NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 891 of 1701

![NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

@K]

Power Steering OilPressure Switch(Cont'd)

@:

ForAustralia

@:

Except forAustralia SEF176R

Repair

harness orcon-

nectors.

CHECK INPUTSIGNAL CIRCUIT. NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

@K]

Power Steering OilPressure Switch(Cont'd)

@:

ForAustralia

@:

Except forAustralia SEF176R

Repair

harness orcon-

nectors.

CHECK INPUTSIGNAL CIRCUIT.](/img/5/57349/w960_57349-890.png)

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

@K]

Power Steering OilPressure Switch(Cont'd)

@:

ForAustralia

@:

Except forAustralia SEF176R

Repair

harness orcon-

nectors.

CHECK INPUTSIGNAL CIRCUIT. NG

Check thefollowing .

1. Disconnect ECMharness connector.

......---..

•Harness connectors

2. Check harness continuity between

aD,

(MID

ECM terminal

@

or

@

and terminal •

Harness connectors

G).

@,@or@,

Continuity shouldexist.

If

OK, check harness forshort. •

Harness foropen or

OK short

between ECMand

power steering oilpres-

sure switch

If NG, repair harness or

connectors.

CHECK COMPONENT NG

Replace powersteering

(Power steering oilpressure switch).

--...

oilpressure switch.

Refer to"COMPONENT INSPECTION"

below.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage or

the connection ofECM harness connec-

tor. Reconnect ECMharness connector

and retest.

@

1

CHECK GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Disconnect powersteering oilpres-

sure switch harness connector.

3. Check harness continuity between

terminal

@

and engine ground.

Continuity shouldexist.

AEC760

IfOK, check harness forshort.

~i5

[i

c:ITb

~i5

ECM

Ef

CONNECTOR

II

43 25

II

INSPECTIONEND

Power steering oilpressure switch

1. Disconnect powersteering oilpressure switchharness con-

nector thenstart engine.

2. Check continuity betweenterminals

@.

[At

IV

ID

~ COMPONENT

INSPECTION

Conditions

Steering wheelisbeing turned

Steering wheelisnot being turned Continuity

Yes

No

AEC762

IfNG, replace powersteering oilpressure switch.

EC-172

Page 892 of 1701

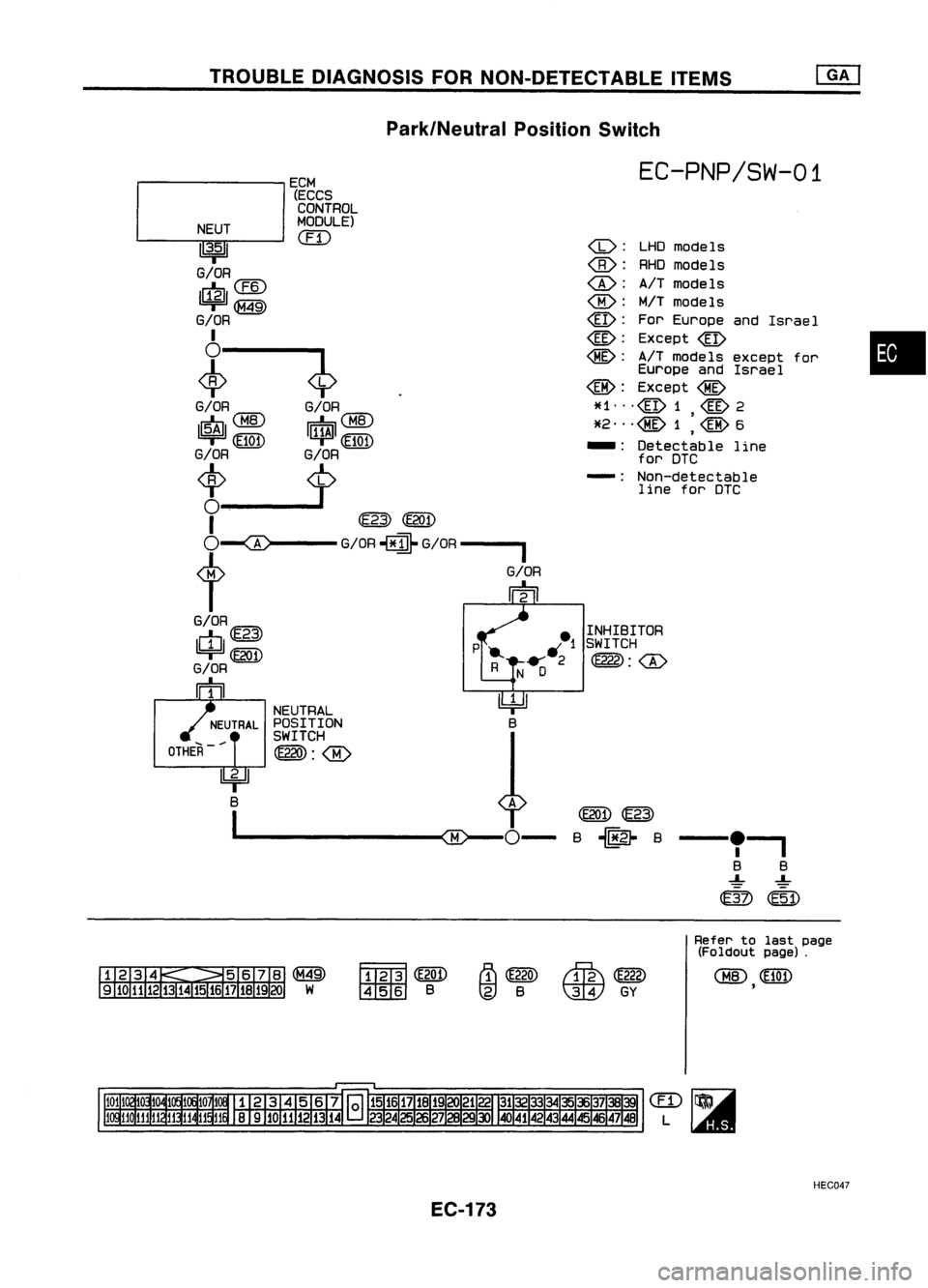

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Park/Neutral PositionSwitch

4J

B A

I

(E20f)~

--------(H)-O-

B~ B

•

,.

B B

~ ~

@rn

EC-PNP/SW-01

:

RHOmode 1s

<:A>:

A/Tmode 1s

M/Tmodels

@:

ForEurope andIsrael

@:

Except

@

@:

A/Tmodels except for

Europe andIsrael

@:

Except

@

*1"'@1 @2

,

*2"'@1 @6

,

-: Detectable line

for DTC

-: Non-detectable

line forOTC

• INHIBITOR

.. 1

SWITCH

...- 2

W>:

<:A>

N 0

l4=Jl

B

reM

(ECCS

CONTROL

MODULE)

CED

NEUTRAL

POSITION

SWITCH

@:

NEUT

I~I

G/OR

I¥J'@

~

G/OR

I

G/OR G/OR

1$1

~~~1)

1$1

~~~1)

G/OR G/OR

*_.

_T

I

~(E201)

O--

t

G/DR

I[b (E23)

=r='@QD

G/DR

m

OTHER -~

~(E20t)

~ B

~

(E222)

~ GY

Refer

tolast page

(Foldout page).

,

HEC047

EC-173

Page 893 of 1701

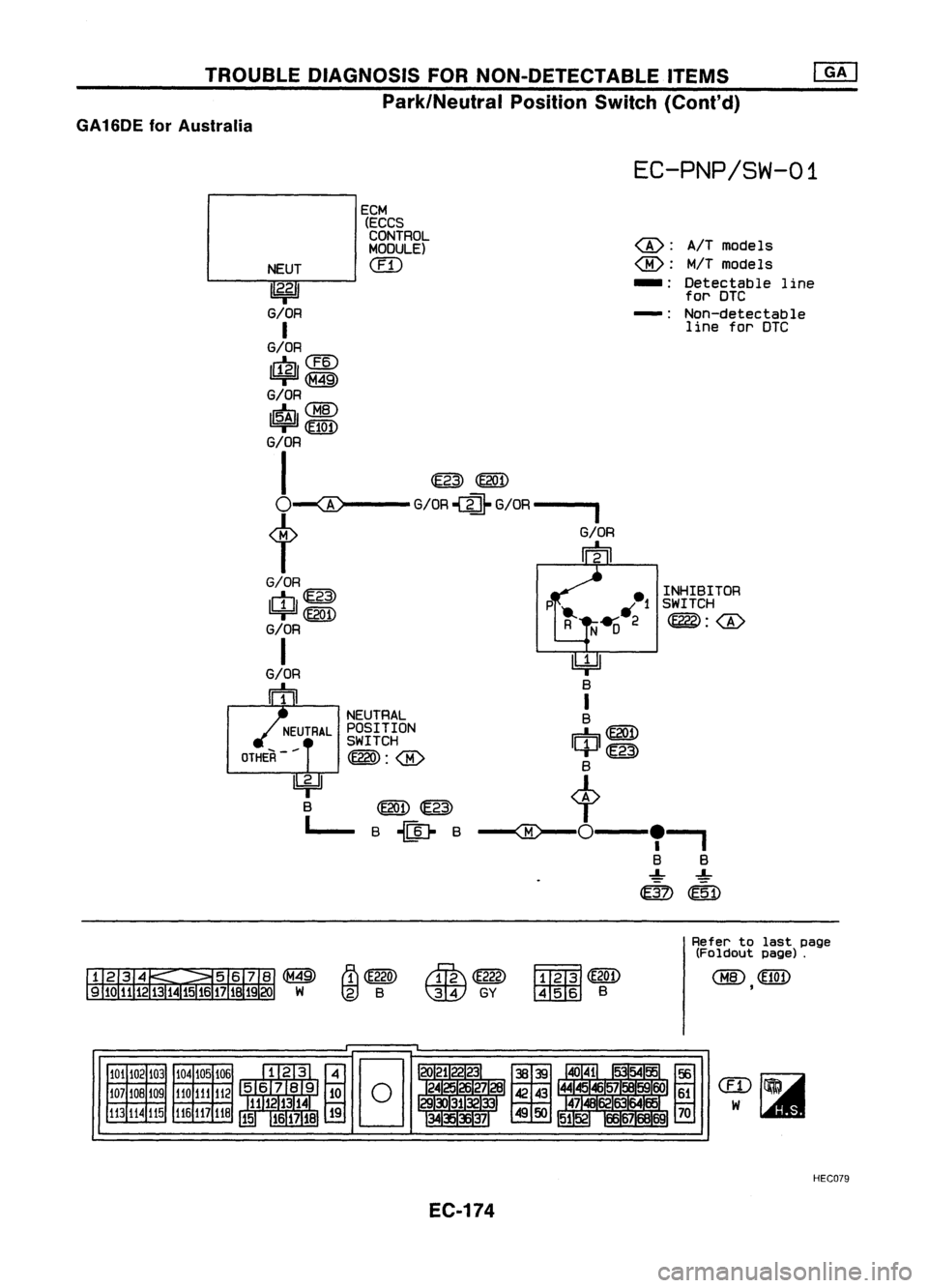

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Park/Neutral PositionSwitch(Cont'd)

GA 16DE forAustralia

EC-PNP/SW-01

AIT

models

MIT

models

Detectable line

fa/"' DTC

Non-detectable line forDTC

ill

:

@:

-:

-:

• INHIBITOR

P __ ..1SWITCH

R N--D 2~:

ill

l4=Jl

B

I

B

Qj:

B

-cM>--O--'-,

BB

~ ~

~ @D

ECM

(ECCSCONTROL

MODULE)

(IT)

NEUTRAL POSITION

SWITCH

(E220):

@

NEUT

1

2•2

1

G/OR

I

G/OR

1$11

CEID

@

G/OR

1$1

~

G/OR

I

~@D

O-

-ca

G/OR---

t

G/OR

[b,~

=r@D

G/OR

I

G/OR

m

OTHER --

~(222)

~ GY

fTIffiI

~B

Refer

tolast page

(Foldout page).

CHID

(E10t)

,

101 102 103

107 108109

113 114

115 104

105 106

110 111 112

116

117

118

HEC079

EC-174

Page 894 of 1701

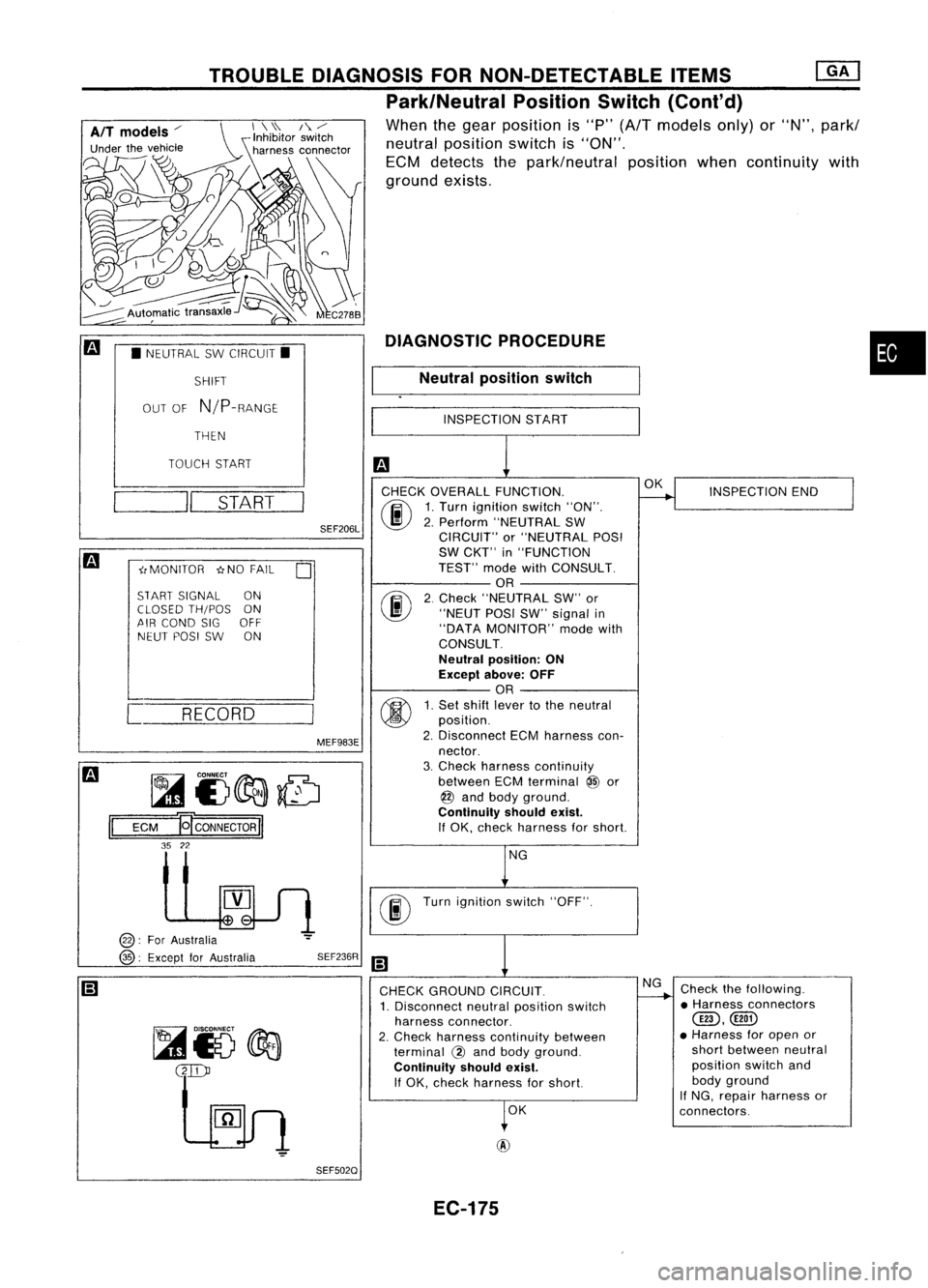

•

Neutral

position switch

INSPECTION START

DIAGNOSTIC

PROCEDURE

SHIFT

OUT OFNIP-RANGETROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

@J

Park/Neutral PositionSwitch

(Cont'd)

When thegear position is"P"

(A/T

models only)or

"N",

parkl

neutral position switchis"ON",

ECM detects thepark/neutral positionwhencontinuity with

ground exists,

• NEUTRAL SWCIRCUIT.

THEN

TOUCH START

MEF983ESEF206L

~ CONNECT~

JA

L41E)~~

1=1

=E=CM~E CONNECTOR!'

35 22

INSPECTION

END

OK

Turn ignition switch"OFF".

NG

CHECK

OVERALL FUNCTION.

(ijJ\ 1.Turn ignition switch"ON".

~ 2.Perform "NEUTRAL SW

CIRCUIT" or"NEUTRAL POSI

SW CKT" in"FUNCTION

TEST" modewithCONSULT.

OR

rF.I\

2.Check "NEUTRAL SW"or

~ "NEUTPOSISW"signal in

"DATA MONITOR" modewith

CONSULT.

Neutral position: ON

Except above:OFF

OR

fff\

1.Set shift lever tothe neutral

~ position.

2. Disconnect ECMharness con-

nector.

3. Check harness continuity

between ECMterminal

@

or

@ and body ground.

Continuity shouldexist.

If OK, check harness forshort.

SEF236R

r:'I

.;,

i,MONITOR

*NOFAIL

0

START SIGNAL ON

CLOSED TH/POS ON

/lIR COND SIGOFF

NEUT POSISW ON

[ RECORD

@:

Fo'Australia

@:

Except forAustralia

__

II

START

CHECKGROUND CIRCUIT.

1. Disconnect neutralposition switch

harness connector.

2. Check harness continuity between

terminal @and body ground.

Continuity shouldexist.

If OK, check harness forshort.

OK NG

Check thefollowing.

• Harness connectors

@,(@)

• Harness foropen or

short between neutral

position switchand

body ground

If NG, repair harness or

connectors.

SEF5020 EC-175

Page 895 of 1701

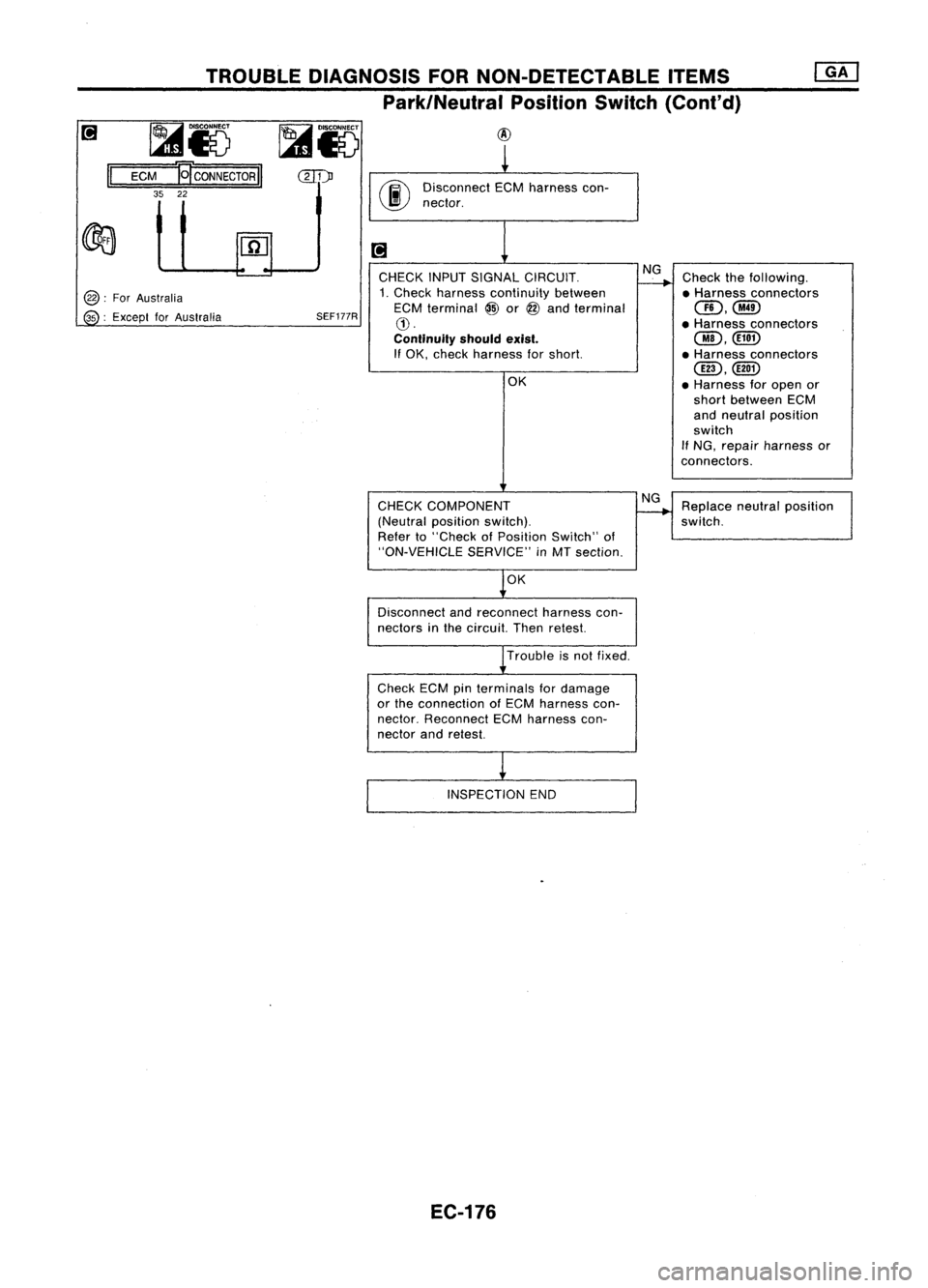

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Park/Neutral PositionSwitch(Cont'd)

Il

~io

ECM

E[coNNECTORII

35 22

~iV

m

@

Disconnect ECMharness con-

nector.

@:

ForAustralia

35 :Except forAustralia

SEF177R

CHECK

INPUTSIGNAL CIRCUIT.

1. Check harness continuity between

ECM terminal

@

or

@

and terminal

CD.

Continuity shouldexist.

If

OK, check harness forshort.

OK

CHECK COMPONENT

(Neutral positionswitch).

Refer to"Check ofPosition Switch"of

"ON-VEHICLE SERVICE"inMT section.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

INSPECTION END

EC-176 NG

NG

Check

thefollowing.

• Harness connectors

@,@

• Harness connectors

@,@!)

• Harness connectors

@),CmD

• Harness foropen or

short between ECM

and neutral position

switch

" NG, repair harness or

connectors.

Replace neutralposition

switch.

Page 896 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Park/Neutral PositionSwitch(Cont'd)

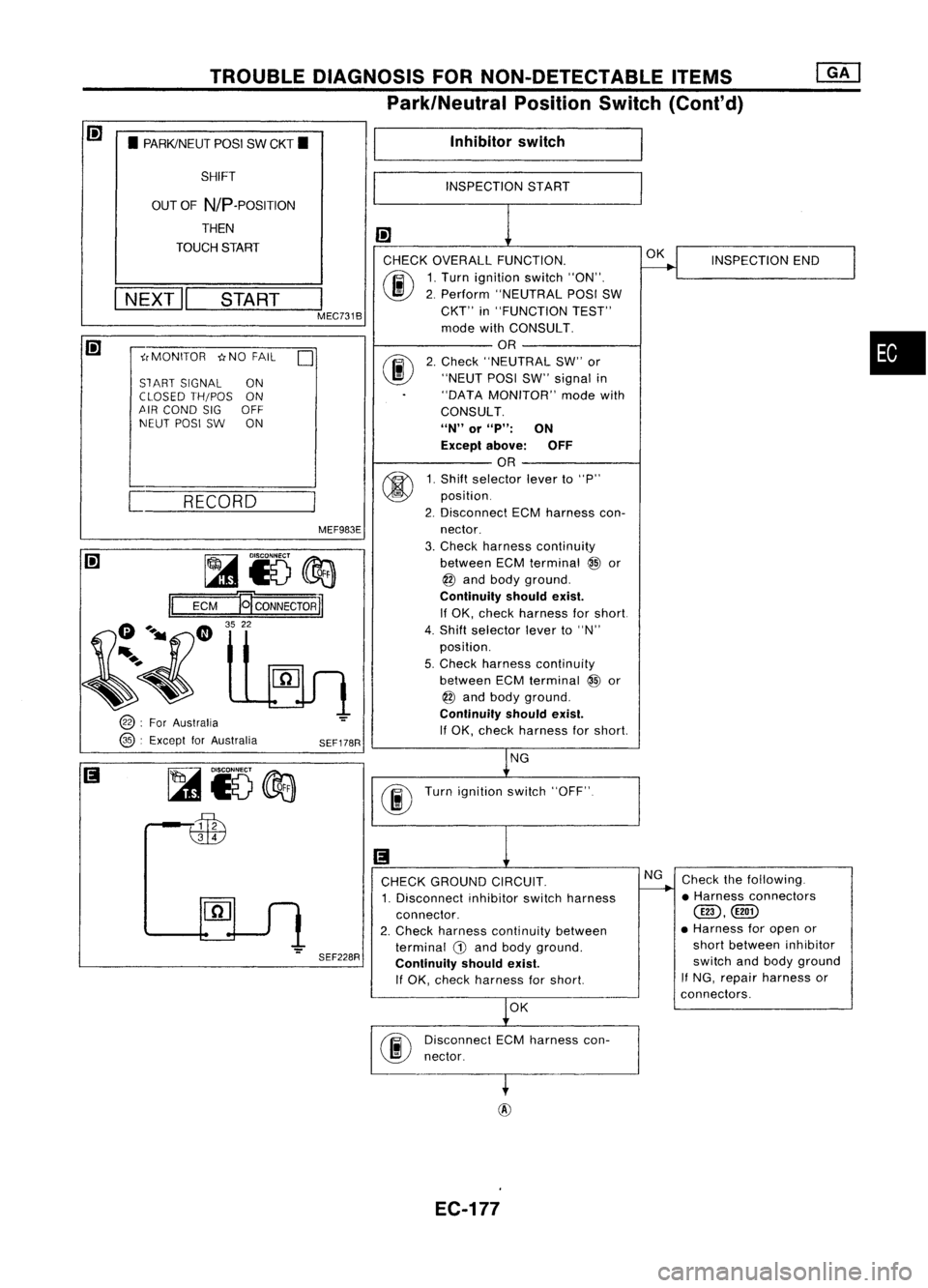

• PARKJNEUT POSISWCKT • Inhibitor

switch

MEF983E

I

NEXT

II__

ST:_A_RT __

I

MEC7318

•

INSPECTION

END

OK

INSPECTION

START

"N"

or

"P":

ON

Except above: OFF

OR

1. Shift selector leverto"P"

position.

2. Disconnect ECMharness con-

nector.

3. Check harness continuity

between ECMterminal

@

or

@ and body ground.

Continuity shouldexist.

If OK, check harness forshort

4. Shift selector leverto"N"

position.

5. Check harness continuity

between ECMterminal

@

or

@ and body ground.

Continuity shouldexist.

If OK, check harness forshort

1!1

CHECK OVERALL FUNCTION.

(ij\

1.Turn ignition switch"ON".

~ 2.Perform "NEUTRAL POSISW

CKT" in"FUNCTION TEST"

mode withCONSULT.

OR

rF.I\

2.Check "NEUTRAL SW"or

~ "NEUTPOSISW"signal in

"DATA MONITOR" modewith

CONSULT.

SEF178R

SHIFT

OUT OFNIP-POSITION

THEN

TOUCH START

~rMONITOR ~NOFAIL

0

SlART SIGNAL ON

CLOSED TH/POS ON

'!\IR COND SIGOFF

NEUT POSISW ON

[ RECORD

@ :

For Australia

@ :

Except forAustralia

~i5@a

II

ECM

19'

CONNECTOR

TI

G ...._ CD

3522

~~

~io@a

6iB

NG

Turn ignition switch"OFF"

SEF228R CHECK

GROUND CIRCUIT.

1. Disconnect inhibitorswitchharness

connector.

2. Check harness continuity between

terminal G)and body ground.

Continuity shouldexist.

If OK, check harness forshort. NG

Check thefollowing.

• Harness connectors

@D,@])

• Harness foropen or

short between inhibitor

switch andbody ground

If

NG, repair harness or

connectors.

OK

Disconnect ECMharness con-

nector.

EC-177

Page 897 of 1701

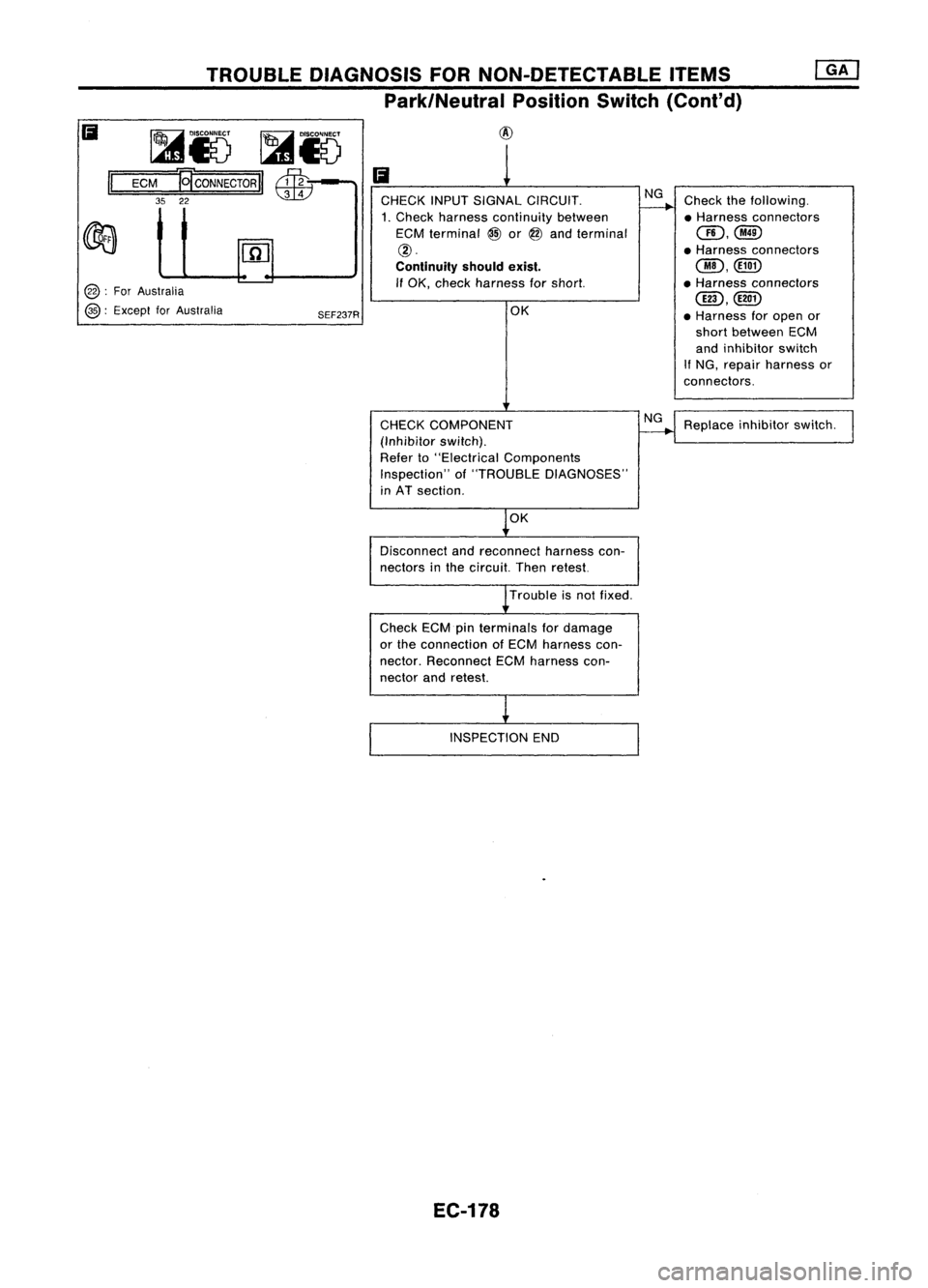

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Park/Neutral PositionSwitch(Cont'd)

@:

ForAustralia

@:

Except forAustralia

iii

II

~i5

~i5

ECM E

CONNECTOR

II

Effij

35 22

SEF237R

iii

CHECK INPUTSIGNAL CIRCUIT.

1. Check harness continuity between

ECM terminal

@

or

@

and terminal

@.

Continuity shouldexist.

If

OK, check harness forshort.

OK

CHECK COMPONENT

(Inhibitor switch).

Refer to"Electrical Components

Inspection" of"TROUBLE DIAGNOSES"

in AT section.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpin terminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

INSPECTION END

EC-178 NG

NG

Check

thefollowing.

• Harness connectors

QD,@)

• Harness connectors

@,@D

• Harness connectors

@),@D

• Harness foropen or

short between ECM

and inhibitor switch

If

NG, repair harness or

connectors.

Replace inhibitorswitch.

Page 898 of 1701

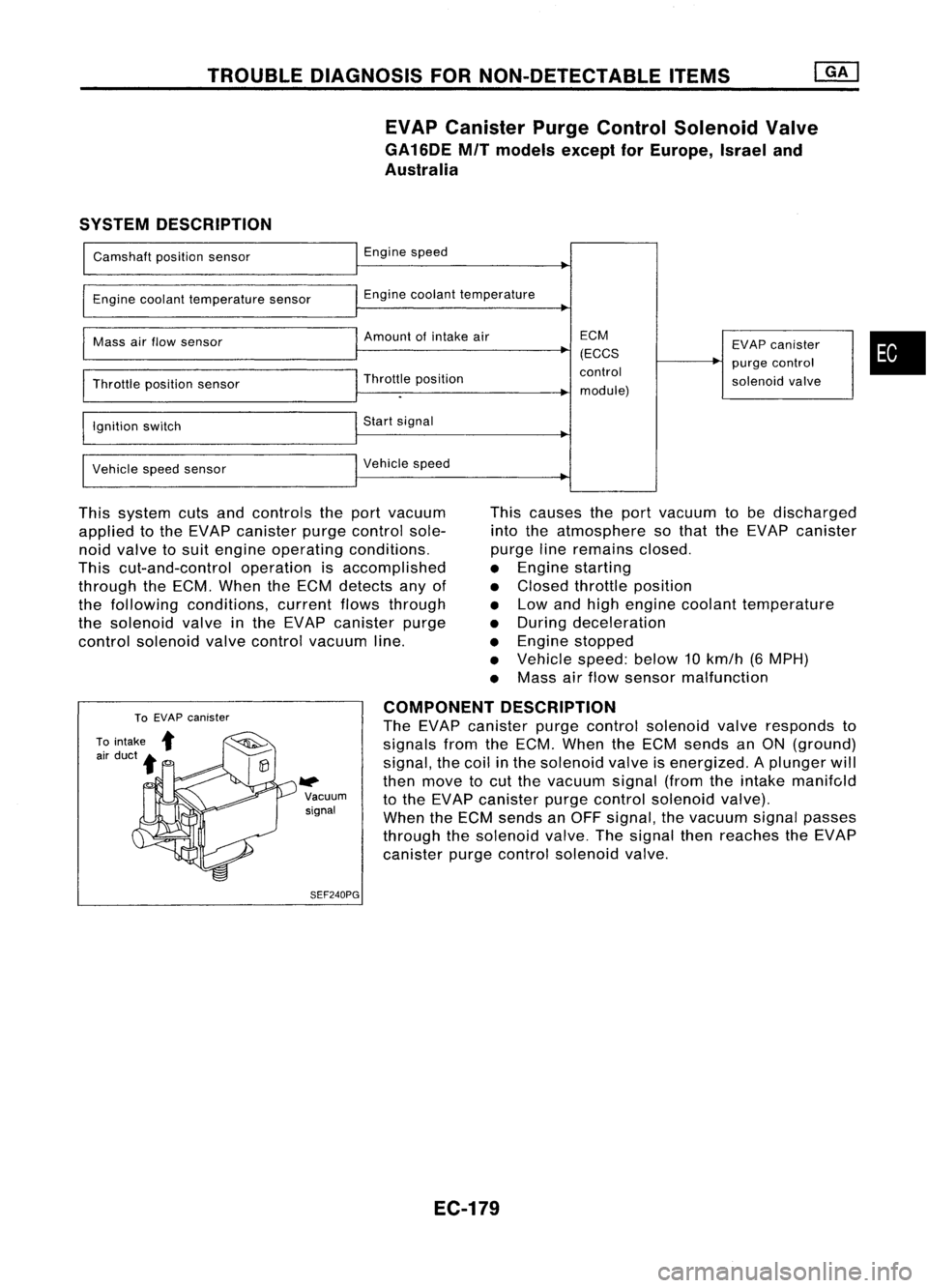

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

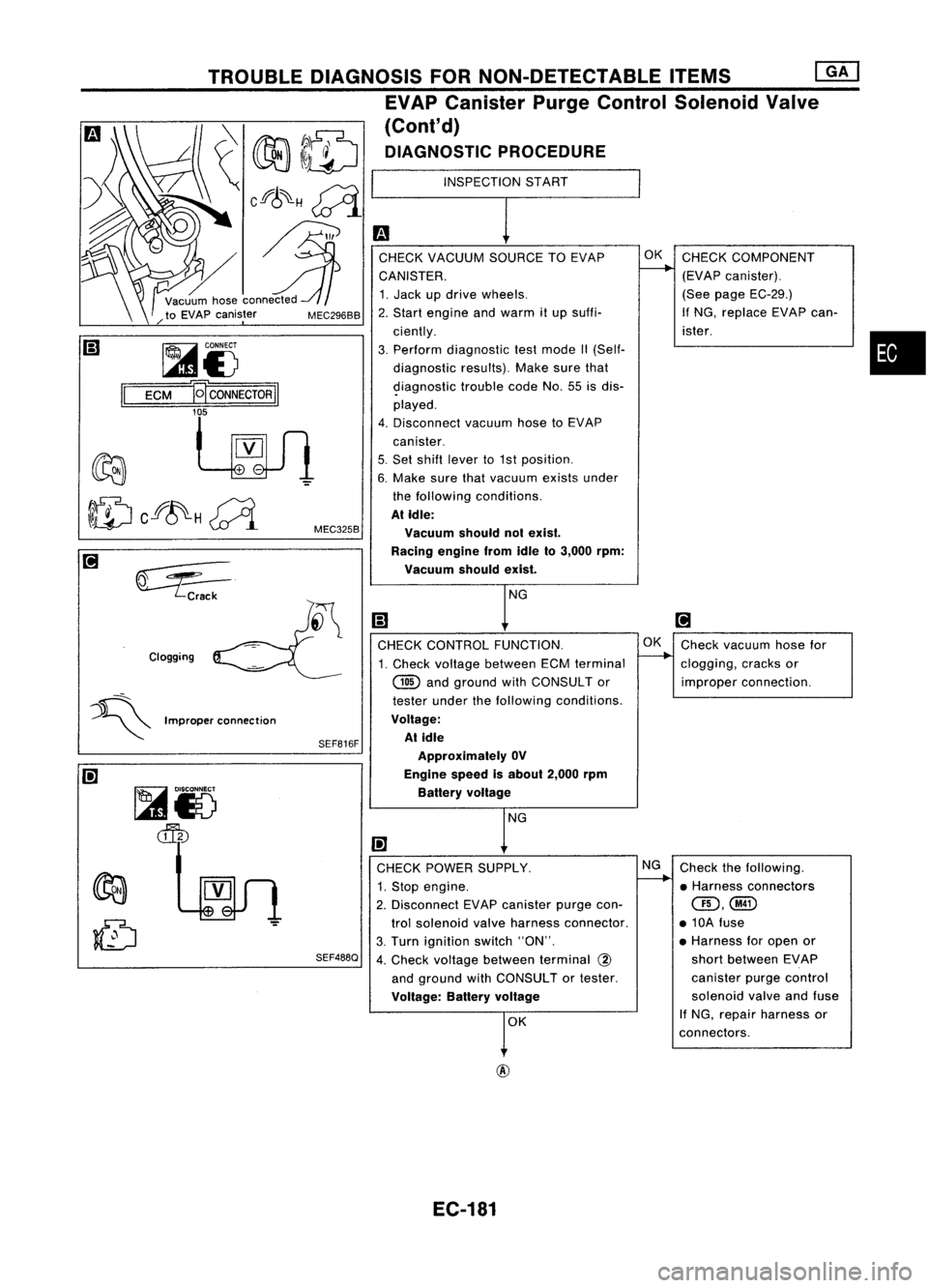

EVAP Canister PurgeControl Solenoid Valve

GA16DE MITmodels exceptforEurope, Israeland

Australia

SYSTEM DESCRIPTION

Camshaft positionsensor

Engine coolant temperature sensor

Mass airflow sensor

Throttle positionsensor

Ignition switch

Vehicle speedsensor Engine

speed

Engine coolant temperature

Amount ofintake air

Throttle position

Start signal

Vehicle speed ECM

(ECCS

control

module) EVAP

canister

purge control

solenoid valve

•

This system cutsandcontrols theport vacuum

applied tothe EVAP canister purgecontrol sole-

noid valve tosuit engine operating conditions.

This cut-and-control operationisaccomplished

through theECM. When theECM detects anyof

the following conditions, currentflowsthrough

the solenoid valveinthe EVAP canister purge

control solenoid valvecontrol vacuum line. This

causes theport vacuum tobe discharged

into theatmosphere sothat theEVAP canister

purge lineremains closed.

• Engine starting

• Closed throttle position

• Low andhigh engine coolant temperature

• During deceleration

• Engine stopped

• Vehicle speed:below10km/h (6MPH)

• Mass airflow sensor malfunction

W>

Vacuum

signal

SEF240PG COMPONENT

DESCRIPTION

The EVAP canister purgecontrol solenoid valveresponds to

signals fromtheECM. When theECM sends anON (ground)

signal, thecoil inthe solenoid valveisenergized. Aplunger will

then move tocut the vacuum signal(fromtheintake manifc,ld

to the EVAP canister purgecontrol solenoid valve).

When theECM sends anOFF signal, thevacuum signalpasses

through thesolenoid valve.Thesignal thenreaches theEVAP

canister purgecontrol solenoid valve.

EC-179

Page 899 of 1701

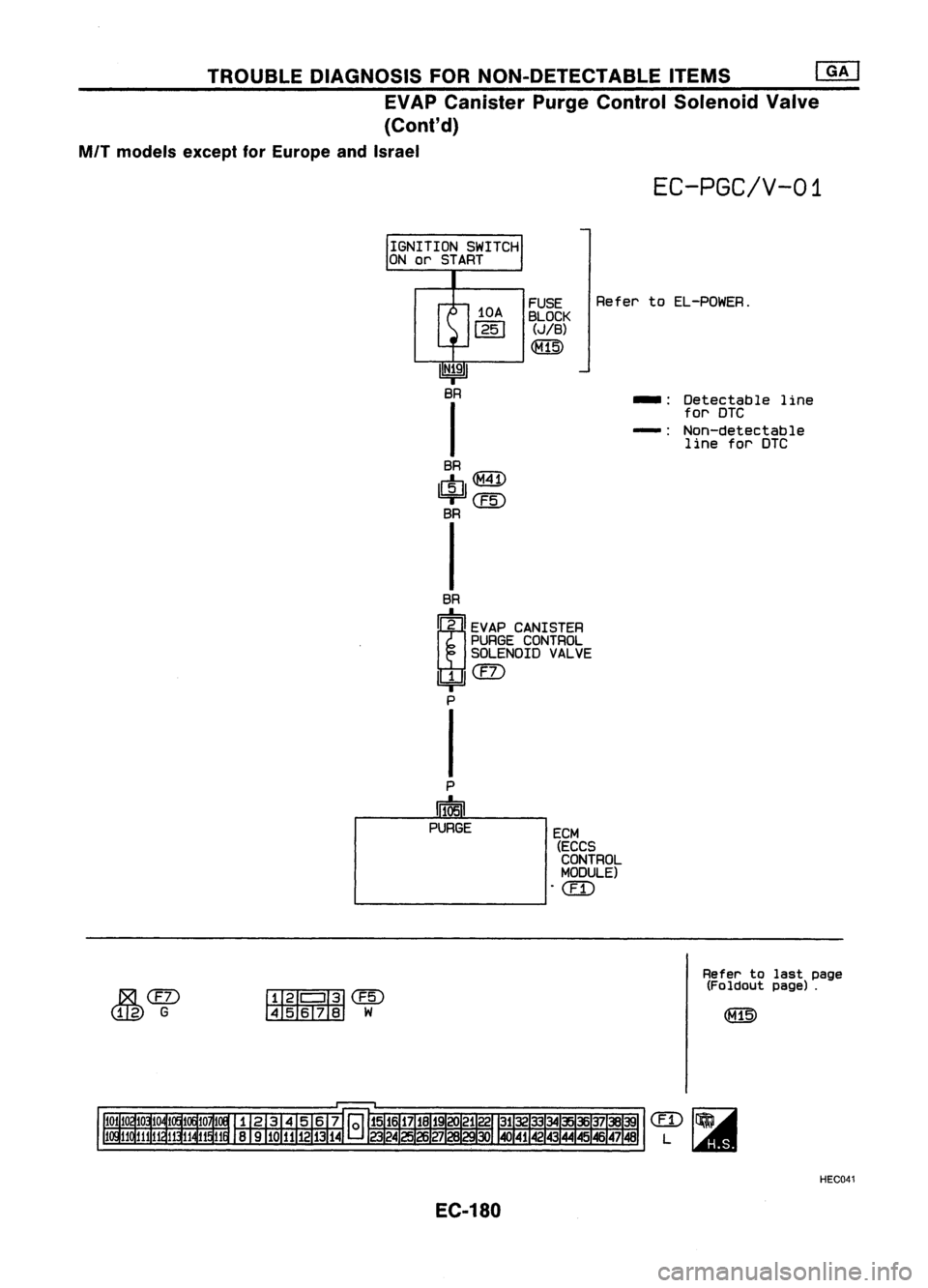

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS~

EVAP Canister PurgeControl Solenoid Valve

(Cont'd)

MIl

models exceptforEurope andIsrael

EC-PGC/V-01

IGNITION SWITCH

ON or START

10A

1251

FUSE

BLOCK

(JIB)

~

Refer

toEL-POWER.

_. Detectable line

for DTC

-: Non-detectable

line forDTC

BR

IlIDl

',=@

BR

I

BR

OCIEVAP CANISTER

PURGE CONTROL

SOLENOID VALVE

'4=JlCW

P

I

~cm

a:IID

G

fmjl

I

I~

CEID

45678 WP

~

PURGE ECM

(ECCS

CONTROL

MODULE)

. (ill

Refertolast page

(Foldout page).

HEC041

EC-180

Page 900 of 1701

•

INSPECTION

START

m

CHECK VACUUM SOURCETOEVAP OK

CHECK COMPONENT

CANISTER.

L---.

(EVAPcanister).

1. Jack updrive wheels. (See

page EC-29.)

2. Start engine andwarm itup suffi- If

NG, replace EVAPcan-

ciently. ister.

3. Perform diagnostic testmode II(Self-

diagnostic results).Makesurethat

9iagnostic troublecodeNo.55isdis-

played.

4. Disconnect vacuumhosetoEVAP

canister.

5. Set shift lever to1st position.

6. Make surethatvacuum existsunder

the following conditions.

At Idle:

Vacuum shouldnotexist.

Racing enginefromIdleto3,000 rpm:

Vacuum shouldexist.

NG

Ii)

[!J

CHECK CONTROL FUNCTION. OK

Check vacuum hosefor

1. Check voltage between ECMterminal

--..

clogging, cracksor

@

andground withCONSULTor improperconnection.

tester underthefollowing conditions.

Voltage: At idle

Approximately OV

Engine speedisabout 2,000rpm

Battery voltage

NG

I!l

CHECK POWER SUPPLY. NG

Check thefollowing.

1. Stop engine.

I-----.

•Harness connectors

2. Disconnect EVAPcanister purgecon-

QD,@

trol solenoid valveharness connector. •10A fuse

3. Turn ignition switch"ON". •

Harness foropen or

4. Check voltage between terminal

@

short

between EVAP

and ground withCONSULTor tester. canister

purgecontrol

Voltage: Batteryvoltage

solenoid

valveandfuse

r

K If

NG, repair harness or

connectors.

SEF816F

SEF488Q

MEC325B

MEC296BB

Clogging TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

[ill

EVAP Canister PurgeControl Solenoid Valve

(Cont'd)

DIAGNOSTIC PROCEDURE

~i5

ECM

B

CONNECTOR

II

'f

~VV1

~ Crack

~i5

~

=:5---

~ Improperconnection

@

EC-181