engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1041 of 1701

Checkthefollowing.

• Harness connectors

QD,@

• 10A fuse

• Harness openorshort

between EGRvalve

&

EVAP canister purge

control solenoid valve

and fuse

If NG, repair harness or

connectors.

NG

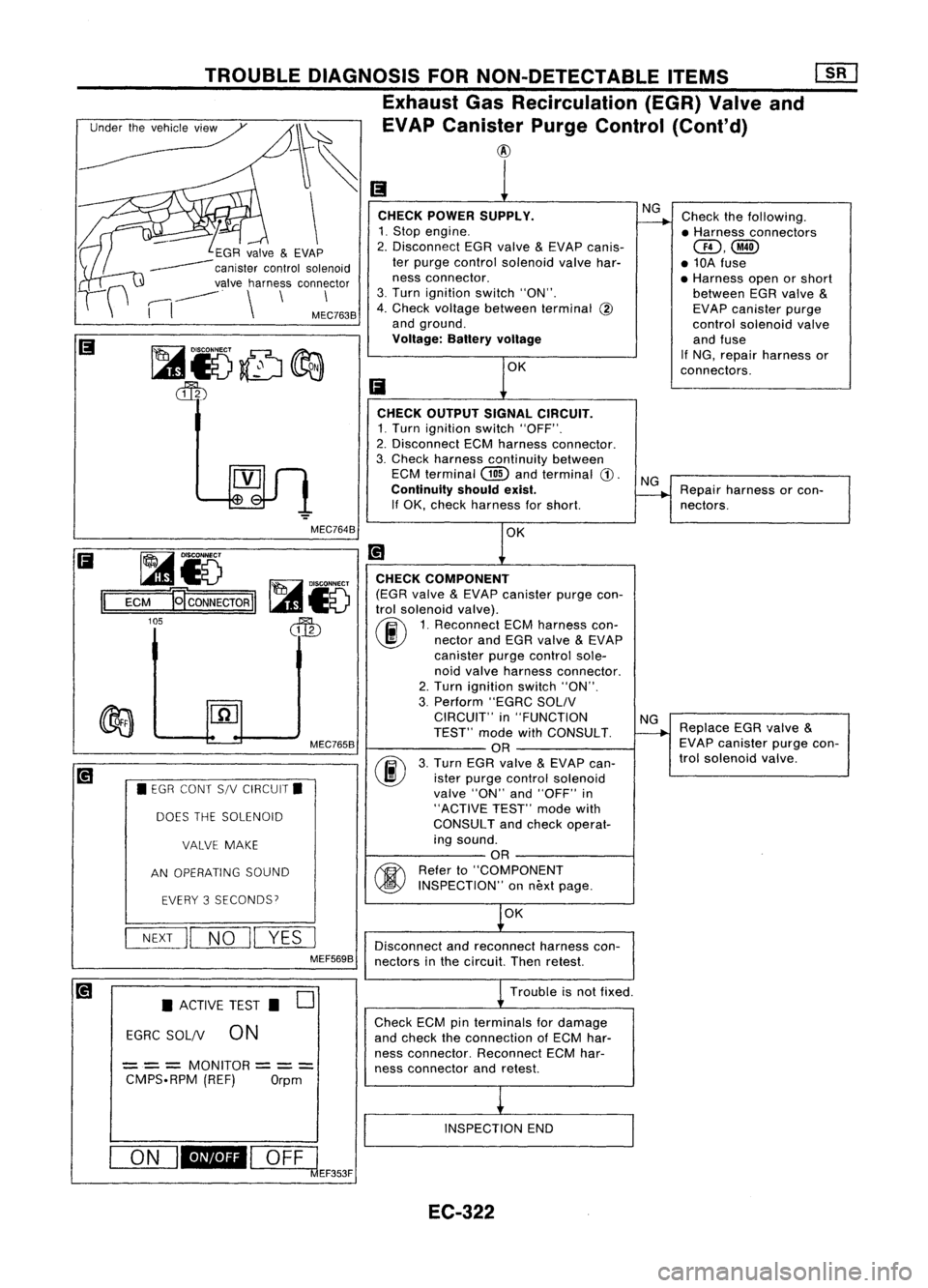

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect EGRvalve

&

EVAP canis-

ter purge control solenoid valvehar-

ness connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

@

and ground.

Voltage: Batteryvoltage

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Exhaust GasRecirculation (EGR)Valveand

_~ ~EVAPcanis:r PurgeControl (Cont'd)

\

~GR valve

&

EVAP

------ canistercontrolsolenoid

valve harness connector

,----,

-----

.

\

\

\

I

I

MEC7638

CHECKOUTPUT SIGNALCIRCUIT.

1. Turn ignition switch"OFF".

2. Disconnect ECMharness connector.

3. Check harness continuity between

ECM terminal

(ill)

andterminal

CD.

Continuity shouldexist.

If OK, check harness forshort.

NG

Repair harness orcon-

nectors.

MEC7648 OK

~i5

1=1

=E=CM=-g CONNECTOR

II

105

MEC7658

• EGR CONT S/VCIRCUIT.

DOES THESOLENOID

VALVE MAKE

AN OPERATING SOUND

EVERY 3SECONDS?

NEXT

II

NO

II

YES

I

MEF5698 CHECK

COMPONENT

(EGR valve

&

EVAP canister purgecon-

trol solenoid valve).

(ij\

1.Reconnect ECMharness con-

~ nectorandEGR valve

&

EVAP

canister purgecontrol sole-

noid valve harness connector.

2. Turn ignition switch"ON".

3. Perform "EGRCSOLIV

CIRCUIT" in"FUNCTION

TEST" modewithCONSULT.

OR

(F./)

3.Turn EGRvalve

&

EVAP can-

~ isterpurge control solenoid

valve "ON"and"OFF" in

"ACTIVE TEST"modewith

CONSULT andcheck operat-

ing sound.

OR

~ Referto"COMPONENT

~ INSPECTION" onnext page.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

NG

Replace EGRvalve

&

EVAP canister purgecon-

trol solenoid valve.

• ACTIVE TEST.

0

EGRC SOL/V

0N

== =

MONITOR

== =

CMPS.RPM (REF)Orpm Trouble

isnot fixed .

Check ECMpinterminals fordamage

and check theconnection ofECM har-

ness connector. ReconnectECMhar-

ness connector andretest.

INSPECTION END

ON

I_I

OFFl

clEF353F

EC-322

Page 1044 of 1701

•

INSPECTION END

Check thefollowing.

• Harness connectors

@,@

• Harness connectors

@,

• Harness foropen or

short between injector

and ignition switch

If NG, repair harness or

connectors.

OK

NG

OK

@

INSPECTION

START

DIAGNOSTIC

PROCEDURE

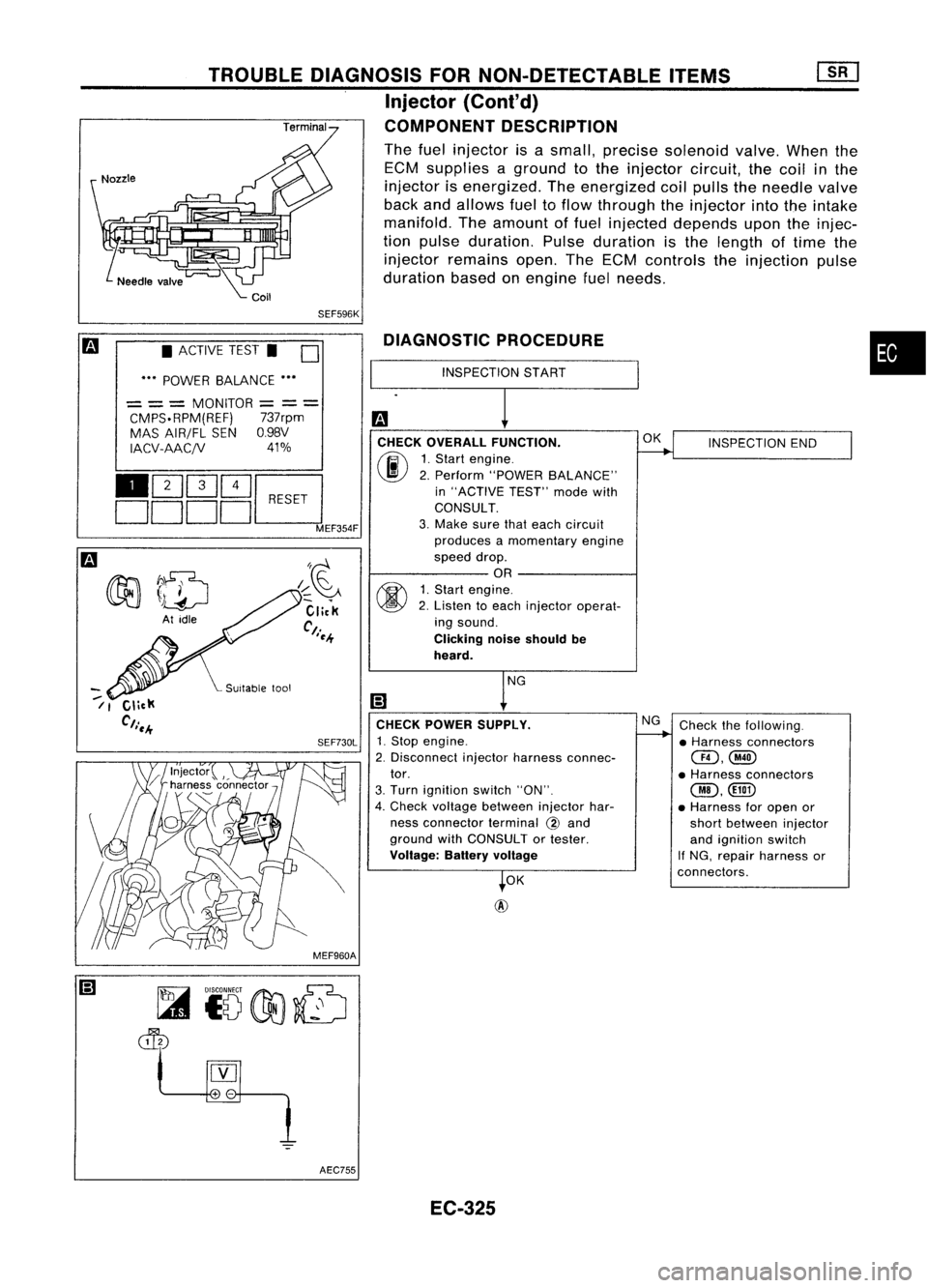

CHECK OVERALL FUNCTION.

(ij\

1.Start engine.

~ 2.Perform "POWER BALANCE"

in "ACTIVE TEST"modewith

CONSULT.

3. Make surethateach circuit

produces amomentary engine

speed drop.

OR

~ 1.Start engine.

~ 2.Listen toeach injector operat-

ing sound.

Clicking noiseshould be

heard.

CHECK POWER SUPPLY.

SEF730L

1.Stop engine.

2. Disconnect injectorharness connec-

tor.

3. Turn ignition switch"ON".

4. Check voltage between injectorhar-

ness connector terminal

@

and

ground withCONSULT ortester.

Voltage: Batteryvoltage

SEF596K

I~~

Click

Ct.

I~-+

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Injector

{Cont'd)

COMPONENT DESCRIPTION

The fuel injector isasmall, precise solenoid valve.Whenthe

ECM supplies aground tothe injector circuit,thecoil inthe

injector isenergized. Theenergized coilpulls theneedle valve

back andallows fueltoflow through theinjector intotheintake

manifold. Theamount offuel injected depends upontheinjec-

tion pulse duration. Pulseduration isthe length oftime the

injector remains open.TheECM controls theinjection pulse

duration basedonengine fuelneeds.

• ACTIVE TEST.

0

••• POWER BALANCE •••

= ==

MONITOR

=

=

=

CMPS.RPM(REF) 737rpm

MAS AIR/FL SENO.98V

IACV-AACjV 41%

110Q]~~

DDDDL:::J

MEF354F

--

/1

MEF960AAEC755 EC-325

Page 1046 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

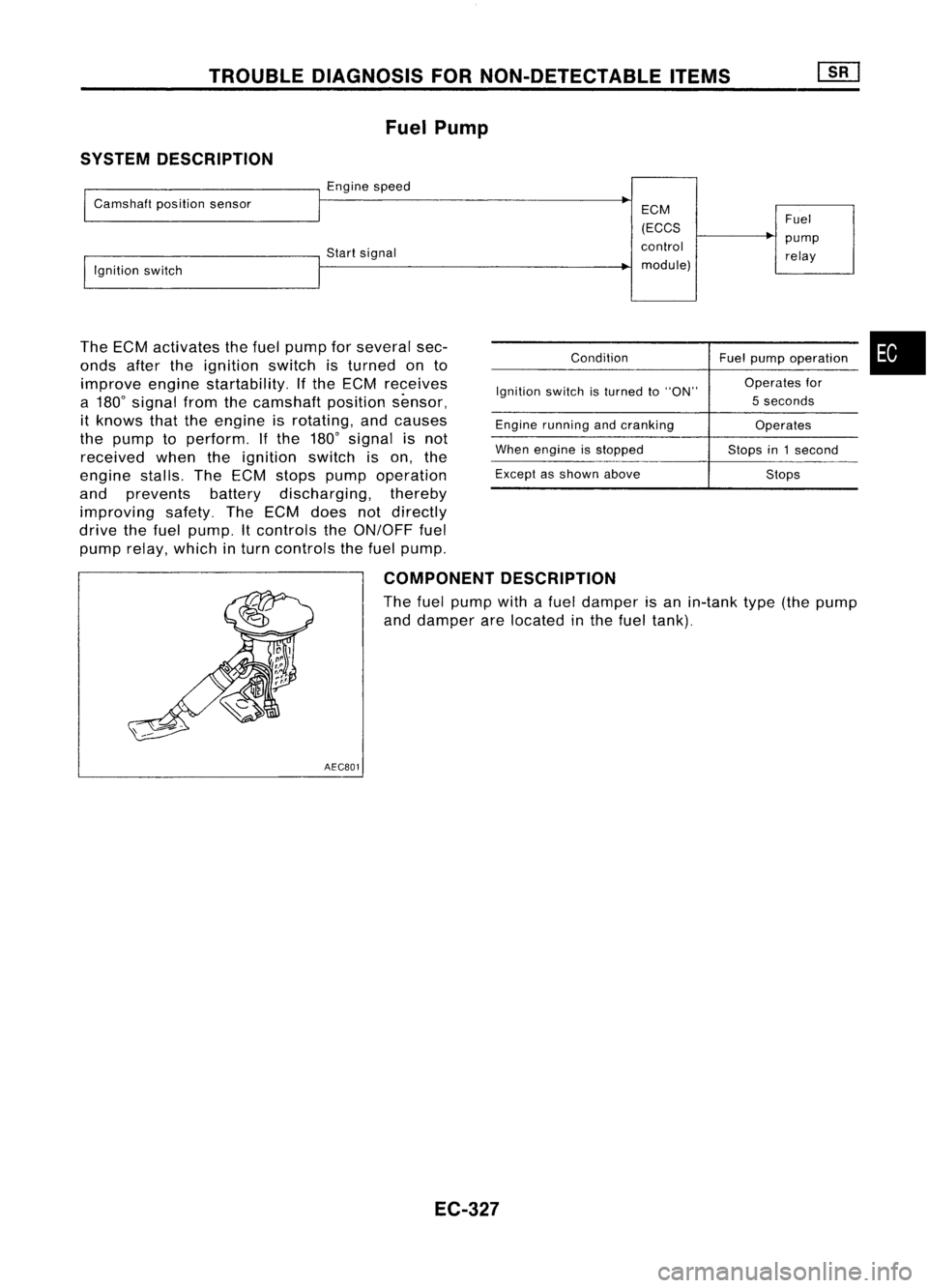

Fuel Pump

SYSTEM DESCRIPTION

I

Camshaft positionsensor

I

Engine speed

~

ECM

(ECCS Fuel

control pump

!,gnition switch Start

signal

relay

I

module)

The ECM activates thefuel pump forseveral sec-

onds aftertheignition switchisturned onto

improve enginestartability. Ifthe ECM receives

a 180

0

signal fromthecamshaft positionsensor,

it knows thattheengine isrotating, andcauses

the pump toperform. Ifthe 180

0

signal isnot

received whentheignition switchison, the

engine stalls.TheECM stops pump operation

and prevents batterydischarging, thereby

improving safety.TheECM does notdirectly

drive thefuel pump. Itcontrols theON/OFF fuel

pump relay,which inturn controls thefuel pump.

Condition

Ignition switchisturned to"ON"

Engine running andcranking

When engine isstopped

Except asshown above Fuel

pump operation •

Operates for

5 seconds

Operates

Stops in1second

Stops

COMPONENT DESCRIPTION

The fuel pump withafuel damper isan in-tank type(thepump

and damper arelocated inthe fuel tank).

AECB01

EC-327

Page 1051 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

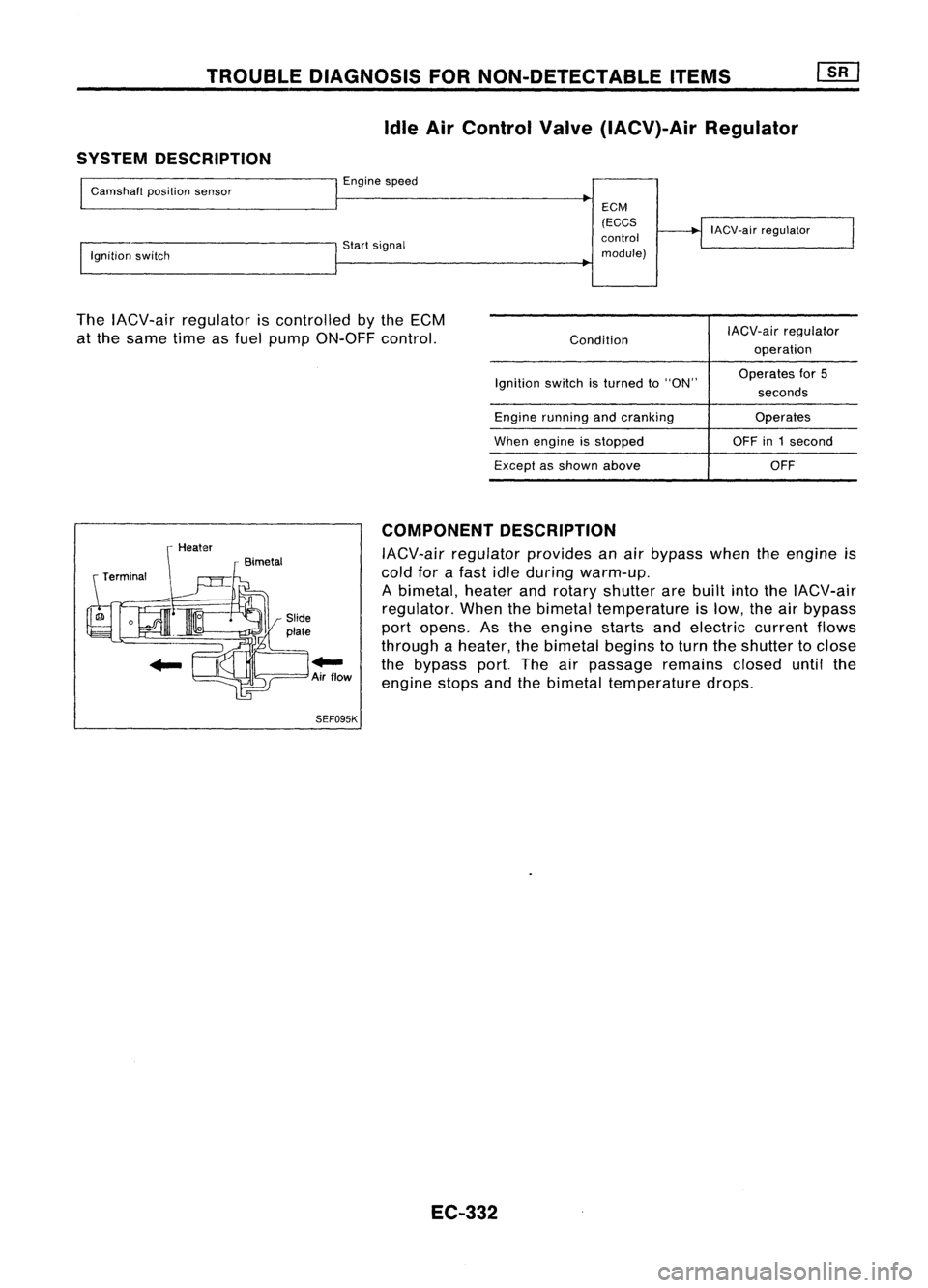

Idle AirControl Valve(IACV)-Air Regulator

SYSTEM DESCRIPTION

Camshaft positionsensor

Ignition switch Engine

speed

Start signal ECM

(ECCS

control

module) IACV-air

regulator

The IACV-air regulator iscontrolled bythe ECM

at the same timeasfuel pump ON-OFF control.

Condition

Ignition switchisturned to"ON"

Engine running andcranking

When engine isstopped

Except asshown above IACV-air

regulator

operation

Operates for5

seconds

Operates

OFF in1second

OFF

Bimetal

...

Air flow

SEF095K COMPONENT

DESCRIPTION

IACV-air regulator providesanair bypass whentheengine ;s

cold forafast idleduring warm-up.

A bimetal, heaterandrotary shutter arebuilt intotheIACV-air

regulator. Whenthebimetal temperature islow, theairbypass

port opens. Asthe engine startsandelectric currentflows

through aheater, thebimetal beginstoturn theshutter toclose

the bypass port.Theairpassage remainscloseduntilthe

engine stopsandthebimetal temperature drops.

EC-332

Page 1054 of 1701

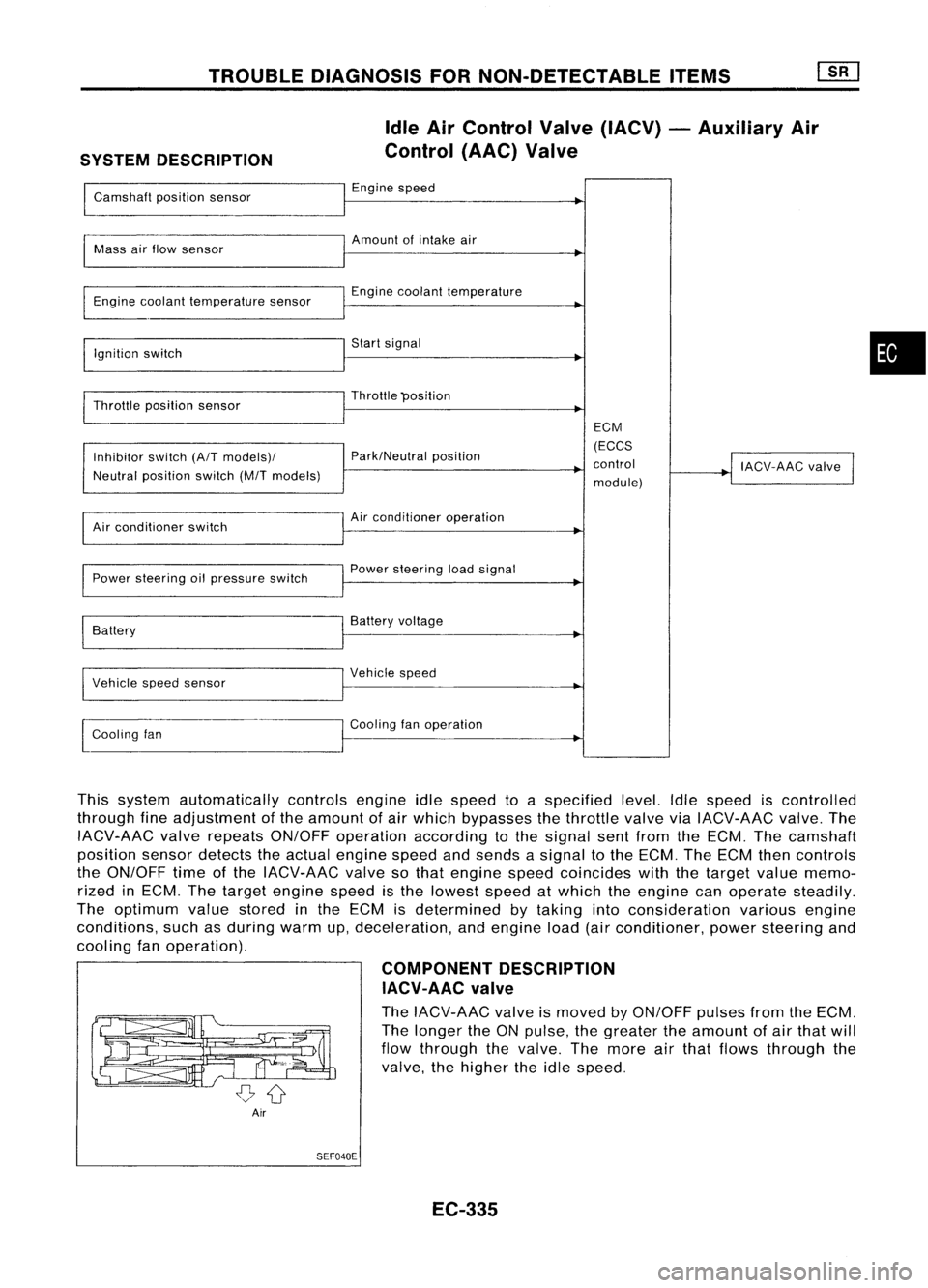

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

SYSTEM DESCRIPTION Idle

AirControl Valve(IACV) -Auxiliary Air

Control (AAC)Valve

Camshaft positionsensor Engine

speed

~

I

Amount ofintake air

Mass airflow sensor

I

Engine coolant temperature sensor Engine

coolant temperature

I

Ignition switch Start

signal

I

Throttle position sensor Throttle

"position

I

ECM

Inhibitor switch(A/Tmodels)/ Park/Neutral

position (ECCS

control

!

IACV-AAC valve

I

Neutral position switch(M/Tmodels)

module)

Air conditioner switch Air

conditioner operation

Power steering oilpressure switch Power

steering loadsignal

I

Battery Battery

voltage

Vehicle speedsensor Vehicle

speed

I

l

Cooling fan Cooling

fanoperation

I

This system automatically controlsengineidlespeed toaspecified level.Idlespeed iscontrolled

through fineadjustment ofthe amount ofair which bypasses thethrottle valveviaIACV-AAC valve.The

IACV-AAC valverepeats ON/OFF operation according tothe signal sentfrom theECM. Thecamshaft

position sensordetects theactual engine speedandsends asignal tothe ECM. TheECM thencontrols

the ON/OFF timeofthe IACV-AAC valvesothat engine speedcoincides withthetarget valuememo-

rized inECM. Thetarget engine speedisthe lowest speedatwhich theengine canoperate steadily.

The optimum valuestored inthe ECM isdetermined bytaking intoconsideration variousengine

conditions, suchasduring warmup,deceleration, andengine load(airconditioner, powersteering and

cooling fanoperation).

COMPONENTDESCRIPTION

IACV-AAC valve

The IACV-AAC valveismoved byON/OFF pulsesfromtheECM.

The longer theONpulse, thegreater theamount ofair that will

flow through thevalve. Themore airthat flows through the

valve, thehigher theidle speed.

Air SEF040E

EC-335

•

Page 1056 of 1701

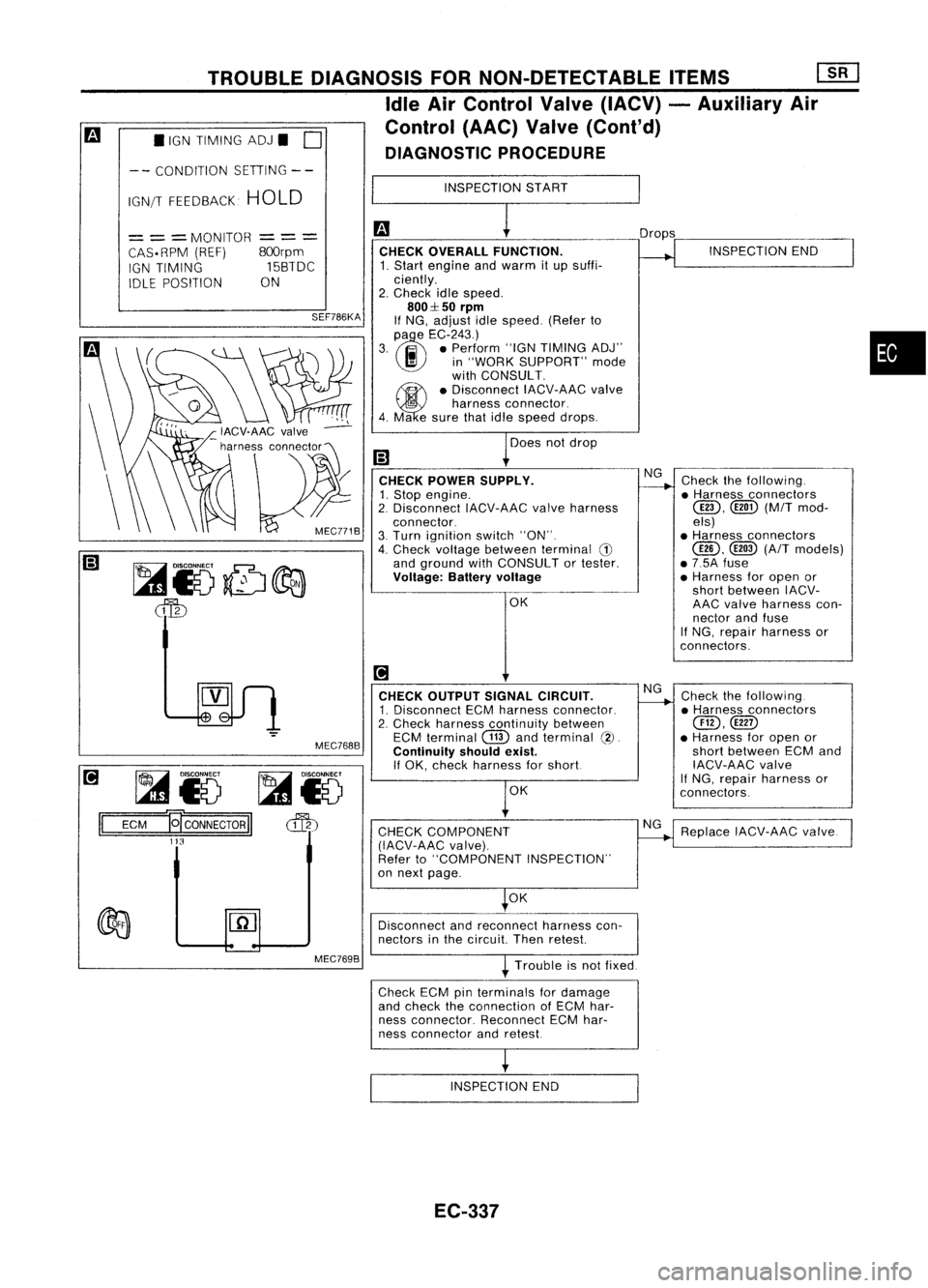

•IGN TIMING ADJ.

0

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

[ill

Idle AirControl Valve(IACV) -Auxiliary Air

Control (AAC)Valve(Cont'd)

DIAGNOSTIC PROCEDURE

-- CONDITION SETIING--

IGN/T FEEDBACK HOLD INSPECTION

START

~i5 ~i5

ECM

E[CONNECTORII

cffb

113

=

= =

MONITOR

CAS. RPM (REF)

IGN TIMING

IDLE POSITION

---

---

800rpm

15BTDC

ON

SEF786KA

MEC768B CHECK

OVERALL FUNCTION.

1. Start engine andwarm itup suffi-

ciently.

2. Check idlespeed.

800::1:50

rpm

If NG, adjust idlespeed. (Referto

(l)

e

EC-243.)

3. .. •Perform "IGNTIMING ADJ"

I!I

in"WORK SUPPORT" mode

with CONSULT.

~ •Disconnect IACV-AACvalve

5

harness connector.

4. Ma esure thatidlespeed drops.

Does notdrop

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect IACV-AACvalveharness

connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

G)

and ground withCONSULT ortester.

Voltage: Batteryvoltage

OK

[!1

CHECK OUTPUT SIGNALCIRCUIT.

1. Disconnect ECMharness connector.

2. Check harness continuity between

ECM terminal

CTID

andterminal

(2).

Continuity shouldexist.

If OK, check harness forshort

OK

CHECK COMPONENT

(IACV-AAC valve).

Refer to"COMPONENT INSPECTION"

on next page.

OK Drops

NG

NG

NG INSPECTION

END

Check thefollowing .

• Harness connectors

@D,

([ill)(M/Tmod-

els)

• Harness connectors

@,

@

(A/T

models)

• 7.5A fuse

• Harness foropen or

short between IACV-

AAC valve harness con-

nector andfuse

If NG, repair harness or

con nectors.

Check thefollowing.

• Harness connectors

@,@D

• Harness foropen or

short between ECMand

IACV-AAC valve

If

NG, repair harness or

connectors.

Replace IACV-AAC valve.

•

Disconnect andreconnect harnesscon-

nectors inthe circuit Thenretest

Trouble isnot fixed.

Check ECMpinterminals fordamage

and check theconnection ofECM har-

ness connector. ReconnectECMhar-

ness connector andretest

INSPECTION END

EC-337

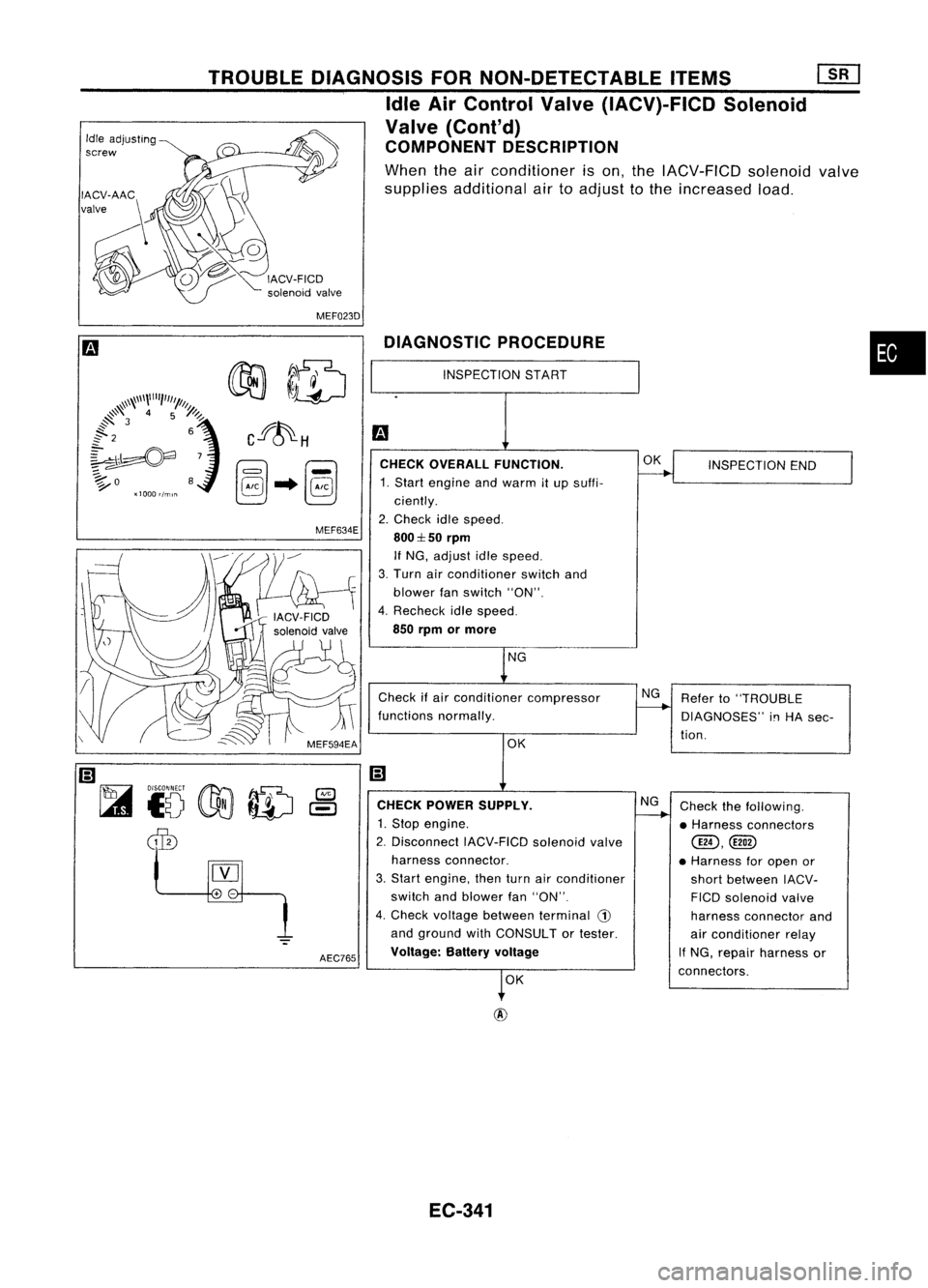

Page 1060 of 1701

MEF023D

•

Refer to"TROUBLE

DIAGNOSES"

i!1

HA sec-

tion. INSPECTION

END

Check thefollowing.

• Harness connectors

@D,@!)

• Harness foropen or

short between IACV-

FICO solenoid valve

harness connector and

air conditioner relay

If NG, repair harness or

connectors.

OK

NG

NG

CHECK

OVERALL FUNCTION.

1. Start engine andwarm itup suffi-

ciently.

2. Check idlespeed.

800:1::50

rpm

If NG, adjust idlespeed.

3. Turn airconditioner switchand

blower fanswitch "ON".

4. Recheck idlespeed.

850 rpm ormore

Check ifair conditioner compressor

functions normally.

DIAGNOSTIC

PROCEDURE

OKNG

OK

INSPECTION

START

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect IACV-FICDsolenoidvalve

harness connector.

3. Start engine, thenturnairconditioner

switch andblower fan"ON".

4. Check voltage between terminal

CD

and ground withCONSULT ortester.

Voltage: Batteryvoltage

AEC765

MEF634E

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

[]liJ

Idle AirControl Valve(IACV)-FICD Solenoid

Valve (Cont'd)

COMPONENT DESCRIPTION

When theairconditioner ison, the IACV-FICD solenoidvalve

supplies additional airtoadjust tothe increased load.

Idle

adjusting

screw

EC-341

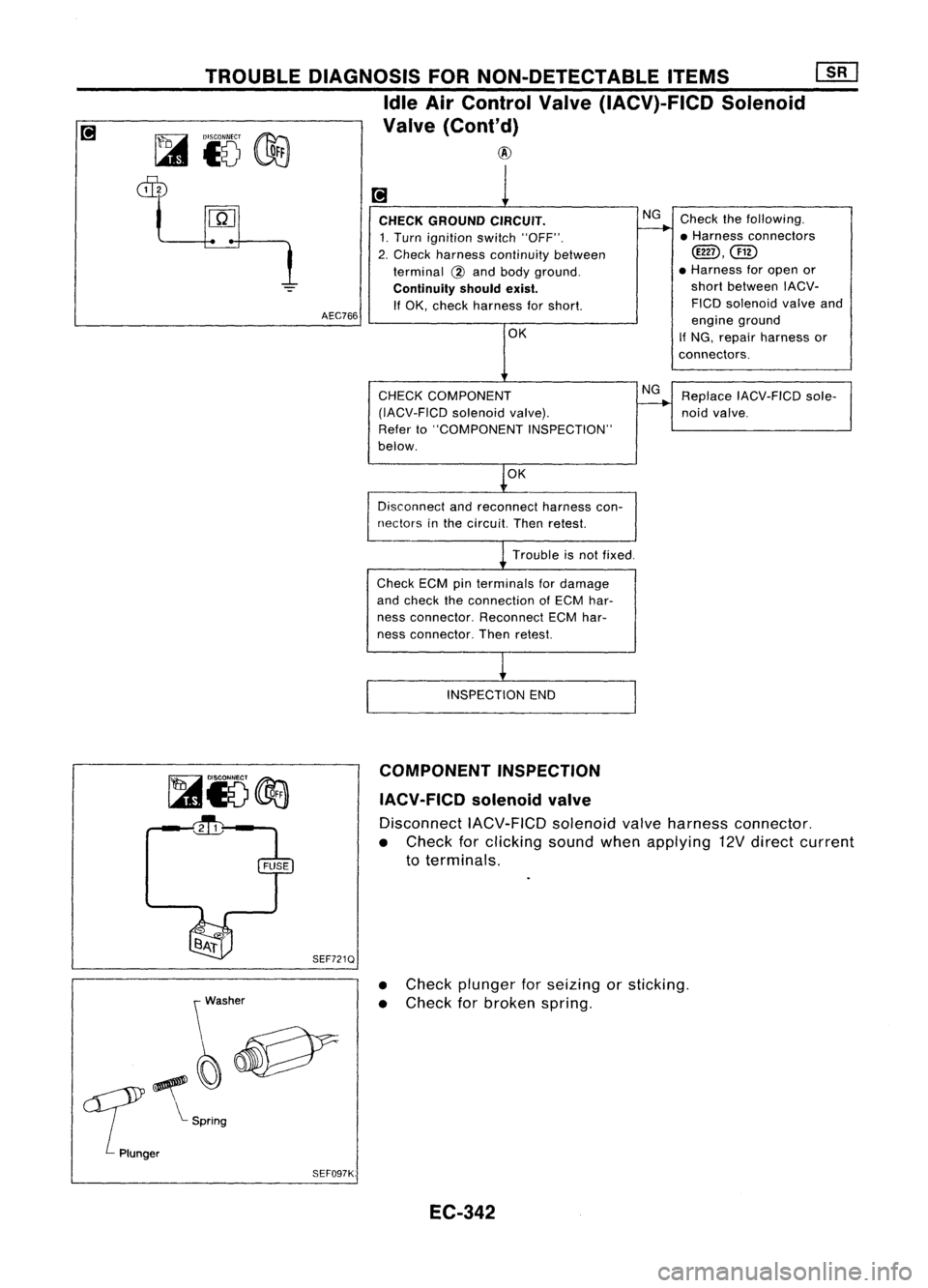

Page 1061 of 1701

~i5

cf0

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Idle AirControl Valve(IACV)-FICD Solenoid

Valve (Cont'd)

@

AEC766 CHECK

GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Check harness continuity between

terminal

@

and body ground.

Continuity shouldexist.

If OK, check harness forshort.

OK

CHECK COMPONENT

(IACV-FICD solenoidvalve).

Refer to"COMPONENT INSPECTION"

below.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

and check theconnection ofECM har-

ness connector. ReconnectECMhar-

ness connector. Thenretest.

INSPECTION END

NG

NG

Check

thefollowing.

• Harness connectors

cmD,@

• Harness foropen or

short between IACV-

FICO solenoid valveand

engine ground

If NG, repair harness or

connectors.

Replace IACV-FICD sole-

noid valve.

~i5@d

~

SEF721Q

\ Washer

~~v

err

~S~log

Plunger SEF097K:COMPONENT

INSPECTION

IACV-FICD solenoidvalve

Disconnect IACV-F1CDsolenoidvalveharness connector.

• Check forclicking soundwhenapplying 12Vdirect current

to terminals.

• Check plunger forseizing orsticking.

• Check forbroken spring.

EC-342

Page 1062 of 1701

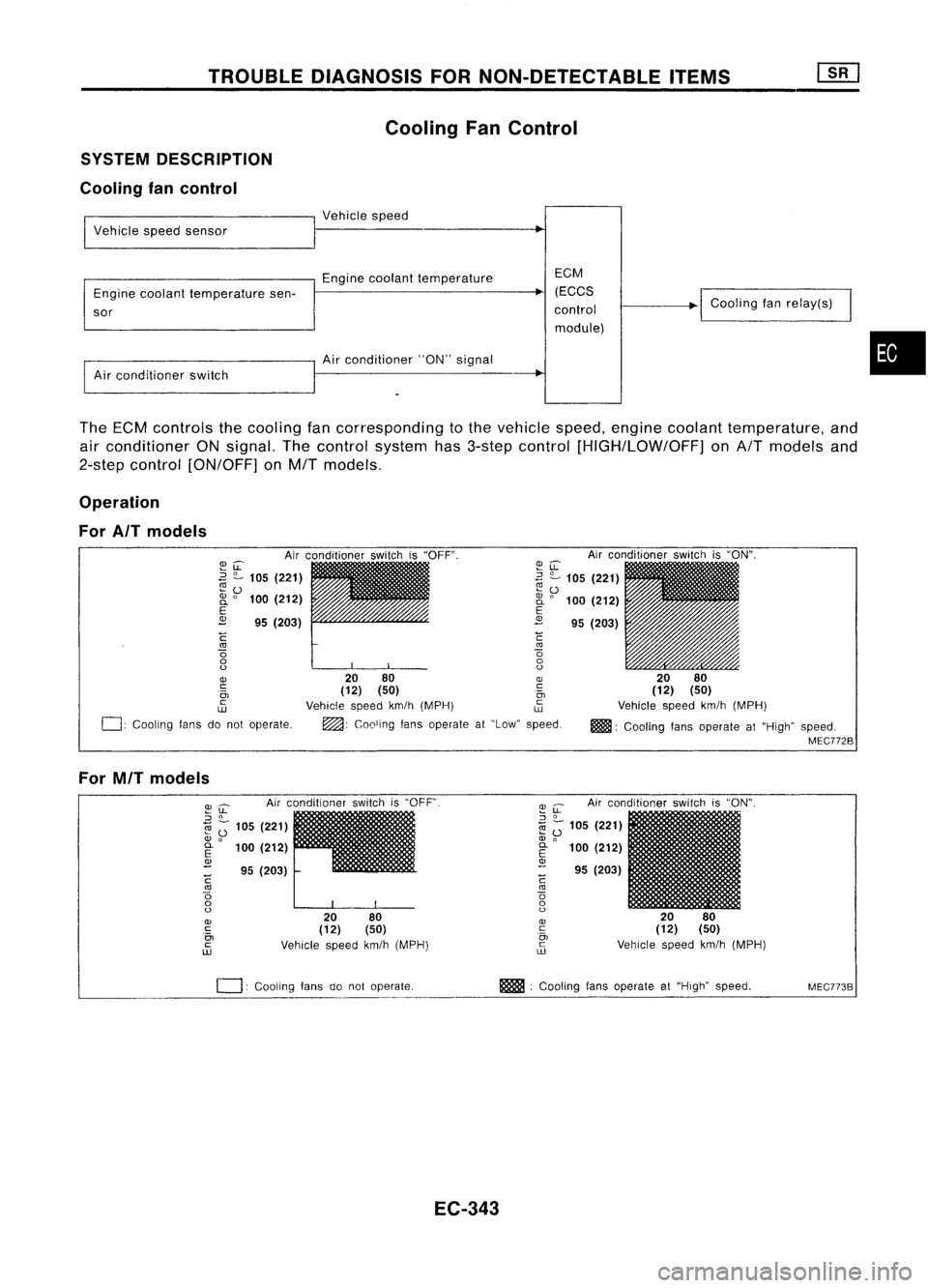

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl

SYSTEM DESCRIPTION

Cooling fancontrol

I

Vehicle speedsensor

I

Vehicle speed

Engine coolant temperature EGM

Engine coolant temperature sen- (EGGS

~

sor control

module)

I

Air conditioner switch

I

Air conditio~er "ON"signal

I

Goaling fanrelay(s)

•

The ECM controls thecooling fancorresponding tothe vehicle speed,engine coolant temperature, and

air conditioner ONsignal. Thecontrol system has3-step control [HIGH/LOW/OFF] onA/T models and

2-step control [ON/OFF] onM/T models.

Operation

For AIT models

Airconditioner switchis"ON".

20 80

(12) (50)

Vehicle speedkm/h(MPH)

m!lll:

Cooling fansoperate at"High" speed.

MEC772B

~u:

~ ?-

105 (221)

~ 0

2i

0

100 (212)

E

2

95(203)

C

'"

o

o

o

20 80

OJ

(12) (50) .~

Vehicle speedkm/h(MPH) ~

~: Cooling fansoperate at"Low" speed.

~LL

.3

?-

105 (221)

~o

2i

0

100 (212)

E

2

95(203)

C

'"

o

o

o

OJ

c:

.0,

c

w

0:

Cooling fansdonot operate.

For MIT models

Airconditioner switchis"OFF".

2080

(12) (50)

Vehicle speedkm/h(MPH)

~

u:

Airconditioner switchis"ON".

::J

0

1il

Z;

105 (221)

OJ

0

E

100(212)

OJ

- 95(203)

C

'"

o

o

o

OJ

c

0,

c

ill

I

20 80

(12) (50)

Vehicle speedkm/h(MPH)

~u:

::J

0

1il ;-

105 (221)

OJ

0

~ 100(212)

<1>

- 95(203)

C

'"

o

o

o

OJ

c

.0,

c

ill

0:

COOling fansdonot operate. m

:Cooling fansoperate at"High" speed.

MEC773B

EC-343

Page 1065 of 1701

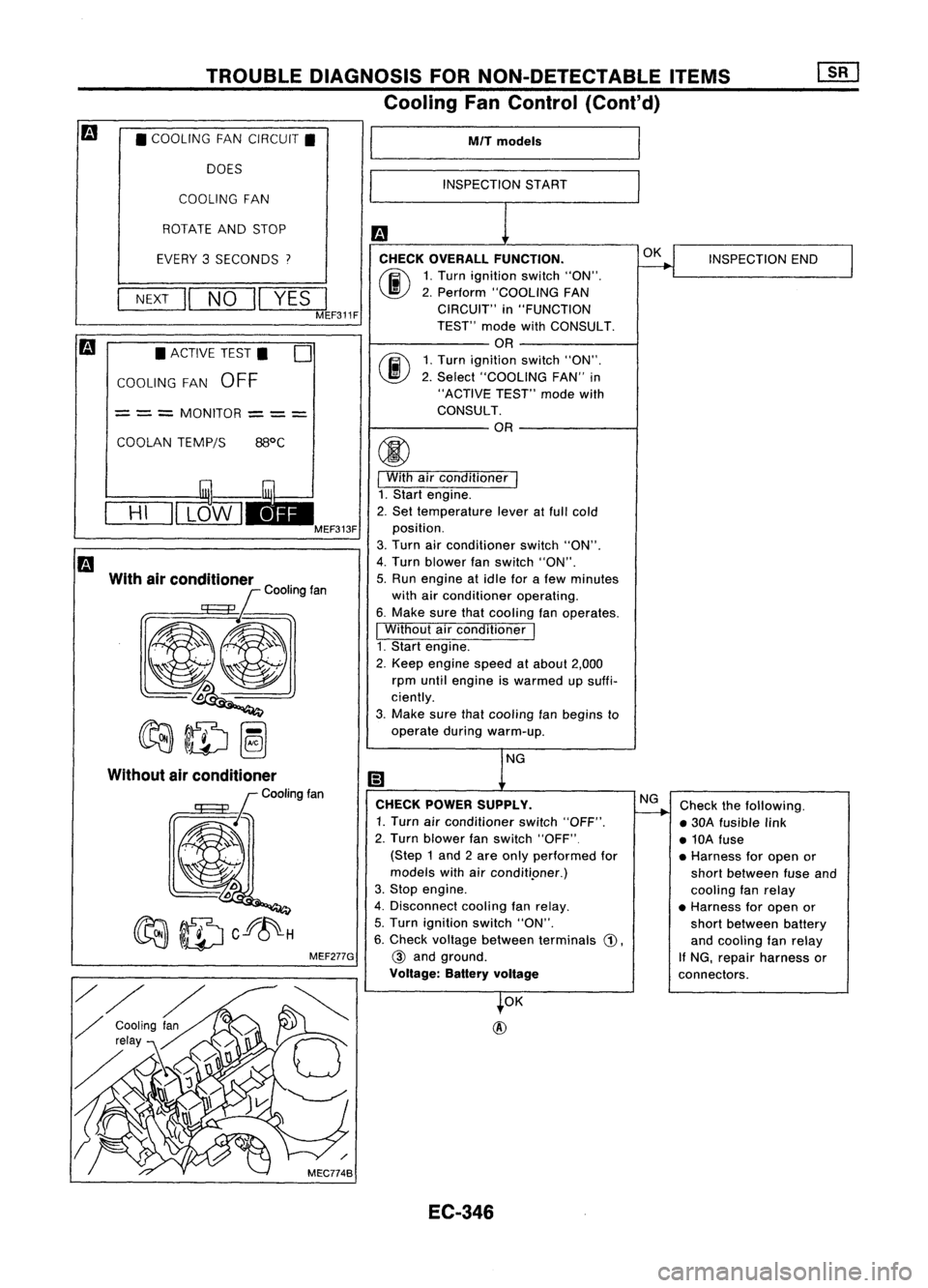

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl (Cont'd)

• COOLING FANCIRCUIT.

DOES

COOLING FAN

ROTATE ANDSTOP

EVERY 3SECONDS

7

NEXT

II

NO

II

YES

I

MEF311F

• ACTIVE TEST.

0

COOLING FAN

OFF

= ==

MONITOR

==

=

COOLAN TEMP/S

HI

With airconditioner

C

k

00lin9fan

Q

~ID~

MEF277G

M/T

models

INSPECTION START

CHECK OVERALL FUNCTION.

(ij\

1.Turn ignition switch"ON".

~ 2.Perform "COOLING FAN

CIRCUIT" in"FUNCTION

TEST" modewithCONSULT.

OR

rij\

1.Turn ignition switch"ON".

\J!V

2.Select "COOLING FAN"in

"ACTIVE TEST"modewith

CONSULT.

OR

I

With airconditioner

I

1. Start engine.

2. Set temperature leveratfull cold

position.

3. Turn airconditioner switch"ON".

4. Turn blower fanswitch "ON".

5. Run engine atidle forafew minutes

with airconditioner operating.

6. Make surethatcooling fanoperates.

I

Without airconditioner

I

1. Start engine.

2. Keep engine speedatabout 2,000

rpm until engine iswarmed upsuffi-

ciently.

3. Make surethatcooling fanbegins to

operate duringwarm-up.

NG

CHECK POWER SUPPLY.

1. Turn airconditioner switch"OFF".

2. Turn blower fanswitch "OFF"

(Step 1and 2are only performed for

models withairconditi.oner.)

3. Stop engine.

4. Disconnect coolingfanrelay.

5. Turn ignition switch"ON".

6. Check voltage between terminals

G),

@

and ground.

Voltage: Batteryvoltage

OK

@

EC-346 OK

NG

INSPECTION

END

Check thefollowing.

• 30A fusible link

• 10A fuse

• Harness foropen or

short between fuseand

cooling fanrelay

• Harness foropen or

short between battery

and cooling fanrelay

If NG, repair harness or

connectors.