engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1020 of 1701

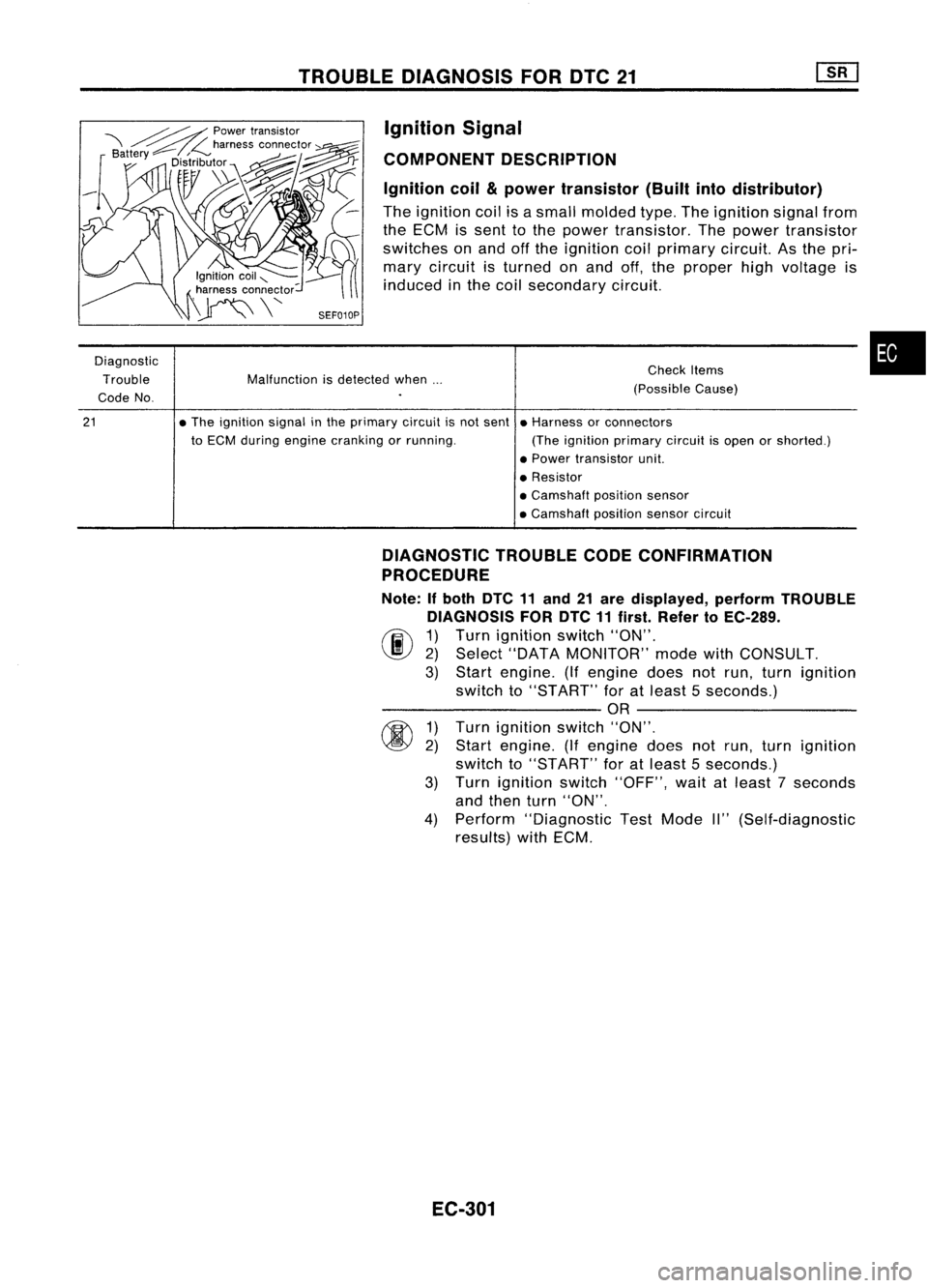

TROUBLEDIAGNOSIS FORDTC21

Ignition Signal

COMPONENT DESCRIPTION

Ignition coil

&

power transistor (Builtintodistributor)

The ignition coilisasmall molded type.Theignition signalfrom

the ECM issent tothe power transistor. Thepower transistor

switches onand offthe ignition coilprimary circuit.Asthe pri-

mary circuit isturned onand off,the proper highvoltage is

induced inthe coil secondary circuit.

Diagnostic Trouble

Code No.

21

Malfunction

isdetected when...

• The ignition signalinthe primary circuitisnot sent

to ECM during engine cranking orrunning. Check

Items

(Possible Cause)

• Harness orconnectors

(The ignition primary circuitisopen orshorted.)

• Power transistor unit.

• Resistor

• Camshaft positionsensor

• Camshaft positionsensorcircuit

•

DIAGNOSTIC TROUBLECODECONFIRMATION

PROCEDURE

Note: Ifboth DTC11and 21are displayed, performTROUBLE

DIAGNOSIS FORDTC11first. Refer toEC-289.

(F.I\ 1)Turn ignition switch"ON".

~ 2)Select "DATA MONITOR" modewithCONSULT.

3) Start engine. (Ifengine doesnotrun, turn ignition

switch to"START" foratleast 5seconds.)

---------- OR----------

~ 1)Turn ignition switch"ON".

~ 2)Start engine. (Ifengine doesnotrun, turn ignition

switch to"START" foratleast 5seconds.)

3) Turn ignition switch"OFF", waitatleast 7seconds

and then turn"ON".

4) Perform "Diagnostic TestMode II"(Self-diagnostic

results) withECM.

EC-301

Page 1022 of 1701

•

Check

thefollowing.

• Harness connectors

QD,@

• Harness connectors

@,@D

• Harness foropen or

short between ignition

coil and ignition switch

If NG, repair harness or

connectors.

Yes

NG

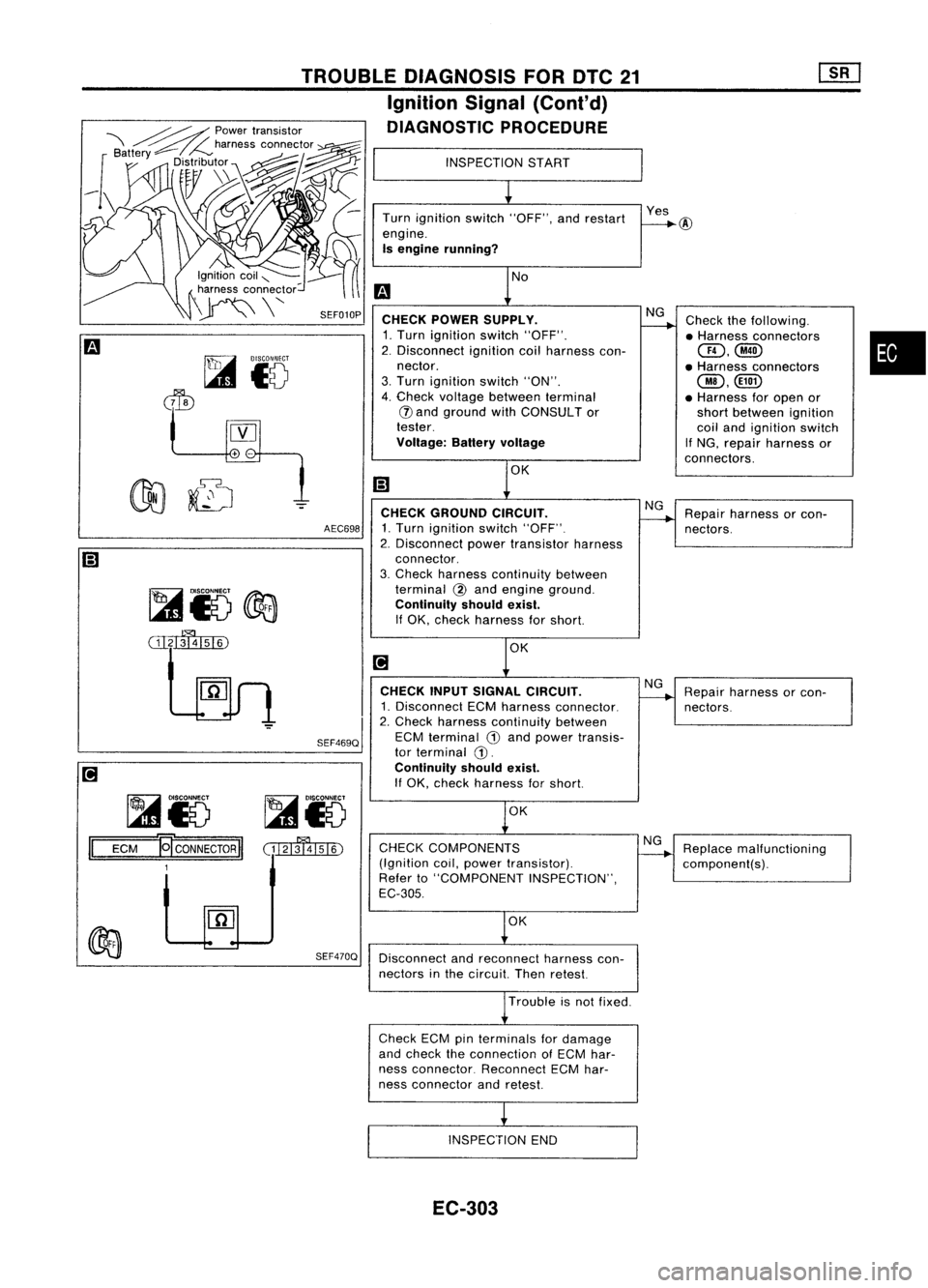

INSPECTION

START

OK

Turn

ignition switch"OFF". andrestart

engine.

Is engine running?

CHECK POWER SUPPLY.

1. Turn ignition switch"OFF".

2. Disconnect ignitioncoilharness con-

nector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

(J)

and ground withCONSULT or

tester.

Voltage: Batteryvoltage

SEF010P

TROUBLE

DIAGNOSIS FORDTe21

Ignition Signal(Cont'd)

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

AEC69a

1.Turn ignition switch"OFF".

2. Disconnect powertransistor harness

connector.

3. Check harness continuity between

terminal

@

and engine ground.

Continuity shouldexist.

If

OK. check harness forshort.

~i5

@a

~ SEF4690

~iv

~i5

II

ECM

'gCONNECTORII

(1!2IffllsI6) CHECK

INPUTSIGNAL CIRCUIT.

1. Disconnect ECMharness connector.

2. Check harness continuity between

ECM terminal

G)

and power transis-

tor terminal

G).

Continuity shouldexist.

If OK. check harness forshort.

OK

CHECK COMPONENTS

(Ignition coil,power transistor).

Refer to"COMPONENT INSPECTION".

EC-305. NG

NG

NG

Repair

harness orcon-

nectors.

Repair harness orcon-

nectors.

Replace malfunctioning

component(s).

OK

SEF4700

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

and check theconnection ofECM har-

ness connector. ReconnectECMhar-

ness connector andretest.

INSPECTION END

EC-303

Page 1023 of 1701

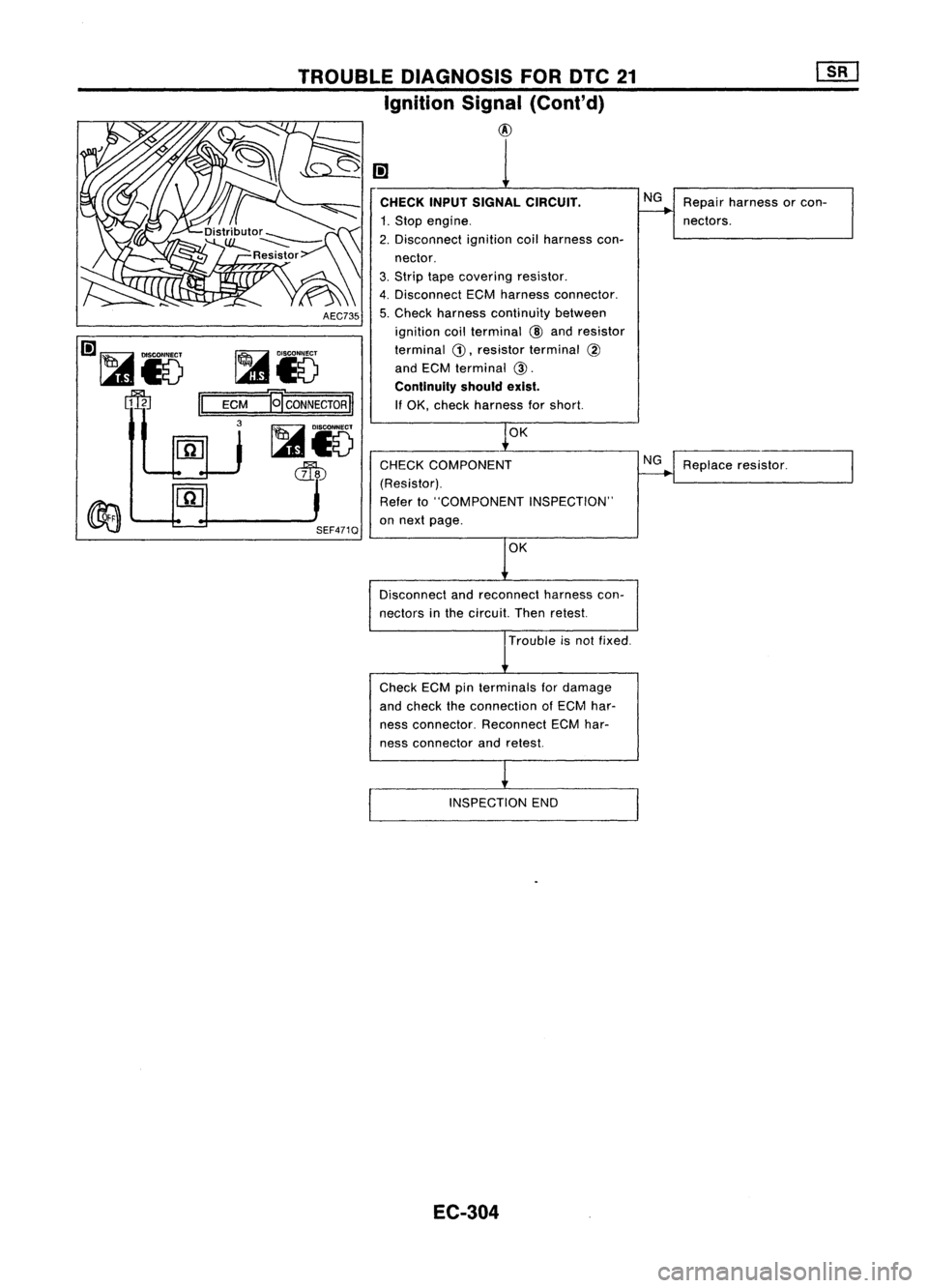

Repairharness orcon-

nectors.

Replace resistor.

NG

NG

CHECK COMPONENT

(Resistor).

Refer to"COMPONENT INSPECTION"

on next page.

CHECK

INPUTSIGNAL CIRCUIT.

1. Stop engine.

2. Disconnect ignitioncoilharness con-

nector.

3. Strip tapecovering resistor.

4. Disconnect ECMharness connector.

5. Check harness continuity between

ignition coilterminal

CID

and resistor

terminal

(!).

resistor terminal

@

and ECM terminal

@.

Continuity shouldexist.

If OK, check harness forshort.

OK

TROUBLE

DIAGNOSIS FORDTC21

Ignition Signal(Cont'd)

@

SEF471Q

(;J~i5

~i5

1

~~Q~

'Cf~OONNlliOR~

LllJ

~i5

cffu

[ill

Disconnectandreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

and check theconnection ofECM har-

ness connector. Reconnect ECMhar-

ness connector andretest.

INSPECTION END

EC-304

Page 1025 of 1701

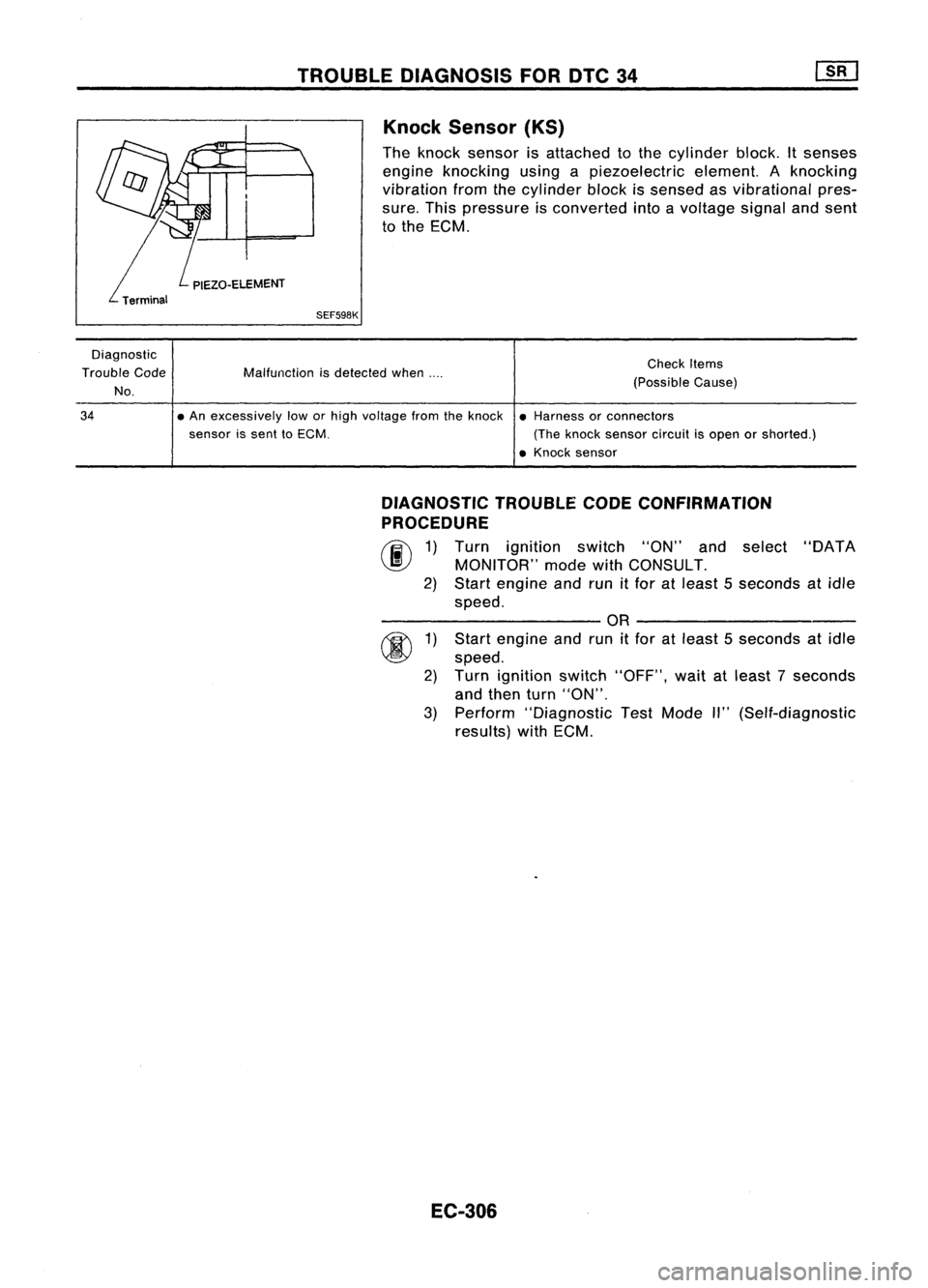

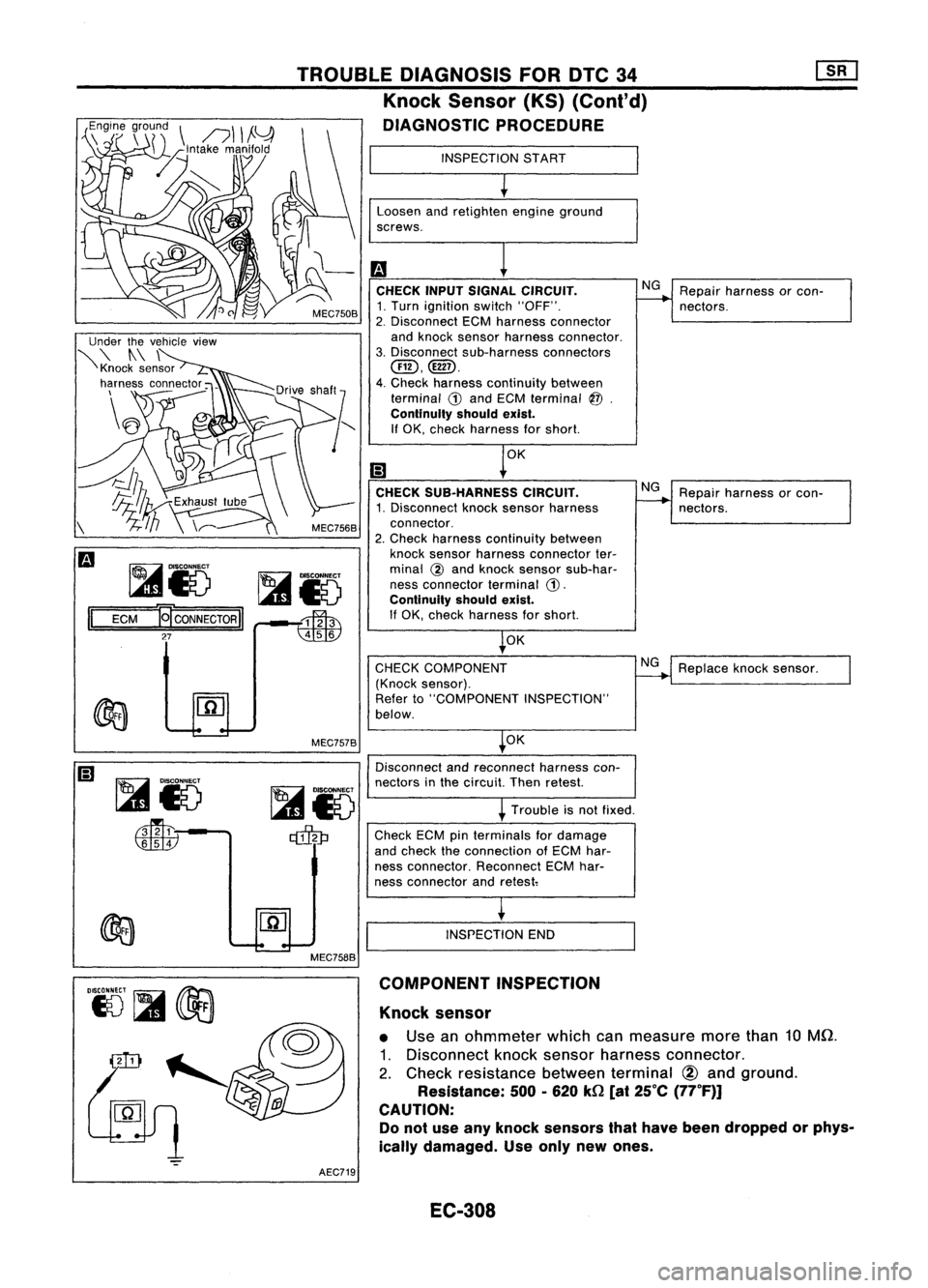

TROUBLEDIAGNOSIS FORDTC34

Knock Sensor (KS)

The knock sensor isattached tothe cylinder block.Itsenses

engine knocking usingapiezoelectric element.Aknocking

vibr

ion

fromthecylinder blockissensed asvibrational pres-

sure. Thispressure is

converted

intoa

voltage

signalandsent

to the ECM.

PIEZO-ELEMENT SEF598K

Diagnostic

Trouble Code Malfunctionisdetected when....

No.

34 •An excessively loworhigh voltage fromtheknock

sensor issent toECM. Check

Items

(Possible Cause)

• Harness orconnectors

(The knock sensor circuitisopen orshorted.)

• Knock sensor

DIAGNOSTIC TROUBLECODECONFIRMATION

PROCEDURE

fiii\

1)Turn ignition switch"ON"andselect "DATA

\J!}

MONITOR" modewithCONSULT.

2) Start engine andrunitfor atleast 5seconds atidle

speed.

----------OR -----------

1) Start engine andrunitfor atleast 5seconds atidle

speed.

2) Turn ignition switch"OFF", waitatleast 7seconds

and then turn"ON".

3) Perform "Diagnostic TestMode II"(Self-diagnostic

results) withECM.

EC-306

Page 1027 of 1701

Repairharness orcon-

nectors.

Repair harness orcon-

nectors.

Replace knocksensor.

NG

~

INSPECTION

START

Loosen andretighten engineground

screws.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

OK

CHECK COMPONENT

(Knock sensor).

Refer to"COMPONENT INSPECTION"

below.

Troubleisnot fixed.

Check ECMpinterminals fordamage

and check theconnection ofECM har-

ness connector. ReconnectECMhar-

ness connector andretest,

OK

m

CHECK SUB.HARNESS CIRCUIT.

1. Disconnect knocksensor harness

connector.

2. Check harness continuity between

knock sensor harness connector ter-

minal

@

and knock sensor sub-har-

ness connector terminal

CD.

Continuity shouldexist.

If

OK, check harness forshorl.

fa

CHECK INPUTSIGNAL CIRCUIT.

1. Turn ignition switch"OFF".

2. Disconnect ECMharness connector

and knock sensor harness connector.

3. Disconnect sub-harness connectors

@,@D.

4. Check harness continuity between

terminal

CD

and ECM terminal

@.

Continuity shouldexist.

If OK, check harness forshorl.

MEC757B

MEC7568

TROUBLE

DIAGNOSIS FORDTC34

Knock Sensor (KS)(Cont'd)

DIAGNOSTIC PROCEDURE

~15

..

~

\ili:tV

~~

\tiiliJ

~15

ECM

BCONNECTORII

27

,,~n~(

r\r~\//\ \

AY

..("'~Inlake manifold

~

\

fa

II

INSPECTIONEND

COMPONENT INSPECTION

Knock sensor

• Use anohmmeter whichcanmeasure morethan10MO.

1. Disconnect knocksensor harness connector.

2. Check resistance betweenterminal

@

and ground.

Resistance: 500-620 kO[at25°C (77°F))

CAUTION:

Do not use any knock sensors thathave been dropped orphys-

ically damaged. Useonly newones.

AEC719

EC-308

Page 1028 of 1701

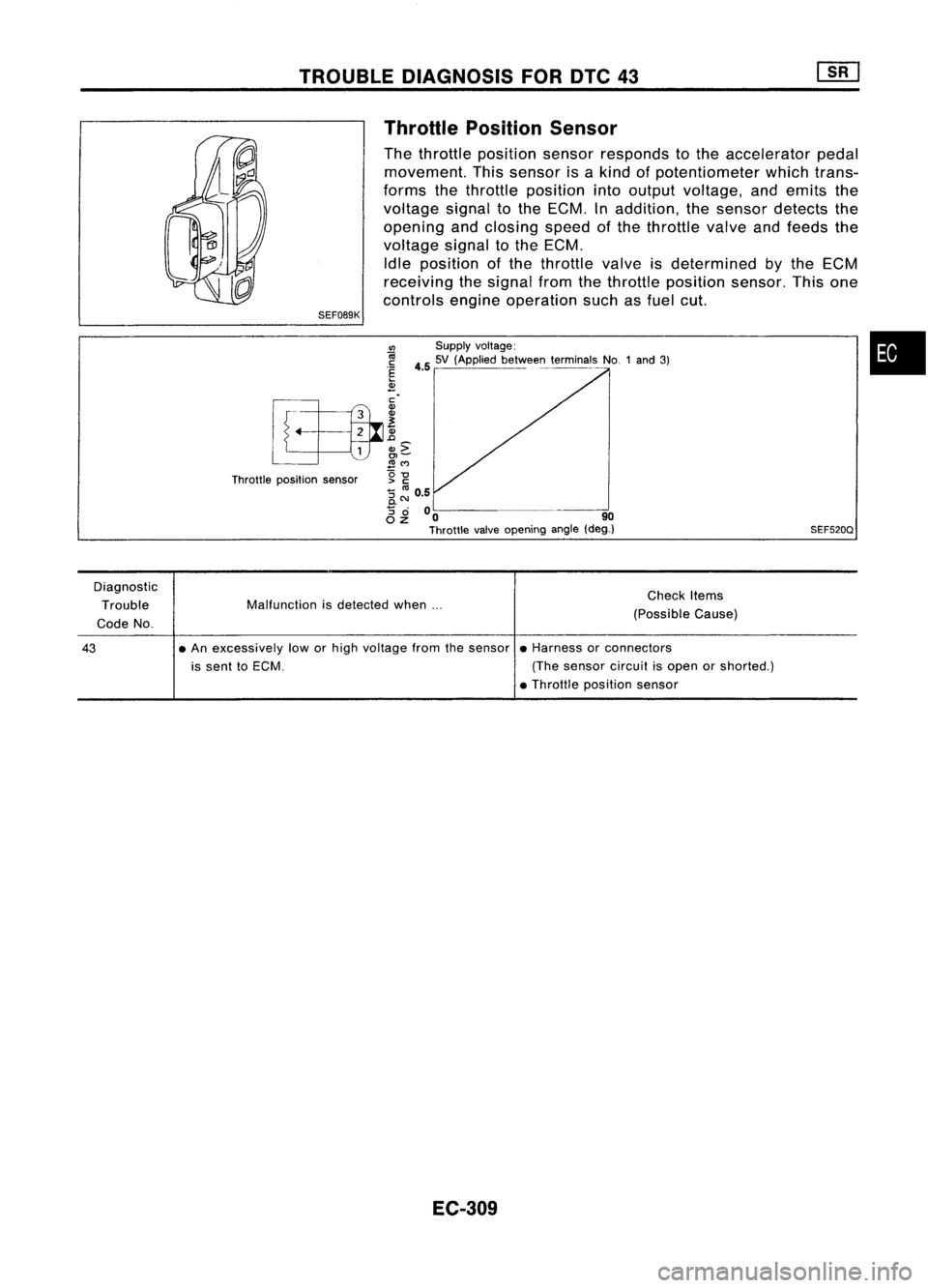

TROUBLEDIAGNOSIS FORDTC43

SEF089K Throttle

Position Sensor

The throttle position sensorresponds tothe accelerator pedal

movement. Thissensor isakind ofpotentiometer whichtrans-

forms thethrottle position intooutput voltage, andemits the

voltage signaltothe ECM. Inaddition, thesensor detects the

opening andclosing speedofthe throttle valveandfeeds the

voltage signaltothe ECM.

Idle position ofthe throttle valveisdetermined

by

the ECM

receiving thesignal fromthethrottle position sensor.Thisone

controls engineoperation suchasfuel cut.

•

SEF520Q

VI

Supplyvoltage:

~ 4.55V (Applied be~VoIee~_terminals NO.1and3)

.~

2

[f~.. ~

L

L

1

&c

~ ~M

Throttle position sensor g

-g

:; ~ 0.5

0.

8 ~

00 -~---_. 90

Throttle valveopening angle(deg.)

Diagnostic Trouble

Code No. Malfunction

isdetected when... Check

Items

(Possible Cause)

43

•

An excessively loworhigh voltage fromthesensor •Harness orconnectors

is sent toECM. (Thesensor circuitisopen orshorted.)

• Throttle position sensor

EC-309

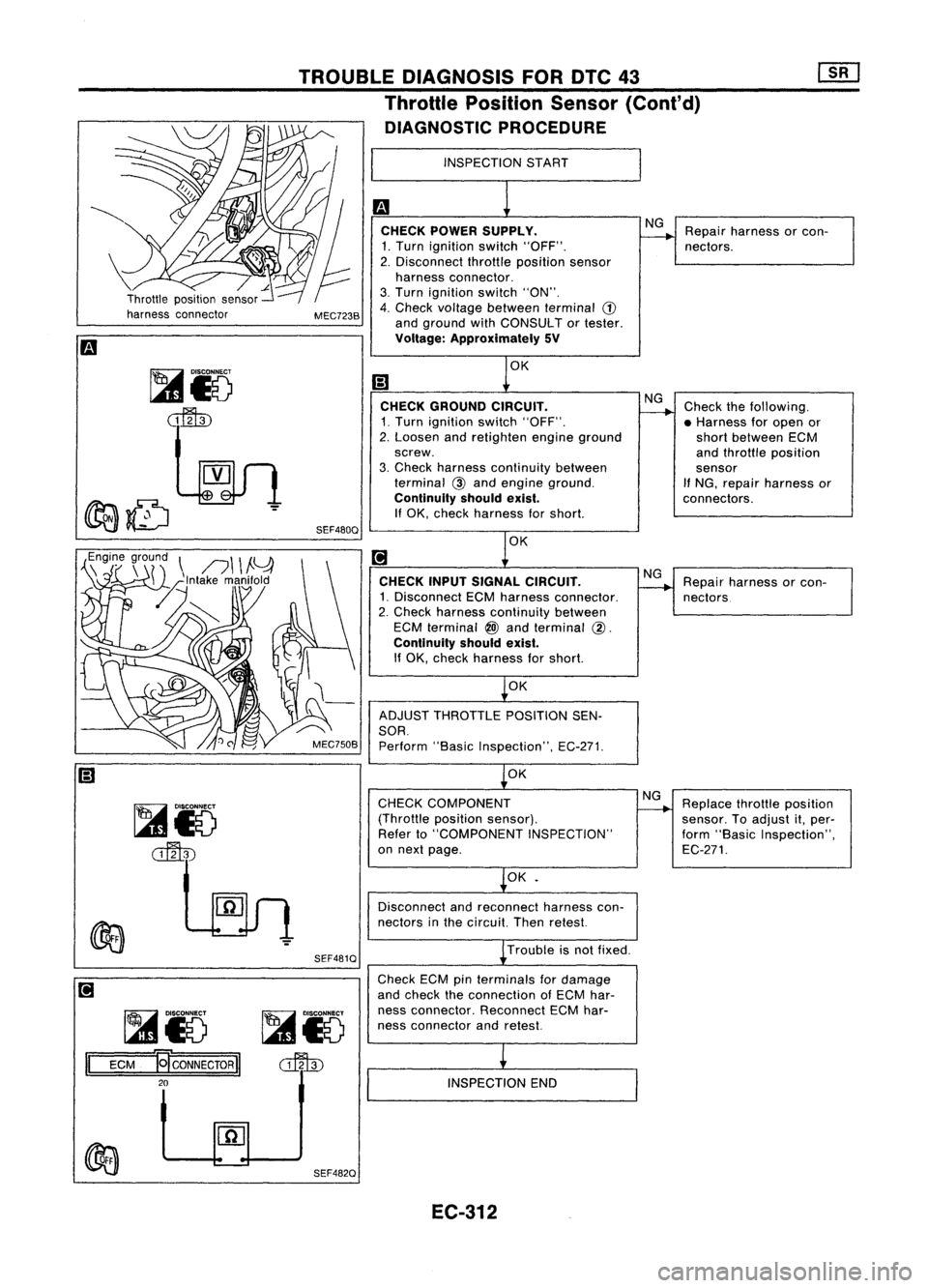

Page 1031 of 1701

Repairharness orcon-

nectors.

NG

CHECK POWER SUPPLY.

1. Turn ignition switch"OFF".

2. Disconnect throttleposition sensor

harness connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

(1)

and ground withCONSULT ortester.

Voltage: Approximately 5V

INSPECTION

START

TROUBLE

DIAGNOSIS FORDTC43

Throttle Position Sensor(Cont'd)

DIAGNOSTIC PROCEDURE

MEC723B

,,~n~7

r~r~\

n\ \

!Y

-z~lntake manifold

[L~

SEF480QOK

CHECK GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Loosen andretighten engineground

screw.

3. Check harness continuity between

terminal

@

and engine ground.

Continuity shouldexist.

If

OK, check harness forshort.

OK

CHECK INPUTSIGNAL CIRCUIT.

1. Disconnect ECMharness connector.

2. Check harness continuity between

ECM terminal

@)

and terminal

@.

Continuity shouldexist.

If OK, check harness forshort.

OK

ADJUST THROTTLE POSITIONSEN-

SOR.

Perform "BasicInspection", EC-271.

OK NG

NG

Check

thefollowing.

• Harness foropen or

short between ECM

and throttle position

sensor

If

NG, repair harness or

connectors.

Repair harness orcon-

nectors

~io

~ SEF481Q

CHECK

COMPONENT

(Throttle positionsensor).

Refer to"COMPONENT INSPECTION"

on next page.

OK•

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

NG

Replace throttleposition

sensor. Toadjust it,per-

form "Basic Inspection",

EC-271.

~io ~i5

II

ECM

~CONNECTORII

o::fl\])

20

Check

ECMpinterminals fordamage

and check theconnection ofECM har-

ness connector. Reconnect ECMhar-

ness connector andretest.

INSPECTION END

SEF482Q EC-312

Page 1037 of 1701

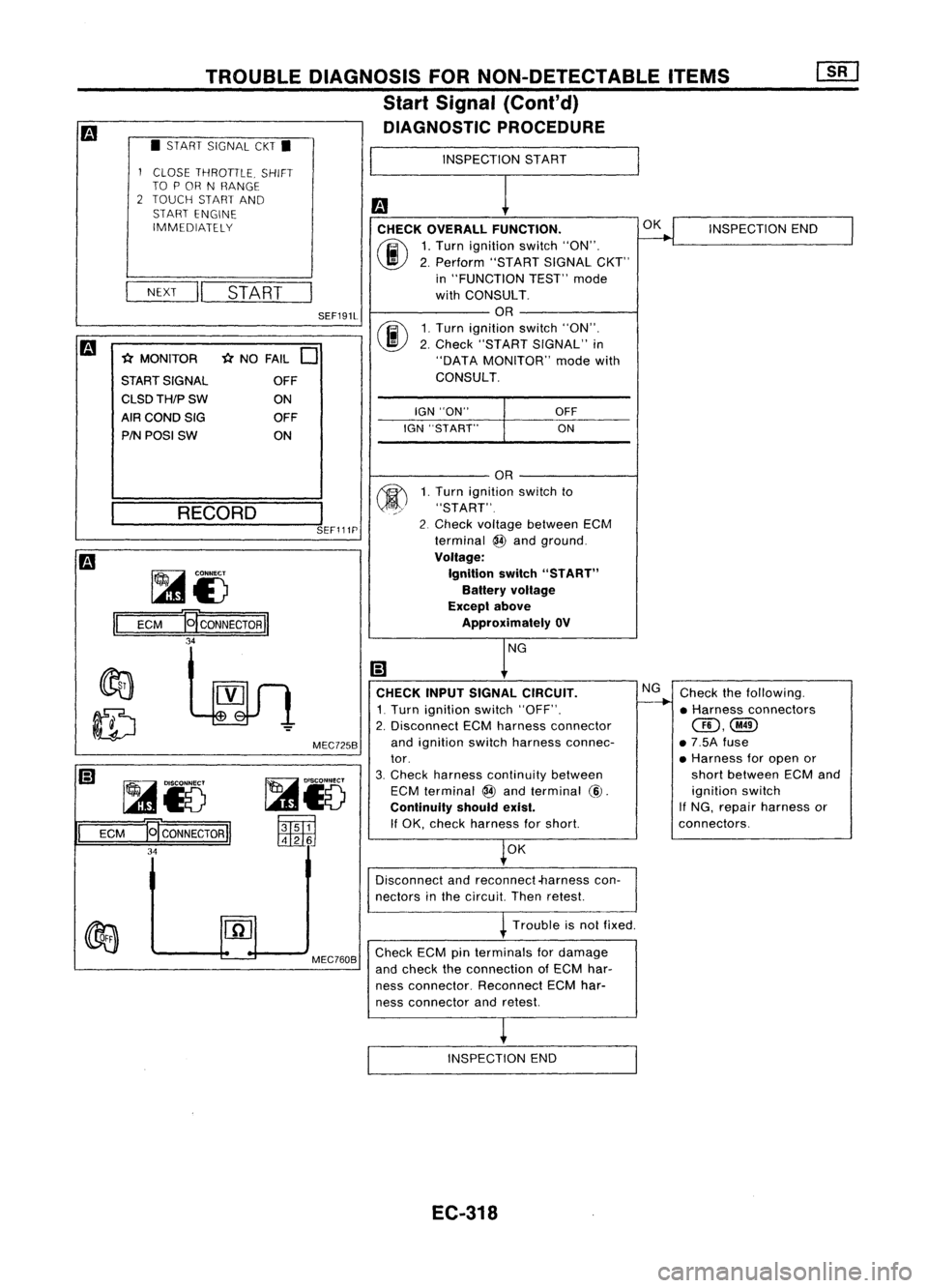

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Start Signal (Cont'd)

DIAGNOSTIC PROCEDURE

• START SIGNAL CKT•

INSPECTIONSTART

fa CHECK OVERALL FUNCTION.

(ij\

1,Turn ignition switch"ON",

~ 2,Perform "STARTSIGNALCKT"

in "FUNCTION TEST"mode

with CONSULT,

OR

rif\

1,Turn ignition switch"ON",

~ 2,Check "START SIGNAL" in

"DATA MONITOR" modewith

CONSULT,

1

CLOSE THROTILE, SHIFT

TO POR NRANGE

2 TOUCH STARTAND

START ENGINE

IMMEDIATELY

NEXT

II

START

fa

-(:(MONITOR -(:(NO FAIL

0

START SIGNAL OFF

CLSDTH/PSW ON

AfRCONDSIG OFF

PIN POSI SW ON

SEF191L

IGN"ON"

IGN "START"

OFF

ON OK

INSPECTION END

___ RE_C_O_R_D __

I

SEF111P

Checkthefollowing,

• Harness connectors

@,@

• 7,5A fuse

• Harness foropen or

short between ECMand

ignition switch

If NG, repair harness or

connectors,

NG

CHECK INPUTSIGNAL CIRCUIT.

1, Turn ignition switch"OFF",

2, Disconnect ECMharness connector

and ignition switchharness connec-

tor,

3, Check harness continuity between

ECM terminal

@

and terminal

@,

Continuity shouldexist.

If OK, check harness forshort

OK

OR

1, Turn ignition switchto

"START",

2 Check voltage between ECM

terminal

@

and ground,

Voltage: Ignition switch"START"

Battery voltage

Exceplabove

Approximately OV

MEC725B

~15

~

t:1tlliJ

~i3

ECM

E[CONNECTORII

34

~

II

ECM ~CONNECTORI

34

Disconnectandreconnect-harness con-

nectors inthe circuit Thenretest

Trouble isnot fixed,

MEC760B

Check

ECMpinterminals fordamage

and check theconnection ofECM har-

ness connector, ReconnectECMhar-

ness connector andretest

INSPECTION END

EC-318

Page 1038 of 1701

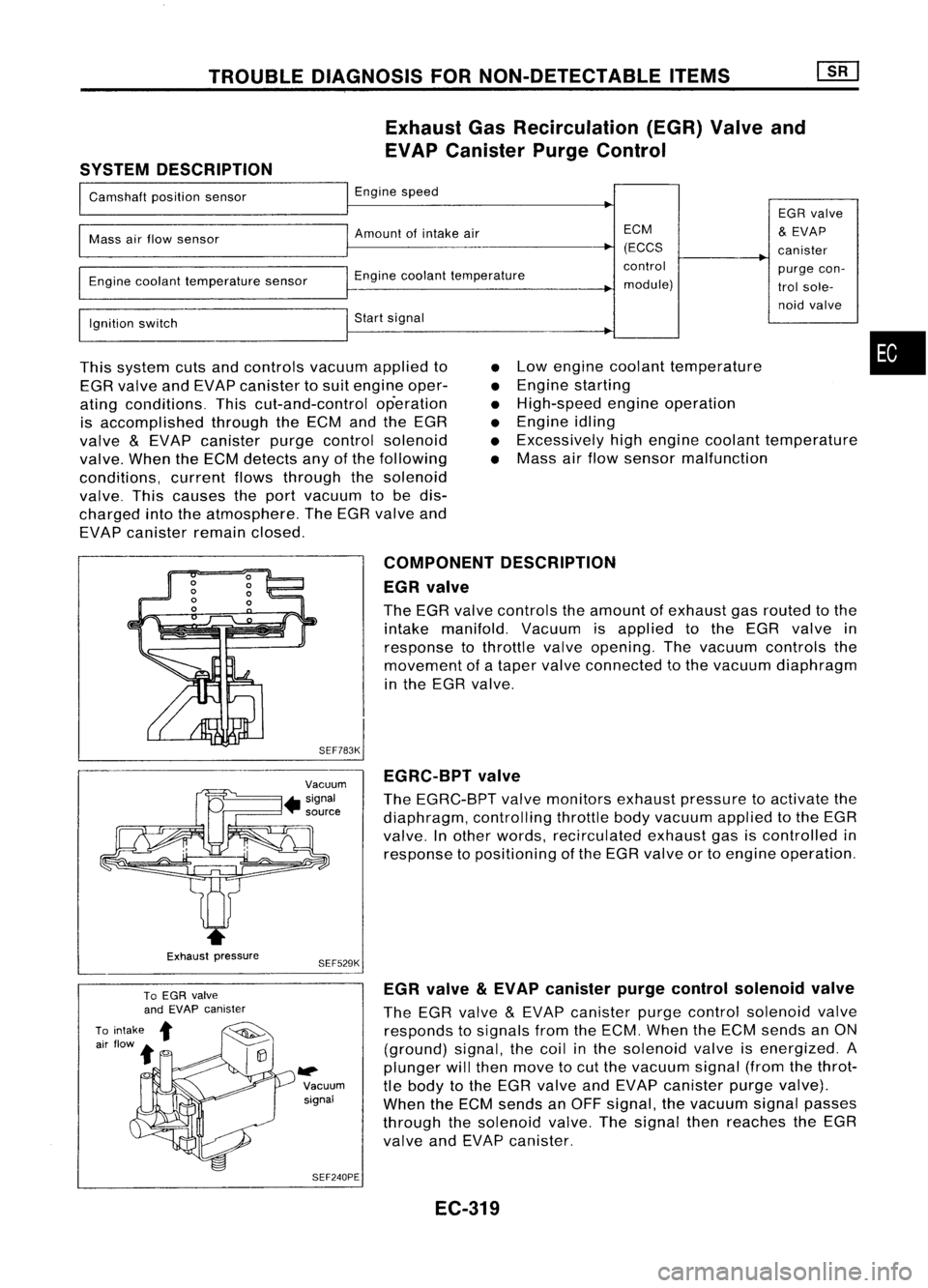

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Exhaust GasRecirculation (EGR)Valveand

EVAP Canister PurgeControl

SYSTEM DESCRIPTION

I

Camshaft positionsensor

I

Engine speed

EGRvalve

I

Mass

airflow sensor

I

Amount ofintake air ECM

&

EVAP

(ECCS canister

I

~Engine

coolanttemperature control

purgecon-

Engine coolant temperature sensor

module)trolsole-

I

noid

valve

Ignition switch

I

Start signal

I

This system cutsandcontrols vacuumappliedto

EGR valve andEVAP canister tosuit engine oper-

ating conditions. Thiscut-and-control operation

is accomplished throughtheECM andtheEGR

valve

&

EVAP canister purgecontrol solenoid

valve. WhentheECM detects anyofthe following

conditions, currentflowsthrough thesolenoid

valve. Thiscauses theport vacuum tobe dis-

charged intotheatmosphere. TheEGR valve and

EVAP canister remainclosed.

•

•

•

•

•

•

Low

engine coolant temperature

Engine starting

High-speed engineoperation

Engine idling

Excessively highengine coolant temperature

Mass airflow sensor malfunction

•

Exhaust pressure COMPONENT

DESCRIPTION

EGR valve

The EGR valve controls theamount ofexhaust gasrouted tothe

intake manifold. Vacuumisapplied tothe EGR valve in

response tothrottle valveopening. Thevacuum controls the

movement ofataper valve connected tothe vacuum diaphragm

in the EGR valve.

SEF783K EGRC-BPT valve

The EGRC-BPT valvemonitors exhaustpressure toactivate the

diaphragm, controllingthrottlebodyvacuum appliedtothe EGR

valve. Inother words, recirculated exhaustgasiscontrolled in

response topositioning ofthe EGR valve ortoengine operation.

SEF529K

~ Vacuumsignal

SEF240PE EGR

valve

&

EVAP canister purgecontrol solenoid valve

The EGR valve

&

EVAP canister purgecontrol solenoid valve

responds tosignals fromtheECM. When theECM sends anON

(ground) signal,thecoil inthe solenoid valveisenergized. A

plunger willthen move tocut the vacuum signal(fromthethrot-

tle body tothe EGR valve andEVAP canister purgevalve).

When theECM sends anOFF signal, thevacuum signalpasses

through thesolenoid valve.Thesignal thenreaches theEGR

valve andEVAP canister.

EC-319

Page 1040 of 1701

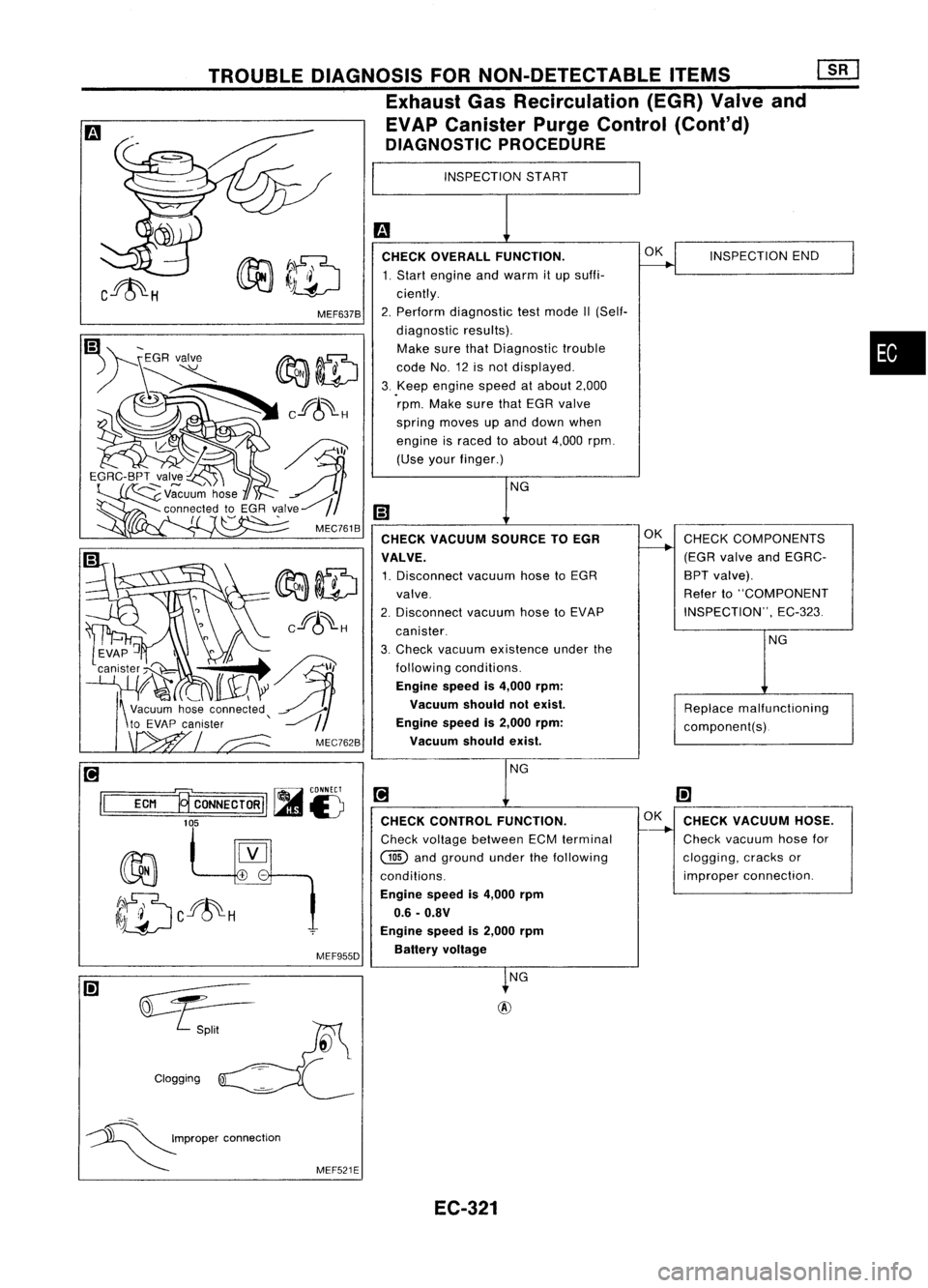

•

INSPECTION

START

m

CHECK OVERALL FUNCTION.

~INSPECTION

END

1. Start engine andwarm itup suffi-

ciently.

2. Perform diagnostic testmode II(Self-

diagnostic results).

Make surethatDiagnostic trouble

code No.12isnot displayed.

3. Keep

engine speedatabout 2,000

rpm. Make surethatEGR valve

spring moves upand down when

engine israced toabout 4,000rpm.

(Use yourfinger.)

NG

m

CHECK VACUUM SOURCETOEGR OK

CHECK COMPONENTS

----..

VALVE. (EGR

valve andEGRC-

1. Disconnect vacuumhosetoEGR BPT

valve).

valve. Refer

to"COMPONENT

2. Disconnect

vacuumhosetoEVAP INSPECTION",

EC-323

canister.

3. Check vacuum existence underthe NG

following conditions.

Engine speedis4,000 rpm:

Vacuum shouldnotexist.

Replacemalfunctioning

Engine speedis2,000 rpm:

component(s).

Vacuum shouldexist.

NG

[!J

(!]

CHECK CONTROL FUNCTION. OK

CHECK VACUUM HOSE.

-----.-

Check voltage between ECMterminal Check

vacuum hosefor

@

andground underthefollowing clogging,

cracksor

conditions. improper

connection.

Engine speedis4,000 rpm

0.6 -O.BV

Engine speedis2,000 rpm

Battery voltage

~NG

+

-

MEF637B

MEF955D

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

[1[J

Exhaust GasRecirculation (EGR)Valveand

EVAP Canister PurgeControl (Cont'd)

DIAGNOSTIC PROCEDURE

~)5

~~II

EGRC-BPT valve

~~uu~ hose

connected toEGR valve~

(

~

'

MEC761B

Clogging

[!J

r----, ~

CONNECT

II

ECM ~CONNECTORIIl.imJ

£)

105

::::.S.-

~P"P"

'00","'00

MEF521E

EC-321