engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1111 of 1701

![NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

EC-GLOW-01

IGNITION SWITCH IGNITIONSWITCH

START ONorSTART

7.5A

1261

10A

1251

10A

IT]

FUSE

BLOCK

(JIB)

@:ID

Refer

toEL-POWER.

<I>:

LHDmodels

NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

EC-GLOW-01

IGNITION SWITCH IGNITIONSWITCH

START ONorSTART

7.5A

1261

10A

1251

10A

IT]

FUSE

BLOCK

(JIB)

@:ID

Refer

toEL-POWER.

<I>:

LHDmodels](/img/5/57349/w960_57349-1110.png)

TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

EC-GLOW-01

IGNITION SWITCH IGNITIONSWITCH

START ONorSTART

7.5A

1261

10A

1251

10A

IT]

FUSE

BLOCK

(JIB)

@:ID

Refer

toEL-POWER.

:

LHDmodels

<£D:

RHOmodels

ECM

(ENGINECONTROL

MODULE)

@

TW

~

G/B

I

Toengine coolant

-------.. temperaturesensor

(Refer toEC-COOL/F.)

1I~11

Y

I

Y

I!i

COMBINATION

METER

(GLOW LAMP)

11

3•3

1

@

OR

I

OR

m

GIL

1Ni91

BR

BR

~

IGN

1Ni91

BR

BR

~

IGN

IN.41

B/Y

GNO-C GNO-C GNO-AGNO-A

12.6

I 11

3•9

I

11~11 11~51

B BB B

I

II I

----.-_-.- __1.

I

.-o-ee-°l

I

<;

A

;>

B

1---.1

B

-!-! .-!-

B/Y

~

START

Refertolast page

(Foldout page).

HEC088

EC-392

Page 1112 of 1701

![NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

•

GLOW

PLUG

(E213)

R

ctJ@

~~

R

I

R

Q

(b):

LHDmodels

<E:>:

RHOmodels

EC-GLDW-02

Refer toEL-POWER.

75A

IT]

!'e"

(ENGINE

CONTR NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

•

GLOW

PLUG

(E213)

R

ctJ@

~~

R

I

R

Q

(b):

LHDmodels

<E:>:

RHOmodels

EC-GLDW-02

Refer toEL-POWER.

75A

IT]

!'e"

(ENGINE

CONTR](/img/5/57349/w960_57349-1111.png)

TROUBLEDIAGNOSES

Quick-glow System(Cont'd)

•

GLOW

PLUG

(E213)

R

ctJ@

~~

R

I

R

Q

(b):

LHDmodels

RHOmodels

EC-GLDW-02

Refer toEL-POWER.

75A

IT]

!'e"

(ENGINE

CONTROL

MODULE)

(M39)

W/L

B/R

1--~

I

W!L B/R

11!11~II~e~y

~m>

~

1!:i=Jll!:i=!J~

W/R R

I

~1

W/R W/R

CHID ~ I~ICHID

W/R W/R

tJ

I

W/R

IL@JI

G/R

+f

W/L W/L

m

rA,

~(E10f)

CHID I~I

I~ICHID

W/L W!L

tJ

I

W/L

1001

BATT

FUSE

BLOCK

(JIB)

(106)

7.5A

1241

I

BATTERY

I

•

. ------.

~ffij

10.

91

P

I

P

~1

KEY-IN

IN SWITCH

OUT--

@

~

BR/Y

I

~~

BR/Y BR/Y

(E10f) .~ ~(EiOf)

CHID

I~I

I~ICHID

BR/Y BR/Y

t-t

I

BR/Y

00 KEY

~ (E115)

[IIg]

W

~---------------~

I I

:Fnm>~~~~:

:rnJ

G

@J

W

l.9J

W:

, ,

-----------------

Refer

tolast page

(Foldout page).

HEC089

EC-393

Page 1114 of 1701

TROUBLEDIAGNOSES

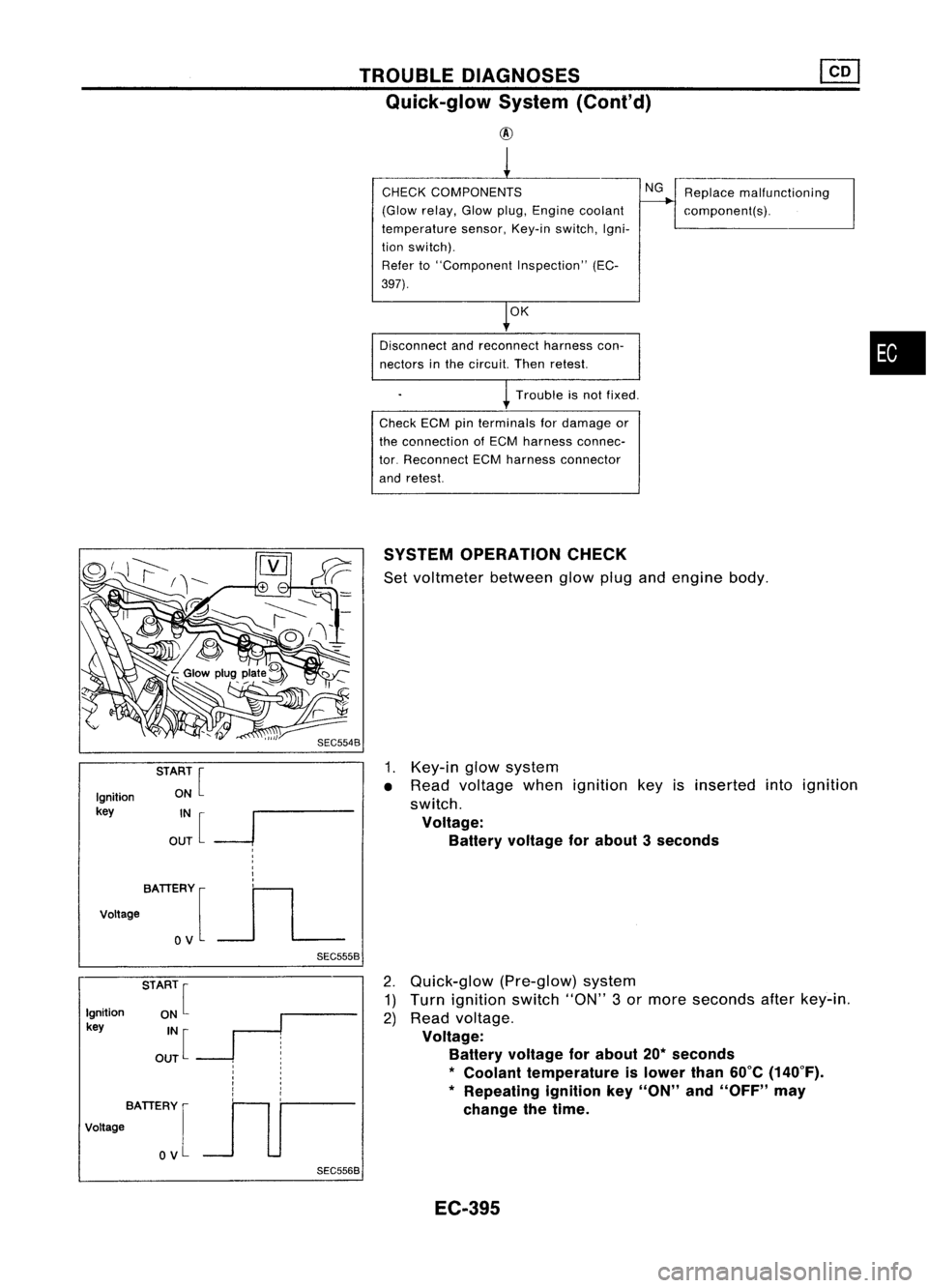

Quick-glow System(Cont'd)

@

CHECK COMPONENTS NG

(Glow relay, Glowplug,Engine coolant

temperature sensor,Key-inswitch, Igni-

tion switch).

Refer to"Component Inspection"(EC-

397).

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage or

the connection ofECM harness connec-

tor. Reconnect ECMharness connector

and retest. Replace

malfunctioning

component(s).

•

BATIERY [

Voltage

OV

Ignition

key

START

[

ON

IN [

OUT

,

,

,

I

,

JL

SEC5558SYSTEM

OPERATION CHECK

Set voltmeter betweenglowplugandengine body.

1. Key-in glowsystem

• Read voltage whenignition keyisinserted intoignition

switch.

Voltage: Battery voltage forabout 3seconds

Ignition

key

BATIERY [

Voltage

OV

SEC5568

2.

Quick-glow (Pre-glow)system

1) Turn ignition switch"ON"3or more seconds afterkey-in.

2) Read voltage.

Voltage: Battery voltage forabout 20*seconds

*

Coolant temperature islower than60°C(140°F).

* Repeating ignitionkey"ON" and"OFF" may

change thetime.

EC-395

Page 1115 of 1701

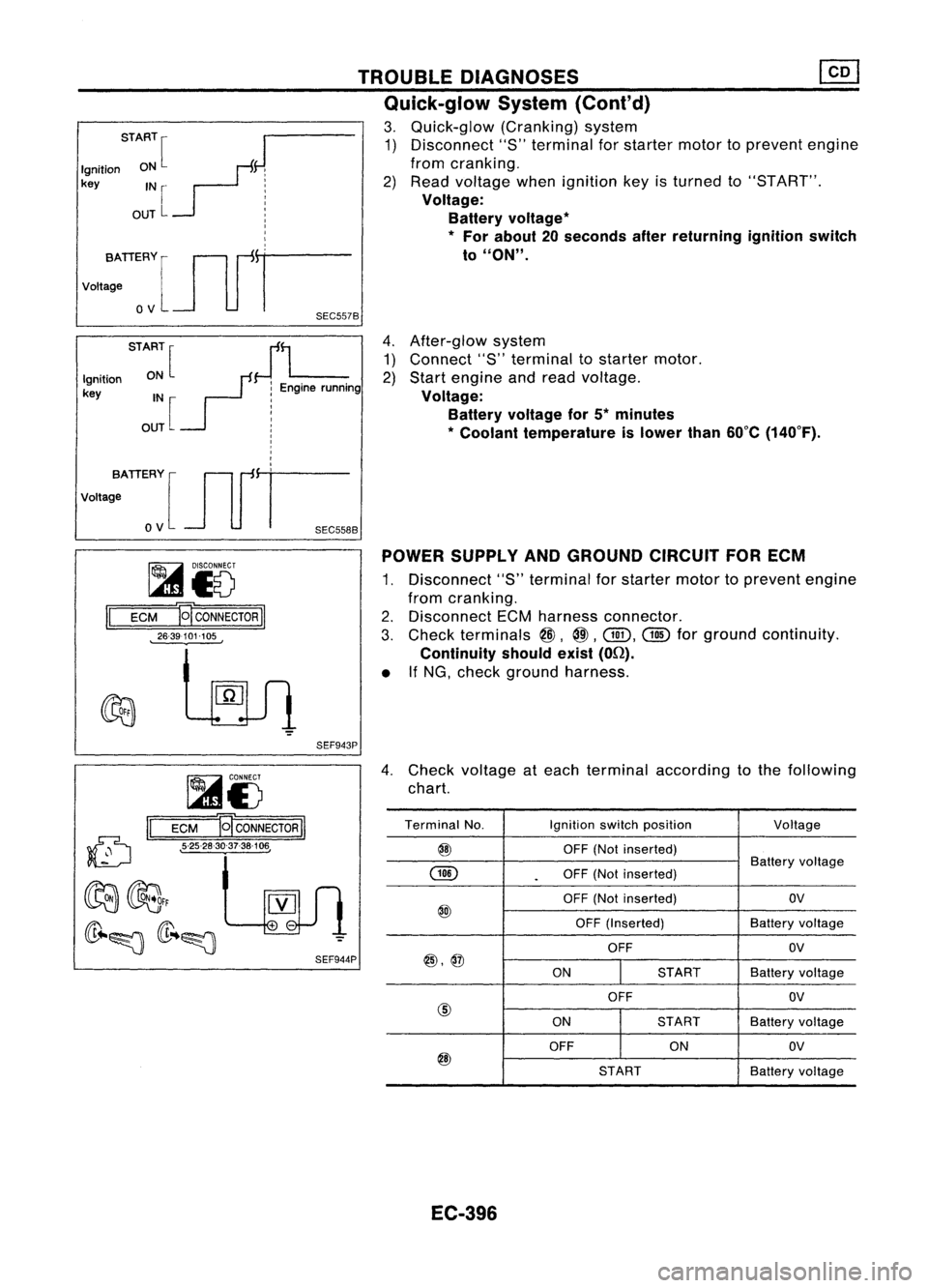

4.After-glow system

1) Connect "8"terminal tostarter motor.

2) Start engine andread voltage.

Voltage: Battery voltage for5*minutes

* Coolant temperature islower than60°C(140°F).

TROUBLE

DIAGNOSES

Quick-glow System(Cont'd)

3. Quick-glow (Cranking)system

1) Disconnect "S"terminal forstarter motortoprevent engine

from cranking.

2) Read voltage whenignition keyisturned to"8T ART".

Voltage: Battery voltage

*

*

For about 20seconds afterreturning ignitionswitch

to

"ON".

START

[

J

Ignition ON

F:

key IN

r- j

OUT

L :

I

I

I

vo,,:TIERYlJlfr

o

V

SEC557B

STA:~[

JL

Ignition

r:

Enginerunning

key IN :

OUT [

!

I

I

,

I

,

votta;ATIERY [Jlfi=

o

V

SEC558B

~i5

II

ECM E

CONNECTOR

II

26-39101-105 POWER

SUPPLY ANDGROUND CIRCUITFORECM

1. Disconnect "S"terminal forstarter motortoprevent engine

from cranking.

2. Disconnect ECMharness connector.

3. Check terminals

@,

@.

Gill.

@

forground continuity.

Continuity shouldexist(On).

• IfNG, check ground harness.

SEF943P

(D

II

~i5

ECM B

CONNECTOR

II

• 5-25-28-30-37-38-106,

4.

Check voltage ateach terminal according tothe following

chart.

Terminal No. Ignitionswitchposition

Voltage

@

OFF(Notinserted)

GID

Battery

voltage

.

OFF

(Notinserted)

OFF (Not inserted) OV

@

OFF(Inserted) Batteryvoltage

OFF OV

@,@

ONSTARTBatteryvoltage

OFF OV

@

ONSTART

Batteryvoltage

OFF ONOV

@

STARTBatteryvoltage

EC-396

Page 1117 of 1701

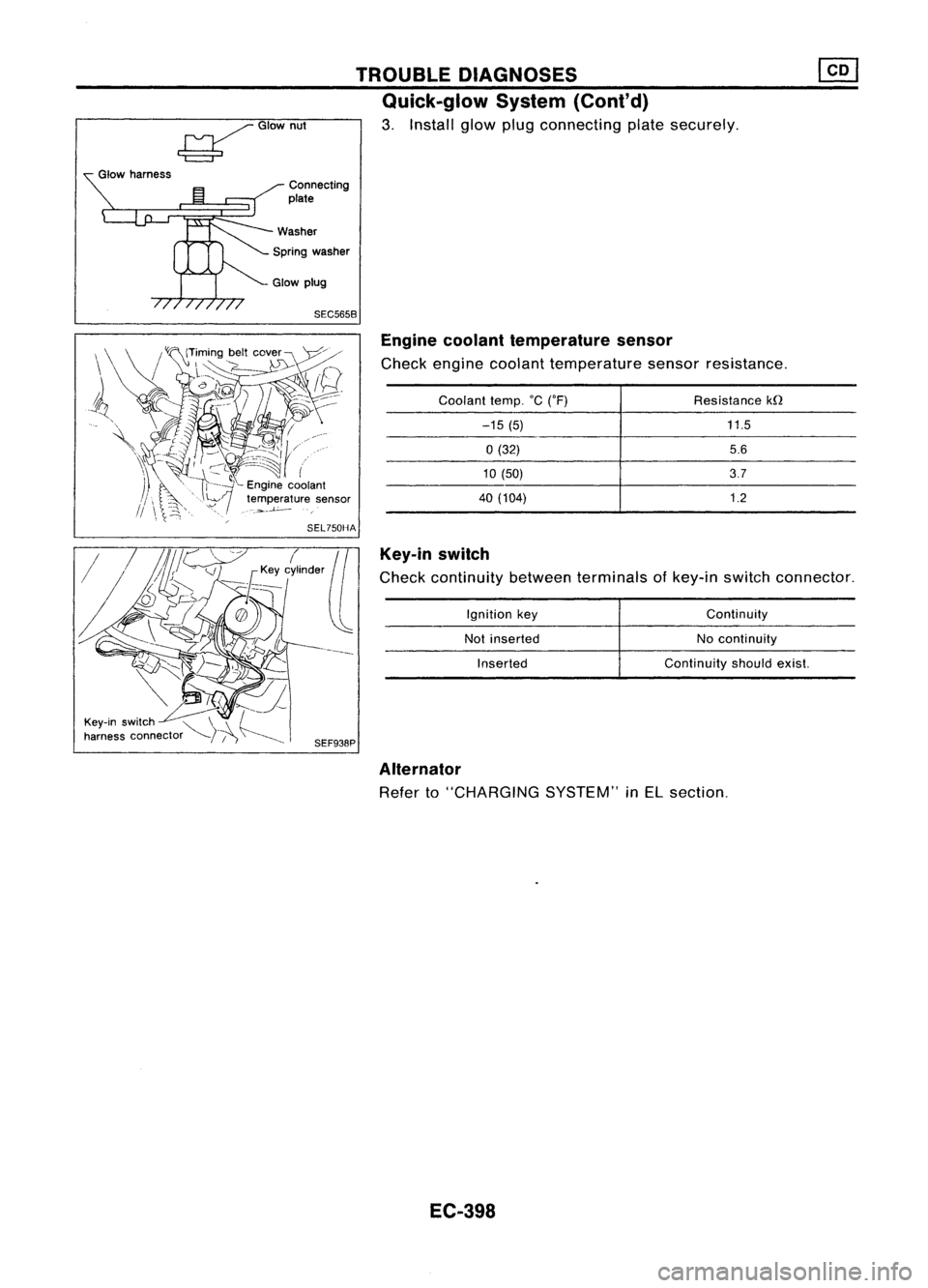

SEC5658Enginecoolant temperature sensor

Check engine coolant temperature sensorresistance.

Key-in switch

Check continuity betweenterminals ofkey-in switch connector.

11.5

5.6

3.7

1.2

Resistance

kfl

Continuity

No continuity

Continuity shouldexist.

Ignition

key

Not inserted

Inserted

Coolant

temp.°C('F)

-15 (5)

0(32)

10 (50)

40 (104)

TROUBLE

DIAGNOSES

Quick-glow System(Cont'd)

3. Install glowplugconnecting platesecurely.

Connecting

plate

Spring washer

~GIOwnut

Glow harness

Alternator

Refer to"CHARGING SYSTEM"inEL section.

EC-398

Page 1118 of 1701

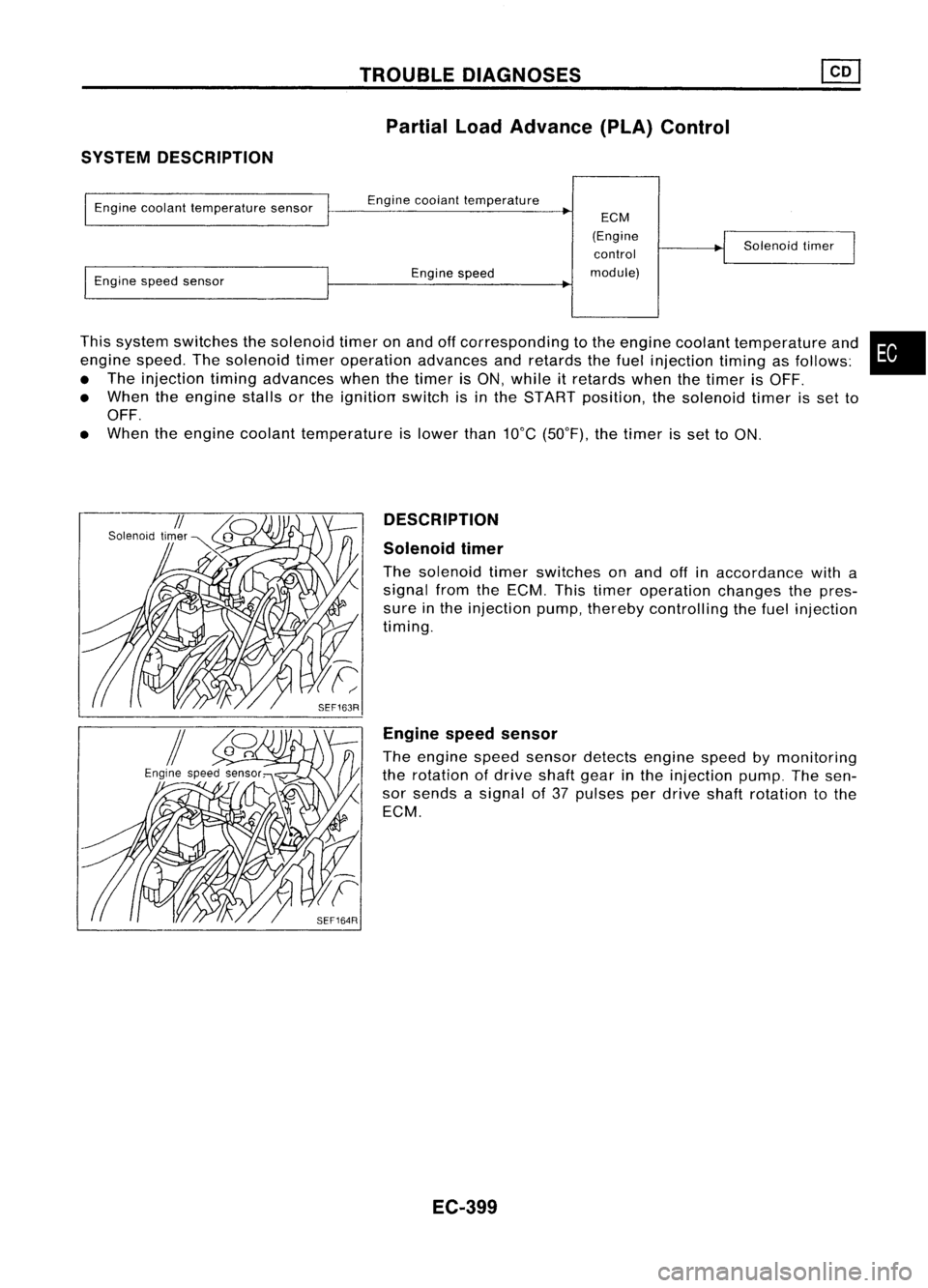

SYSTEMDESCRIPTION TROUBLE

DIAGNOSES

Partial LoadAdvance (PLA)Control

This system switches thesolenoid timeronand offcorresponding tothe engine coolant temperature and

engine speed.Thesolenoid timeroperation advancesandretards thefuel injection timingasfollows:

• The injection timingadvances whenthetimer isON, while itretards whenthetimer isOFF.

• When theengine stallsorthe ignition switchisin the START position, thesolenoid timerisset to

OFF.

• When theengine coolant temperature islower than10°C(50°F), thetimer isset toON.

Engine

coolant temperature sensor

Engine speedsensor Engine

coolant temperature

Engine speed

ECM

(Engine control

module) Solenoid

timer

•

DESCRIPTION

Solenoid timer

The solenoid timerswitches onand offinaccordance witha

signal fromtheECM. Thistimer operation changesthepres-

sure inthe injection pump,thereby controlling thefuel injection

timing.

Engine speedsensor

The engine speedsensor detects enginespeedbymonitoring

the rotation ofdrive shaftgearinthe injection pump.Thesen-

sor sends asignal of37 pulses perdrive shaftrotation tothe

ECM.

EC-399

Page 1119 of 1701

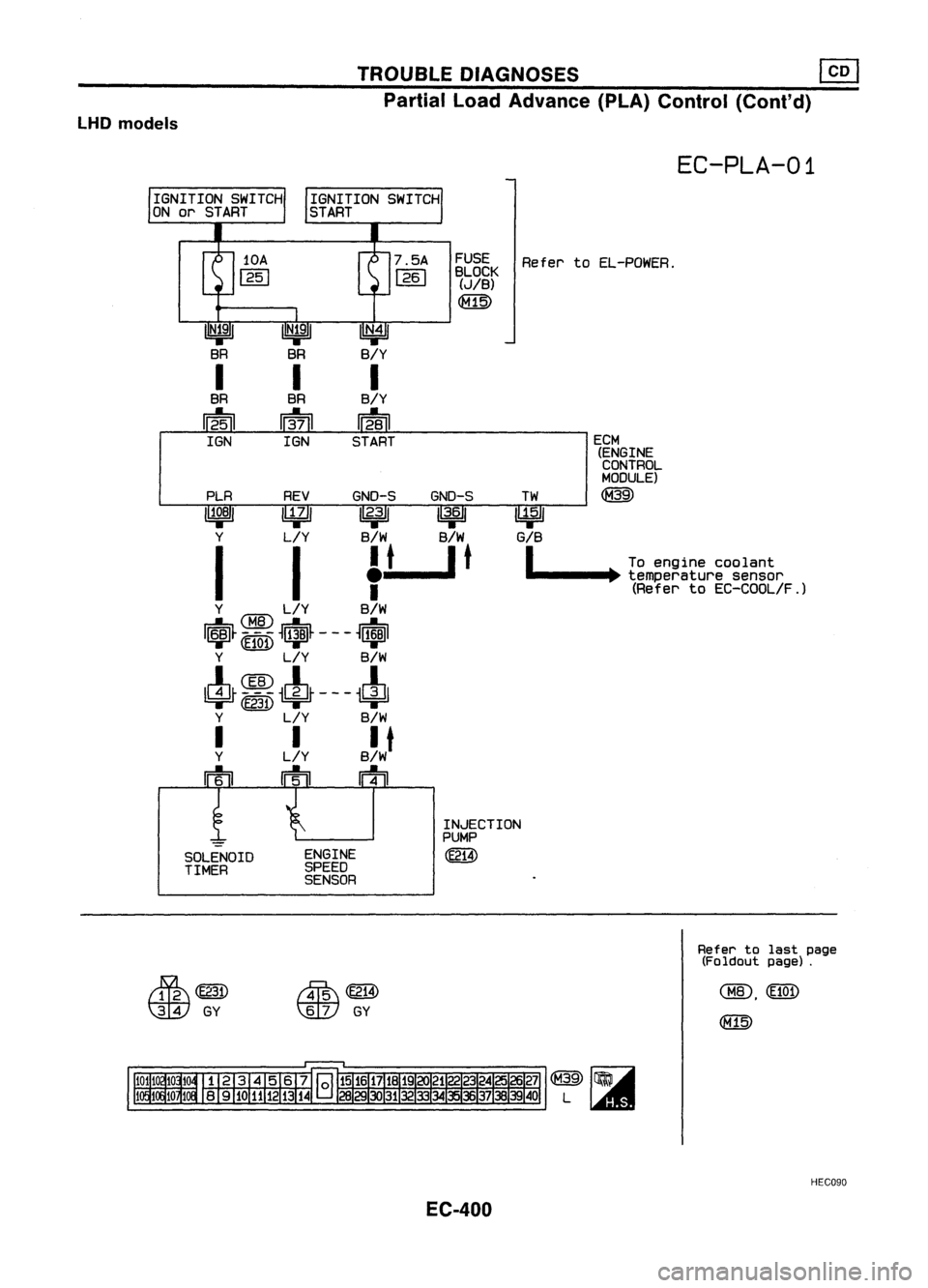

TROUBLEDIAGNOSES ~

Partial LoadAdvance (PLA)Control (Cont'd)

LHD models

EC-PLA-01

~~~~K RefertoEL-POWER.

(JIB)

PLR REVGND-S GND-S

11~81 ~

/12.3

11

13.61

Y L!Y B/W B/W

I

I

f-

t

_I

t

Y ~ L!Y B!W

IrlsJ~ -

M.-B -

~I&~ ---

~r;]ID1

'T'

(E101)

L:jf'

"T'

Y L!Y B!W

1c!J~ ~

~cL~ ---

~c!J1

<=j=

(E231)

=r' =r'

Y L!Y B!W

!

L~Y B~Wt

rrh

m m

ECM

(ENGINECONTROL

MODULE)

@

TW

~

G!B

1

Toengine coolant

._--~. temperature sensor

(Refer toEC-COOL!F.)

II

N•4

1

B/Y

I

B/Y

Iffsn

START

IN;91

BR

I

BR

~

IGN

SOLENOID

TIMER ENGINE

SPEED

SENSOR INJECTION

PUMP

(E214)

~~

~ GY

~

(E214)

\ill)

GY

Refer

tolast page

(Foldout page).

HEC090

EC-400

Page 1120 of 1701

TROUBLEDIAGNOSES ~

Partial LoadAdvance (PLA)Control (Cont'd)

RHO models

EC-PLA-02

FUSE RefertoEL-POWER.

BLOCK

(JIB)

~

PLR REVGND-S GND-S

11~BI ~

11

2•3113.,61

Y L/Y B/wB/W

I

I

f-

t-,t

Y ~ L/Y B/W

I$t _M~-

~t~ -- -

~$I

~

Y L/Y B/W

4r=~~t---~

Y L/Y B/W

!

L~Y B~Wt

m mrn

ECM

(ENGINE

CONTROL

MODULE)

~

•

TW

~

G/B

I

Toengine coolant

.......... ~.temperature sensor

(Refer toEC-COOL/F.)

IN.41

B/Y

I

B/Y

Wail

START

IN;91

BR

I

BR

~

IGN

SOLENOID

TIMER ENGINE

SPEED

SENSOR INJECTION

PUMP

(E214)

Refertolast page

(Foldout page).

~(E203)

rn:rn:tIlID

GY

M\

(~!4)

t:]lV

GY

HECC91

EC-401

Page 1121 of 1701

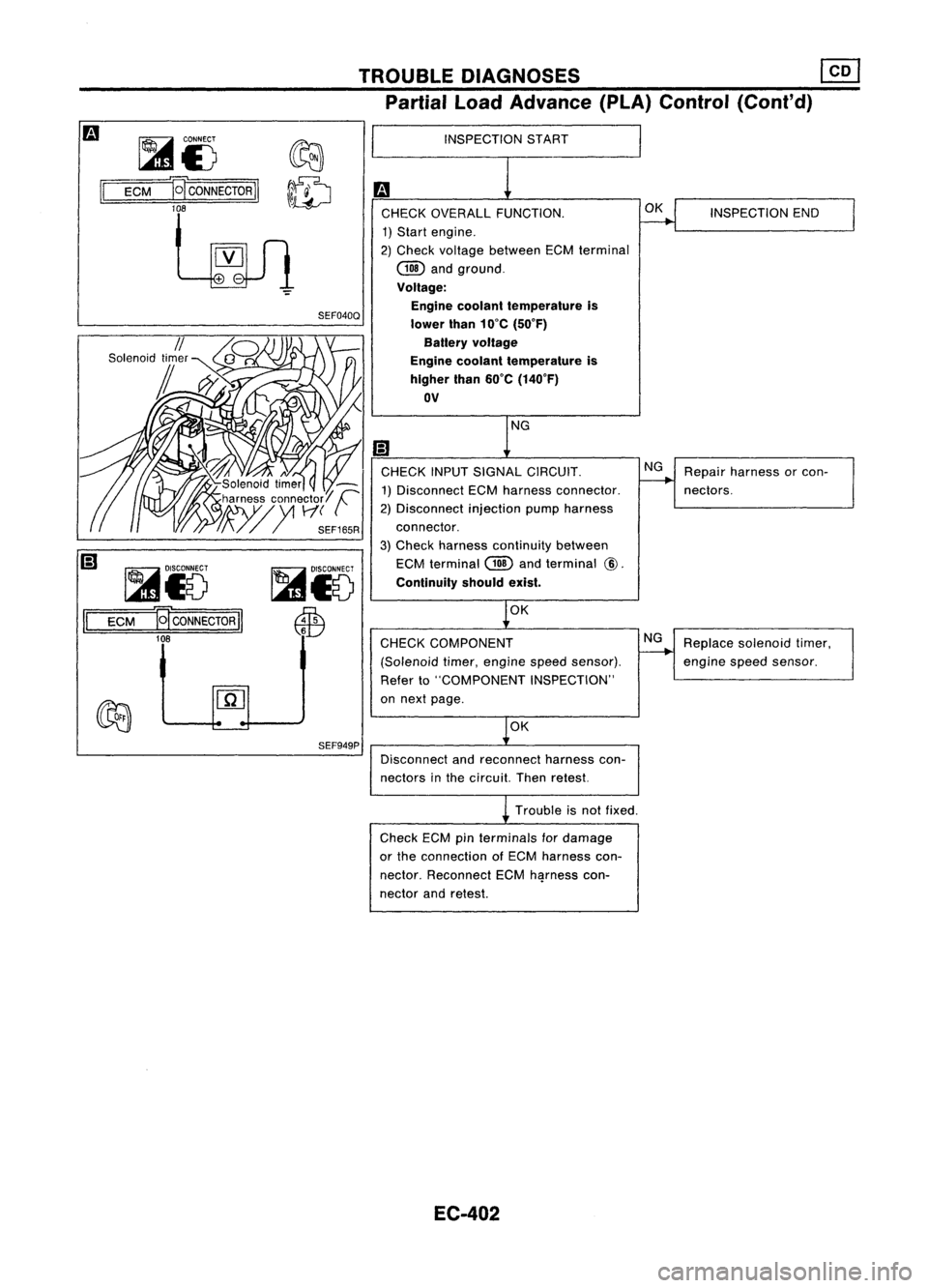

TROUBLEDIAGNOSES ~

Partial LoadAdvance (PLA)Control (Cont'd)

II

~i5

D~CONNECTORII

lOB

~i5

ECM

M

CONNECTOR

II

10B

SEF040Q

SEF949P

INSPECTION

START

CHECK OVERALL FUNCTION.

1) Start engine.

2) Check voltage between ECMterminal

COO

andground.

Voltage: Engine coolant temperature is

lower than10'C (50'F)

Battery voltage

Engine coolant temperature is

higher than60'C (140'F)

OV

CHECK INPUTSIGNAL CIRCUIT.

1) Disconnect ECMharness connector.

2) Disconnect injectionpumpharness

connector.

3) Check harness continuity between

ECM terminal

COO

andterminal

@.

Continuity shouldexist.

OK

CHECK COMPONENT

(Solenoid timer,engine speedsensor).

Refer to"COMPONENT INSPECTION"

on next page.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpin

terminals

fordamage

or the connection ofECM harness con-

nector. Reconnect ECMh~rness con-

nector andretest.

EC-402 OK

NG

NG

INSPECTION

END

Repair harness orcon-

nectors.

Replace solenoid timer,

engine

speedsensor.

Page 1122 of 1701

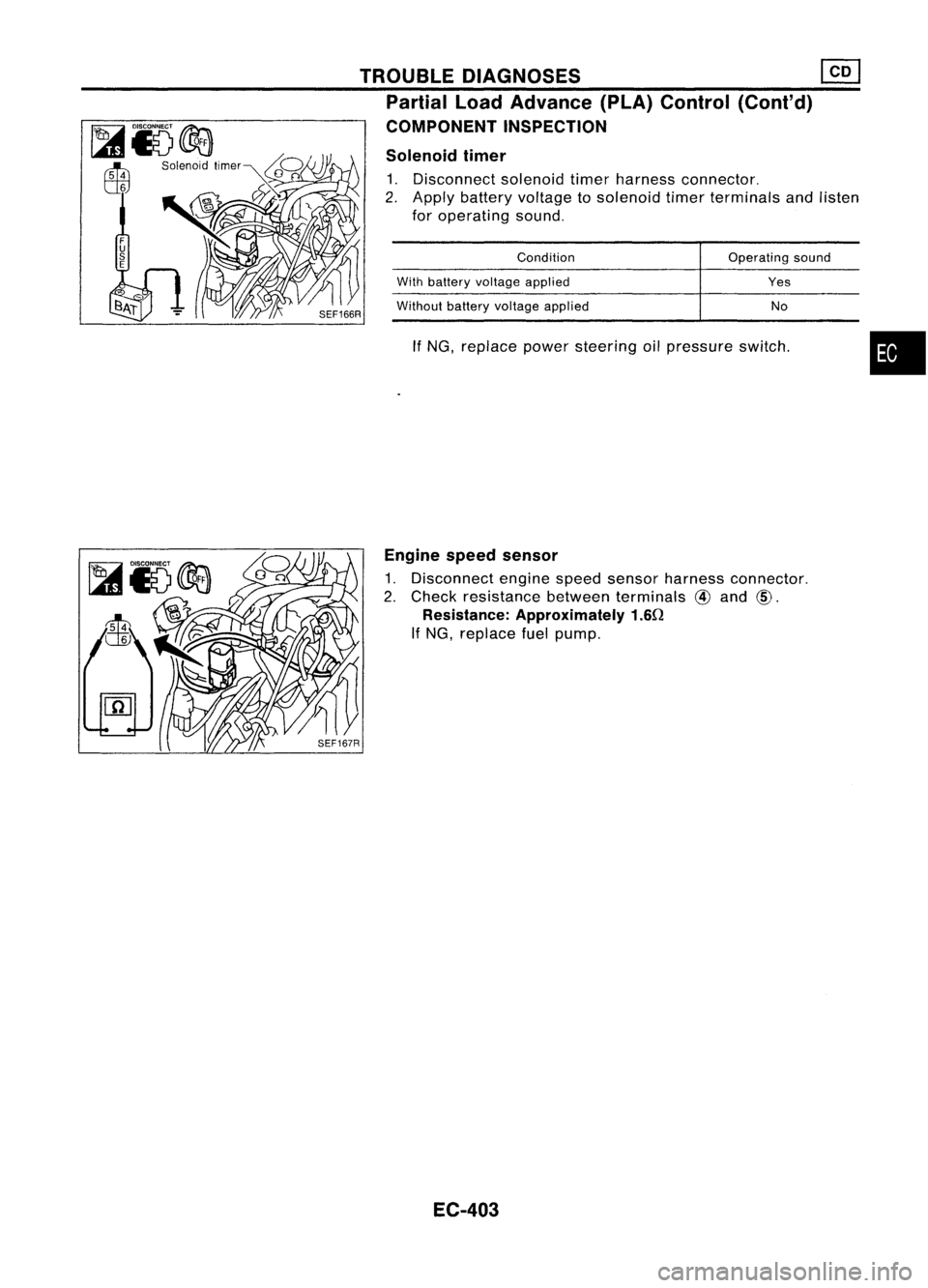

If

NG, replace powersteering oilpressure switch.

Solenoid

timer

1. Disconnect solenoidtimerharness connector.

2. Apply battery voltage tosolenoid timerterminals andlisten

for operating sound.

•

No

Operating

sound

Yes

Condition

With battery voltage applied

Without batteryvoltage applied

TROUBLE

DIAGNOSES ~

Partial LoadAdvance (PLA)Control (Cont'd)

COMPONENT INSPECTION

Engine speedsensor

1. Disconnect enginespeedsensor harness connector.

2. Check resistance betweenterminals

@

and

CID.

Resistance: Approximately 1.6Q

If

NG, replace fuelpump.

EC-403