engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1094 of 1701

VE-TVPEINJECTION PUMP ~

Adjustment (Cont'd)

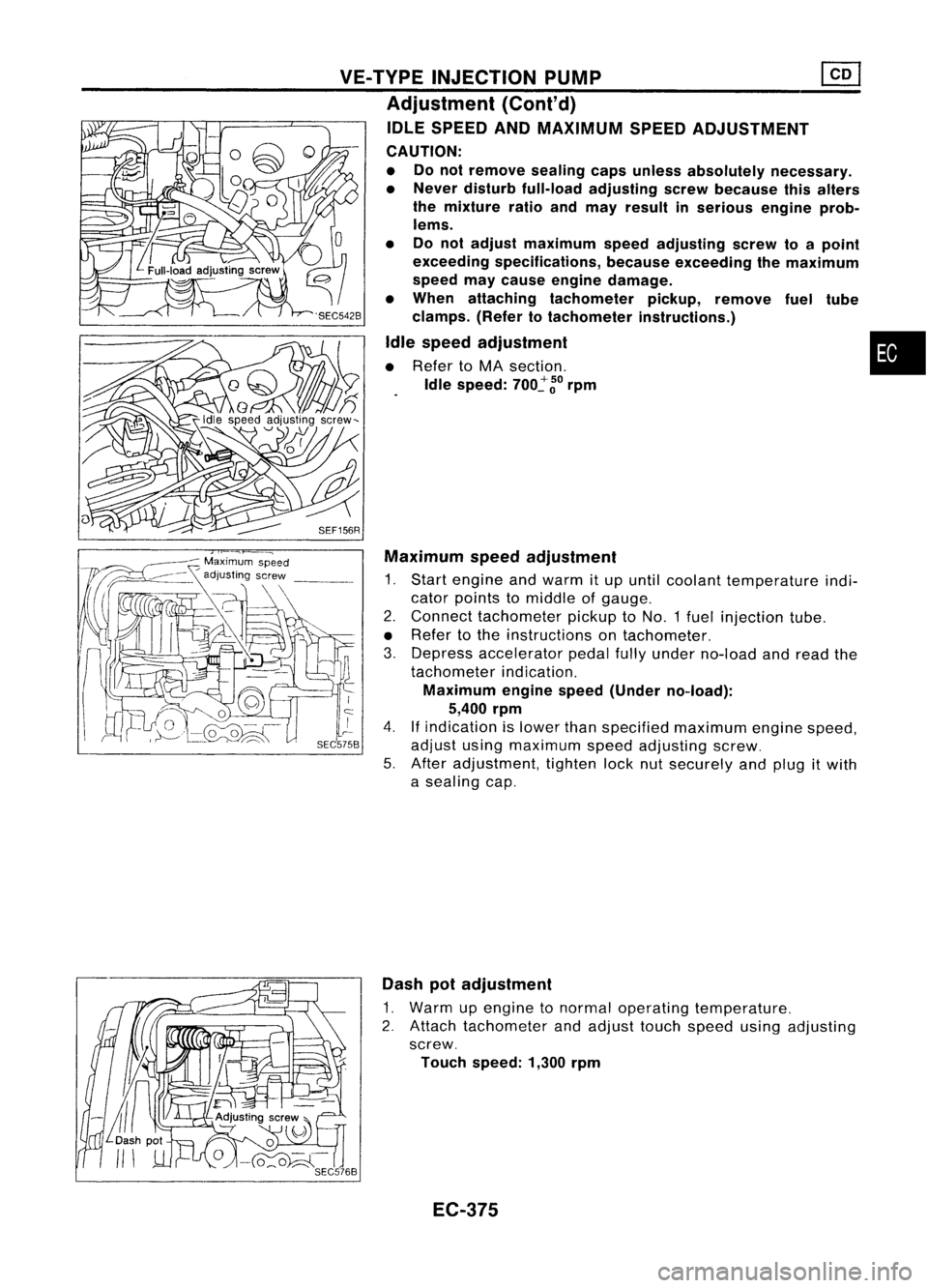

IDLE SPEED ANDMAXIMUM SPEEDADJUSTMENT

CAUTION:

• Donot remove sealingcapsunless absolutely necessary.

• Never disturb full-load adjusting screwbecause thisalters

the mixture ratioandmay result inserious engineprob-

lems.

• Donot adjust maximum speedadjusting screwtoapoint

exceeding specifications, becauseexceeding themaximum

speed maycause engine damage.

• When attaching tachometer pickup,remove fueltUbe

clamps. (Refertotachometer instructions.)

Idle speed adjustment •

• Refer toMA section.

Idle speed:

700~

~o

rpm

SEF156R Maximum speedadjustment

1. Start engine andwarm itup until coolant temperature indi-

cator points tomiddle ofgauge.

2. Connect tachometer pickuptoNO.1 fuelinjection tube.

• Refer tothe instructions ontachometer.

3. Depress accelerator pedalfullyunder no-load andread the

tachometer indication.

Maximum enginespeed(Under no-load):

5,400 rpm

4.

If

indication islower thanspecified maximum enginespeed,

adjust usingmaximum speedadjusting screw.

5. After adjustment, tightenlocknutsecurely andplug itwith

a sealing cap.

Dash potadjustment

1. Warm upengine tonormal operating temperature.

2. Attach tachometer andadjust touchspeed usingadjusting

screw.

Touch speed: 1,300rpm

EC-375

Page 1095 of 1701

Nozzleside

Combustion

chamber side

SEF668A

SEF781A

SEF669A

:S

older ~Adiusting shim

c:,

Nozzlespring

~ '~[;{~I:,""'

pi,",

Nozzle needle~~(''''-

Nozzle bOdyr ~

Nozzle nut)

SEF670A INJECTION

NOZZLE

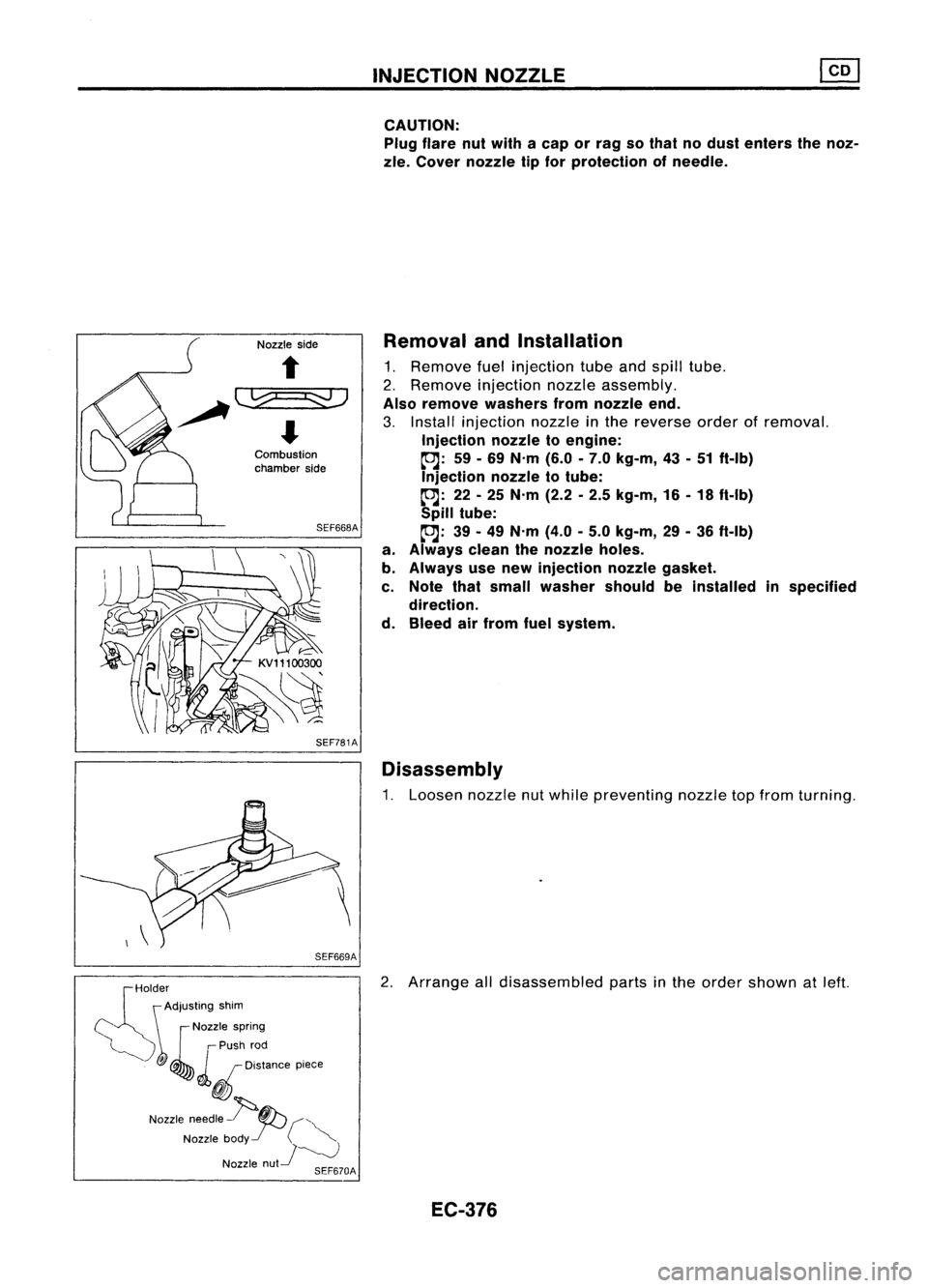

CAUTION: Plug flare nutwith acap orrag sothat nodust enters thenoz-

zle. Cover nozzle tipfor protection ofneedle.

Removal andInstallation

1. Remove fuelinjection tubeandspill tube.

2. Remove injection nozzleassembly.

Also remove washers fromnozzle end.

3. Install injection nozzleinthe reverse orderofremoval.

Injection nozzletoengine:

~: 59-69 N'm (6.0-7.0 kg-m, 43-51 ft-Ib)

Injection nozzletotube:

~: 22-25 N'm (2.2-2.5 kg-m, 16-18 ft-Ib)

Spill tube:

~: 39-49 N'm (4.0-5.0 kg-m, 29-36 ft-Ib)

a. Always cleanthenozzle holes.

b. Always usenew injection nozzlegasket.

c. Note thatsmall washer shouldbeinstalled inspecified

direction.

d. Bleed airfrom fuelsystem.

Disassembly

1. Loosen nozzlenutwhile preventing nozzletopfrom turning.

2. Arrange alldisassembled partsinthe order shown atleft.

EC-376

Page 1102 of 1701

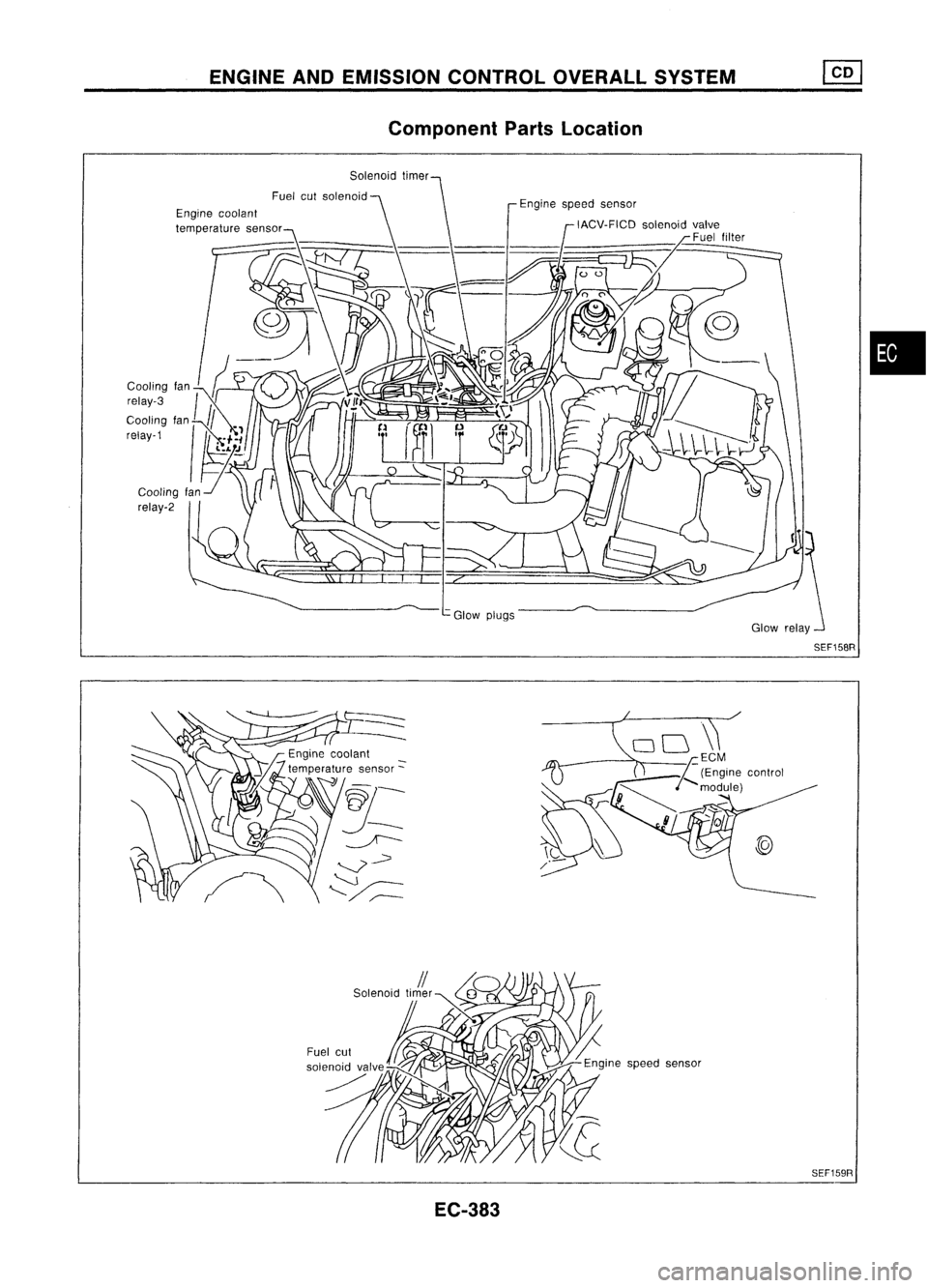

relay-2ENGINE

ANDEMISSION CONTROLOVERALLSYSTEM

Component PartsLocation

Engine coolant

temperature sensor

Glowplugs

•

EC-383 SEF159R

Page 1103 of 1701

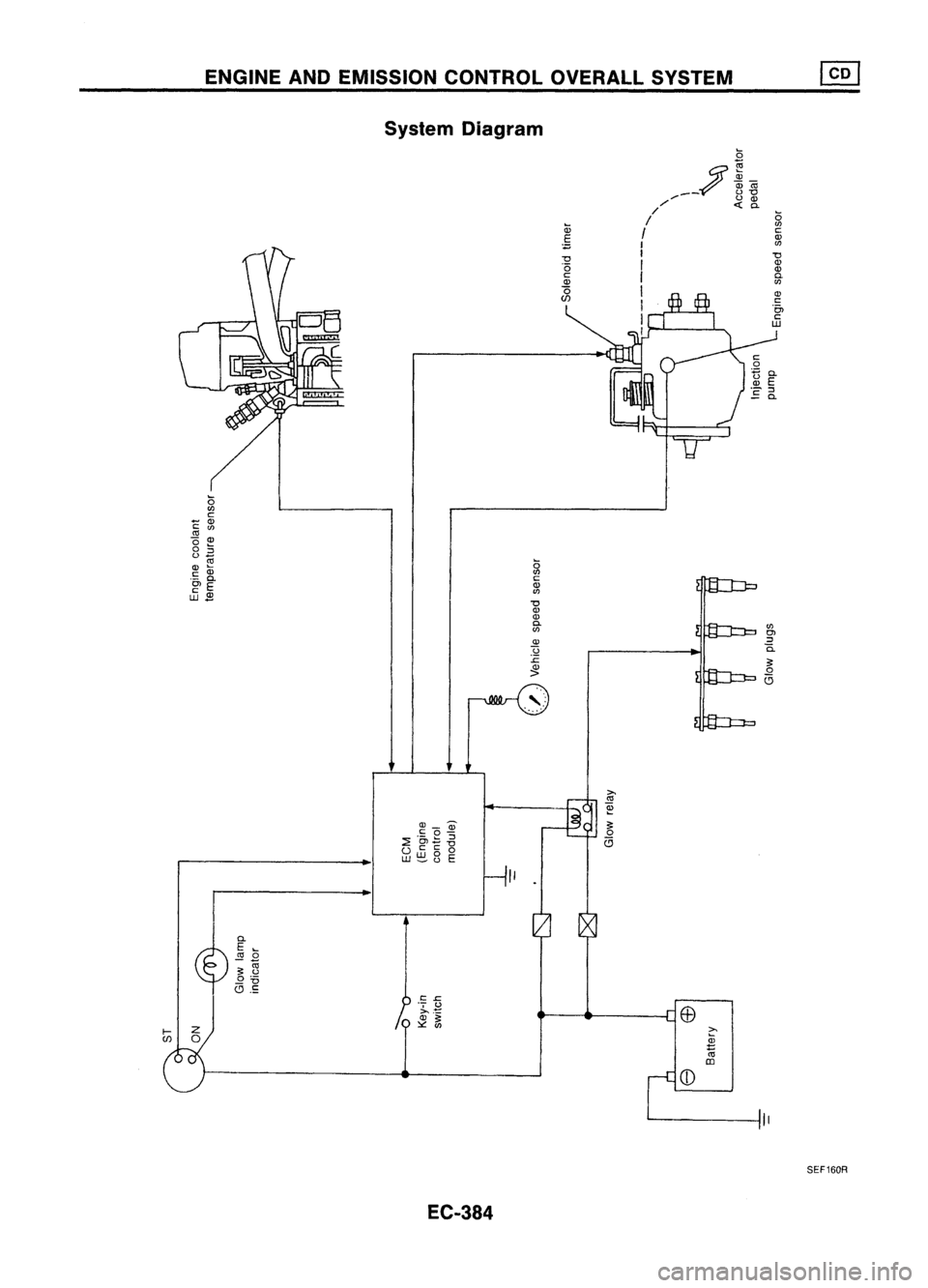

ENGINEANDEMISSION CONTROLOVERALLSYSTEM

System Diagram

~

/

~

OlCii

__ 0"'0

/' 0

OJ

//

I

g

I ~

I (/)

I

"0

I

OJ

I ~

I

OJ

I

"5,

I Jj

I

c:

o

:+=:a.

~ E

'- ::l

E

c.

o

f/)

c:

- OJ

c: (/)

o

::l

0_

OJ ~

c:

OJ

.- c.

OlE

c:

OJ

w_

I

$

C.

E~

i .~

_ "0

(9.S

EC-384

g

c:

OJ

f/)

"0

OJ

OJ

C.

f/)

OJ

u

:c

~

,:

Ii .

f/)

Ol

::l

0.

SEF160R

Page 1104 of 1701

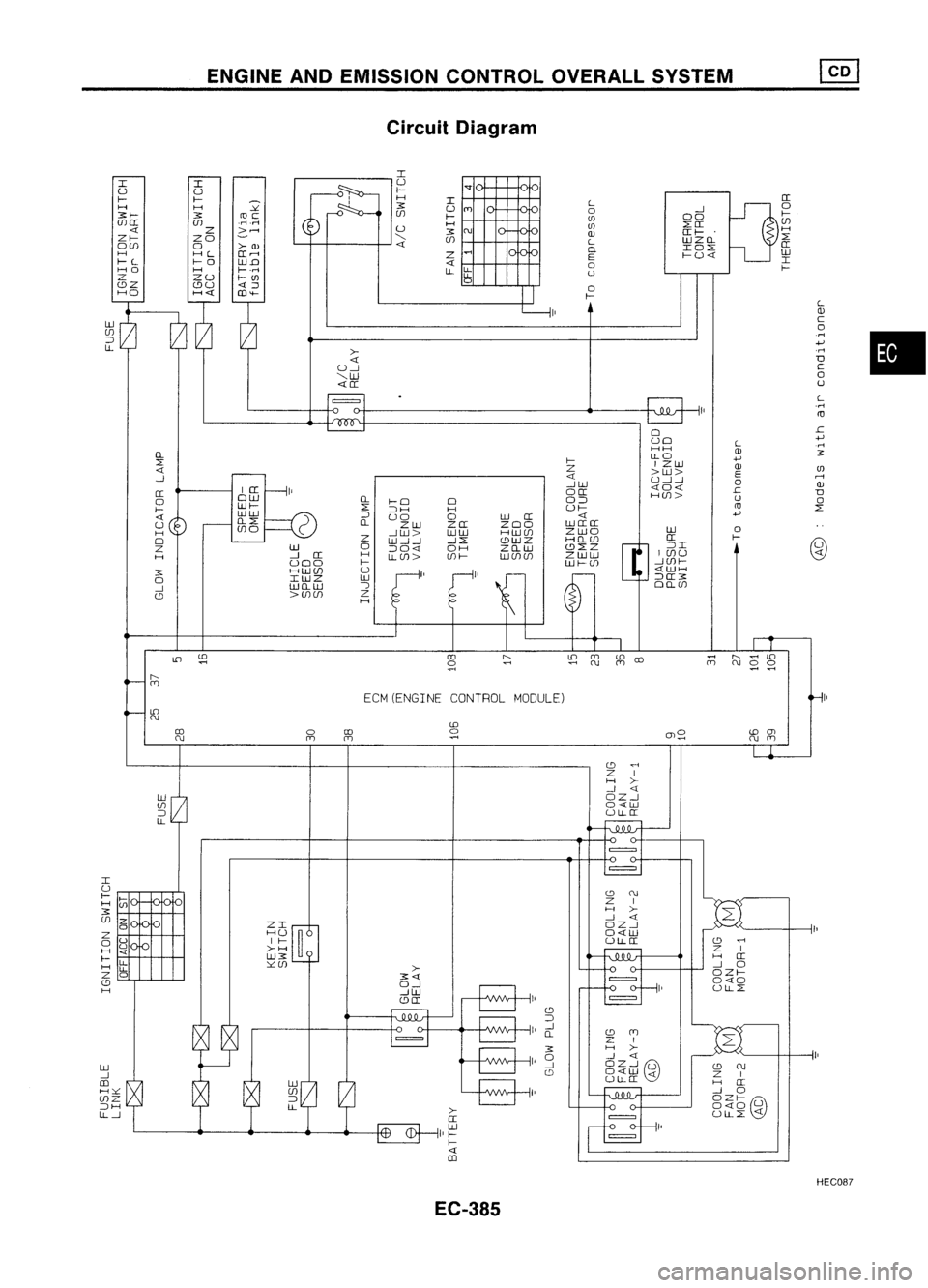

ENGINEANDEMISSION CONTROLOVERALLSYSTEM

Circuit Diagram

•

I

--:c-

~

-

U

U U I-

'"

l- I-

-

soL

H

I L

~)~

H

H

.Y.

3:

U

(T)

0-.J

3:1- 3:

roc

D

-0 ~

UJ

I- Ul

00

UlIT Ul

.rl

.M

Q

H

Ul:LIT

4 Z>

..... U

3:

N

ill

ITI-

ZI- ZO

"'-

Ul

LWZO-

Oul

0

>-ill

4

D.

IO:L

~~

H

HLIT.....

Z

~

E

I-U4

I-L 1-0

WD

4

0

HO H

I--rl

LL

LL

U

I-

Z ZUI-Ul

LL

CDZ CDU4::J

0

I

0

HO H4

CO-.-

I-

----y- L

'---11'

Ql

0 0

C

0

-rl

....,

>-

-rl

4

D

U-.J

C

"'-W

0

4IT

u

= GL

I,L

-rl

I~I

L::::::::::J

ro

vvv

0

.c

uo

....,

HH L

rl

0-

LLO

Ql

~

:L I-

IZW

....,

4 Z

>W>

Ql

Ul

-.J

.--

4

U-.J-.J

E

.....

---11' -.JW

404

0

Ql

IT lIT

OIT

HUl>

.c

TI

0 OW

0-

1-0 0 O::J

u

0

I- WI-

:L

=>H H UI-

ro

:L

8Q

WW

==0

::J

UO 0

WIT 4

....,

0

-

81t5 ;:

0-

ZW ZIT

zoo

WITIT

,-

-.JW>

ww

HWUJ ZWO W

0

0 '--W Z

W-.J-.J -.J:L

CDWZ HO-Ul IT

I-

Z 0

::J04 OH

ZO-W

CD:LZ

U

::JI

U

H -.J

IT H

LLUl> Ull-

WUlUl ZWW lUlU

4

UOO I-

WI-Ul-.JUlI-

3: HWUl

U

,-11'

I'

(

~

4

WI-<

0

IWZ

W

=>IT3:

-.J WO-W

J

~

~

V

OO-ul

CD >Ulul

Z

H

I

IT

LO

(D

OJr--

~

0'1

(D

OJ

....

r--

....

LO

....

s:

....

(\j

0'1 0'1

(\j

SS

~ r--

0'1

ECM(ENGINECONTROLMODULE)

H

~ LO

(\j

(D

OJ

0

OJ

0

010

(D

01

(\j

0'10'1

....

(\j

0'1

I

j

CD

....

Z I

H

>-

-.J

~0

OZ-.J

O

~-

=

=

~

CD

(\j

t-

ZI

Ul

H

>-

2:

z

-.J

0

ZI

OZ-.J

:1

1

HU

~

04W

u

II- ULLITCD

....

U

>-1-<

~

Z

I

W3: H

IT

LL

'Y.UJ

~

-.J0

LL

>-

-f-o

0

3:4 OZI-

O-.J

=

~I'

040

-.JW

~

-

f-o

0-

ULL:L

CD IT

I'

=

~

6

CD

~

::J

~

I'

-.J

m

6

0-

CD

(Y]

=

Z

I

3: H

>-

I'

0

-.J

-

I'

6

-.J

OZ-.J@ CD

(\j

19

8L;':~

~~ ~~~

~

H

IT:

I'

~

-.J

0

L..:..'J

-I'

000,

OZI-

(g)

>-

8L;':~

4

IT:

=

~

W

I~~I'

"-'

I'

l-

I-

4

ill

I

U

I-

H

3:

UJ

Z

o

H

I-

H

Z

CD

I-<

W

-.J

ill

H

Ul

::J

LL

HEeD8?

EC-385

Page 1105 of 1701

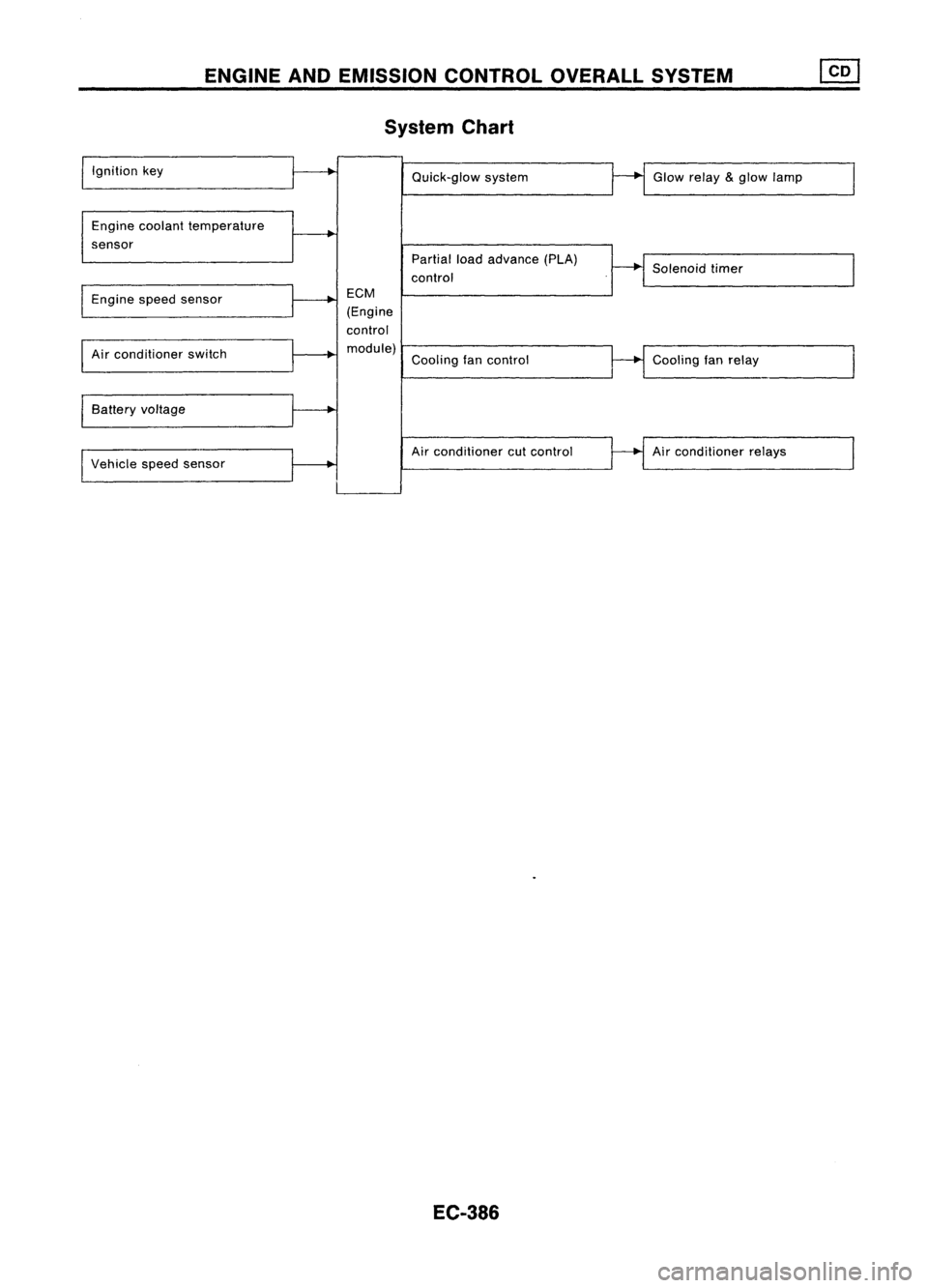

ENGINEANDEMISSION CONTROL OVERALLSYSTEM

System Chart

Ignition key

Engine coolant temperature

sensor Quick-glow

system

Partial loadadvance (PLA)

control Glow

relay

&

glow lamp

Solenoid timer

Engine speedsensor

Air conditioner switch

Battery voltage

Vehicle speedsensor

ECM

(Engine

control module) Coolingfancontrol

Air conditioner cutcontrol

EC-386

Cooling

fanrelay

Air conditioner relays

Page 1107 of 1701

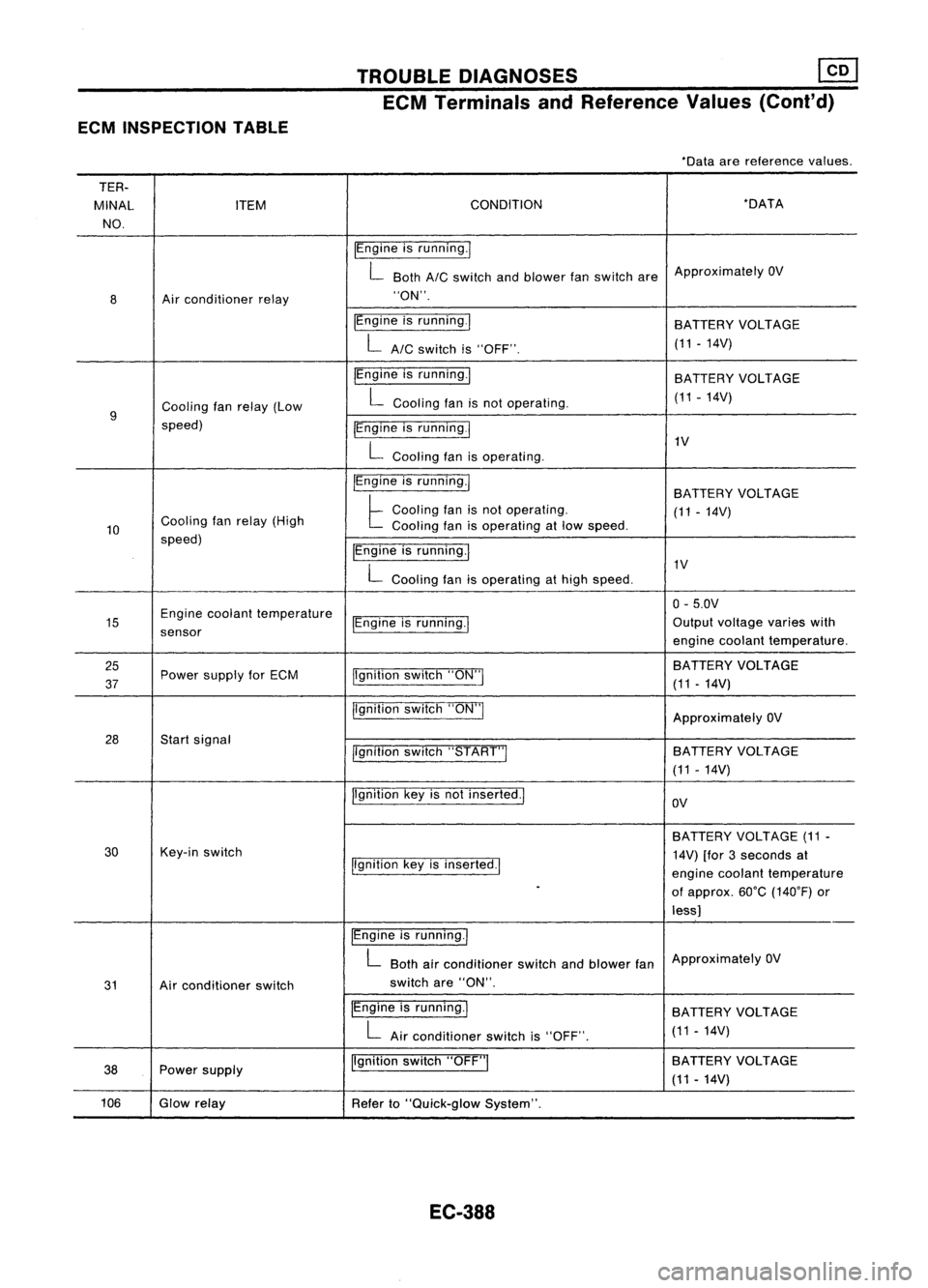

ECMINSPECTION TABLE TROUBLE

DIAGNOSES ~

ECM Terminals andReference Values(Coni'd)

-Data arereference values.

TER-

MINAL ITEM CONDITION -DATA

NO.

IEngineisrunning.1

L Both

AIC

switch andblower fanswitch areApproximately

OV

8 Air

conditioner relay "ON".

IEngine isrunning.1

BATTERYVOLTAGE

LAIC switchis"OFF". (11

-14V)

IEngine isrunning.1

BATTERY VOLTAGE

Cooling fanrelay (Low L

Cooling fanisnot operating. (11-14V)

9

speed) IEngineisrunning

I

L

Cooling fanisoperating. 1V

IEngine isrunning.1

BATTERYVOLTAGE

Cooling fanrelay (High

t

Cooling fanisnot operating.

(11-14V)

10 Cooling

fanisoperating atlow speed.

speed) IEngineisrunning.1

L

Cooling fanisoperating athigh speed. 1V

0- 5.0V

15 Engine

coolant temperature

IEngineisrunning.1 Output

voltage varieswith

sensor enginecoolant temperature.

25 jlgnitionswitch"ON"I BATTERY

VOLTAGE

37 Power

supply forECM

(11-14V)

jlgnition switch"ON"I

ApproximatelyOV

28 Startsignal

llgnitionswitch"START"I SA

TTERY VOLTAGE

(11 -14V)

Ilgnition keyisnot inserted.1

OV

BATTERY VOLTAGE (11-

30 Key-in

switch

14V)[for3seconds at

Ilgnition keyisinserted.1

enginecoolant temperature

-

ofapprox. 60°C(140°F) or

less)

IEngine isrunning.1

L

Both airconditioner switchandblower fanApproximately

OV

31 Airconditioner switch switch

are"ON".

IEngine isrunning.1

BATTERYVOLTAGE

L

Airconditioner switchis"OFF". (11

-14V)

38 Power

supply Ilgnition

switch"OFF"I BATTERY

VOLTAGE

(11 -14V)

106 Glowrelay

Referto"Quick-glow System".

EC-388

Page 1108 of 1701

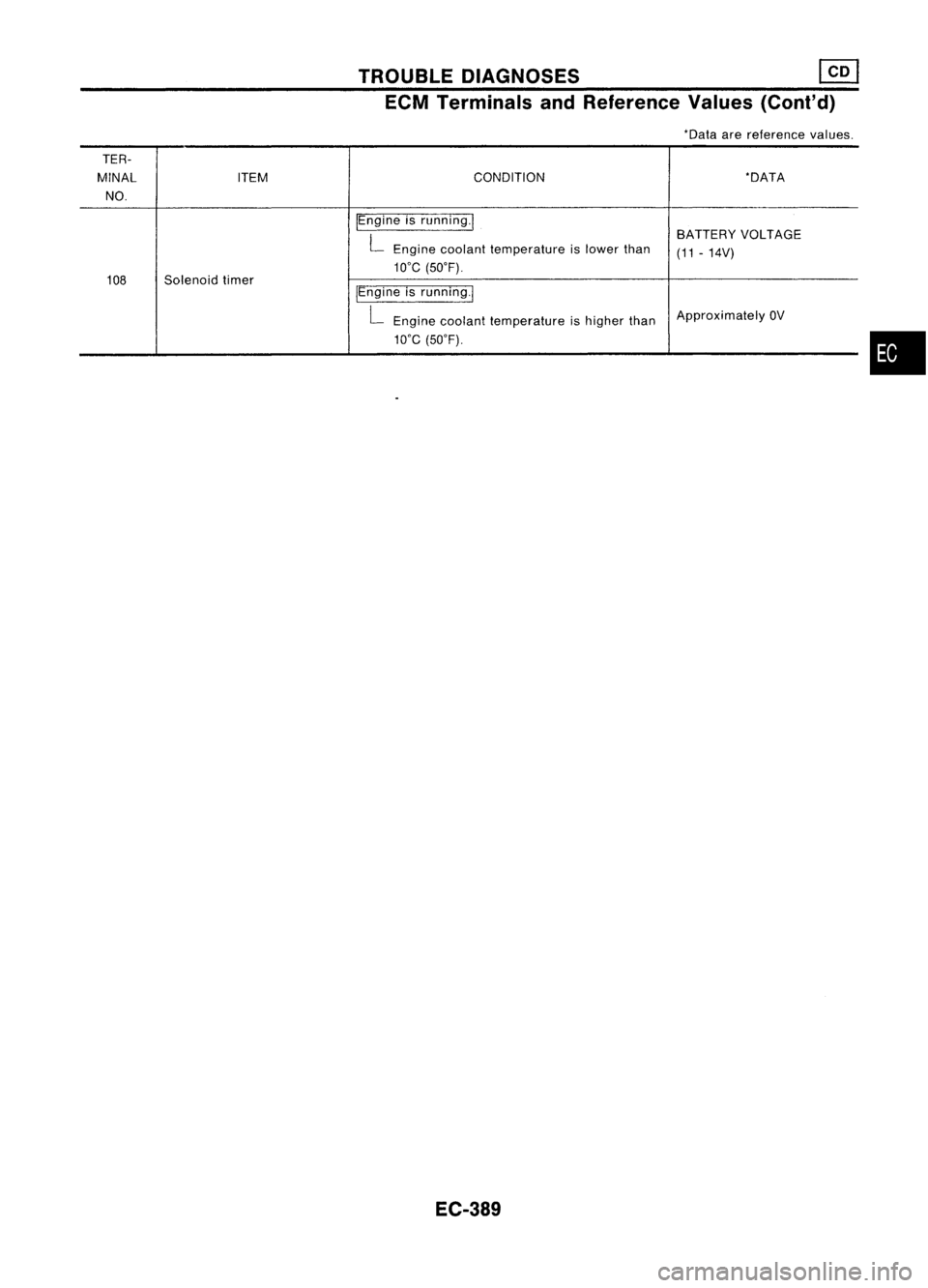

TROUBLEDIAGNOSES ~

ECM Terminals andReference Values(Cont'd)

*Data arereference values.

TER-

MINAL ITEM CONDITION

*DATA

NO.

IEngineisrunning.1

BATTERYVOLTAGE

L

Engine coolant temperature islower than

(11-14V)

we

(50'F).

108 Solenoid timer

/Engineisrunning.1

L

Engine coolant temperature ishigher than Approximately

OV

we

(50'F).

EC-389

•

Page 1109 of 1701

TROUBLEDIAGNOSES

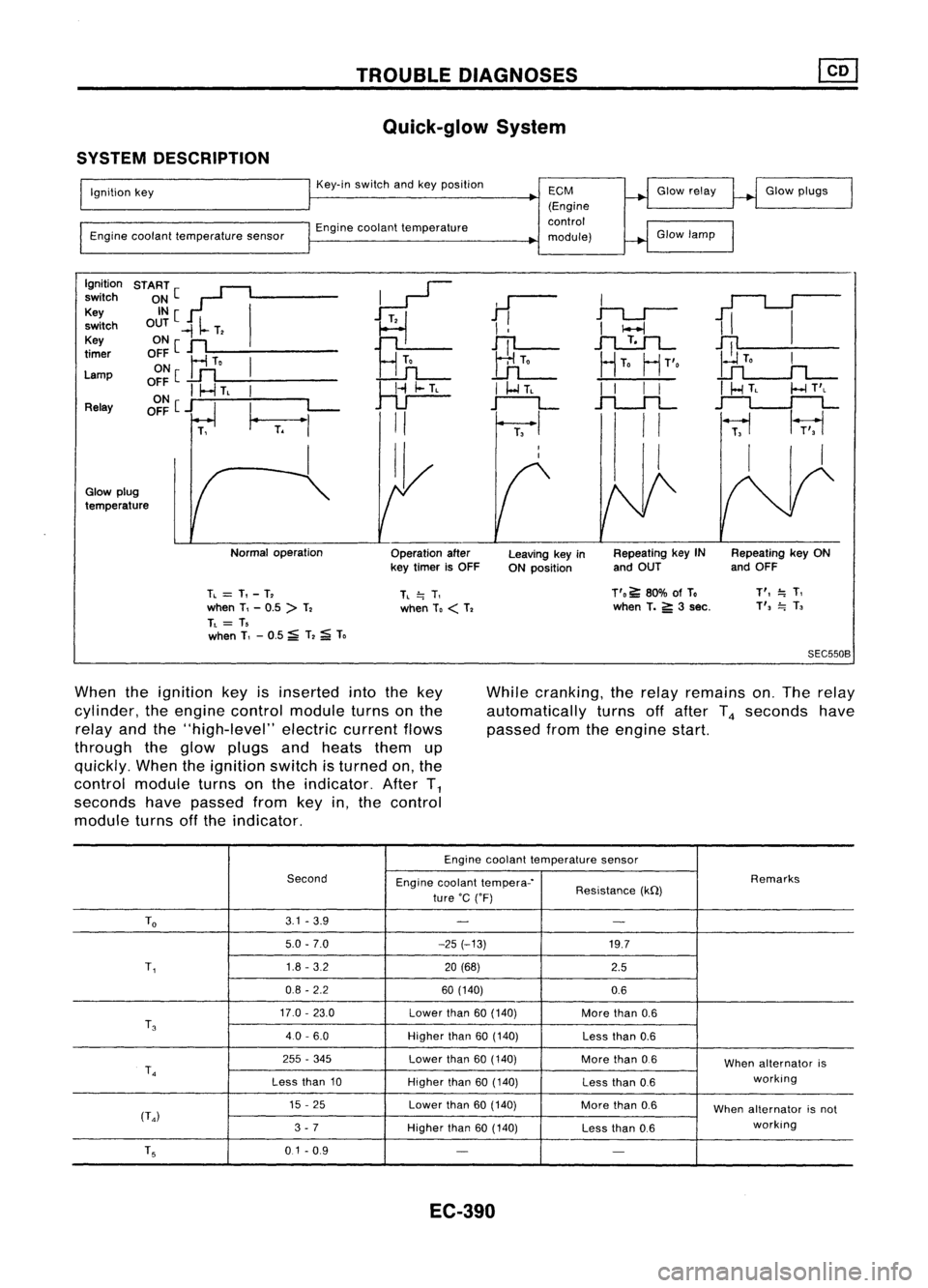

Quick-glow System

SYSTEM DESCRIPTION

Ignition key

Engine coolant temperature sensorKey-in

switch andkeyposition

Engine coolant temperature

ECM

(Engine

control

module) Glow

relay

Glow lamp Glow

plugs

Ignition START[~

~

switch

~~[ I

11

I

1iI

Key

~

switch OUT

-II-

T,

I

!

I

I-l

Key ONe

n

Hn

JTl-

.1"l....!:.1L-

~

timer

OFF

Ir1

To

I

UL

HTo

HT'o

Lamp ON

[

..Lfl

o~~

I

I-.J

TL

I

~

I

I-l

TL

I

I

I

I

I

HTL

I-l

T'L

Relay OFF

[j

I_

L-

r--L

.f"l.-.JL

~

T.

"'

II

I

II

~

1r;,1

I II I

I,

Glow plug

temperature

Normaloperation

Operationafter

key timer isOFF Leaving

keyin

ON position Repeating

keyIN

and OUT Repeating

keyON

and OFF

TL

=

T,-T,

when T,-0.5 >T,

TL

= T,

when T,-0.5 ~T,

;a;

To

TL

=.

T,

when To

<

T, T'o

~80% ofTo

when T.

5':

3sec.

T',

=.

T,

T',

=.

T,

SEC550B

When theignition keyisinserted intothekey

cylinder, theengine control module turnsonthe

relay andthe"high-level" electriccurrentflows

through theglow plugs andheats themup

quickly. Whentheignition switchisturned on,the

control module turnsonthe indicator. AfterT

1

seconds havepassed fromkeyin,the control

module turnsoffthe indicator. While

cranking, therelay remains on.The relay

automatically turnsoffafter T

4

seconds have

passed fromtheengine start.

Engine coolant temperature sensor

Second Enginecoolant tempera-' Remarks

ture 'C('F) Resistance

(kQ)

To

3.1

-3.9

- -

5.0 -7.0 -25(-13)

19.7

T,

1.8

-3.2

20(68)

2.5

0.8 -2.2 60(140)

0.6

17.0 -23.0

Lowerthan

60(140)

Morethan

0.6

T

3

40-6.0

Higherthan

60(140)

Lessthan

0.6

255 -345

Lowerthan

60(140)

Morethan

0.6

Whenalternator is

T

4

working

Less than

10

Higherthan

60(140)

Lessthan

0.6

15 -25

Lowerthan

60(140)

Morethan

0.6

Whenalternator isnot

(T

4)

working

3 -7

Higherthan

60(140)

Lessthan

0.6

T

5

0.1-0.9

- -

EC-390

Page 1110 of 1701

TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

DESCRIPTION

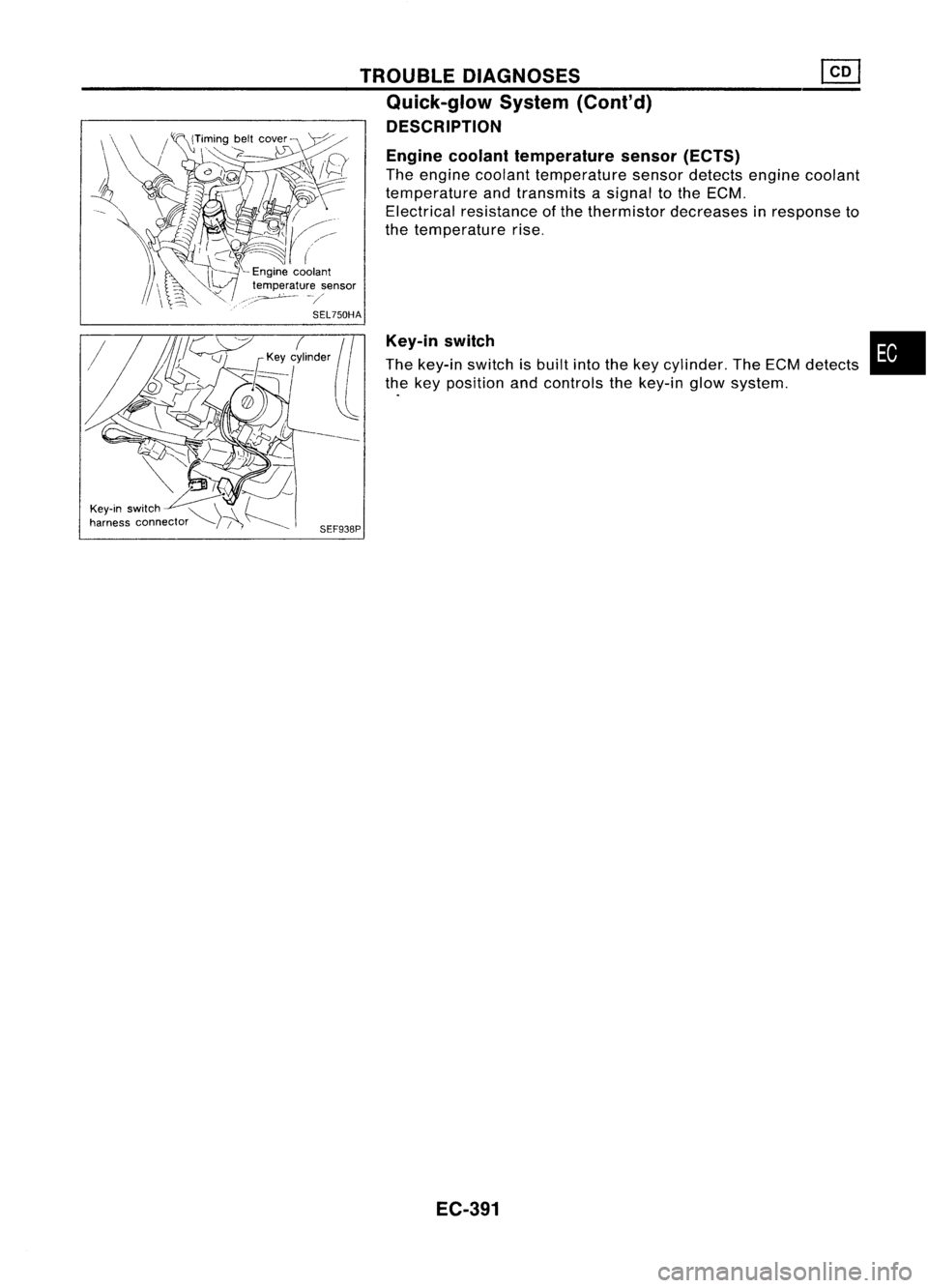

Engine coolant temperature sensor(ECTS)

The engine coolant temperature sensordetects enginecoolant

temperature andtransmits asignal tothe ECM.

Electrical resistance ofthe thermistor decreases inresponse to

the temperature rise.

Key-in switch

The key-in switch isbuilt intothekey cylinder. TheECM detects

the key position andcontrols thekey-in glowsystem.

SEF938P

EC-391

•