 156-166 (6.14 -6.54)'1

149-159 (5.87 -6.26)'2

Pedal freetravel "A"

11-15 (0.43 -0.59)

9-16 (0.35 -0.63)

(at pedal pad)

Withdrawal leverplay"8" 2.5-3.5 (0.098 -0.138)

-

'1: Measured fromsurface ofdash reinforcement paneltosurface ofpedal pad.

'2: Measured fromsurface ofdash lower paneltosurface ofpedal pad.

CLUTCH DISC

Unit:mm(in)

Disc model

180190

I

200

215

Wear limitoffacing surface torivet head

0.3(0.012)

Runout limitoffacing 1.0(0.039)

Distance ofrunout checkpoint(from hub

85(3.35) 90(3.54)

I

95

(3.74) 102.5(4.04)

center)

Maximum backlashofspline (atouter edgeof

0.7(0.028) 0.8(0.031)

0.9(0.035)

disc)

CLUTCH COVER

Cover model

Uneven limitofdiaphragm springtoeheight 180

1.0 (0.039)

CL-14 190

I

200

0.7 (0.028)

I

Unit:

mm(in)

215

Page 375 of 1701

CONTENTS(Cont'd.)

Component PartsLocation 248

Wiring Diagram -NATS - 249

Trouble Diagnoses 251

LOCATION OFELECTRICAL UNITS

266

Engine Compartment 266

Passenger Compartment 267

HARNESS LAyOUT

269

How toRead Harness Layout... 269

Outline 270

Engine Control Harness 271

Engine RoomHarness 274

Main Harness '" 280

Body Harness :284

Body No.2 Harness 292

Engine Harness 294Air

Bag Harness 297

Room LampHarness 298

Back DoorHarness 299

Front DoorHarness (LHside) 300

Front DoorHarness (RHside) 302

Rear Door Harness 304

SUPER MULTIPLE JUNCTION

(SMJ) Foldout

Terminal Arrangement Foldout

FUSE BLOCK -Junction Box

(JIB)

Foldout

Terminal Arrangement Foldout

ELECTRICAL UNITS

Foldout

Terminal Arrangement Foldout

JOINT CONNECTOR

(J/C)

Foldout

Terminal Arrangement Foldout

WIRING DIAGRAM REFERENCE CHART

COOLING SYSTEM

LC

SECTION

ECCS (Ignition syslem) ECSECTION

AUTOMATIC TRANSAXLECONTROLSYSTEM ATSECTION

ANTI-LOCK BRAKESYSTEM BRSECTION

SRS "AIR BAG" RSSECTION

HEATER ANDAIRCONDITIONER HASECTION

•

Page 381 of 1701

![NISSAN ALMERA N15 1995 Workshop Manual POWERSUPPLY ROUTING

Schematic (Cont'd)

l5A~

F/FOG

20A

@J

LOAD,DEF

lOA

[8J

ABS,SToP/L

lOA

[ill

TURN

FICO, A!CCUT,

HEATER, A!e

HEATER, A!e

7.5A@Q]

lOA

@]

l5A

[ill

INT/L

GLOW, AIM,BUZZ NISSAN ALMERA N15 1995 Workshop Manual POWERSUPPLY ROUTING

Schematic (Cont'd)

l5A~

F/FOG

20A

@J

LOAD,DEF

lOA

[8J

ABS,SToP/L

lOA

[ill

TURN

FICO, A!CCUT,

HEATER, A!e

HEATER, A!e

7.5A@Q]

lOA

@]

l5A

[ill

INT/L

GLOW, AIM,BUZZ](/img/5/57349/w960_57349-380.png)

POWERSUPPLY ROUTING

Schematic (Cont'd)

l5A~

F/FOG

20A

@J

LOAD,DEF

lOA

[8J

ABS,SToP/L

lOA

[ill

TURN

FICO, A!CCUT,

HEATER, A!e

HEATER, A!e

7.5A@Q]

lOA

@]

l5A

[ill

INT/L

GLOW, AIM,BUZZER,

HORN, AUDIO, NATS

ILL, AUDIO

WIP/R

ACCESSORY

RELAY

20A

[ill

lOA ~

l5A ~ HORN

WIPER

MIRROR, DEF

HLC

20A []]

•

LOAD,

DEF

LOAD, MIL,BUZZER, WINDOW,

SROOF, DEF,NATS

LKUP, AIT,BACK/L,

METER, WARN

TURN

ABS

H/SEAT

H02S

F/PUMP, AIRREG

SRS

SRS

PGC/V, EGRC/V, AAC/V,VTC,

COOL/F, LOAD,GLOW,PLA,

FCUT, A/C,START, DTRL,DEF

3A

IE]

lOA

[ill

lOA

[ill

lOA ~

l5A

@]

7.

5A

[ill

n

IGNITION

U

RELAY

TAIL. F/FoG

LOAD, AIM,TAIL, F/FO~

ILL, BUZZER

RHO

models

eo engine

SR engine

SR engine A/Tmodels

and COengine

For Europe andIsrael

Except

@

LHD models without

daytime lightsystem

Except

@

LHo models with

daytime lightsystem

Without daytime lightsystem

With single airbag system

With dualairbag system

@

@

@

@

@

@

@

@

@

@

@

@)

HEL096

EL-9

Page 382 of 1701

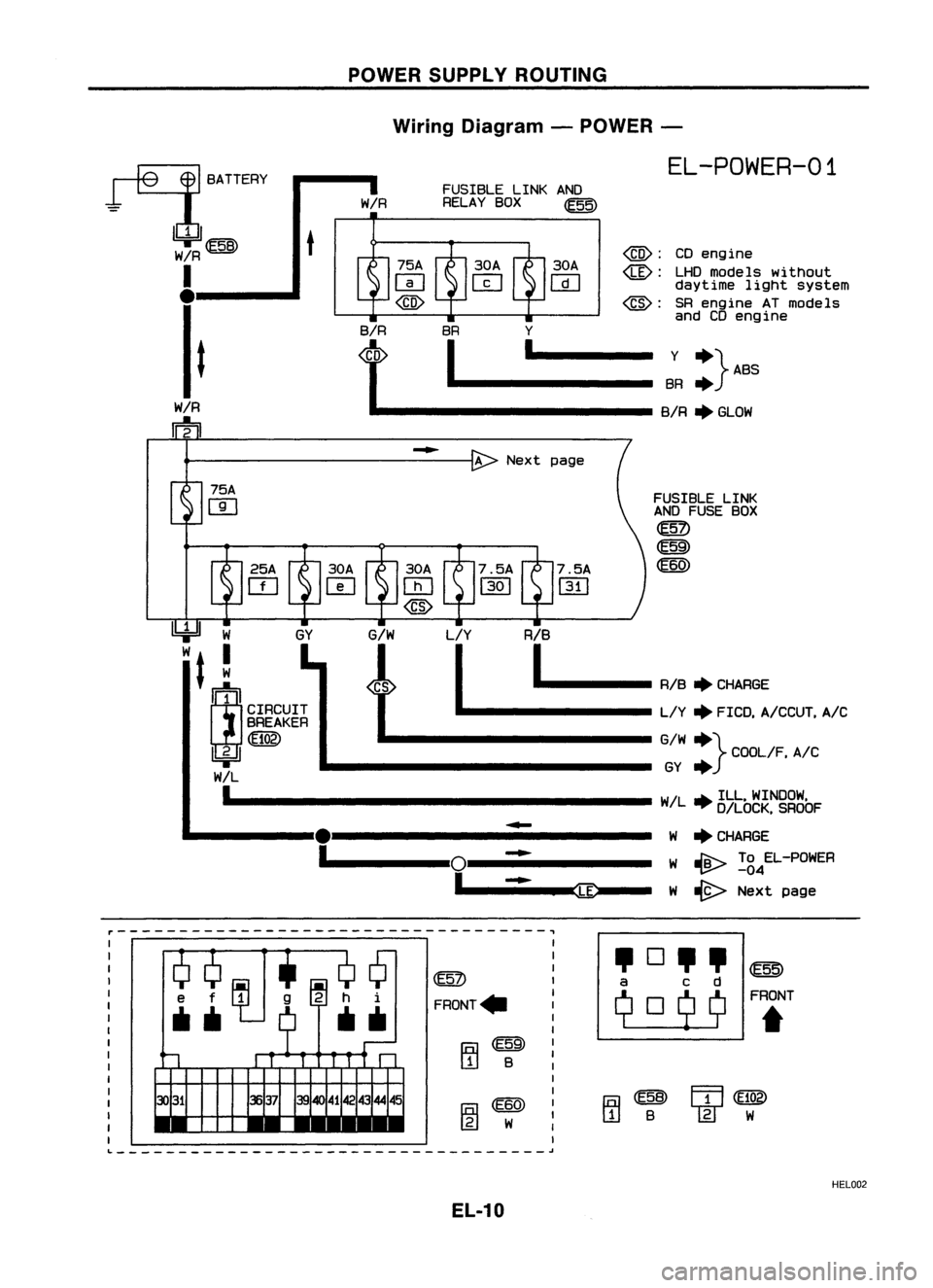

POWERSUPPLY ROUTING

Wiring Diagram -POWER -

~

.--------------

1-----0---------

1._.-__-

~:--.

CD

engine

LHD models without

daytime lightsystem

SR engine ATmodels

and CDengine

EL-POWER-01

FUSIBLE LINK

AND FUSE BOX

~

~

~

@:

@:

@:

30A

W

Next page

A

L!Y RIB

I

1

RIB+CHARGE

--------- L/Y+FICO, A/CCUT,

A/C

G/W

+}

COOL/F,A/C

GY

+

W/L

+

57tb~R~~2~bF

W +CHARGE

W

JB----

ToEL-POWER

~ -04

W

-f9>

Next page

FUSIBLE

LINKAND

RELAY BOX ~

-

G/W

W/R

B/R BR Y

t

o

1_-_-_-_-

_-I:::::::

BYR:} ABS

- B/R+GLOW

t

Il:jdI

W GY

Wt

!

~1

CIRCUIT

BREAKER

(102)

~

W!L

I

~

BATTERY

~ ~

W/R~

I

Jt

W/R

rn

75A

[]]

~-----------------------------------,

~

FRONT

t

CE57>

FRONT"

-----------------------------------~

HEL002

El-10